Star polycarboxylic-acid high-performance water reducing agent and preparation method thereof

A technology of polycarboxylic acid series and water reducing agent is applied in the preparation of this kind of water reducing agent, in the field of star-shaped polycarboxylic acid series high-performance water reducing agent, which can solve the problem of high slump and restriction of water reducing rate of water reducing agent. The transportation radius of commercial concrete, affecting the effect of water reducing agent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

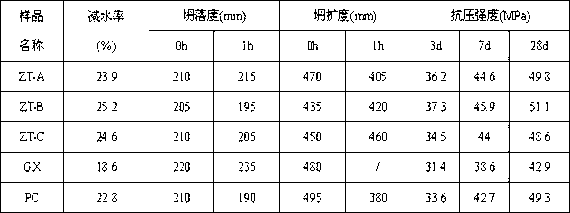

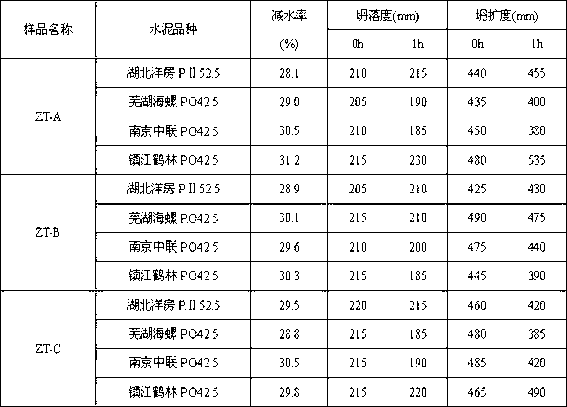

Embodiment 1

[0012] Add 12.5 parts of GL to a dry four-neck bottle equipped with a stirrer, thermometer, condenser and water separator, and heat up to 70°C under stirring; divide 35 parts of MAD into 3~4 times, and add slowly at intervals of 10 minutes each time . After feeding, raise the temperature to 110°C, keep it warm for 6 hours, add 20 parts of water to make a solution with a mass fraction of 70%, and obtain a light yellow transparent liquid. Add 305 parts of TPEG and the prepared star-shaped monomer into a four-necked bottle, add 460 parts of water, stir and raise the temperature to 90°C, add 26 parts of AA and 5.8 parts of MAS to 45 parts of water to make drop solution A, 2.8 parts of APS and 1.5 parts Add 60 parts of water to MPA to form the dripping liquid B, slowly add the two kinds of dripping liquids A and B respectively, and finish the dripping for 3 hours. After the heat preservation reaction for 2 hours, the temperature is lowered to below 40°C, and 22 parts of liquid alka...

Embodiment 2

[0014] Add 18.3 parts of GL to a dry four-necked bottle equipped with a stirrer, thermometer, condenser and water separator, and heat up to 70°C under stirring; divide 44 parts of MAD into 3~4 times, and slowly add each time at intervals of 10 minutes . After feeding, raise the temperature to 110°C, keep it warm for 6 hours, add 27 parts of water to make a solution with a mass fraction of 70%, and obtain a light yellow transparent liquid. Add 290 parts of TPEG and the prepared star-shaped monomer into a four-necked bottle, add 450 parts of water, stir and raise the temperature to 90°C, add 28.5 parts of AA and 6.6 parts of MAS to 45 parts of water to make drop solution A, 3.1 parts of APS and 1.7 parts Add 60 parts of water to MPA to prepare the dripping liquid B, slowly add the two kinds of dripping liquids A and B respectively, and finish the dripping for 3 hours. After the heat preservation reaction for 2 hours, the temperature is lowered to below 40°C, and 26 parts of liqu...

Embodiment 3

[0016] Add 15.5 parts of GL to a dry four-neck bottle equipped with a stirrer, thermometer, condenser and water separator, and heat up to 70°C under stirring; divide 47 parts of MAD into 3~4 times, slowly add each time at intervals of 10 minutes . After feeding, raise the temperature to 110°C, keep it warm for 6 hours, add 27 parts of water to make a solution with a mass fraction of 70%, and obtain a light yellow transparent liquid. Add 280 parts of TPEG and the prepared star-shaped monomer into a four-necked bottle, add 428 parts of water, stir and raise the temperature to 90°C, add 25 parts of AA and 4.6 parts of MAS to 45 parts of water to make drop solution A, 2.6 parts of APS and 1.3 parts Add 60 parts of water to MPA to make the dripping liquid B, slowly add the two kinds of dripping liquids A and B respectively, and finish the dripping for 3 hours. After the heat preservation reaction for 2 hours, the temperature is lowered to below 40°C, and 18 parts of liquid alkali i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com