Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73 results about "Sinusoidal oscillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sinusoidal Oscillator. An electronic device that generates sinusoidal oscillations of desired frequency is known as a sinusoidal oscillator. The oscillator does not create energy, but it acts as an energy converter.

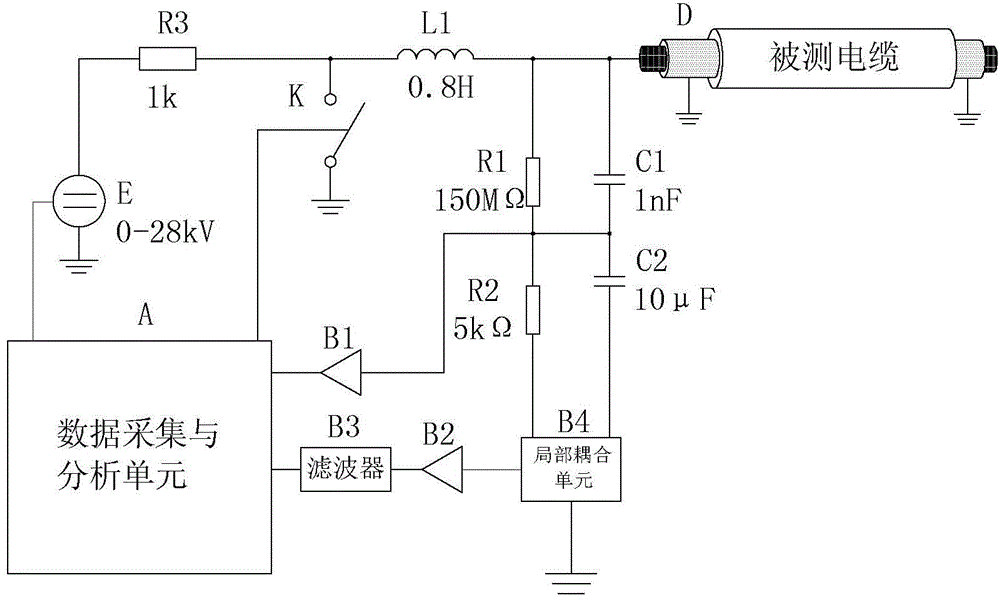

Distributing cable partial discharge test method based on oscillatory wave test

InactiveCN104808121AWon't hurtNarrow down testing blind spotsTesting dielectric strengthCapacitanceEngineering

Disclosed is a distributing cable partial discharge test method based on oscillatory wave test. The method includes that a cable partial discharge testing and locating system based on oscillatory wave test is established; by means of the testing system, a cable is charged through a method of voltage increasing to a preset value at a tested cable end, and damped oscillation voltage is generated at the tested cable end through resonance oscillation that occurs by an inductor and a tested cable capacitor in the system; when partial discharge occurs at a position of the tested cable in a distance from a testing end, pulses can spread in two directions along the cable, and the position where the partial discharge occurs can be determined according to time difference that two pulses such as incident wave and radioactive wave reach the testing end. According to the distributing cable partial discharge test method based on oscillatory wave test, oscillatory wave is applied to partial discharge test of the distributing cable, and voltage increasing is performed on the cable through sine oscillatory wave that is generated by resonance oscillation of fixed inductor and the cable. By means of the distributing cable partial discharge test method based on oscillatory wave test, insulating conditions of the cable can be timely known within short time by the system, and thereby, accidents of the cable can be effectively prevented.

Owner:STATE GRID CORP OF CHINA +1

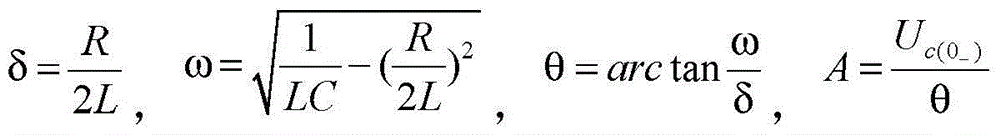

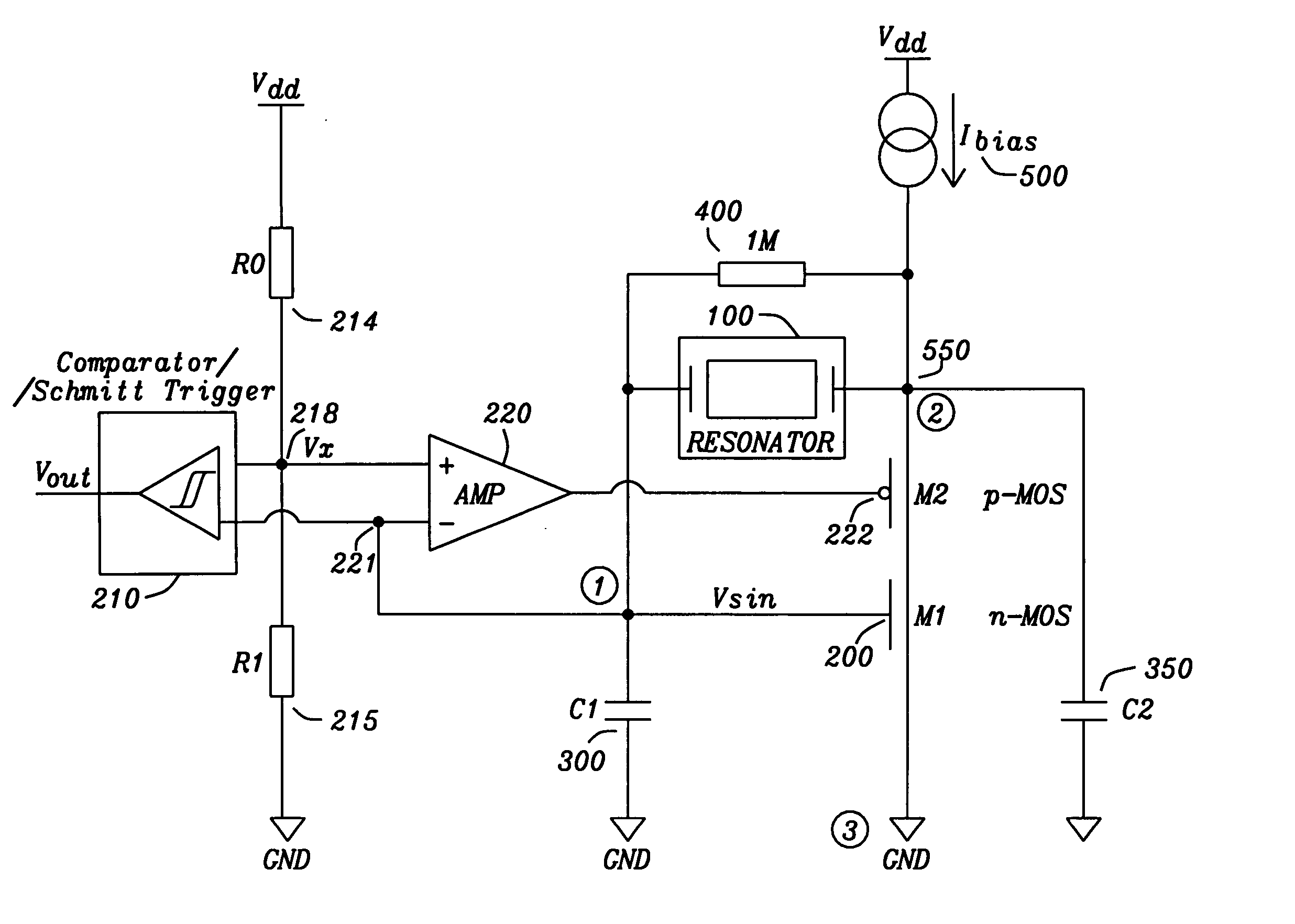

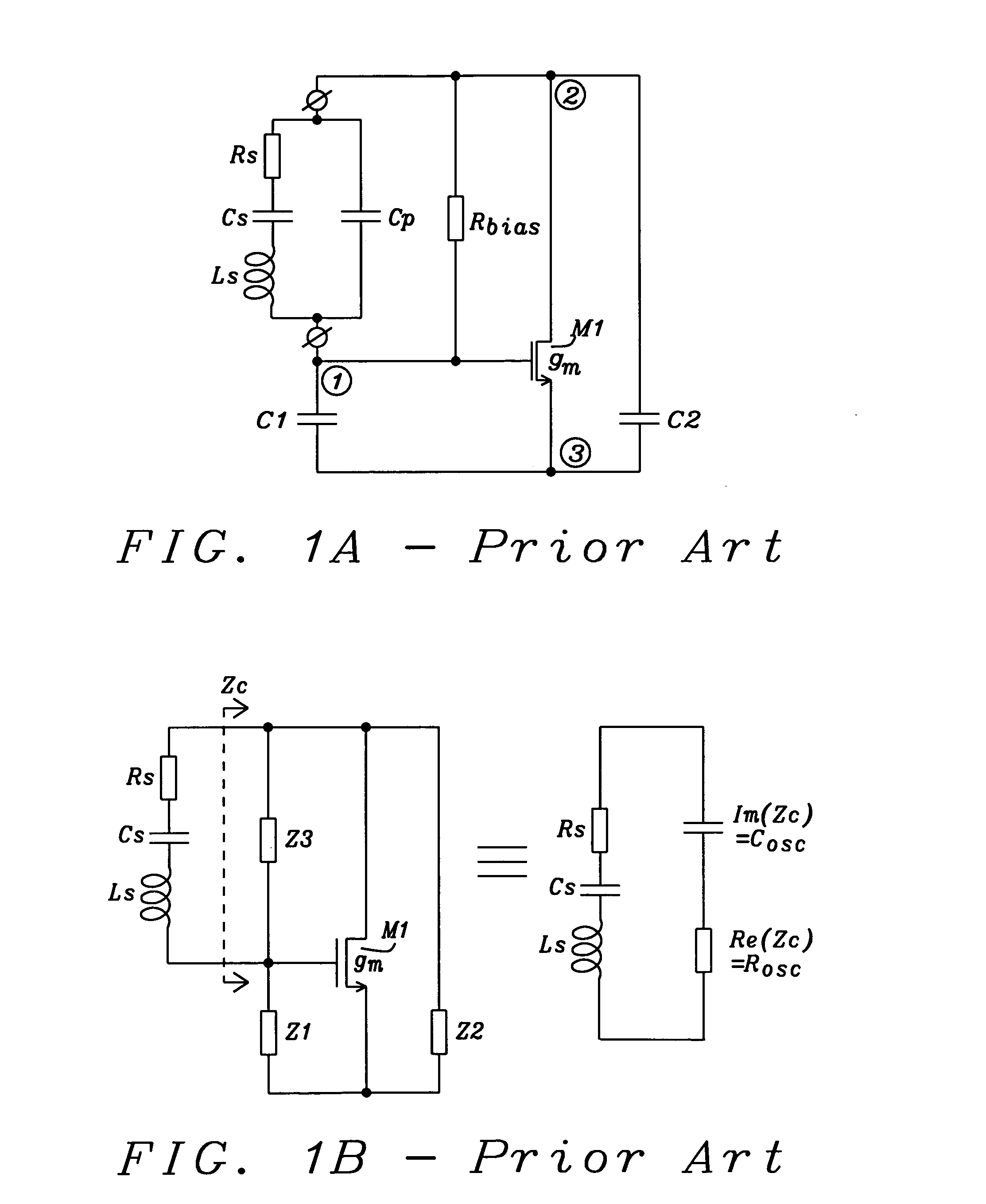

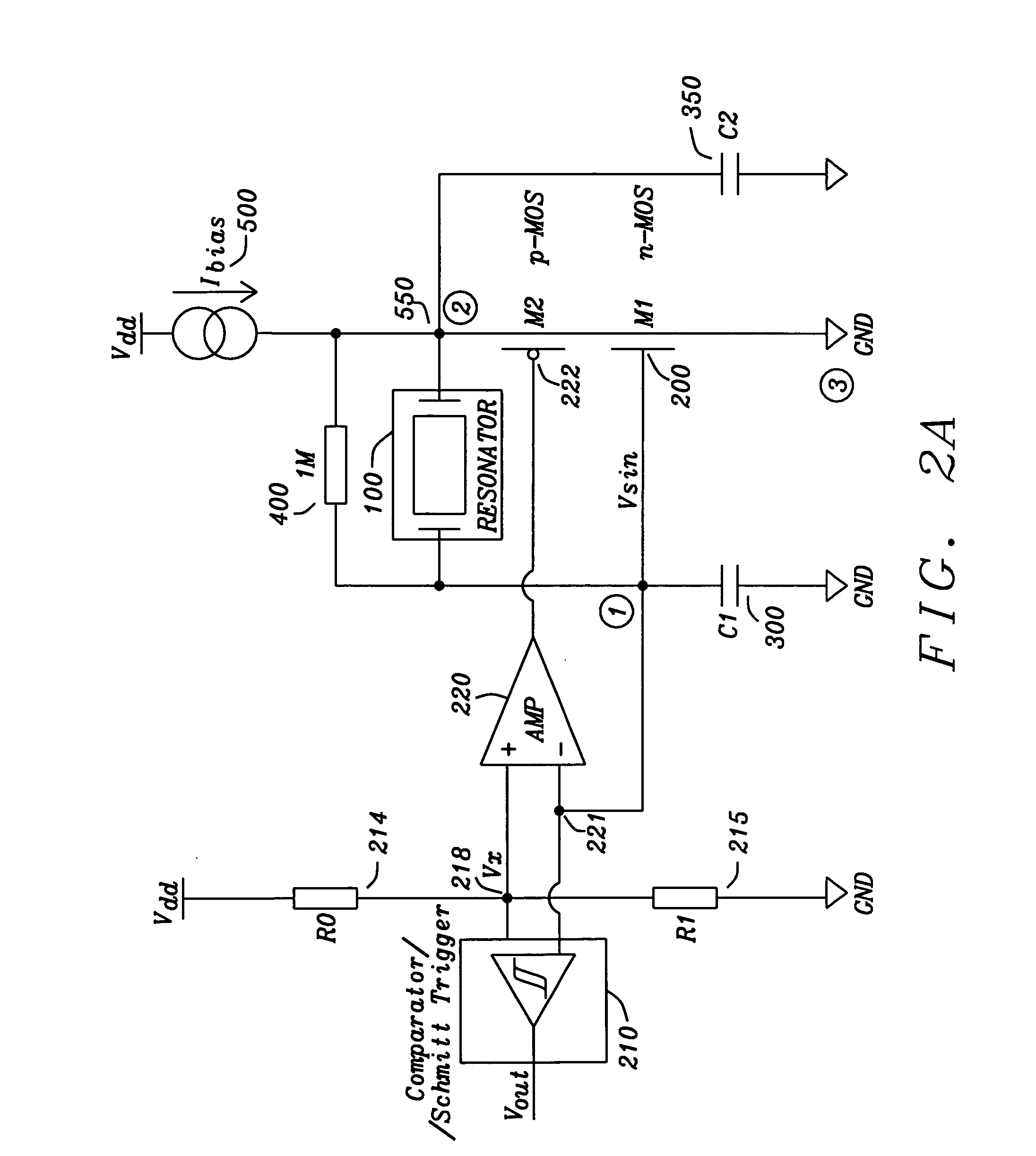

Average controlled (AC) resonator driver

InactiveUS7061338B2Low costReduce dependencePulse automatic controlElectric pulse generatorDriver circuitLoop control

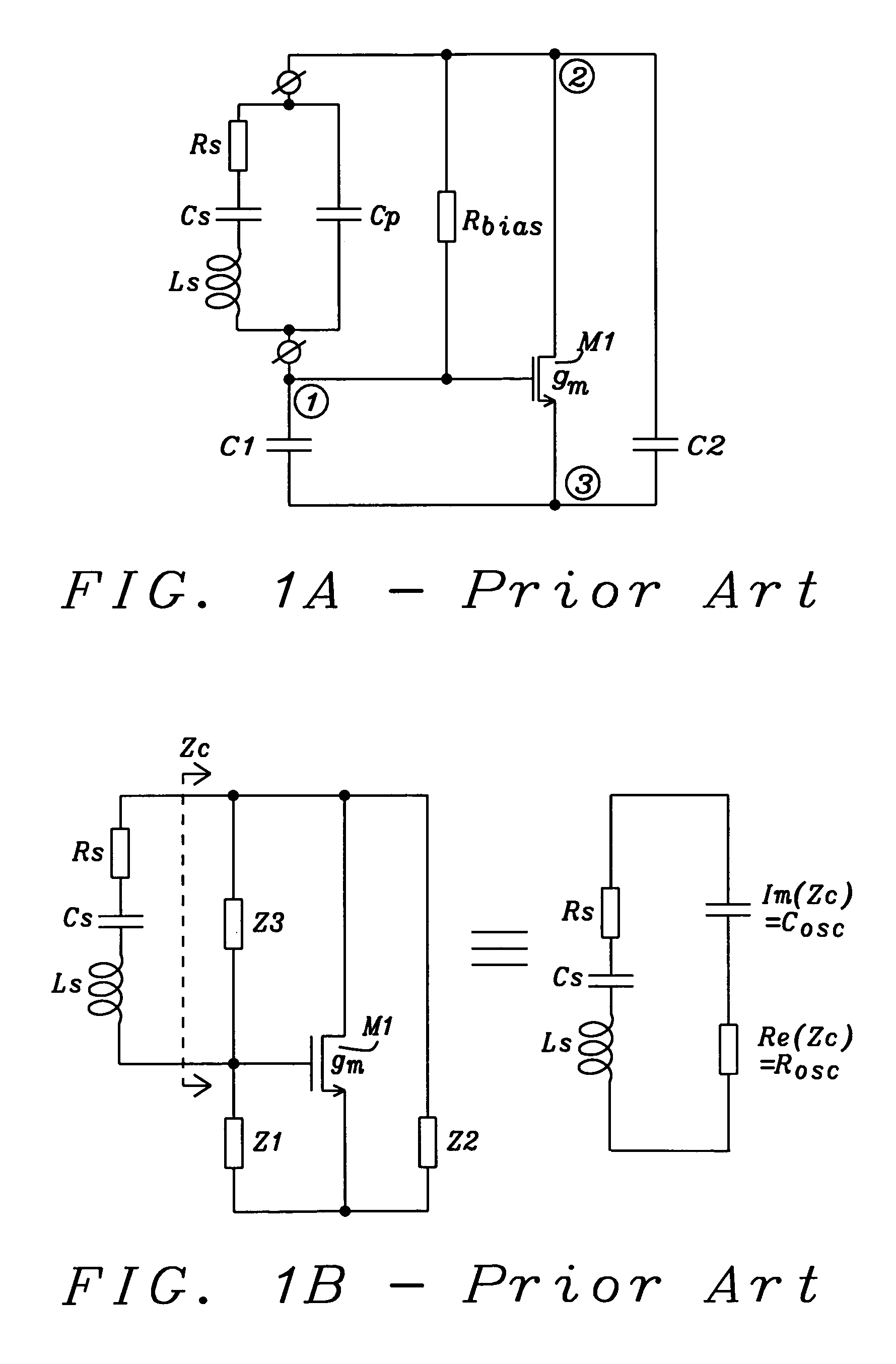

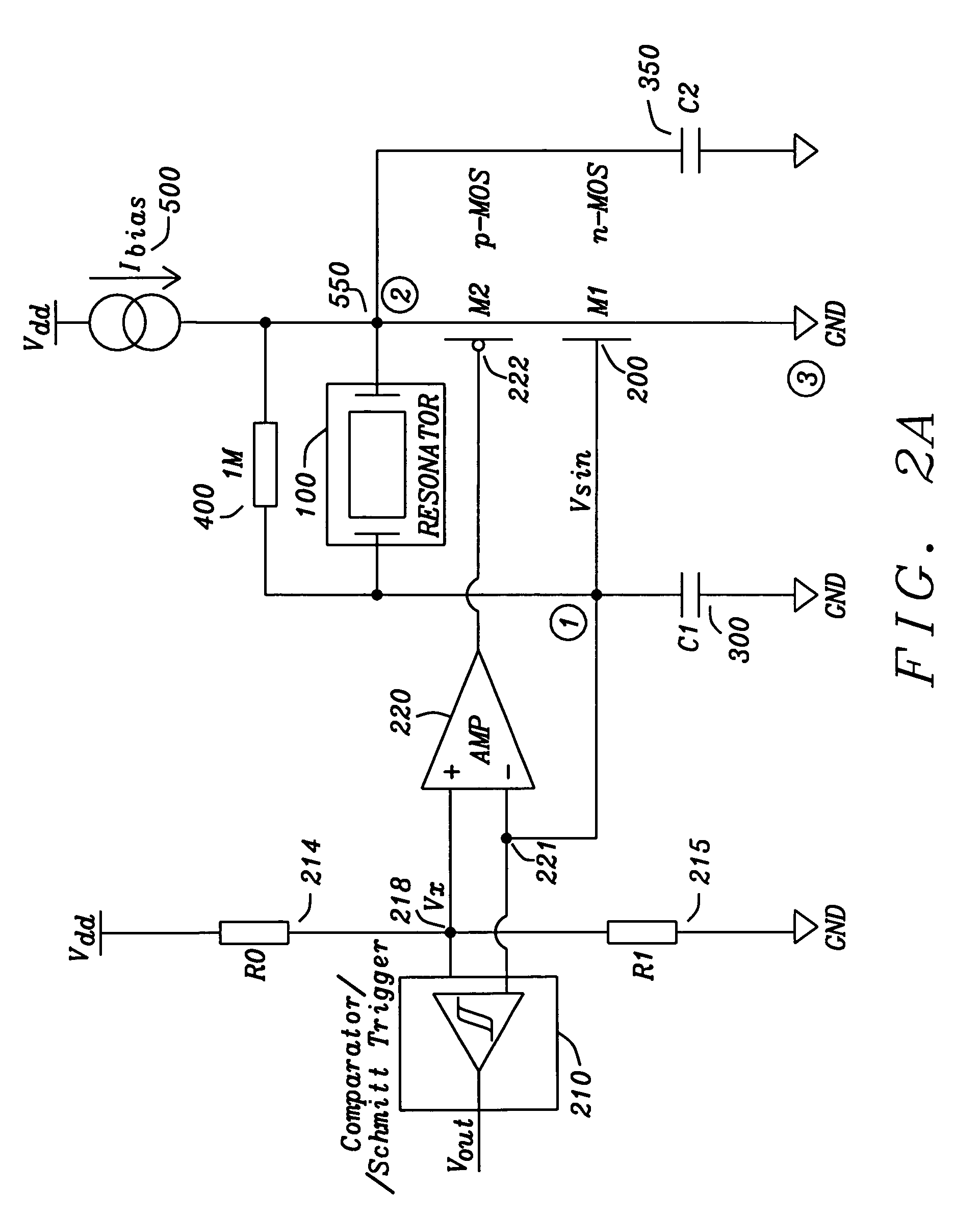

Circuits and methods are given, to realize and implement an oscillator circuit with an Average Controlled (AC) Resonator Driver. A newly introduced additional Field Effect Transistor within a voltage average stabilizing regulation loop controlling the crystal oscillator's amplifier element produces an average voltage value stabilized sinusoidal oscillation signal which is then transformed into a square wave with a precise duty-cycle of exactly 50%. Said circuits and methods are designed in order to be implemented with a very economic number of components, capable to be realized with modern integrated circuit technologies.

Owner:DIALOG SEMICONDUCTOR GMBH

Piezoactuator and drive circuit therefor

InactiveUS20020171410A1Improve efficiencyPiezoelectric/electrostriction/magnetostriction machinesFrequency analysisPhase differencePiezoelectric actuators

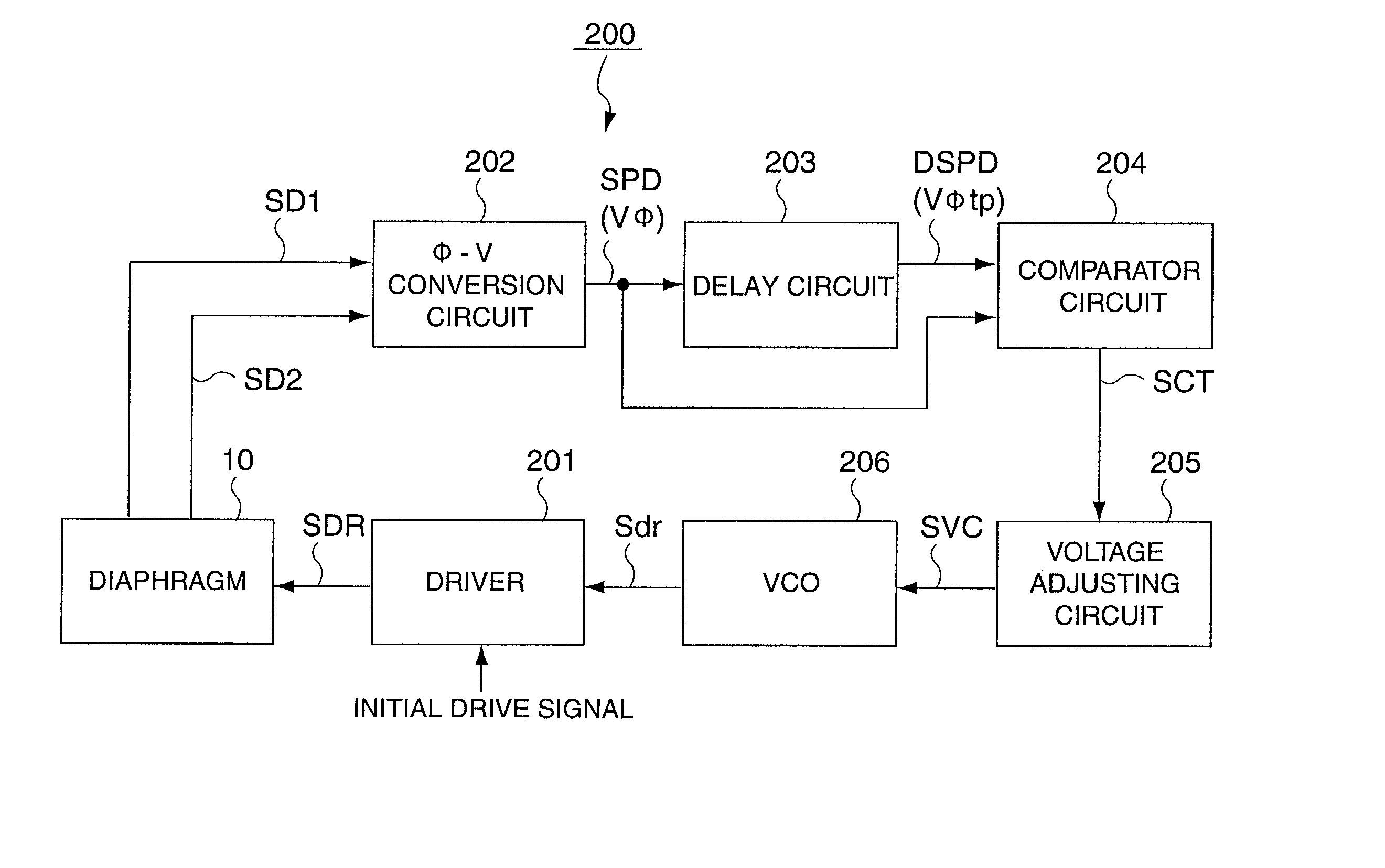

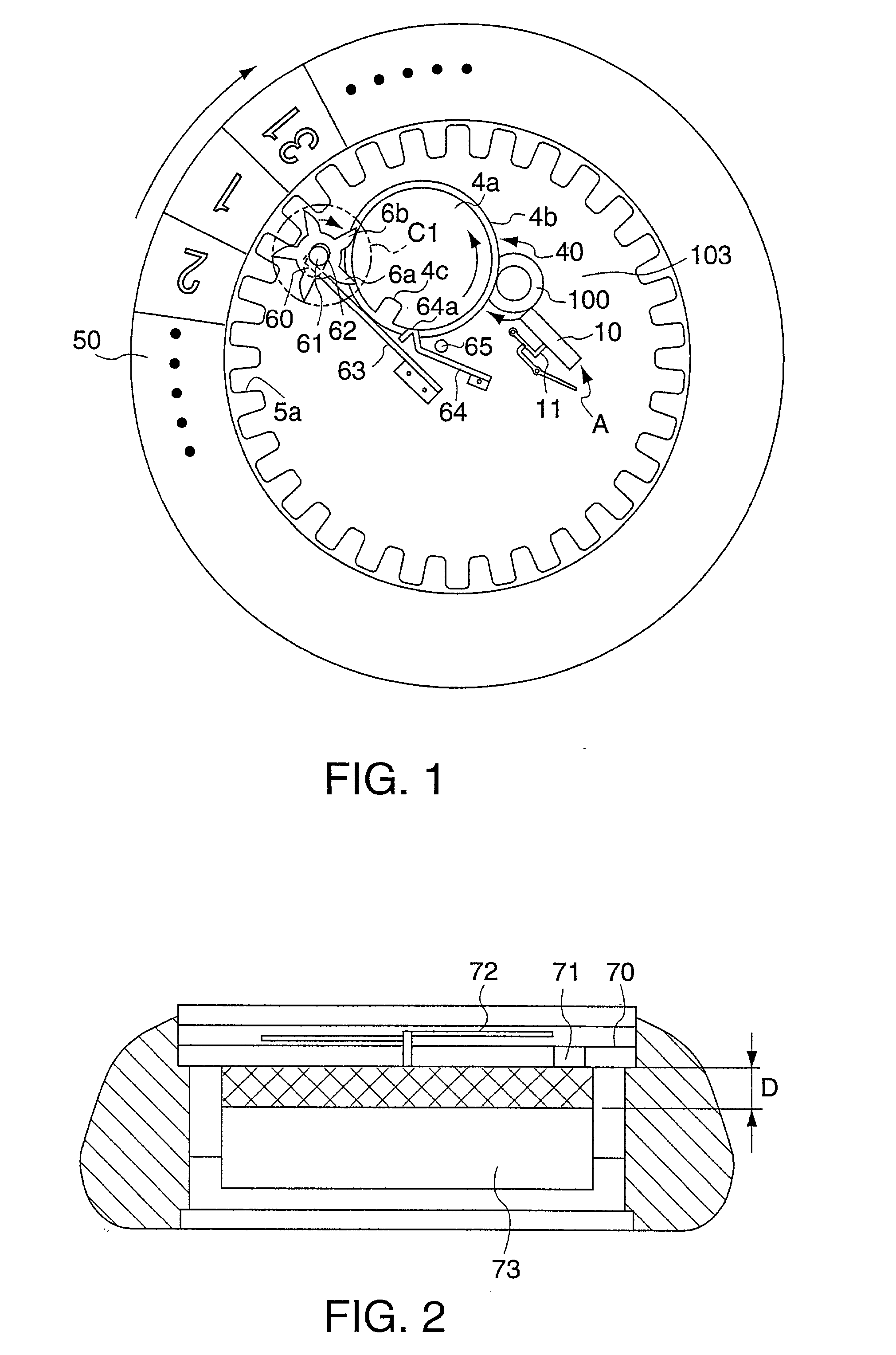

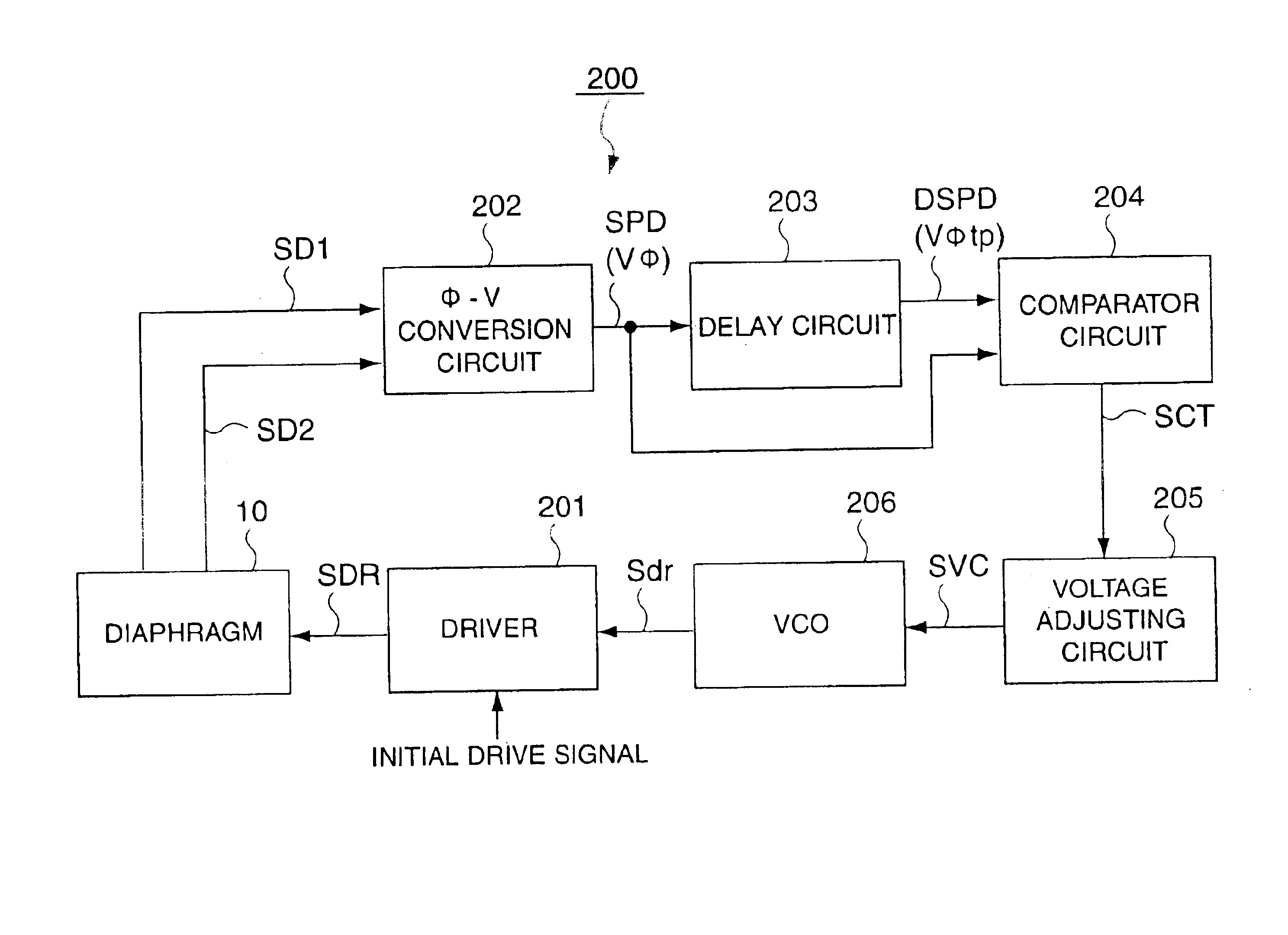

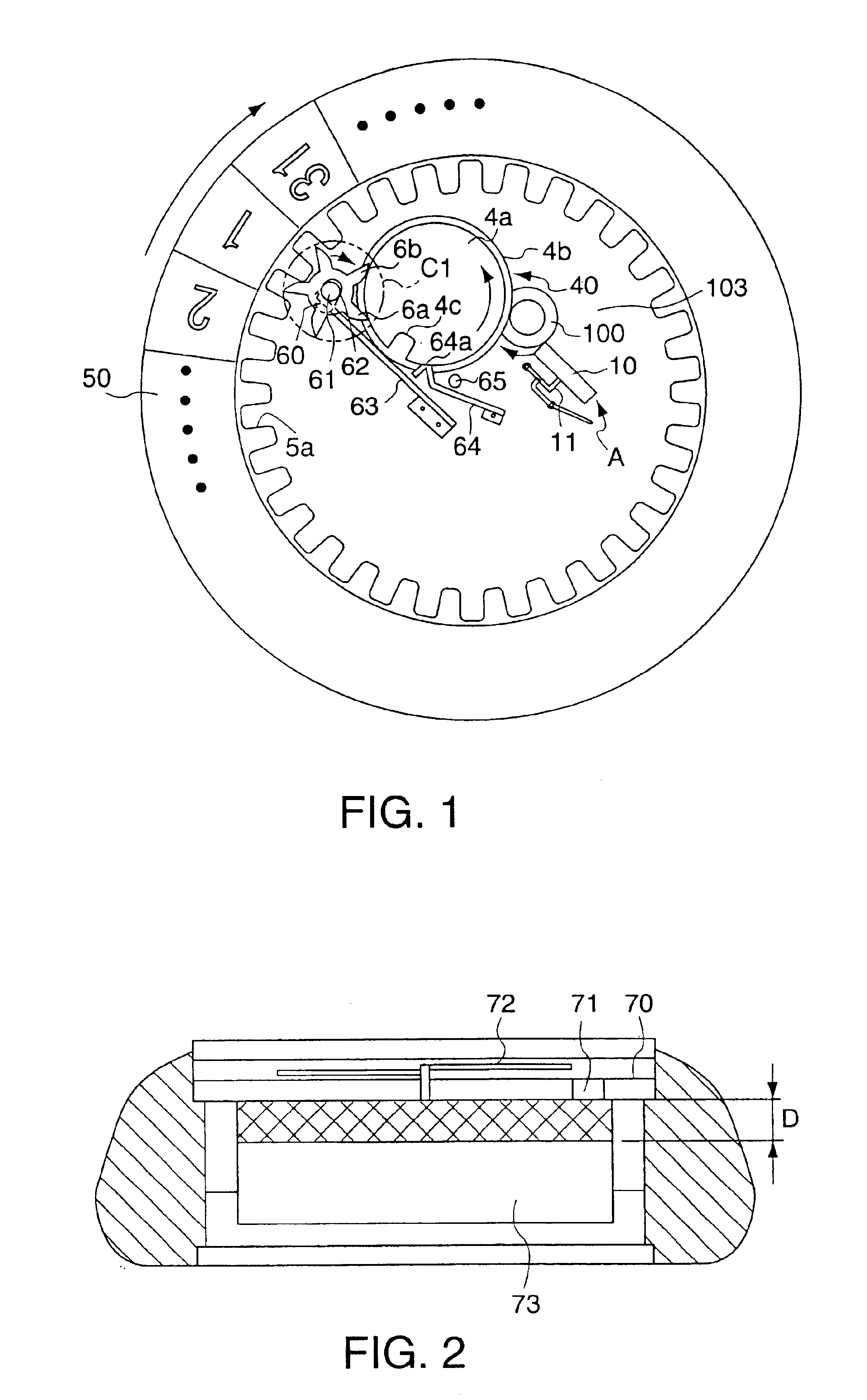

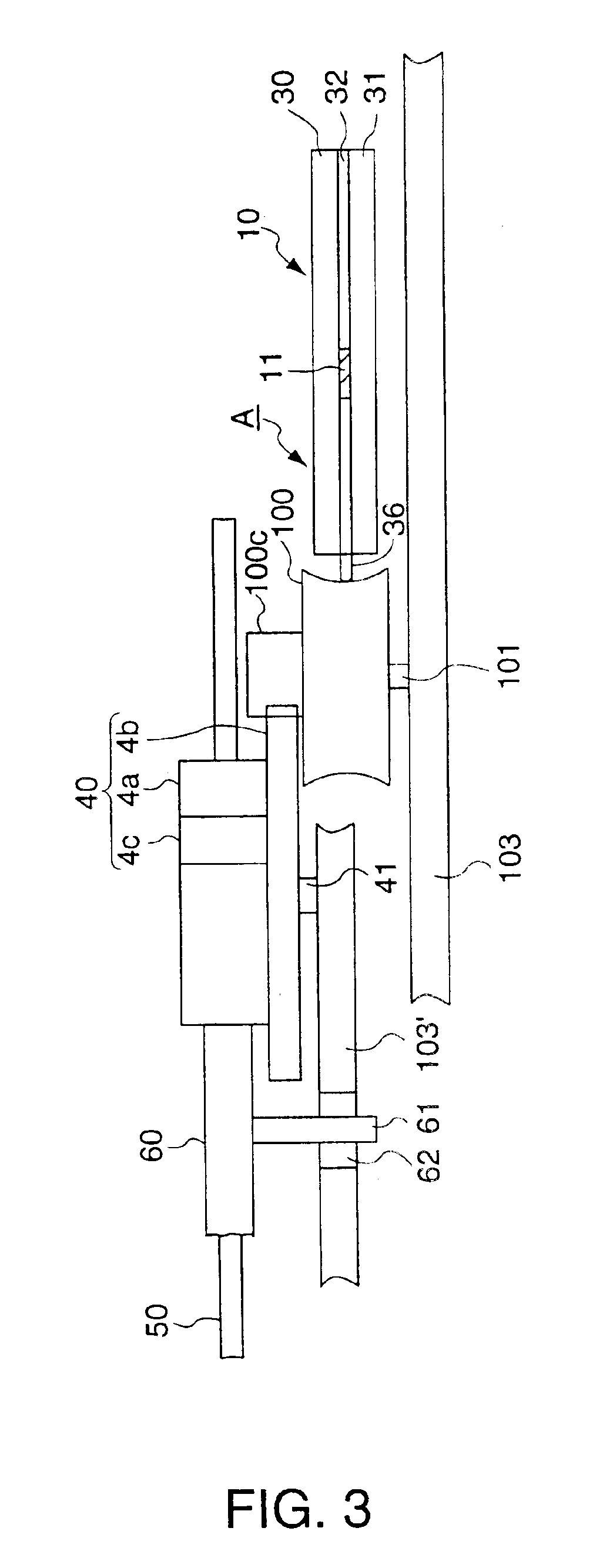

A piezoactuator has a diaphragm, and the diaphragm has flat piezoelectric elements that oscillate in a longitudinal oscillation mode and a sinusoidal oscillation mode. A first electrode for detecting oscillation in the longitudinal oscillation mode, and a second electrode for detecting the amplitude of oscillation in the sinusoidal oscillation mode, are disposed on the surface of the diaphragm. When the piezoactuator is driven with a drive signal, the phase difference of a first detection signal output from the first electrode and a second detection signal output from the second electrode is detected. The frequency at which the detected phase difference becomes the maximum phase difference is then obtained, and a drive signal of a matching frequency is applied to the piezoelectric elements.

Owner:SEIKO EPSON CORP

Electric furnace continuous casting short process production method of oil well pipe billets

InactiveCN101653822ASolve quality problemsMeet the quality requirements of rolled pipeElectric furnaceElectric arc furnaceOil well

The invention relates to an electric furnace continuous casting short process production method of oil well pipe billets and the method comprises electric arc furnace smelting, LF external refining, VD vacuum treating, full protection pouring and continuous casting of round tube billet and tube rolling; a conticaster for both square and round billets is used, when producing square or round billets, only the crystallizer assembly and nozzles in second cooling zone first section, second cooling zone second section and second cooling zone third section are needed to change, in the crystallizer assembly, the conical degree of the crystallizer copper tube is parabolic shape, and the crystallizer adopts hydraulic non-sinusoidal oscillation, wherein the amplitude is 0+ / -5mm, the vibration frequency is 40-360 times / min and the maximum skewness of non-sinusoidal wave is 40%. The method of the invention can realize the electric furnace continuous casting short process production method of zero defect oil well pipe billets, solve the surface and inner quality problem of continuous casting well pipe billets and meet the quality requirements for rolling the oil well pipe.

Owner:KUNMING IRON & STEEL

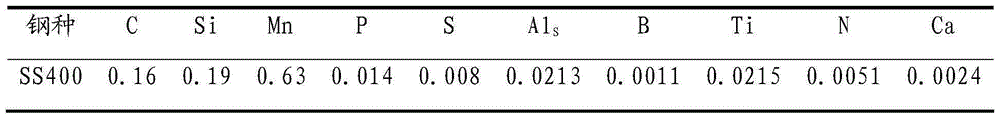

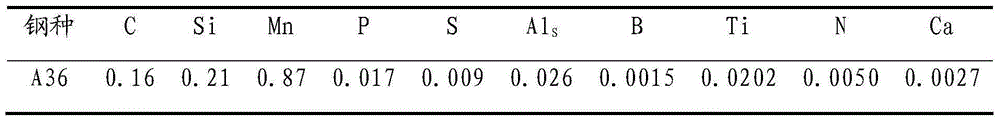

Method for controlling corner cracks of boron micro-alloy steel continuous-casting billet

The invention discloses a method for controlling corner cracks of a boron micro-alloy steel continuous-casting billet. The method comprises the following steps: a refining step: after adjusting components and temperature, feeding an aluminum wire to steel liquid, wherein in the treated steel liquid: S is less than or equal to 0.01 percent, Mn / S is more than or equal to 40, N is less than or equal to 0.0055 percent, Als is equal to 0.015 to 0.035 percent; after feeding the aluminum wire, slightly blowing argon for four minutes, adding ferrotitanium into the steel liquid, wherein the content of Ti in the steel liquid is 0.015 to 0.025 percent, then feeding ferro-boron into the steel three minutes later, carrying out the calcium treatment for the steel liquid; a continuous casting step: the width of the casting billet is 1600mm to 2100mm, the thickness of the casting billet is 180mm to 250mm, controlling the pulling speed at 0.9 to 1.4 m / min when pouring the steel liquid; oscillating a crystallizer in a non-sinusoidal manner when the steel liquid is poured, the waveform deflection rate of the non-sinusoidal oscillation curve is 10 percent, and the negative slip time tn is 0.137 to 0.145s; stabilizing the water amount on a wide surface and a narrow surface of the crystallizerat 4100 to 4500L / min and 410 to 450L / min; adding protection residue into the crystallizer, wherein the alkalinity of the protection residue is 1.2+ / -0.1, a melting point is 1140+ / -20DEG C, and the viscosity at 1300 DEG C is 0.15+ / -0.05Pa.s; controlling the secondary cooling water amount at 0.5 to 0.55 L / kg during the continuous casting process.

Owner:TIANJIN IRON & STEEL GRP

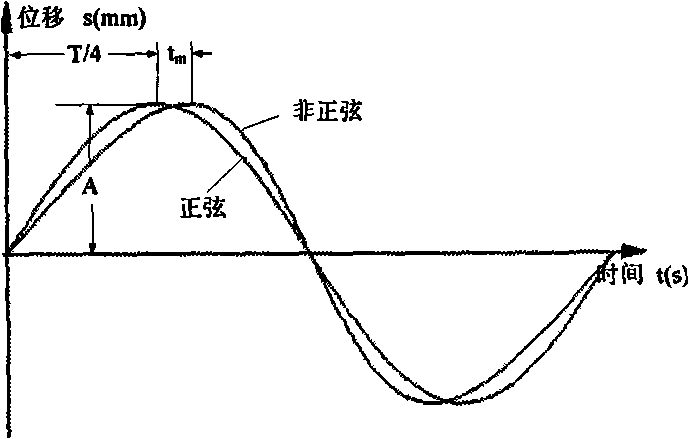

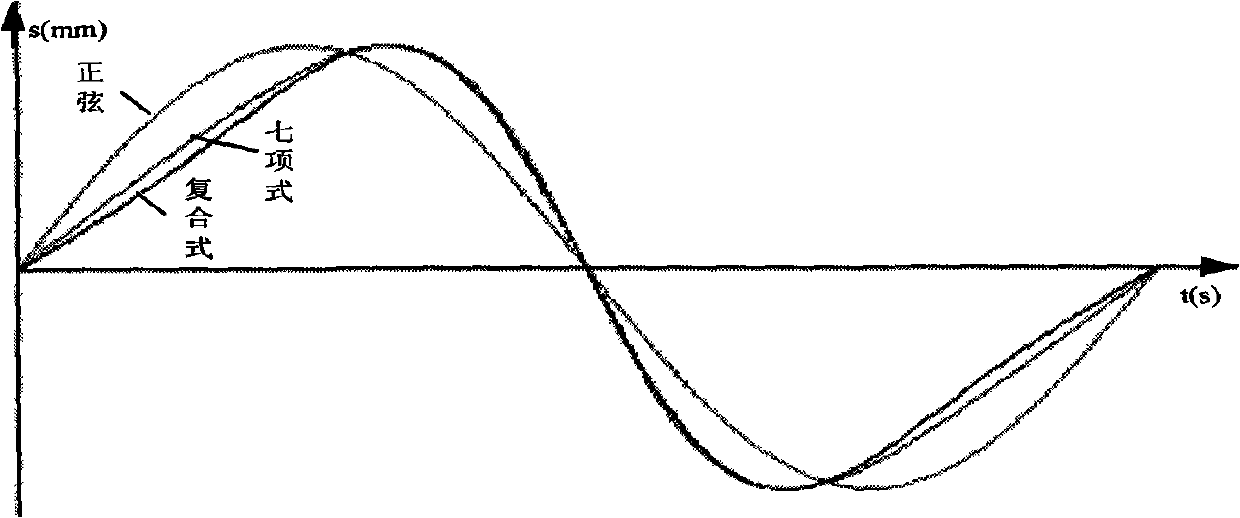

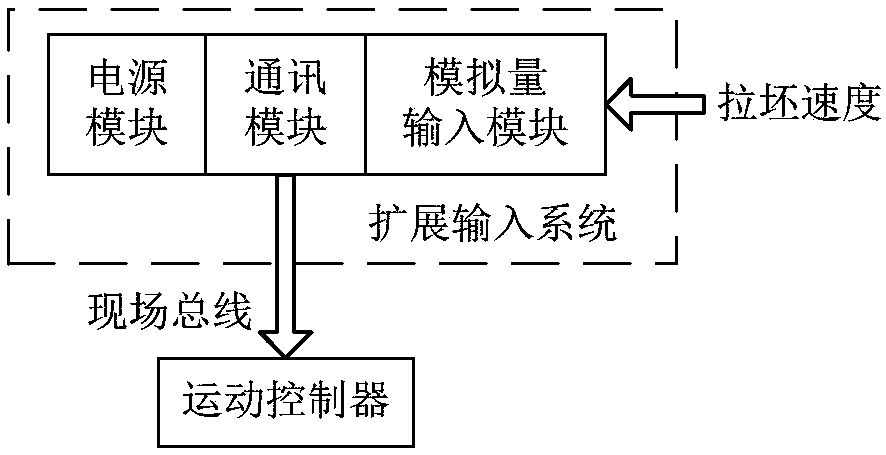

Non-sinusoidal waveform generator used for mold oscillation

ActiveCN101537477AImprove surface qualityReduce frictionMechanical oscillations controlVibration controlComputer module

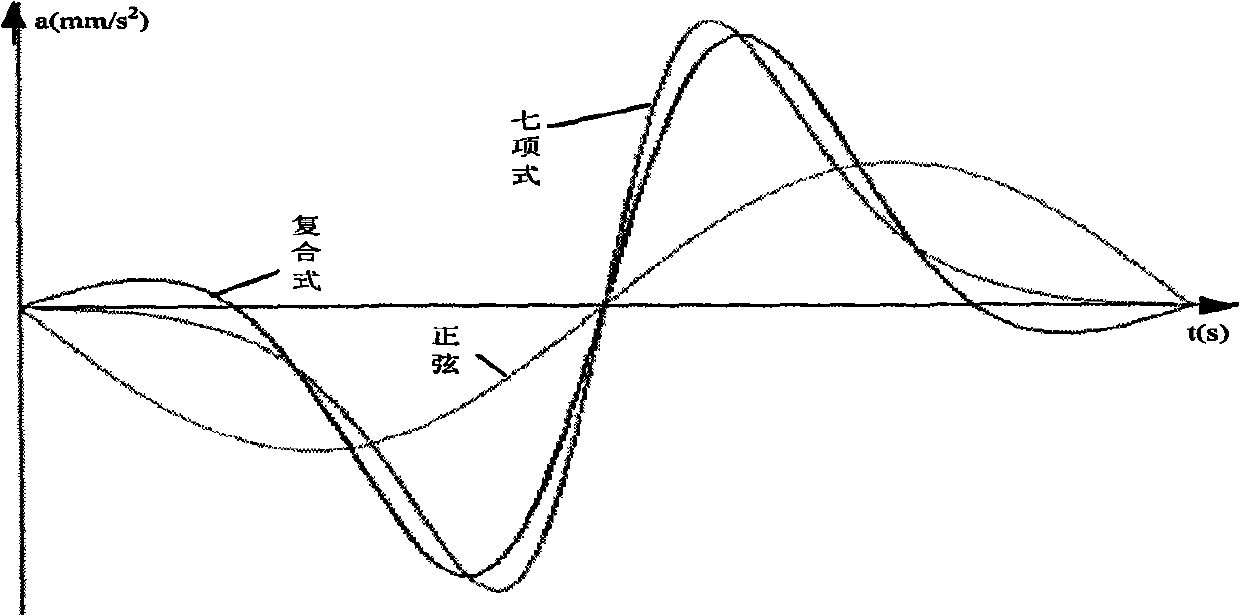

The invention discloses a non-sinusoidal waveform generator used for mold oscillation, comprising a signal input module, a waveform generation module and a waveform output module, wherein the signal input module is used for inputting the amplitude, the frequency and the deviating rate of the non-sinusoidal waveform; the waveform generation module is used for receiving the amplitude, the frequency and the deviating rate of the signal input module to generate corresponding waveform; and the waveform output module is used for outputting the waveform generated by the waveform generation module to an oscillation controller. The waveform generation module executes the following function: s is equal to Ah x*(-delta)<m-1>Sin(m omega t). The non-sinusoidal oscillation waveform generated by the waveform generator can greatly improve the non-sinusoidal deviating rate, and avoid oscillation during the motion process of the equipment so as to lead the equipment to run smoothly; and the non-sinusoidal oscillation waveform can further greatly improve the negative slip time and the effective control range of the negative slip rate, minimize the friction force between the molten steel and the casting mold, reduce oscillation marks on the surface of casting blank and improve the surface quality of the casting blank.

Owner:CISDI ENG CO LTD

Piezoactuator and drive circuit therefor

InactiveUS6841919B2Stably and highly efficiently drivingImprove efficiencyPiezoelectric/electrostriction/magnetostriction machinesFrequency analysisPhase differencePiezoelectric actuators

A piezoactuator has a diaphragm, and the diaphragm has flat piezoelectric elements that oscillate in a longitudinal oscillation mode and a sinusoidal oscillation mode. A first electrode for detecting oscillation in the longitudinal oscillation mode, and a second electrode for detecting the amplitude of oscillation in the sinusoidal oscillation mode, are disposed on the surface of the diaphragm. When the piezoactuator is driven with a drive signal, the phase difference of a first detection signal output from the first electrode and a second detection signal output from the second electrode is detected. The frequency at which the detected phase difference becomes the maximum phase difference is then obtained, and a drive signal of a matching frequency is applied to the piezoelectric elements.

Owner:SEIKO EPSON CORP

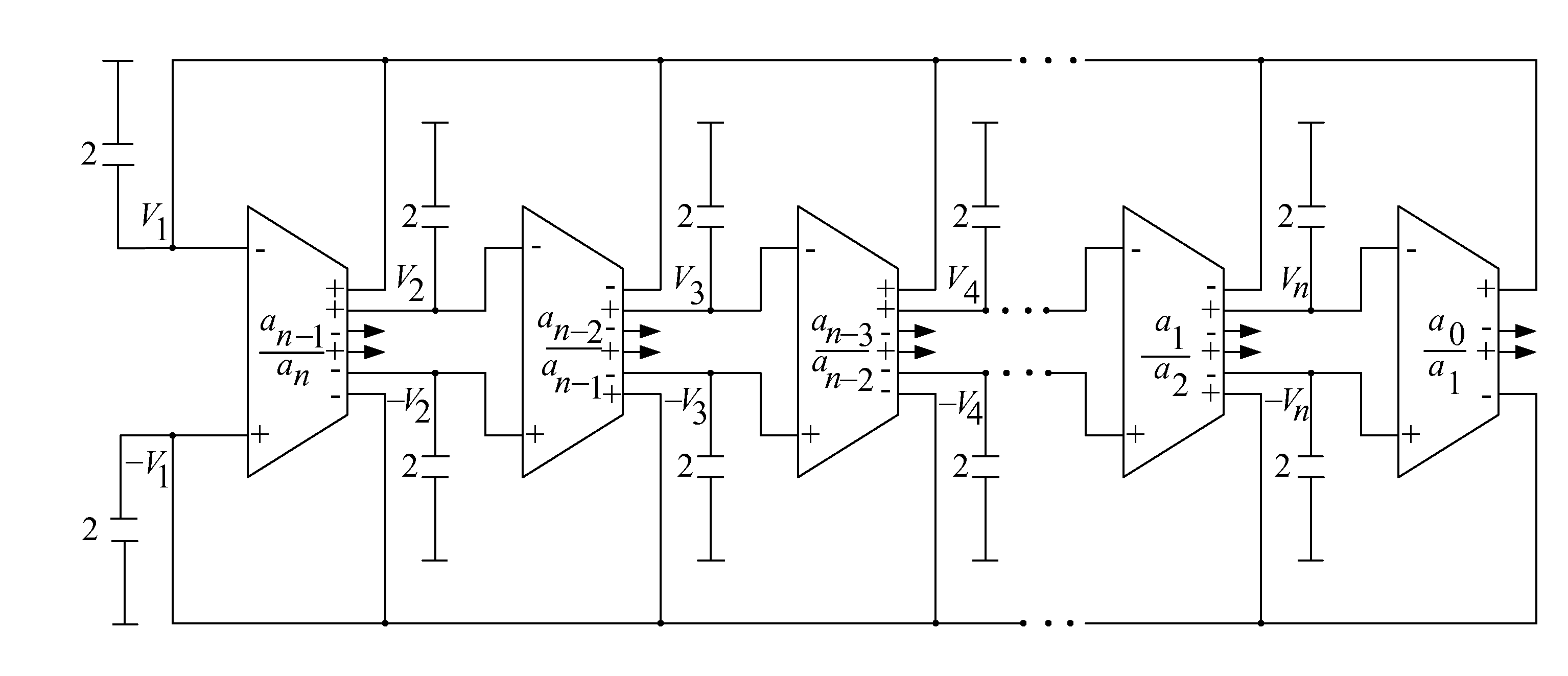

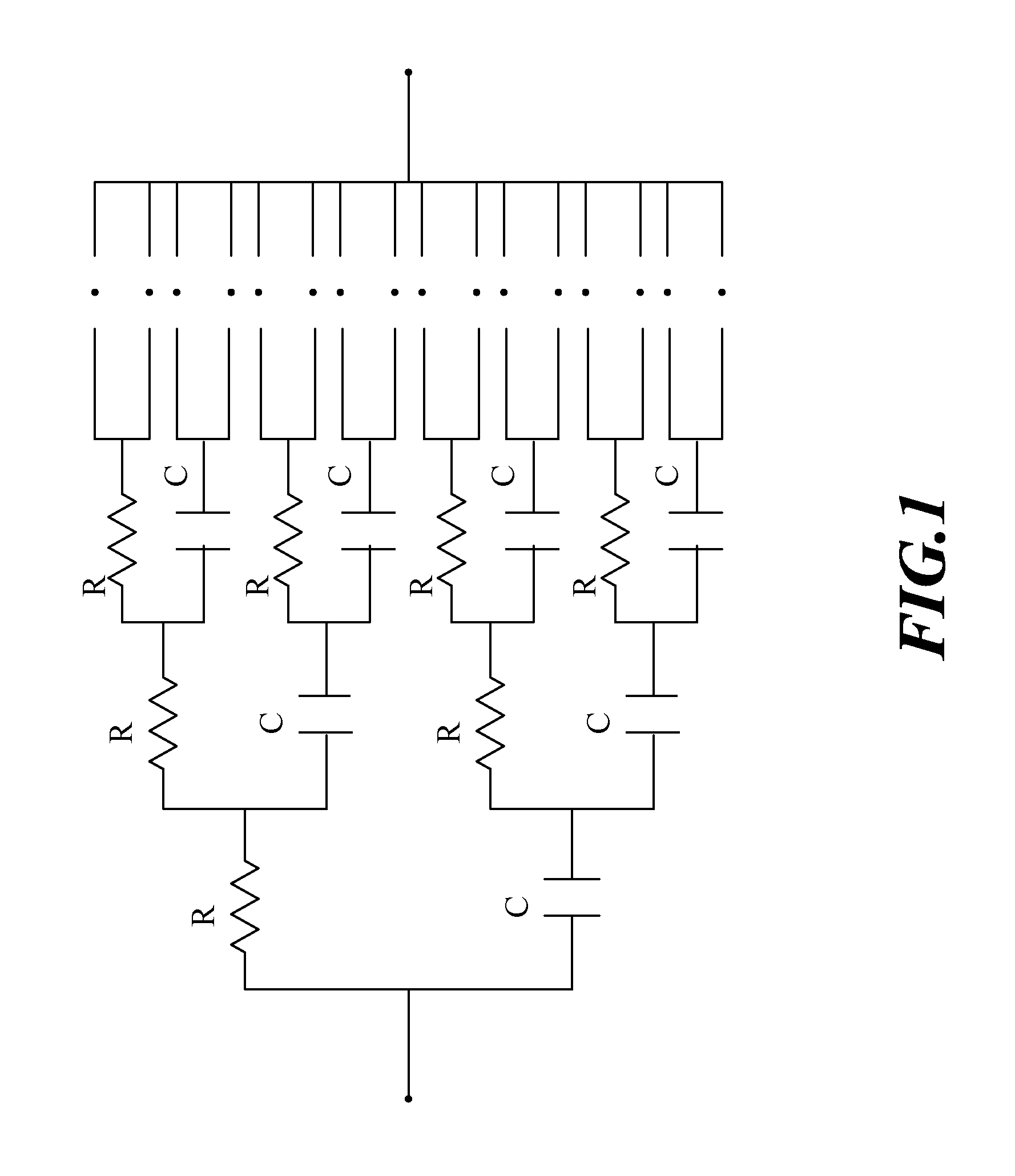

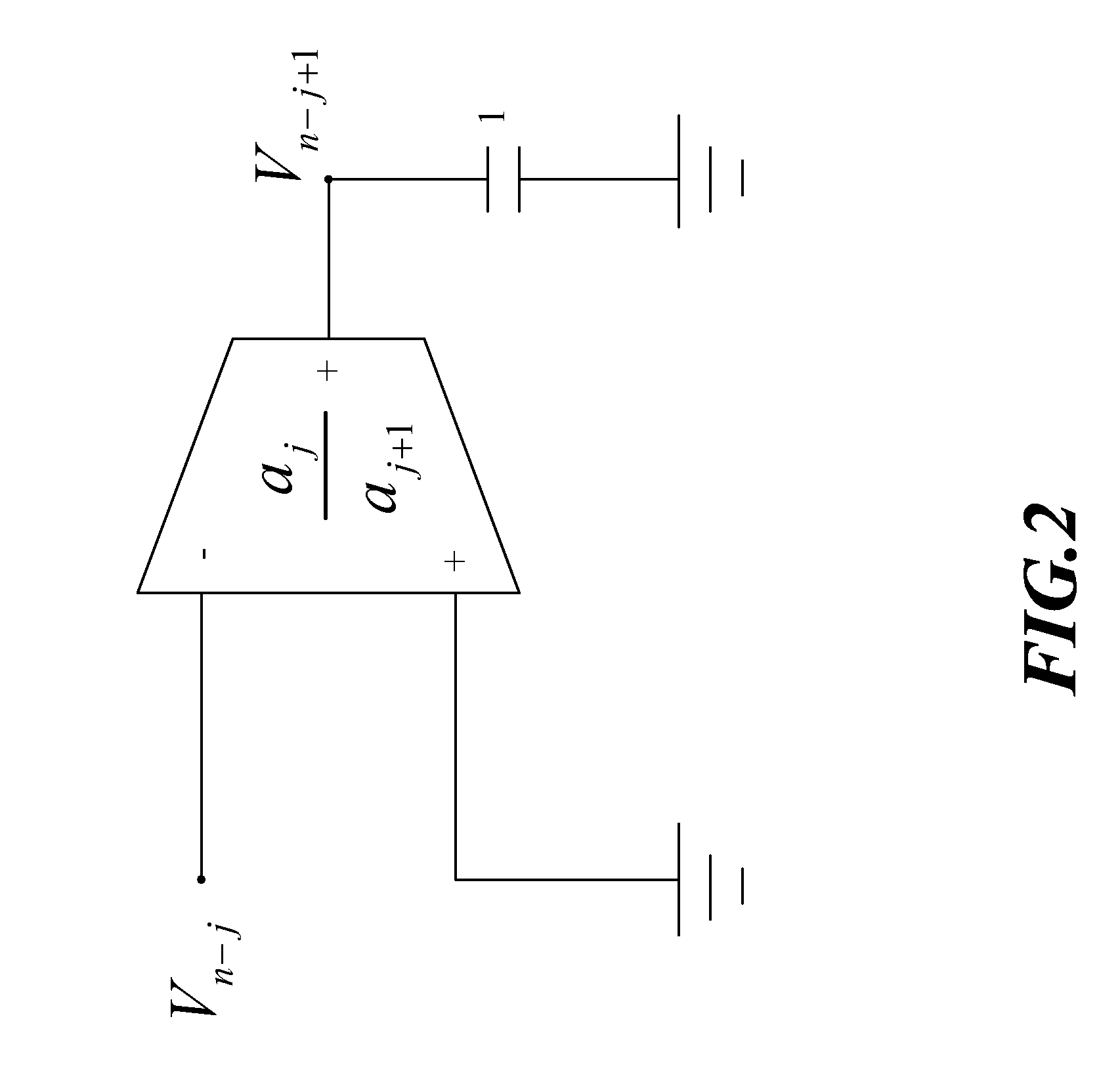

Nth-Order Arbitrary-Phase-Shift Sinusoidal Oscillator Structure and Analytical Synthesis Method of Making the same

InactiveUS20100264996A1Reduce parasiticsReduce power consumptionOscillations generatorsCapacitancePhase shifted

Nth-order voltage- and current-mode arbitrary phase shift oscillator structures are synthesized using n operational trans-conductance amplifiers (OTAs) or second-generation current controlled conveyors (CCCIIs) and n grounded capacitors. Linking up the I / O characteristics of the OTA and the CCCII and the reactance of grounded capacitor, the step of synthesis is first based on the algebraic analysis to oscillatory characteristic equations, resulting in a quadrature oscillator structure. Secondly, instead of the quadrature characteristic, to control each output signal with one another by a desired phase difference > or <90°, selectively superposing any of two fundamental OTA / CCCII-C sub-circuitries benefits the transformation of quadrature to arbitrary-phase-shift characteristic for the sinusoidal oscillator structure. Furthermore, several compensation schemes are presented for reducing the output parameter deviation due to the non-ideal effects.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

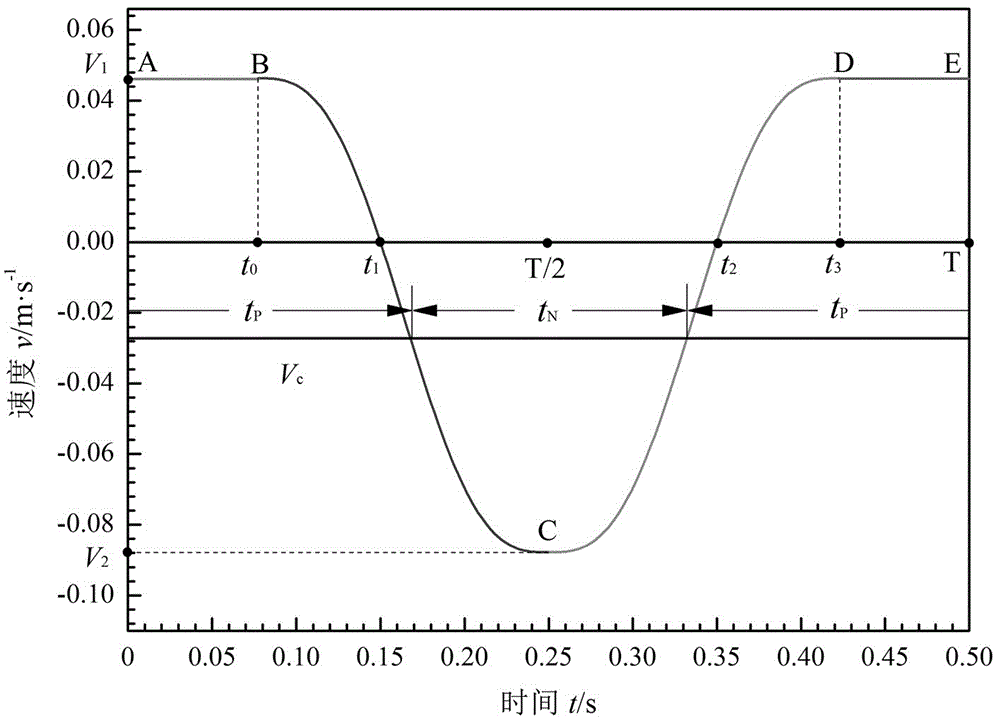

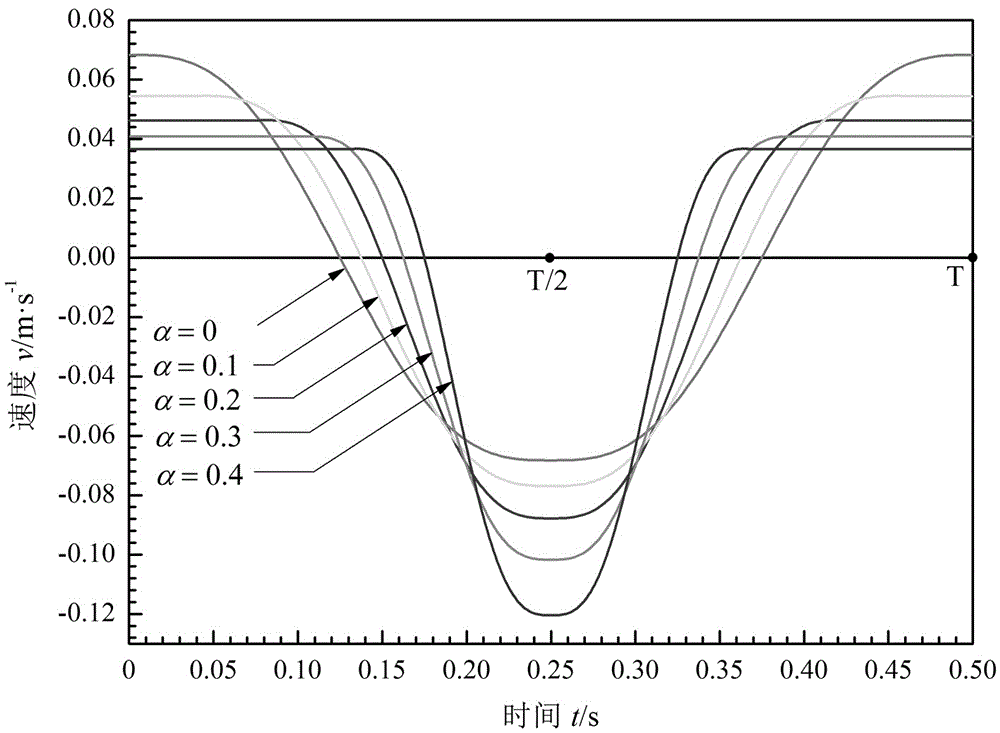

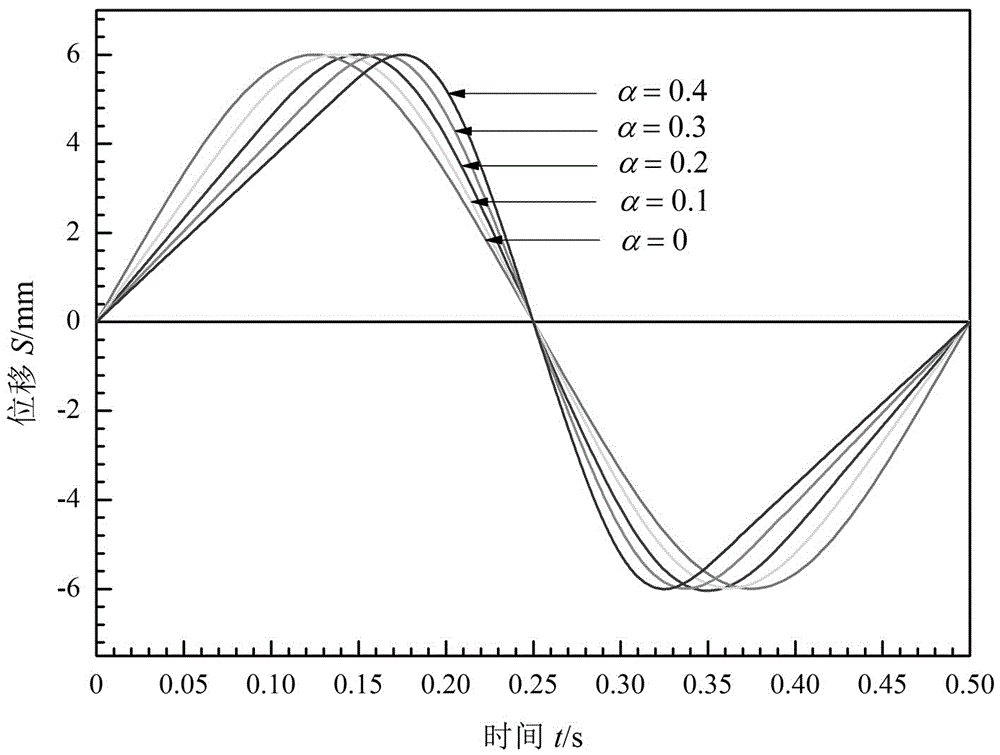

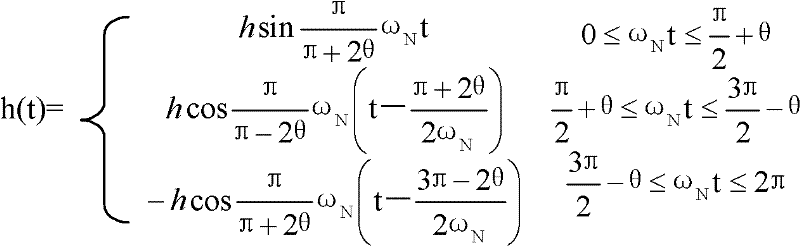

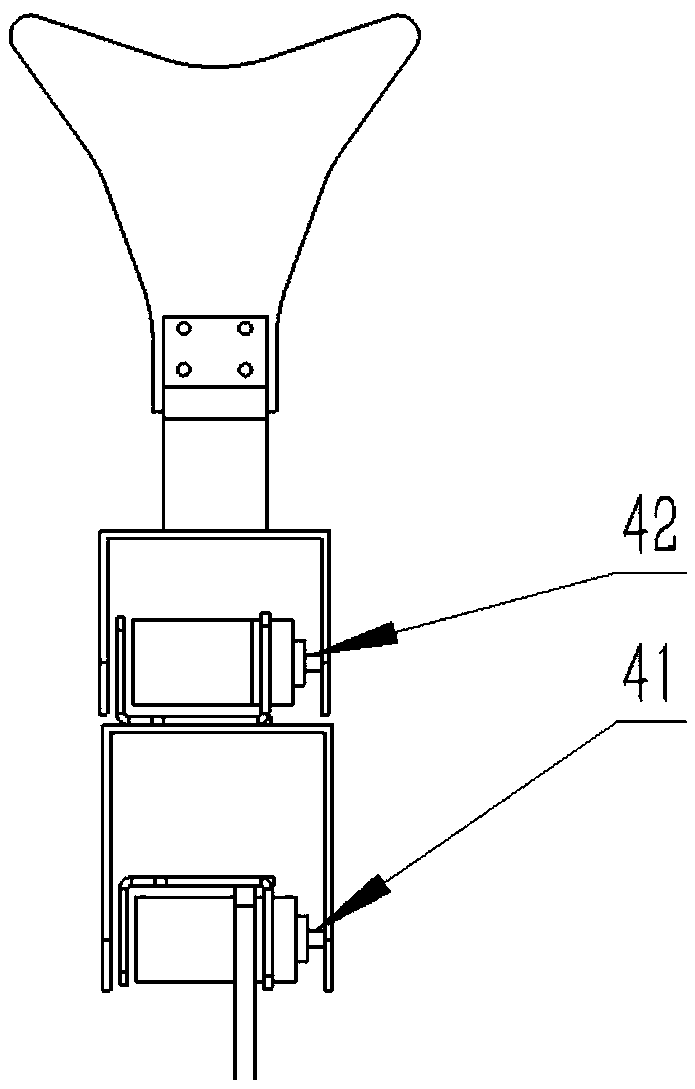

Non-sinusoidal oscillation method for continuous casting crystallizer

The invention provides a non-sinusoidal oscillation method for a continuous casting crystallizer. The non-sinusoidal oscillation method concretely comprises the following steps: controlling a drive device of the continuous casting crystallizer to make the continuous casting crystallizer, driven by the drive device, carry out non-sinusoidal oscillation according to a four-stage speed waveform determined by the following four-stage function within each oscillation period: wherein in each oscillation period, the oscillation process is divided into the following four stages: at the first stage, the continuous casting crystallizer moves upwards at a constant upward oscillation speed; at the second stage, the continuous casting crystallizer carries out decelerated motion upwards firstly and then carries out accelerated motion downwards when the upward oscillation speed is slowed down to 0 until the downward accelerated motion speed reaches T / 2; at the third stage, the continuous casting crystallizer carries out decelerated motion downwards firstly and then carries out accelerated motion upwards when the downward oscillation speed is slowed down to 0 until the upward accelerated motion speed reaches t3; and at the fourth stage, the continuous casting crystallizer moves upwards at a constant upward oscillation speed. According to the non-sinusoidal oscillation method, a non-sinusoidal oscillation waveform is constructed by a four-stage function method, the form is simple, and in addition, speed, displacement and acceleration curves in each oscillation period are all smooth without an inflection point.

Owner:山西建龙实业有限公司

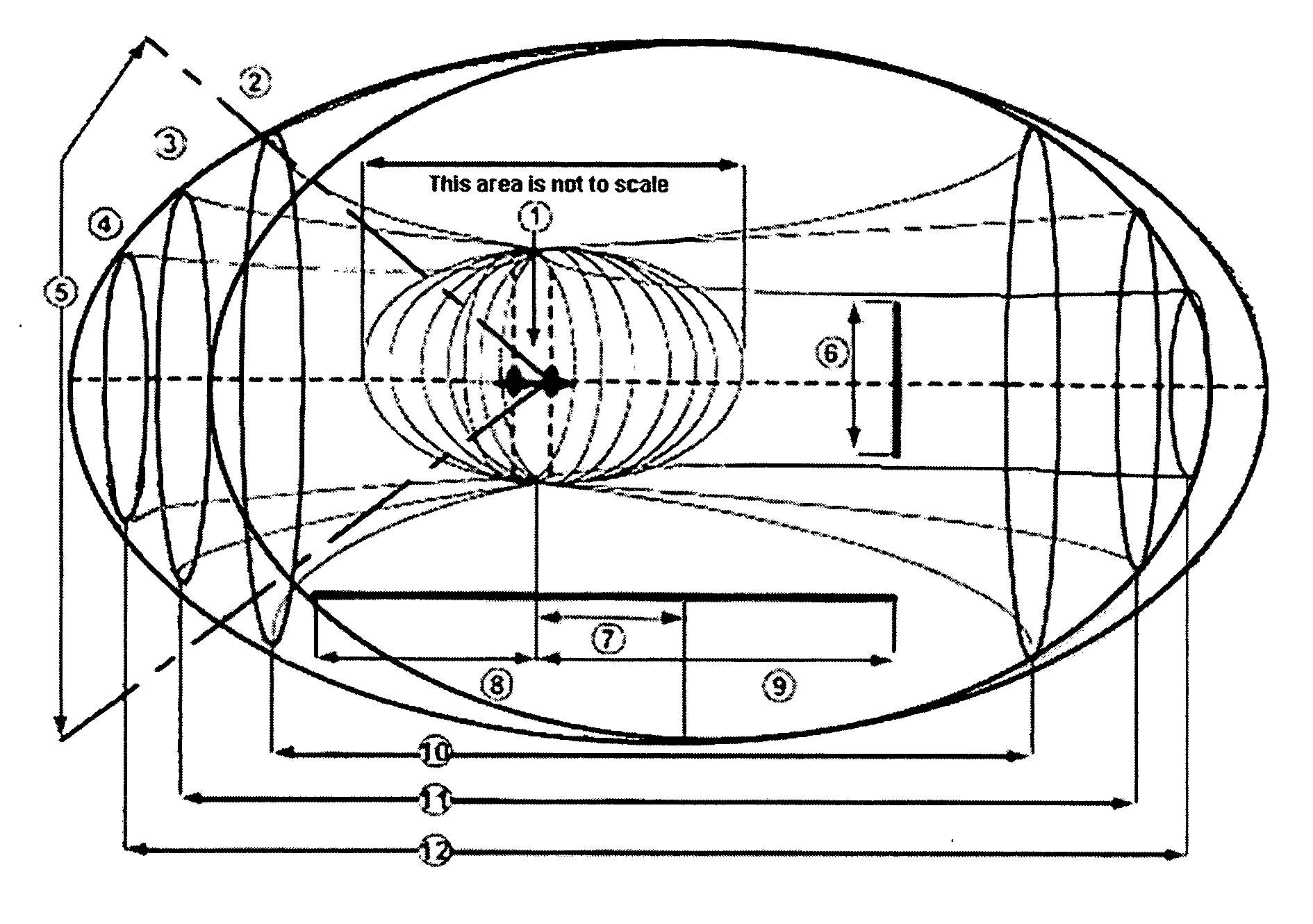

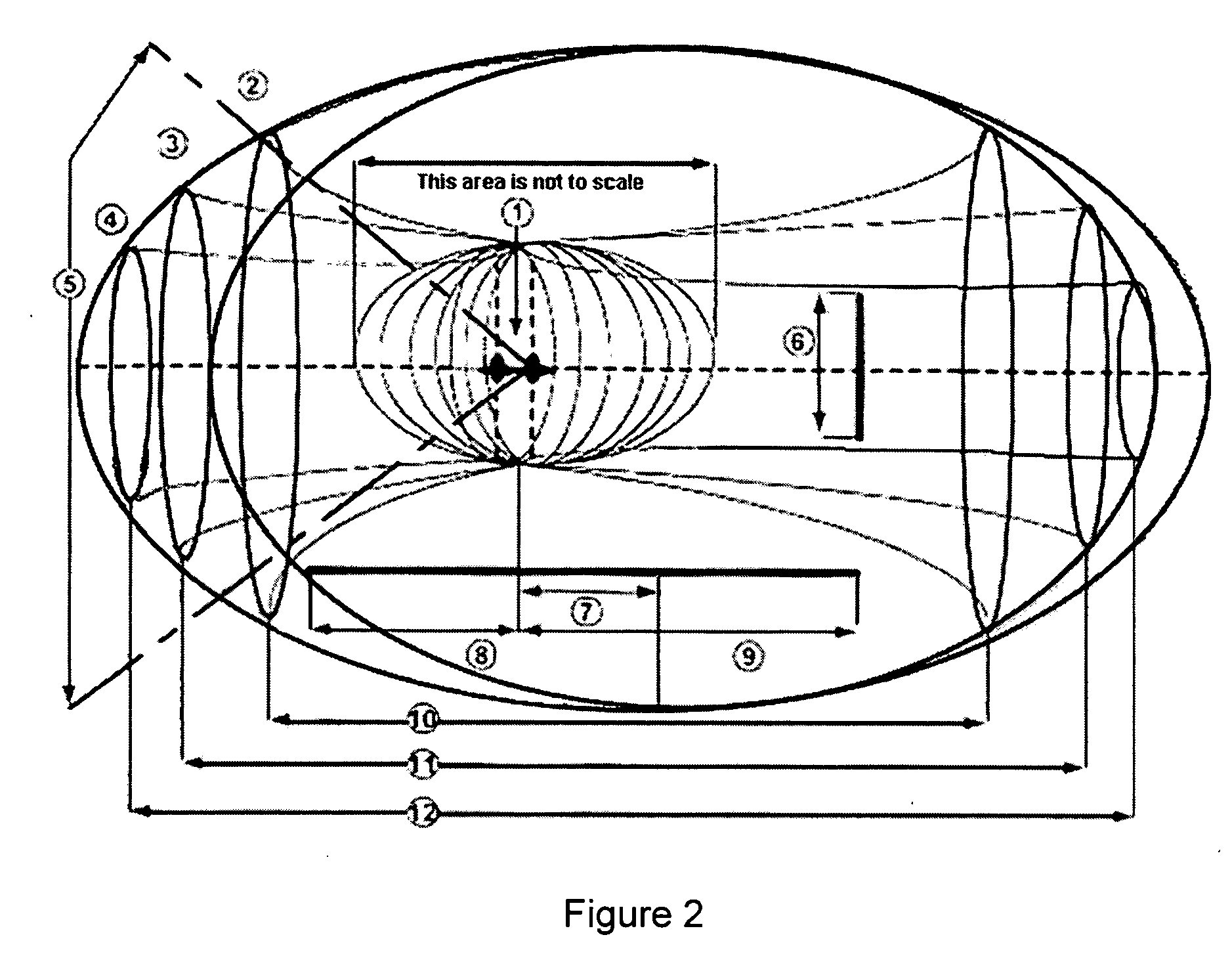

Method of gravity distortion and time displacement

InactiveUS20060073976A1Electromagnetic launchersExcitation process/apparatusClosed timelike curveDistortion

A method for employing sinusoidal oscillations of electrical bombardment on the surface of one Kerr type singularity in close proximity to a second Kerr type singularity in such a method to take advantage of the Lense-Thirring effect, to simulate the effect of two point masses on nearly radial orbits in a 2+1 dimensional anti-de Sitter space resulting in creation of circular timelike geodesics conforming to the van Stockum under the Van Den Broeck modification of the Alcubierre geometry (Van Den Broeck 1999) permitting topology change from one spacelike boundary to the other in accordance with Geroch's theorem (Geroch 1967) which results in a method for the formation of G{umlaut over ( )}odel-type geodesically complete spacetime envelopes complete with closed timelike curves.

Owner:POHLMAN MARLIN B

Average controlled (AC) resonator driver

InactiveUS20060061425A1Low costReduce dependencePulse automatic controlAngle modulation detailsDriver circuitLoop control

Circuits and methods are given, to realize and implement an oscillator circuit with an Average Controlled (AC) Resonator Driver. A newly introduced additional Field Effect Transistor within a voltage average stabilizing regulation loop controlling the crystal oscillator's amplifier element produces an average voltage value stabilized sinusoidal oscillation signal which is then transformed into a square wave with a precise duty-cycle of exactly 50%. Said circuits and methods are designed in order to be implemented with a very economic number of components, capable to be realized with modern integrated circuit technologies.

Owner:DIALOG SEMICONDUCTOR GMBH

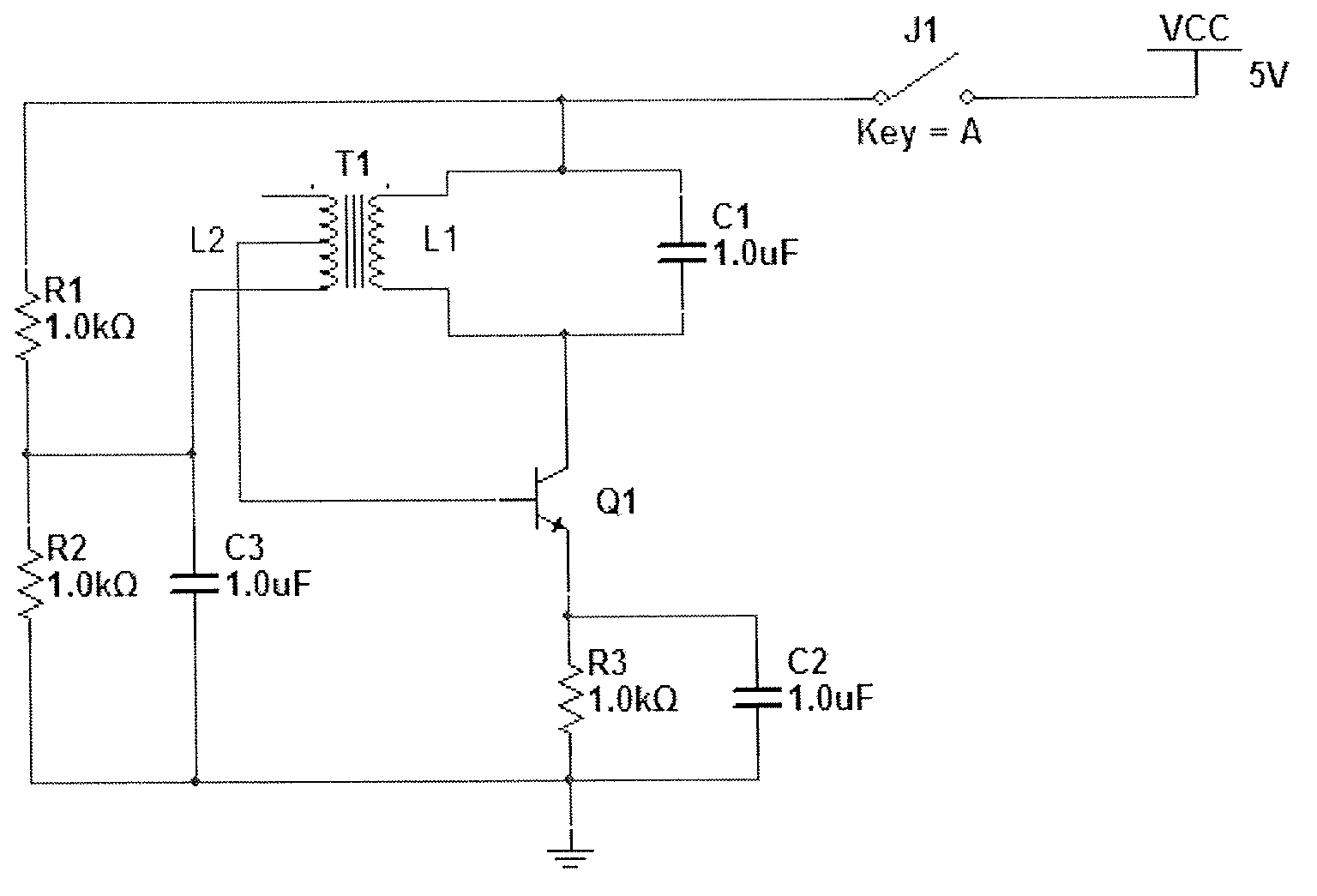

Sine oscillator

InactiveCN103326667AHigh sensitivityReduce lossOscillations generatorsCapacitanceAudio power amplifier

The invention discloses a sine oscillator. The sine oscillator comprises a main amplifier, a LC (Inductor-Capacitor) parallel resonance loop, an operational amplifier and a signal control switch, wherein the main amplifier is provided with a base electrode, a collector electrode and an emitter electrode; the LC parallel resonance loop is formed by connecting an inductor and a capacitor in parallel and connected with the collector electrode of the main amplifier; the operational amplifier is used for providing a positive feedback signal; the operational amplifier is provided with a same-phase input end, an inverted-phase input end and an output end, wherein the output end of the operational amplifier is connected with the base electrode of the main amplifier; the inverted-phase input end of the operational amplifier is connected with the collector electrode of the main amplifier by a first resistor; the inverted-phase input end of the operational amplifier is further connected with the output end of the operational amplifier by a second resistor; and the signal control switch is connected with the same-phase input end of the operational amplifier. The sine oscillator disclosed by the invention is high in sensitivity, small in loss, small in size and convenient to integrate. Besides, the on-off way of the oscillating circuit of the sine oscillator disclosed by the invention is more reasonable.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

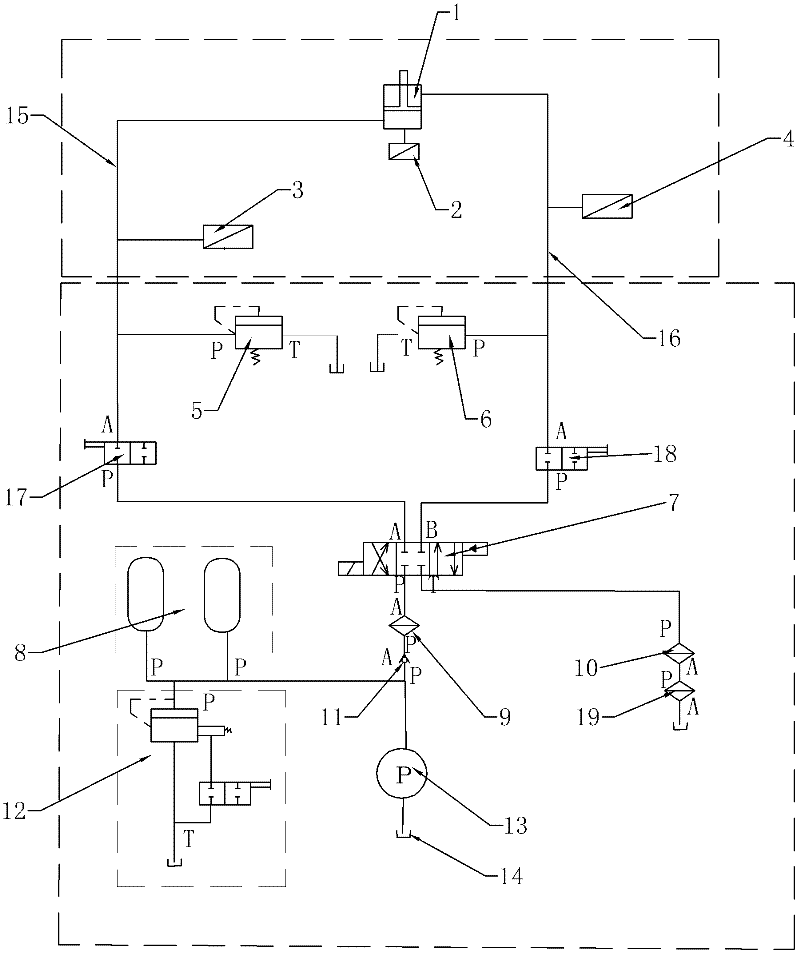

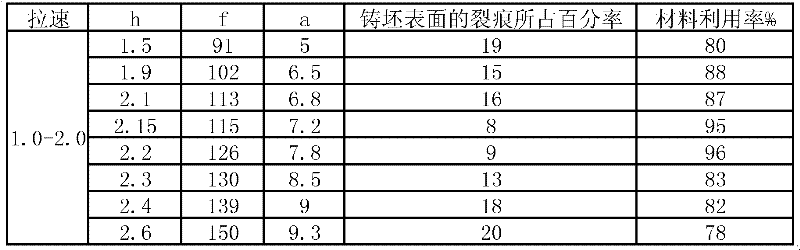

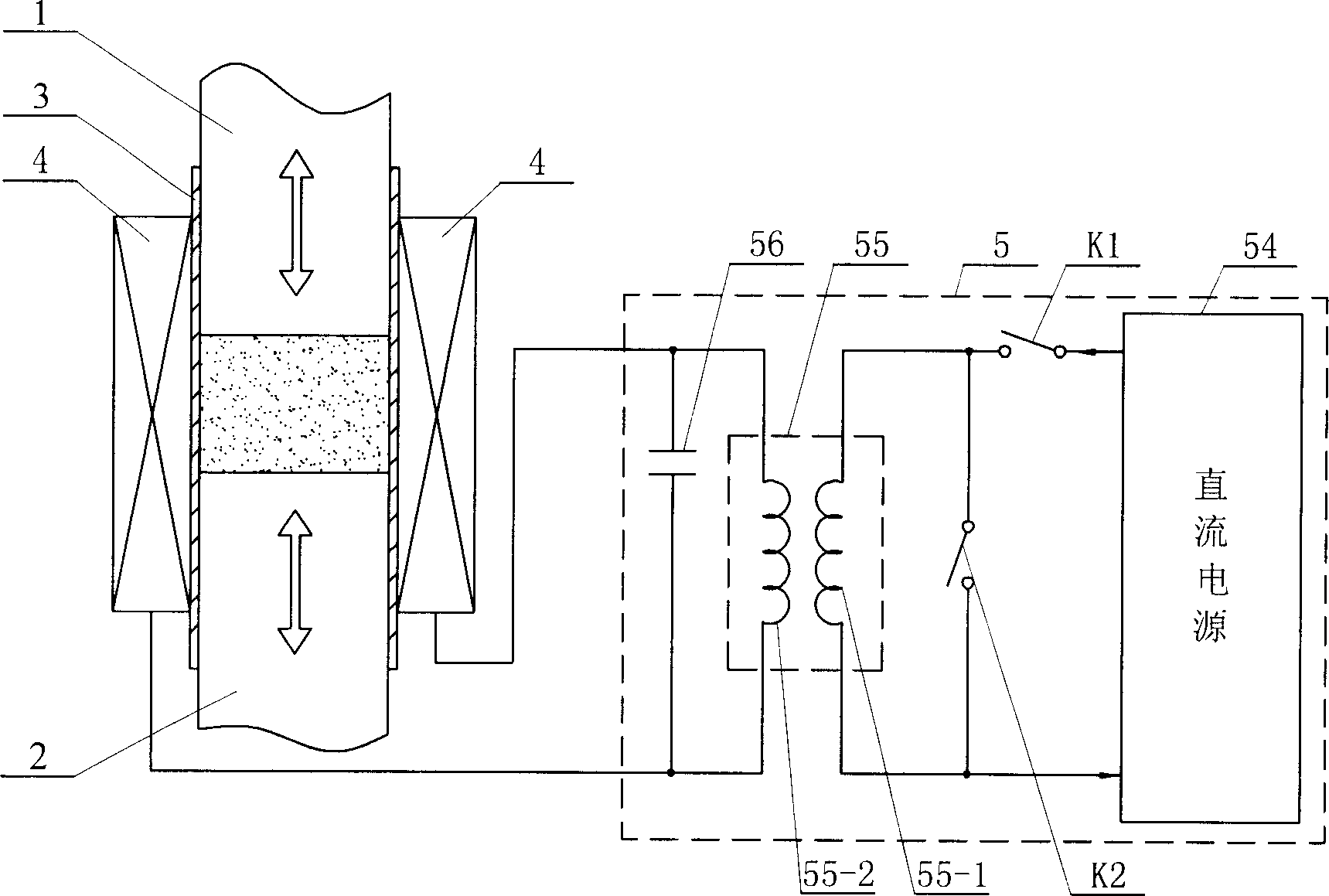

Non-sinusoidal oscillation method for mold and hydraulic system for same

InactiveCN102554152AImprove stressful situationsFluid-pressure actuator componentsProgrammable logic controllerControl system

The invention relates to a non-sinusoidal oscillation control method for a mold of a continuous casting machine and a hydraulic control system for the same, and aims to provide a non-sinusoidal oscillation method for the mold to decrease the depth of a surface oscillation mark of a casting blank and to improve the surface quality of the casting blank. The non-sinusoidal oscillation method for the mold is characterized in that the mold is driven by a servo hydraulic system, and a PLC (programmable logic controller) control system of the mold generates a non-sinusoidal oscillation curve by inputting the control parameters of oscillation amplitude h, oscillation frequency f and deflection rate a to control the servo hydraulic system to work, wherein 1.9mm<=h<=2.3mm, 101cpm<=f<=138cpm, 6.5%<a<8.5%. The hydraulic system comprises a servo hydraulic oscillation cylinder, a position sensor, a pressure sensor, an overflow valve, an electro-hydraulic servo valve, an energy accumulator set, a pressed oil filter, a filter, a one-way valve, an electromagnetic overflow valve and a hydraulic pump.

Owner:XINXING DUCTILE IRON PIPES CO LTD

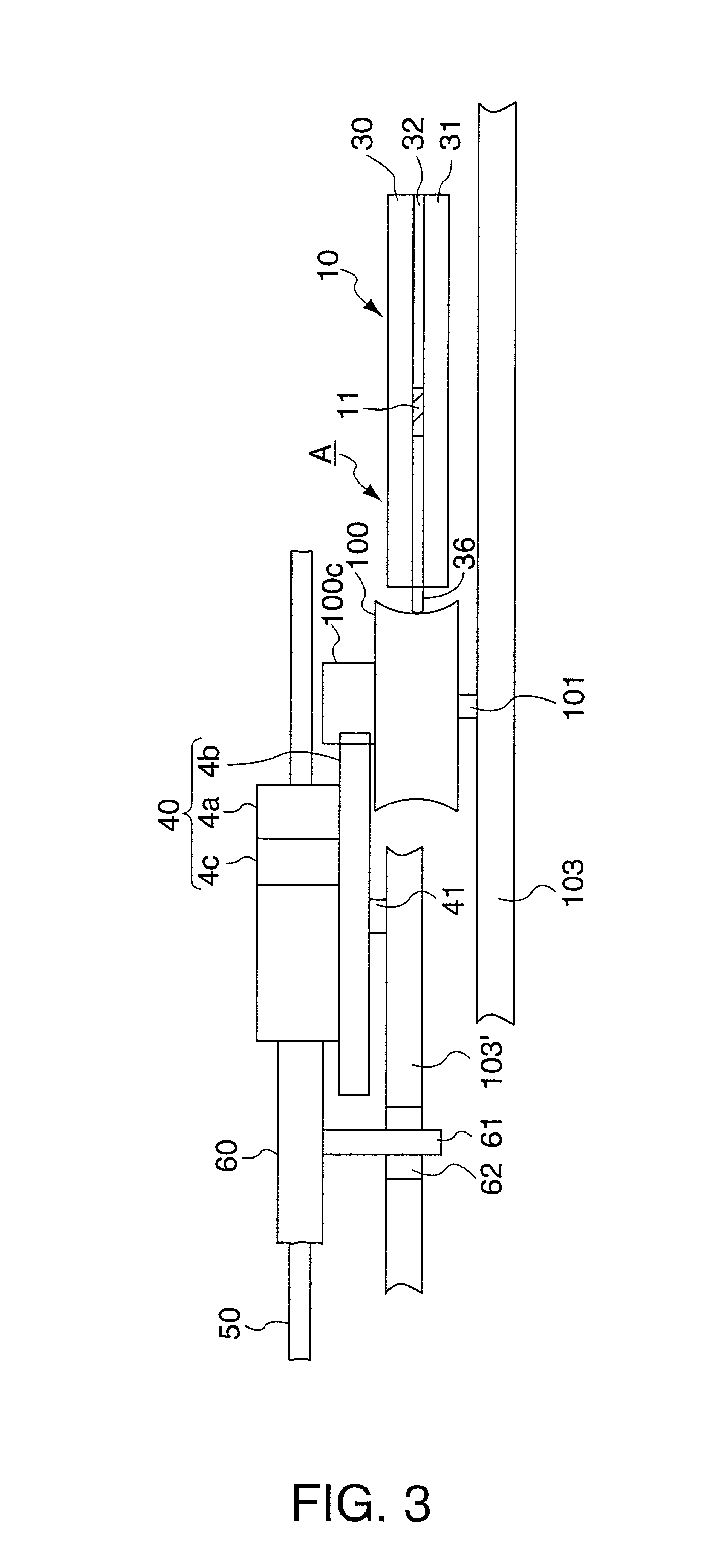

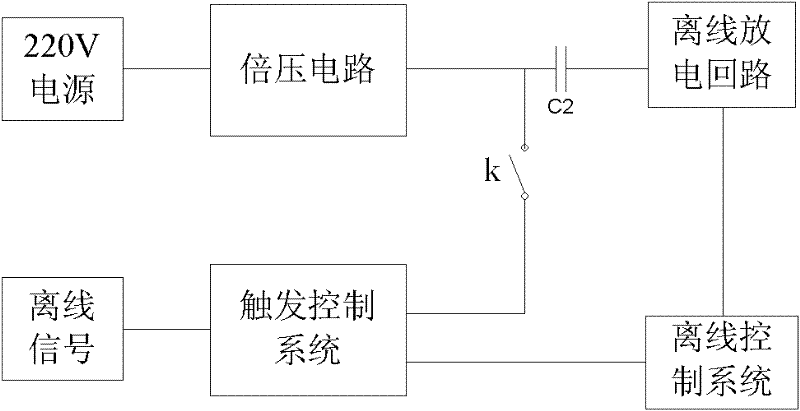

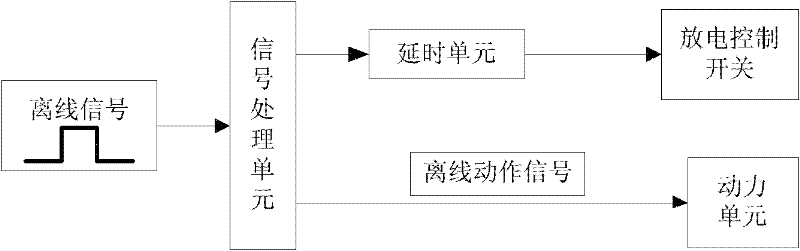

Offline experimental device for 25kV-grade pantograph

ActiveCN102590653ATrue restorationRestore accuratelyTesting dielectric strengthCapacitanceUltrasound attenuation

The invention discloses an offline experimental device for a 25kV-grade pantograph. The device comprises a voltage doubling circuit and a trigger control unit. The voltage doubling circuit adopts a 220V power supply, and is connected with an offline discharge circuit as an input power supply. The offline discharge circuit comprises a discharge capacitor, a discharge control switch, the pantograph, a contact line and a regulating load, which are sequentially connected. An offline control system controls the pantograph to be offline through a power unit. The trigger control unit controls the pantograph to be offline when discharge voltage is attenuated to a 25kV grade by controlling the discharge control switch and the offline control system. The sinusoidal oscillation attenuation discharge of different frequencies and different amplitudes is realized by regulating parameters of the offline discharge circuit, and the pantograph is separated from the contact line at any moment immediately when the capacitor discharges, so that a high-voltage heavy current offline phenomenon is produced to really and accurately recover realistic conditions and further make related researches.

Owner:BEIJING JIAOTONG UNIV

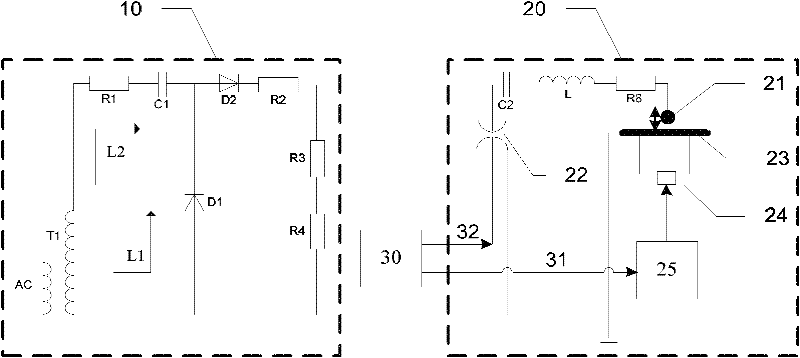

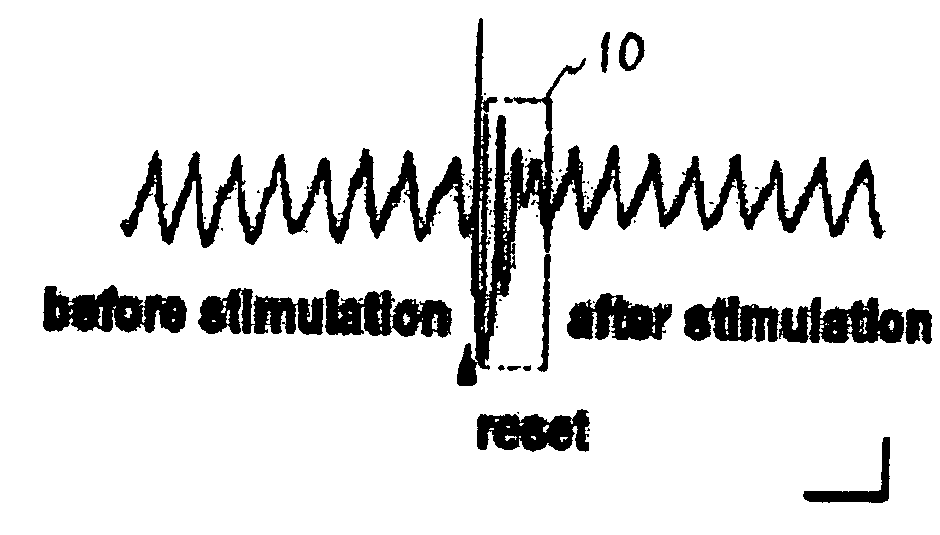

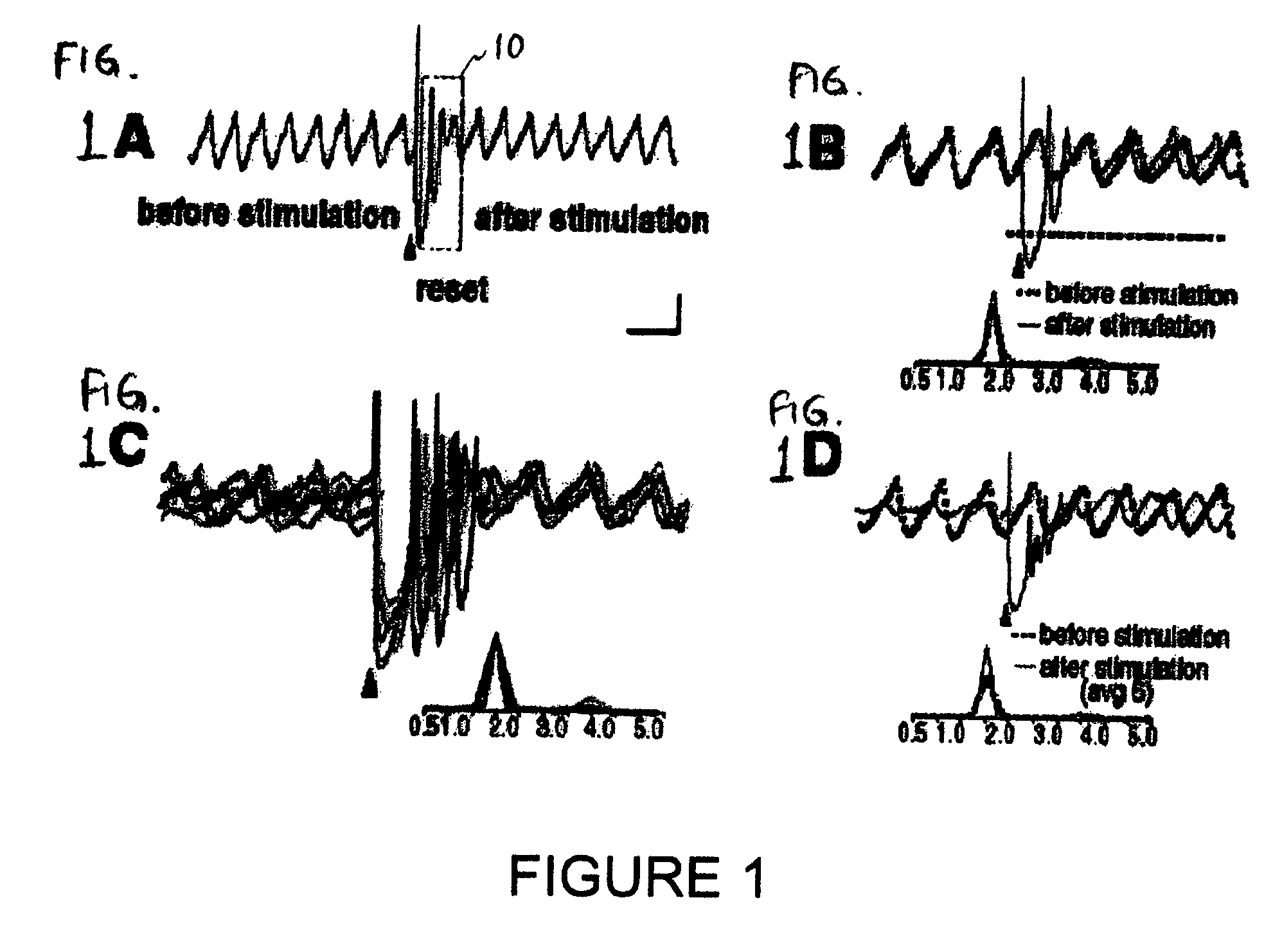

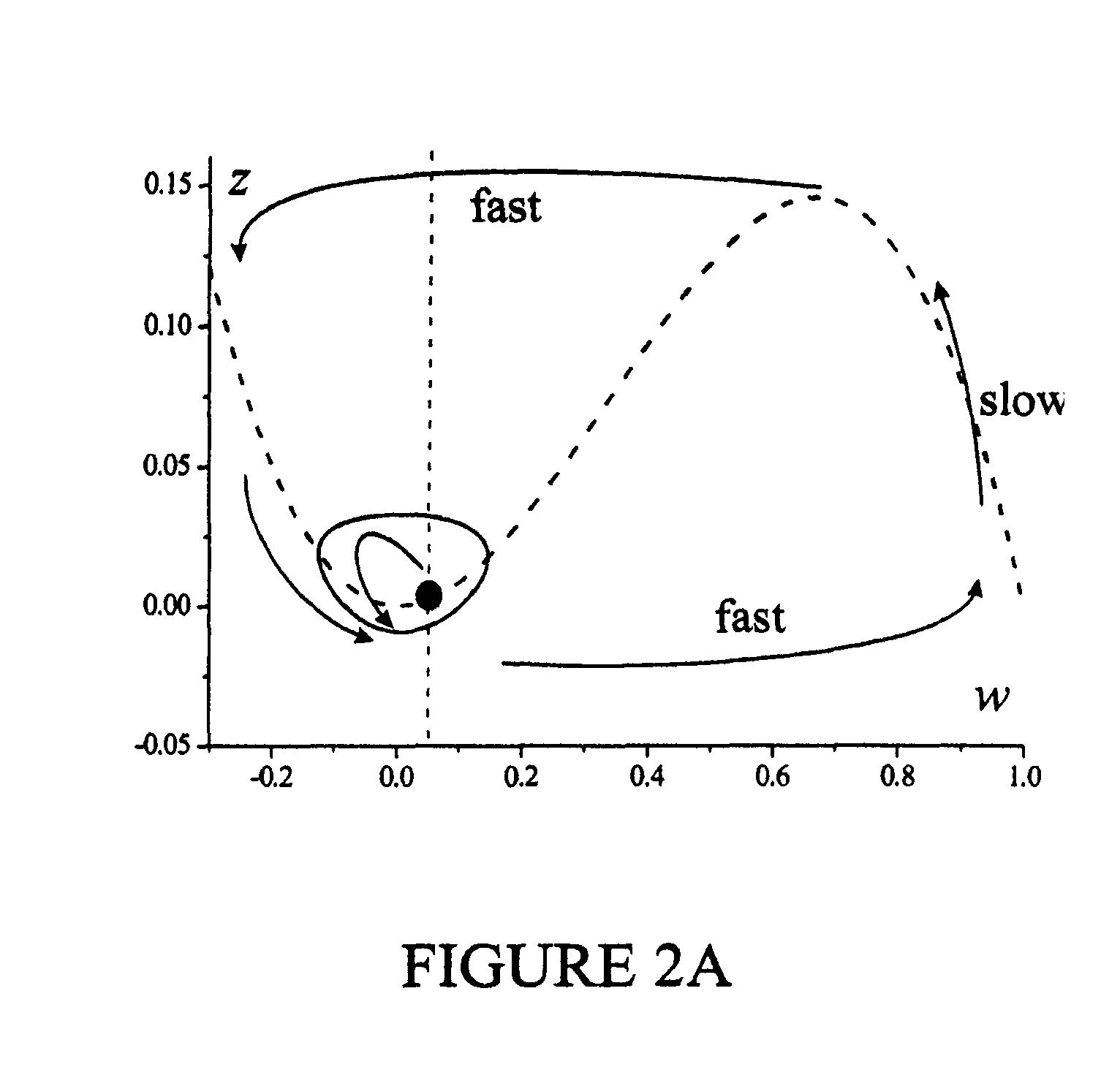

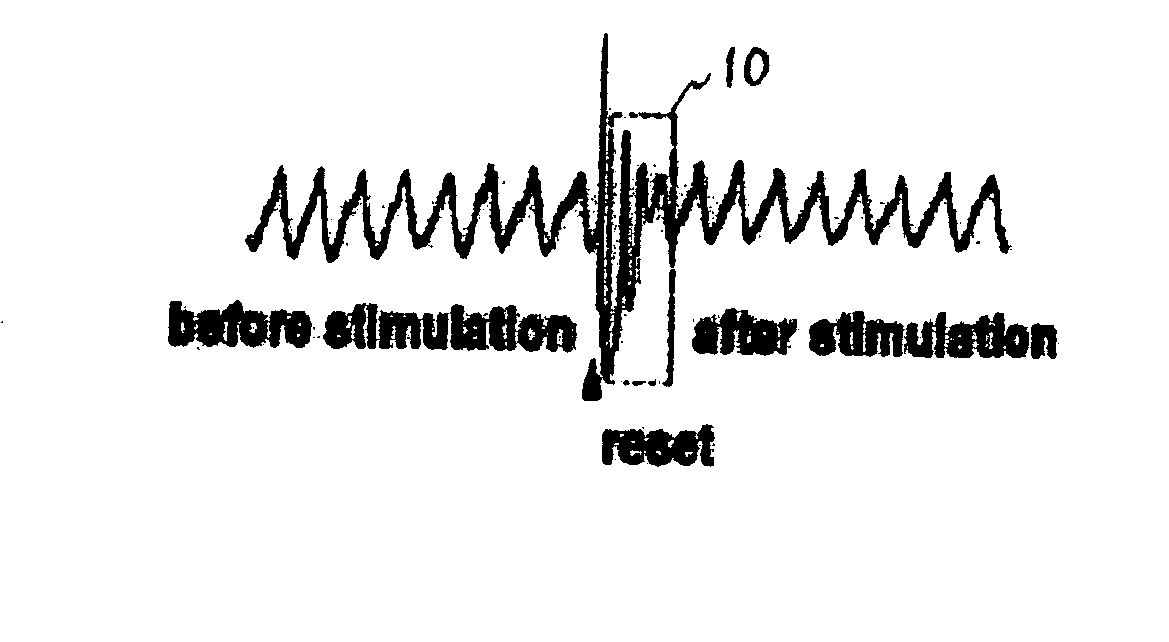

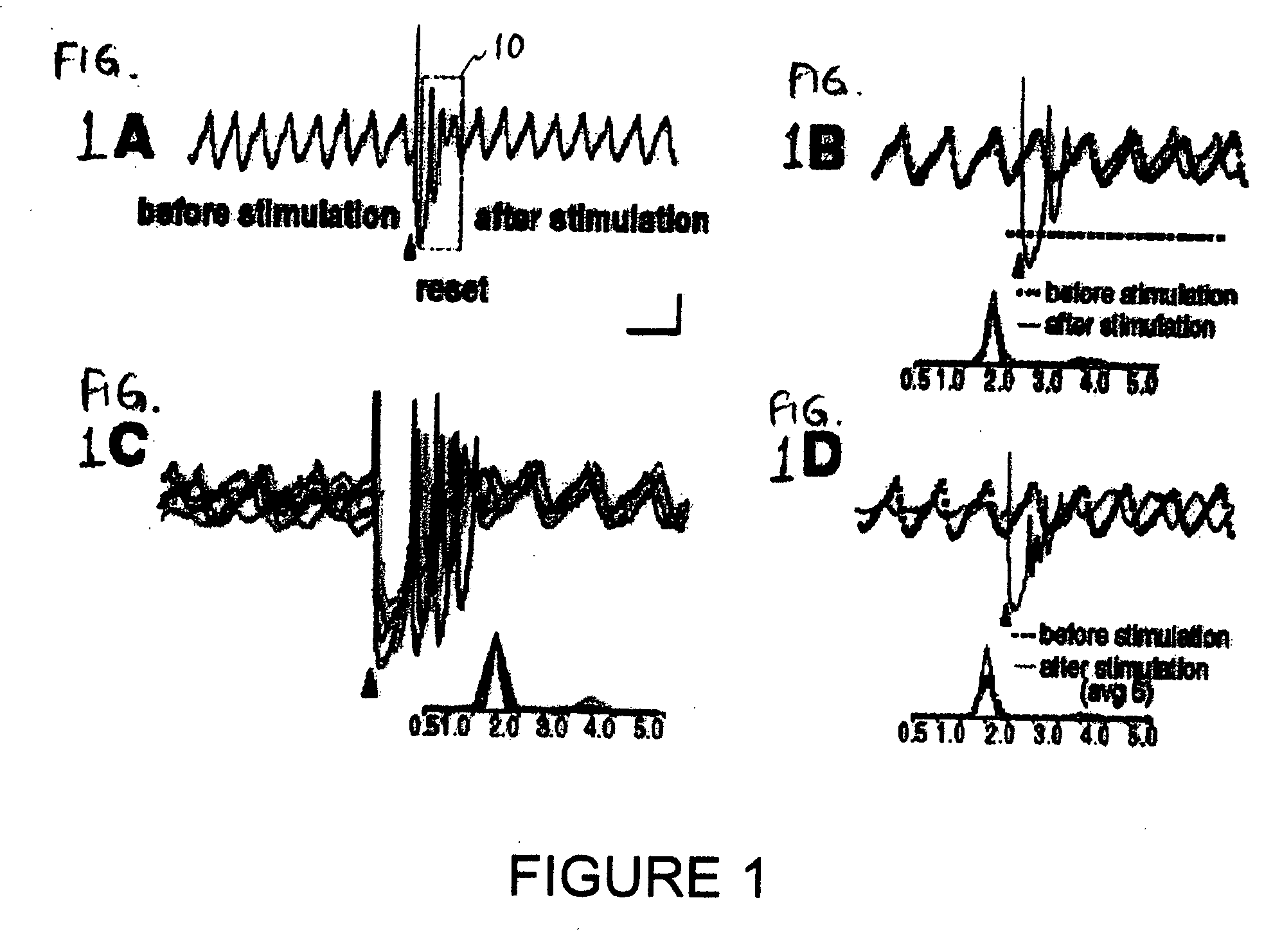

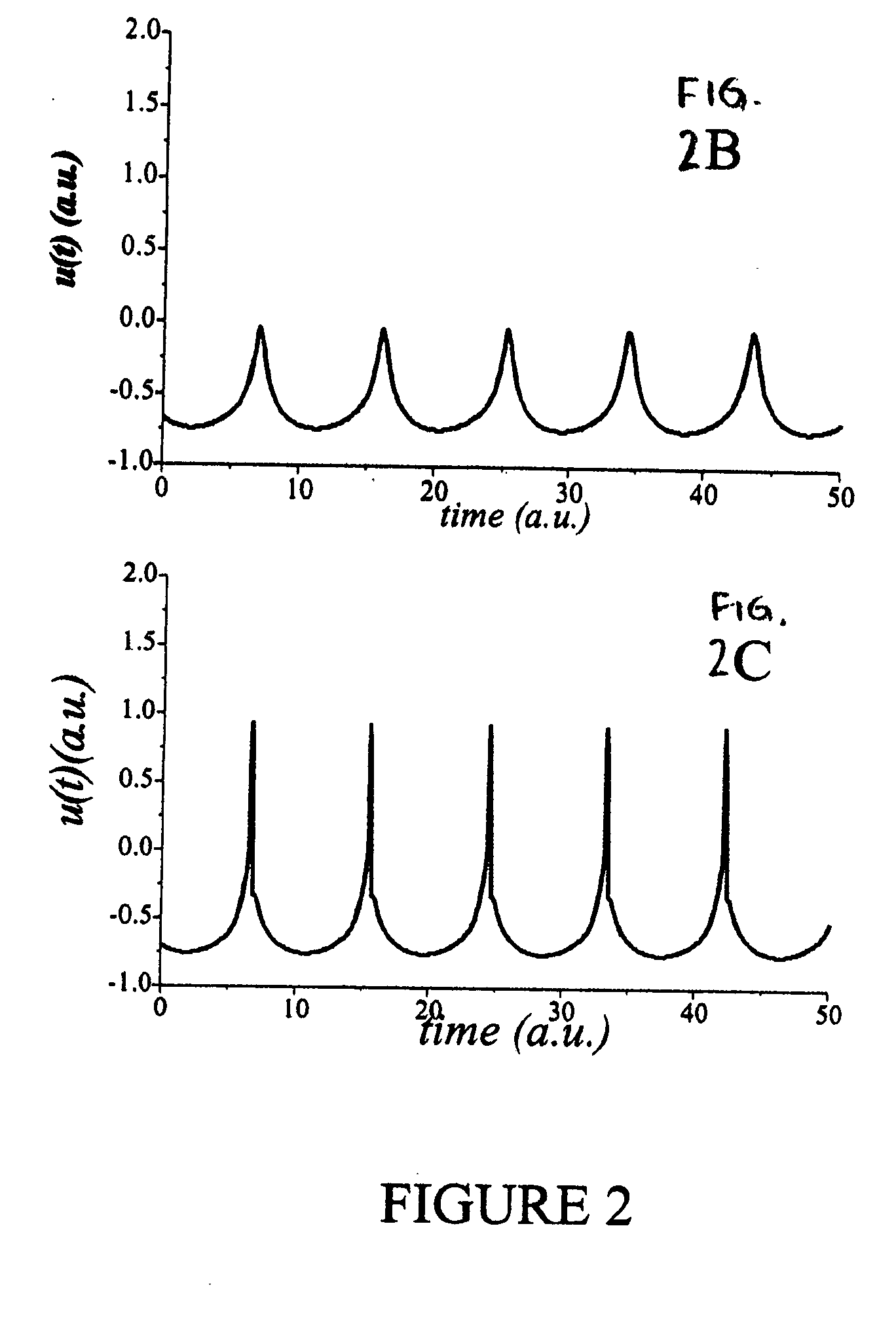

Method and apparatus for phase-independent predictable resetting

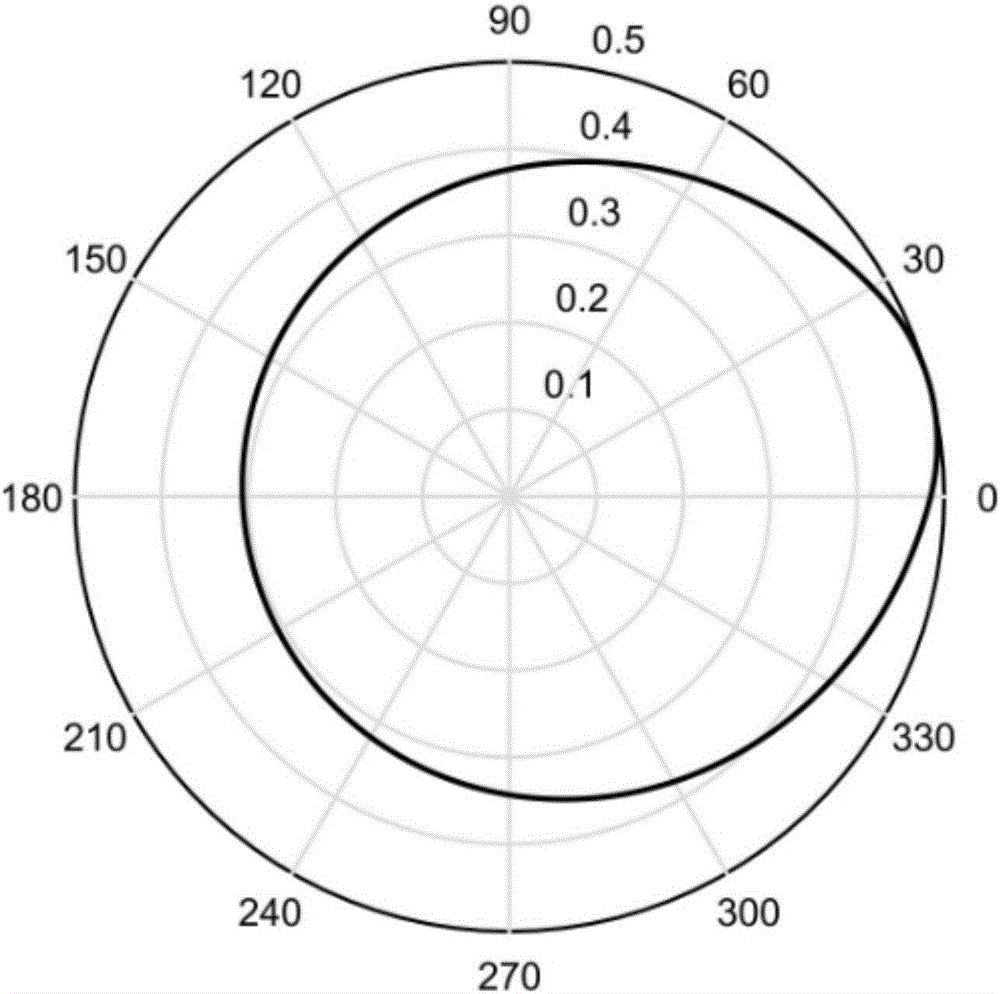

The oscillatory dynamics of inferior olive (IO) neurons found in the olivo-cerebellar network of the brain are reproduced and applied to various control applications. An IO neuron model is provided which produces quasi-sinusoidal oscillations with a characteristic amplitude and frequency. Action potentials occur at the peaks of the oscillations and have precise timing properties. Stimuli applied to the IO neuron model show no changes in oscillation amplitude and frequency but do produce a shift of the oscillation phase, and hence a time shift of the corresponding action potentials. The resulting phase is defined by the strength of the stimulus and does not depend on when the stimulus is applied, thus providing a self-referential phase reset (SPR) effect. The oscillations of multiple IO neurons, or their models, coupled together tend to become organized in space and time in the form of oscillatory phase clusters. The phases of the IO oscillators can be quickly set to a desired phase pattern irrespective of the history of phase evolution. A circuit for implementing the IO neuron model and a control system based on the circuit are described.

Owner:NEW YORK UNIV

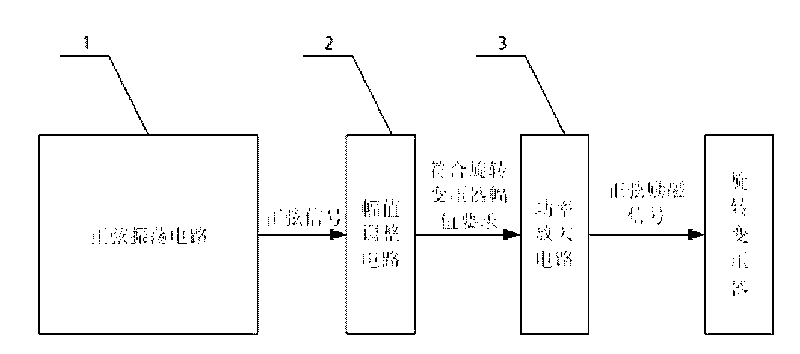

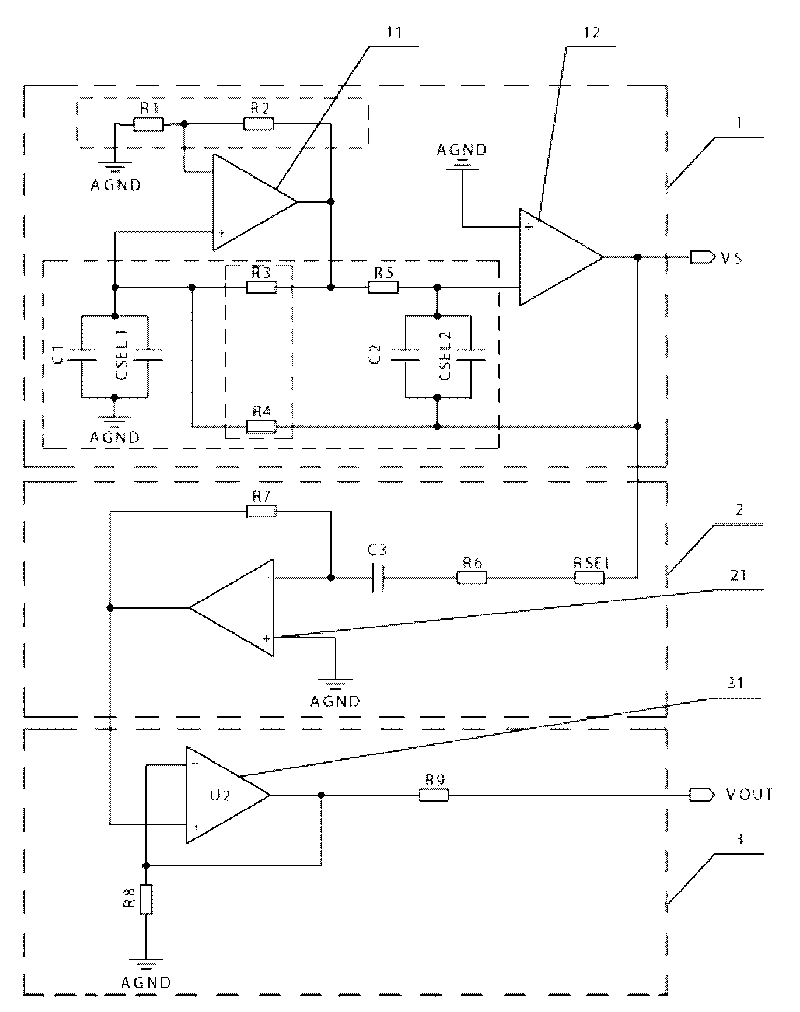

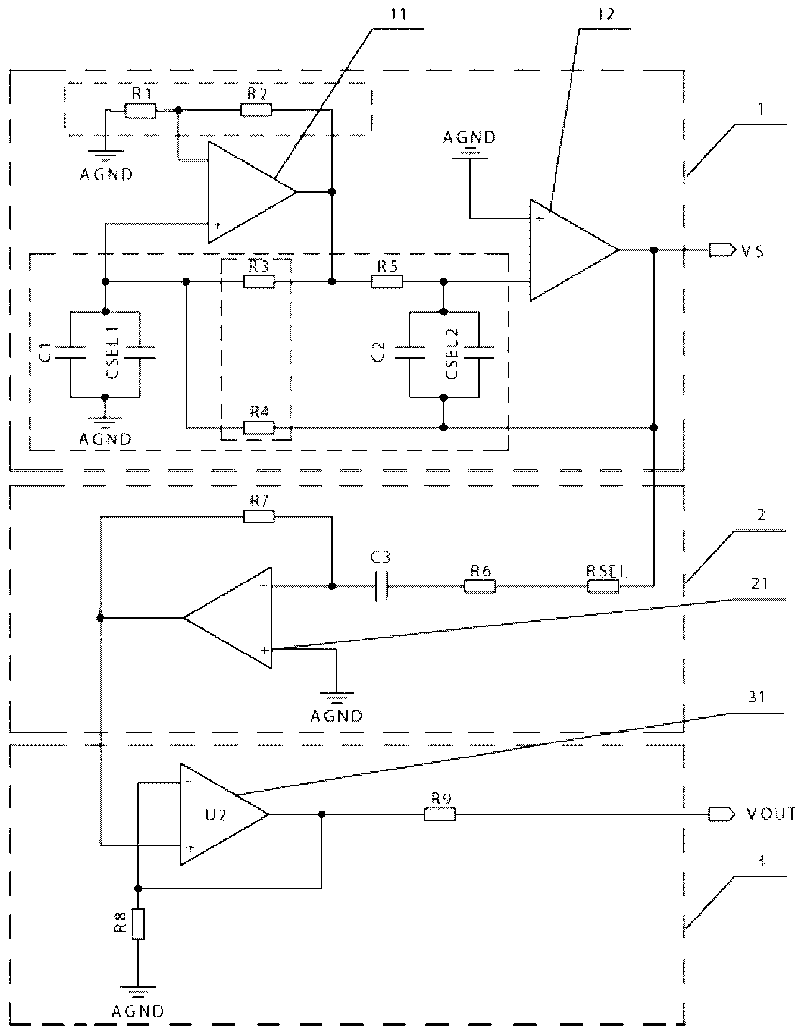

Excitation power circuit of rotary transformer

InactiveCN101714821AImprove reliabilityLow costConversion without intermediate conversion to dcCapacitanceAudio power amplifier

The invention discloses an excitation power circuit of a rotary transformer, belongs to the field of drive power sources, and solves the problems of complex circuit and incapability of independently working in the traditional excitation power of the rotary transformer. The excitation power circuit consists of a sinusoidal oscillation circuit, an amplitude adjusting circuit and a power amplifying circuit, wherein the sinusoidal oscillation circuit consists of a resistor R1, a resistor R2, a resistor R3, a resistor R4, a resistor R5, a capacitor C1, a capacitor C2, a capacitor CSEL1, a capacitor CSEL2, a first operational amplifier and a second operational amplifier; the amplitude adjusting circuit consists of a resistor R6, a resistor R7, a resistor RSEL, a capacitor C3 and a third operational amplifier; and the power amplifying circuit comprises a resistor R8 and a power amplifier. The frequency of a sinusoidal excitation power source generated by the circuit of the invention is modulated by selecting a capacitance value of the capacitor CSEL1 and the capacitor CSEL2, and the amplitude value of the sinusoidal excitation power source is adjusted by changing the resistance value of the resistor RSEL. The excitation power circuit of the invention serves as the drive power source of the rotary transformer.

Owner:HARBIN INST OF TECH

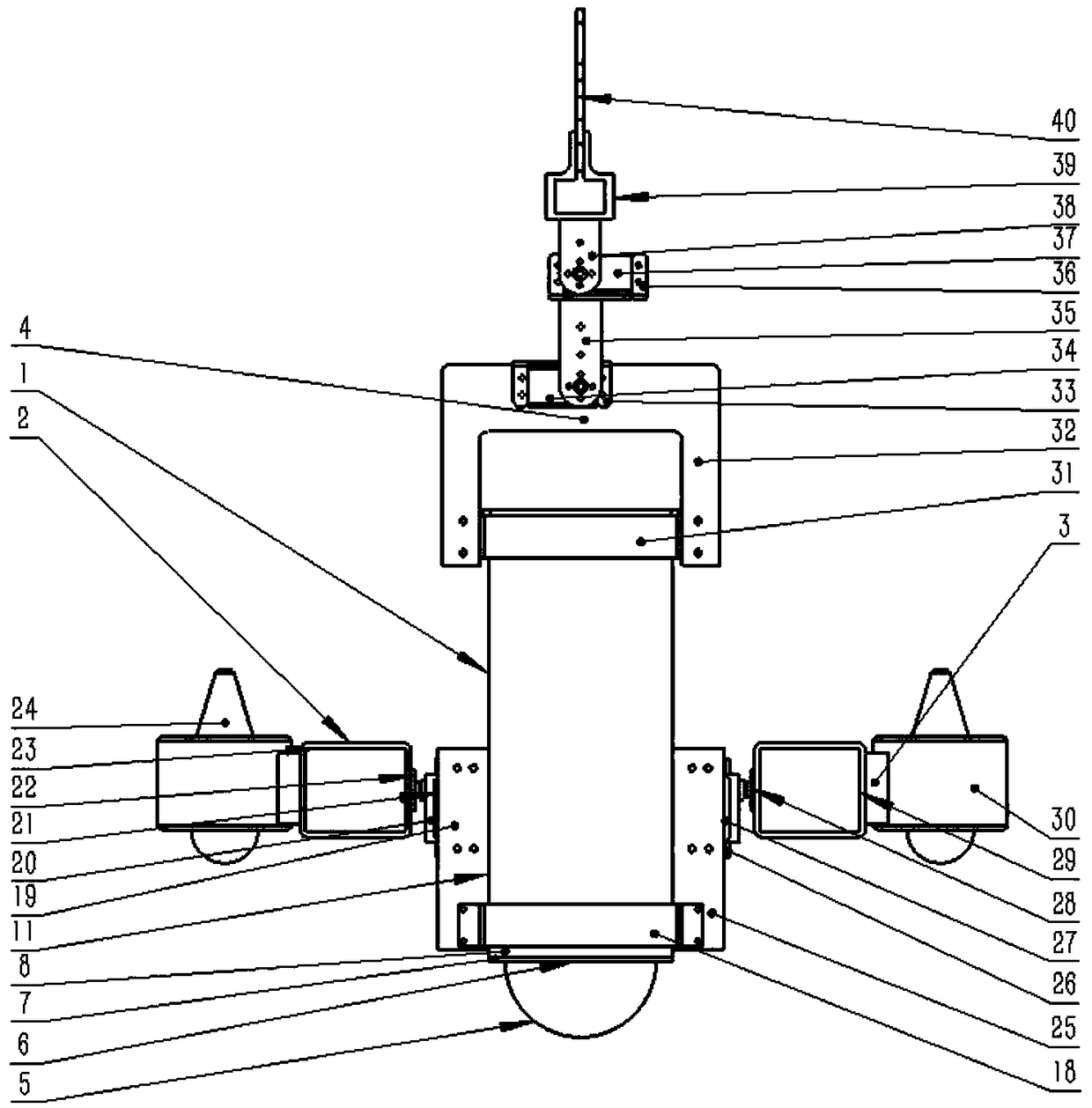

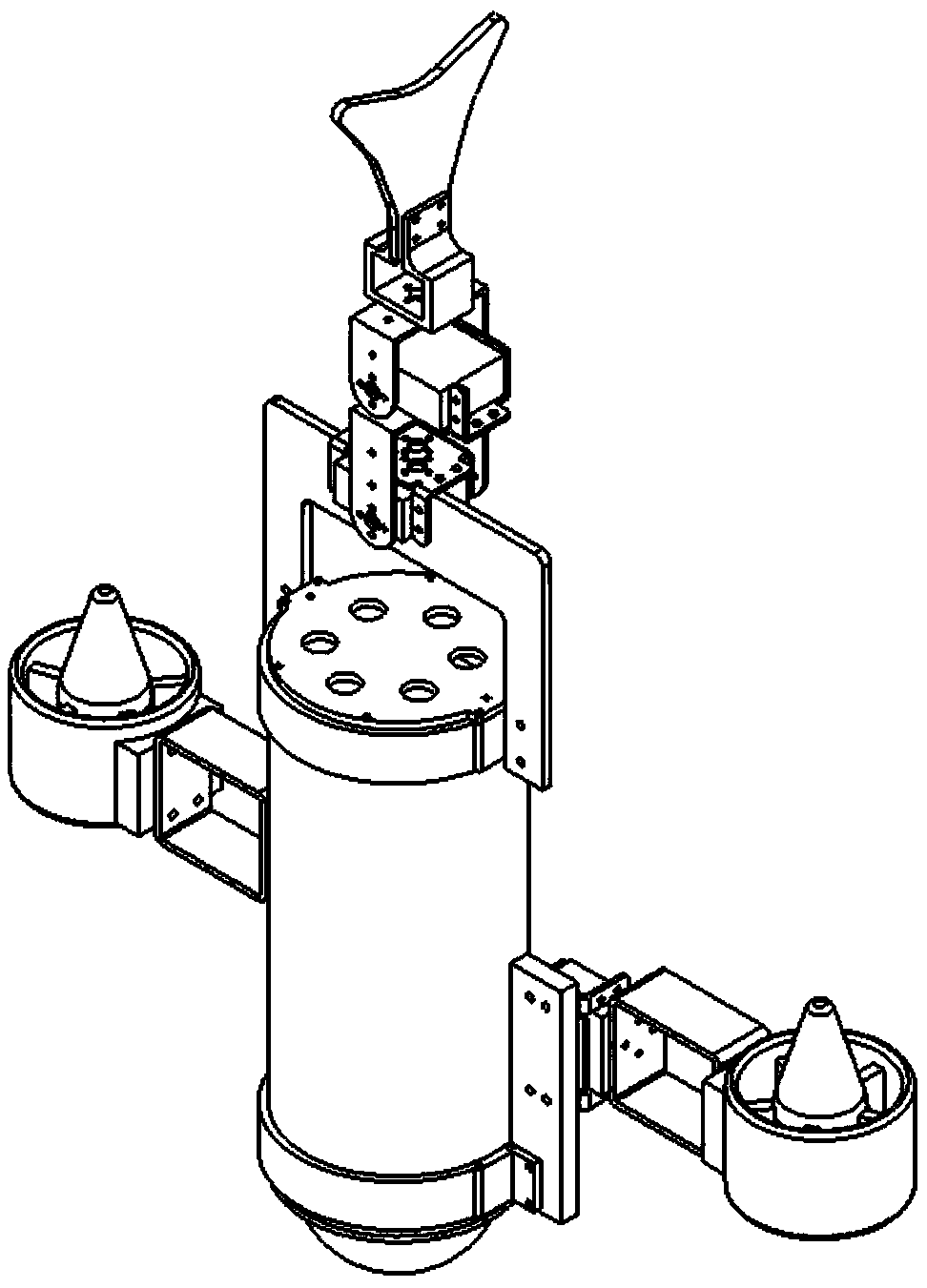

An unmanned aerial vehicle based on tail vertebra swinging propulsion

InactiveCN109131809ASimple structureMultiple sealing effect is goodSteering ruddersPropulsive elements of non-rotary typeEngineeringSmall range

The invention discloses an unmanned aerial vehicle based on tail vertebra swinging propulsion, which is composed of a pressure-resistant cabin, a tail fin and a propulsion device. The three parts areall rigid solid conjoined bodies, and force is transmitted through a U-shaped frame. A wireless switch, a temperature sensor, a water pressure sensor, a posture sensor, a power supply device and a control device are arranged in the pressure-resistant cabin; wherein the cabin front cover is threaded with the front cabin flange and sealed by a double-layer sealing ring. The canopy front cover is connected with the underwater camera through the internal thread, so that the vehicle can transmit the image signal in real time under the water. The propeller frame is connected with the front cabin flange and the propellers on both sides respectively, so as to realize the sinking and floating motion of the aircraft and the high-speed navigation; the tail cone propulsion device is connected with therear cabin flange by the tail connector, and the tail fin enables the aircraft to advance through the power provided by the biomimetic sinusoidal oscillation, and the sinusoidal oscillation tail vertebra causes the aircraft to make small-radius steering in a small range, and the motion process noise is small.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

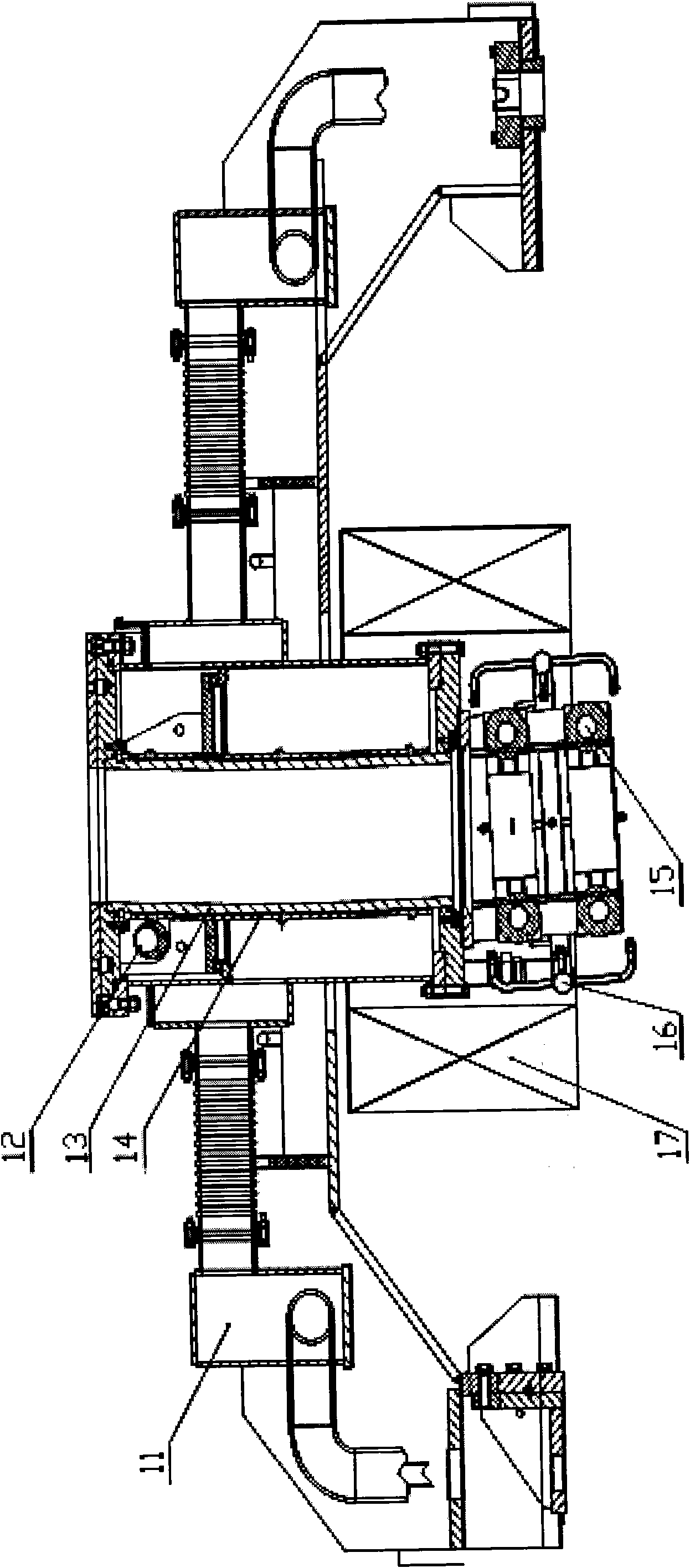

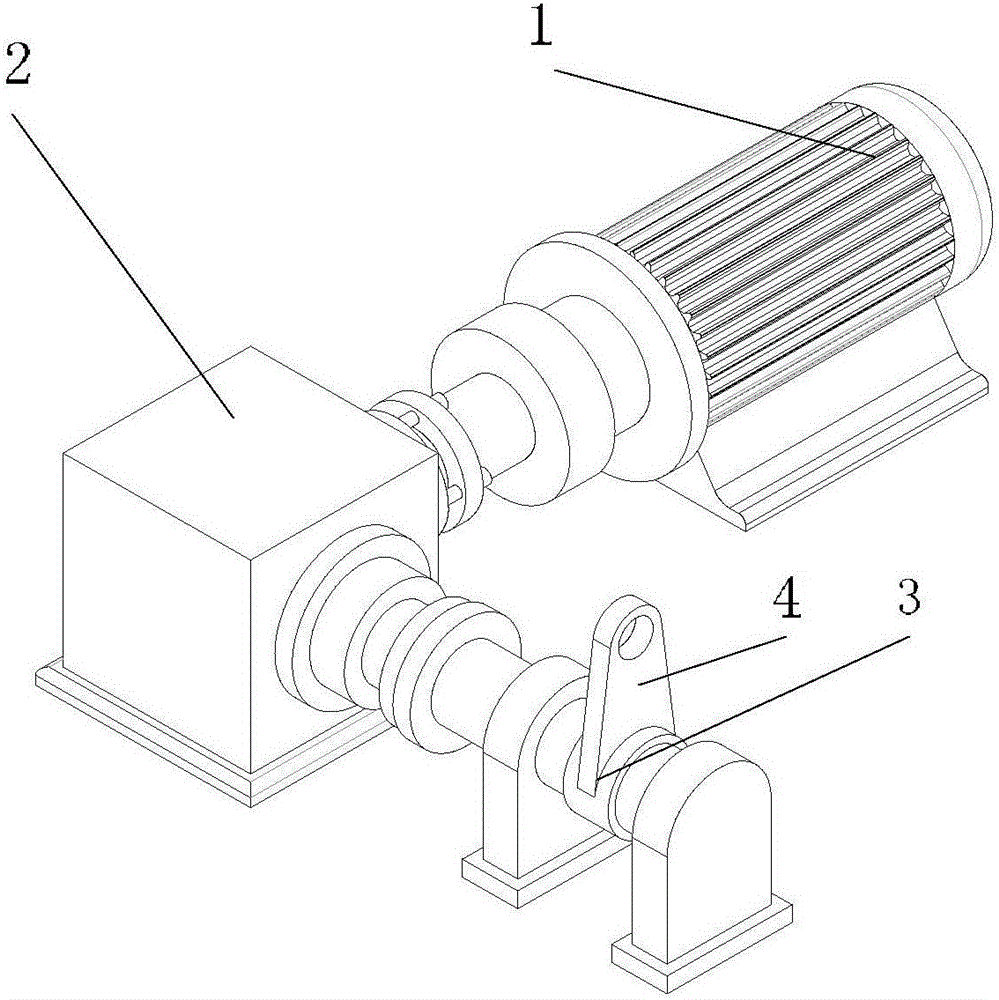

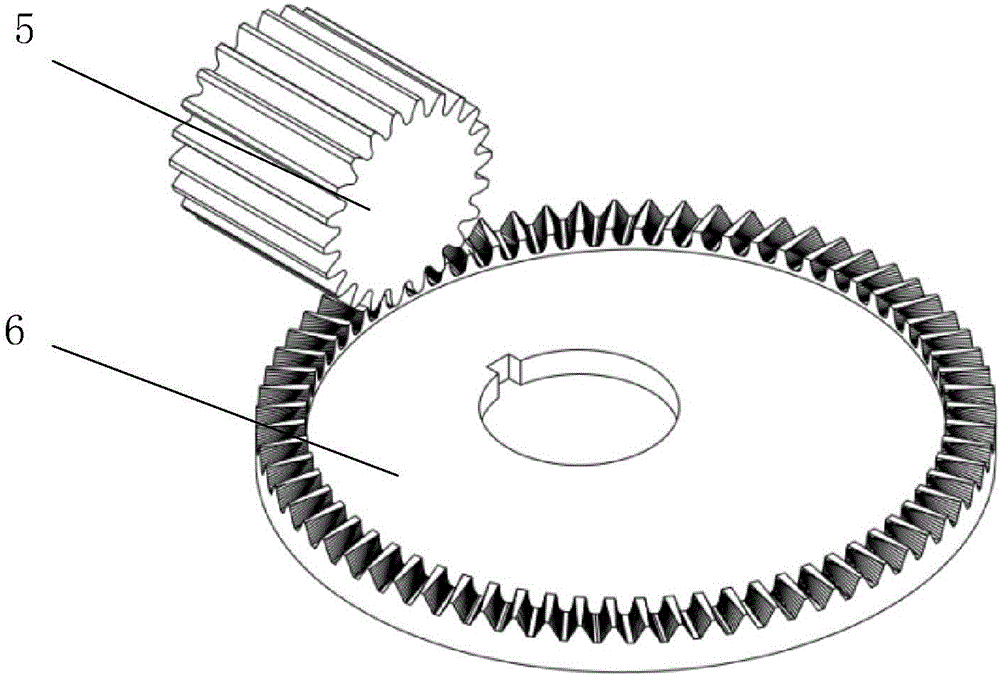

Non-sinusoidal oscillation device of continuous casting crystallizer and oscillation method thereof

The invention provides a non-sinusoidal oscillation device of a continuous casting crystallizer and an oscillation method thereof. The device mainly comprises a variable-frequency motor, a reducer variator, an eccentric shaft and a connecting rod. The invention relates to a method for achieving non-sinusoidal oscillation. The device is characterized in that a driving spur gear and a driven noncircular gear are arranged in a reducer variator housing; an axis of the driving spur gear is vertically intersected with the axis of the driven noncircular gear; an output shaft of the variable-frequency motor is connected to the driving spur gear through a coupling; the driving spur gear is engaged with the driven noncircular gear, and the driven noncircular gear is connected with one end of the eccentric shaft through the coupling; one end of the connecting rod is hinged with the eccentric shaft while the other end of the connecting rod is hinged with an oscillation frame. According to the device, a transmission chain is short; the structure is compact; the device cost is low; sudden stopping, oil leaking and other phenomena can be avoided; the reliability is high; the bearing capacity is high; the control is simple; the waveforms are accurate; the displacement and speed waveforms are smooth and continuous; the acceleration is free of sudden changing; rigid and flexible impacting are avoided; the waveforms and dynamic characteristic properties are outstanding.

Owner:YANSHAN UNIV

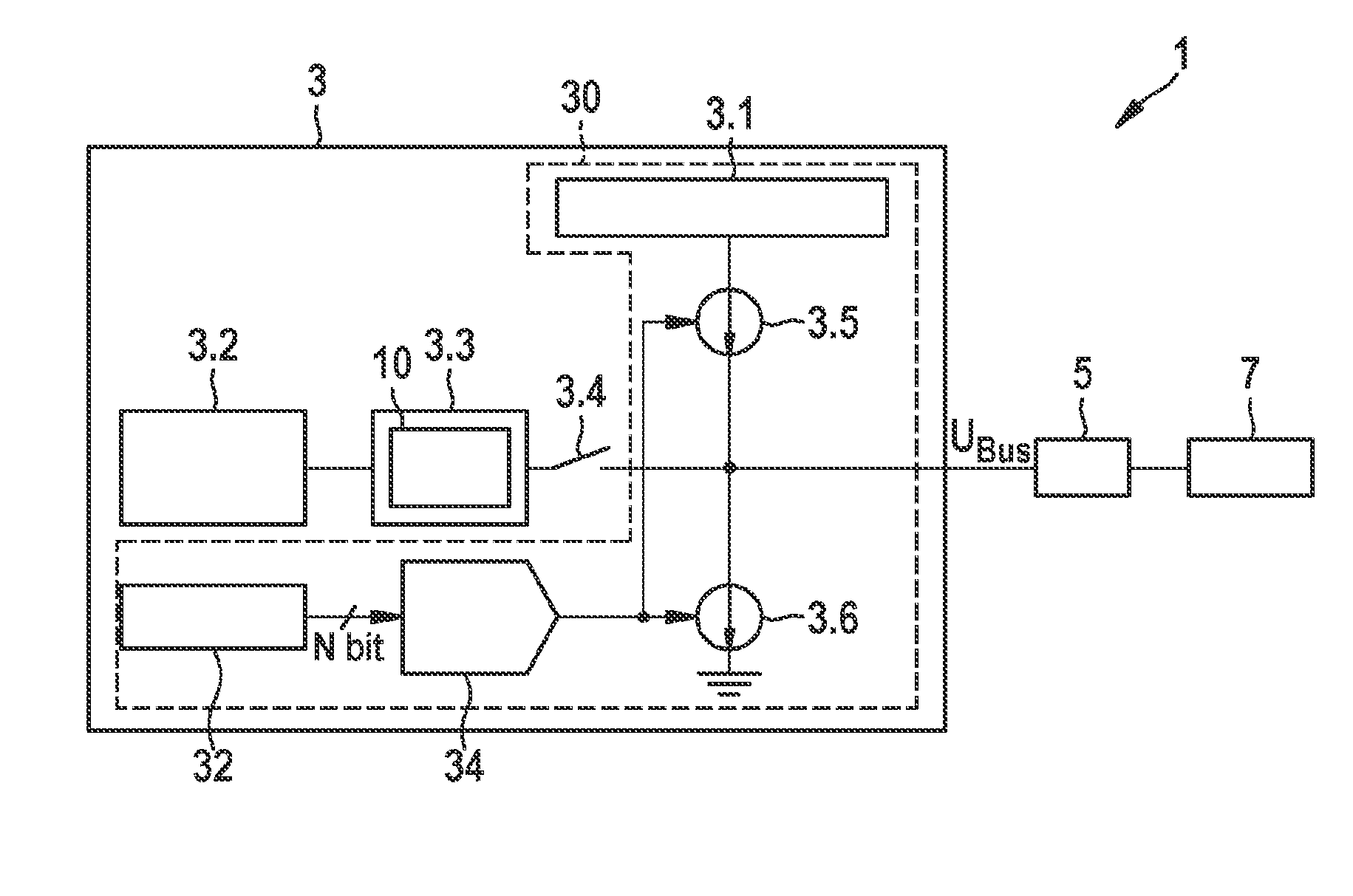

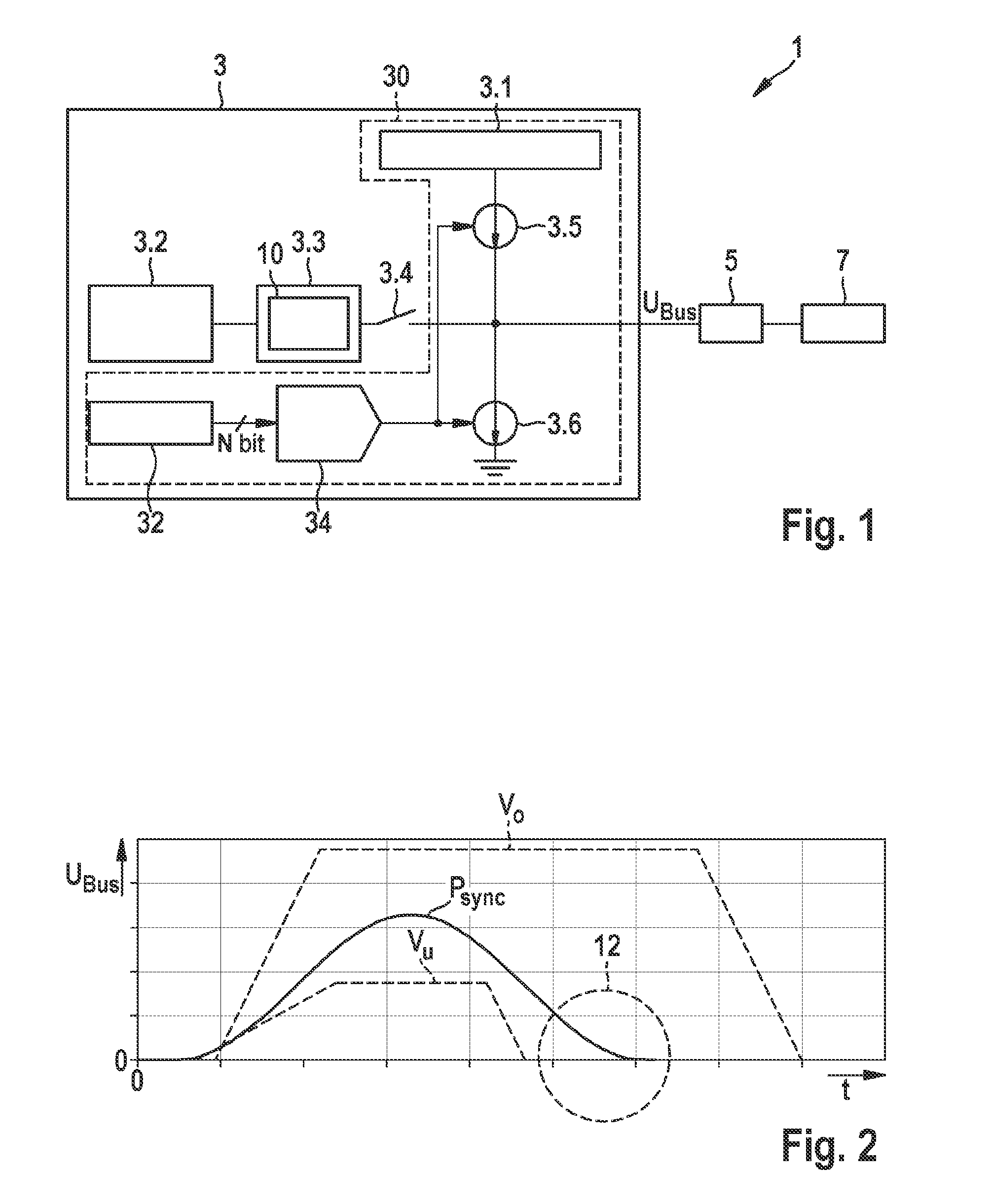

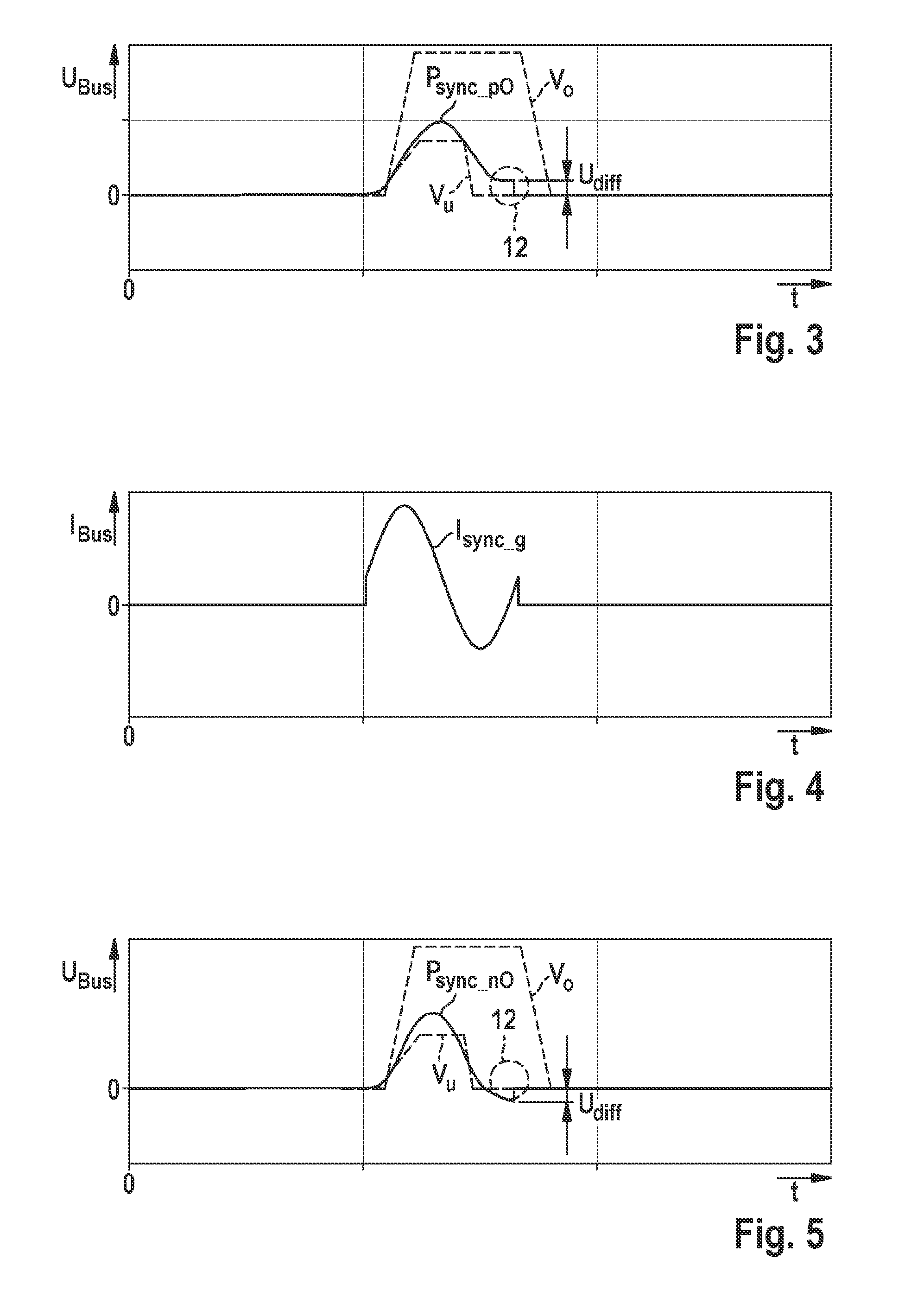

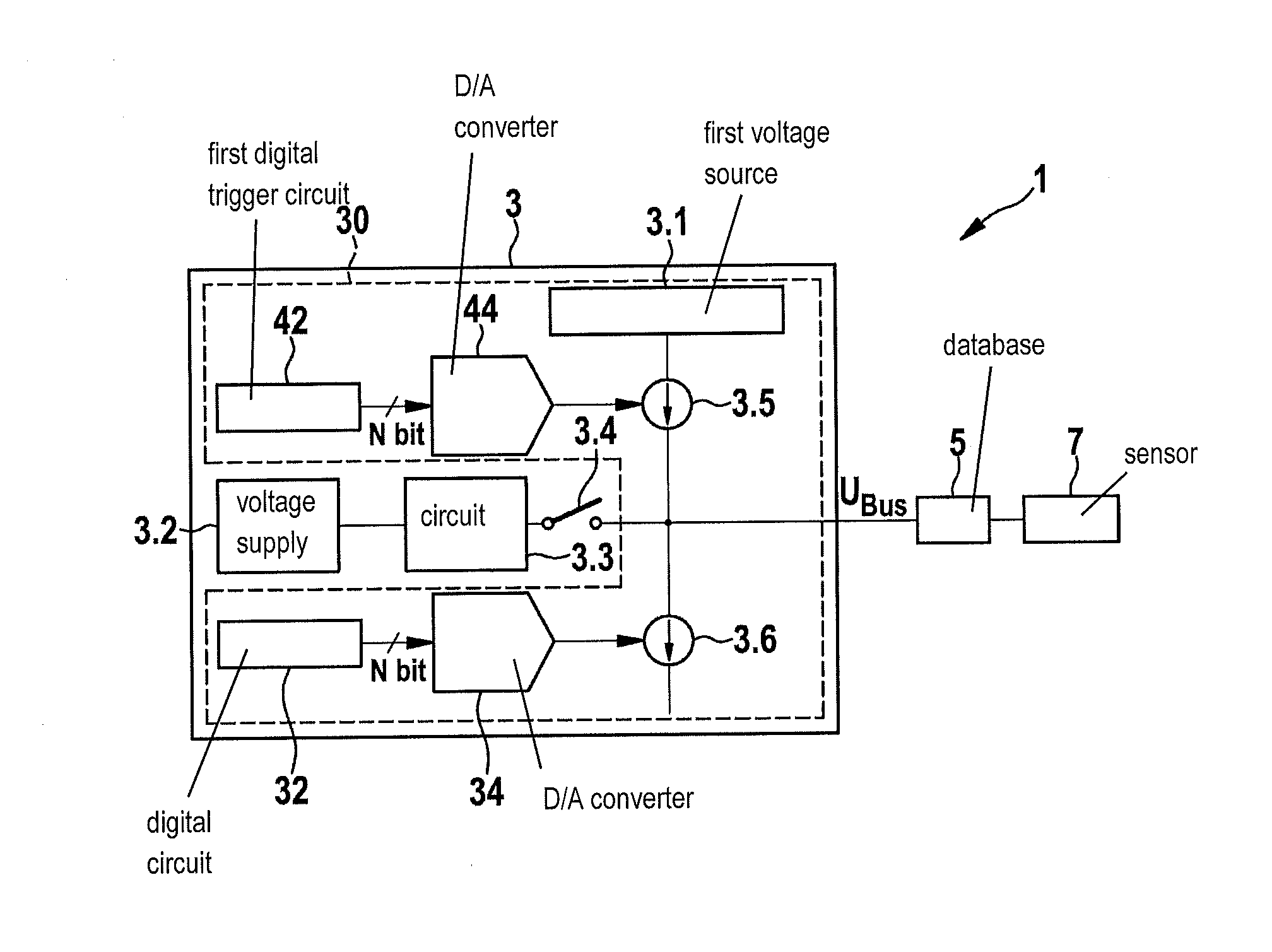

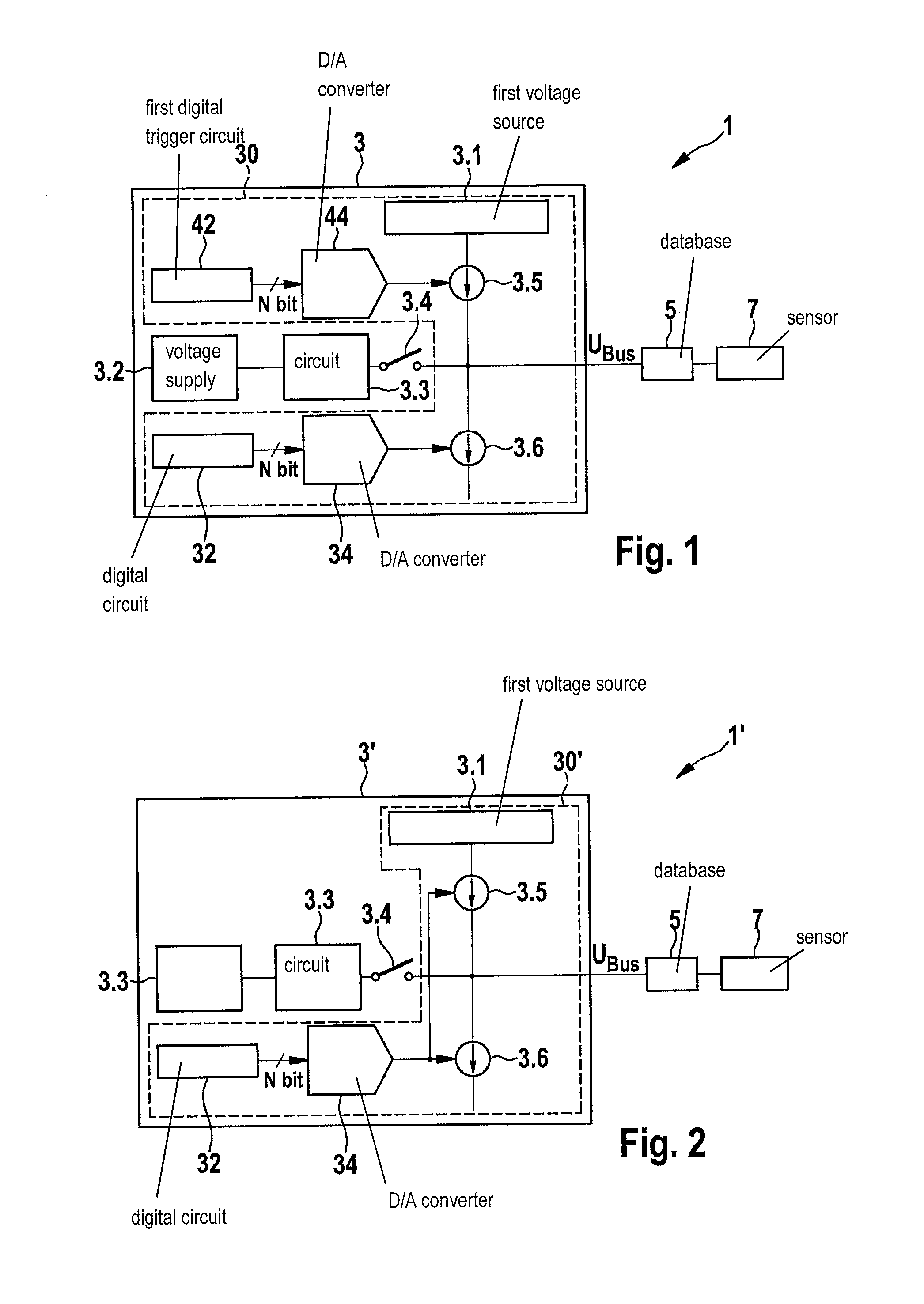

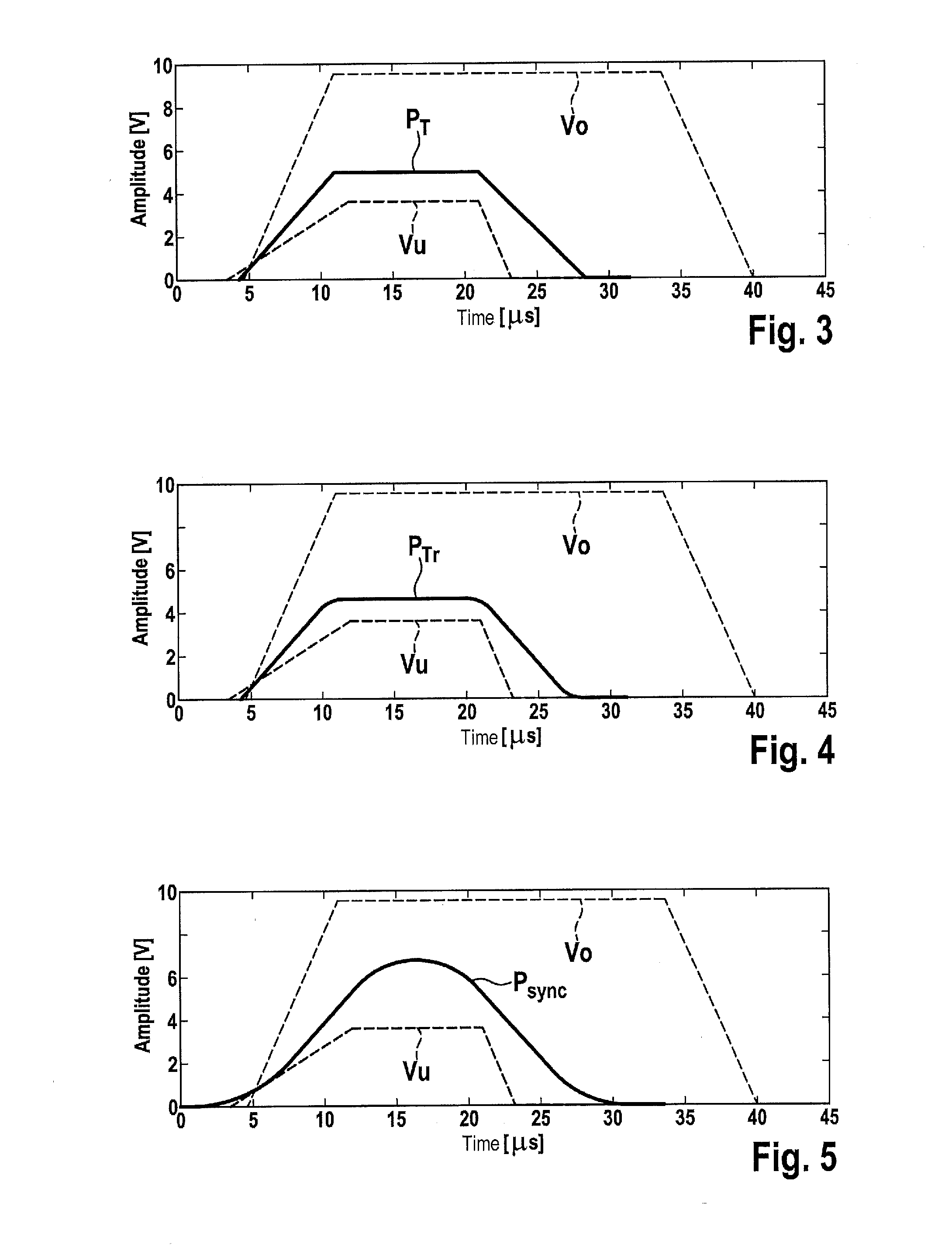

Receiving arrangement for a control device in a vehicle, and method for generating a synchronization pulse

ActiveUS20150321629A1Accurate collectionRobust implementationElectric devicesPulse generatorVoltage generatorEngineering

A receiving assemblage is provided for a control device in a vehicle, having a voltage generator for generating a synchronization pulse, which encompasses a first voltage source, a current source, and a current sink, the voltage generator generating the synchronization pulse within predefined specification limits with a predefined shape and a predefined time-related behavior, and the receiving assemblage outputting the synchronization pulse via a data bus to at least one sensor for synchronization of a subsequent signal transfer, the voltage generator generating the synchronization pulse via the current source and the current sink, substantially as a sinusoidal oscillation, by charging and / or discharging a bus load, and to a method for generating a synchronization pulse.

Owner:ROBERT BOSCH GMBH

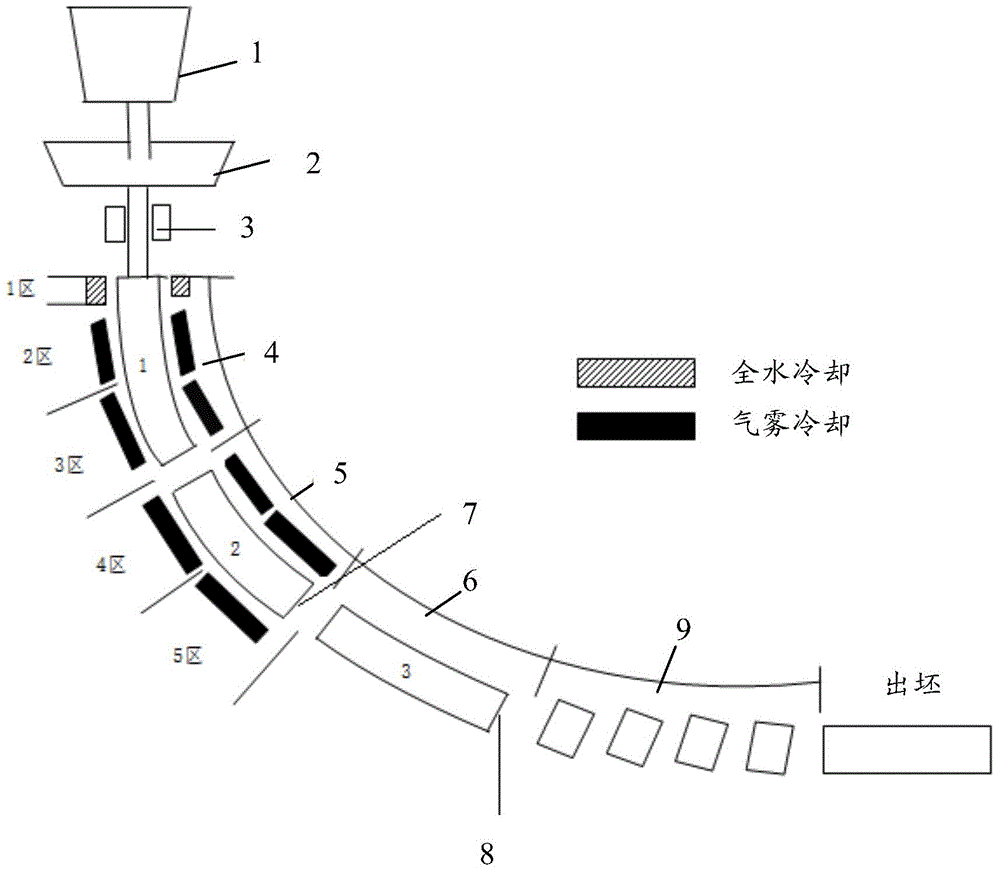

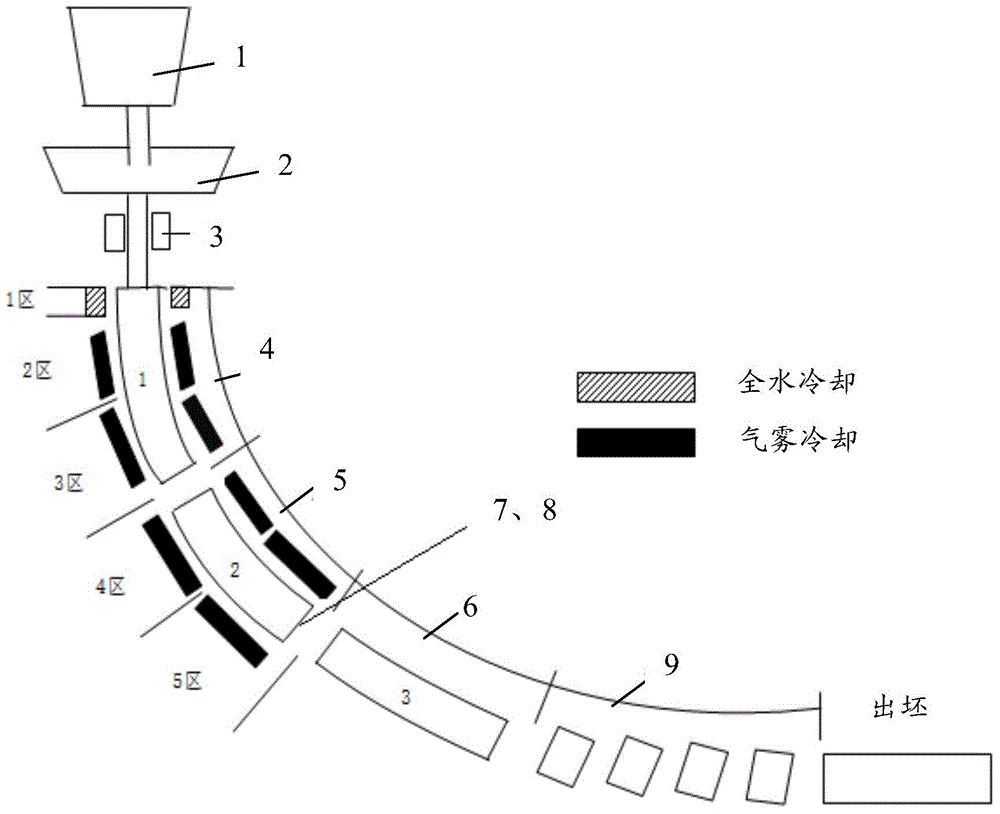

Profiled-blank continuous casting machine and profiled-blank continuous casting secondary cooling water blowing method

The invention discloses a profiled-blank continuous casting machine and a profiled-blank continuous casting secondary cooling water blowing method. By improving the positions of cooling water blowing devices in the secondary cooling zone of profiled-blank continuous casting and the water blowing method, the problem of non-uniform casting blank cooling caused by accumulated water in an inner arc of a profiled blank is solved, and the quality defects of the casting blank are avoided. The continuous casting machine comprises a steel ladle, a tundish, a crystallizer, and a fan-shaped section I, a fan-shaped section II and a fan-shaped section III of a cooling chamber, wherein the steel ladle, the tundish, the crystallizer, and the fan-shaped section I, the fan-shaped section II and the fan-shaped section III of the cooling chamber are connected in sequence. Two or more water blowing devices are installed on the fan-shaped section II of the cooling chamber. Low cooling is adopted for the water flow of the crystallizer. The water flow of the inner arc and the outer arc is 2200 L / min. The water flow of the left side and the right side is 1200 L / min. The temperature difference is controlled within the range of 4 DEG C-5 DEG C. Non-sinusoidal oscillation and double-nozzle full-protective casting are adopted. Intercooling is adopted for secondary cooling. The superheat degree of molten steel ranges from 15 DEG C to 30 DEG C. The specific water flow of the secondary cooling zone is 0.8 L / kg.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

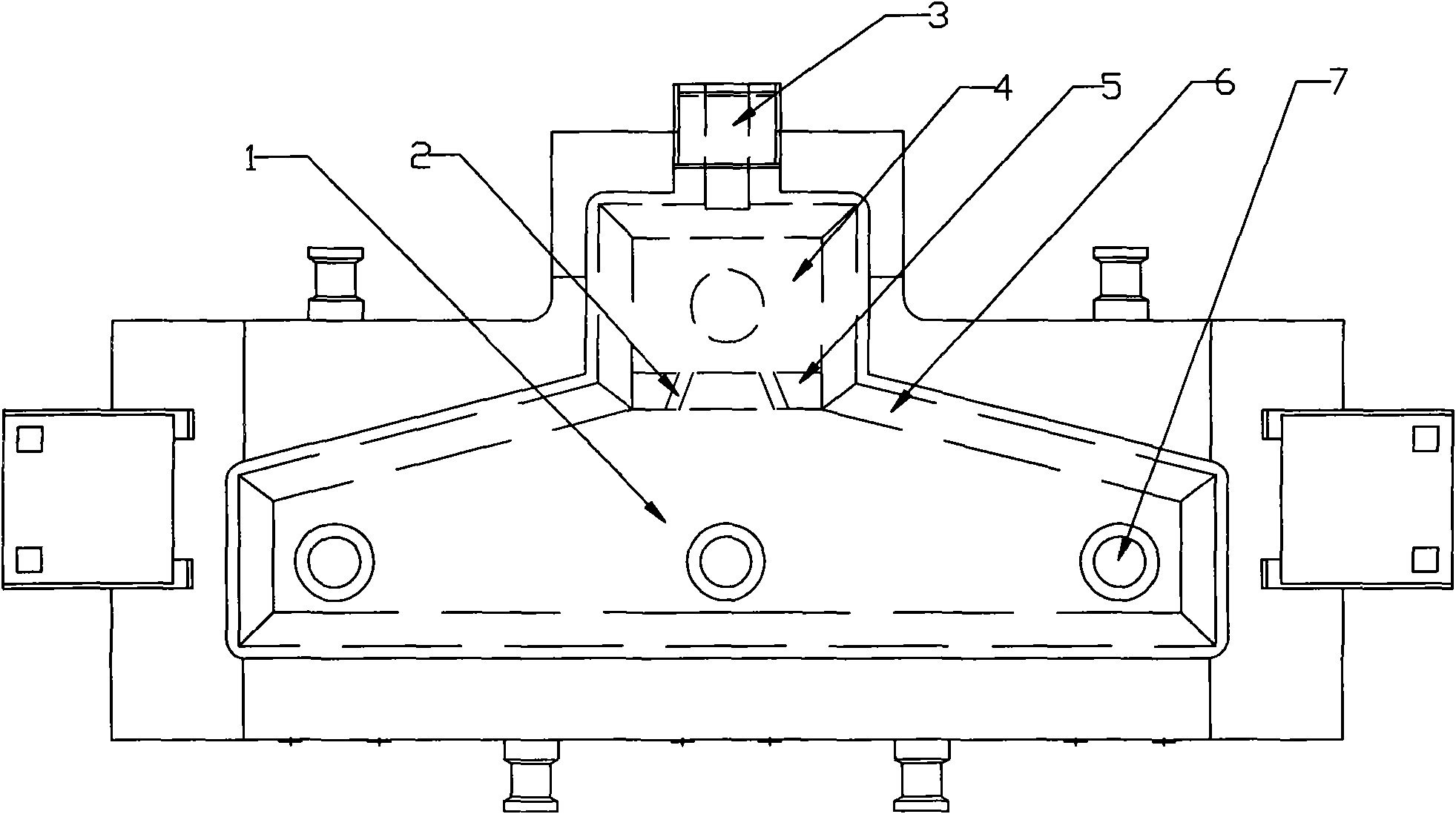

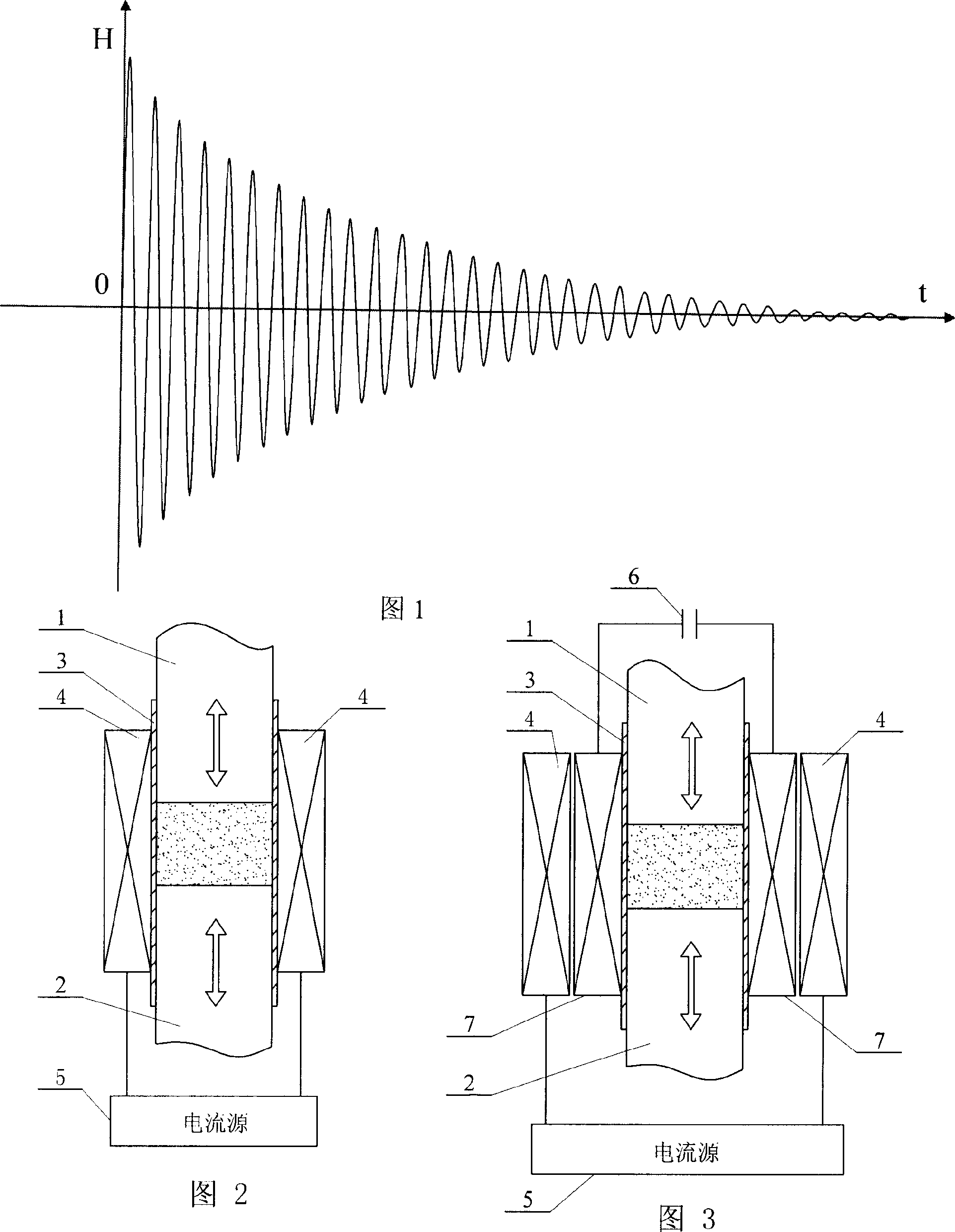

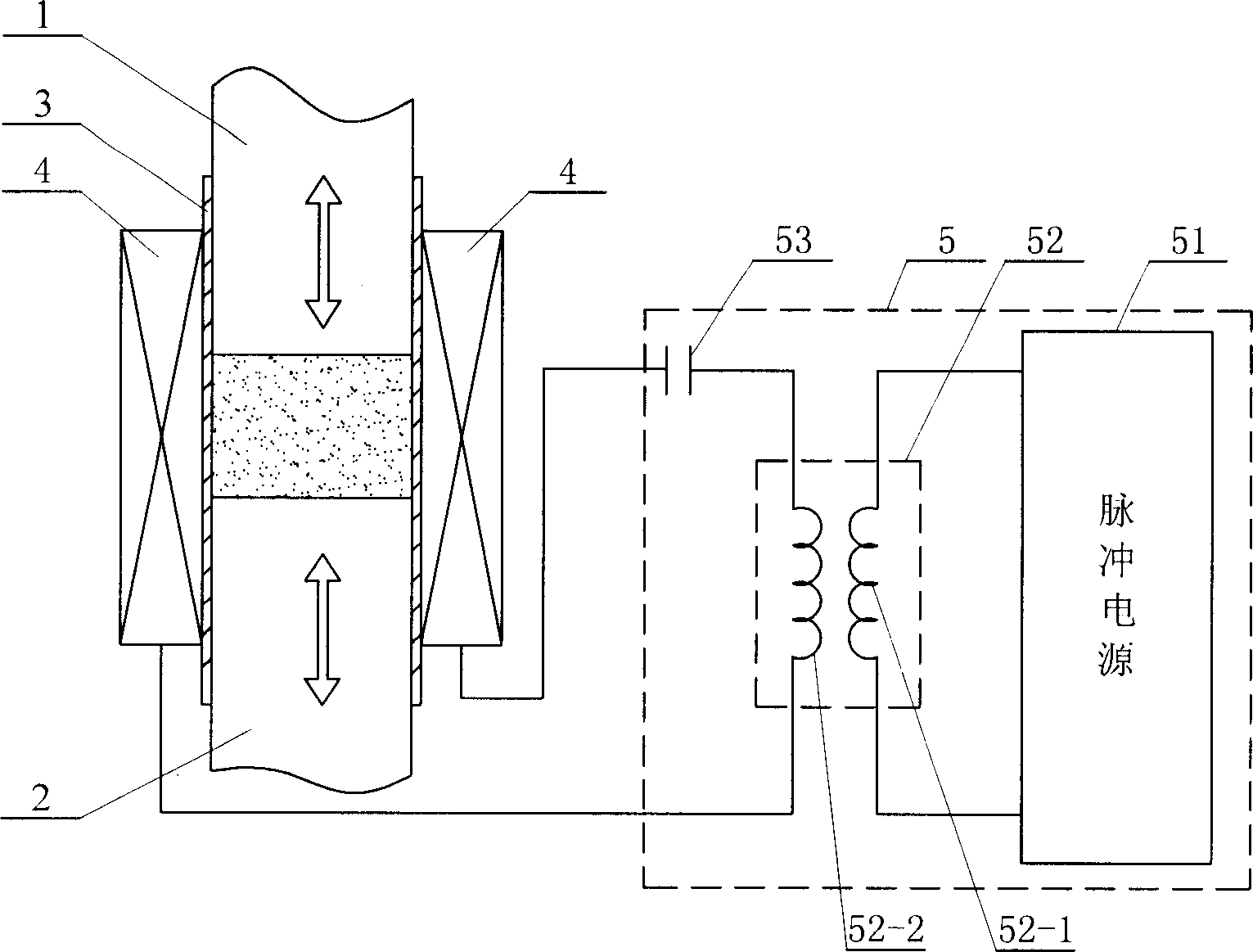

Anisotropic binding rare earth permanent magnet oriontation shaping device

The anisotropic adhered RE permanent magnet orientating and forming apparatus includes an upper molding punch head, a lower molding punch head, a mold sleeve, a winding and a current source. The lower end of the upper molding punch head and the upper end of the lower molding punch head are set inside the mold sleeve, the winding is wound outside the mold sleeve, the current source is connected across the winding to form amplitude reducing sinusoidal oscillation magnetic field. The amplitude reducing sinusoidal oscillation magnetic field can complete both magnetic orientation process and ideal demagnetization process during orientating and forming the mixture of magnetic alloy powder and binding resin inside the mold sleeve, so that the present invention can produce anisotropic adhered RE permanent magnet in low cost.

Owner:李志平

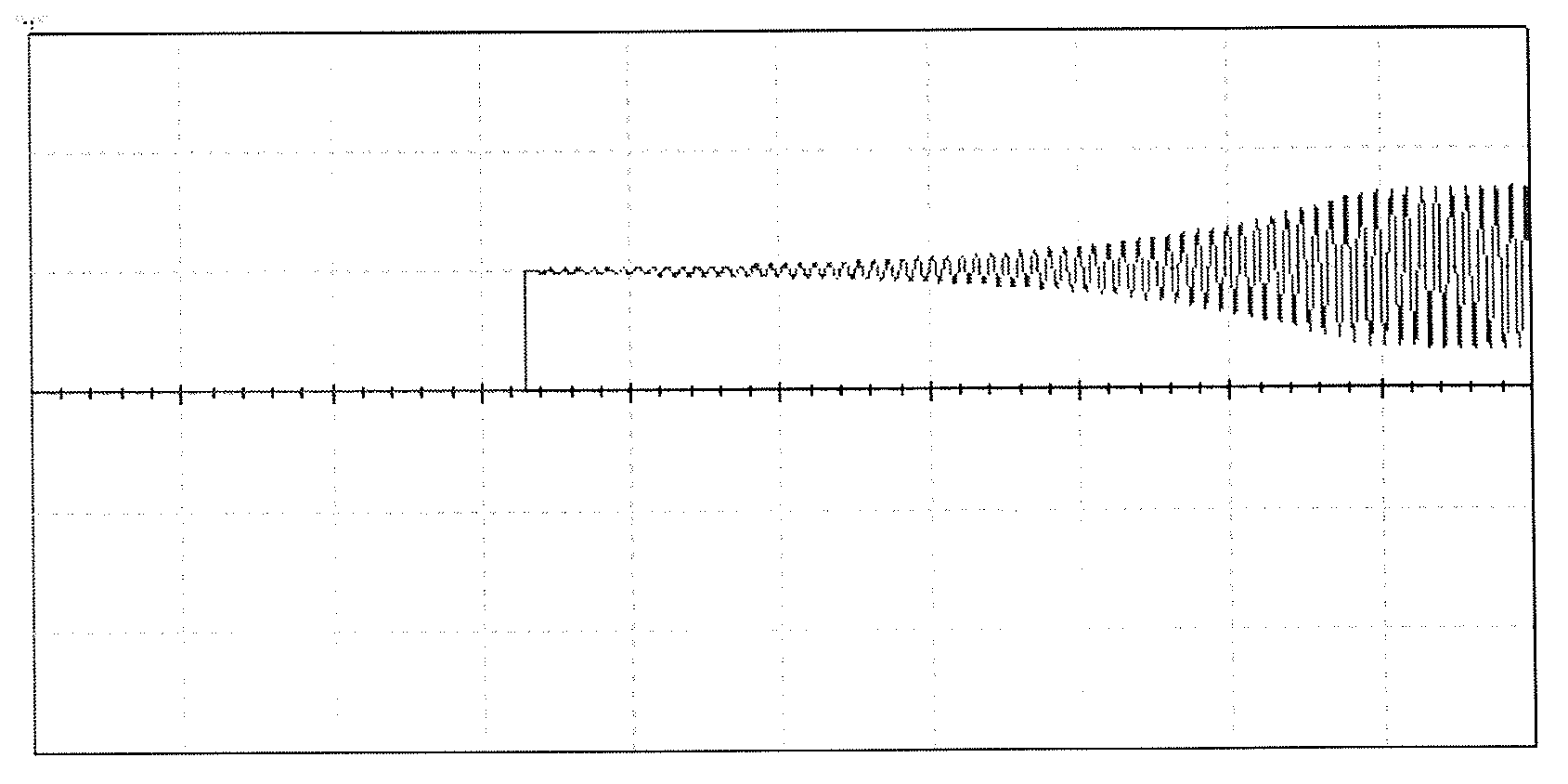

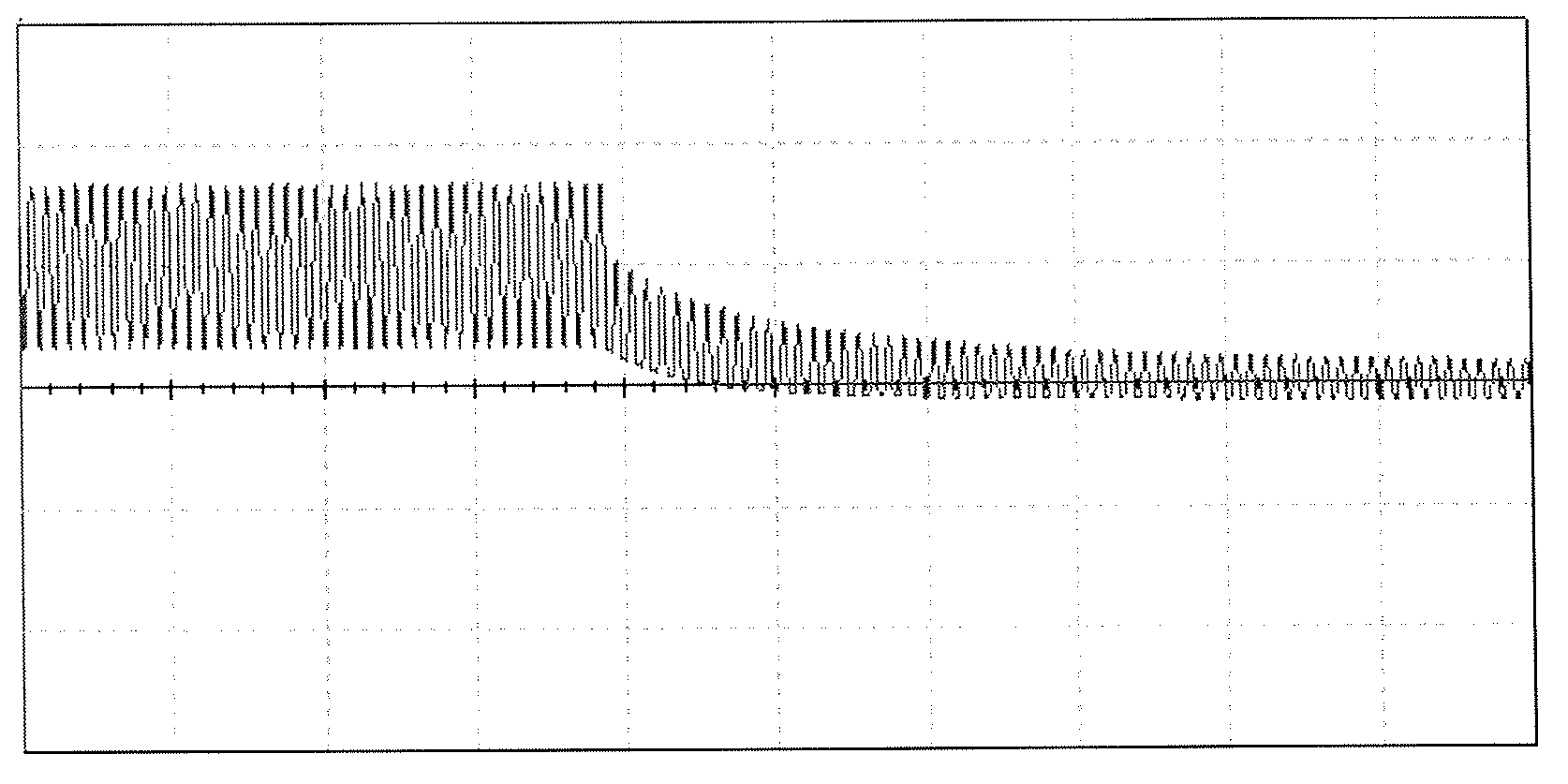

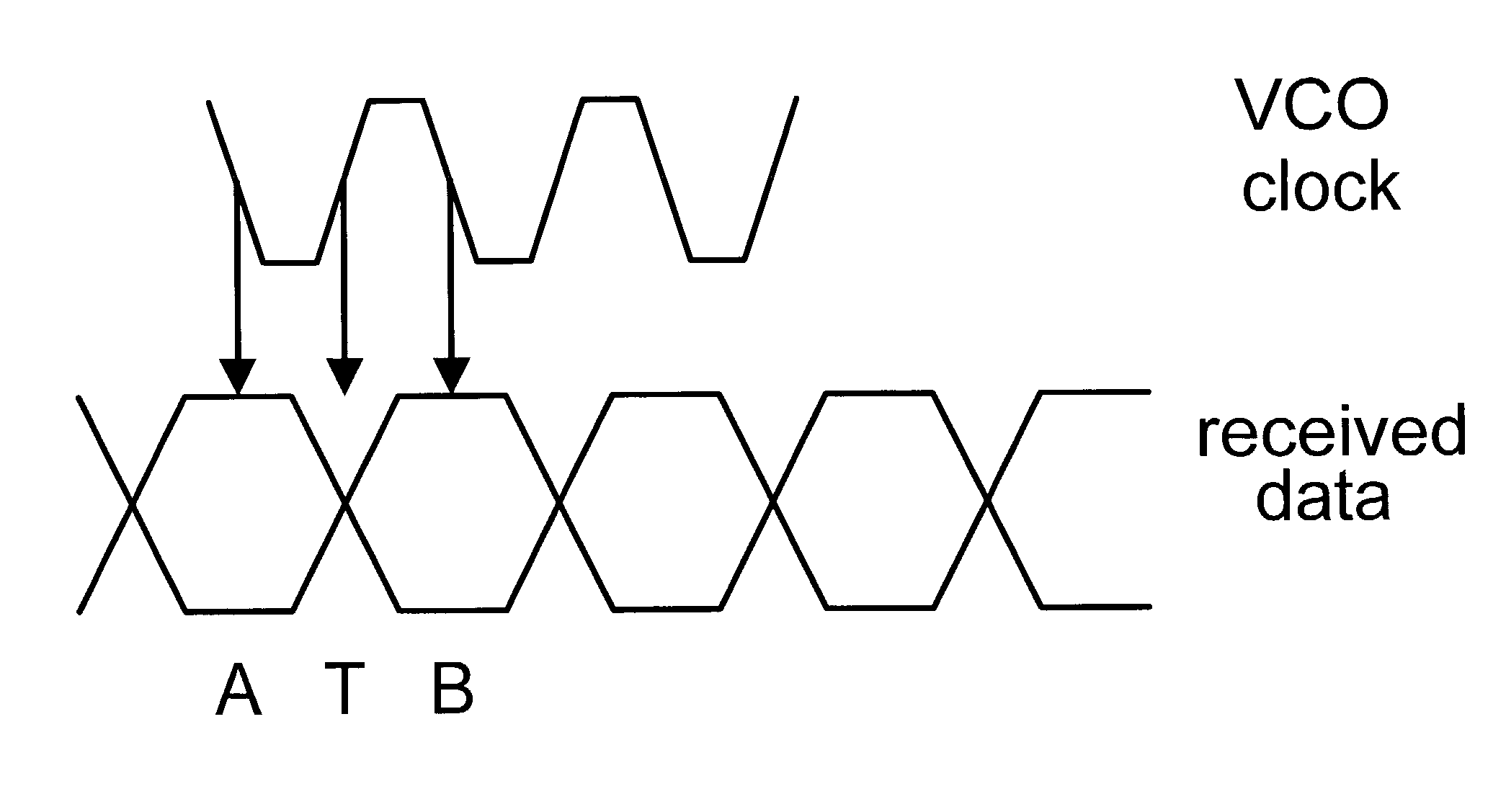

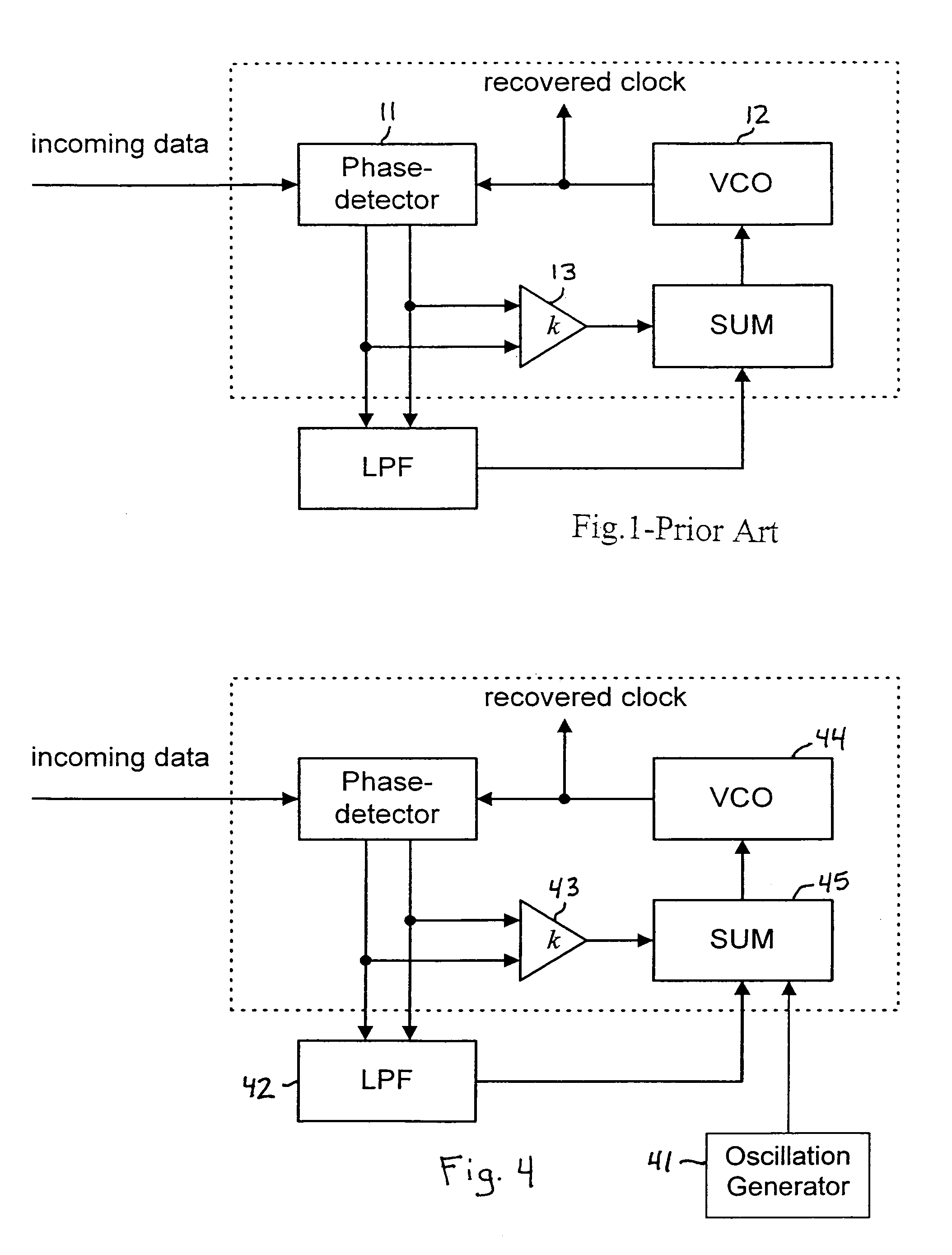

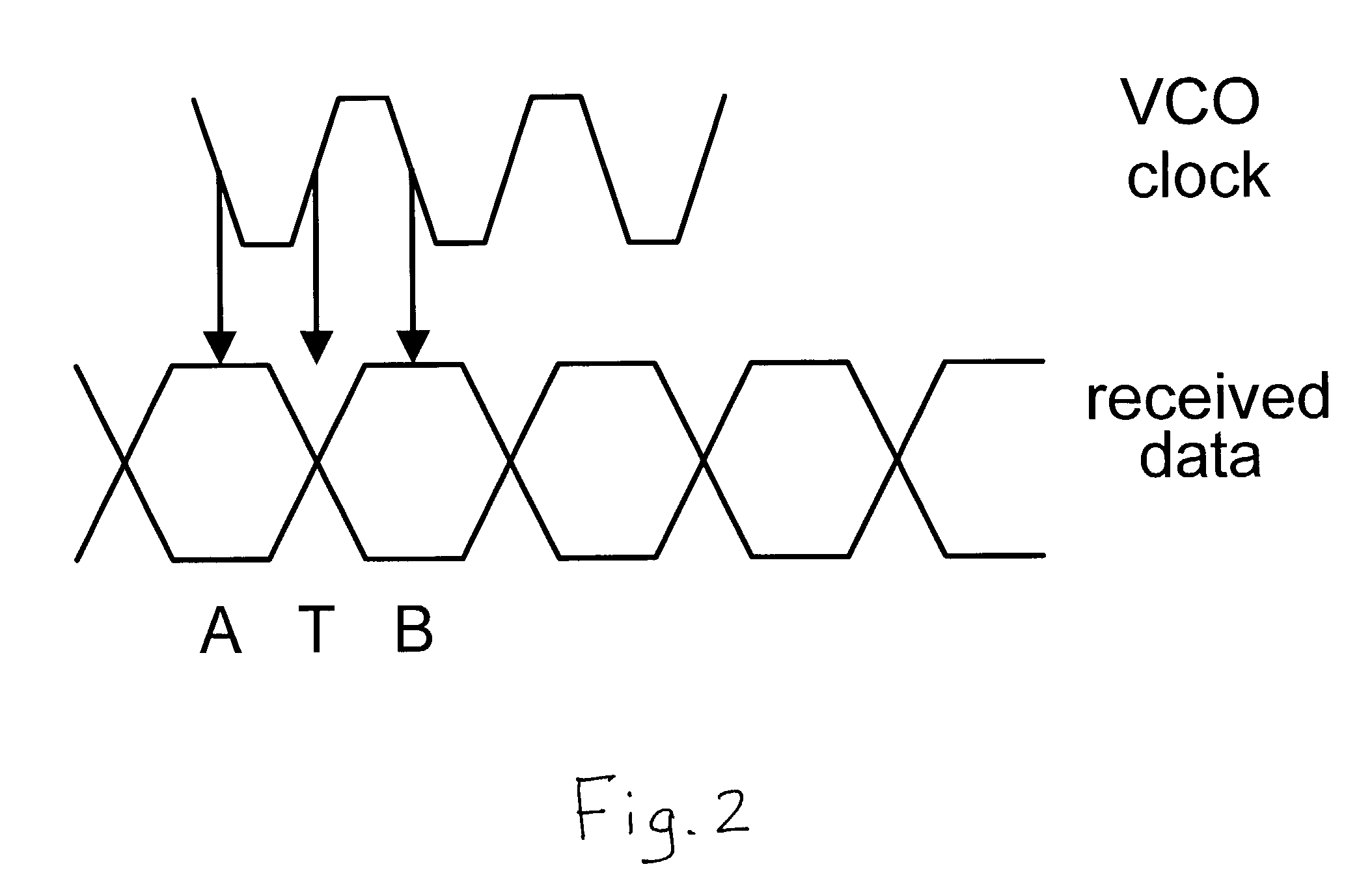

Fast clock acquisition enable method using phase stir injection to PLL for burst mode optical receivers

InactiveUS7421053B1Shorten the timeExtension of timePulse transformerPulse automatic controlStable statePhase shifted

Systems and methods for aligning the phase of a PLL with an incoming data signal. In one embodiment, when a data signal is received in a PLL, a phase perturbation signal is generated and injected into the PLL. The PLL then performs a phase alignment procedure to lock on to the received data signal. The phase perturbation signal is a damped sinusoidal oscillation that is injected into the PLL when each of a plurality of data packets is received. The perturbation signal has an amplitude sufficient to bump the PLL out of a quasi-stable state around 180 degrees out of phase with the incoming data signal, but is damped to less than a degree of phase shift within 30 ns of being injected.

Owner:S AQUA SEMICONDUCTOR LLC

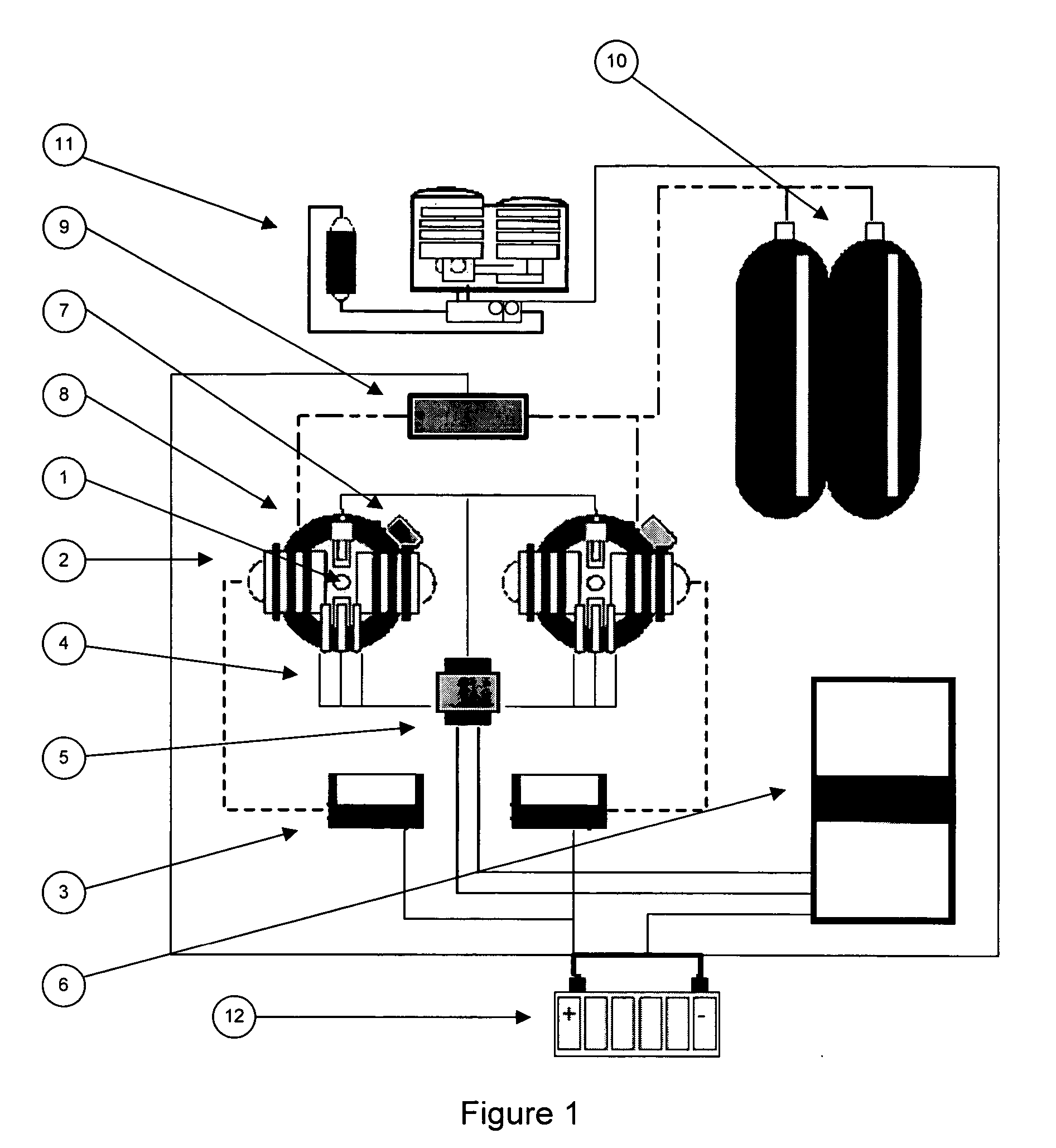

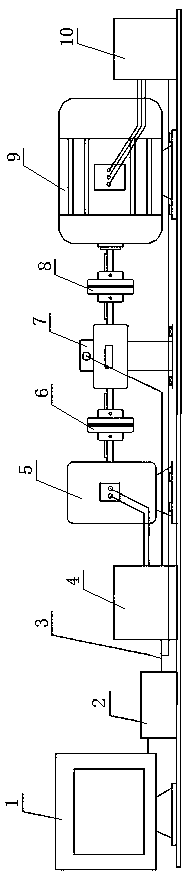

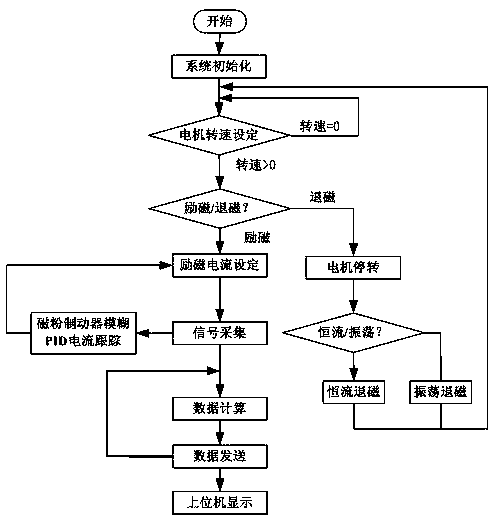

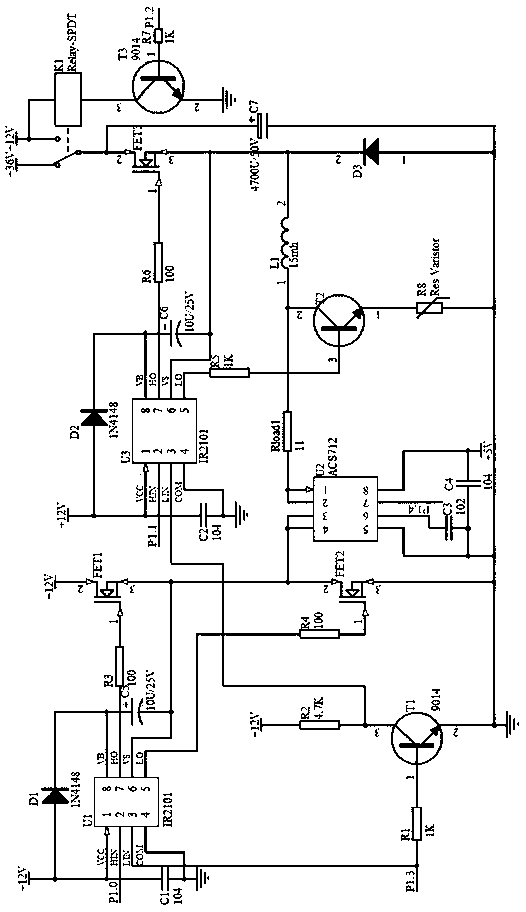

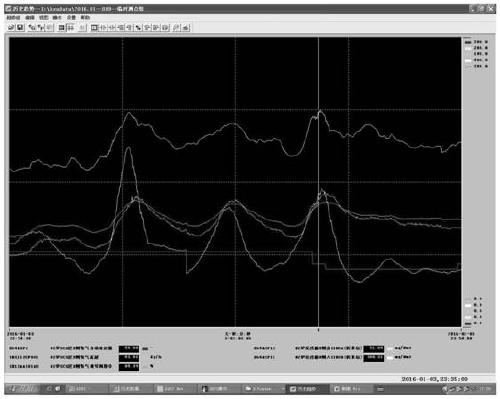

CAN bus-based motor bench experiment device and load control method

InactiveCN108776302AControl speedReal-time display speedBase element modificationsDynamo-electric machine testingCouplingElectric machine

The invention relates to a CAN bus-based motor bench experiment device and a load control method. The traditional magnetic powder brake has two demagnetization modes, in a situation with low precisionrequirements, a reverse constant current demagnetization mode is adopted, and in a situation with high precision requirements, a sinusoidal oscillation demagnetization mode is adopted. The CAN bus-based motor bench experiment device comprises the magnetic powder brake (5); the magnetic powder brake has an excitation control end interface; the excitation control end interface is connected with anexcitation controller (4) through a wire; the excitation controller is connected with a CAN analyzer (2) through a CAN bus (3); the CAN analyzer is connected with a computer (1) through a USB interface; the magnetic powder brake is connected with a torque sensor (7) through a coupling A (6); the torque sensor is connected with a tested motor (9) through a coupling B (8); and the tested motor is connected with a motor controller (10) through a wire. Thus, the CAN bus-based motor bench experiment device is arranged.

Owner:HARBIN UNIV OF SCI & TECH

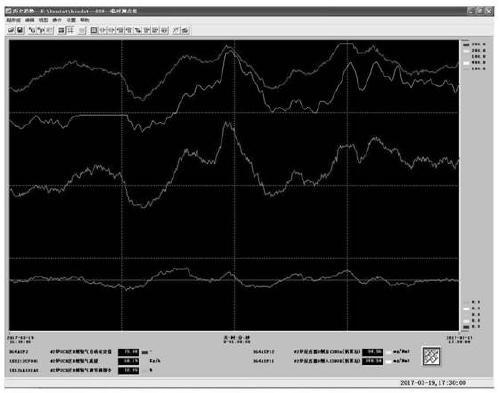

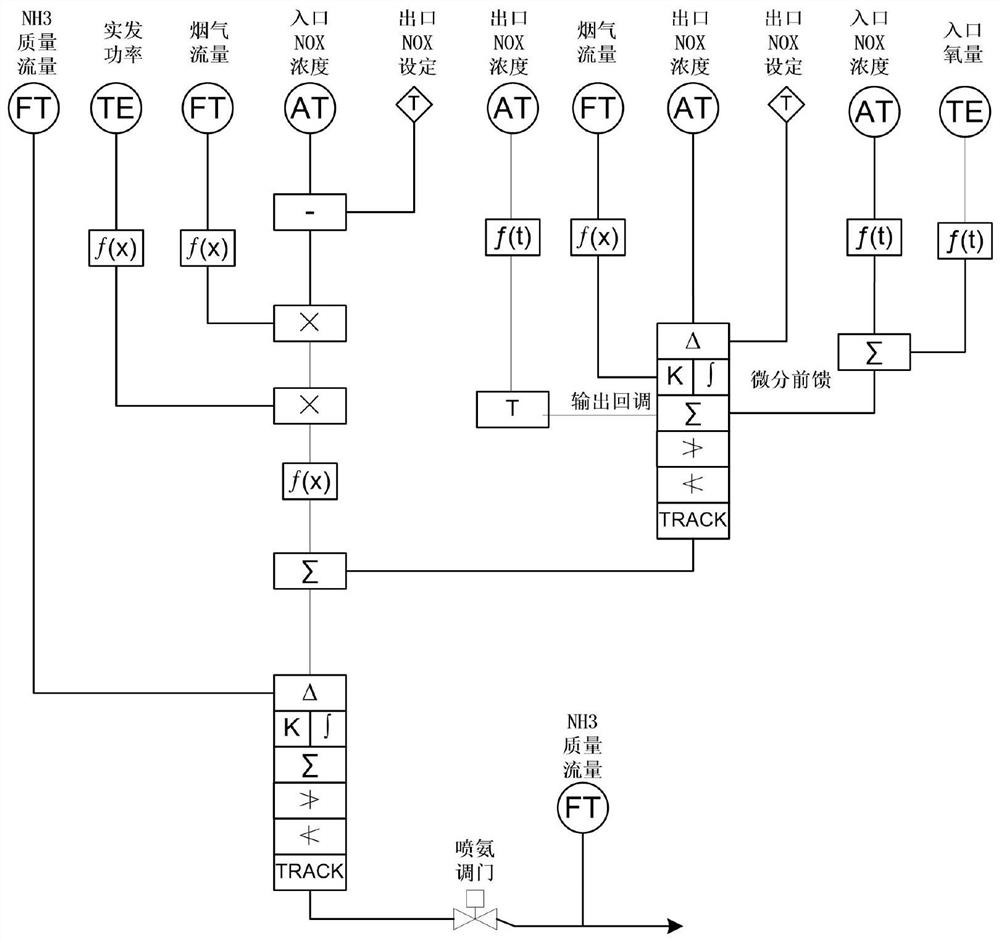

Power plant denitration ammonia injection control system

ActiveCN111644054AQuick responseEliminate static biasDispersed particle separationControllers with particular characteristicsPower stationReaction zone

The invention discloses a power plant denitration ammonia injection control system, wherein a cascade control system is adopted to improve the response speed of inlet NOX concentration disturbance andcomprises: a dynamic differential feedforward of reactor inlet NOX concentration, a denitration efficiency feedforward, a load change feedforward, PID modification parameters and a control process ofoutlet NOX deviation correction, and the denitration ammonia injection control system adopts a waveform judgment method for callback. The judgment logic of the waveform judgment method is as follows:when the outlet NOX concentration curve has a sinusoidal oscillation waveform, the ammonia injection amount is quickly called back in the second quarter period of the sinusoidal oscillation waveform.According to the cascade control system for calculating the NH3 demand quantity according to NOX at the inlet of the SCR reaction zone, the ammonia spraying response speed is increased; outlet NOx deviation correction is added in a control algorithm, so that static deviation is eliminated; and meanwhile, a waveform judgment method is adopted for callback, so that the phenomenon of output oscillation is prevented, and thereby, the problems of response lag of inlet NOx concentration disturbance and output oscillation are solved.

Owner:DATANG LUBEI POWER GENERATION

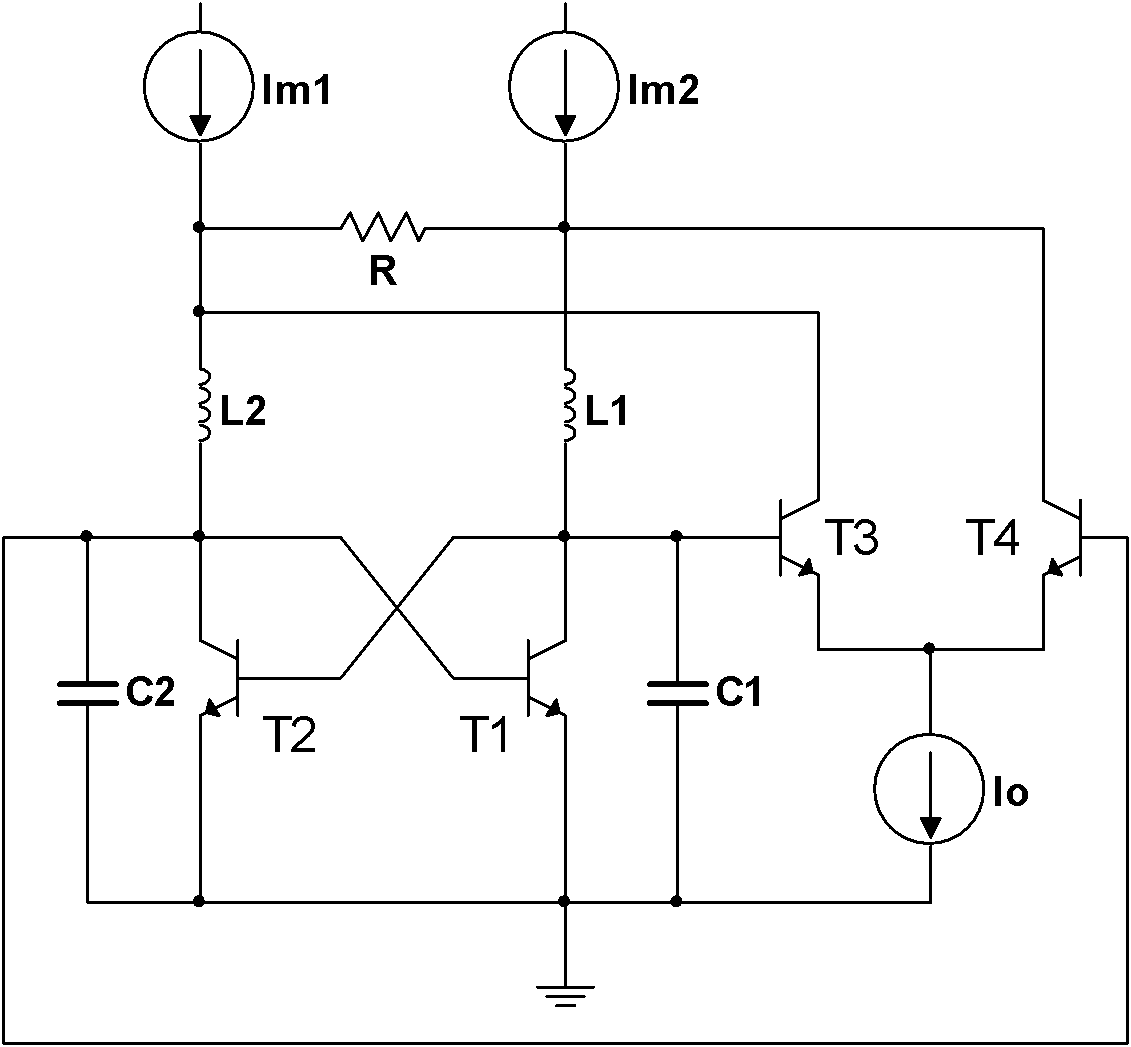

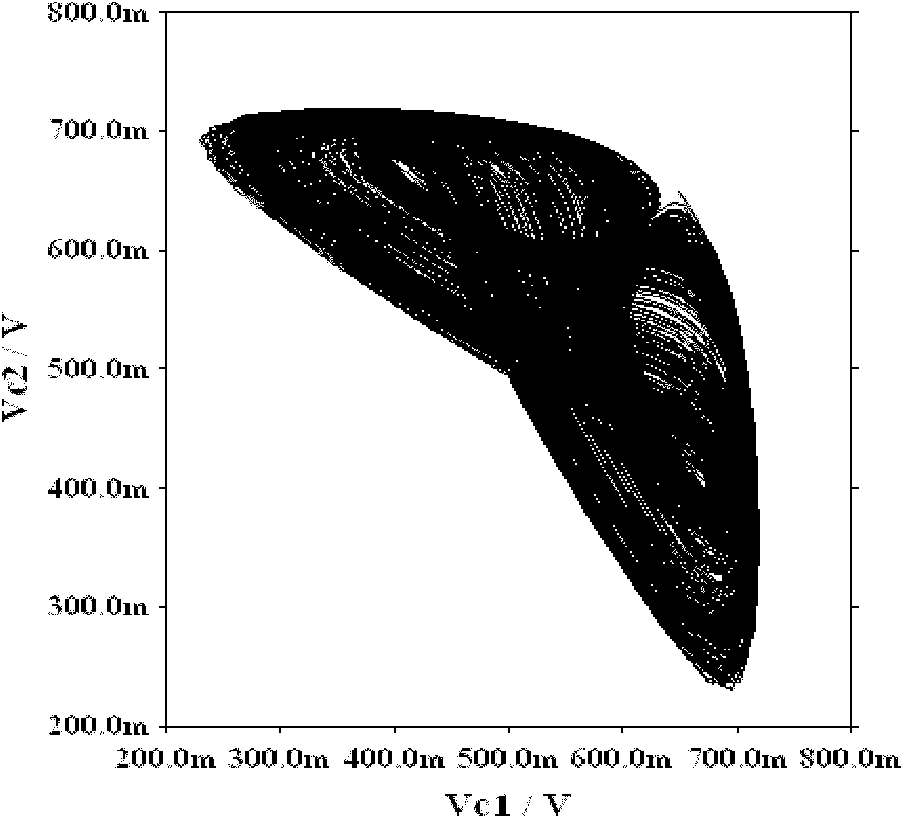

Chaotic oscillator and application thereof as random bit generator

InactiveCN102185562ACompact structureLow costOscillations generatorsBalance performanceTransconductance

The invention discloses a chaotic oscillator, which comprises a negative transconductance sinusoidal oscillator circuit and a differential amplification circuit unit, wherein an output signal of the sinusoidal oscillator circuit is amplified by the differential amplification circuit unit, and the amplified signal is taken as output to obtain a continuous chaotic oscillation signal. Meanwhile, the invention discloses the application of the chaotic oscillator as a random bit generator. A sinusoidal oscillator provided by the invention is suitable to be realized on a single integrated circuit chip, and has a compact structure, low manufacturing cost, very high output frequency, high balance performance and high source suppression and noise immunity functions. The random bit generator designed according to the sinusoidal oscillator inherits the advantages. As a design scheme of a real random bit generator, the invention has a very high practical value.

Owner:SOUTHWEST UNIV

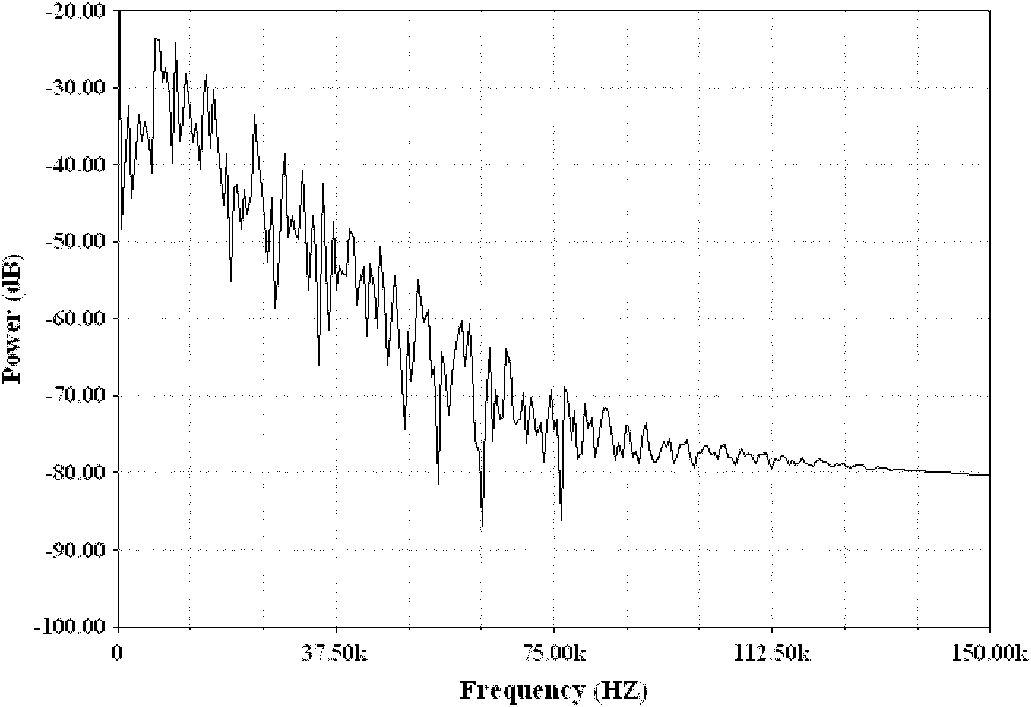

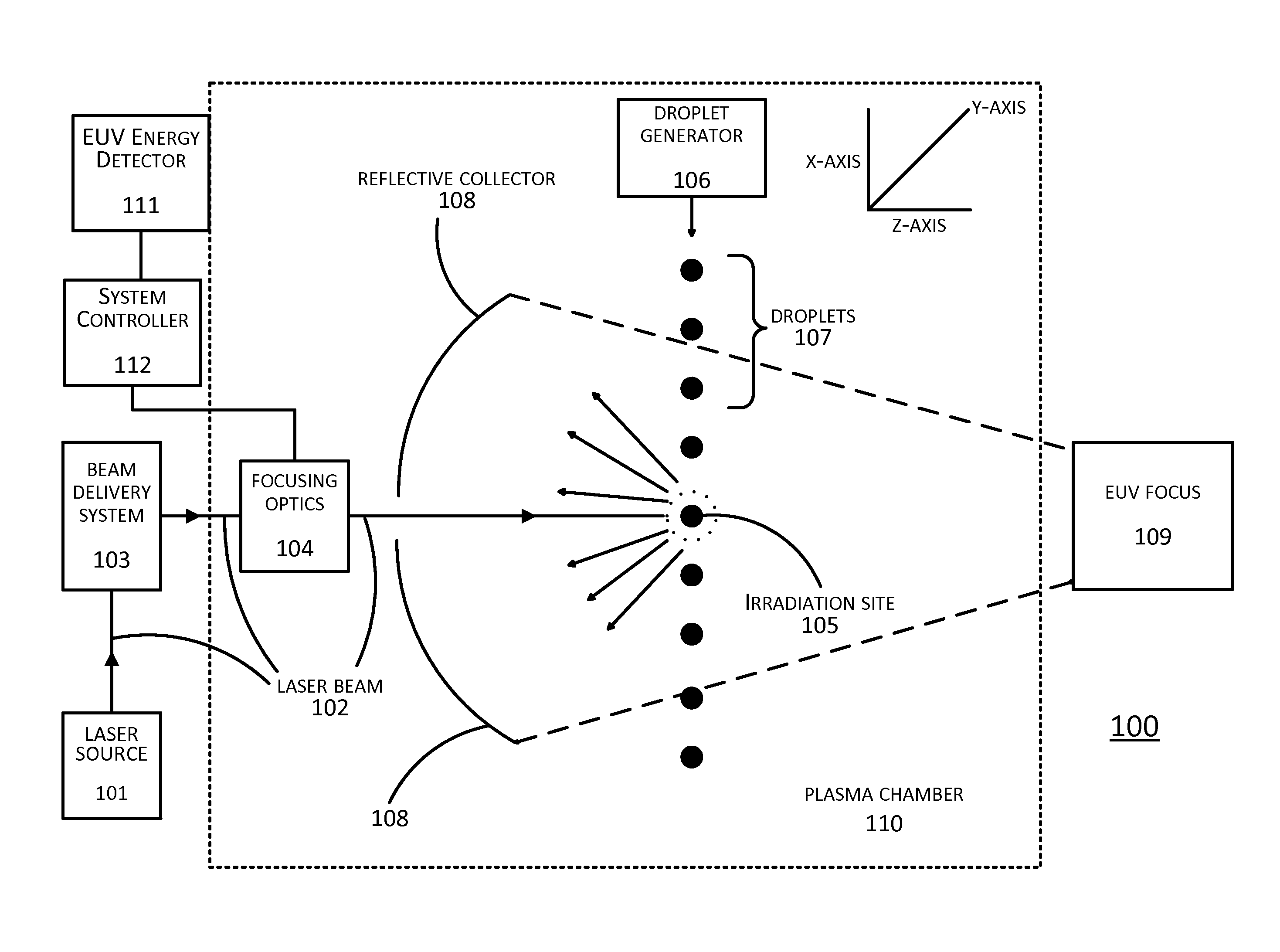

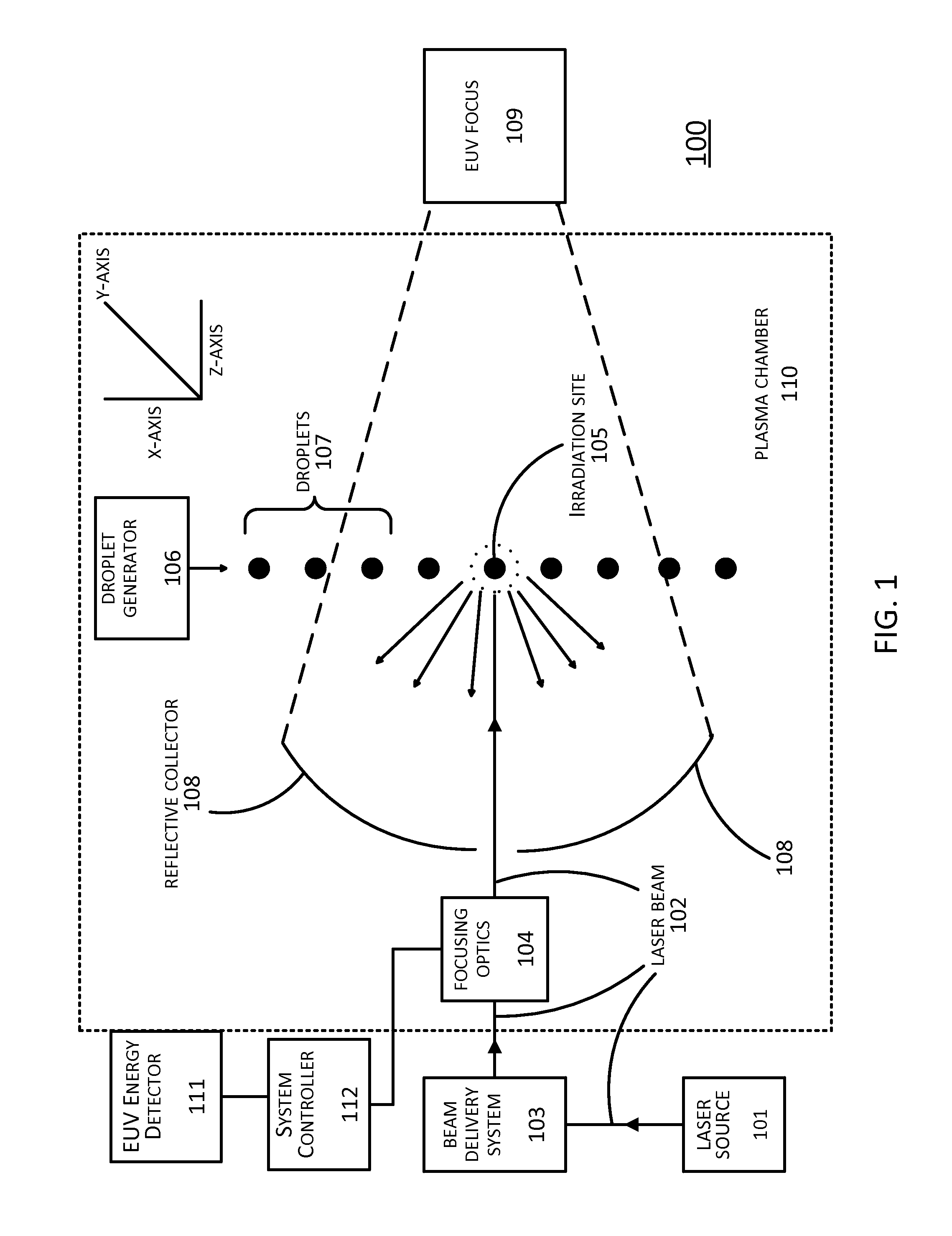

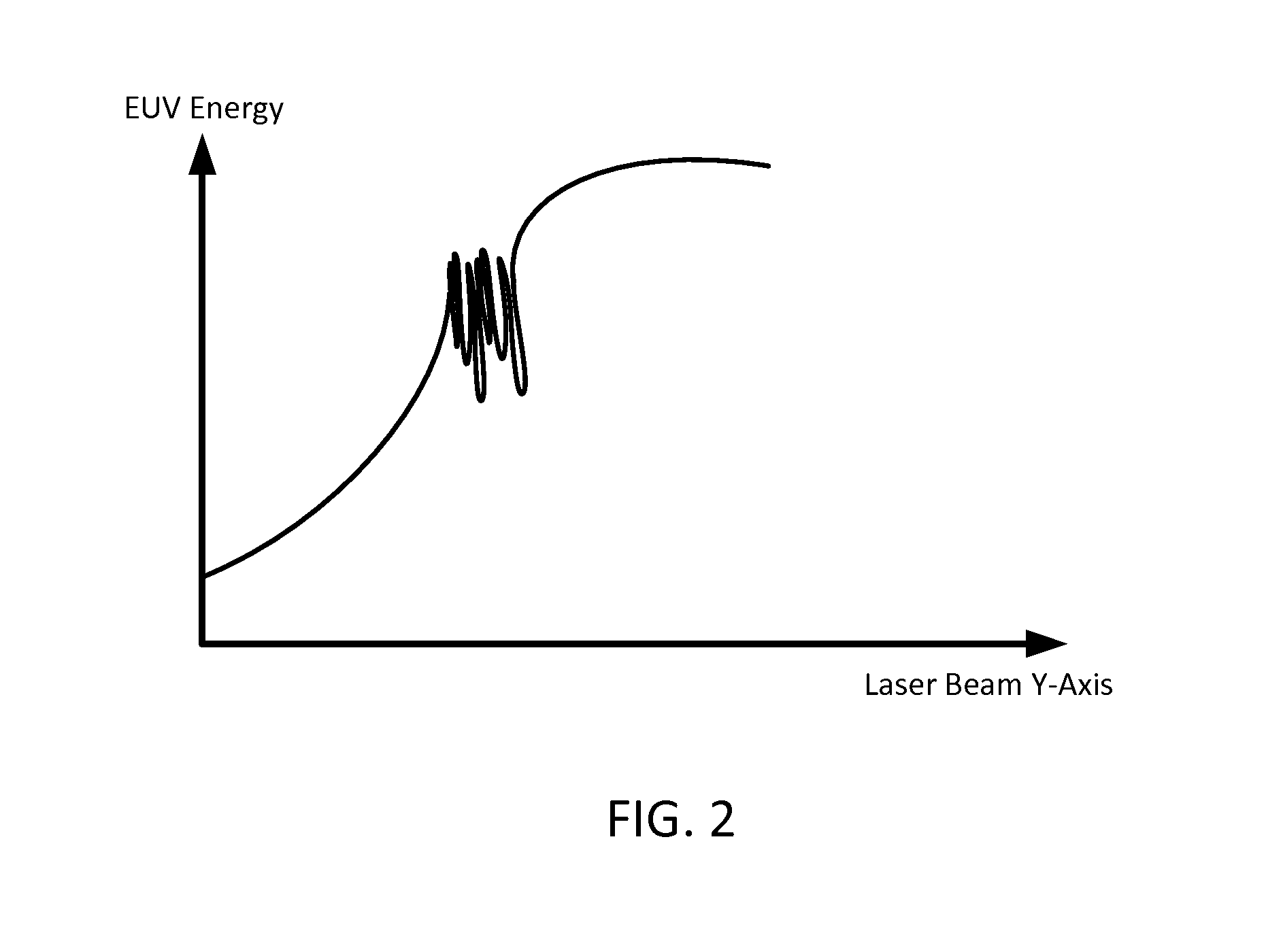

Systems and methods to avoid instability conditions in a source plasma chamber

ActiveUS9536631B1Beam deviation/focusing by electric/magnetic meansX-ray tube with very high currentInstabilityLaser beams

In LPP EUV systems, sinusoidal oscillations or instabilities can occur in the generated EUV energy. This is avoided by detecting when the LPP EUV system is approaching such instability and adjusting the LPP EUV system by moving the laser beam of the LPP EUV system. Detection is done by determining when the generated EUV energy is at or above a primary threshold. Adjusting the LPP EUV system by moving the laser beam is done for a fixed period of time, until a subsequently generated EUV energy is below the primary threshold, until a subsequently generated EUV energy is below the primary threshold for a fixed period of time, or until a subsequently generated EUV energy is at or below a secondary threshold below the primary threshold.

Owner:ASML NETHERLANDS BV

Servo motor driven continuous casting crystallizer non-sinusoidal oscillation distributed control system

PendingCN107900296AReal-time monitoring of non-sinusoidal vibrationCircumstances affecting productionMotor driveComputer monitoring

The invention discloses a servo motor driven continuous casting crystallizer non-sinusoidal oscillation distributed control system which comprises an upper computer monitoring system and n flows of continuous casting crystallizer non-sinusoidal oscillation control systems; each flow of continuous casting crystallizer non-sinusoidal oscillation control system comprises a motion controller, a servodriver, a servo motor, a speed reducer, a driving mechanism, a continuous casting crystallizer vibrating table, a continuous casting crystallizer, a displacement sensor and the like; each flow of continuous casting crystallizer non-sinusoidal oscillation control system is independently controlled by the corresponding motion controller; the upper computer monitoring system monitors non-sinusoidal oscillation situations of all flows of continuous casting crystallizers; and when one flow of motion controller breaks down, the upper computer monitoring system gives an alarm, while normal working ofthe other continuous casting flows are not affected. Compared with a centralized control system based on a high-performance programmable logic controller, the situation that production of all continuous casting flows is affected due to a programmable logic controller failure can be avoided, the safety and the reliability of the servo motor driven continuous casting crystallizer non-sinusoidal oscillation distributed control system are improved and the servo motor driven continuous casting crystallizer non-sinusoidal oscillation distributed control system has the advantages of low cost, simplicity in structure and the like.

Owner:YANSHAN UNIV

Receiver configuration for a control unit in a vehicle and method for generating a synchronization pulse

ActiveUS20150151701A1Reduce electromagnetic radiationRobust implementationElectric devicesPedestrian/occupant safety arrangementVoltage generatorEngineering

A receiver configuration for a control unit in a vehicle having a voltage generator for generating a synchronization pulse, which includes a first voltage source, a current source and a current sink, the voltage generator generating the synchronization pulse within predefined specification limits having a predefined shape and a predefined time behavior, and the receiver configuration outputting the synchronization pulse for synchronizing a signal transmission via a databus to at least one sensor. A method is also provided for generating a synchronization pulse. The voltage generator generates the synchronization pulse via the current source and the current sink by charging and / or discharging a bus load essentially as a sinusoidal oscillation.

Owner:ROBERT BOSCH GMBH

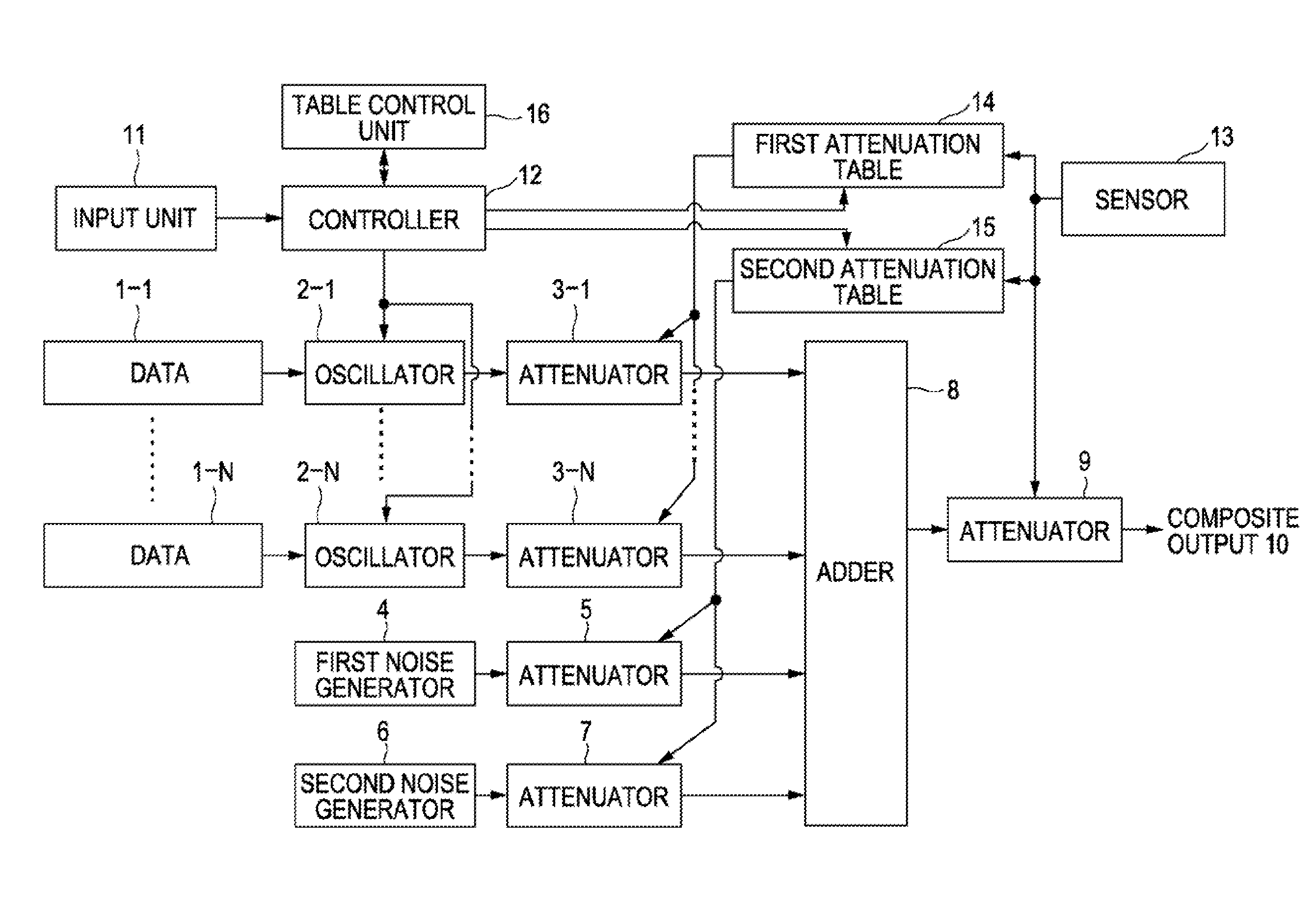

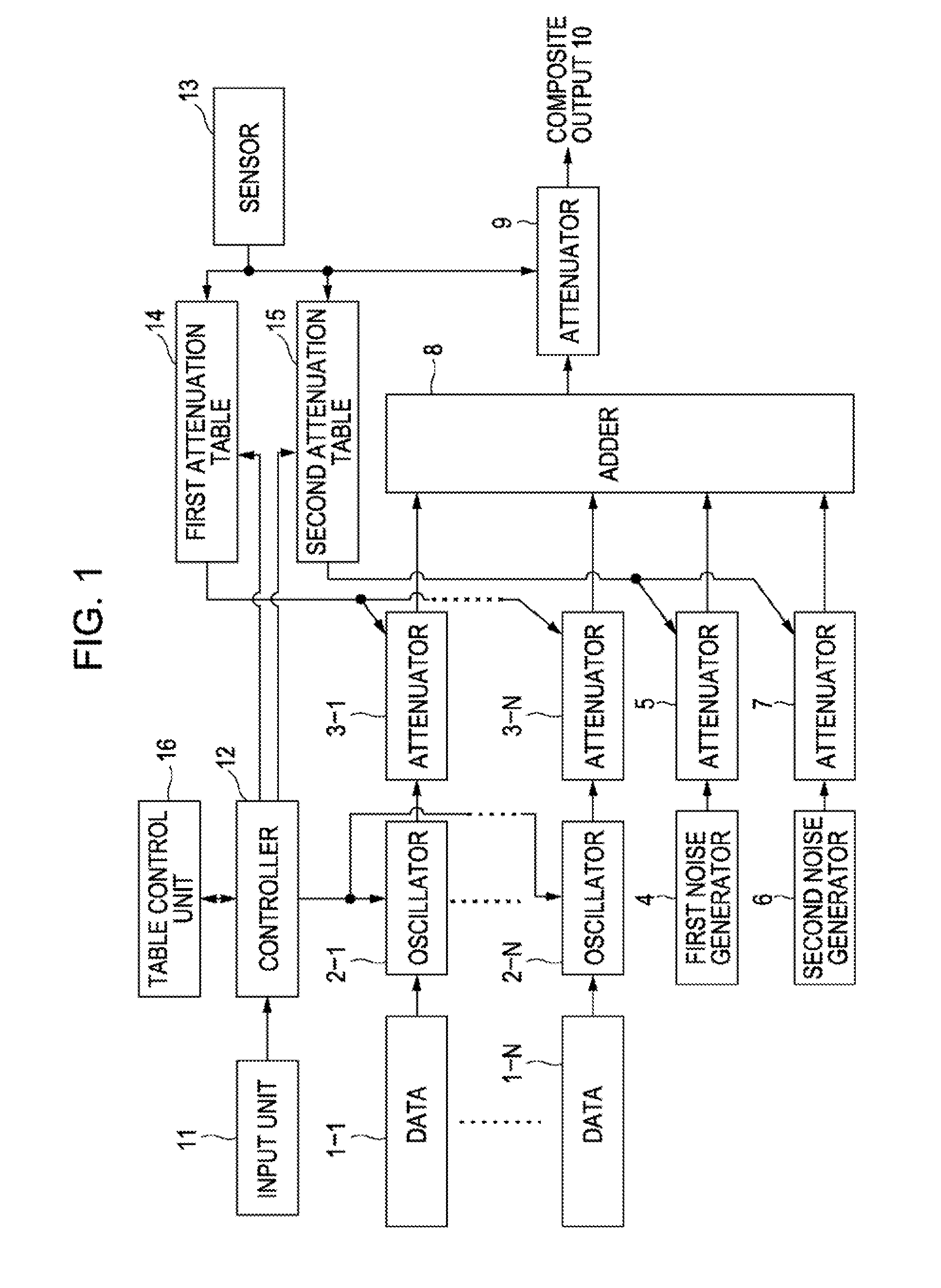

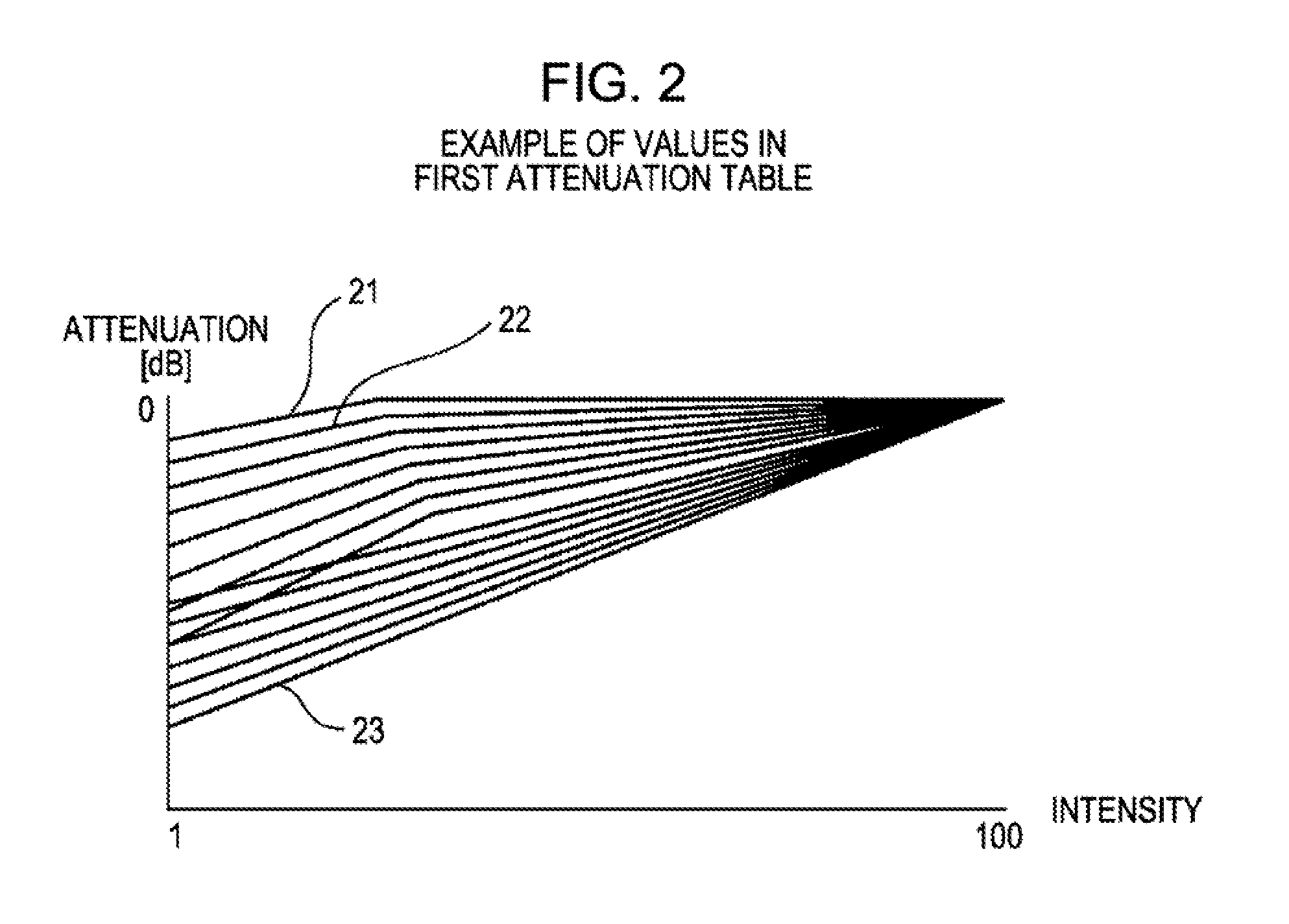

Piano sound source apparatus, method and program for piano sound synthesis

InactiveUS7468482B2Quality improvementLow costElectrophonic musical instrumentsAmplifier modifications to reduce noise influencePianoSound sources

Disclosed is a piano sound source apparatus for adding a piano sound source providing a plurality of sinusoidal oscillation frequencies and a noise source providing a plurality of noise oscillation frequencies to output a composite tone. The apparatus includes an oscillation control unit that controls the frequency and amplitude of each of sine waves corresponding to the sinusoidal oscillation frequencies on the basis of time, an amplitude control unit that controls the amplitude of each of the sine waves corresponding to the sinusoidal oscillation frequencies in accordance with the intensity of the composite tone, and a mixing-proportion control unit that controls the amplitude of each of the noise oscillation frequencies in accordance with the intensity of the composite tone to control the mixing proportion of the amplitudes of the noise oscillation frequencies and those of the sine waves corresponding to the sinusoidal oscillation frequencies.

Owner:SONY CORP

Method and apparatus for phase-independent predictable resetting

InactiveUS20050280446A1Digital computer detailsVoltage-current phase angleControl systemNeuronal models

The ocillatory dynamics of inferior olive (IO) neurons found in the olivo-cerebellar network of the brain are reproduced and applied to various control applications. An IO neuron model is provided which produces quasi-sinusoidal oscillations with a characteristic amplitude and frequency. Action potentials occur at the peaks of the oscillations and have precise timing properties. Stimuli applied to the IO neuron model show no changes in oscillation amplitude and frequency but do produce a shift of the oscillation phase, and hence a time shift of the corresponding action potentials. The resulting phase is defined by the strength of the stimulus and does not depend on when the stimulus is applied, thus providing a self-referential phase reset (SPR) effect. The oscillations of multiple IO neurons, or their models, coupled together tend to become organized in space and time in the form of oscillatory phase clusters. The phases of the IO oscillators can be quickly set to a desired phase pattern irrespective of the history of phase evolution. A circuit for implementing the IO neuron model and a control system based on the circuit are described.

Owner:NEW YORK UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com