Power plant denitration ammonia injection control system

A technology for control systems and power plants, applied in the direction of electric controllers, comprehensive factory control, controllers with specific characteristics, etc., can solve problems such as difficulty in quickly responding to changes in NOX concentration at the inlet, and no effect has been achieved, so as to prevent output shocks, Effects of improving response speed and eliminating static deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

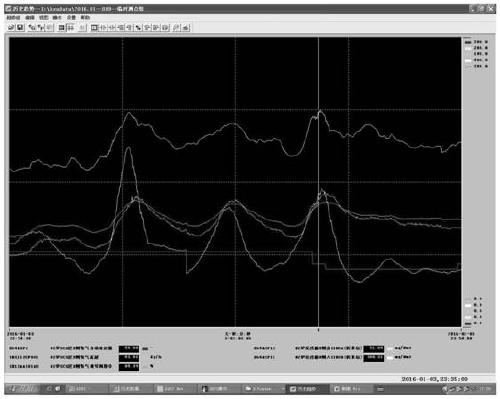

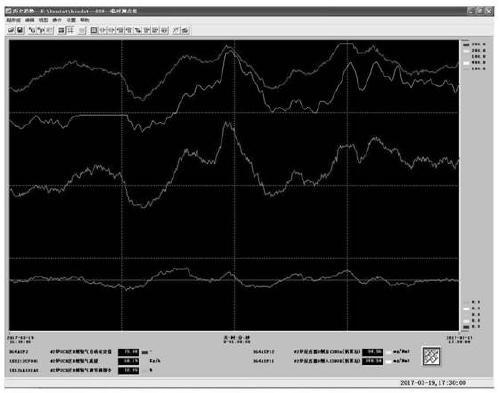

Image

Examples

Embodiment Construction

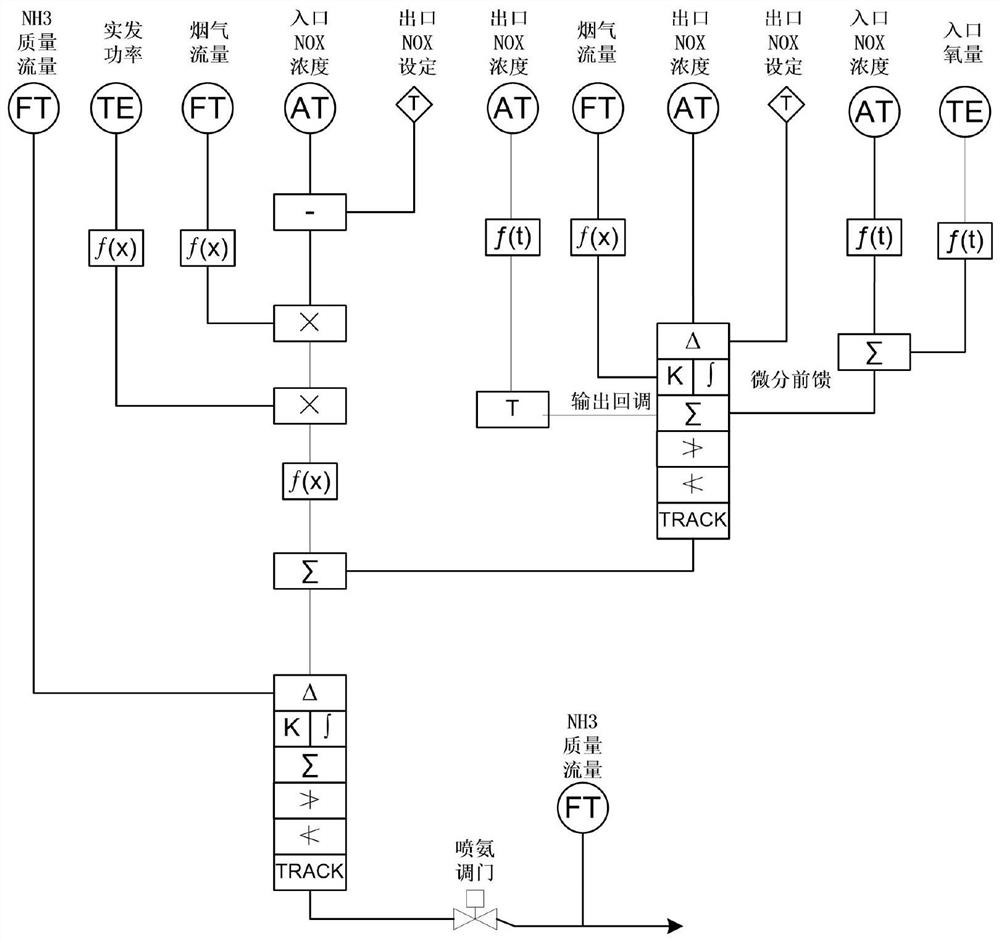

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted in advance that the upper, lower, left, and right orientation words in this application are consistent with the upper, lower, left, and right orientation words in the drawings of the specification, but are not limited to the orientation of specific structures.

[0025] A control system for denitrification and ammonia injection in a power plant, which adopts a cascade control system to improve the response speed of inlet NOX concentration disturbances, such as figure 1 As shown, the cascade control system includes: dynamic differential feedforward of NOX concentration at the reactor inlet, feedforward of denitrification efficiency, load change feedforward, PID modification parameters, and control process of outlet NOX deviation correction. The control logic of outlet NOX deviation correction includes The following steps:

[0026] Step 1 Calculate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com