Non-sinusoidal oscillation method for continuous casting crystallizer

A continuous casting crystallizer and non-sinusoidal technology, which is applied in the field of metallurgical continuous casting, can solve the problems that the stability of the vibration mechanism is greatly affected, the long-term operation of the vibration mechanism is unfavorable, and the stability of the vibration mechanism is unfavorable, and it is easy to control the waveform transformation and acceleration. The effect of smooth curves and simple forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

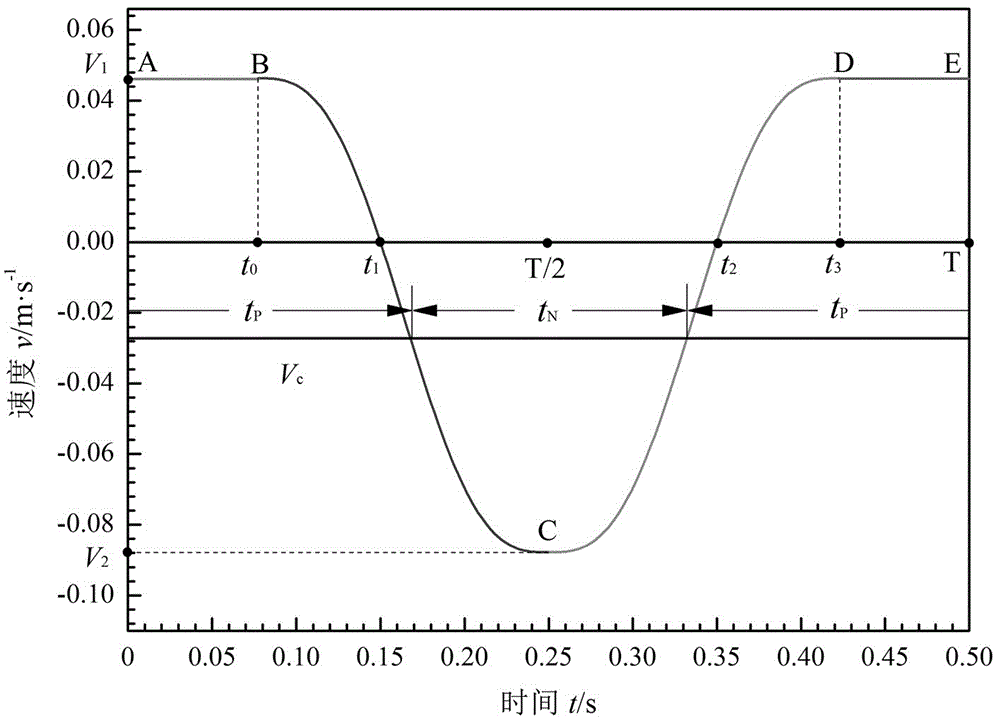

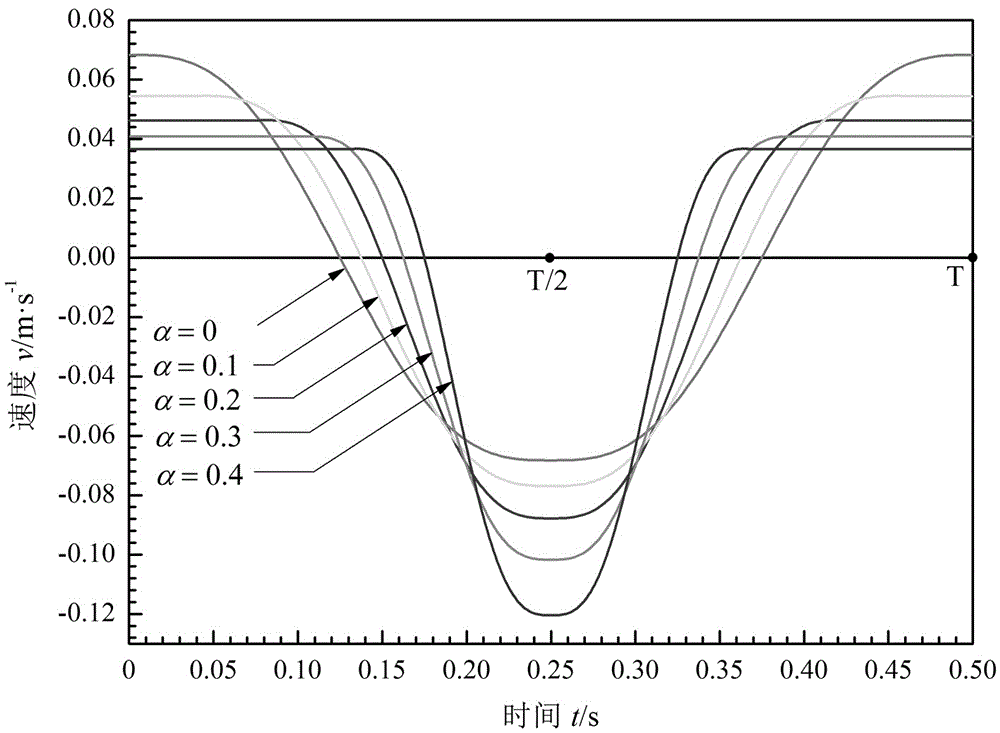

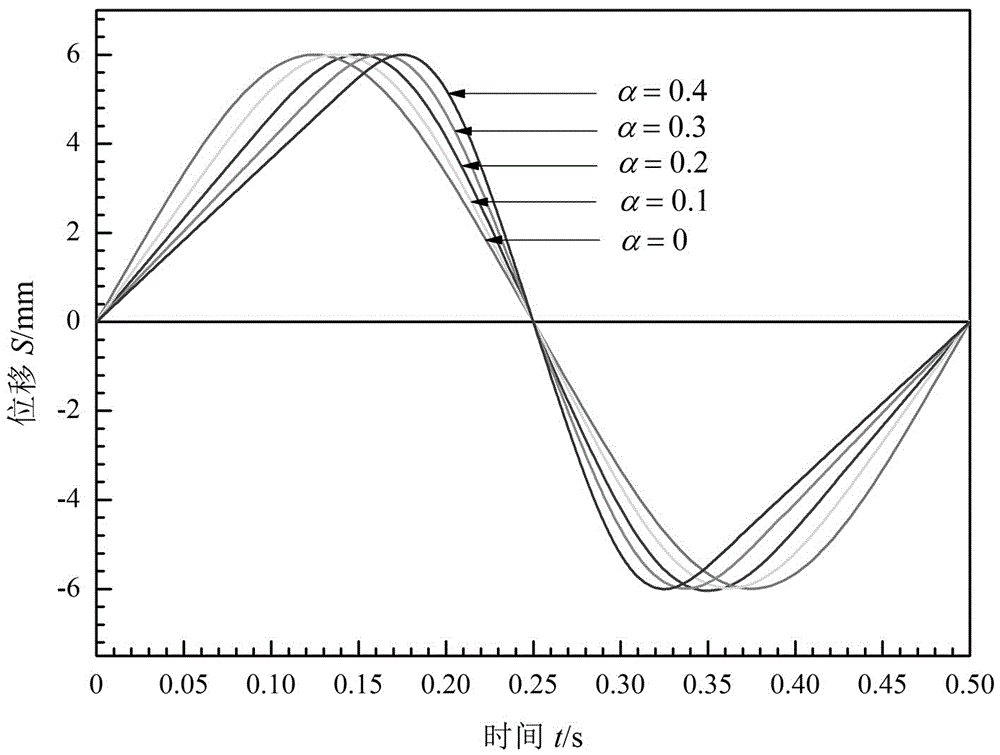

[0030] The non-sinusoidal vibration method of the continuous casting mold, the specific process is: control the driving device of the continuous casting mold, so that the continuous casting mold is driven by the driving device, and in each vibration cycle, the four-stage speed determined by the following four-stage function The waveform vibrates non-sinusoidally: (1)

[0031] in, v Vibration speed of continuous casting mold (m s -1 ); V 1 is the maximum upward vibration speed of the crystallizer (m s -1 ); T is the vibration period of the continuous casting mold (s); t is the non-sinusoidal vibration time (s); t 0 is the end time of the first horizontal straight line segment or the start time of the second curved line segment (s); t 3 is the end time of the third curve segment or the start time of the fourth horizontal straight line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com