Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78 results about "Silicon cantilever" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

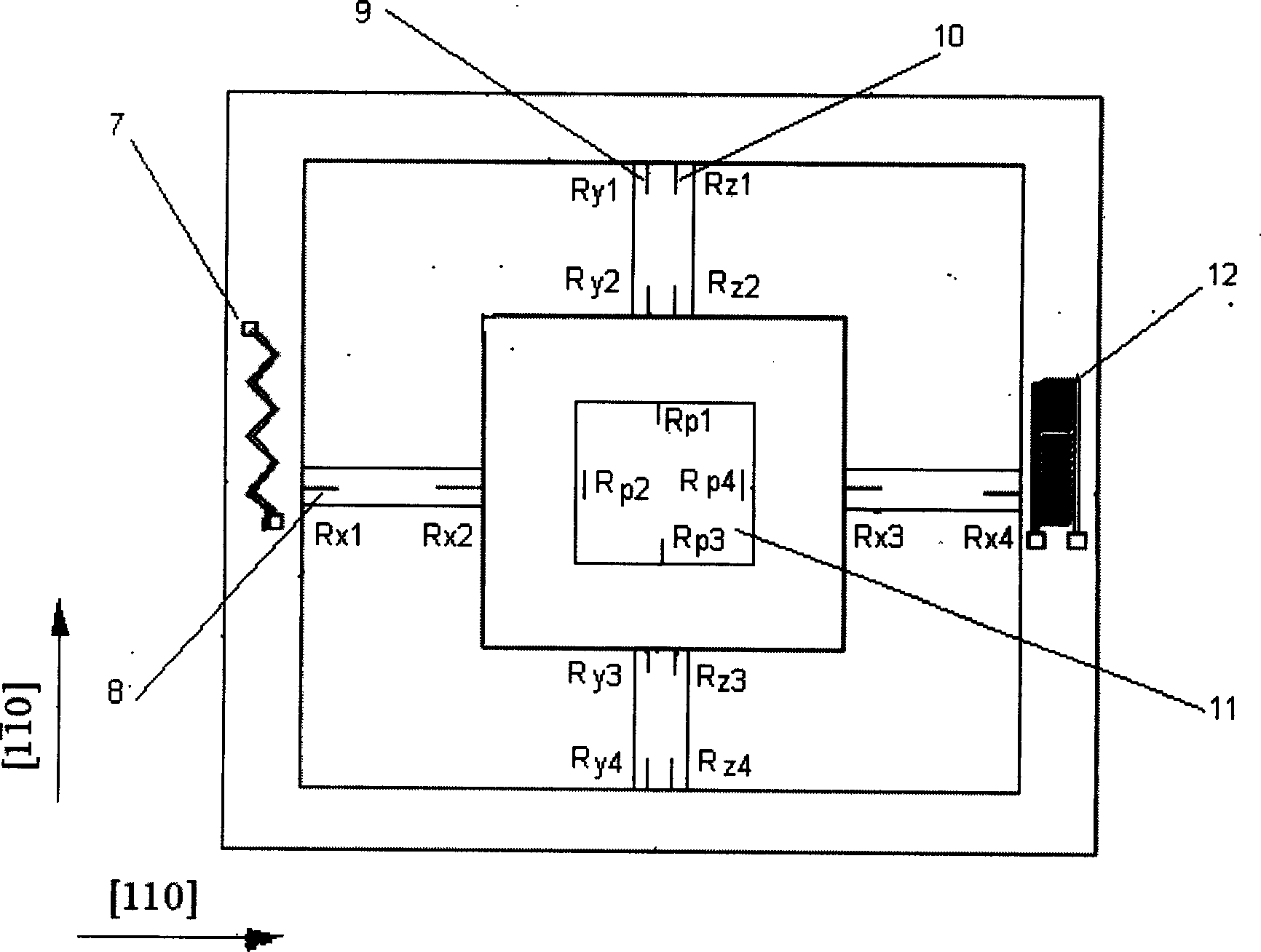

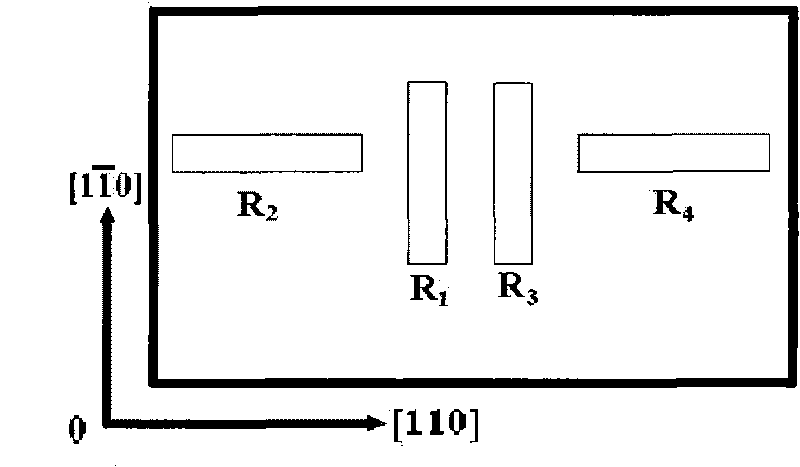

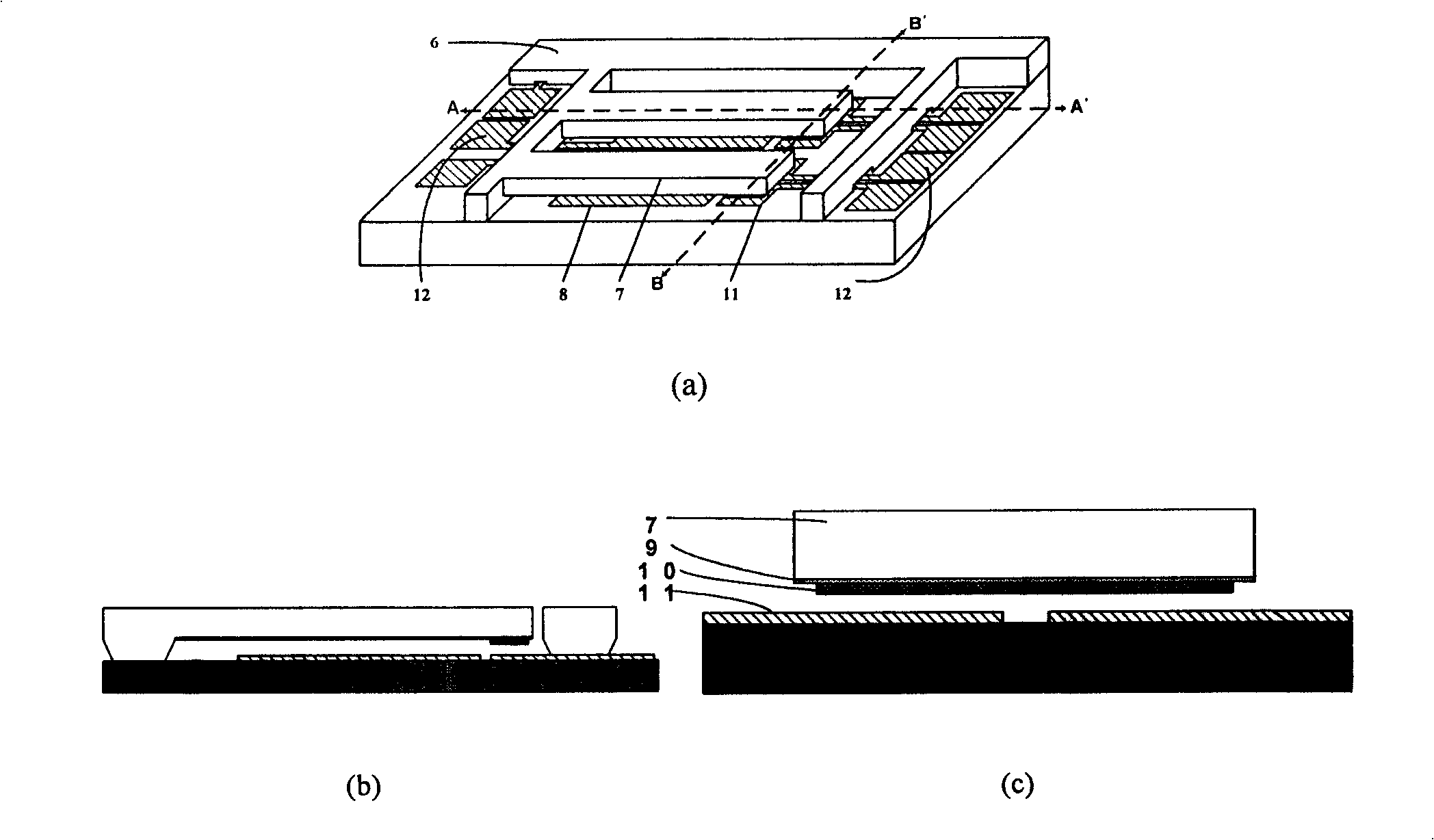

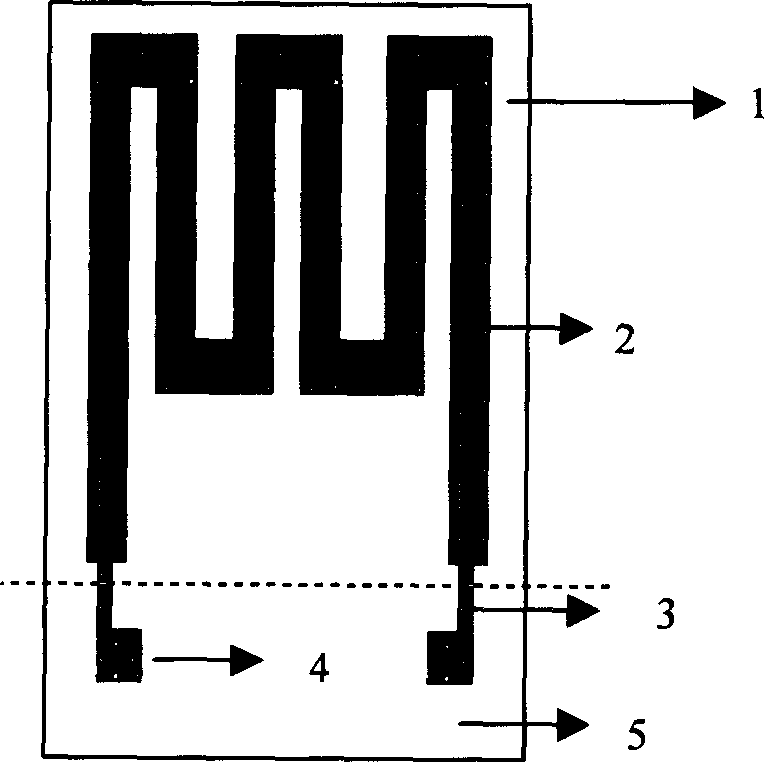

Silicon piezoresistance type wind velocity and wind direction sensor based on micro-electromechanical technology

InactiveCN101294977AEasy to makeReduce residual stressIndication/recording movementFluid speed measurementElectrical resistance and conductanceCantilevered beam

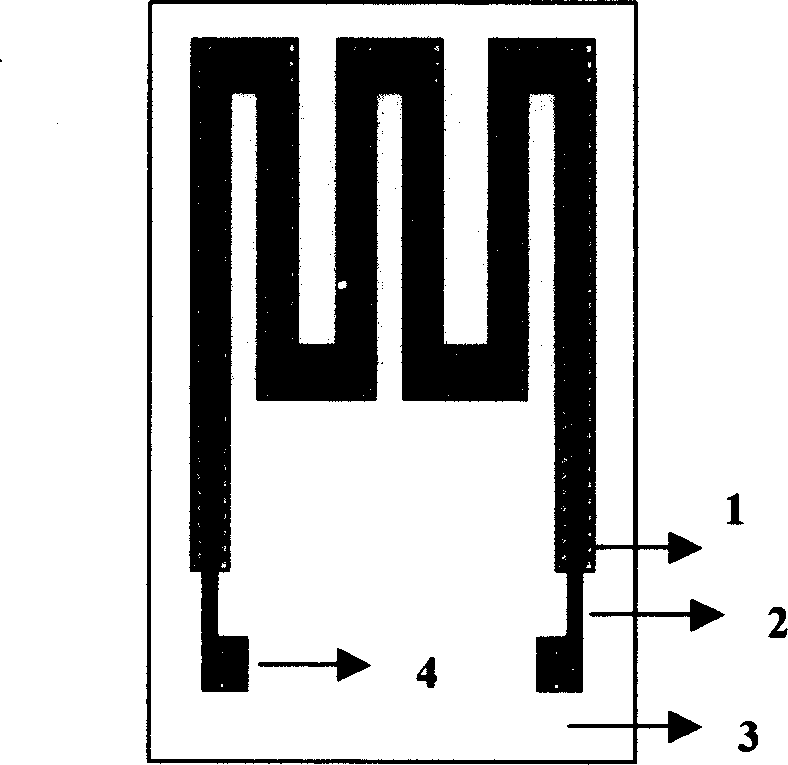

The invention discloses a silicon piezoresistive wind speed and direction sensor based on the microelectronic mechanical technology, which consists of an insulating substrate and four wind speed measuring units which are same and are distributed symmetrically, and detects the components of wind speed in the two orthogonal directions respectively; each wind speed measuring unit consists of an electrode, a mechanical anchor point, a silicon piezoresistive beam, a silicon support beam and a silicon cantilever beam; when the wind blows the surface, the cantilever beam is taken as a wind-sensing element and is pressed by a force of airflow vertical to the cantilever beam so as to generate deformation and acts on the silicon piezoresistive beam by an axial stress mode through a microlever structure consisting of the silicon piezoresistive beam, the silicon support beam and the silicon cantilever beam, thus causing the change of the value of silicon piezoresistive; the wind speed and the wind direction are detected by detecting the change of piezoresistance of each wind speed measuring unit; two-dimension wind speed and the measurement of wind direction are realized by differential detection; the piezoresistive wind speed and direction sensor has simple manufacture, high sensitivity and better anti-interference performance.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

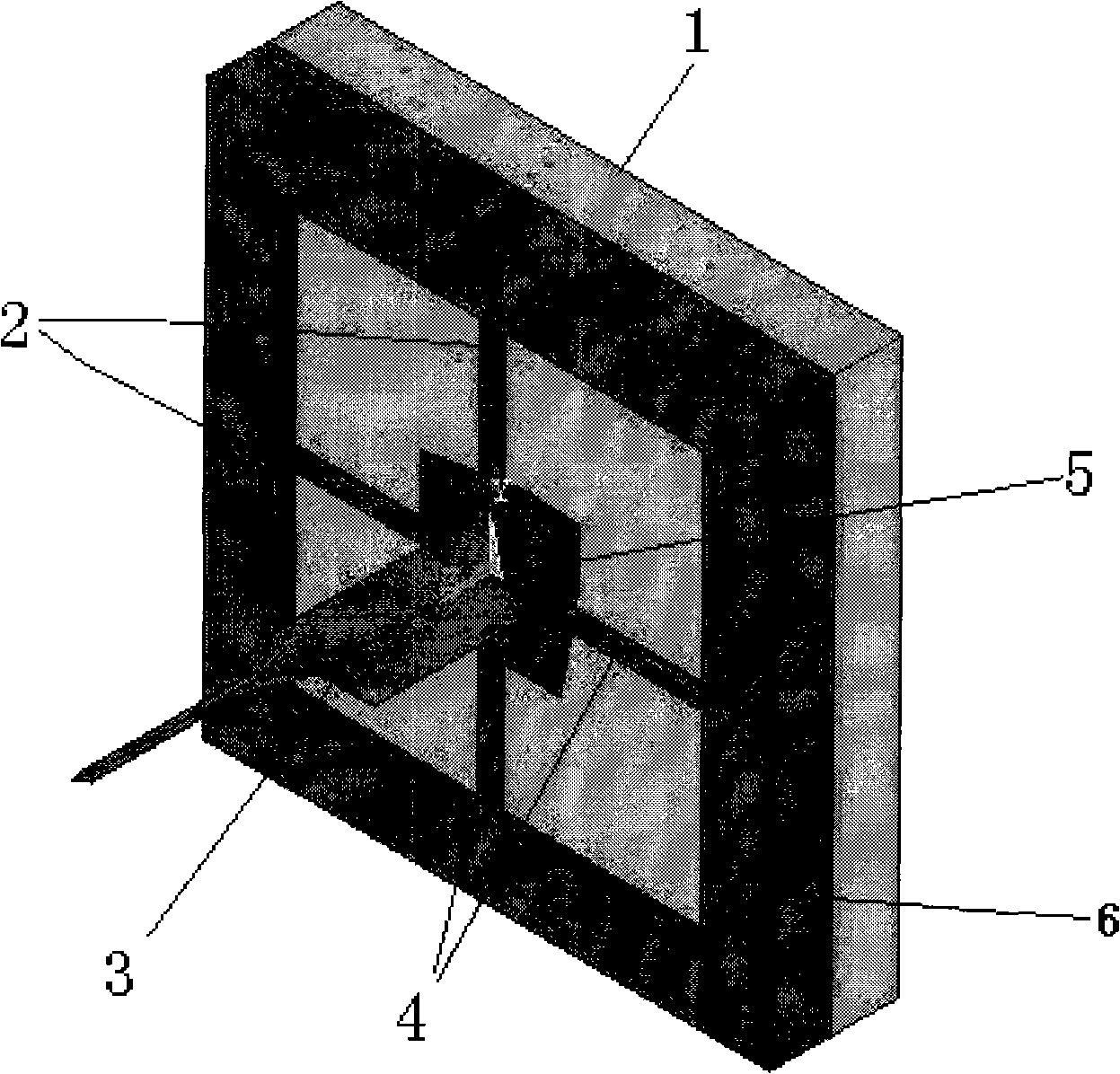

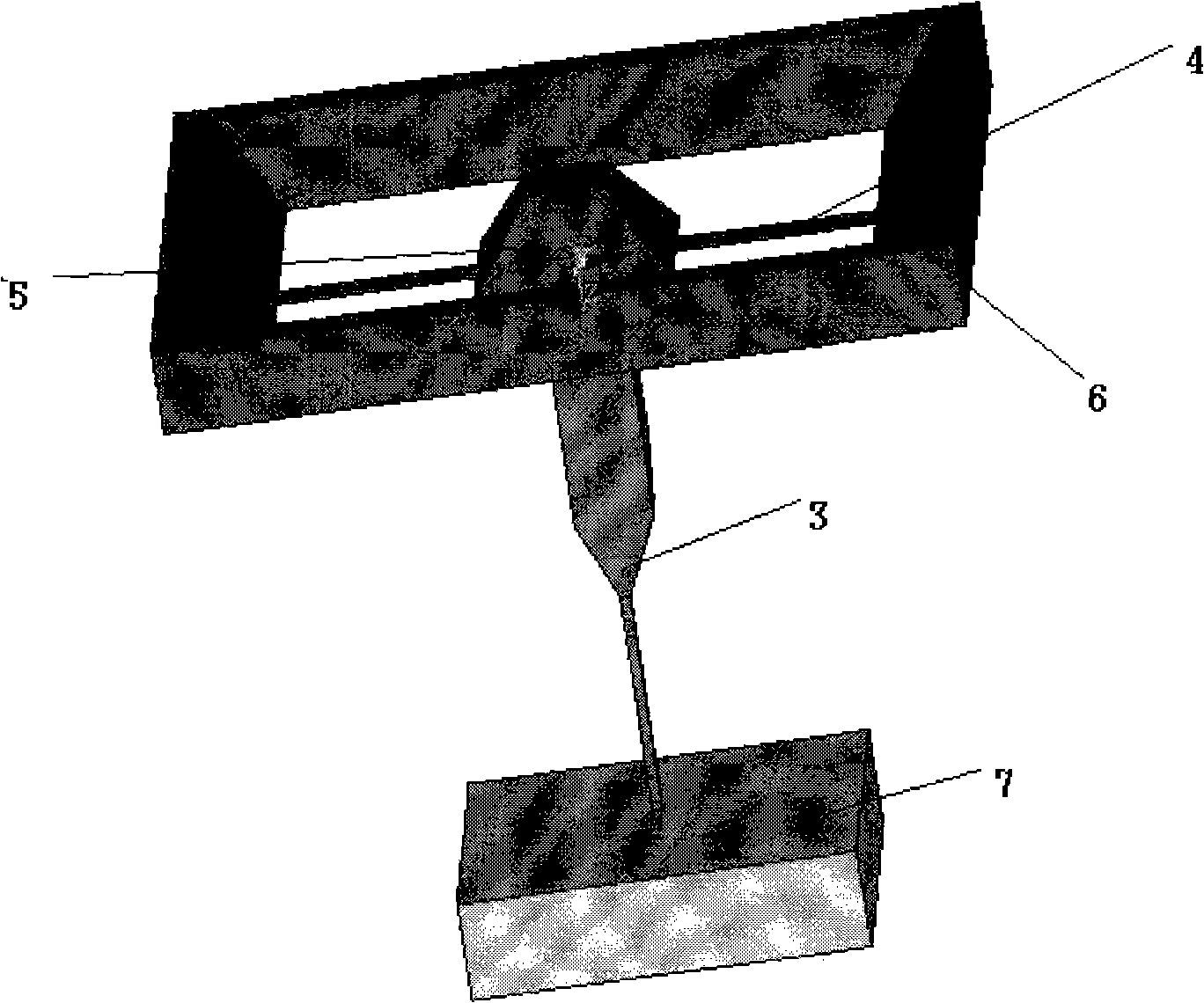

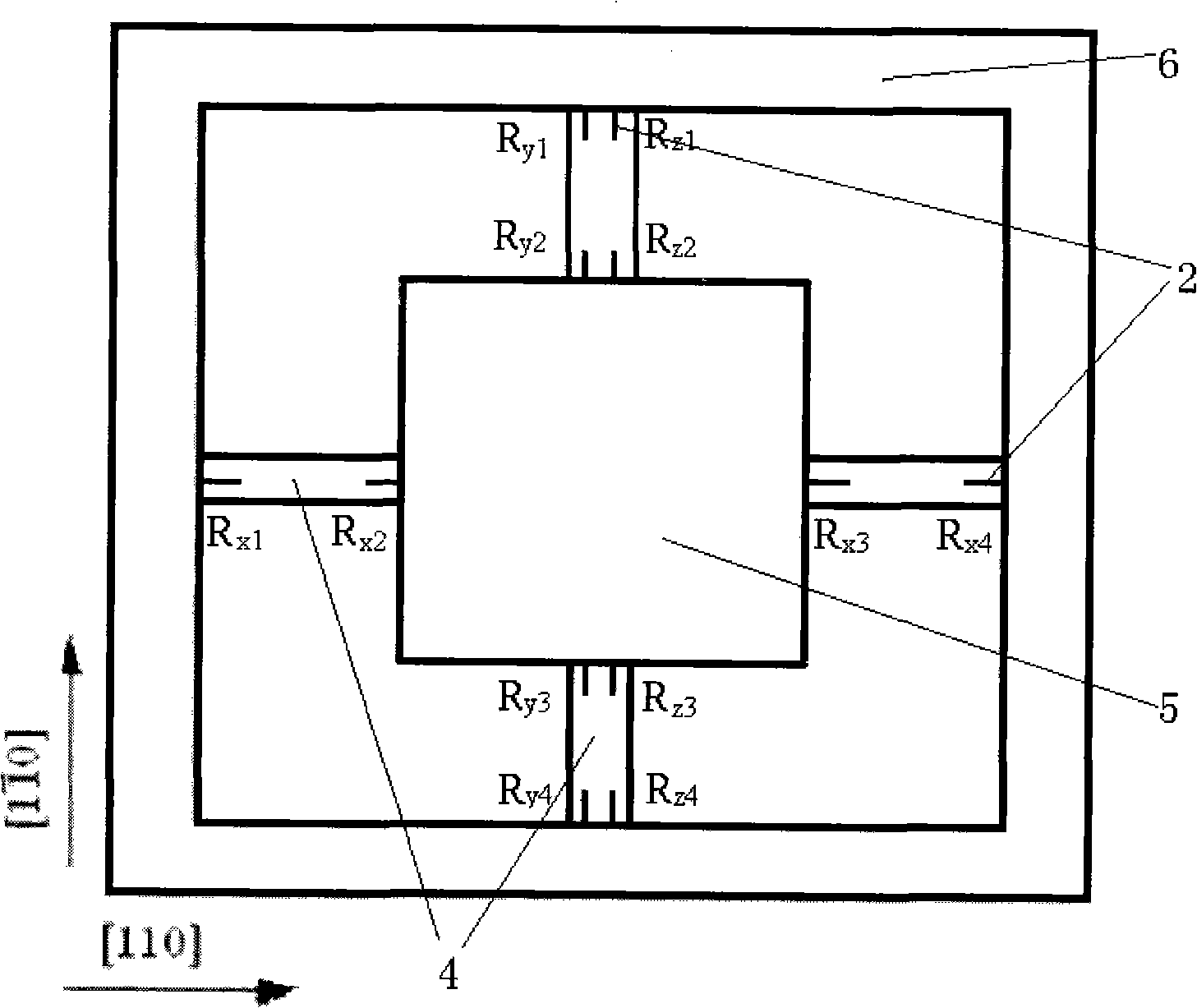

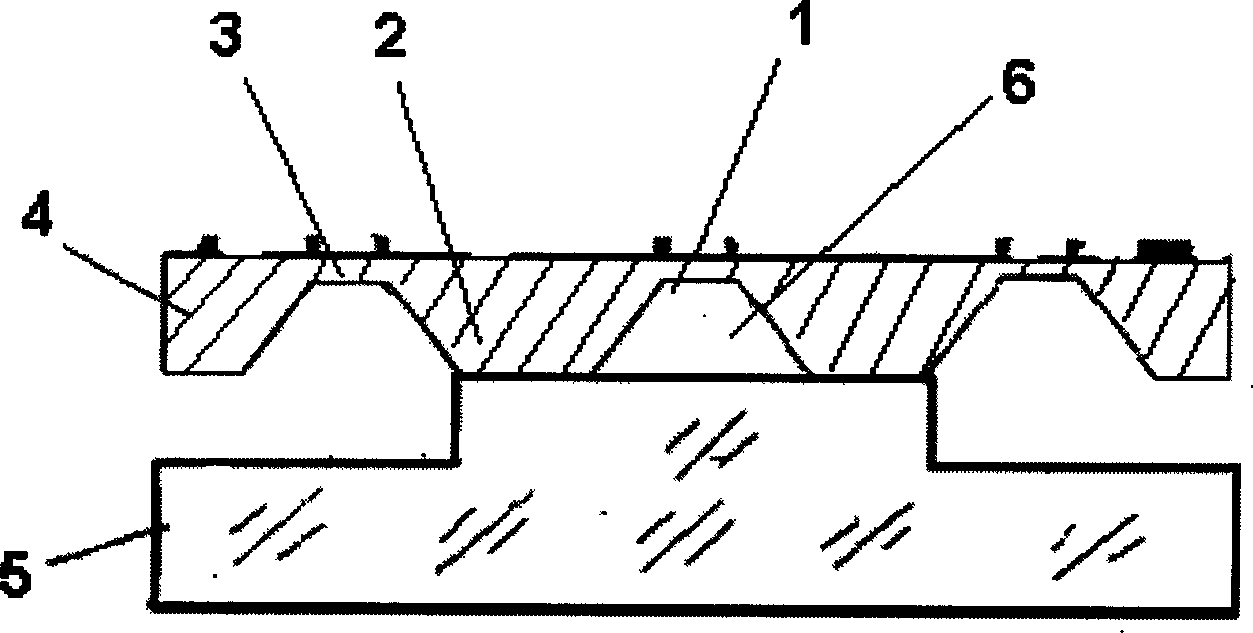

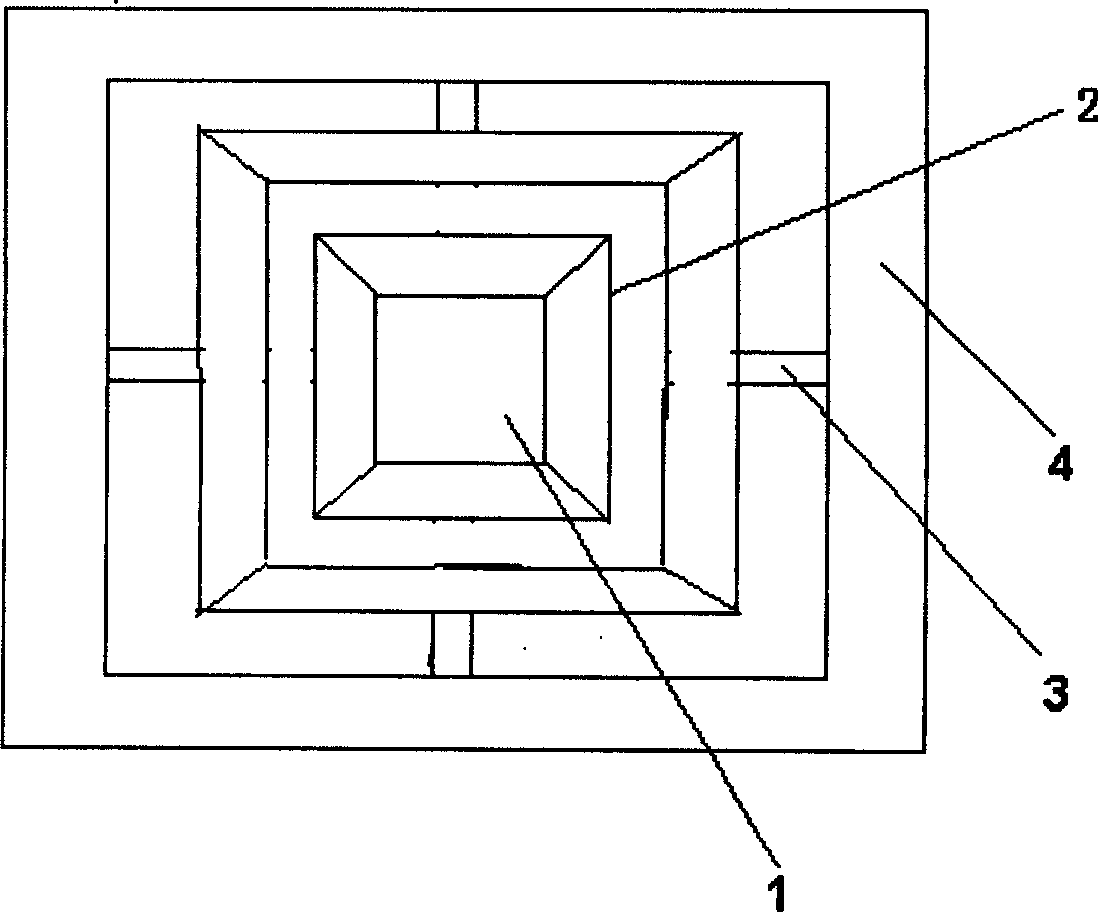

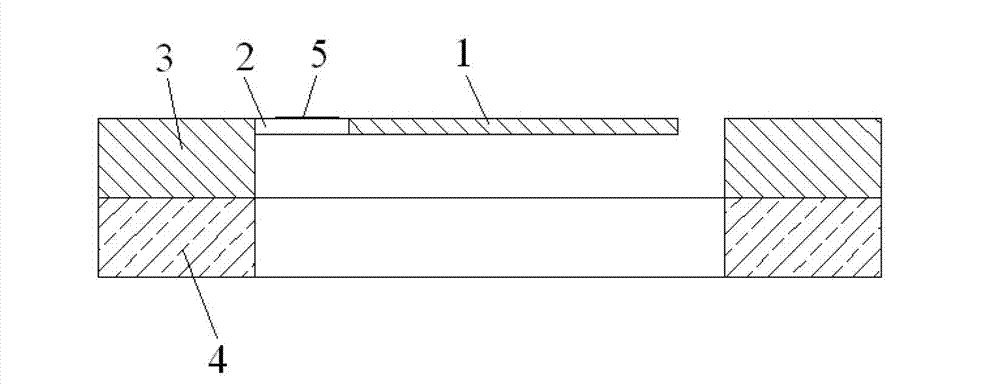

Three-dimensional micro- force silicon micro- sensor

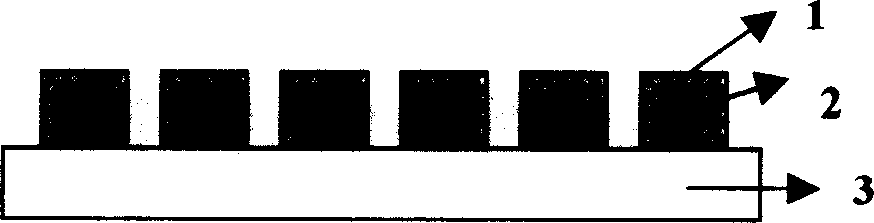

Disclosed is a three-dimensional micro-force silicon micro-sensor, which comprises a glass substrate 1, four single end-clamped silicon cantilever beams 4 vertical to one another are arranged on the glass substrate 1, the cantilever beams 4 support a middle mass hanging block 5, a nano-indenter 3 is arranged on the mass hanging block 5, a piezoresistive strip 2 is disposed on the four cantilever beams 4 respectively, and the four piezoresistive strips 2 are designed into a Wheatstone bridge. The sensor integrates stress sensitivity and force-power conversion detection into one body, and has advantages of high sensitivity, good dynamic response, high precision and easy miniaturization and integration.

Owner:XI AN JIAOTONG UNIV

Cantilever structure and its making process and application

InactiveCN101066749AImprove manufacturing yieldImprove yieldDecorative surface effectsChemical vapor deposition coatingCapacitanceCantilever

The present invention relates to cantilever structure manufactured based on the anisotropic silicon etching and its making process, and belongs to the field of microelectronic mechanical system. The present invention features that the cantilever has pentagonal cross section, upper surface of (100) monocrystalline silicon face and lower surface of two (111) monocrystalline silicon faces. The cantilever structure is manufactured through anisotropic etching with the (111) faces as the automatic etching terminating face, and may be controlled precisely to result in high product quality. The present invention may be used in several MEMS devices, such as capacitance type acceleration sensor, resistance type acceleration sensor, micro mechanical gyro, etc for raised device manufacturing control level and device quality.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Multiple sensor integrated chip

InactiveCN1715838AResolve mutual interferenceReduce volumeMeasurement devicesMultiple sensorMoisture sensor

The multiple sensor chip integrated based on SOI technology includes silicon cantilever beam, silicon film, supporting silicon base around the silicon film, peripheral silicon mass block and glass substrate. The silicon film, the supporting silicon base and the glass substrate form the relatively independent vacuum environment as the pressure sensor inside the silicon chip; the silicon cantilever beam structure is connected to the peripheral silicon mass block to form the 3D speed sensor; and on the peripheral silicon mass block, there are integrated humidity sensor and temperature sensor. The present invention integrates several sensors on the same chip to solve the problem of mutual interference and result in small size and light weight, and may find its important application in various fields.

Owner:XI AN JIAOTONG UNIV

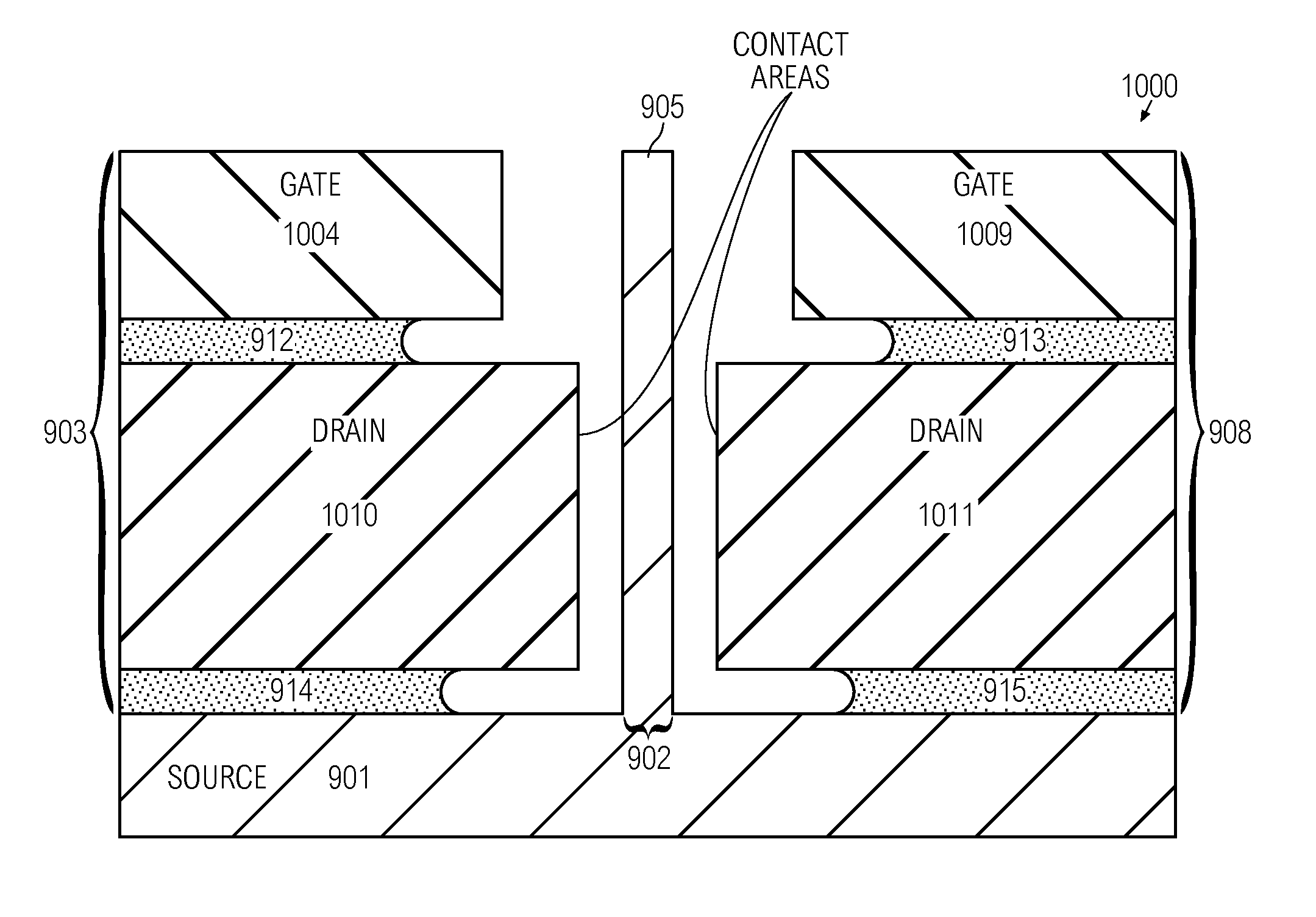

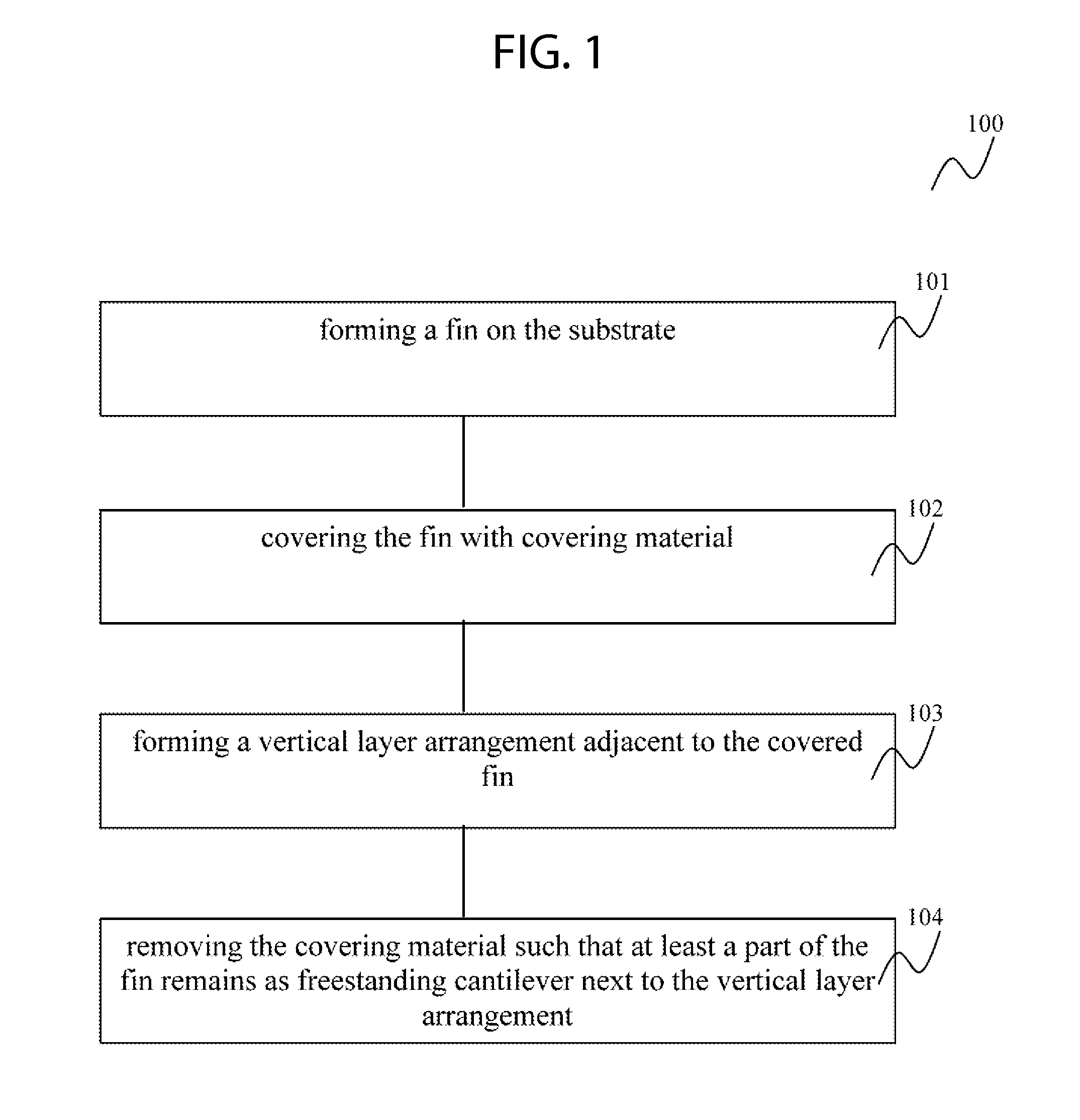

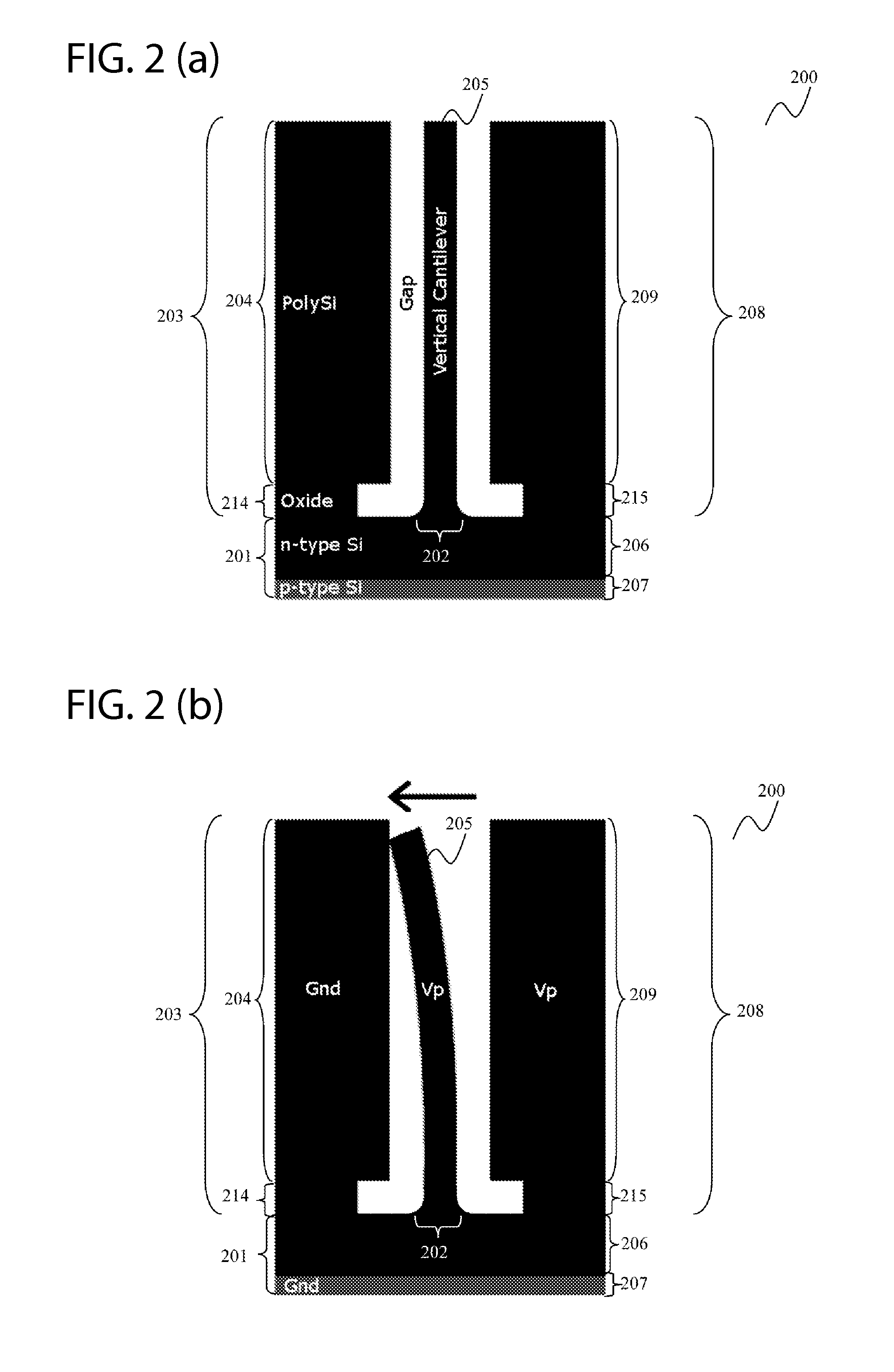

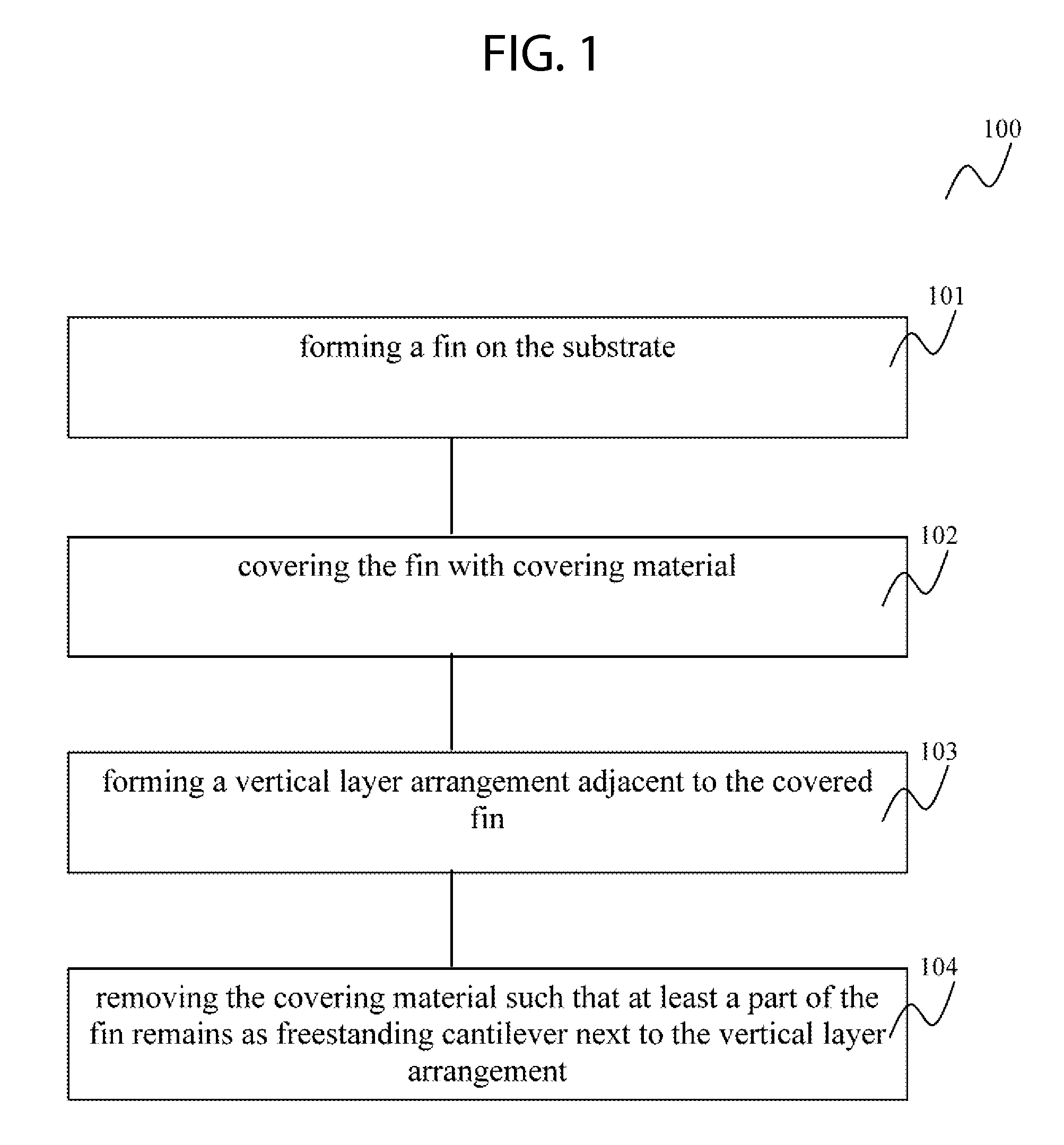

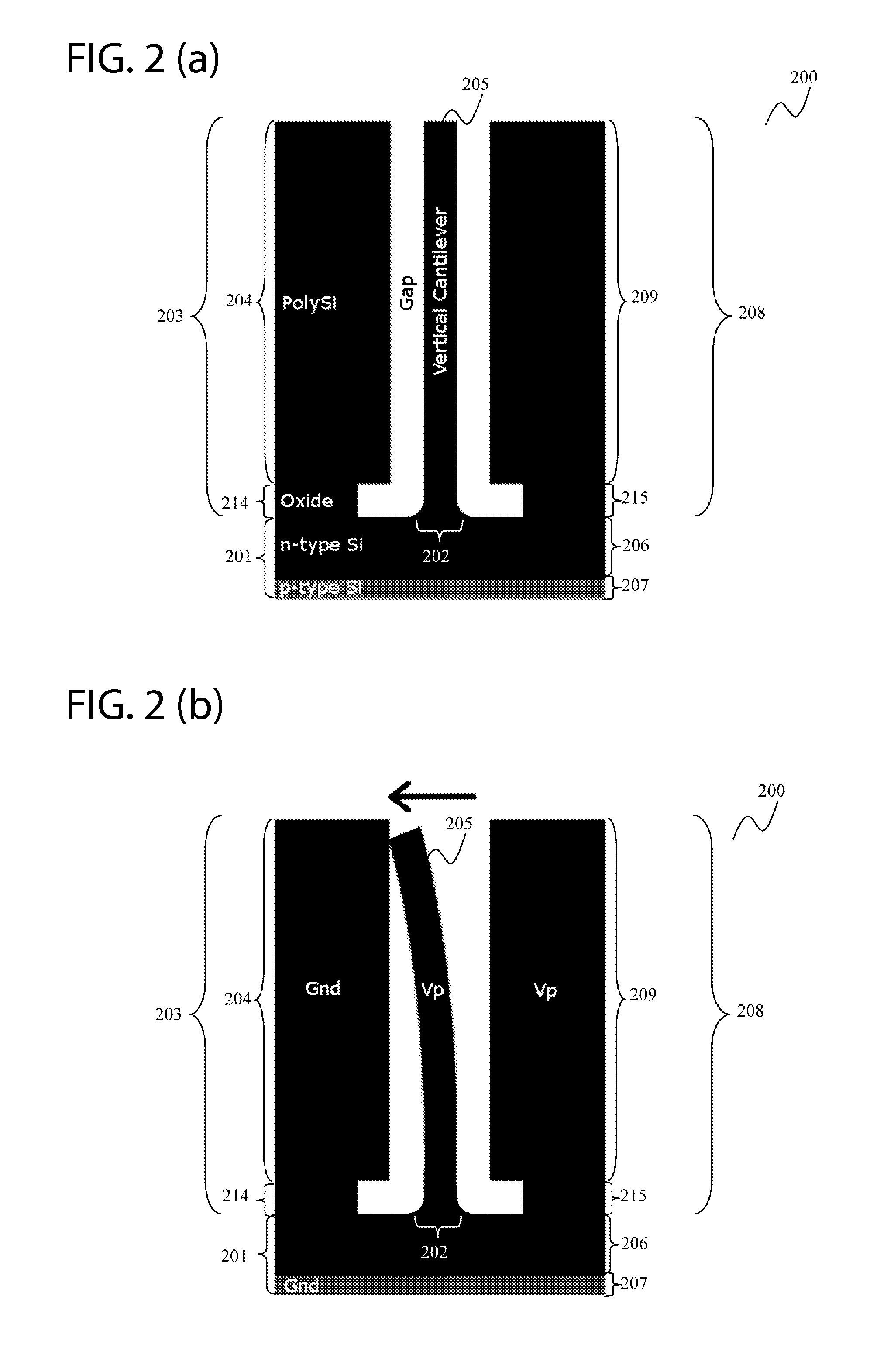

Switching device and a method for forming a switching device

InactiveUS20120138437A1Electrostatic/electro-adhesion relaysNanoelectromechanical switchesControl layerEngineering

Embodiments provide a switching device. The switching device includes a substrate, which includes a contact region. The switching device further includes a vertical layer arrangement extending from the substrate next to the contact region. The vertical layer arrangement includes a control layer. The switching device further includes a freestanding silicon cantilever extending vertically from the contact region.

Owner:AGENCY FOR SCI TECH & RES

Silicon micro-acceleration sensor chip

InactiveCN101738494AReduce volumeReduce weightAcceleration measurement using interia forcesCentral massElectric signal

The invention discloses a silicon micro-acceleration sensor chip, which comprises a central silicon mass block which is positioned in the center of a peripheral support silicon substrate; two silicon films are arranged at two ends of one side of the front of the peripheral support silicon substrate adjacent to the central silicon mass block; one surface of one silicon film and one surface of the other silicon film are connected with the peripheral support silicon substrate and the central silicon mass block, while the other surfaces are connected with a silicon cantilever; the middle of the silicon cantilever is provided with four piezoresistive strips so as to form a Wheatstone bridge; when acceleration is acted on the sensor chip, inertia force is acted on the central mass block to deform the cantilever-film structure, the resistance of the piezoresistive strips is changed under the stress action of the silicon cantilever, the Wheatstone bridge loses balance and outputs an electric signal corresponding to the external acceleration so as to measure the acceleration by the sensor chip. The silicon micro-acceleration sensor chip has the advantages of small volume, light weight, high frequency response and high sensitivity.

Owner:XI AN JIAOTONG UNIV

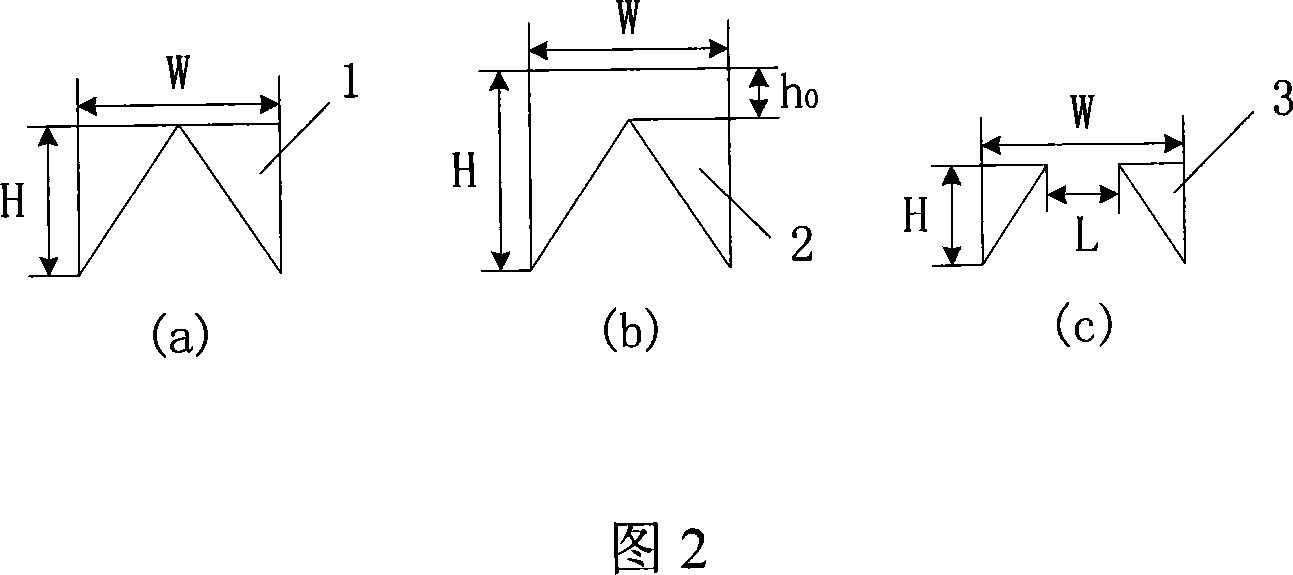

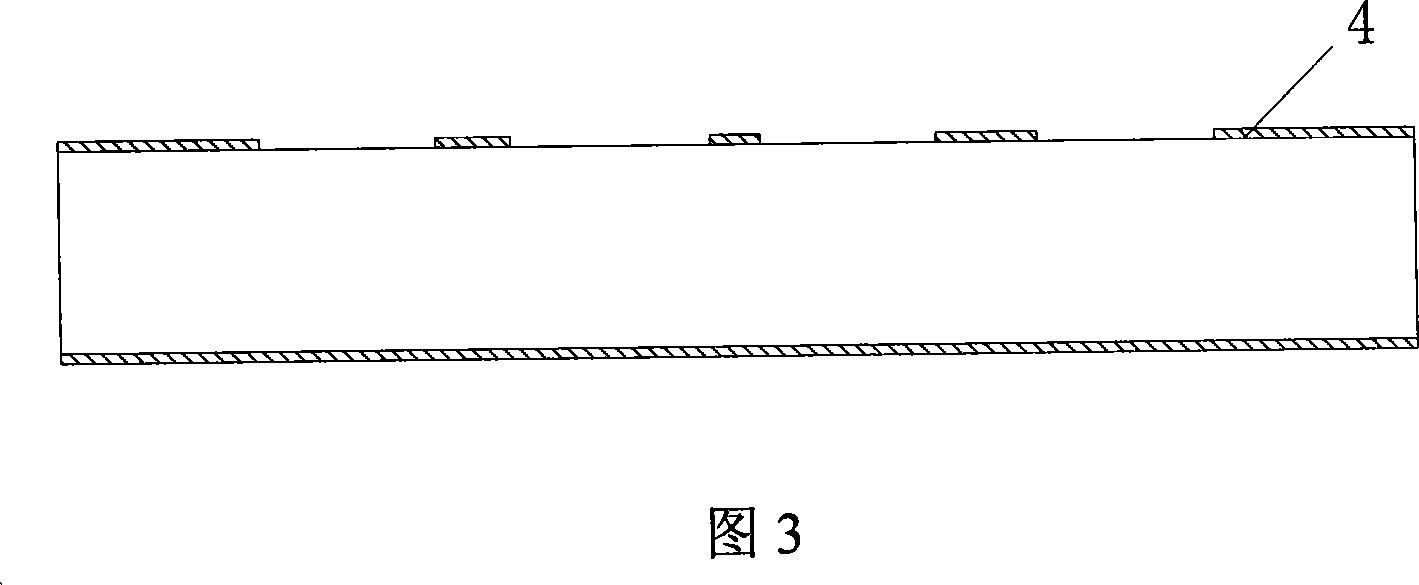

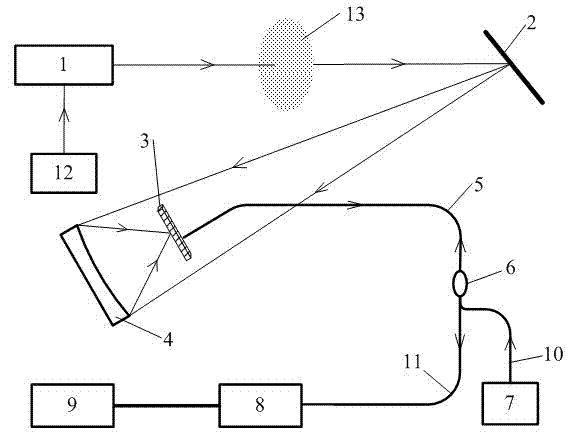

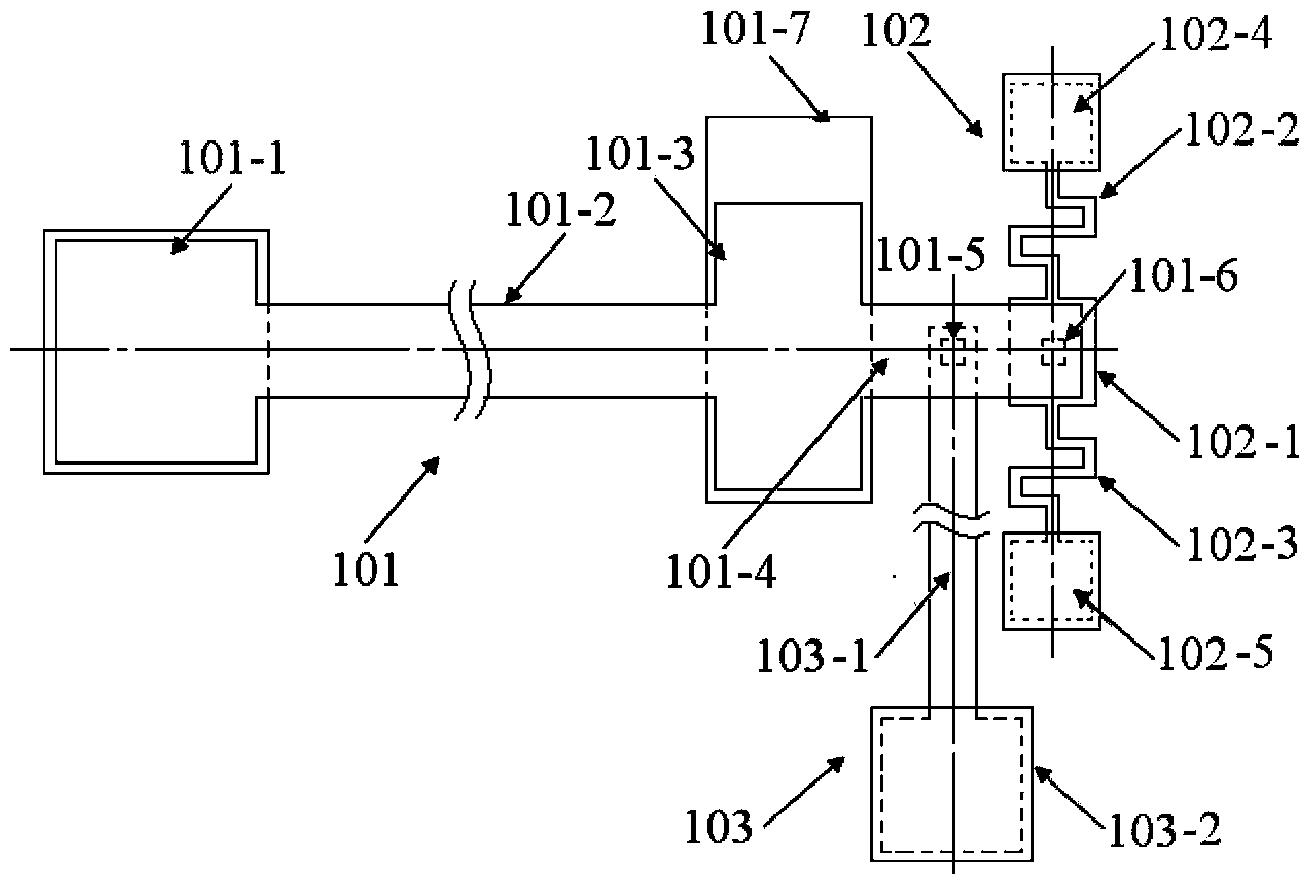

Surface microstructure silicon cantilever enhancement type optical-thermal spectrum trace gas detection method and device

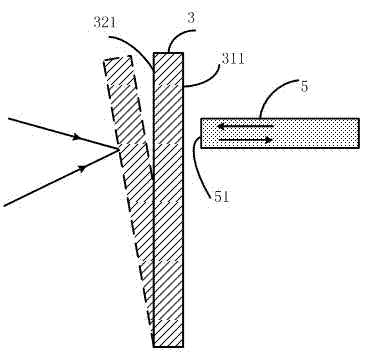

ActiveCN102590112AImprove absorption rateAchieving Broad Spectrum Detection RequirementsColor/spectral properties measurementsResonance amplitudeOptical fiber coupler

The invention relates to a surface microstructure silicon cantilever enhancement type optical-thermal spectrum trace gas detection method and device. The device comprises a tunable laser, a reflective object, a surface microstructure silicon cantilever, a concave mirror, an optical fiber, an optical fiber coupler, a continuous laser, a laser controller, an optical detector, a signal processing system and the like. Modulated light emitted from the tunable laser is reflected on the concave mirror by the reflective object after passing through the gas to be detected, the received reflective light on the concave mirror is focused on a silicon surface of the cantilever beam. After the optical energy is absorbed by the cantilever beam, the optical-thermal deflection occurs to generate resonance. If the gas concentration is higher, the optical intensity absorbed by the gas is larger, and if the optical energy absorbed by the cantilever beam is smaller and the resonance amplitude is smaller. A length adjustable Fabry-Perot cavity is formed by an optical fiber end surface and a metal surface of the cantilever beam, the amplitude of the cantilever beam is demodulated to obtain gas absorption spectrum, furthermore the concentration of the detected trace gas is obtained. The device has the advantages of cheap price, small size, simple structure, convenience in use, strong flexibility, high detection sensitivity, and field work capacity and can be widely used in remotely detecting the components and concentration of a variety of or multi-component trace gas.

Owner:CHONGQING UNIV

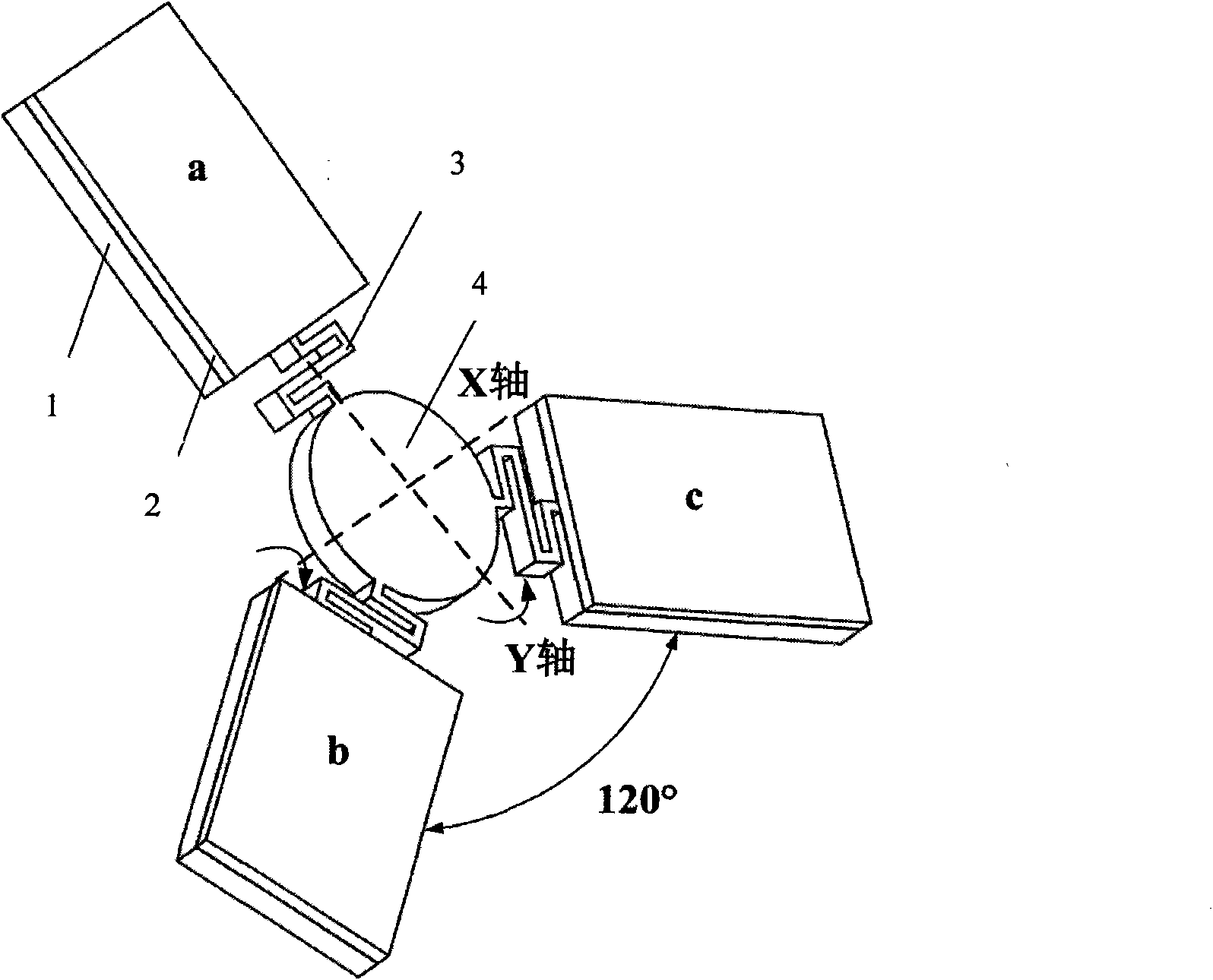

MEMS micro-lens driven by three piezoelectric cantilever beams and manufacturing method thereof

InactiveCN101937128ALow working voltageSmall sizeDecorative surface effectsChemical vapor deposition coatingSurface patternPiezoelectric mems

The invention relates to an MEMS micro-lens driven by three piezoelectric cantilever beams and a manufacturing method thereof and belongs to the technical field of piezoelectric MEMS appliance designs and integrated manufacturing. The MEMS micro-lens comprises a micro-reflecting mirror surface, the piezoelectric cantilever beams and arched bent elastic narrow beams, wherein each of the piezoelectric cantilever beams is formed by fixing a PZT driving membrane with more than 2 mu m thickness on the surface of a silicon cantilever beam; the three piezoelectric cantilever beams are connected with the micro-lens micro-reflecting mirror surface through three arched bent elastic narrow beams respectively; and the piezoelectric cantilever beams are distributed in a way that an included angle of 120 degrees is formed between every two piezoelectric cantilever beams. The manufacturing method comprises the following steps of: firstly, preparing a piezoelectric thick membrane on a substrate and etching piezoelectric cantilever beam patterns on the piezoelectric thick membrane; secondly, preparing a Au / Cr two-layer metal top electrode and a micro micro-reflecting mirror surface pattern on the PZT piezoelectric thick membrane; and finally, etching a Si substrate on the front and back faces so as to form the MEMS micro-lens driven by the three piezoelectric cantilever beams. The MEMS micro-lens has the advantages of many deflecting directions, strong driving force of the PZT thick membrane and low optical loss. The manufacturing process is compatible with the MEMS process, so that the MEMS micro-lens has the potential of mass production and can be widely applied in the field of optical communication.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

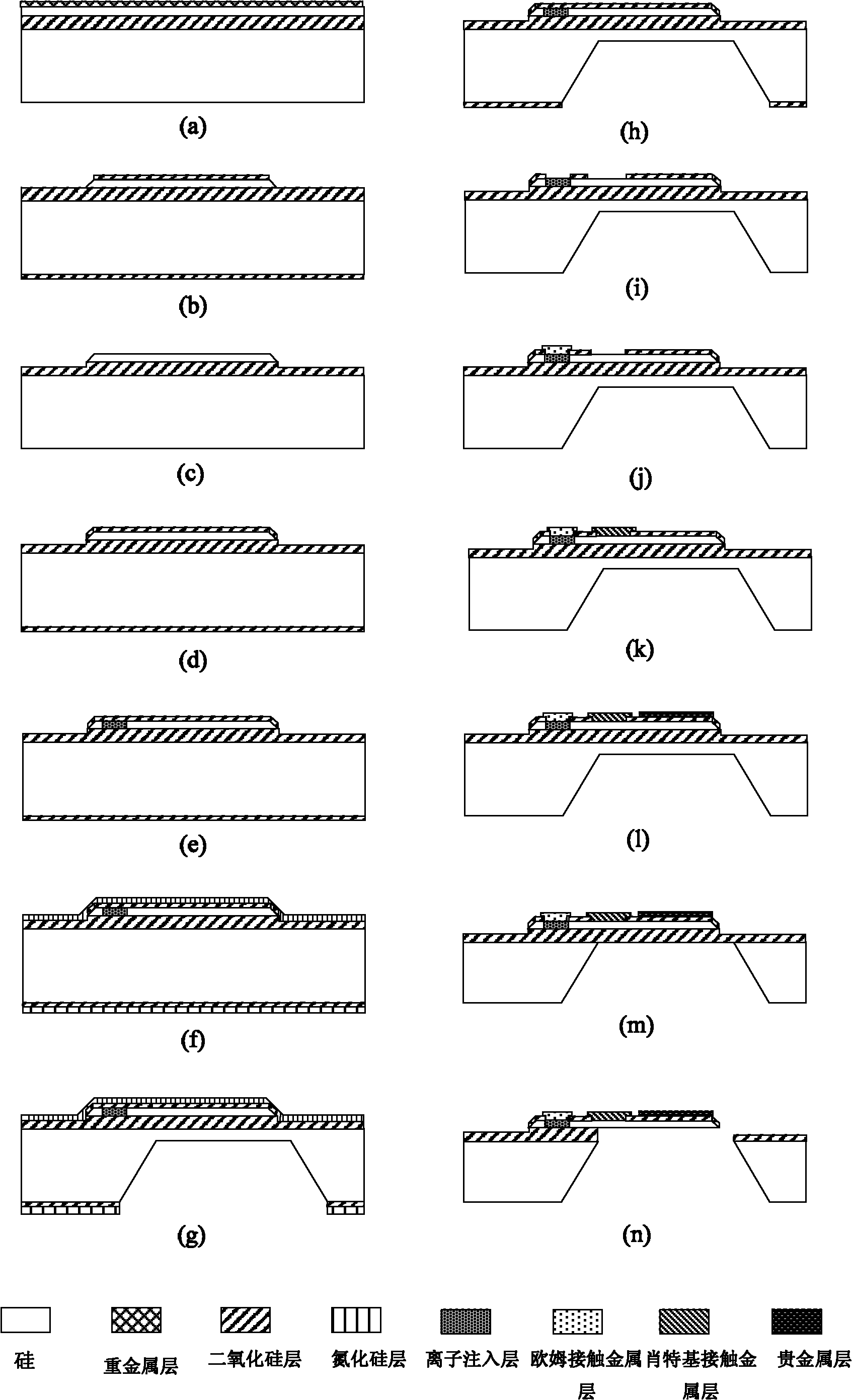

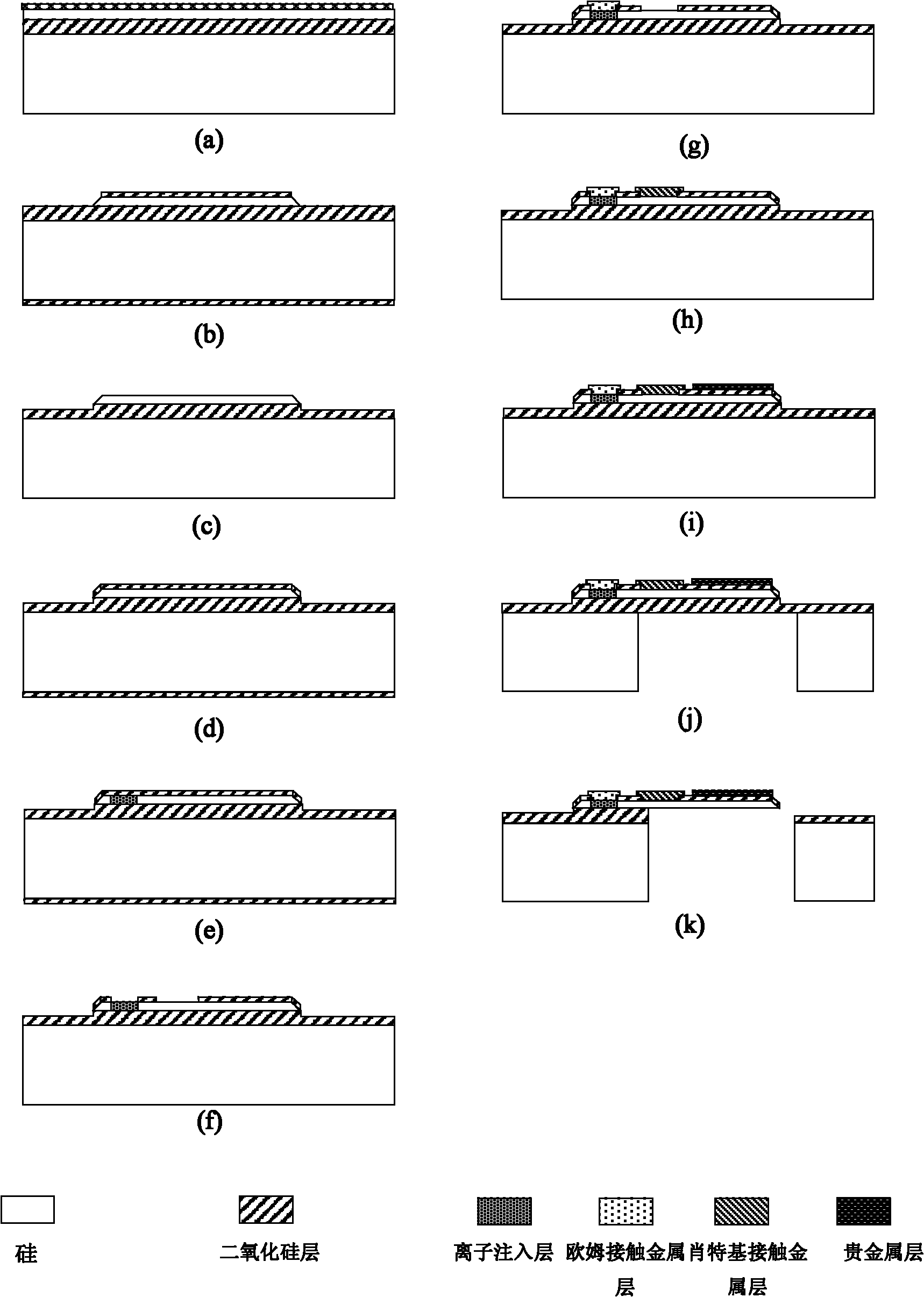

Micro gas sensor recoverable for repeated preparation and preparation method thereof

InactiveCN103472097AImprove performanceImprove electricity-heating efficiencyMaterial resistanceCMOSOhmic contact

The invention discloses a micro gas sensor recoverable for repeated preparation and a preparation method thereof, and belongs to micro gas sensors and preparation methods thereof. The silicon heater of the micro gas sensor is provided with a heat dissipation-support silicon block at the center; one ends of silicon cantilevers are connected with the silicon heater, and the other ends of the silicon cantilevers are connected with fixing ends of a silicon bearer; the fixing ends are arranged on silicon oxide buried layer of the silicon bearer; the silicon layer of each fixing end is provided with a doped silicon layer; a metal layer contacts the doped silicon layer of each fixing end via the window of the silicon oxide layer for formation of ohmic contact; the silicon heater is completely embedded in a catalyst carrier, and the catalyst carrier penetrates the center of the silicon heater and forms an own integrated structure. The MEMS processing technology is employed for the low-energy-consumption gas sensor for detecting gas concentration in coal mines, the preparation technology is compatible with the CMOS technology, and batch production can be realized; the catalyst carrier and the catalyst can be prepared repeatedly after the gas sensor is recovered; and the micro gas sensor is long in service life, stable in performance, small in volume and low in cost.

Owner:CHINA UNIV OF MINING & TECH

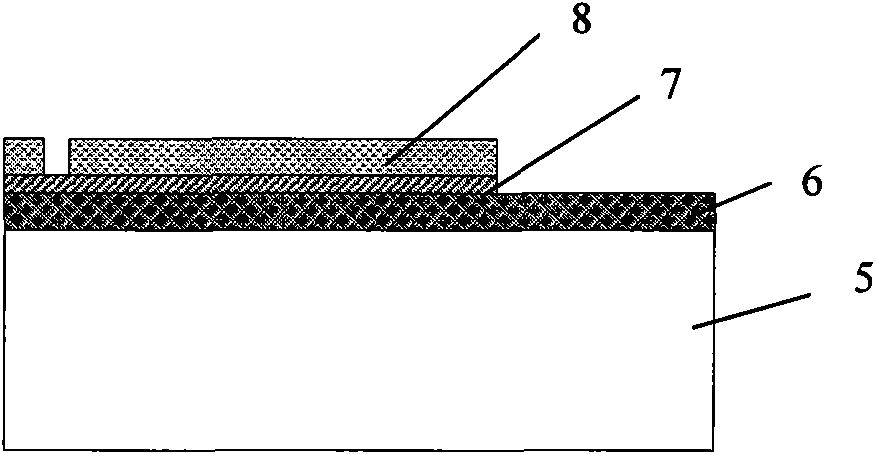

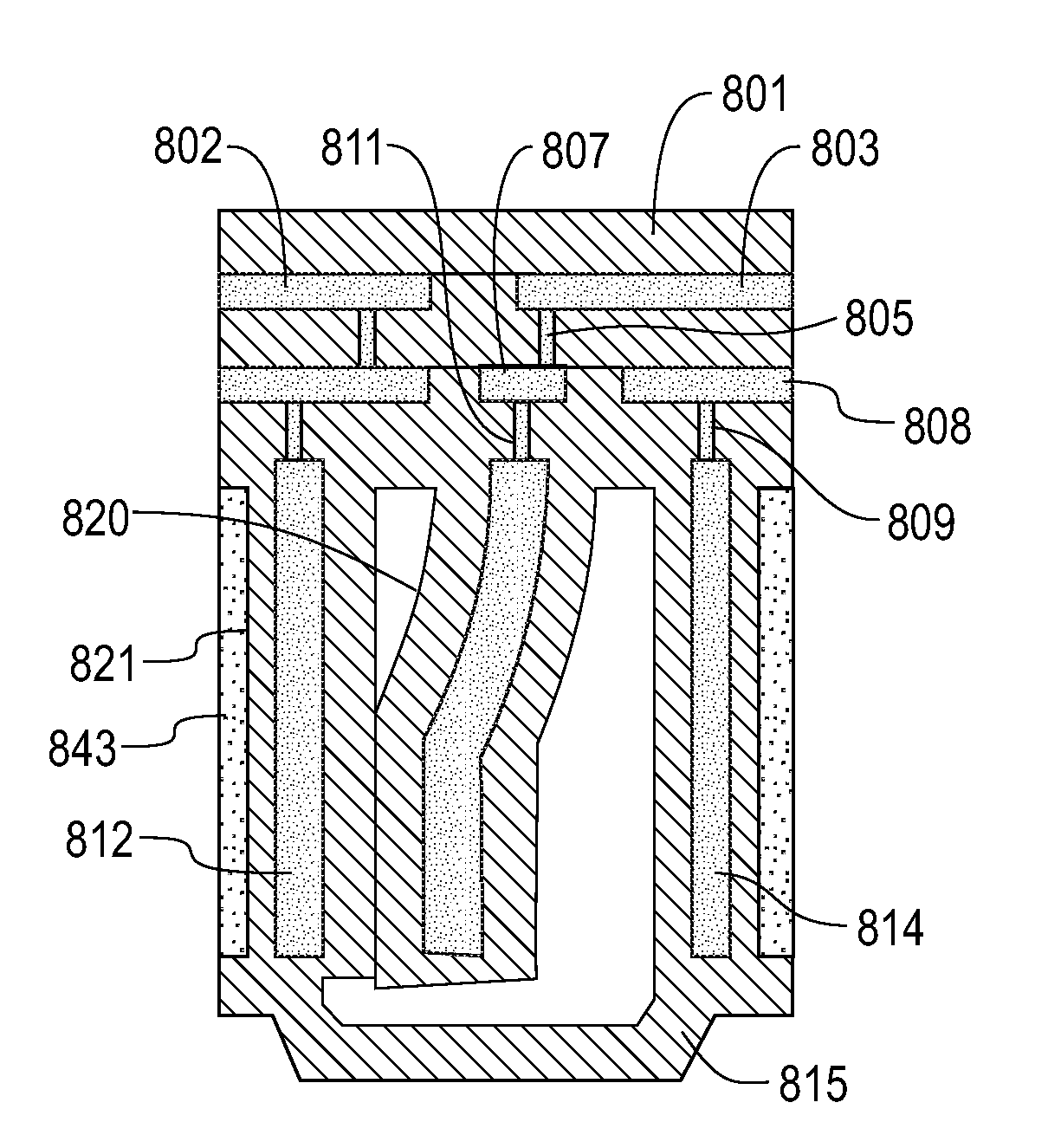

Piezoelectric-triboelectric combined MEMS wideband-energy harvester and preparation method thereof

InactiveCN105186922ABoost and improve output performanceSolve long-term energy supply problemsPrecision positioning equipmentPiezoelectric/electrostriction/magnetostriction machinesElectricityEnergy harvester

The invention discloses a piezoelectric-triboelectric combined MEMS wideband-energy harvester and a preparation method thereof. The harvester comprises a main structure of a piezoelectric energy harvester, a stop block and a gasket, wherein the main structure of the piezoelectric energy harvester comprises a fixed silicon base, silicon-based piezoelectric cantilever beams and masses; the fixed silicon base comprises a silicon layer and silicon dioxide layers at two sides of the silicon layer; the silicon-based piezoelectric cantilever beam comprises a silicon cantilever beam supporting layer and a piezoelectric thick film layer arranged on the silicon cantilever beam supporting layer; the silicon cantilever beam supporting layer comprises a silicon layer, silicon dioxide layers and a supporting layer electrode layer; the piezoelectric thick film layer comprises a piezoelectric thick film and a piezoelectric thick film electrode layer arranged on the surface of the piezoelectric thick film; each mass comprises an integrated silicon mass and a frictional layer arranged on the surface of the integrated silicon mass; the stop block comprises a frictional layer base, an electrode layer and a frictional layer; and the gasket is located between the fixed silicon base and the stop block. By using the piezoelectric-triboelectric combined MEMS wideband-energy harvester, a transduction element can obtain relatively high output power in a low-frequency vibration environment, so that the problems of low output power, narrow frequency band and the like of the traditional MEMS piezoelectric energy harvester are solved.

Owner:NANCHANG INST OF TECH

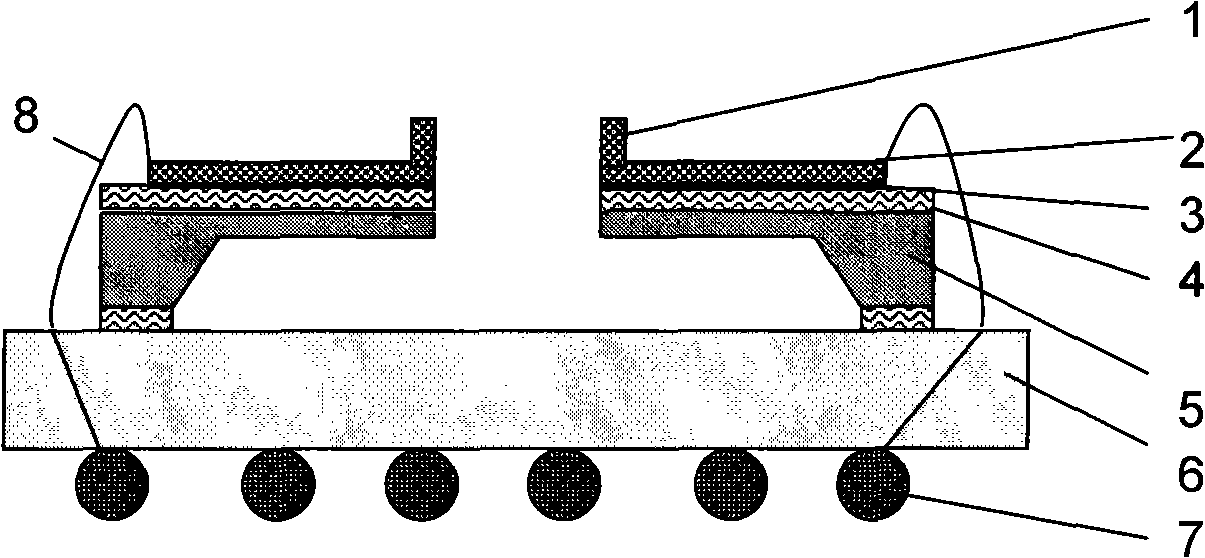

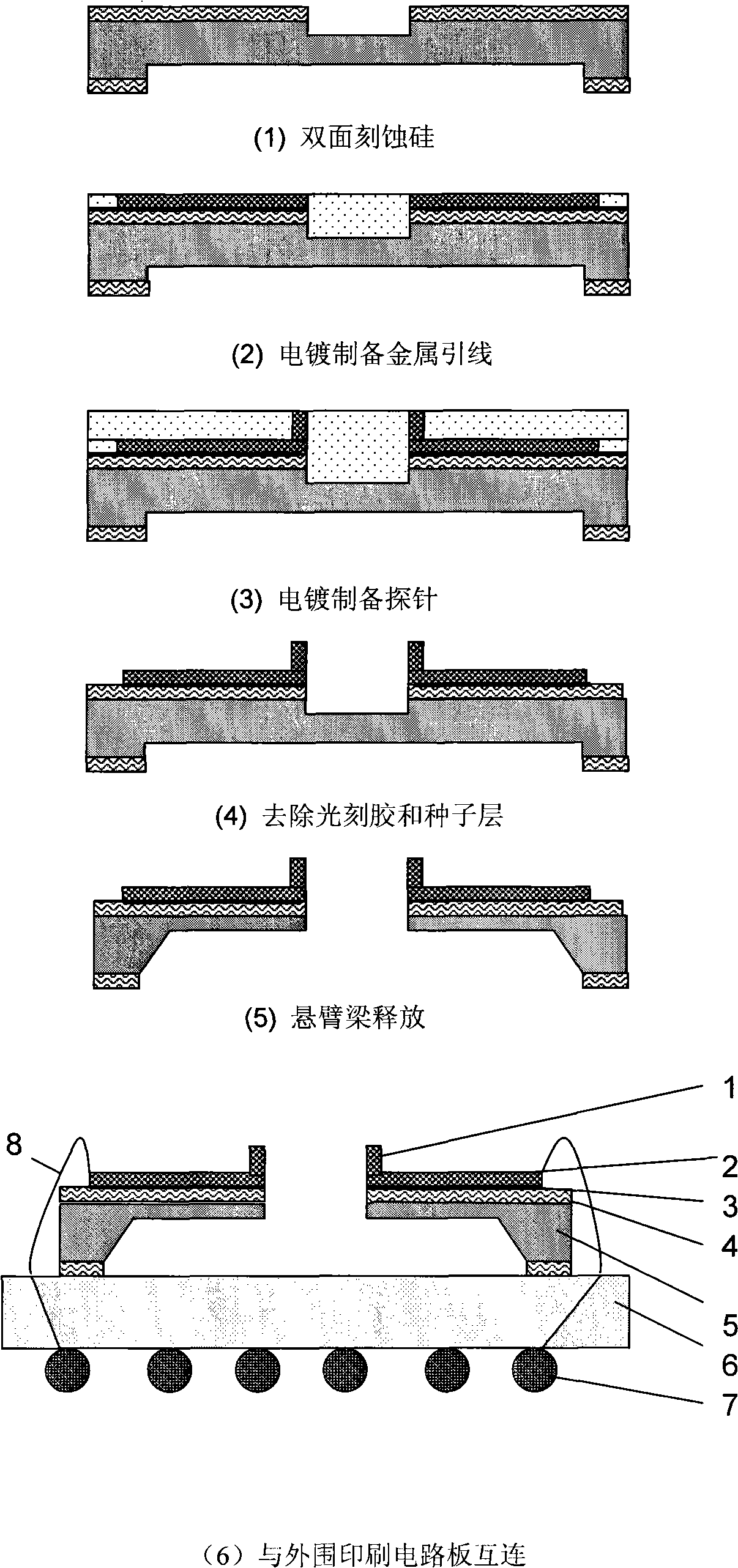

Metal-silicon compound cantilever beam type microelectronic mechanical system probe card and manufacture method thereof

InactiveCN101354404AImprove electrical performanceImprove mechanical propertiesTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamProbe card

The invention relates to a metal-silicon composite cantilever beam typed micron-electronic mechanical system probing card and a preparation method thereof; an ultraviolet thick film photolithography and bulk silicon micro-processing composite process is adopted to prepare a metal-silicon composite cantilever beam probing card structure, thus replacing an existing probing card structure consisting of single silicon or metal. The ultraviolet thick film photolithography process is used for preparing the metal probe with high depth / width ratio and metal circuit transmission wires below the probes, and the bulk silicon micro-processing composite process is used to prepare the silicon cantilever beam structure. The force during the testing process is commonly borne by the silicon cantilever beam and the metal circuit above the silicon cantilever beam; the electric and mechanical property of the probing card structure is controlled by adjusting the geometrical parameters of the metal circuit leads and the silicon cantilever beam; the probes above the probing card can be arranged by the positions of the pins of the chip to be tested; the probe tips are corresponding to the position of the pins of the chip one by one. The end of the metal circuit transmission wire leads the circuit to be connected on the back surface by a through hole electro-plating or wire punching type on a silicon substrate and leads the circuits to be connected onto printing circuit boards and test machine platforms further.

Owner:SHANGHAI JIAO TONG UNIV

Acceleration switch sensor with adjustable threshold value of silicon base band locking function and manufacturing method thereof

ActiveCN101303366ASmall input/output isolationGood input/output isolationAcceleration measurementEngineeringLow resistance

The invention relates to silicon-based adjustable threshold acceleration switch sensor with lock-up function and a manufacturing method thereof. The switch sensor is characterized by consisting of an anchorage zone and a silicon frame which are arranged at an insulation substrate, a low resistance silicon cantilever with a singe end fixed in the anchorage zone, a metal electrostatic drive conductive fixed polar plate at the insulation substrate, an insulation medium layer on the lower surface of the cantilever, a metal contact electrode on the medium layer, a fixed metal contact electrode and a signal drive / detection loop. The drive voltage and threshold acceleration of the sensor provided have certain relationship and the sensor provided has the lock-up function. The signal output mode of the working state of the sensor is detected by the on-and-off of a metal bridge circuit, which ensures that the acceleration switch sensor produced by utilizing MEMS has the advantages of simple structure, small volume, low energy consumption, low on-resistance, convenient interface circuit and good input and output insulation performance, etc.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Double-faced parallel symmetric silicon beam mass block structure and method for preparing same

ActiveCN102642801AImprove manufacturing yieldImprove impact performanceDecorative surface effectsChemical vapor deposition coatingCross sensitivityCapacitance

The invention provides a double-faced parallel symmetric silicon beam mass block structure and a method for preparing the same, which belong to the field of micro-electronic machinery. The method includes forming a double-faced parallel symmetric beam mass block graphic area on a double-polished silicon wafer (100) by the aid of a double-faced front and back aligned photolithographic process; then performing dry etching and wet anisotropic etching; using surfaces (111) of a cantilever beam as corrosion termination surfaces to automatically stop corrosion to the silicon cantilever beam; and finally forming the double-faced parallel symmetric beam mass block structure. The method for preparing the double-faced parallel symmetric silicon beam mass block is simple in process, the dimensions of the double-faced parallel symmetric beam mass block structure can be accurately controlled, and the manufacturing yield of beam mass block structures is greatly increased. In addition, a prepared device is high in normal symmetry, lateral impact resistance and torsional impact resistance of the device are improved, cross sensitivity is reduced, and the double-faced parallel symmetric silicon beam mass block structure and the method can be applied to structures of various MEMS (micro-electromechanical system) devices such as capacitance type acceleration transducers, resistance type acceleration transducers, micromechanical gyroscopes and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

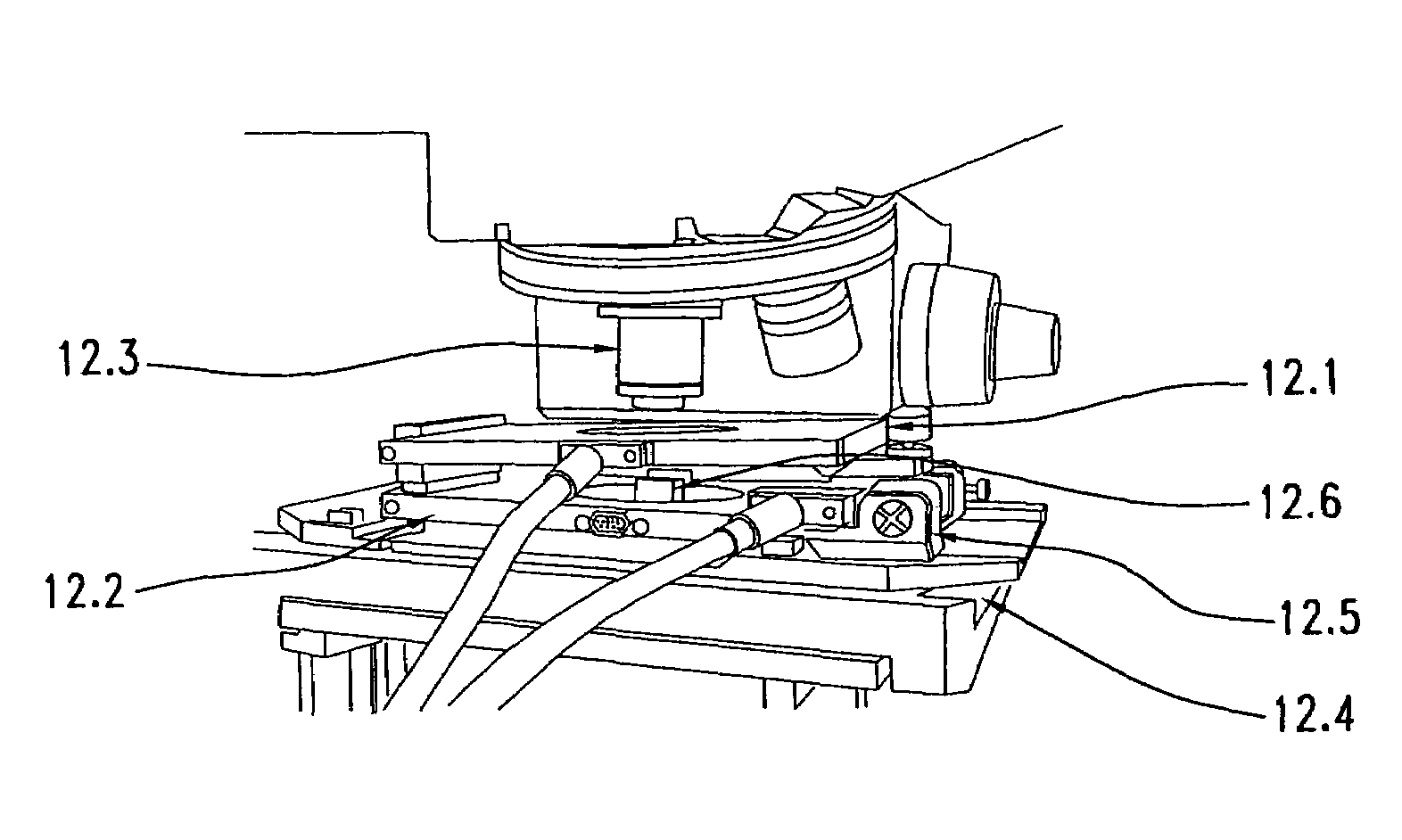

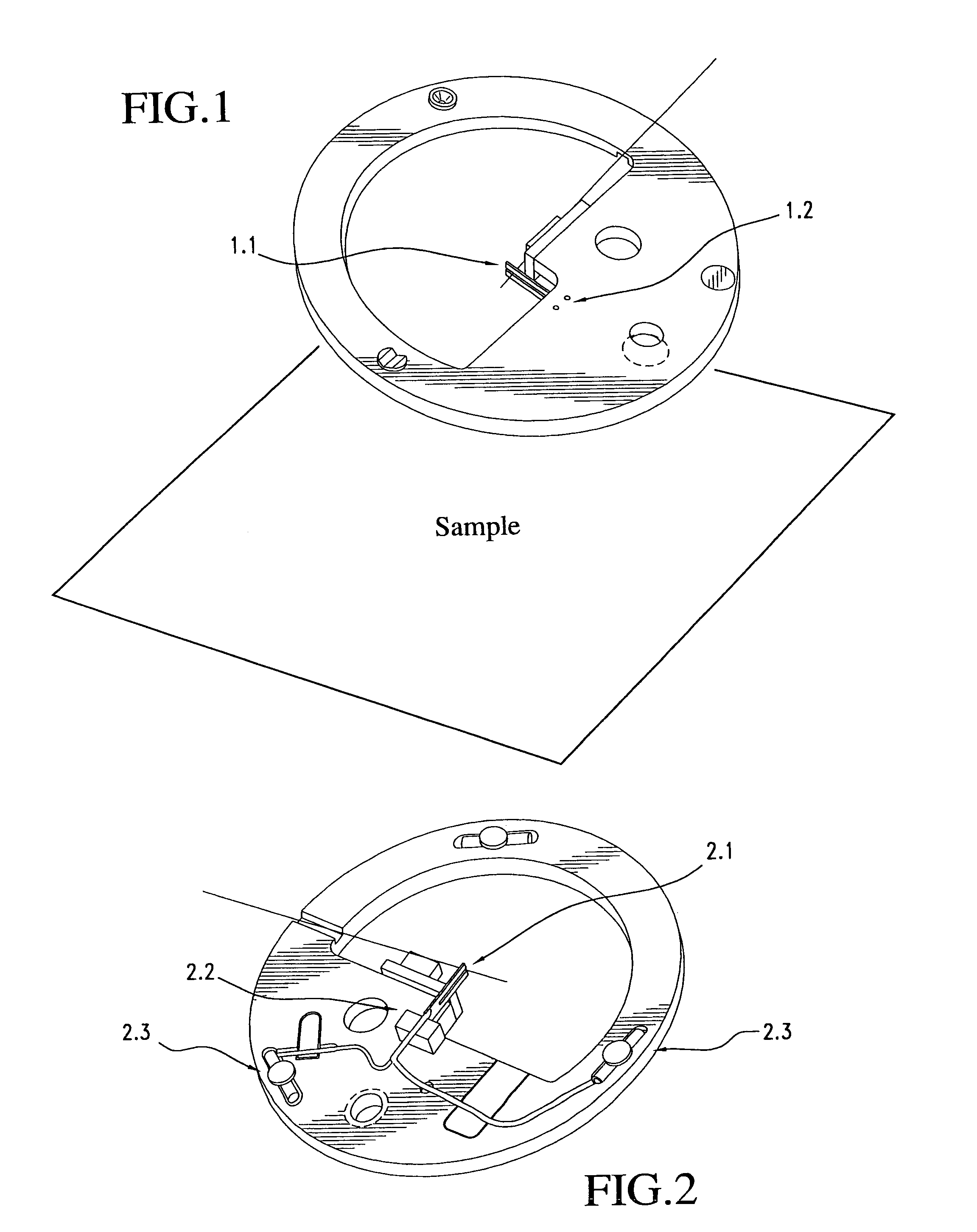

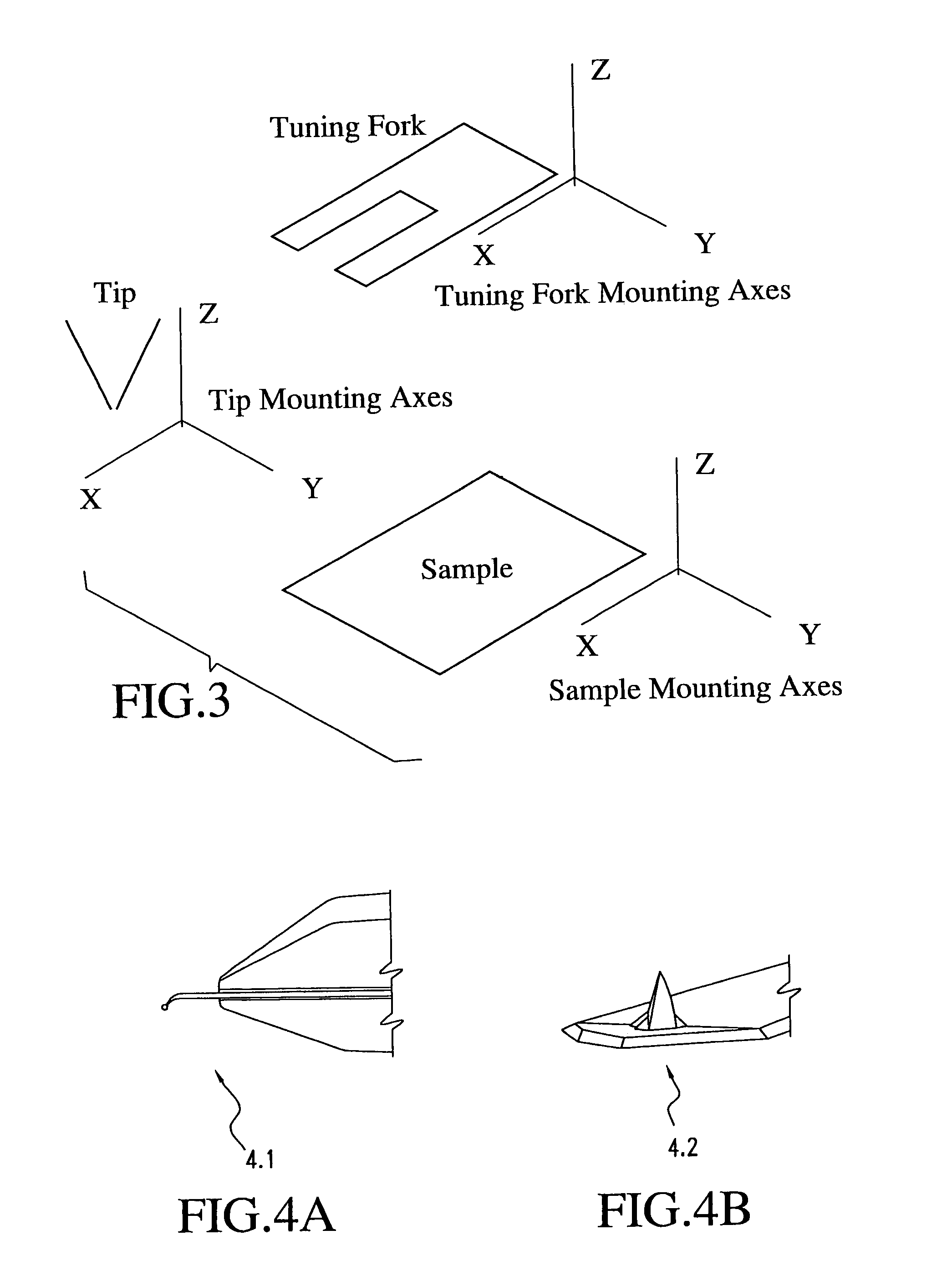

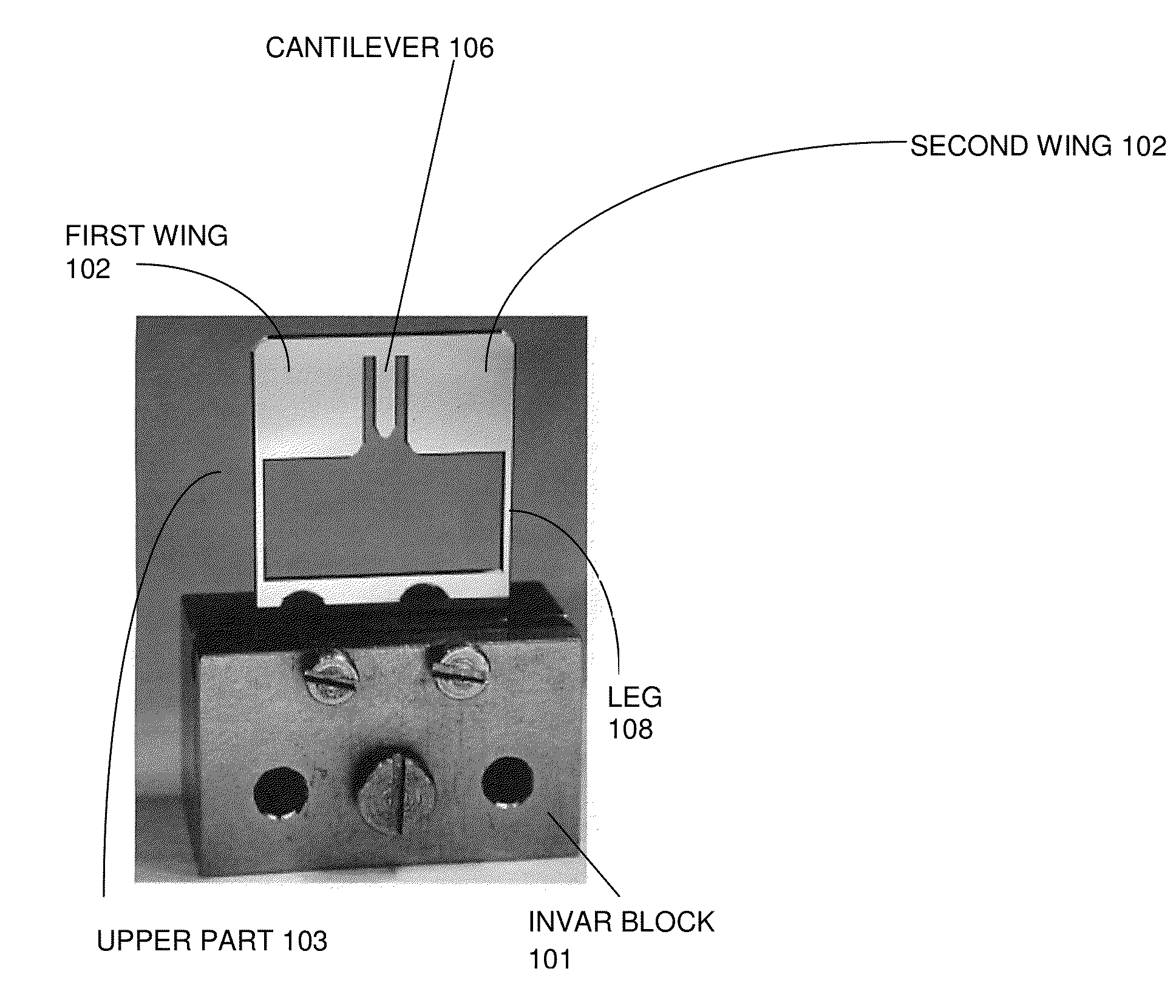

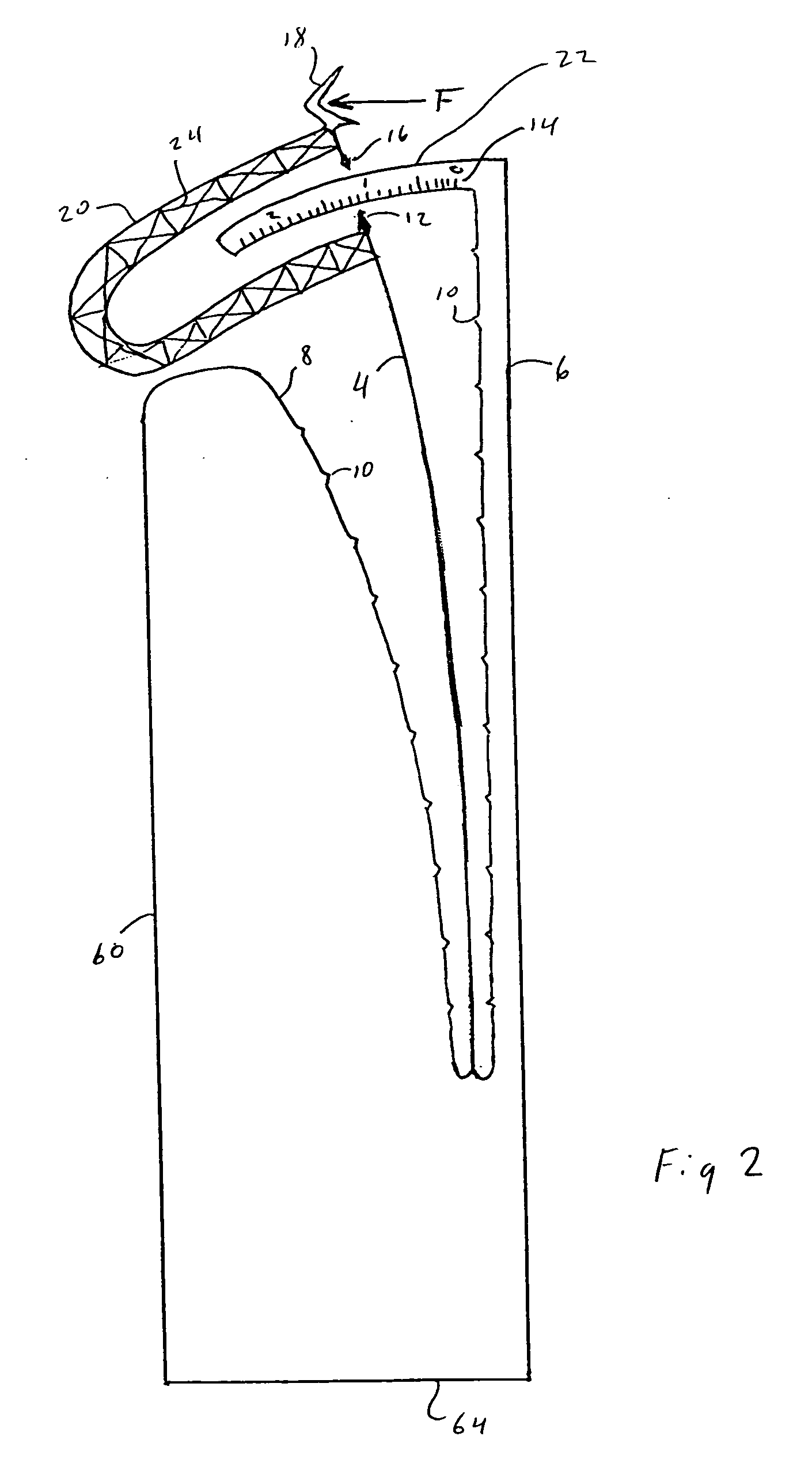

Multiple plate tip or sample scanning reconfigurable scanned probe microscope with transparent interfacing of far-field optical microscopes

InactiveUS7047796B2Simple designReduce the total massMaterial analysis using wave/particle radiationSurface/boundary effectFiberLiquid cell

The invention is directed to a scanned probe microscope including one plate allowing for tip scanning and the other allowing for sample scanning, with the optical axis of the scanned probe microscope being free to permit incorporation into standard optical microscopes. The top plate can be hinged onto the bottom plate, or the top plate can simply be placed on the bottom plate and a rough approach is caused by a dc motor or other mechanism which will enable the two flat plate scanners to have a large z range. In another embodiment, the microscope includes three plates which allow sample scanning, tip scanning and two tips to be operational at the same time.A microscope in accordance with the invention may use a liquid cell, may use a near-field optical element made of silicon cantilever technology, or may use an apertureless probe for apertureless near-field scanning optical microscopy.The microscope may use a tuning fork for feedback in any combination of geometries of tip, sample and tuning fork and with or without gluing of the tip to the tuning fork and with control of tip attachment or near-attachment to the tuning fork. The control of tip attachment to the tuning fork may be based on near zero backlash movement technology, and the tuning fork can be used in non-contact, contact and intermittent contact modes of operation. A fiber based feedback system may use either straight or cantilevered fibers, and the detection of signals may be based on amplitude, phase, wavelength or other optical parameters that can be used to monitor the movement of an SPM sensor.

Owner:NANONICS IMAGING LTD

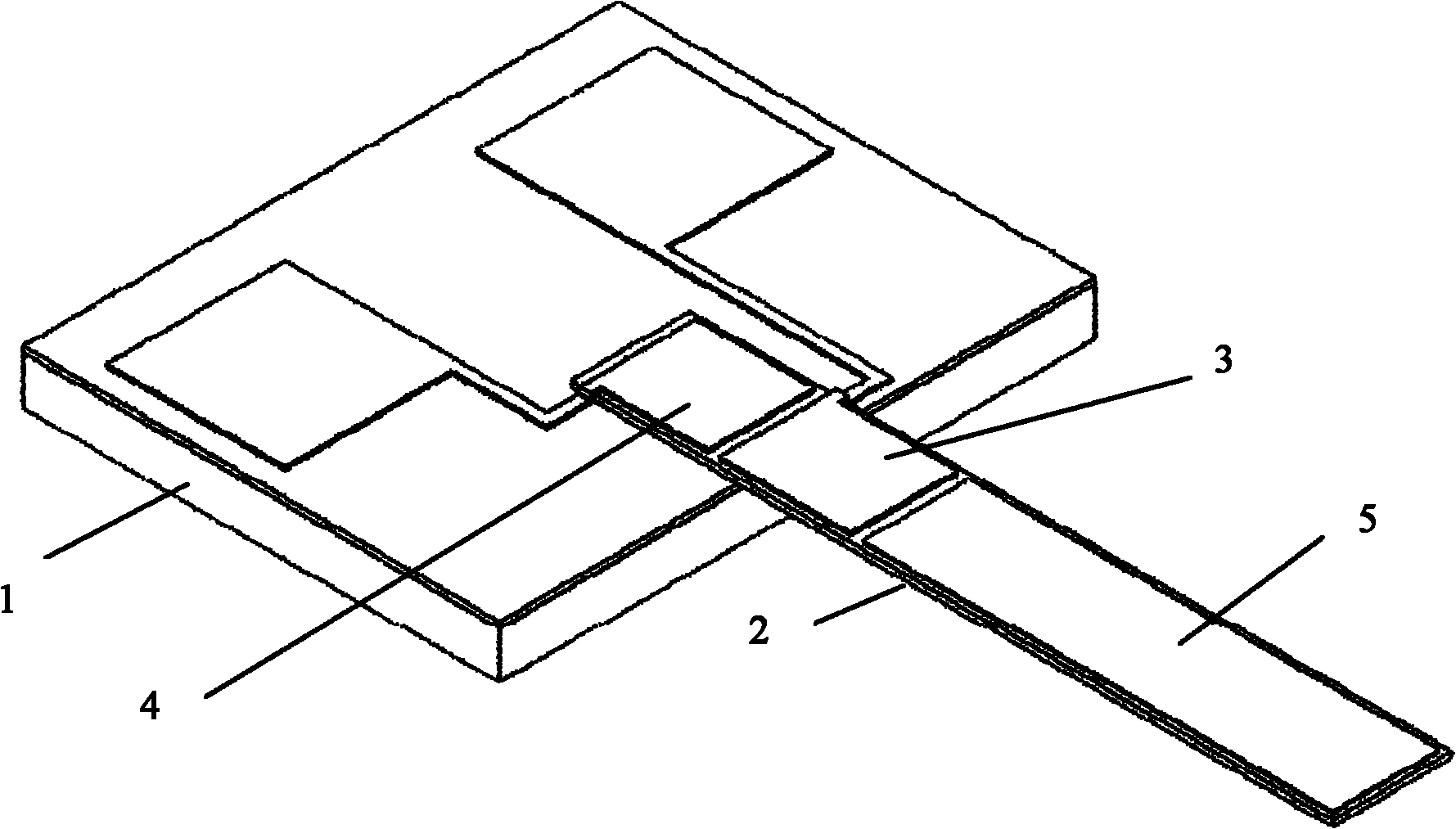

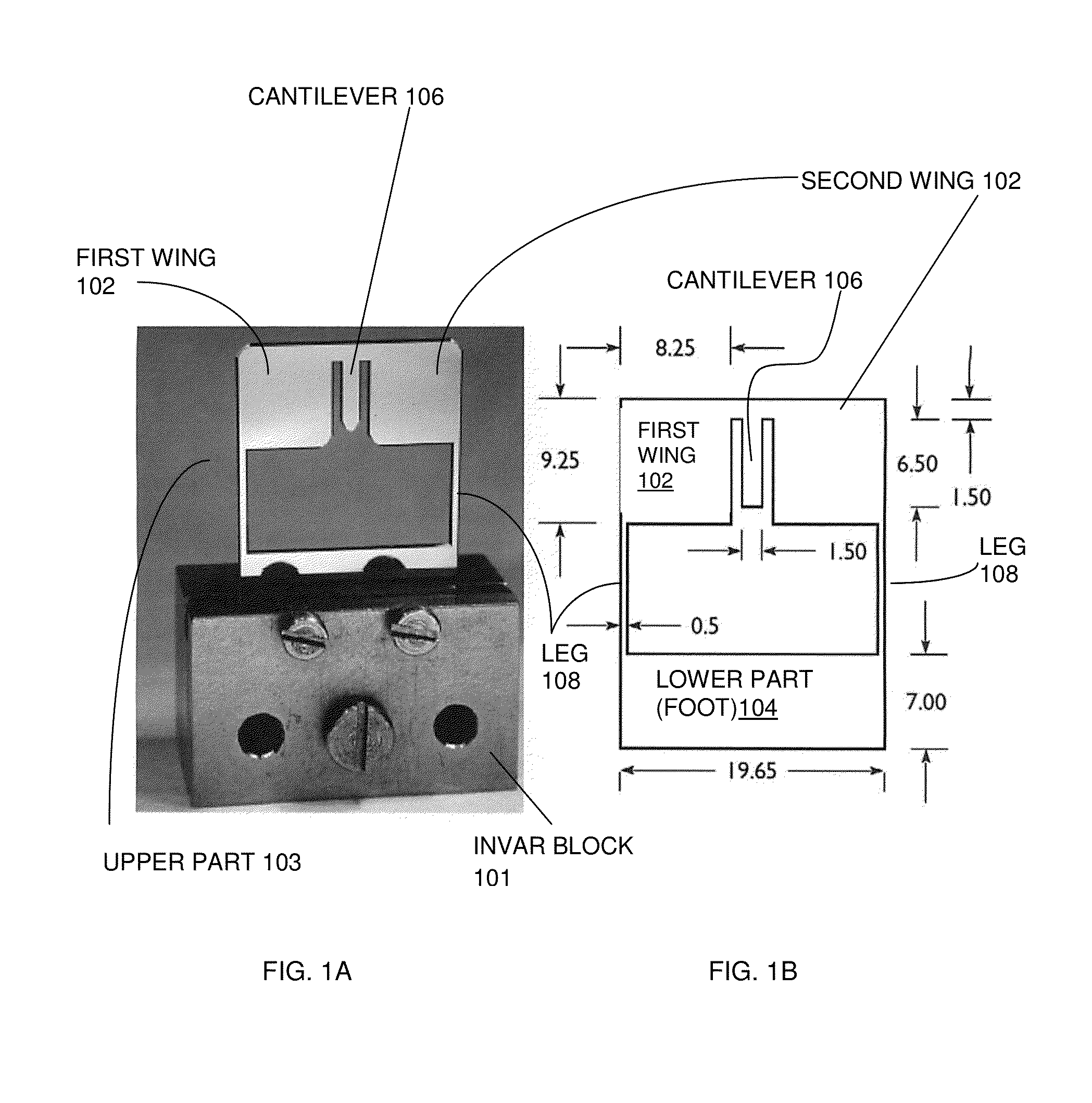

Cantilever trace detection sensor and preparation method thereof

ActiveCN102079499AHigh sensitivityEasy to controlDecorative surface effectsChemical vapor deposition coatingGamma ray irradiationMaterials science

The invention discloses a cantilever trace detection sensor and a preparation method thereof. A metal-silicon Schottky diode subjected to heavy metal diffusion or gamma ray irradiation treatment is embedded into the surface of an appropriate position of a silicon cantilever and is used for converting mechanical signal into electrical signals. A thin precious metal layer is deposited on one surface of the cantilever, and a monomolecular sensitive layer with specific absorptive capacity grows on the metal layer by a self-assembly method. The surface stress difference is produced on upper and lower surfaces of the cantilever when a detected chemical substance is combined with molecules of the sensitive layer to cause the cantilever to be bent, so that the concentrated bending stress is produced at the root of the cantilever; and the stress is detected by the Schottky diode embedded into the surface of the cantilever. The sensor has the advantages of simple structure, simple and convenient manufacturing, high sensitivity and high resolution, can be applied to force sensors, scanning probes and the like, and has important application in the fields such as environmental detection, food safety, military aerospace and the like.

Owner:PEKING UNIV

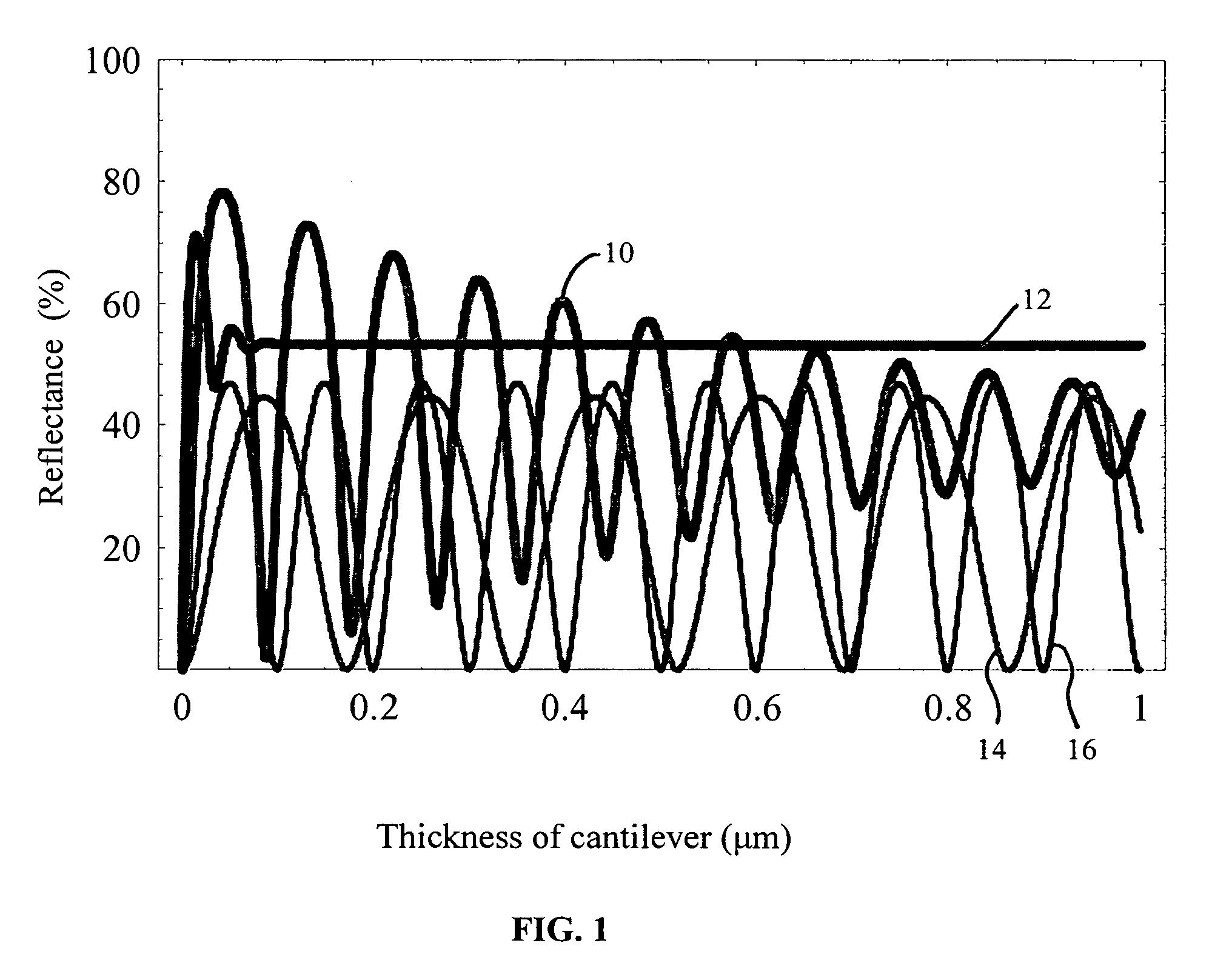

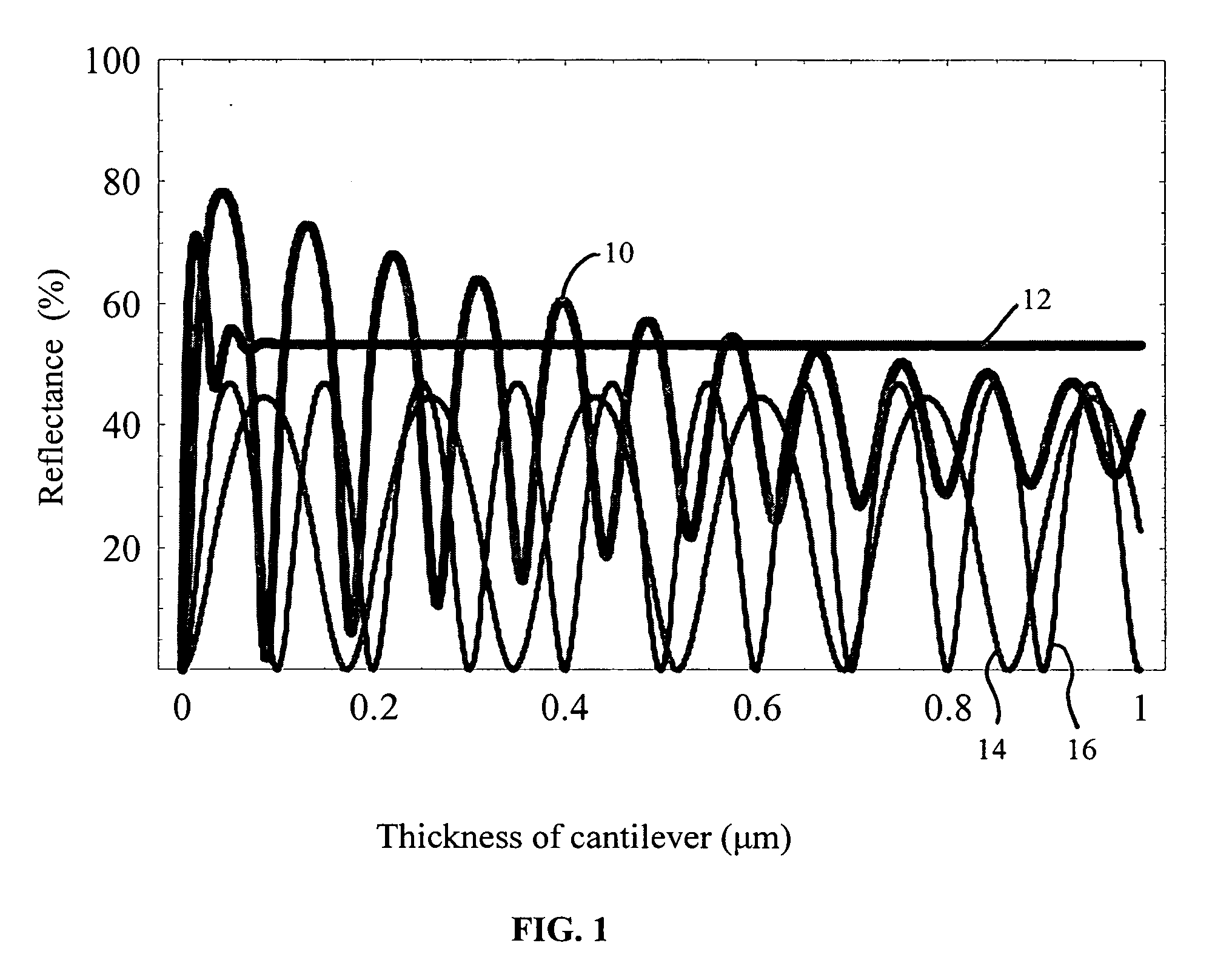

Method and system of an ultra high q silicon cantilever resonator for thin film internal friction and young's modulus measurements

ActiveUS20140002203A1High quality factorImprove vibrationAnalysing solids using sonic/ultrasonic/infrasonic wavesSemiconductor/solid-state device testing/measurementResonanceYoung's modulus

This invention provides an extremely accurate way to characterize the Young's modulus of thin film materials with thicknesses in the nanometer range. It takes advantage of a recently developed high Q silicon Young's modulus resonator (YMR), which has a record high quality factor of about fifty million in operation at temperatures below 10 degrees Kelvin (10K). Because of the high Q of the YMR, the temperature stability of the YMR's resonance frequency below 1K, and the extremely high degree of vibration isolation inherent in the inventive design, the relative resolution of the resonant frequency is typically in 2×10−7. This is enough to resolve a resonant frequency shift after a deposition of a thin film onto the sensitive part of the resonator, and to compute the Young's modulus of thin film materials of even a few monolayers thickness.

Owner:US GOVT SEC OF THE NAVY CHIEF OF NAVAL RES OFFICE OF COUNSEL ONR NRL

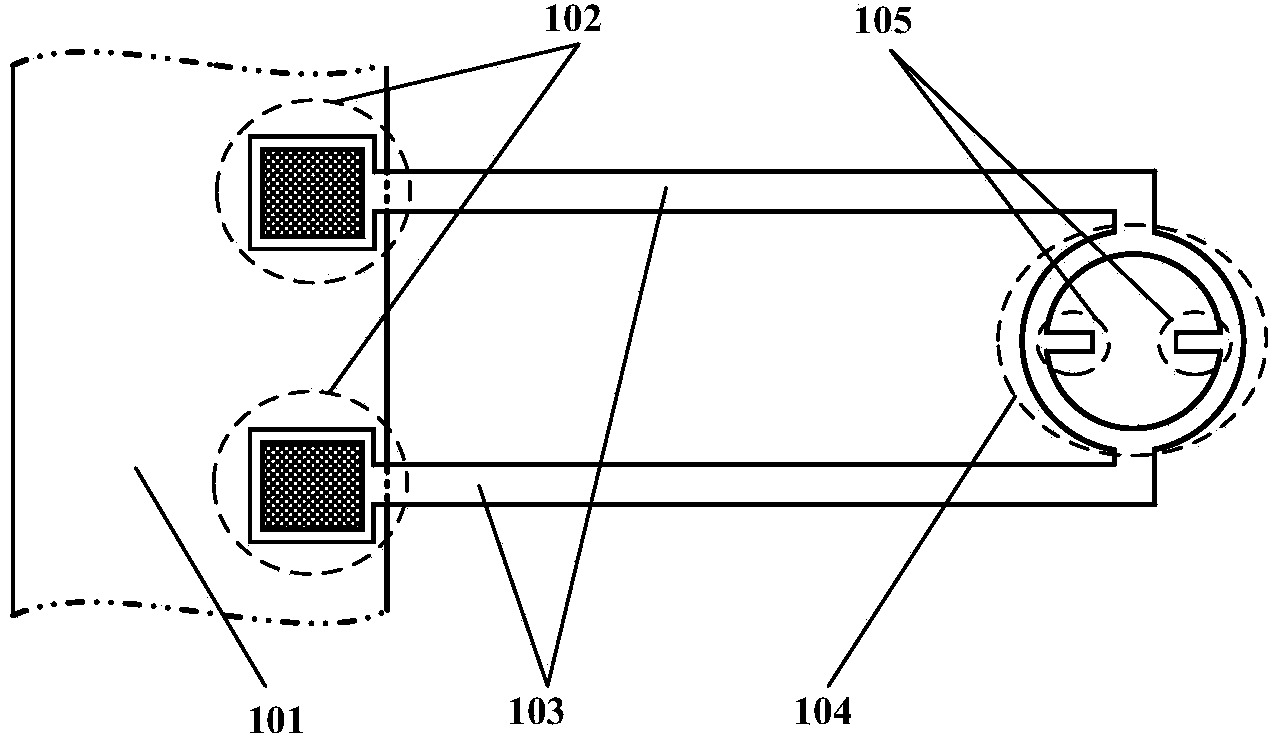

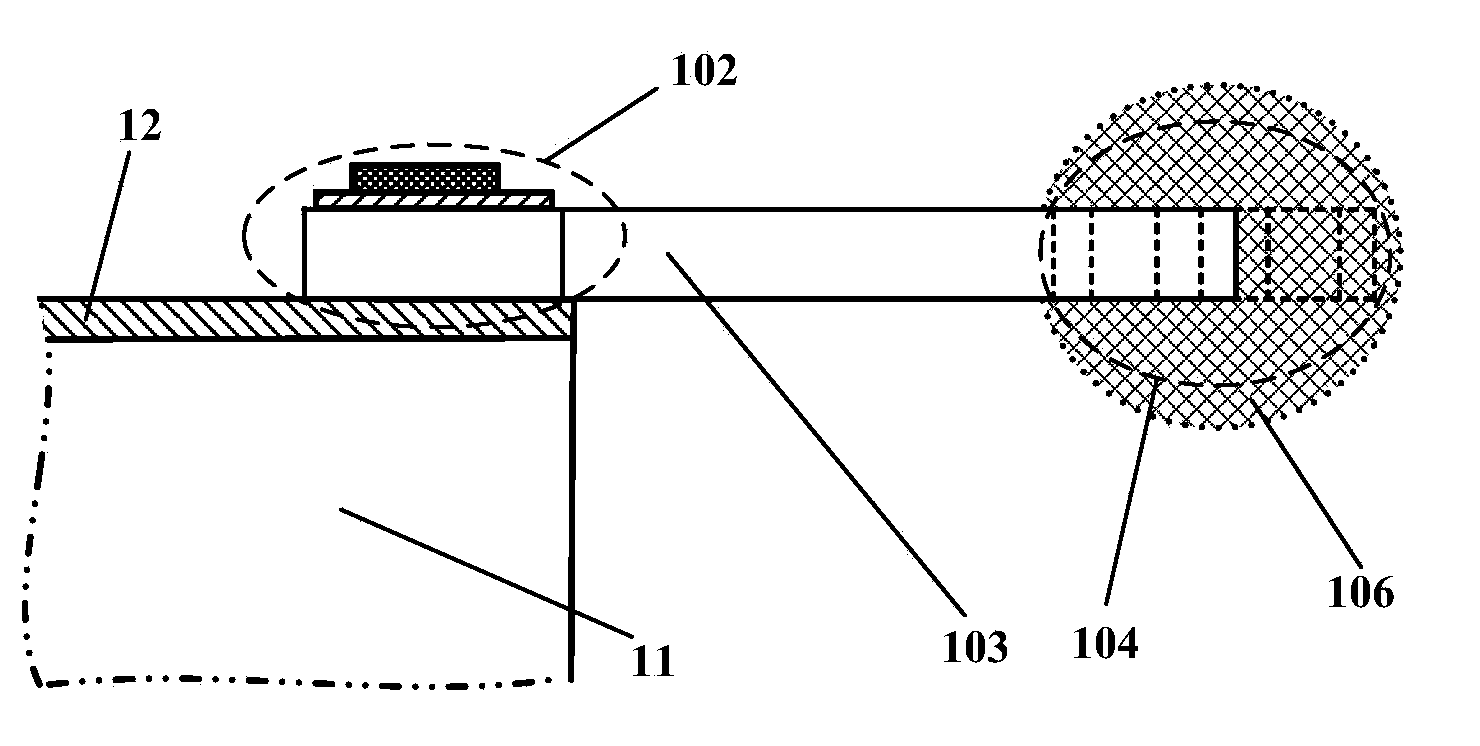

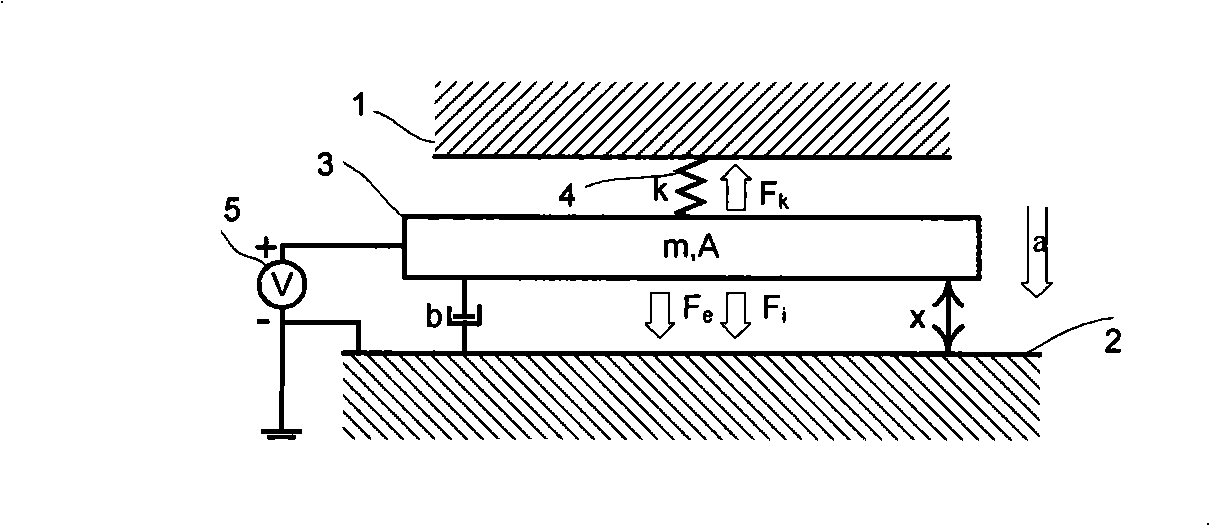

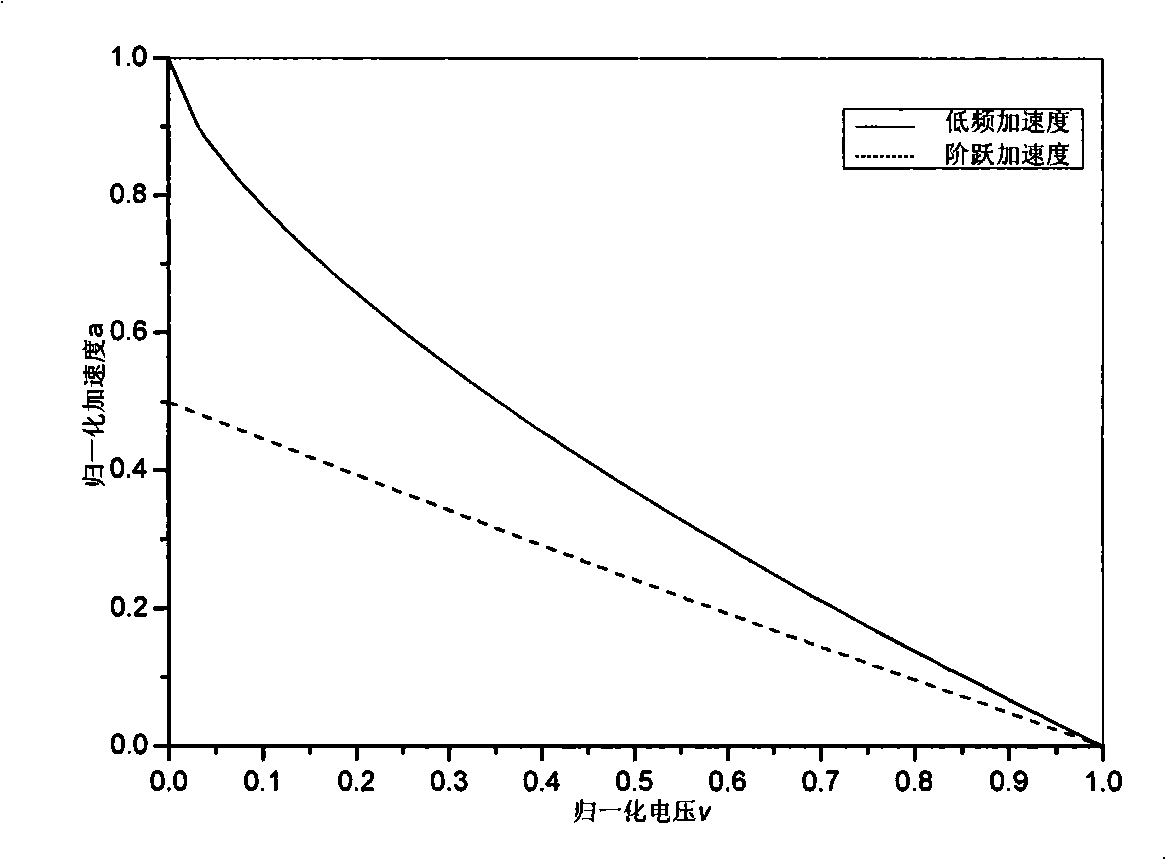

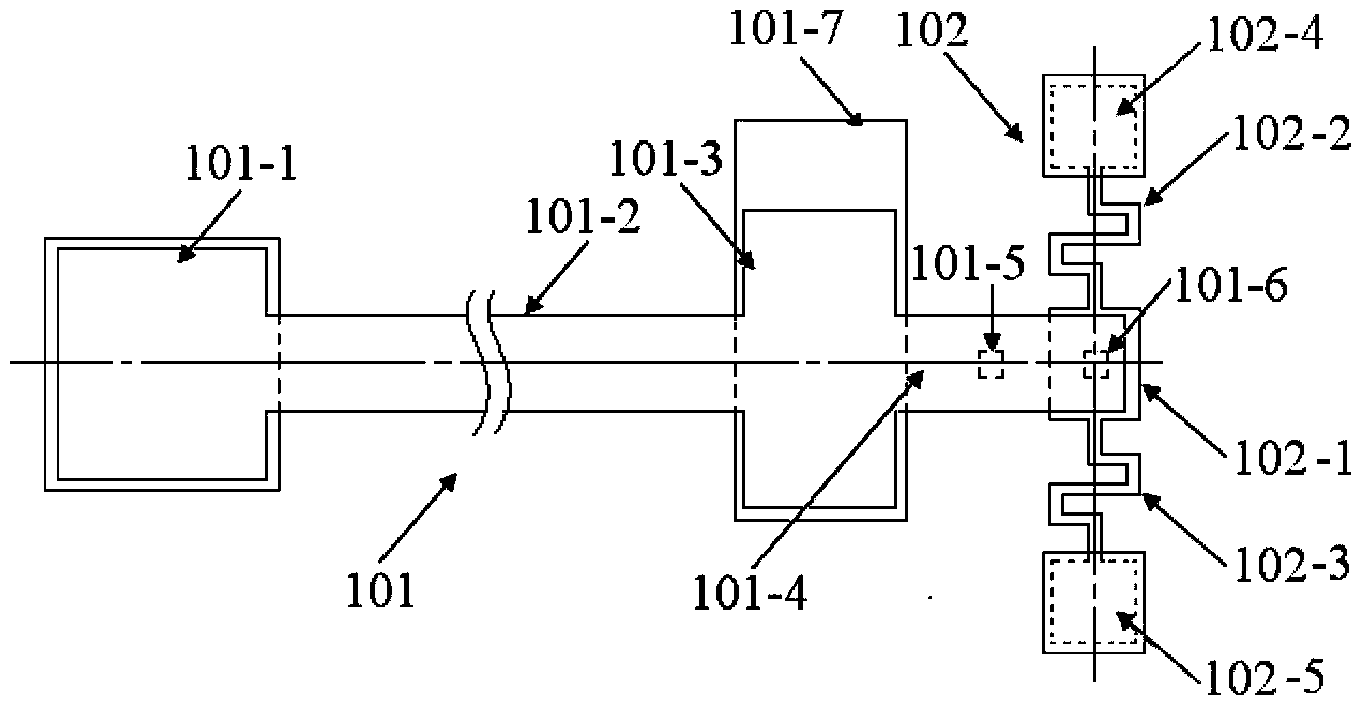

Structure and method for testing Young modulus of thin film silicon material on insulating substrate

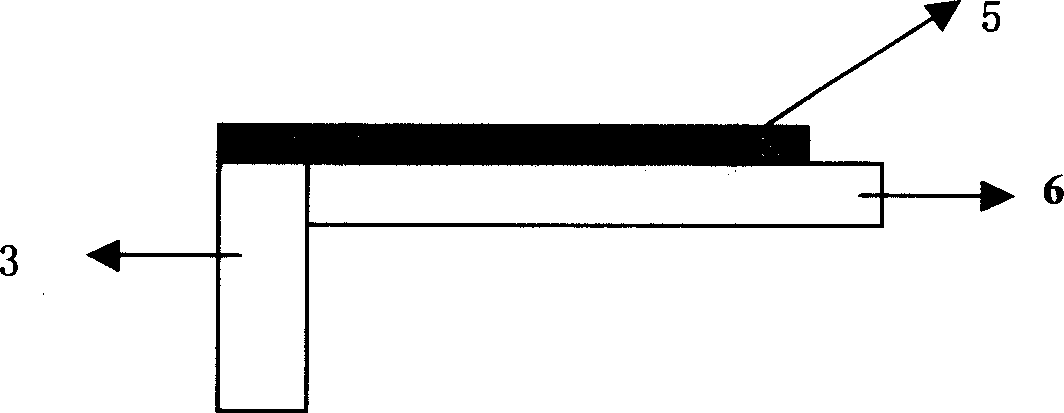

InactiveCN104034603ASimple test methodLow test equipment requirementsMaterial strength using steady bending forcesYoung's modulusCushion

The invention provides a structure and a method for testing Young modulus of a thin film silicon material on an insulating substrate. The structure comprises two groups of structures, wherein the first group of structures consists of a polycrystalline silicon cantilever beam (101), a thin film silicon cantilever beam (103) and a cushion plate (102) made from polycrystalline silicon; the second group of structures consists of a polycrystalline silicon cantilever beam and a cushion plate made from the polycrystalline silicon. According to the structure, units for actually testing the Young modulus of thin film silicon are the thin film silicon cantilever beams, the only difference of the two groups of structures is whether the thin film silicon cantilever beam exists, and corresponding structures and geometric dimensions of other units in the two groups of structures are completely the same. According to the method, by applying an electrostatic force, the polycrystalline silicon cantilever beams are bent downwards to press the thin film silicon cantilever beam and the cushion plates to contact with the substrate; by testing with the two groups of test structures, a force for independently driving the thin film silicon cantilever beam to be bent to reach test deflection is extracted, and the Young modulus of the thin film silicon material on the insulating substrate can be calculated by virtue of the force, the test deflection and the geometric dimensions.

Owner:SOUTHEAST UNIV

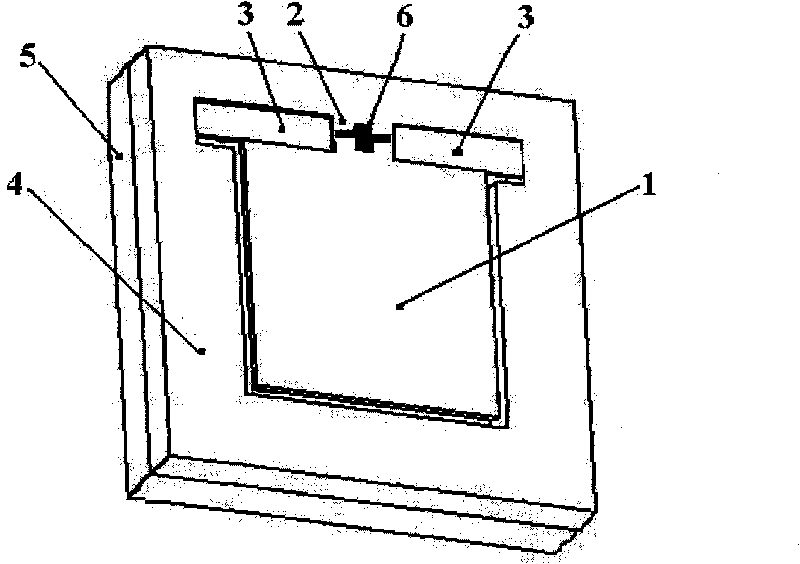

Cantilever beam type membrane stress power generation structure

InactiveCN106966356ALower natural frequencyLarge deformationDecorative surface effectsChemical vapor deposition coatingInsulation layerMembrane stress

The invention belongs to the field of Micro-Electro-Mechanical System (MEMS), more specifically, the invention relates to a cantilever beam type membrane stress power generation structure, which comprises a frame type substrate, wherein a silicon cantilever beam suspended in the frame type substrate is positioned on a beam facing an opening of the frame type substrate, the free end of the silicon cantilever beam is fixedly provided with a mass block, a silicon dioxide insulation layer is also positioned above the beam facing the opening of the frame type substrate, a bottom electrode layer is positioned on the silicon dioxide insulation layer, a strip bottom electrode layer positioned above the silicon cantilever beam extends on the bottom electrode layer in the direction towards the opening of the frame type substrate, a PZT piezoelectric layer is positioned on the mass block, a strip PZT piezoelectric layer positioned above the strip bottom electrode layer extends on the PZT piezoelectric layer in the direction towards the silicon dioxide insulation layer, and a top electrode layer is positioned above the strip PZT piezoelectric layer. When the system is in a vibration environment, the vibration in the external environment can be transferred to the system, vibration and bending deformation of the silicon cantilever beam are caused, mechanical energy is stored in the silicon cantilever beam, thereby, the piezoelectric layer is stretched and contracted and an electrical signal is generated, and the conversion of mechanical energy to electrical energy is realized.

Owner:ZHONGBEI UNIV

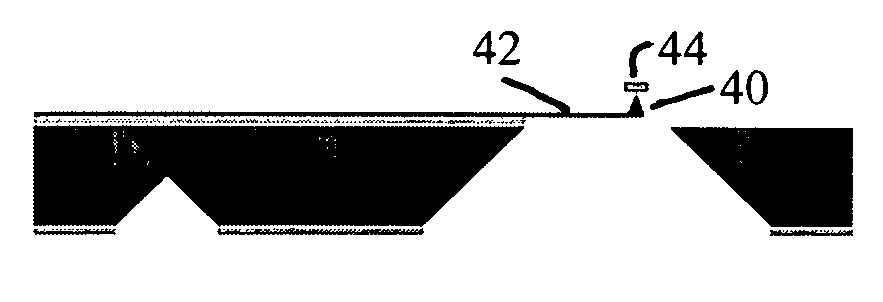

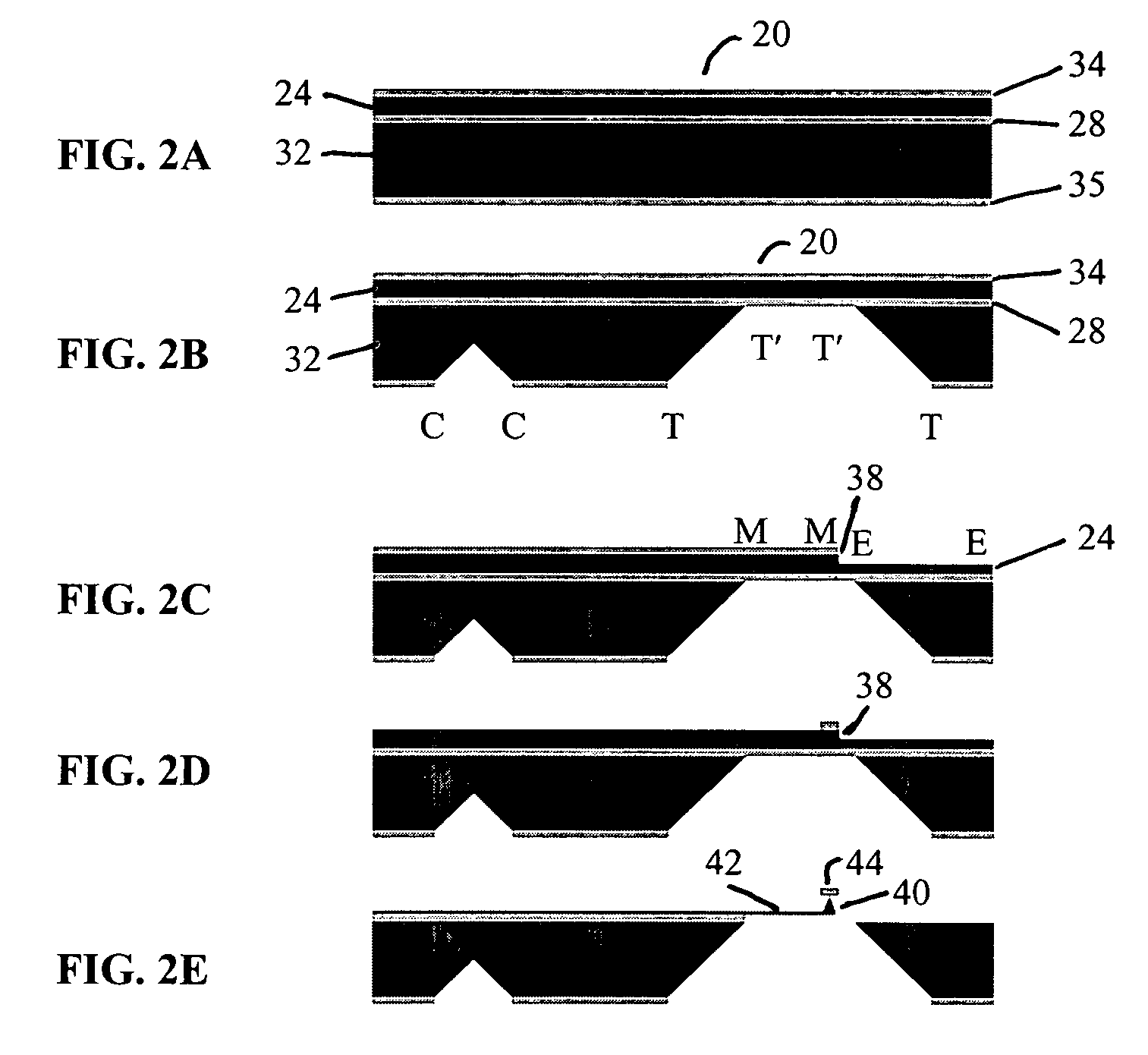

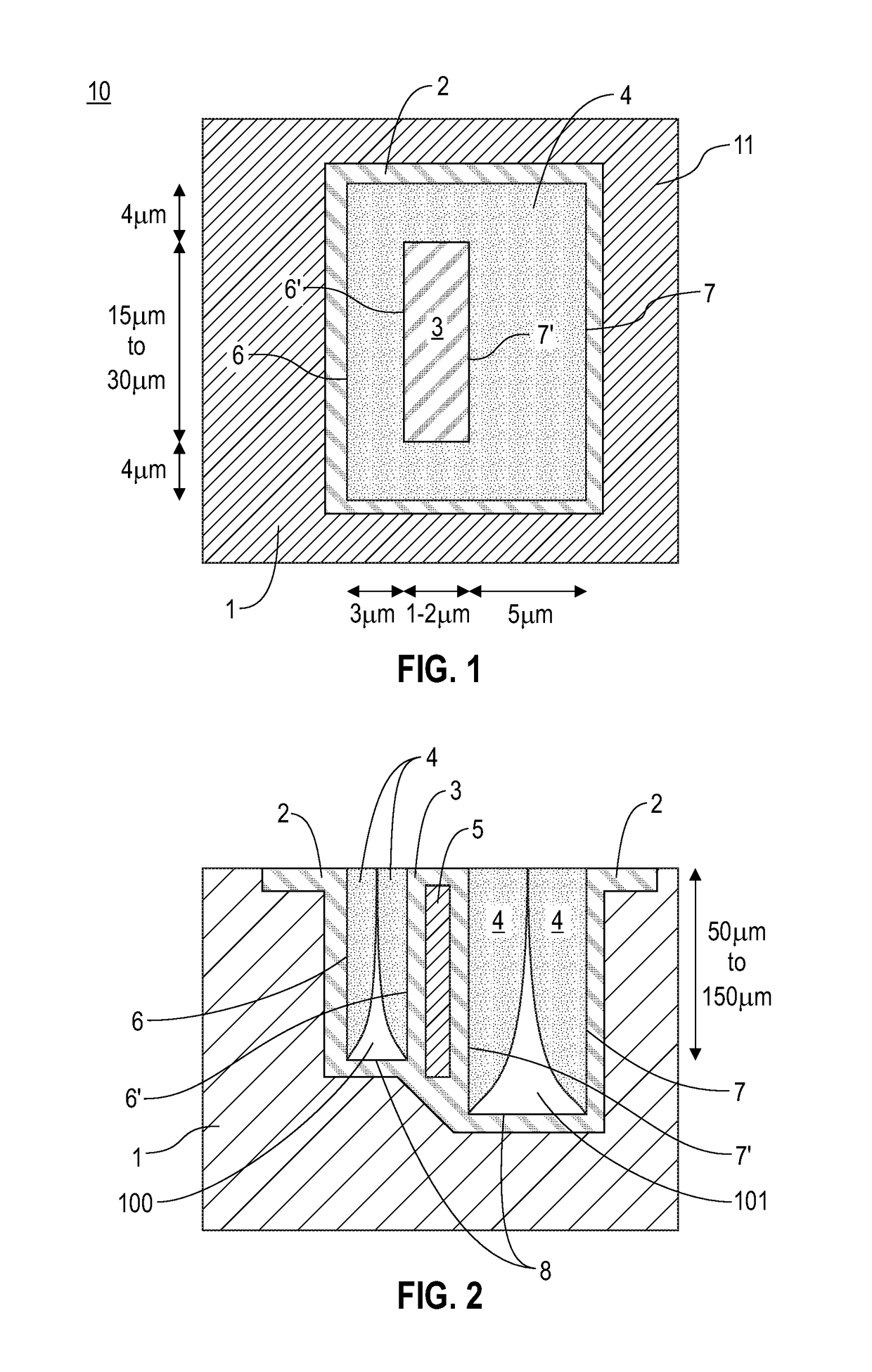

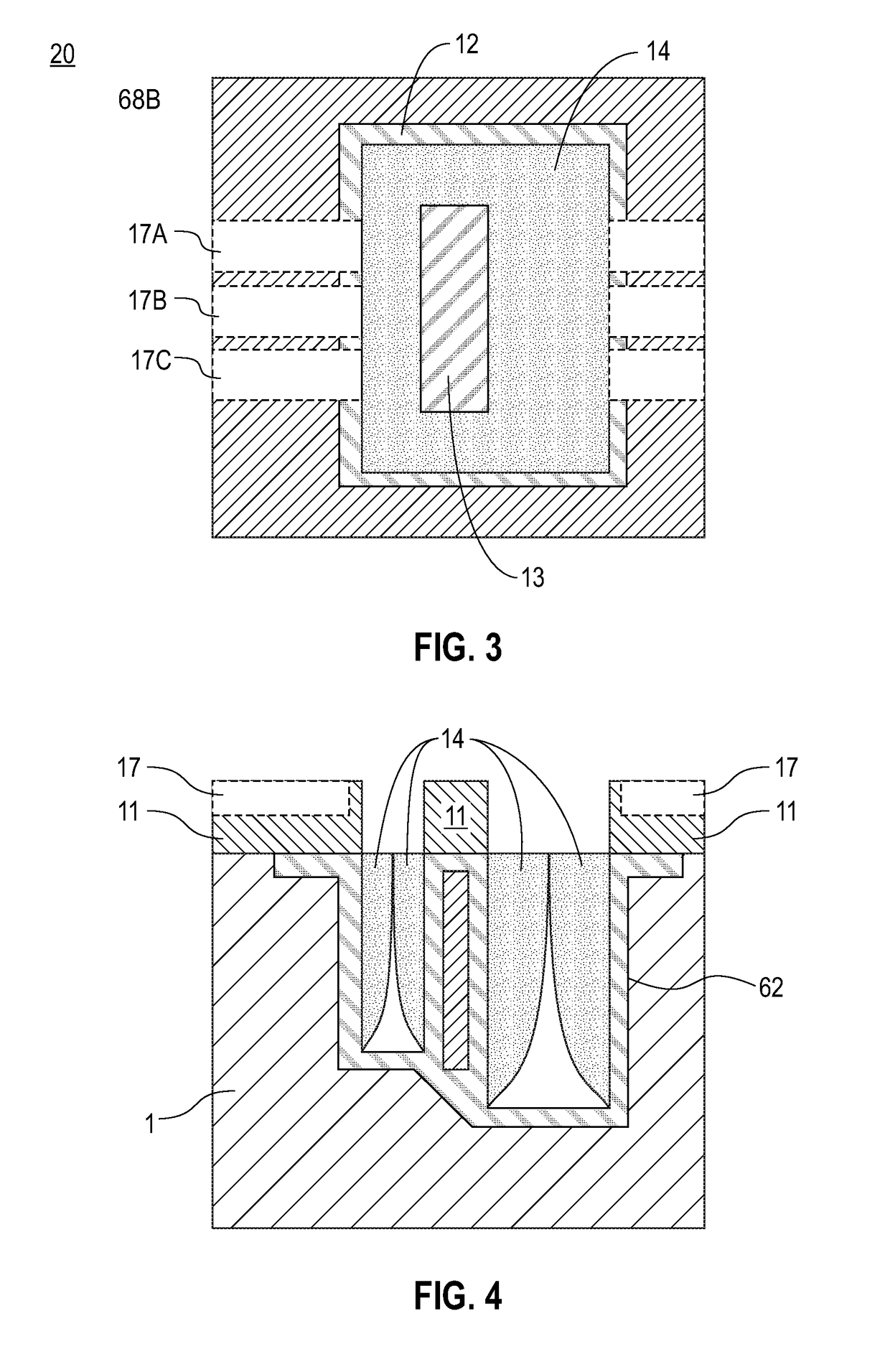

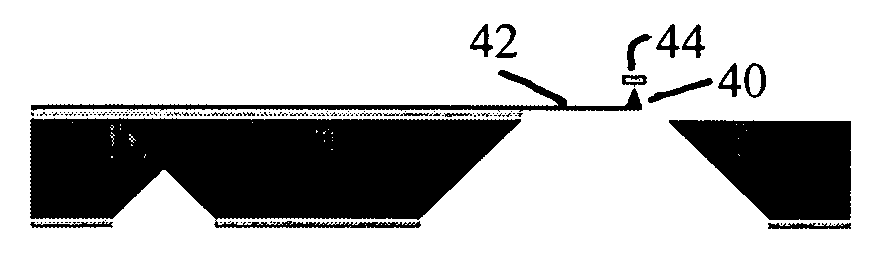

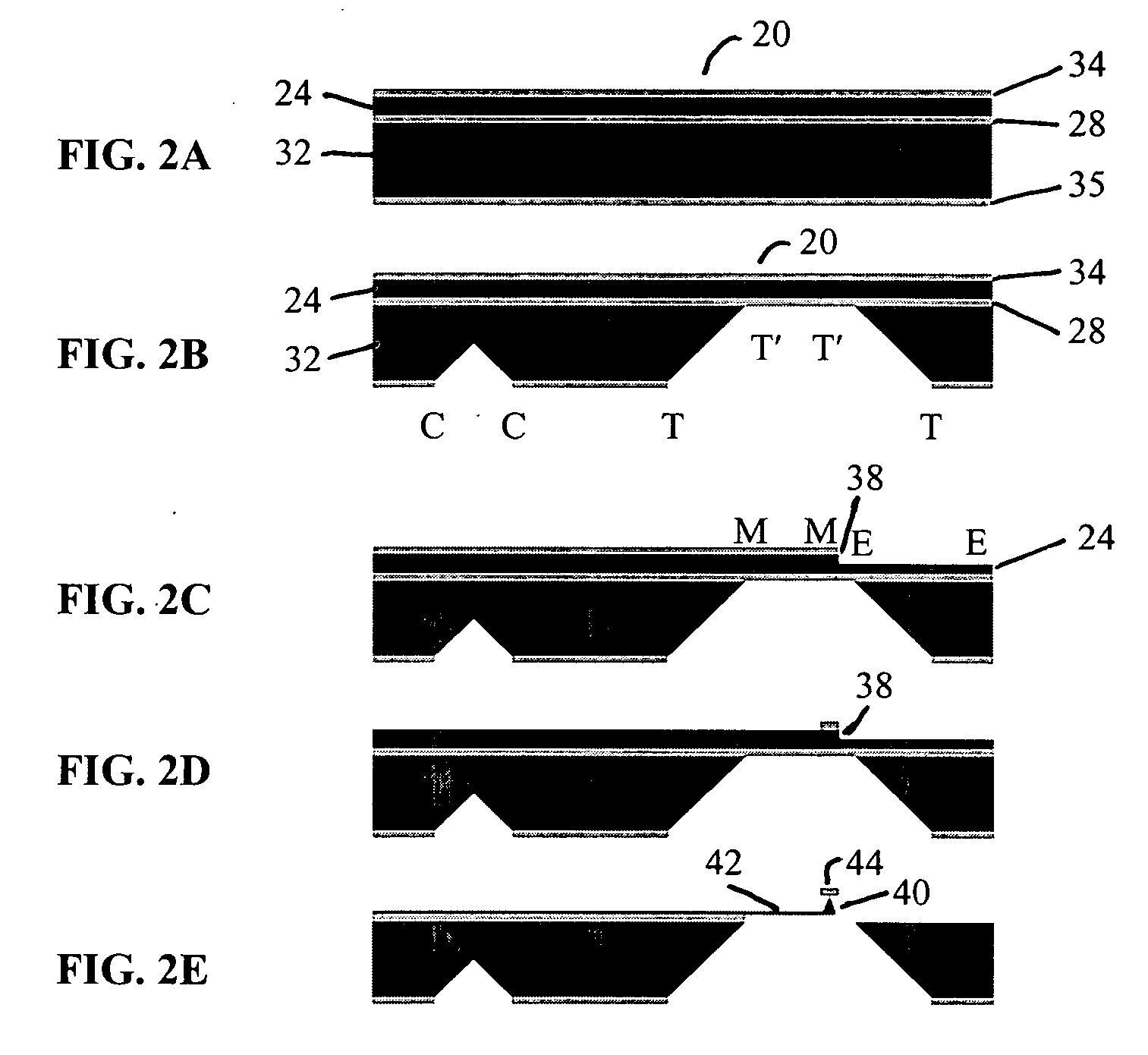

Short and thin silicon cantilever with tip and fabrication thereof

ActiveUS7637960B2Low force constantRaise the resonance frequencyNanotechSemiconductor/solid-state device manufacturingManufacturing technologyForce constant

Thin and short cantilevers possess both a low force constant and a high resonance frequency, thus are highly desirable for atomic force microscope (AFM) imaging and force measurement. According to some embodiments, the invention provides small silicon (Si) cantilevers integrated with a Si tip, for example fabricated from SOI wafers that are used for reducing the variation of thickness of the cantilevers. In one example, the fabrication process provided SOI chips containing 40 silicon cantilevers integrating with an ultra-sharp Si tip. The resolution of images obtained with these tips was much higher than those obtained with the commercial tips, while the force constants were much less, that is, more suitable for imaging soft samples. The availability of such SOI chips greatly facilitates large scale modification of the surfaces of the silicon cantilever tips with a monolayer of oligo(ethylene glycol) derivatives that resist the non-specific interactions with proteins, rendering them most suitable for imaging and measurement of biological samples.

Owner:UNIV HOUSTON SYST

Silicon micro-flow-rate sensor chip in beam film single-beam structure

InactiveCN103076050AReduce volumeReduce weightVolume/mass flow by electric/magnetic effectsElectric signalStress effects

The invention relates to a silicon micro-flow-rate sensor chip in a beam film single-beam structure. The silicon micro-flow-rate sensor chip comprises a peripheral support silicon base, wherein a glass substrate is arranged at the back side of the peripheral support silicon base, the back side of the peripheral support silicon base is in bonding connection with the glass substrate, a center silicon film is positioned in the middle of the peripheral support silicon base, one edge of the center silicon film is connected with the peripheral support silicon base through a silicon cantilever beam, the middle on the silicon cantilever arm is provided with four pressure resistance strips, the four pressure resistance strips are connected for forming a Whetstone electric bridge, a beam film structure formed by the center silicon film and the silicon cantilever beam forms a sensor measuring part, when fluid with certain speed acts on the sensor chip, the inertia force acts on the center silicon film, further, the beam film structure deforms, the resistance value of the pressure resistance strip is changed under the stress effect of the silicon cantilever beam, the Whetstone electric bridge is out of balance, and an electric signal corresponding to the external flow rate is output, so the measurement of the sensor chip on the flow rate is realized. The silicon micro-flow-rate sensor chip has the advantages that the size is small, the weight is light, the response speed is high, and the sensitivity is high.

Owner:XI AN JIAOTONG UNIV

Micro force gages and calibration weights

InactiveUS20040139808A1Apparatus for force/torque/work measurementForce measurement by elastic gauge deformationEngineeringMillinewton

The invention is a microfabricated silicon cantilever with a stiffness appropriate to resolve forces of interest in working with micro objects. Stiffnesses may range from about 10 piconewtons per micron of deflection, to about 1 millinewton per micron of deflection. There is a set of micro weights of appropriate masses that is used to calibrate the force gages. The weights are captive to a ring on a handle so that they are free to move, but will not get lost.

Owner:KELLER CHRISTOPHER GUILD

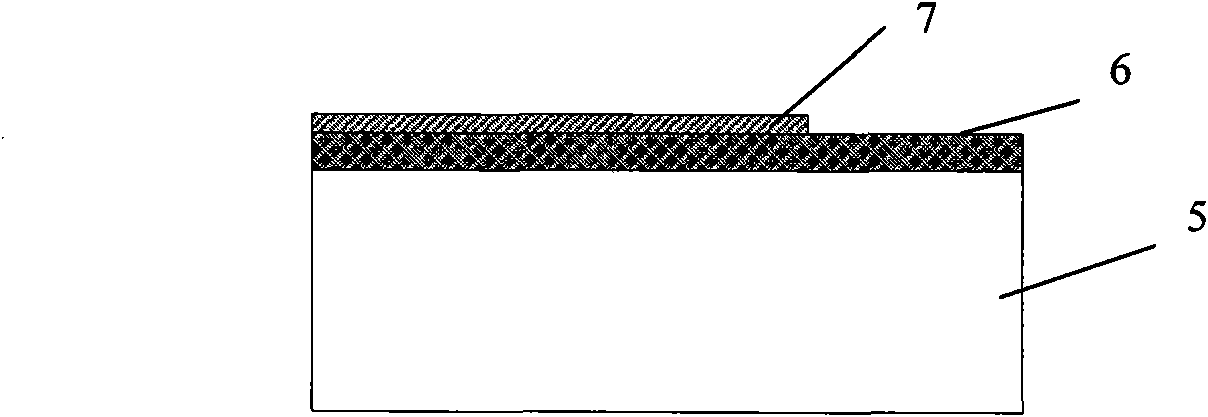

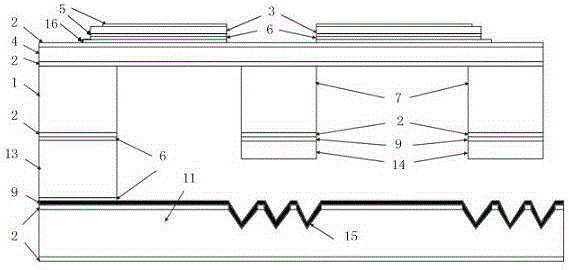

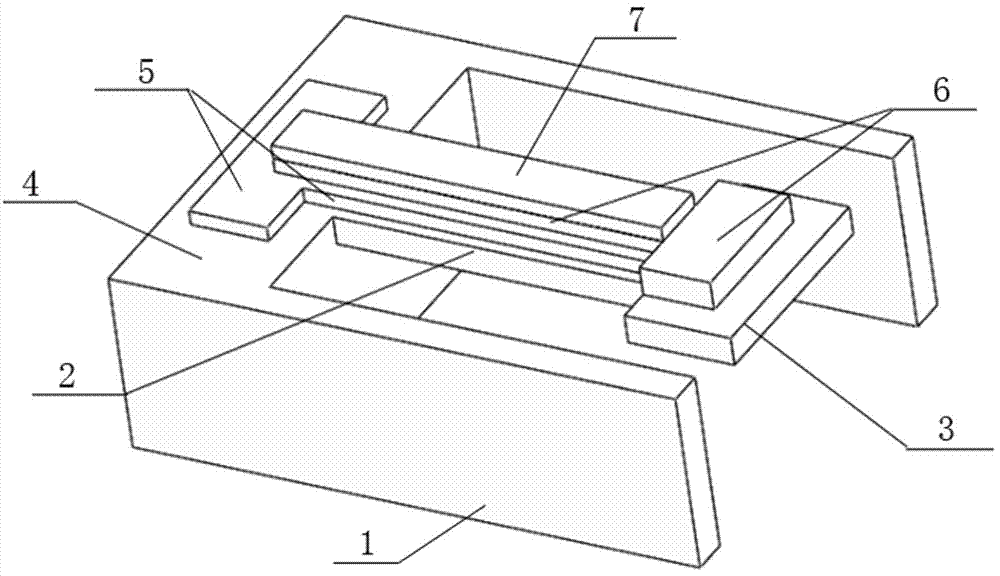

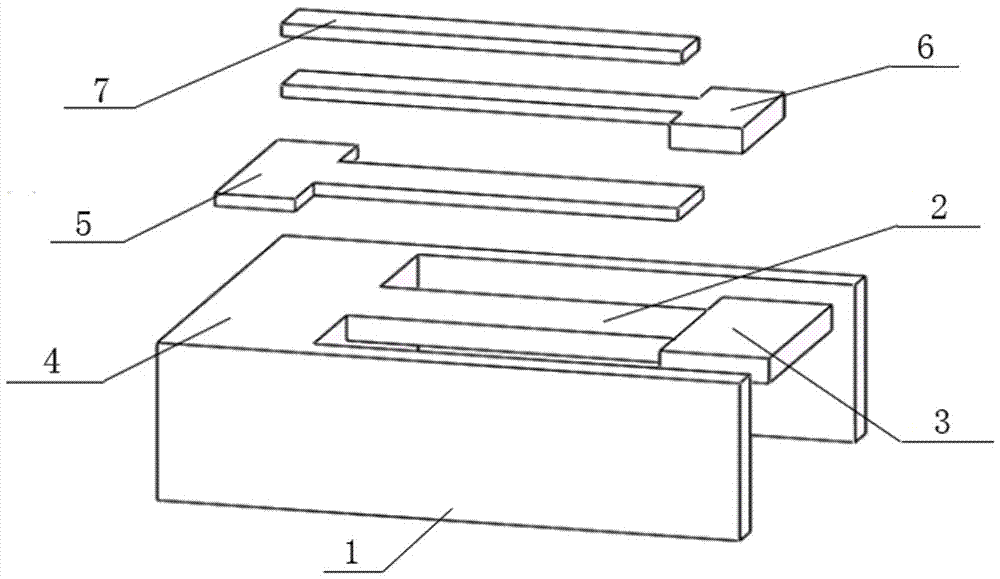

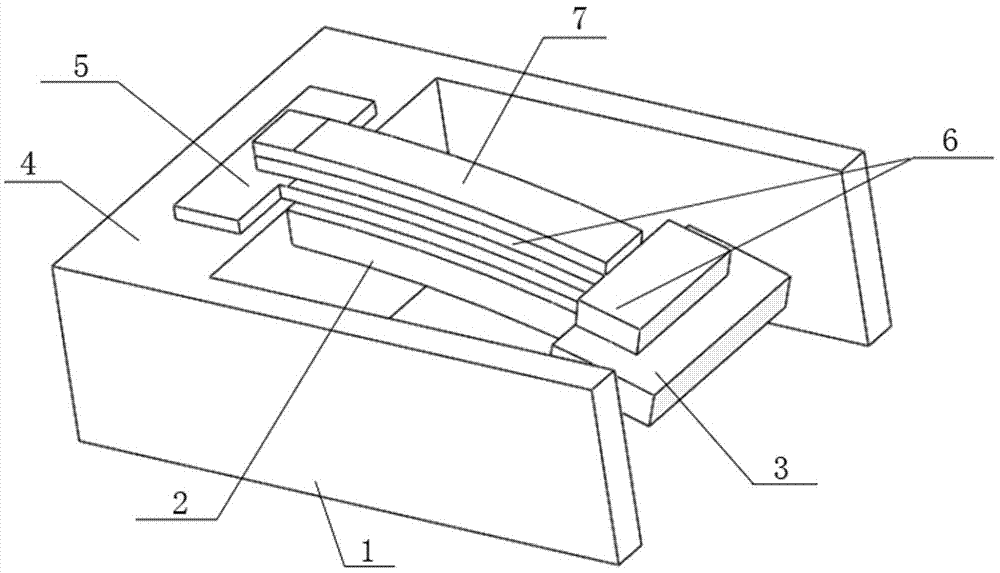

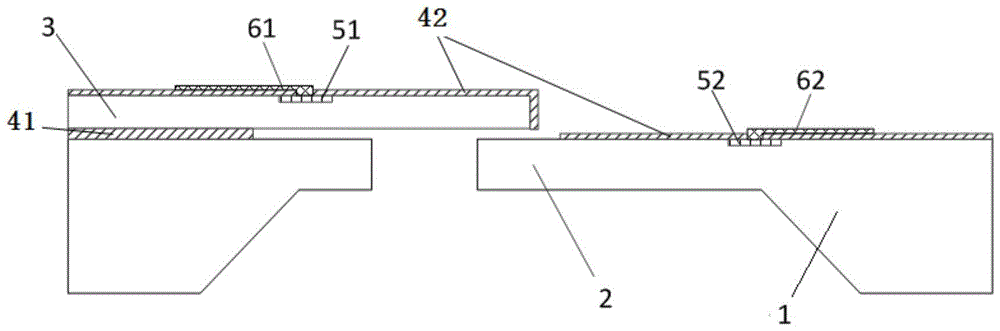

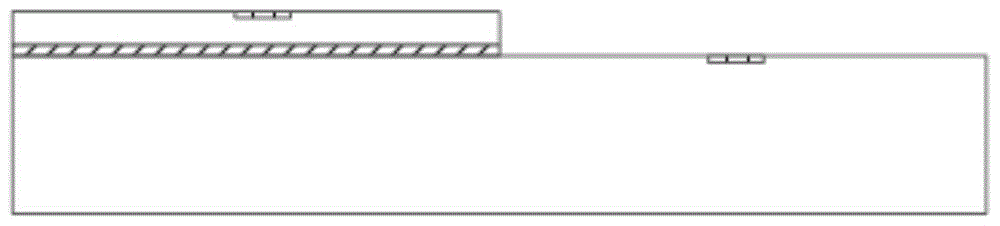

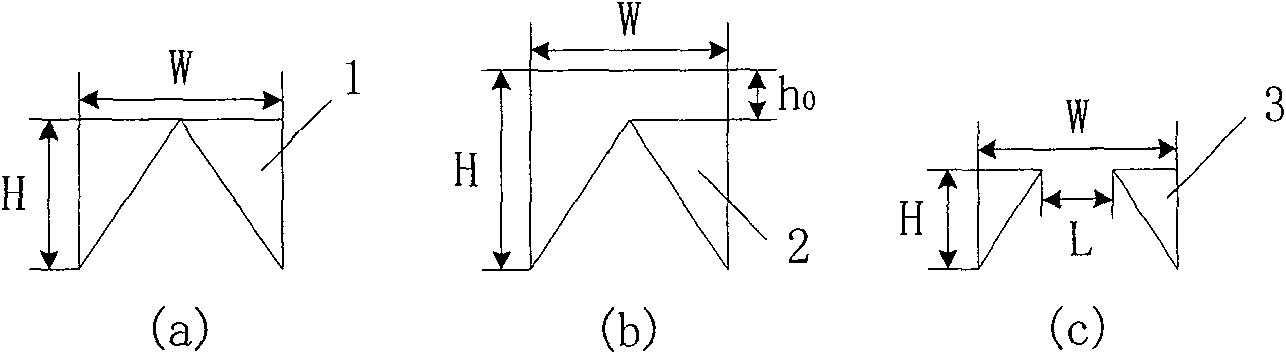

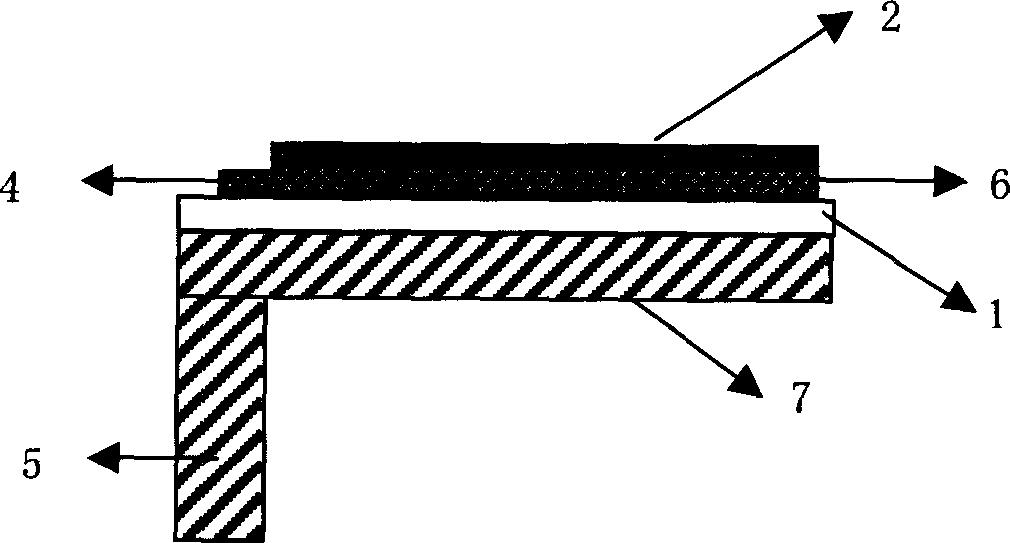

High-sensitivity wide-range force sensor and manufacturing method thereof

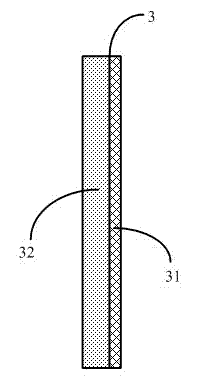

InactiveCN105668500AHigh sensitivityIncrease rangeDecorative surface effectsForce measurement using piezo-resistive materialsSilicon thin filmDielectric layer

The invention discloses a high-sensitivity wide-range force sensor and a manufacturing method thereof. The sensor comprises a substrate (1), a lower-layer silicon cantilever beam (2), an upper-layer silicon thin film (3), a first dielectric layer (41), second dielectric layers (42), a first piezoresistor (51), a second piezoresistor (52), a first outgoing guide line (61) and a second outgoing guide line (62), wherein the first outgoing guide line (61) and the second outgoing guide line (62) are outgoing lines of the first piezoresistor (51) and the second piezoresistor (52); the substrate (1) is hollow, the lower-layer silicon cantilever beam (2) is located in a hollow area of an upper surface of the center of the substrate (1), and the surface of the lower-layer silicon cantilever beam (2) is level with the upper surface of the substrate (1), one end of the lower-layer silicon cantilever beam (2) is connected with the substrate (1), and the other end of the lower-layer silicon cantilever beam (2) is suspended. The sensor provided by the invention has high sensitivity under the action of a small force, and also has a wide measurement range. The whole process of the manufacturing method of the sensor is simple.

Owner:SOUTHEAST UNIV

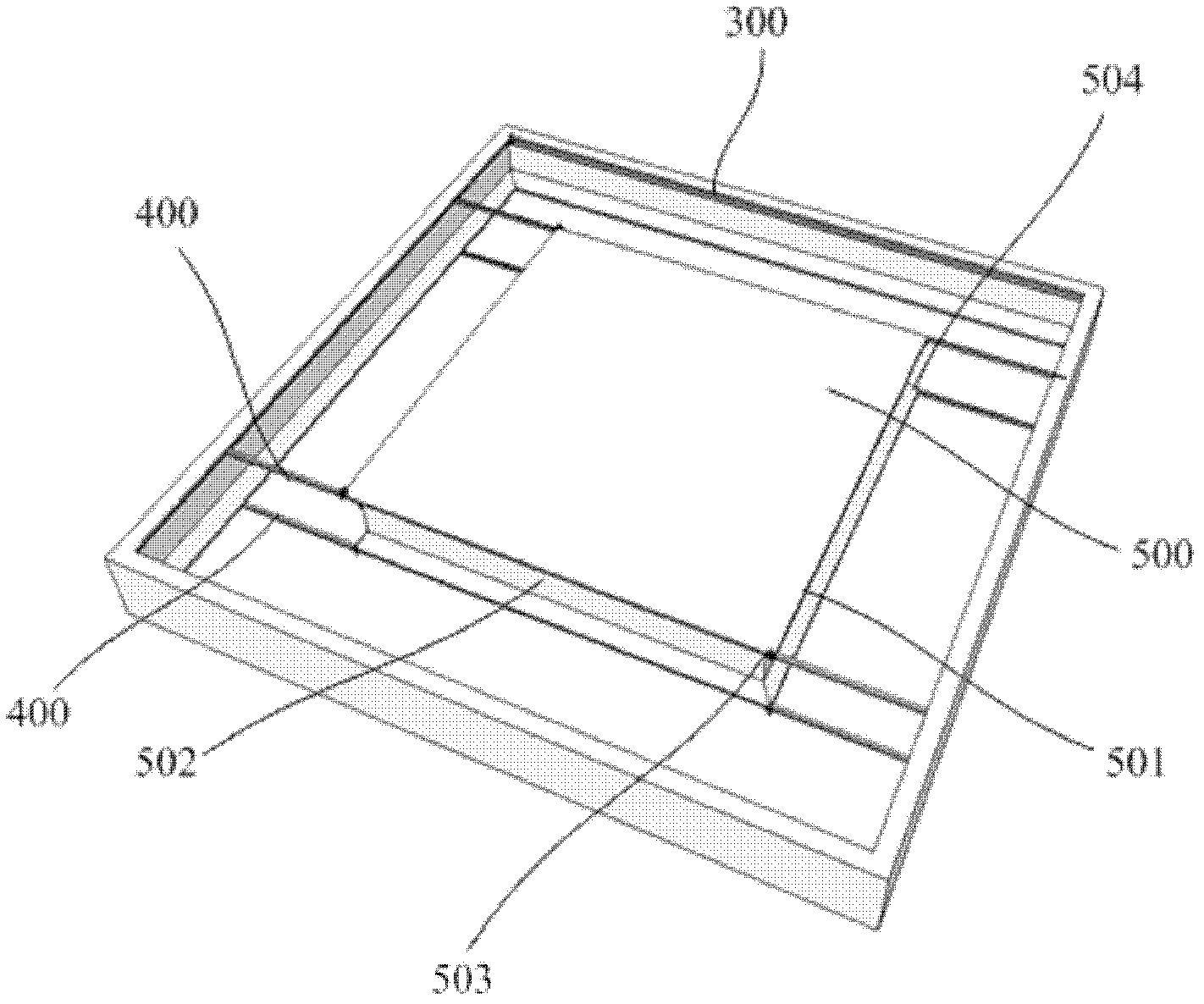

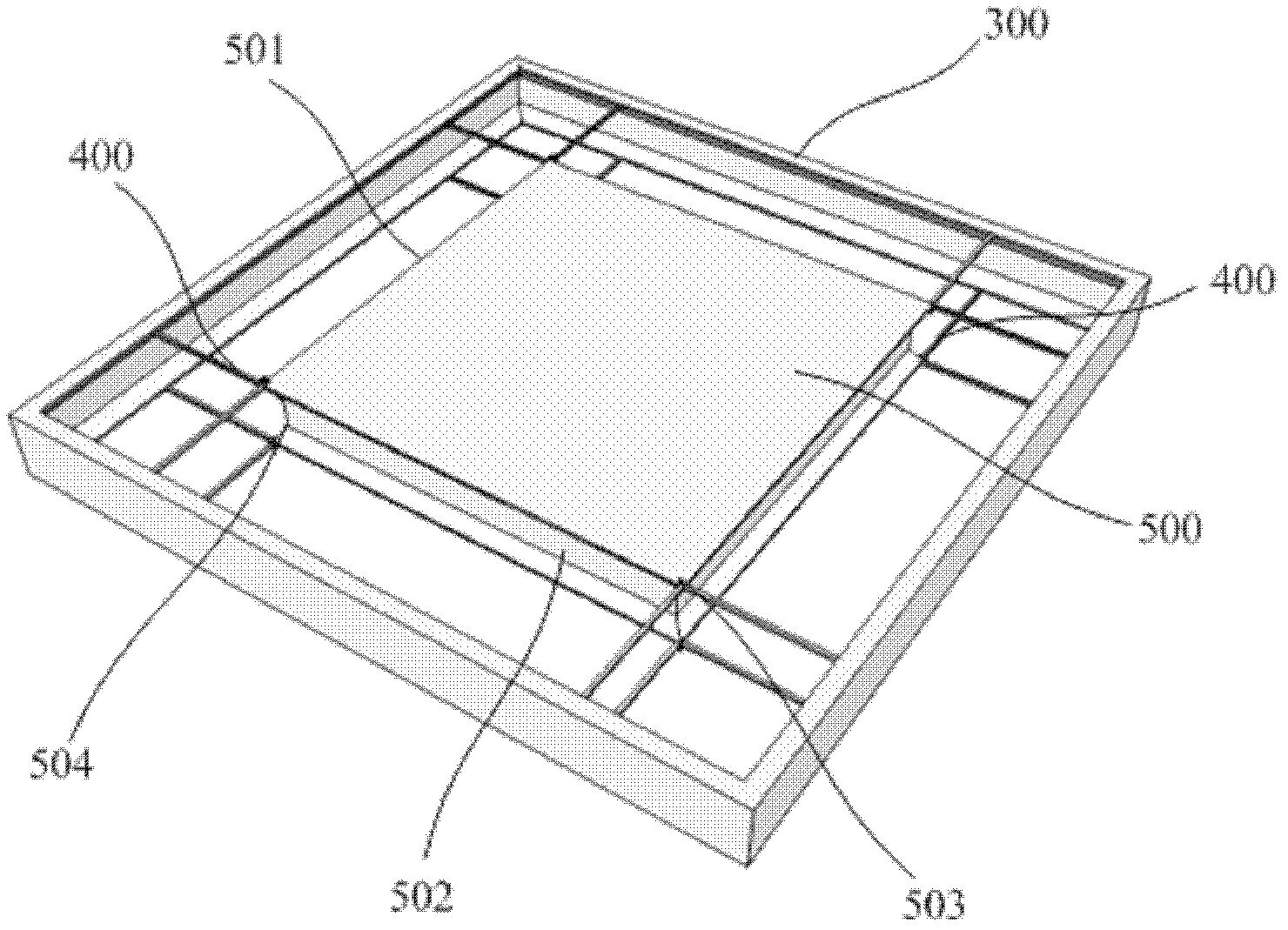

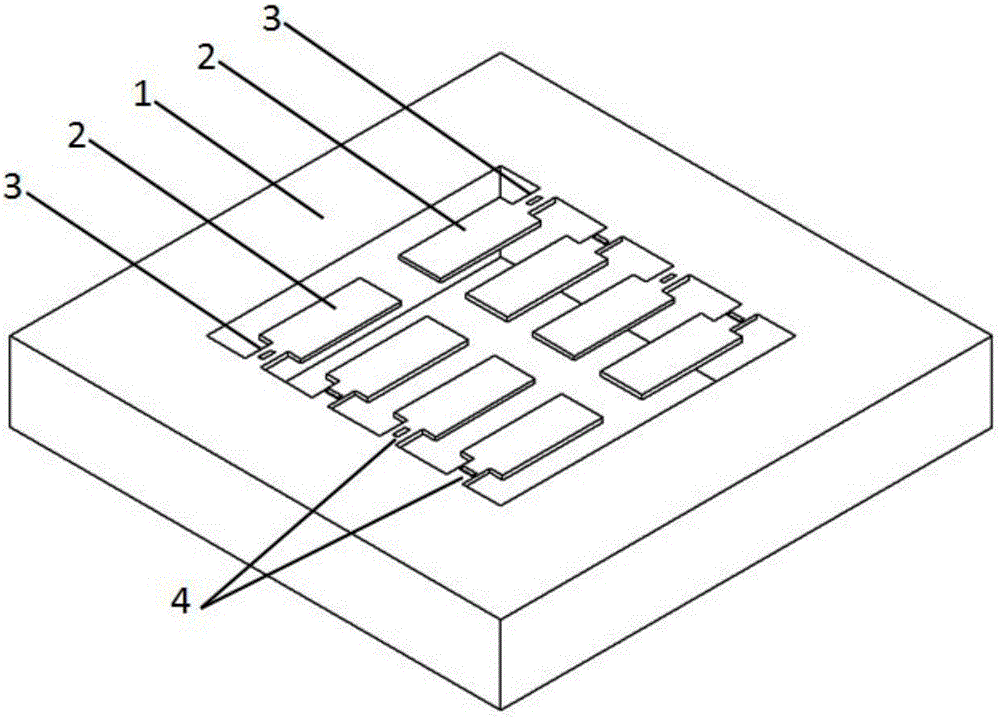

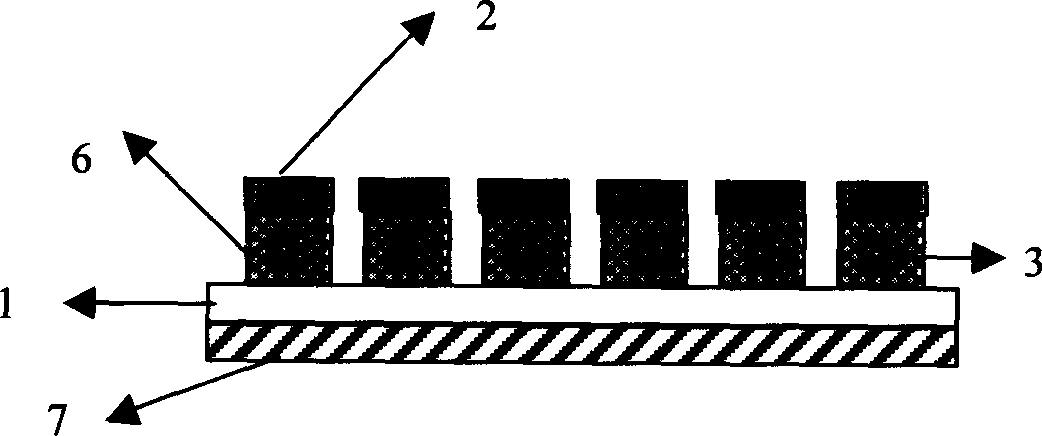

Silicon micro-flow sensor chip with arrayed cantilever beam membrane structure

ActiveCN106595786AHigh measurement accuracySelf-calibratingVolume/mass flow measurementElectric signalStress effects

A silicon micro-flow sensor chip with an arrayed cantilever beam membrane structure comprises a peripheral supporting silicon substrate, wherein two groups of opposite silicon films which are arranged in an arrayed manner are arranged in the middle of the peripheral supporting silicon substrate; each group has four silicon films; each silicon film is connected with the peripheral supporting silicon substrate through a silicon cantilever beam; each silicon cantilever beam is provided with a piezoresistance strip; the four piezoresistance strips of the silicon cantilever beams of each group are connected through leads to form a wheatstone bridge; the arrayed cantilever beam membrane structure formed by the silicon films and the silicon cantilever beams forms a measurement part of a sensor, a gap is formed between each silicon film and the peripheral supporting silicon substrate so that the silicon film is suspended, a gap is formed between each two adjacent silicon films of each group, when fluid passes through the arrayed cantilever beam membrane structure, the arrayed cantilever beam membrane structure deforms, the resistance value of the piezoresistance strips is changed under the stress effects of the silicon cantilever beams, the wheatstone bridges are out of balance, an electric signal which corresponds to the effect of fluid is output, and therefore, measurement of the flow by the sensor chip is realized. The silicon micro-flow sensor chip with an arrayed cantilever beam membrane structure has the advantages of small size, light weight, high sensitivity and self-calibration ability.

Owner:XI AN JIAOTONG UNIV

Cantilever structure and its making process and application

InactiveCN100562484CImprove manufacturing yieldImprove yieldDecorative surface effectsChemical vapor deposition coatingGyroscopeManufacturing technology

The invention relates to a cantilever beam structure and a manufacturing method manufactured by taking silicon anisotropic corrosion as a key technology, and belongs to the field of micro-electronic mechanical systems. It is characterized in that the section of the cantilever beam is pentagonal, the upper surface of the cantilever beam is a single crystal silicon (100) crystal plane, and the lower surface of the cantilever beam is composed of two (111) crystal planes. The cantilever beam structure is produced by anisotropic etching, and the (111) surface is used as the etching termination surface to automatically terminate the corrosion of the silicon cantilever beam. The cantilever beam structure can be precisely controlled, which greatly improves the manufacturing yield of the cantilever beam. The invention can be applied to the structures of various MEMS devices, such as capacitive acceleration sensors, resistive acceleration sensors, micromechanical gyroscopes, resonators, etc., which can greatly improve the control level of the device manufacturing process and improve the yield of device manufacturing.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Small wafer area MEMS switch

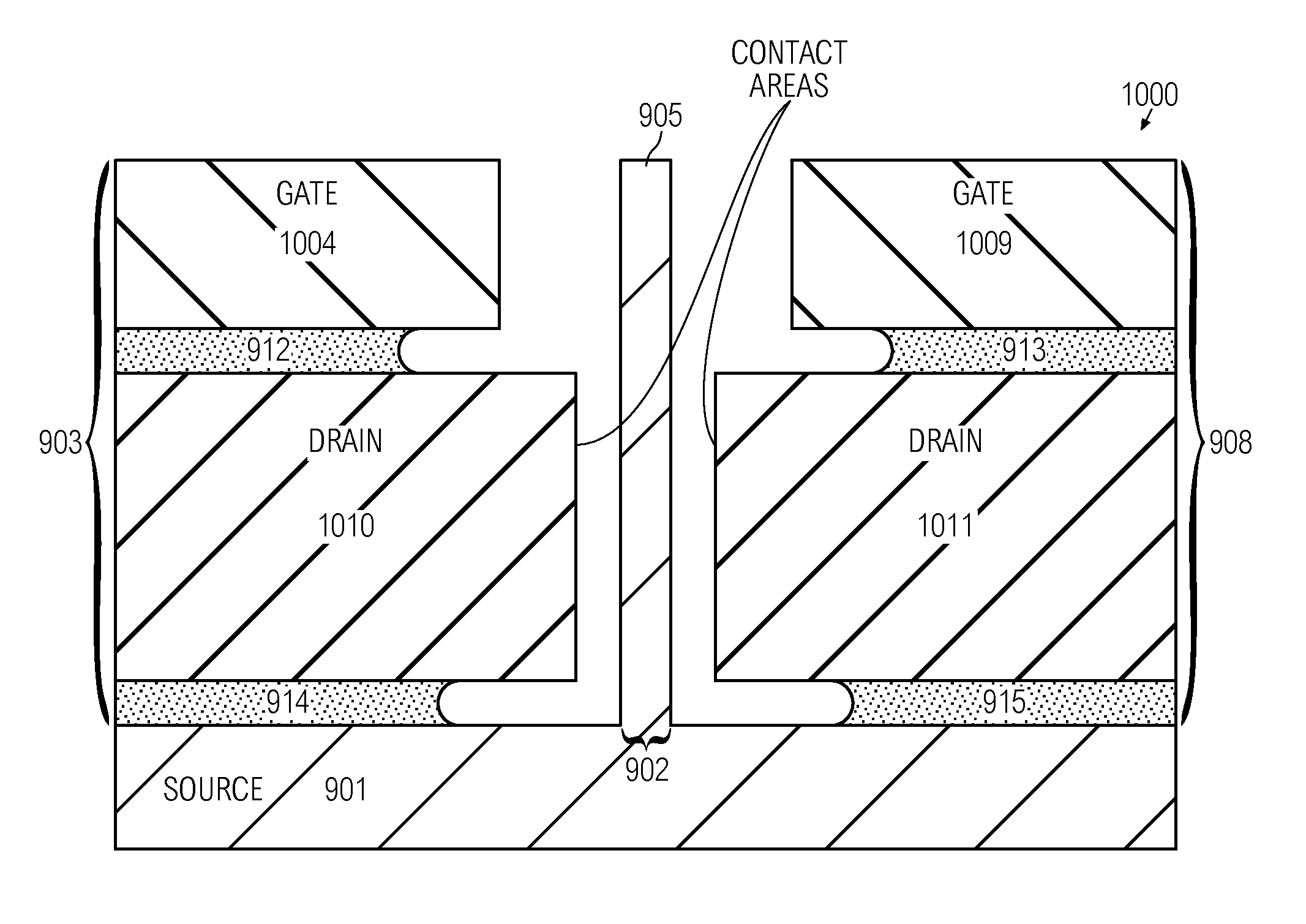

InactiveUS20170166438A1Electrostatic/electro-adhesion relaysDecorative surface effectsVertical planeEngineering

Deep via technology is used to construct an integrated silicon cantilever and cavity oriented in a vertical plane which creates an electrostatically-switched MEMS switch in a small wafer area. Another embodiment is a small wafer area electrostatically-switched, vertical-cantilever MEMS switch wherein the switch cavity is etched within a volume defined by walls grown internally within a silicon substrate using through vias.

Owner:IBM CORP

Soft-magnetic multilayer film force-sensitive sensor and preparation method thereof

InactiveCN1603765AReduce volumeQuick responseTelevision system detailsForce measurement by measuring magnetic property varationMicro structureCopper

This invention provides a soft-magnetic multiple-film piezo-sensor and its process method, wherein, the piezo-sensor is a sandwich structure composed of central copper conductive layer, soft magnetic thin film coated on the surface of copper layer and top protection layer. When in process, it adopts photo etching technique to get the aligning signs of double side cover etching; it adopts thin film process technique and micro-electroplating technique to get soft-magnetic multiple-film piezo-sensor; it adopts physics etching technique to remove the under layer and adopts special chemical formula to wet etch the soft-magnetic multiple-film material to form piezo-sensor; finally it adopts silicon wet etching technique to form piezo-sensor micro structure.

Owner:SHANGHAI JIAO TONG UNIV

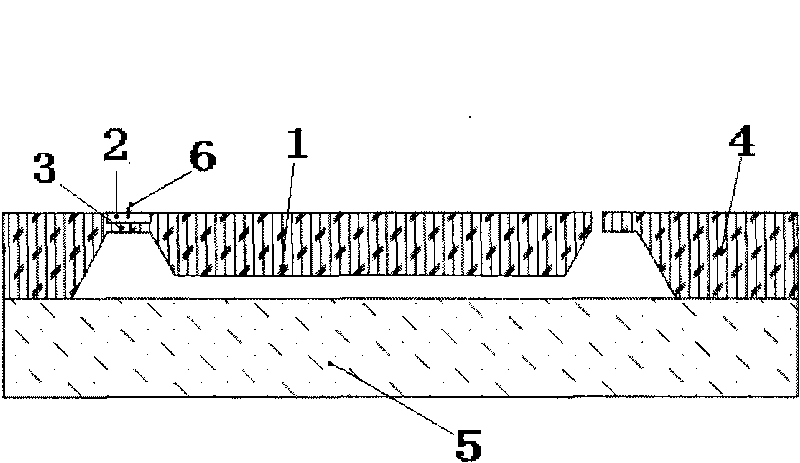

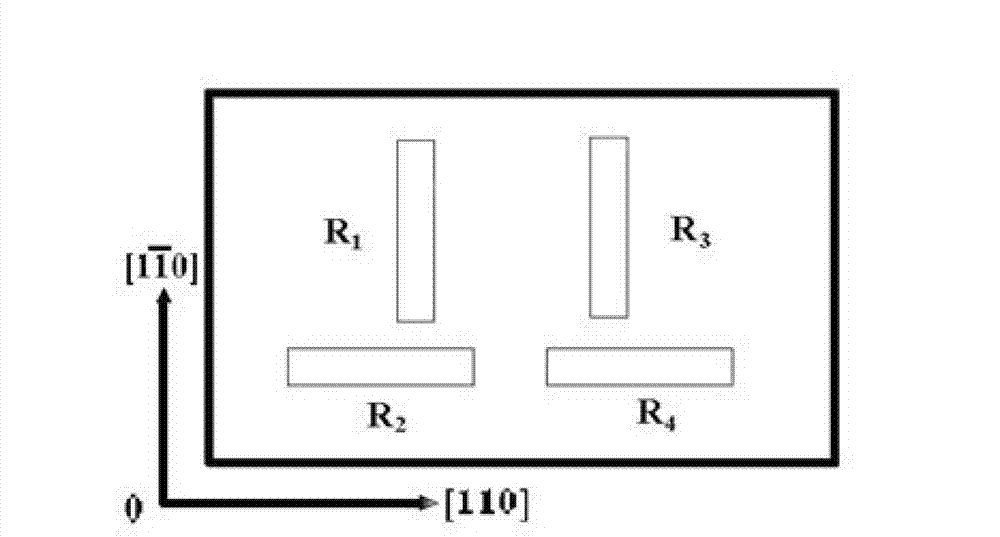

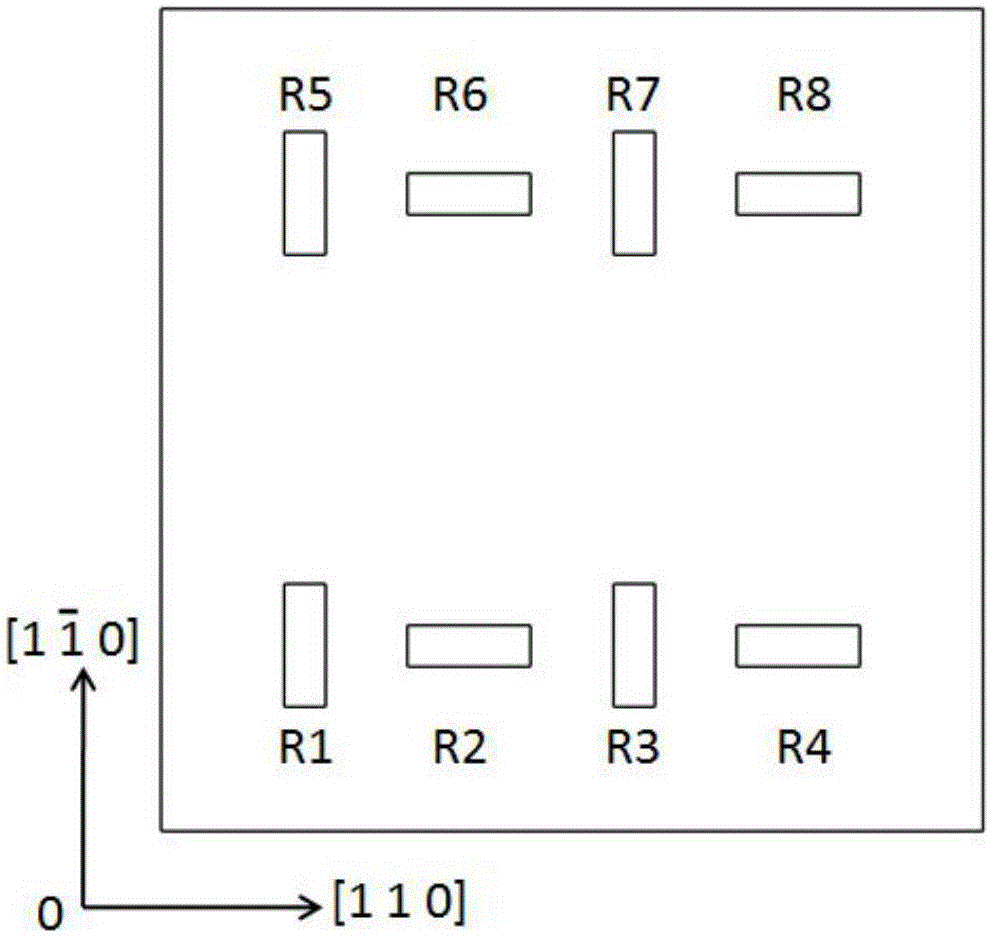

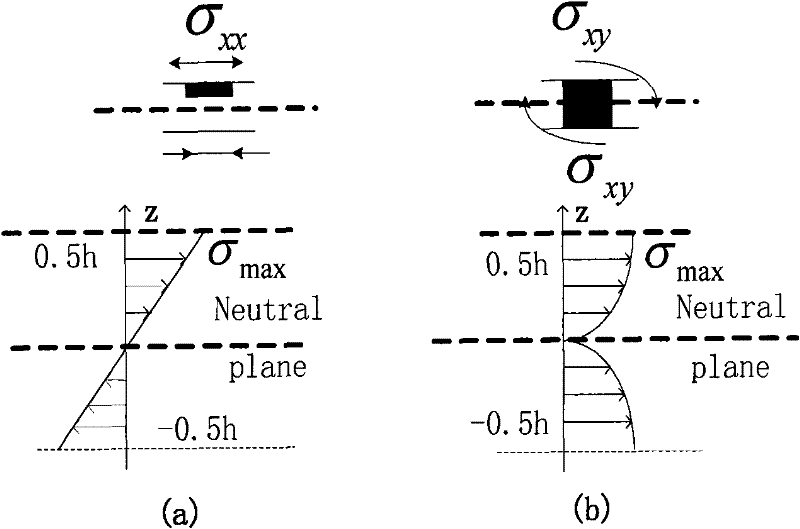

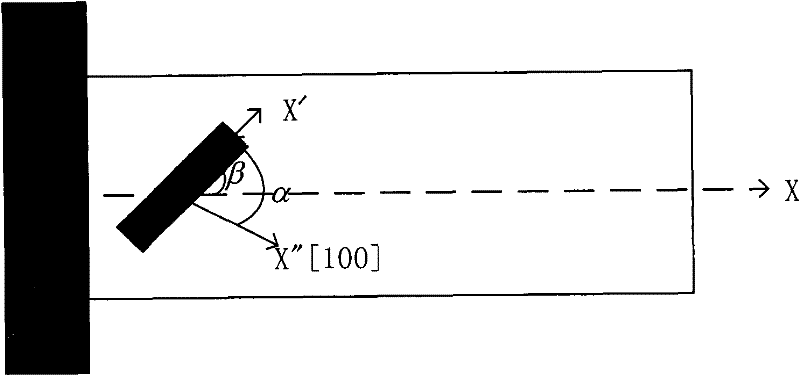

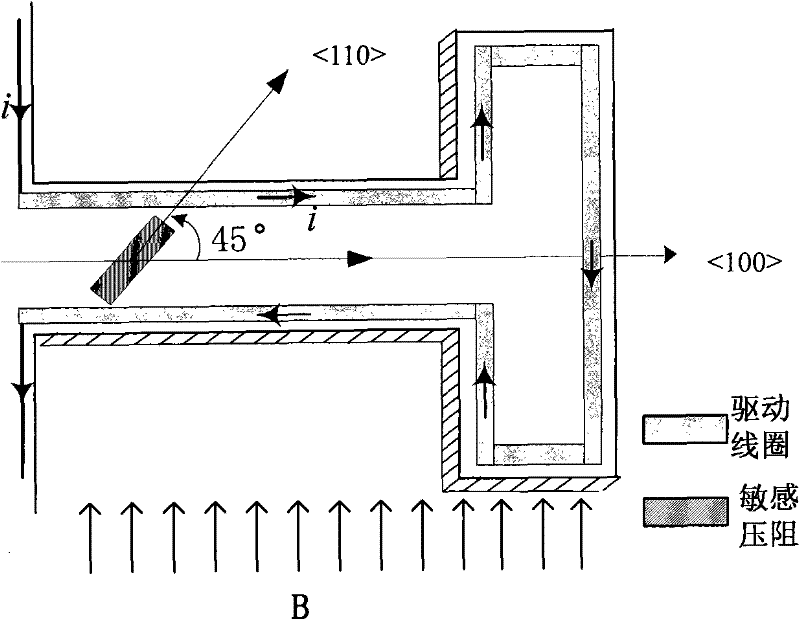

Detection piezoresistance and method for ultrathin silicon micromechanical cantilever beam under torsion mode

ActiveCN101475138BAvoid the problem of high concentration shallow dopingSimple structureTelevision system detailsSemi-permeable membranesShear stressDistribution characteristic

The invention relates to a detection piezoresistor for an ultrathin silicon micromechanical cantilever beam under a torsional mode and a method for detecting the piezoresistor, and belongs to the technical field of micromechanical sensing. The method is specifically characterized in that the method uses shear stress distribution characteristics of the micromechanical cantilever beam under the torsional mode to penetrate a piezoresistive doped region for signal detection to the thickness of the whole silicon cantilever beam, thereby breaking through the limit that the piezoresistive sensing region of the micromechanical cantilever beam cannot overpass half of the beam thickness under the prior bending mode; and the method simultaneously combines anisotropy of silicon piezoresistive coefficient and distribution characteristic of stress tensor on the cantilever beam to optimally design the arrangement direction of the cantilever beam and the piezoresistor, so that the relative variable of the piezoresistor reaches the maximum, and the mechanical property of the cantilever beam is improved. The piezoresistor and the method have the advantages of simple structure, convenient manufacture and easy realization.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Short and thin silicon cantilever with tip and fabrication thereof

ActiveUS20070125160A1Low force constantRaise the resonance frequencyNanotechSemiconductor/solid-state device manufacturingResonanceForce constant

Thin and short cantilevers possess both a low force constant and a high resonance frequency, thus are highly desirable for atomic force microscope (AFM) imaging and force measurement. According to some embodiments, the invention provides small silicon (Si) cantilevers integrated with a Si tip, for example fabricated from SOI wafers that are used for reducing the variation of thickness of the cantilevers. In one example, the fabrication process provided SOI chips containing 40 silicon cantilevers integrating with an ultra-sharp Si tip. The resolution of images obtained with these tips was much higher than those obtained with the commercial tips, while the force constants were much less, that is, more suitable for imaging soft samples. The availability of such SOI chips greatly facilitates large scale modification of the surfaces of the silicon cantilever tips with a monolayer of oligo(ethylene glycol) derivatives that resist the non-specific interactions with proteins, rendering them most suitable for imaging and measurement of biological samples.

Owner:UNIV HOUSTON SYST

Force sensing device based on microelectromechanical system

InactiveCN1693864AHigh sensitivityImprove response speedGalvano-magnetic devicesFluid pressure measurement by electric/magnetic elementsHigh volume manufacturingMicroelectromechanical systems

The invention relates to a force sensitive component used in microelectromechanical system that includes silicon substrate, pin, flexural sandwich structure soft magnetic multilayer force sensitive component and silicon cantilever. The pin is leading from the copper layer of the two ends of the force sensitive component and is set on the silicon cantilever with silicon dioxide layer. The flexural sandwich structure soft magnetic multiplayer force sensitive component is located on the silicon cantilever that connects to the silicon substrate. The invention has the advantage of high sensitivity and fast response speed. The membrane material could be compatible to most large integrated circuit and is easy to manufacture. The SI effect of the multilayer membrane and sensitivity of the force sensitive component are sharply increased. It could realize the detecting for acceleration, pressure, and libration, and filtering, tuning, surging as well.

Owner:SHANGHAI JIAO TONG UNIV

Switching device and a method for forming a switching device

InactiveUS8735750B2Electrostatic/electro-adhesion relaysNanoelectromechanical switchesControl layerEngineering

Embodiments provide a switching device. The switching device includes a substrate, which includes a contact region. The switching device further includes a vertical layer arrangement extending from the substrate next to the contact region. The vertical layer arrangement includes a control layer. The switching device further includes a freestanding silicon cantilever extending vertically from the contact region.

Owner:AGENCY FOR SCI TECH & RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com