Surface microstructure silicon cantilever enhancement type optical-thermal spectrum trace gas detection method and device

A trace gas and detection device technology, applied in the field of photothermal spectrum trace gas detection, can solve the problems of reducing the ability to detect weak light signals, inability to detect long-distance spectra, and low thermal deflection efficiency, etc., to eliminate external electromagnetic interference , improved anti-interference ability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

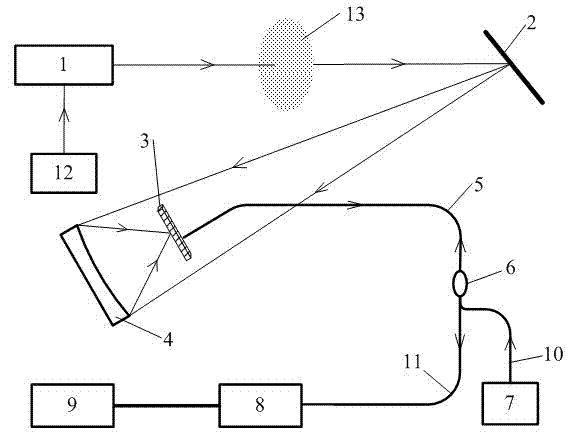

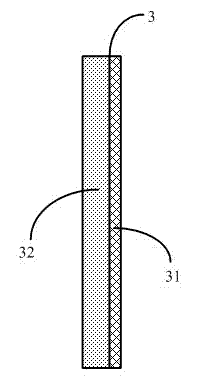

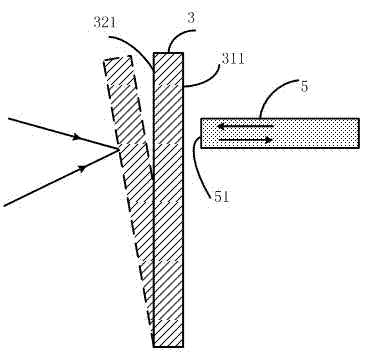

[0024] Photothermal spectroscopic trace gas detection devices based on surface microstructured silicon cantilever beams working in an open environment such as figure 1 As shown, the tunable laser 1 is on the same optical path as the reflective object 2 and the concave mirror 4 , and the silicon cantilever beam 3 with the surface microstructure is placed at the focal point of the concave mirror 4 . The metal surface 311 of the surface microstructure silicon cantilever 3 and the end face 51 of the optical fiber 5 form a Fab cavity, the continuous laser 7 is connected with the fiber coupler 6 through the optical fiber 10, the fiber coupler 6 is connected with the optical fiber 5, and the photodetector 8 It is connected with the optical fiber coupler 6 by an optical fiber 11, and the photodetector receives the optical signal and converts it into an electrical signal. The output end of the photodetector 8 is electrically connected to the input end of the signal processing system 9,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com