Force sensing device based on microelectromechanical system

A technology of micro-electromechanical systems and devices, applied in the field of force-sensitive devices, can solve problems such as fragile wires and thin strips, complex device structures, and complicated preparation processes, and achieve the effects of improving sensitivity, good repeatability, and improving SI effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

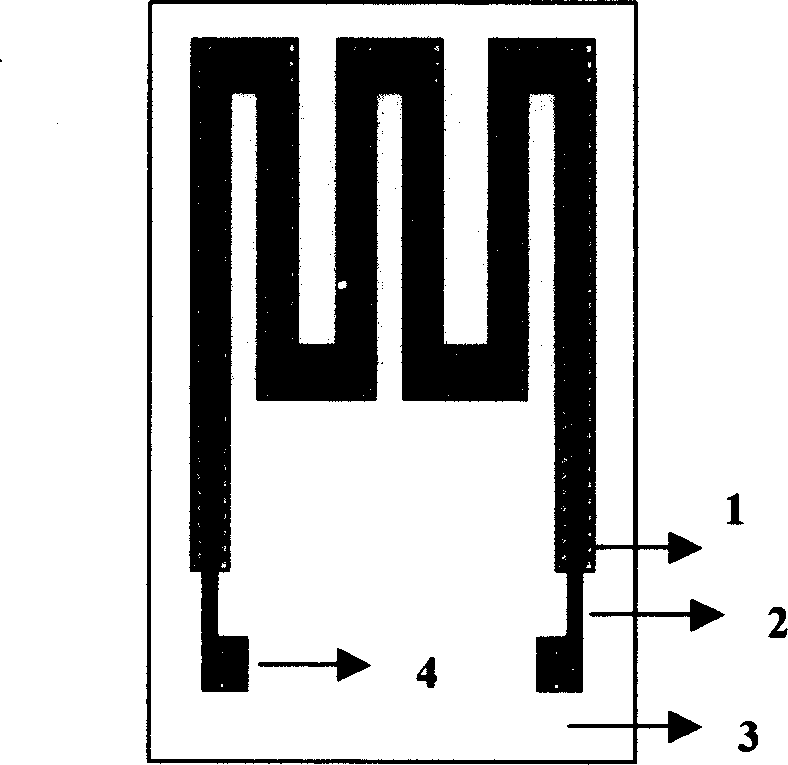

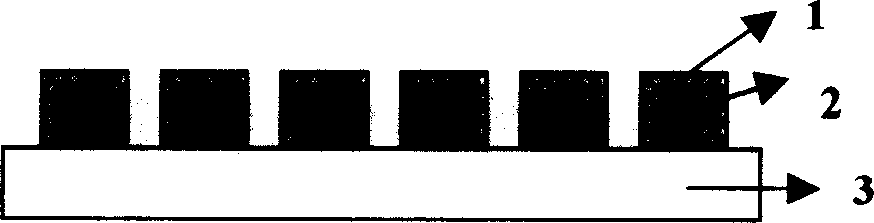

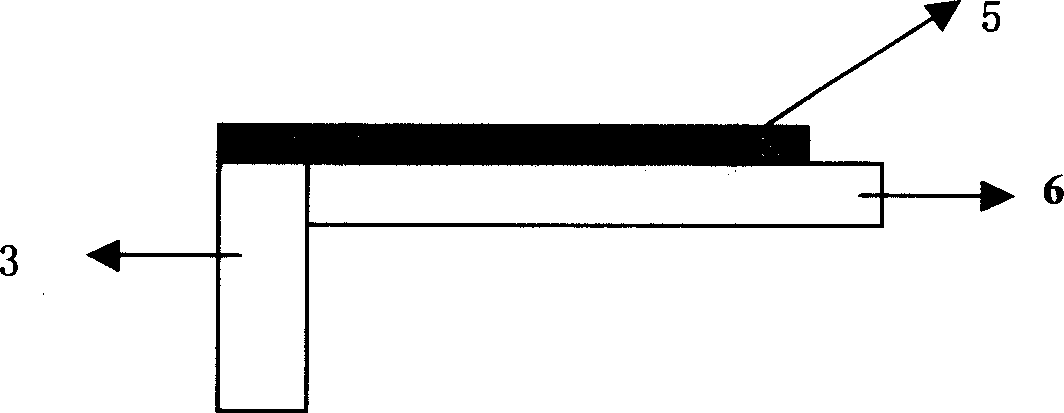

[0026] Such as Figure 1-3 As shown, the present invention is made up of silicon substrate 3, pin 4, zigzagging sandwich structure soft magnetic multilayer film 5 and silicon cantilever beam 6, and pin 4 is drawn from the copper layer 2 at both ends of the force sensitive device, and is arranged on the band SiO 2 On the silicon cantilever beam 6 of the first layer, the soft magnetic multilayer film 5 with a zigzag sandwich structure is located on the silicon cantilever beam 6 , and the silicon cantilever beam 6 is connected with the silicon substrate 3 .

[0027] The meandering sandwich soft magnetic multilayer film 5 is a meandering sandwich structure consisting of a copper layer 2 in the middle and a FeCuNbSiB thin film 1 wrapped around the copper layer 2 . The width of the copper layer 2 is smaller than that of the FeCuNbSiB thin film 1 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com