Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "Sec-Butylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sec-Butylamine is an organic chemical compound (specifically, an amine) with the formula CH₃CH₂CH(NH₂)CH₃. It is a colorless liquid. sec-Butylamine is one of the four isomeric amines of butane, the others being n-butylamine, tert-butylamine, and isobutylamine. sec-Butylamine is chiral and therefore can exist in either of two enantiomeric forms.

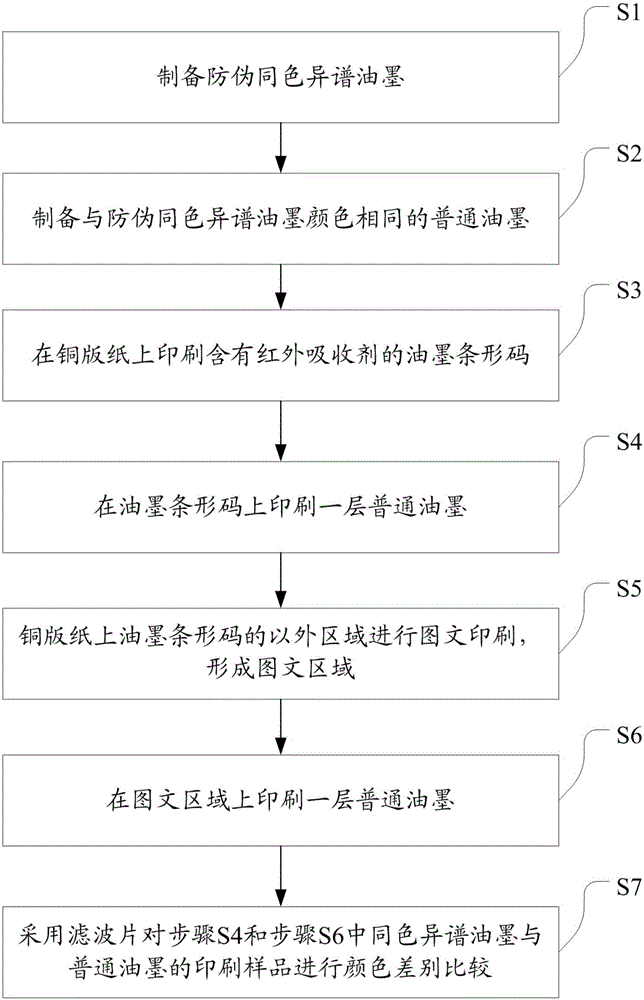

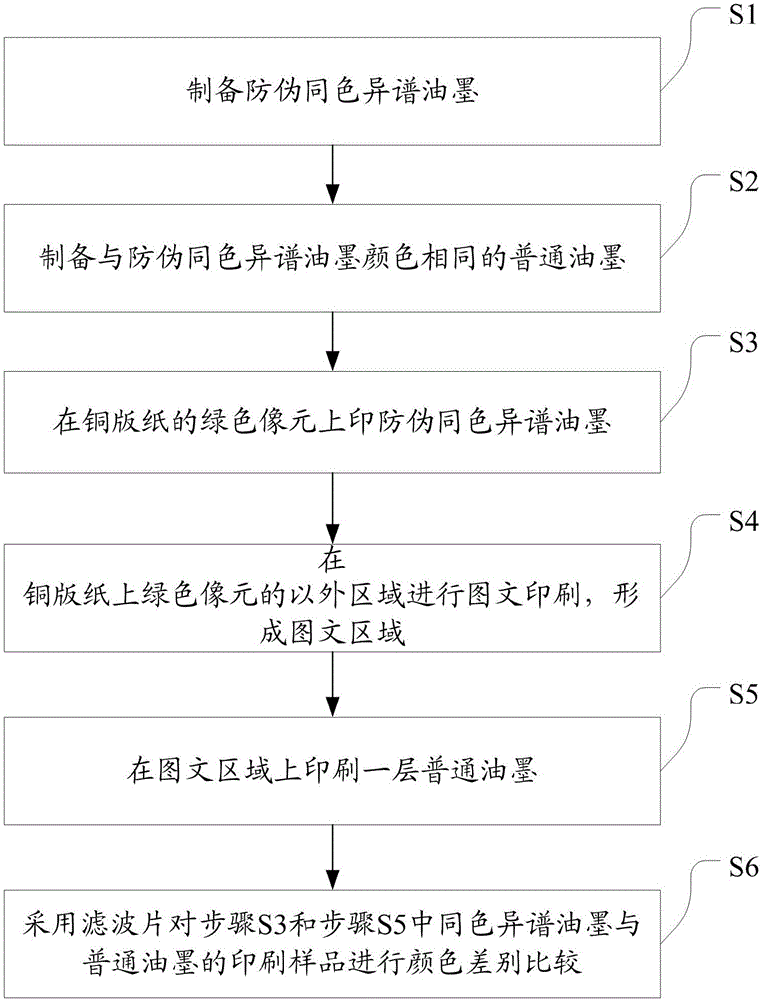

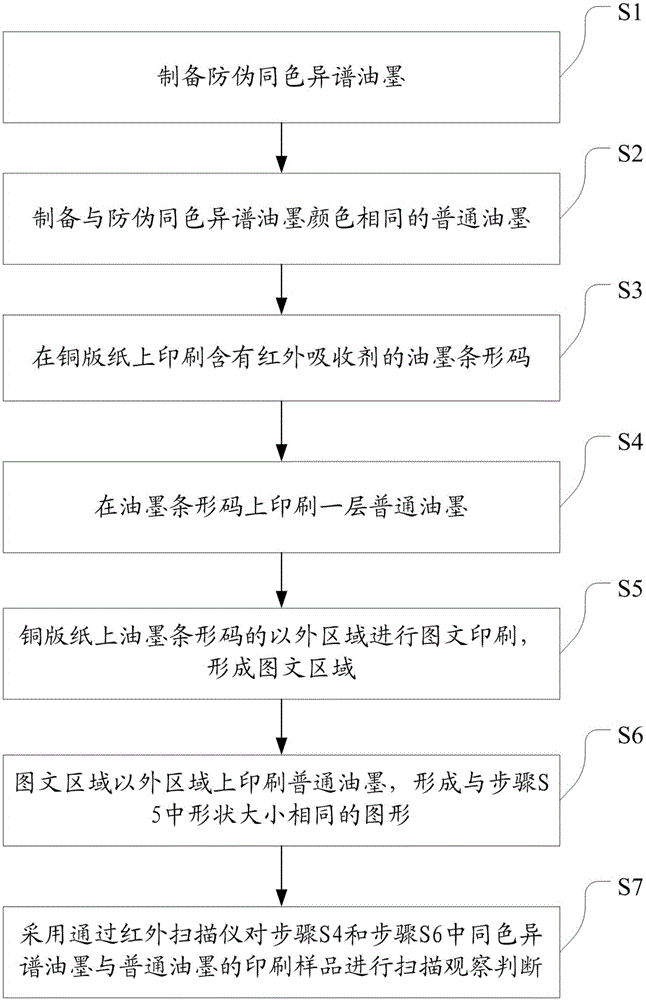

Anti-counterfeiting metamerism ink as well as preparation method and printing method of anti-counterfeiting metamerism ink

The invention discloses anti-counterfeiting metamerism ink. The anti-counterfeiting metamerism ink is prepared from 50 to 60 mass percent of metamerism pigments, 14 to 20 mass percent of silicon modified acrylate resin, 6 to 9 mass percent of butyl acrylate, 4 to 8 mass percent of epoxy resin, 2 to 3 mass percent of near-infrared absorbing agents, 3 to 5 mass percent of isopropanol, 3 to 5 mass percent of absolute ethyl alcohol, 4 to 8 mass percent of deionized water, 0.5 to 1.5 mass percent of secondary butyl amine,0.5 to 1 mass percent of terpilenol, 0.2 to 0.5 mass percent of antifoaming agents and 0.1 to 0.3 mass percent of flatting agents. The invention also discloses a preparation method of the anti-counterfeiting metamerism ink and a printing method adopting the anti-counterfeiting metamerism ink. The fusion of various anti-counterfeiting technologies in the same anti-counterfeiting region is realized; the anti-counterfeiting region shows different colors under the illumination of different light sources; the recognition is easy; the accepting degree of people on products can be improved, so that the product has multiple anti-counterfeiting performance; the anti-counterfeiting intensity is high.

Owner:永发印务(东莞)有限公司

3,4-dichlorophenyl-propenoyl-sec-butylamine composition

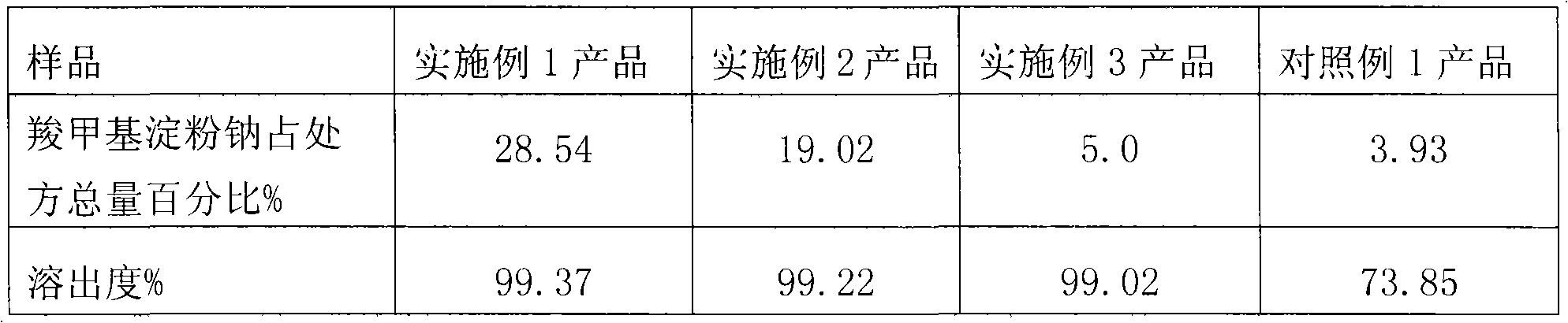

InactiveCN101991561AHigh dissolution ratePromote absorptionOrganic active ingredientsNervous disorderEpilepsySodium carboxymethyl starch

The invention relates to a 3,4-dichlorophenyl-propenoyl-sec-butylamine composition for treating epilepsy. The 3,4-dichlorophenyl-propenoyl-sec-butylamine composition is characterized by containing 3,4-dichlorophenyl-propenoyl-sec-butylamine and sodium carboxymethyl starch. The 3,4-dichlorophenyl-propenoyl-sec-butylamine and the sodium carboxymethyl starch are reasonably compounded, thereby increasing the dissolution rate of the pharmaceutical composition.

Owner:DISHA PHARMA GRP

Catalyst for preparing sec-butylamine through catalyzing, aminating and hydrogenizing butanone, and preparaation method

InactiveCN1795986AHigh activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureKetone

The invention relates to a catalyst for preparing secondary bulylamine by making methyl ethyl ketone undergo the process of catalytic ammoniation and hydrogenation and its preparation method. Said catalyst carrier is Al2O3-TiO2 composite oxide, its active component is formed from 10-25 wt% of NiO and 1-10 wt% of two kinds of CuO, Cr2O3, MgO and BaO. Said catalyst is prepared by adopting impregnation method. Said catalyst uses industrial methyl ethyl ketone, liquid ammonia and hydrogen gas as raw material, the mole ratio of methyl ethyl ketone, liquid ammonia and hydrogen gas is 1:1.2:1.2, under the condition of normal pressure and reaction temperature with 170-200deg.C the methyl ethyl ketone conversion rate can be up to 30-42% and the selectivity can be up to 70-97%.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for removing hyocholic acid from chenodeoxycholic acid

The invention discloses a method for removing hyocholic acid from chenodeoxycholic acid. The method comprises the steps of dissolving, residue removing, complexing, crystallizing, centrifugal separating, emulsifying, acidifying, drying, mother liquor treating and the like; high-boiling-point butyl acetate is utilized as solvent, volatilization of the solvent is reduced, a good separation effect is achieved by utilizing the unique dissolution property of butyl acetate to impurities, and the solvent belongs to a three-level low-toxicity dangerous chemical; the selective complexing characteristic of sec-butylamine to bile acid is utilized, and the hyocholic acid and other impurities can be separated to a higher degree. According to the separation and purification method, impurity removing is qualified in one time, the loss rate of the chenodeoxycholic acid is 5% or below and is greatly lower than the effective ingredient loss of 30% in a conventional crystallization method, the solvent can be recycled, three wastes are not generated, and the method is an environment-friendly, low-cost and efficient separation method.

Owner:CHANGDE YUNGANG BIOTECHNOLOGY CO LTD

Method for preparing sec-butylamine

InactiveCN1775736AMild reaction conditionsGood effectOrganic compound preparationAmino compound preparationFixed bedReaction temperature

The invention relates to a method for preparing sec-butyl amine by continuous fixed bed solid phase catalysis, feeding raw materials sec-butyl alcohol, ammonia and hydrongen into a fixed bed reactor in the molar concentration of 1 to (1-5) to (2-6), and producing the sec-butyl amine by reacting under the action of catalyst, at temperature 110-180 deg.C, at pressure 1.0-2.0 MPa, and at airspeed 0.2-0.6h-1, where sec-butyl amine per ton consumes 0.4kg of catalyst. The effects of the invention: the invention uses Al and Ba containing denatured cobalt as catalyst and the sec-butyl alcohol conversion is up to 100%, and the sec-butyl amine yield can be up to 98.5%, higher than that of each of methyl alcohol aminating method and butylenes aminating method.

Owner:ZHEJIANG JIANYE CHEM

Multi-component fresh-keeping formula and fresh-keeping method of sweet persimmons at room temperature

InactiveCN106720279AMetabolic Balance and RegulationAvoid mutual interferenceFruits/vegetable preservation by coatingSodium diacetateGibberellin

The invention relates to a multi-component fresh-keeping formula and a fresh-keeping method of sweet persimmons at room temperature, and belongs to the technical field of persimmon preservation. The multi-component fresh-keeping formula comprises the following raw materials: gibberellin, sodium diacetate, ethanol, a honeysuckle extract, a forsythia extract, a clove extract, a radix stemonae extract, a persimmon leaf extract, a licorice root extract and pure water; 1-methyl cyclopropylene, sec-butylamine, sodium hydroxide and water; chitosan, pectin, potassium permanganate, ethanol, kojic acid, sodium D-isoascorbate, vitamin E, proanthocyanidins and water; and reduced iron powder, granular activated carbon, potassium permanganate, sodium D-isoascorbate, calcium peroxide and sodium polyacrylate. The formula provided by the invention is reasonable in design, the nutrition and taste of the sweet persimmons are maximized, and the fresh-keeping effect is good.

Owner:范长山

Method for preparing sec-butylamine through methyl ethyl ketone catalytic ammonization hydrogenation

InactiveCN102898312AReduce loadSimple preparation processPreparation by reductive alkylationSec-ButanolHydrogenation reaction

The invention relates to a method for preparing sec-butylamine through methyl ethyl ketone catalytic ammonization hydrogenation. According to the invention, a tubular reactor is adopted; methyl ethyl ketone is adopted as a raw material; under the existence of a catalyst containing Ni and Cu or Cr or Zn or Fe, and under the condition that a methyl ethyl ketone volume space velocity is 0.3-2.5h<-1>, methyl ethyl ketone, hydrogen gas and ammonia gas are simultaneously delivered from the upper end of the reactor according to a molar ratio of 1:1-10:1-10; and a methyl ethyl ketone continuous ammonization hydrogenation reaction is carried out under a temperature of 80-160 DEG C and a normal pressure, such that sec-butylamine can be obtained by continuous preparation. According to the invention, a preparation process of the catalyst is simple, a metal load is low, and a catalytic activity is high; the reaction conditions are mild, and high-yield sec-butylamine can be obtained under normal pressure; and only trace sec-butanol and di-sec-butylamine by-products are produced. The volume space velocity of methyl ethyl ketone is high, the process is simple, and continuous production can be carried out, such that production cost is reduced, and the method is suitable for industrialization and popularization. A conversion rate of methyl ethyl ketone can reach 90-100%, and sec-butylamine selectivity is higher than 90%.

Owner:泰州石油化工有限责任公司

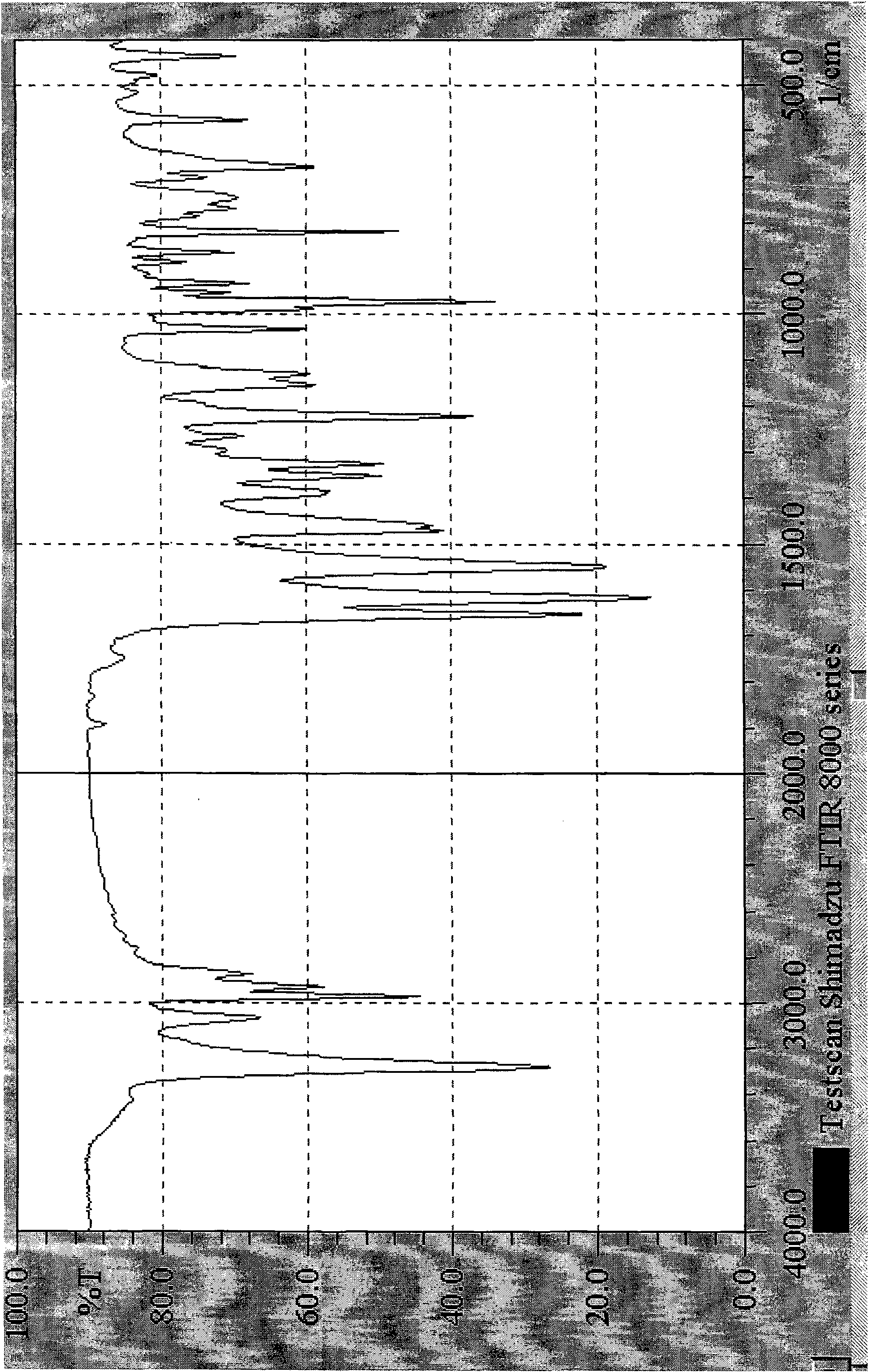

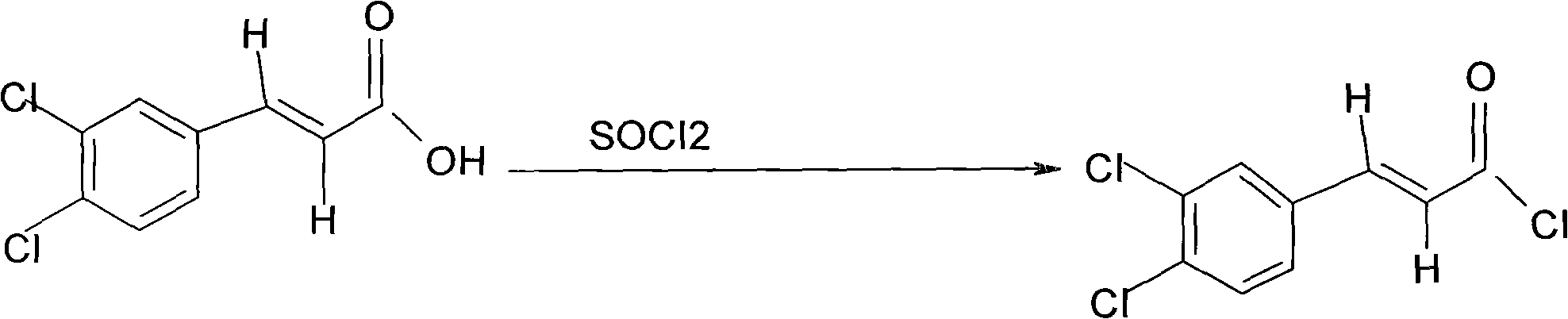

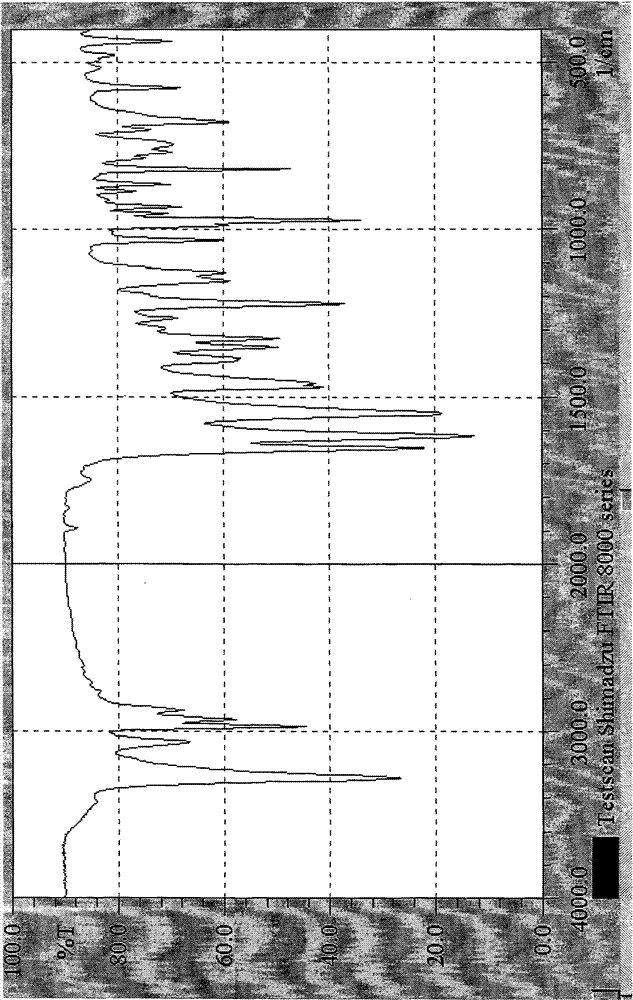

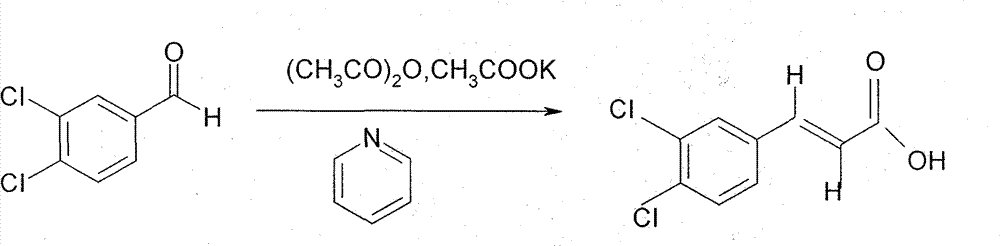

Preparation method of chlocibutamine

InactiveCN101838216AOrganic compound preparationCarboxylic acid amides preparationAcetic anhydridePotassium acetate

The invention relates a preparation method of chlocibutamine, which is characterized by comprising the following steps: 1. reacting 3, 4-dichlorobenzaldehyde serving as a starting material with acetic anhydride and potassium acetate to obtain 3, 4-dichlorobenzene crylic acid; 2. reacting the 3, 4-dichlorobenzene crylic acid with thionyl chloride to obtain 3, 4-dichorophenyl acryloyl chloride; and 3. reacting the 3, 4-dichorophenyl acryloyl chloride with sec-butylamine to obtain the chlocibutamine.

Owner:WEIHAI DISU PHARMA CO LTD +1

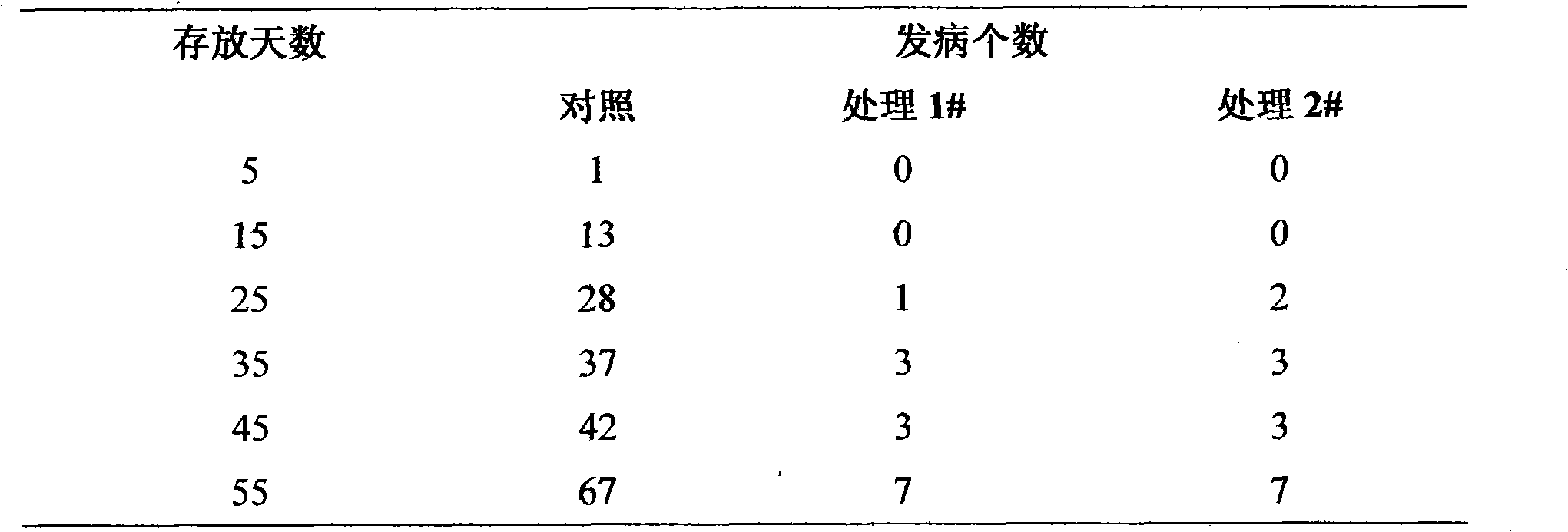

Composite storage and transportation antistaling agent for persimmons

InactiveCN102334540AEasy to useOperational usage reductionFruit and vegetables preservationThiophanate-methylPotassium

Provided is a composite storage and transportation antistaling agent for persimmons. According to the invention, main reagents of the antistaling agent are sec-butylamine, thiophanate methyl and natamycin, and a main reinforced component of the antistaling agent is one or more selected from the group consisting of trichloroisocyanuric acid, sodium trichlorisocyanurate, potassium trichlorisocyanurate, dichloroisocyanuric acid, sodium dichlorisocyanurate, potassium dichlorisocyanurate, sodium chlorite and potassium chlorite; the main reagents and the main reinforced component are evenly mixed according to a certain weight ratio; when used, the antistaling agent is diluted as required and is used to wash or dip persimmons. The antistaling agent for persimmons has the characteristics of a simple fabrication process, low cost, a little investment and convenient usage. The antistaling agent is applicable to short term storage and transportation of persimmons at normal temperature and to long term preservation of persimmons at low temperature, enables rot of fruit stalks of persimmons in the process of storage and transportation to be reduced, the senescence of persimmons to be delayed, original quality of persimmons to be retained, etc., and has the advantages of safety, high efficiency, a long storage period and a good preserving effect.

Owner:天津市食品加工工程中心

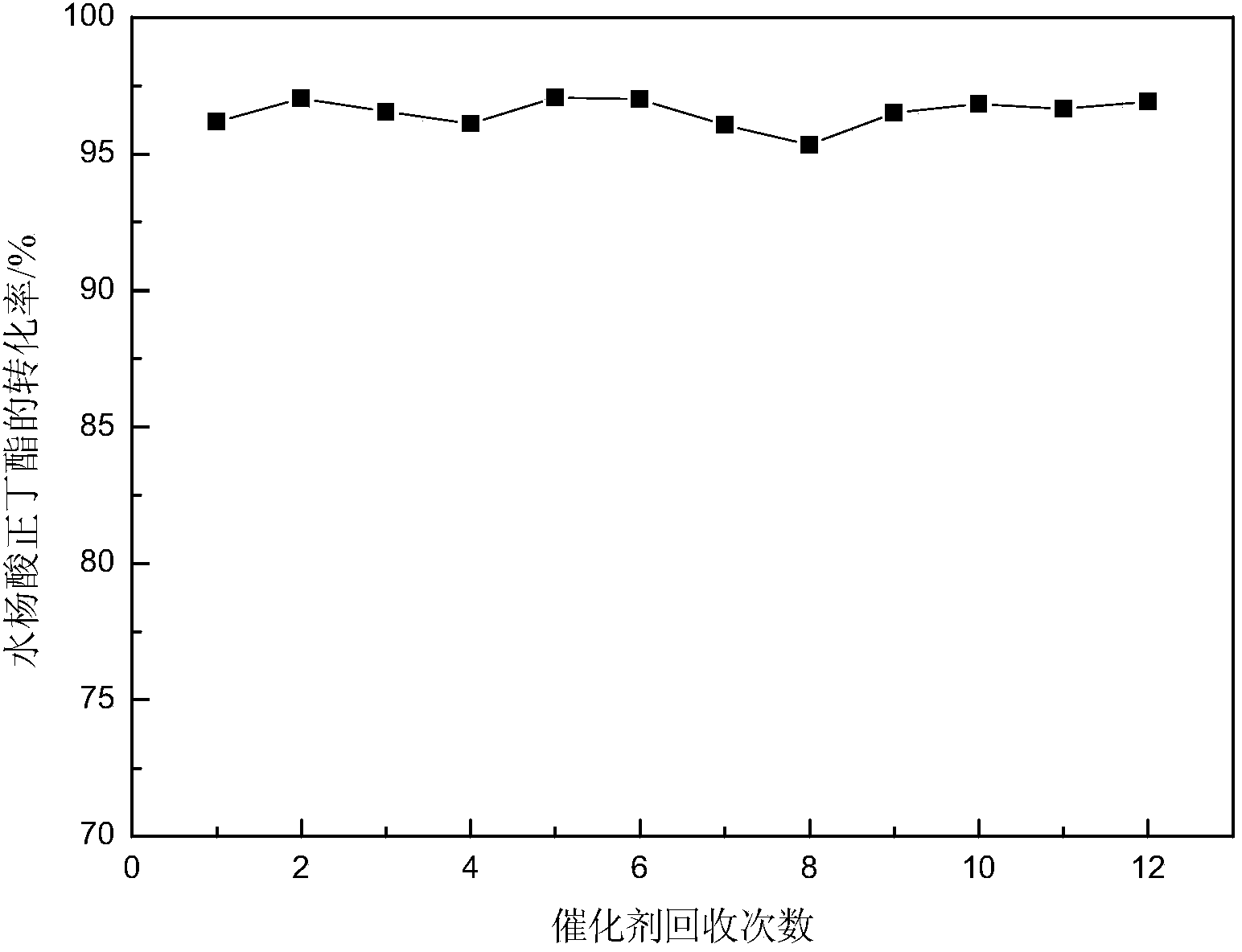

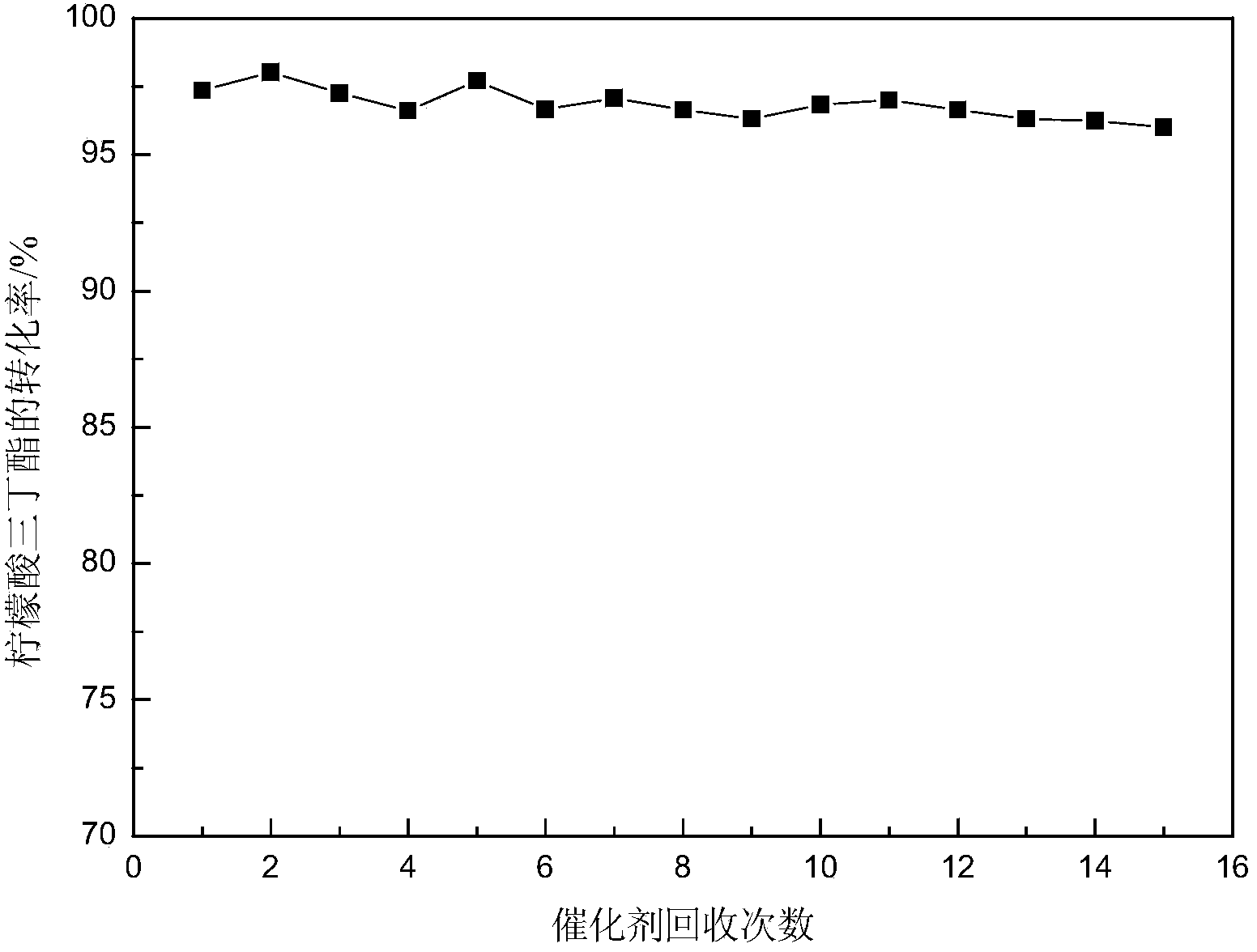

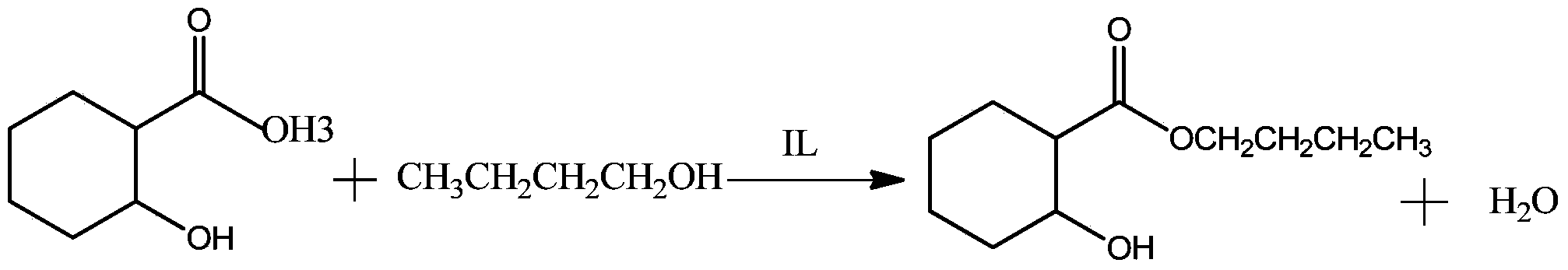

Method for catalyzed synthesis of n-butyl salicylate and tributyl citrate by di-sec-butylamine acidic ionic liquids

InactiveCN103880677AExpensive to fixAvoid adverse effects of colorOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen SulfateButyl salicylate

The technical scheme adopted by the invention is as follows: the invention discloses a method for catalyzed synthesis of n-butyl salicylate and tributyl citrate by di-sec-butylamine acidic ionic liquids, and a structural formula of the ionic liquids is as shown in the specification, wherein Y is hydrogen sulfate radical or p-toluenesulfonic acid radical. The invention develops novel varieties of acidic ion liquids, wherein the novel acidic ion liquids are dual-core high-piperidine structures which are very stable; thermal decomposition points of two ionic liquids according to a thermogravimetric analysis test are over 340 DEG C; the stability of the novel two ionic liquids is higher than that of most of ionic liquids; the two ionic liquids have stronger acidity, and the PH values are stronger than that of sulfuric acid under the same concentration. According to the invention, two ionic liquids are developed and utilized as acidic catalysts for respectively synthesizing n-butyl salicylate and tributyl citrate in a catalytic manner, so that the conversion rate of about 96% can be obtained, and ionic liquids can be recycled; compared with the normal method, the conversation rate of the n-butyl salicylate in the method disclosed by the invention is greatly improved.

Owner:CHANGZHOU UNIV

Modified polycarbodiimide compound, curing agent, and thermosetting resin composition

ActiveUS20180094095A1Curing be suppressPrevent curingPolyurea/polyurethane coatingsEpoxy2,6-Dimethylpiperidine

The modified polycarbodiimide compound of the present invention is obtained by modifying a polycarbodiimide compound derived from a diisocyanate compound with at least one aliphatic amine selected from the group consisting of diethylamine, methylisopropylamine, tert-butylethylamine, di-sec-butylamine, dicyclohexylamine, 2-methylpiperidine and 2,6-dimethylpiperidine. The curing agent of the present invention comprises the modified polycarbodiimide compound of the present invention. The thermosetting resin composition of the present invention comprises a carboxyl group-containing resin having a carboxyl group in a molecule or an epoxy resin having two or more epoxy groups in one molecule, and the curing agent of the present invention. Thus, a modified polycarbodiimide compound that can allow a resin composition to be cured at a relatively low temperature and that can suppress curing of a resin composition in a drying step before a thermal curing step of a resin composition, a curing agent comprising the modified polycarbodiimide compound, and a thermosetting resin composition comprising the curing agent can be provided.

Owner:NISSHINBO CHEM

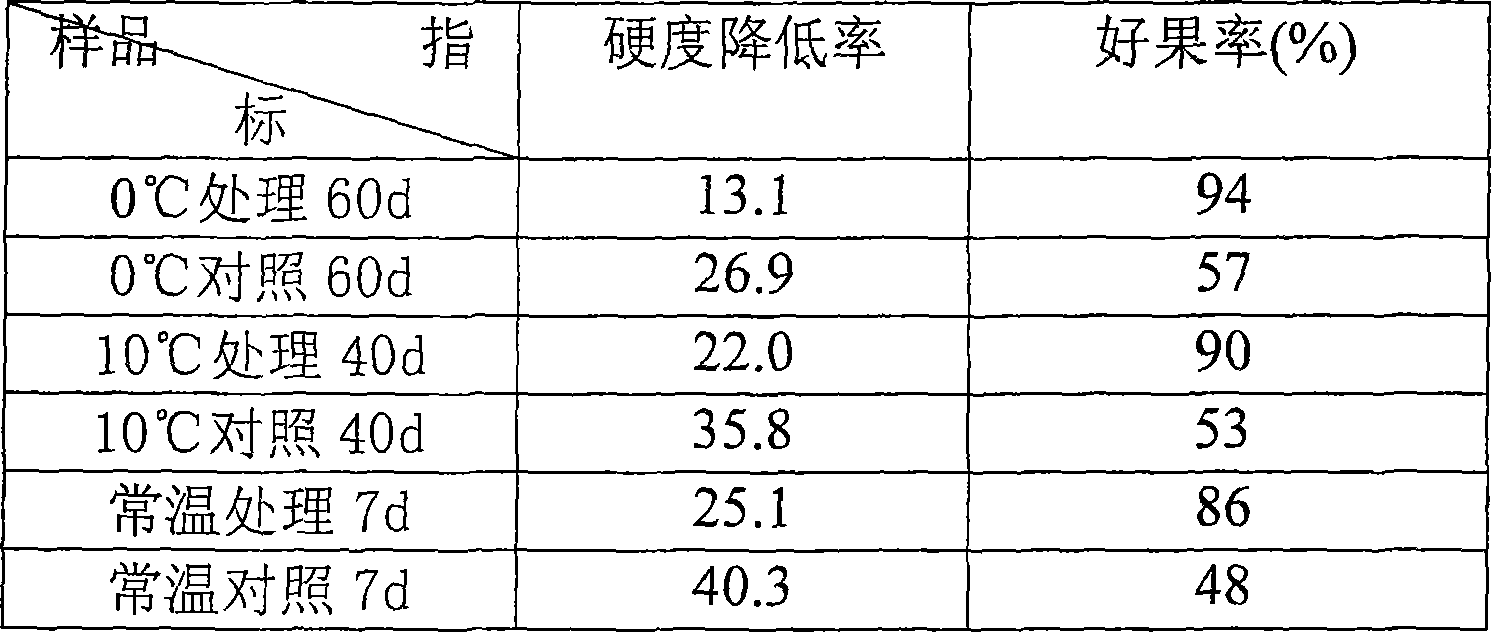

Fumigation type drupe fruit antistaling agent

InactiveCN101502280AEasy to useRemarkable anti-mold and fresh-keeping effectFruit and vegetables preservationScavengerAdditive ingredient

A fumigation type stone fruit type fruit preservative is composed of the following four functional components: (1) highly effective ethylene antagonist, (2) ethylene absorbing-oxidization scavenger, (3) microencapsulated pyrosulfite mould inhibitor, and (4) 601f sec-butylamine liquid mould inhibitor. The fumigation absorbent is prepared through the following steps: enclosing the component (1) and component (4) into a small package A according to a standard proportion, wherein firstly enclosing the component (4) into a phial with a standard of 4ml / p and then enclosing the small package A; and enclosing the component (2) and component (3) into a small package B. The sealing strips on the packages (A) and (B) are respectively eliminated in using. The phial of mould inhibitor (4) in the package A is slightly broken for mixing and contacting the component (1) and component (4). The modified atmosphere storage period of honey beach which is processed with the method for keeping fresh are respectively 60 days, 40 days and 7 days in the conditions of 0 DEG C, 10 DEG C and normal temperature (about 20 DEG C). The good fruit rates are respectively 94%, 90% and 86% at the three conditions.

Owner:天津市食品加工工程中心

Synthetic method for secondary butylamine

ActiveCN1900048AHigh purityMild reaction conditionsPreparation by reductive alkylationRaney catalystsHydrogenButanone

The process of synthesizing secondary butylamine includes the reduction reaction of butanone oxime and hydrogen under the action of ammonia at pressure of 1-6 MPa and temperature of 20-150 deg.c in the presence of Raney Ni catalyst; and the dewatering and rectification of the reaction product. The Raney Ni catalyst amount is 0.28-10 wt% of butanone oxime, and the weight ratio between ammonia and butanone oxime is 0-2 to 1. The secondary butylamine synthesizing process has low cost and high yield.

Owner:ZHEJIANG JIANYE CHEM

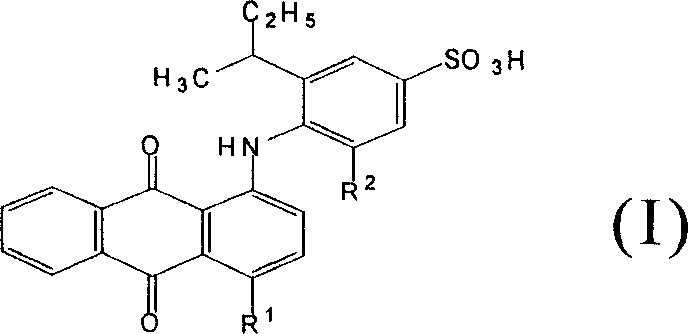

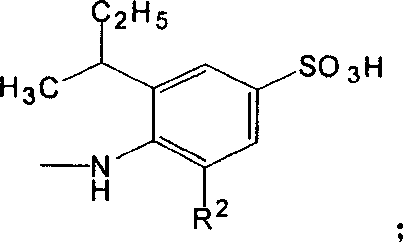

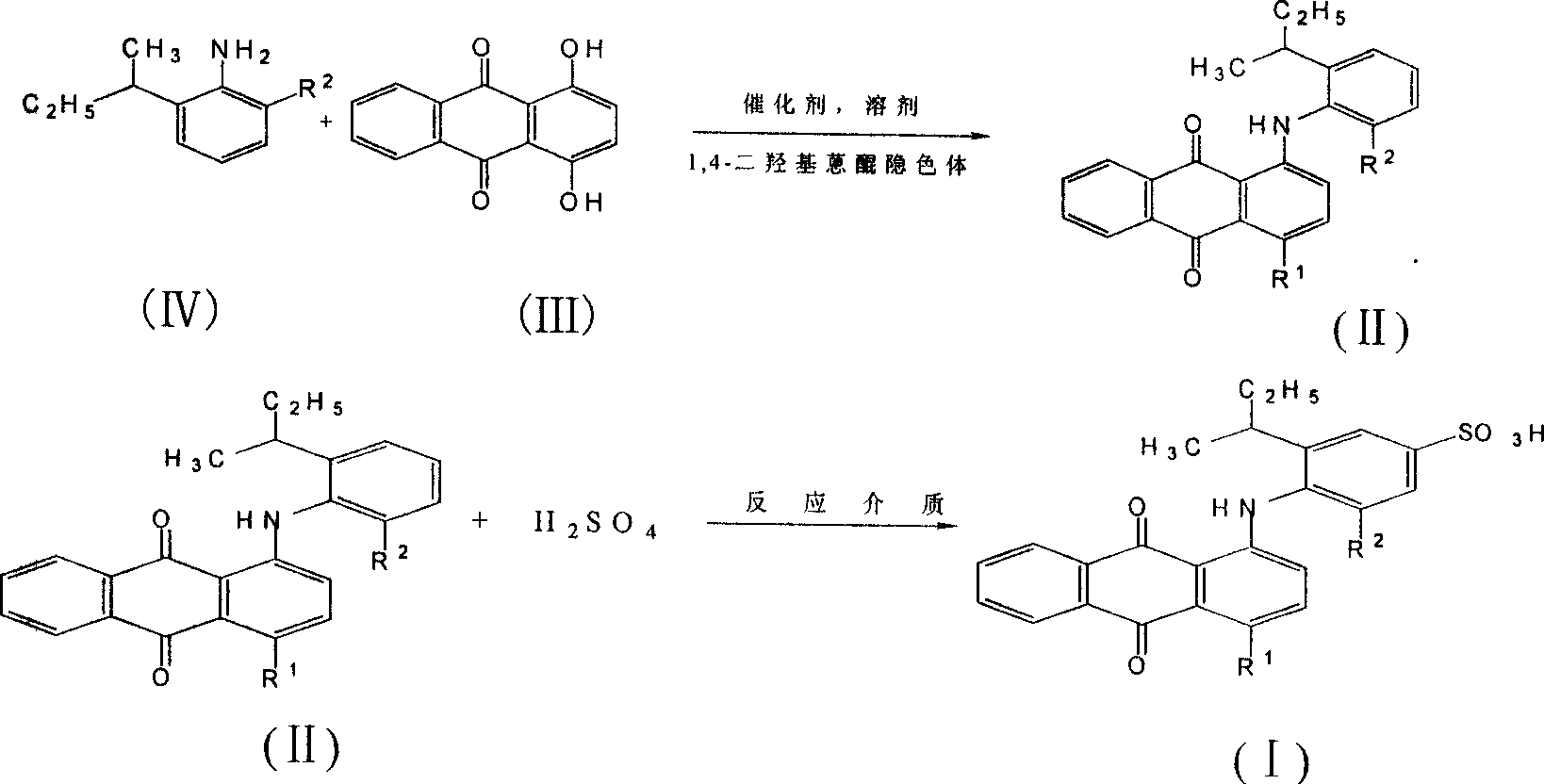

Acid anthraquinone dye and its prepn and application

InactiveCN101089050AImprove dyeing effectHigh fastnessDyeing processAmino-hydroxy-anthraquinone dyesSolventAcid dye

The present invention belongs to the field of dye technology, and is especially one kind of acid anthraquinone dye and its preparation process and application. The acid anthraquinone dye in the structure as shown is prepared through extracting 2-ethyl-6-sec-butylamine or 2-methyl-6-sec-butylamine from waste industrial oil, condensation reaction with 1, 4-dihydroxy anthraquinone, and sulfonating in a solvent process. The acid anthraquinone dye is applied in dyeing wool and wool fabric to obtain glow blue or bright purple, and has fastness performance similar to available acid anthraquinone dye.

Owner:SHENYANG RES INST OF CHEM IND +1

Method for separating sec-butylamine

ActiveCN101648874AImprove qualityTake advantage ofAmino compound purification/separationOrganic compound preparationOil phaseSec-butyl alcohol

The invention discloses a method for continuously separating sec-butylamine, comprising the following steps: separating a mixture containing sec-butyl alcohol, sec-butylamine, water and di-sec-butylamine in a sec-butylamine separating tower, collecting the sec-butylamine product from the top of the tower, separating oil and water in a mixture containing the water, the sec-butyl alcohol and the di-sec-butylamine in a phase separator from a tower bottom, and then separating an upper oil phase in the middle part of an azeotrope tower, collecting the sec-butyl alcohol and a little sec-butylamine from the top of the tower, returning to a synthetic reaction system for recycle, after separating the mixture containing the water and the di-sec-butylamine in the middle of the di-sec-butylamine tower, collecting the water from the top of the tower to be discharged in standard, collecting the qualified di-sec-butylamine products from the tower bottom; getting the lower water phase of the phase separator into the middle of a recycling tower, through separating, collecting a little sec-butyl alcohol from the top of the tower to return to the synthetic reaction system for recycle, and dischargingthe water from the bottom of the tower in standard. The invention has advantages that the process of separating the sec-butylamine is simple, the consumption of the energy and raw materials is low and the production cost is low.

Owner:ZHEJIANG XINHUA CHEM

Synthetic method for secondary butylamine

ActiveCN100384812CHigh purityMild reaction conditionsPreparation by reductive alkylationRaney catalystsHydrogenButanone

The process of synthesizing secondary butylamine includes the reduction reaction of butanone oxime and hydrogen under the action of ammonia at pressure of 1-6 MPa and temperature of 20-150 deg.c in the presence of Raney Ni catalyst; and the dewatering and rectification of the reaction product. The Raney Ni catalyst amount is 0.28-10 wt% of butanone oxime, and the weight ratio between ammonia and butanone oxime is 0-2 to 1. The secondary butylamine synthesizing process has low cost and high yield.

Owner:ZHEJIANG JIANYE CHEM

Method for continuously preparing di-sec-butylamine

ActiveCN101648875AReduce consumptionSimple processPreparation by reductive alkylationChemical recyclingChemical synthesisHydrogen

The invention discloses a chemical synthesizing method, in particular a method for continuously preparing di-sec-butylamine using butanone as a raw material. In the invention, the butanone is used asthe raw material, and the butanone is pumped into a pre-heater to mix with ammonia and hydrogen to preheat and evaporate; Ni-Cu / gamma-Al2O3-diatomite is used as a catalyst, the temperature with a certain pressure is controlled, after reaction, the materials are condensed and cooled to separate gas and liquid, the gas phase enters a reactor by circulating to be used repeatedly; the liquid phase enters a rectifying tower to separate and purify the di-sec-butylamine to obtain the product; the separated ammonia, butanone and sec-butylamine return to a feeding system and enter the reactor to reactwith the supplementary hydrogen, the ammonia and the butanone. The invention has advantages of simple process, high conversion rate, good selectivity, simple process of separating, low consumption ofenergy and raw materials and low production cost.

Owner:ZHEJIANG XINHUA CHEM

Catalyst for preparing sec-butylamine through catalyzing, aminating and hydrogenizing butanone, and preparaation method

InactiveCN100342967CHigh activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystReaction temperature

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

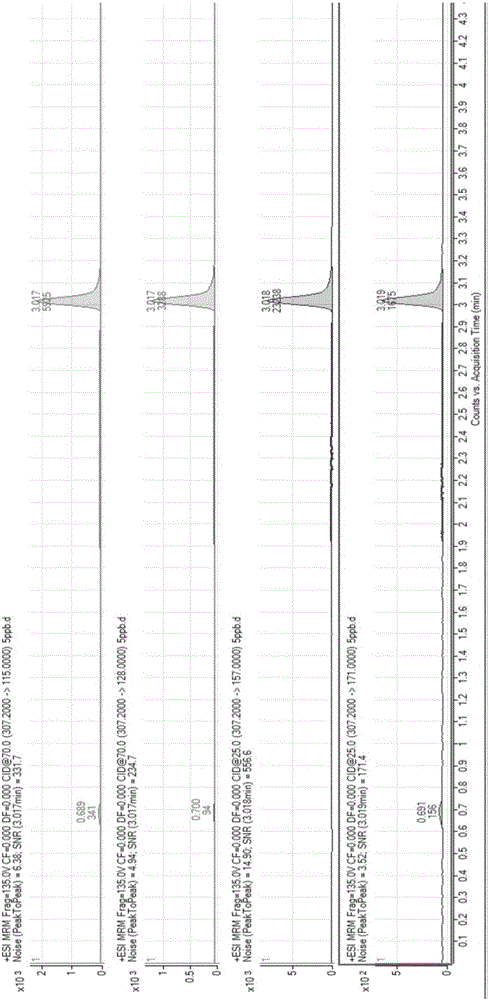

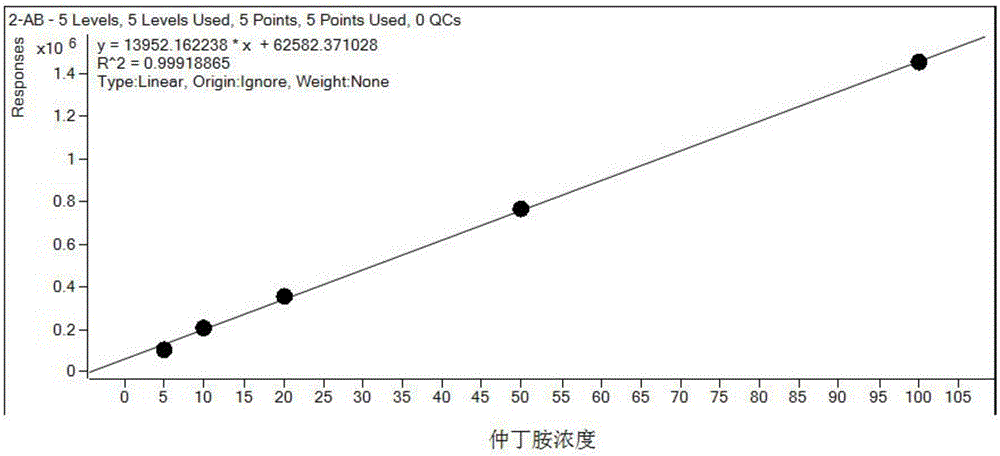

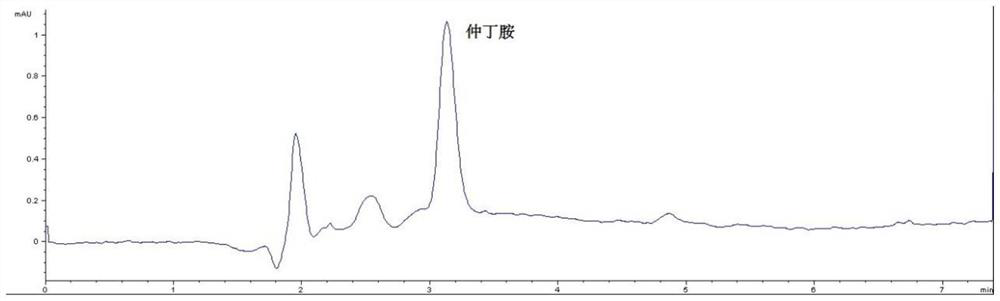

Method for detecting sec-butylamine residue and application of method

ActiveCN106645476AEasy to purifyLow recovery rateComponent separationDansyl chlorideMaterial consumption

The invention discloses a method for detecting sec-butylamine residue and belongs to the technical field of medicine detection. The method comprises: using methanol solution to extract sec-butylamine in a sample, subjecting carbonate buffer solution and dansyl chloride acetone solution to derivatization, and detecting with high-performance liquid chromatography-tandem mass spectrometry apparatus; the methanol has a concentration of 80%. The method has the advantages that the derivatization of carbonate buffer solution and dansyl chloride acetone solution helps purify sec-butylamine; liquid-mass detection for sec-butylamine residue is reforming progress, the detection is sensitive and high in performance, and the detection limit is low; the methanol solution is used as an extracting solvent, material consumption is low, and the cost is saved.

Owner:QINGDAO HARWARS BIOLOGY GRP LTD

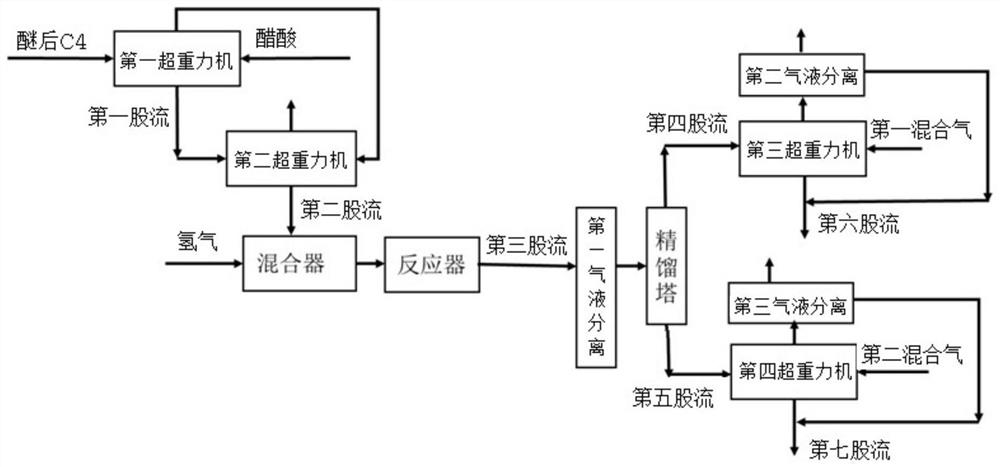

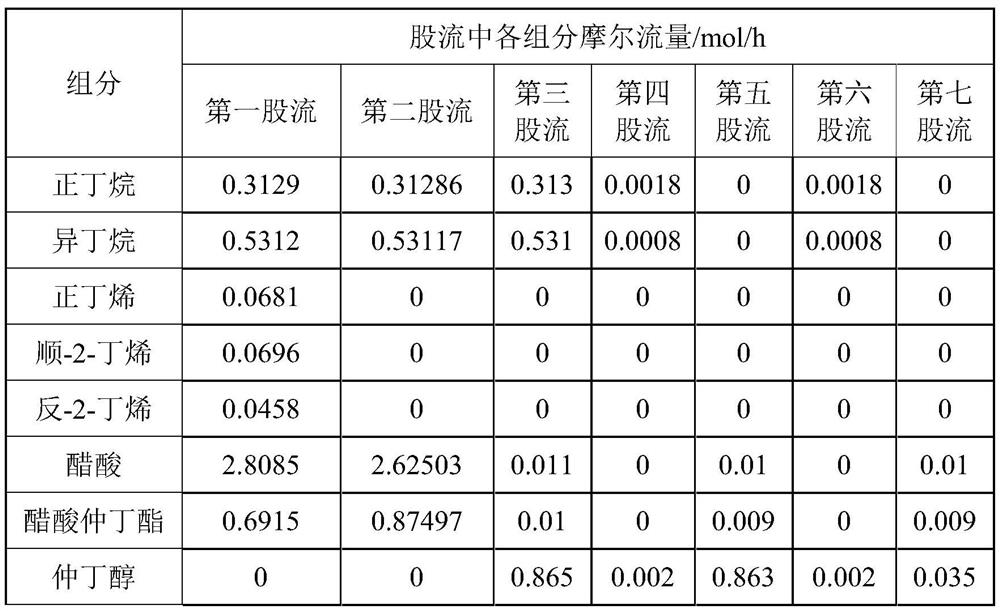

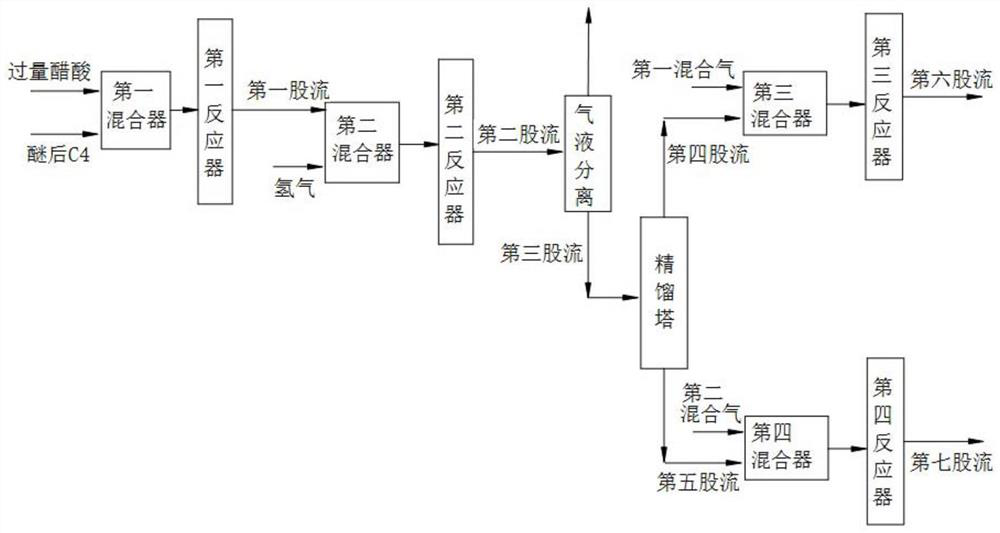

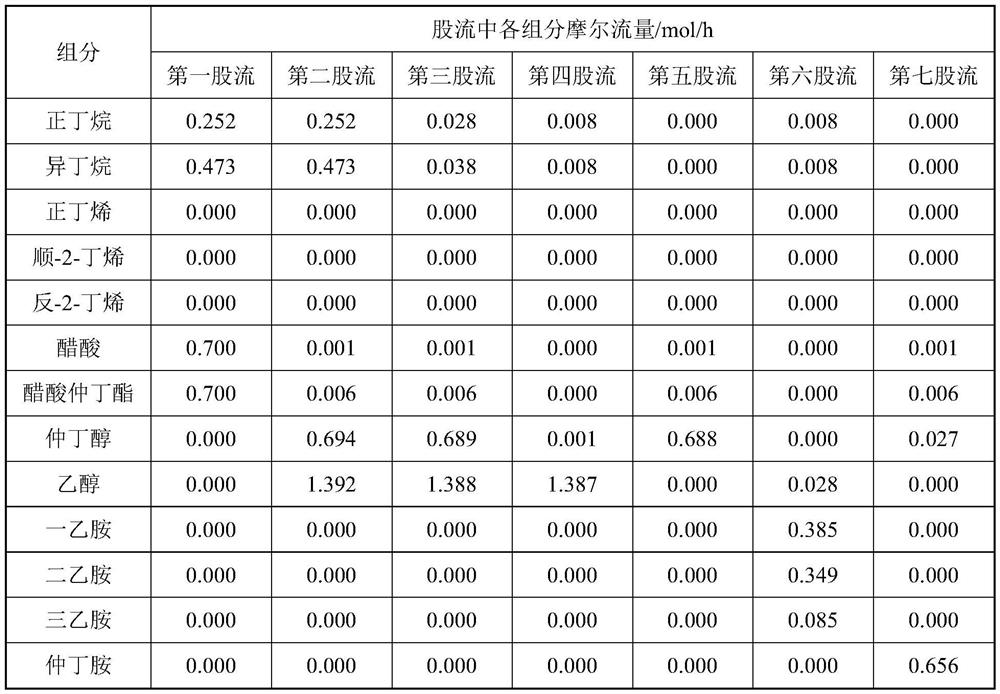

Method for co-producing monoethylamine and sec-butylamine by supergravity method

PendingCN114436850ASimple processGood social significanceOrganic compound preparationCarboxylic acid esters preparationAcetic acidHydrogenation reaction

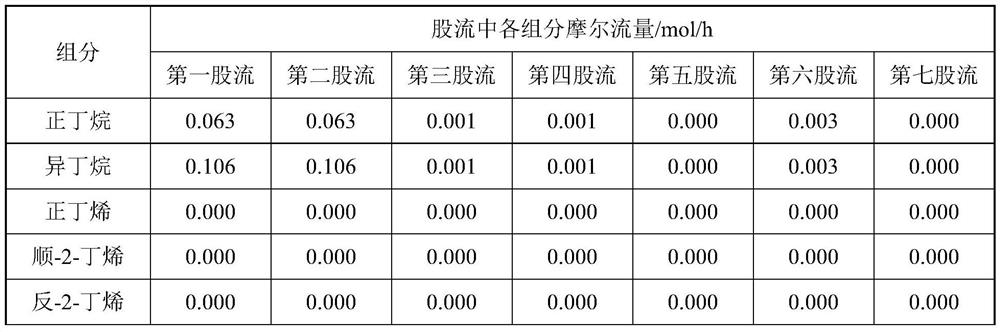

The invention belongs to the technical field of chemical engineering, and relates to a method for co-producing monoethylamine and sec-butylamine by a supergravity method. Comprising the following steps: carrying out first reaction on acetic acid and etherified C4 to obtain a first gas-phase material flow and a first stream; performing a second reaction on the first gas-phase material flow and the first stream to obtain a second gas-phase material flow and a second stream; uniformly mixing the second stream with hydrogen, and carrying out hydrogenation reaction to obtain a third stream; carrying out first gas-liquid separation and rectification on the third stream to obtain a fourth stream and a fifth stream; the fourth stream and the first mixed gas are subjected to a first hydrogen ammonification reaction, and a third gas phase stream and a sixth stream are obtained; and the fifth stream and the second mixed gas are subjected to a second hydrogen ammonification reaction to obtain a fourth gas-phase stream and a seventh stream. The method is simple in process, can be used for a high space velocity process, can be used for preparing sec-butylamine and monoethylamine with high added values from acetic acid and etherified C4 resources, has good social significance and economic benefits, is simple in process and is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for removing hyocholic acid from chenodeoxycholic acid

Owner:CHANGDE YUNGANG BIOTECHNOLOGY CO LTD

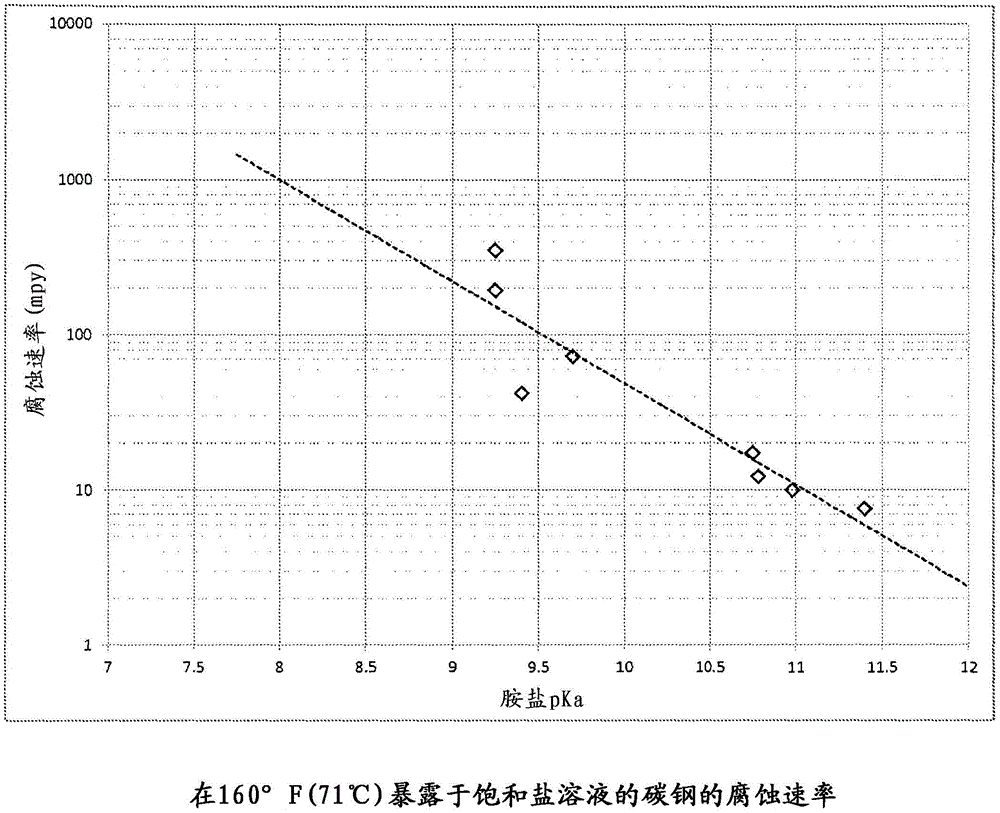

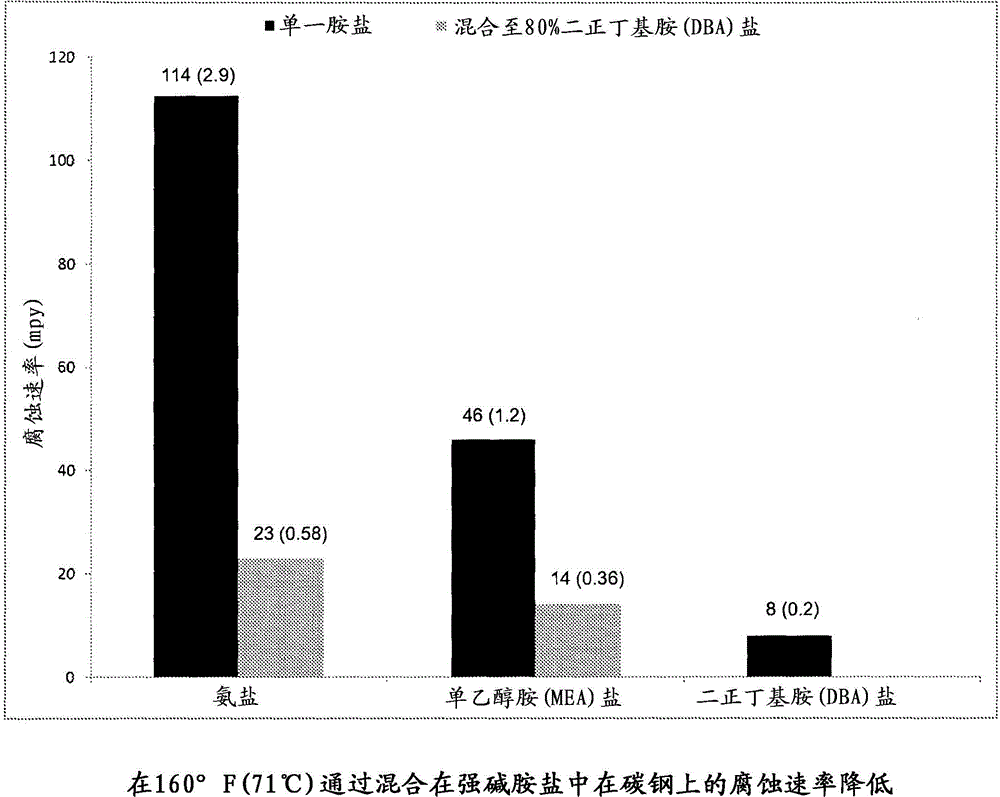

Strongly basic amines for minimizing corrosion in systems prone to corrosive salt formation

ActiveCN103228768BReduce corrosionDistillation corrosion inhibitionHydrocarbon oils refiningDistillationDipropylamine

Corrosion by ammonia / amine salts in hydrocarbon streams such as distillation overhead streams that contain a mineral acid and water can be prevented, avoided or minimized by adding certain strong amines to the streams. The amines have a pKa between about 10.5 to about 12 and include, but are not necessarily limited to, dimethylamine, diethylamine, dipropylamine, diisopropylamine, di-n-butylamine, diisobutylamine, di-sec-butylamine, di-tert-butylamine, pyrrolidine, piperidine, and combinations thereof. If the hydrocarbon stream further includes a nitrogen-containing compound such as ammonia, a tramp and / or a residual amine which can form a corrosive salt with the mineral acid, then the added amine is a stronger base than the tramp or residual amine, if present. The amount of added amine is greater than total amount of nitrogen-containing compound, so that any corrosive salts formed are less corrosive than the salts that would otherwise form from the ammonia and / or tramp amine.

Owner:BAKER HUGHES INC

Sprouting inhibition agent emulsifiable solution for white potato

InactiveCN101371660BReduce manufacturing costSimple production methodBiocidePlant growth regulatorsStearic acidPalmitic acid

The invention provides a sucker controlling agent emulsifiable concentrate of potato, and relates to a sucker controlling agent of potato. The present sucker controlling agent of potato is sprout inhibitor DEECO with high price mainly produced by United Phosphorus Limited. The invention provides the sucker controlling agent emulsifiable concentrate of potato, and the formula thereof by weight proportion is that: 20-50 portions of chlorpropham, 20-50 portions of oleic acid, 8-34 portions of palmitic acid, 5-30 portions of stearic acid, 6-25 portions of tween, 4-30 portions of span, 2-22 portions of ethanol, 2-36 portions of acetone, 6-30 portions of sec-butylamine and 4-25 portions of thiabendazole(TBZ). The invention is characterized by simple production, low cost and good sprouting inhibition effect.

Owner:甘肃省农业科学院农产品贮藏加工研究所

Method for separating sec-butylamine

ActiveCN101648874BImprove qualityTake advantage ofAmino compound purification/separationOrganic compound preparationOil phaseSec-butyl alcohol

The invention discloses a method for continuously separating sec-butylamine, comprising the following steps: separating a mixture containing sec-butyl alcohol, sec-butylamine, water and di-sec-butylamine in a sec-butylamine separating tower, collecting the sec-butylamine product from the top of the tower, separating oil and water in a mixture containing the water, the sec-butyl alcohol and the di-sec-butylamine in a phase separator from a tower bottom, and then separating an upper oil phase in the middle part of an azeotrope tower, collecting the sec-butyl alcohol and a little sec-butylamine from the top of the tower, returning to a synthetic reaction system for recycle, after separating the mixture containing the water and the di-sec-butylamine in the middle of the di-sec-butylamine tower, collecting the water from the top of the tower to be discharged in standard, collecting the qualified di-sec-butylamine products from the tower bottom; getting the lower water phase of the phase separator into the middle of a recycling tower, through separating, collecting a little sec-butyl alcohol from the top of the tower to return to the synthetic reaction system for recycle, and discharging the water from the bottom of the tower in standard. The invention has advantages that the process of separating the sec-butylamine is simple, the consumption of the energy and raw materials is low and the production cost is low.

Owner:ZHEJIANG XINHUA CHEM

Preparation method of chlocibutamine

InactiveCN101838216BOrganic compound preparationCarboxylic acid amides preparationAcetic anhydridePotassium acetate

The invention relates a preparation method of chlocibutamine, which is characterized by comprising the following steps: 1. reacting 3, 4-dichlorobenzaldehyde serving as a starting material with acetic anhydride and potassium acetate to obtain 3, 4-dichlorobenzene crylic acid; 2. reacting the 3, 4-dichlorobenzene crylic acid with thionyl chloride to obtain 3, 4-dichorophenyl acryloyl chloride; and3. reacting the 3, 4-dichorophenyl acryloyl chloride with sec-butylamine to obtain the chlocibutamine.

Owner:WEIHAI DISU PHARMA CO LTD +1

Method for co-producing ethylamine and sec-butylamine

PendingCN114436827ASolve excess capacitySolve rationalityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidHydrogenation reaction

The invention belongs to the technical field of chemical engineering, and particularly relates to a method for co-producing ethylamine and sec-butylamine. The method comprises the following steps: mixing excessive acetic acid with etherified C4, carrying out esterification reaction, mixing with hydrogen, carrying out hydrogenation reaction, and carrying out gas-liquid separation, rectification and hydrogen ammonification reaction to respectively obtain products containing ethylamine and sec-butylamine. According to the method for preparing and co-producing ethylamine and sec-butylamine provided by the invention, etherified C4 with a certain proportion is mixed into excessive acetic acid, a series of catalytic reactions are carried out, hydrogen and ammonia are sequentially added in the technological process, and finally, the acetic acid and etherified C4 are converted into ethylamine and sec-butylamine. The method for co-producing ethyl amine and sec-butylamine provided by the invention is simple in separation process, is suitable for industrial application, and can solve the phenomena of excessive acetic acid production capacity and unreasonable utilization of etherified C4 to a certain extent.

Owner:CHINA PETROLEUM & CHEM CORP +1

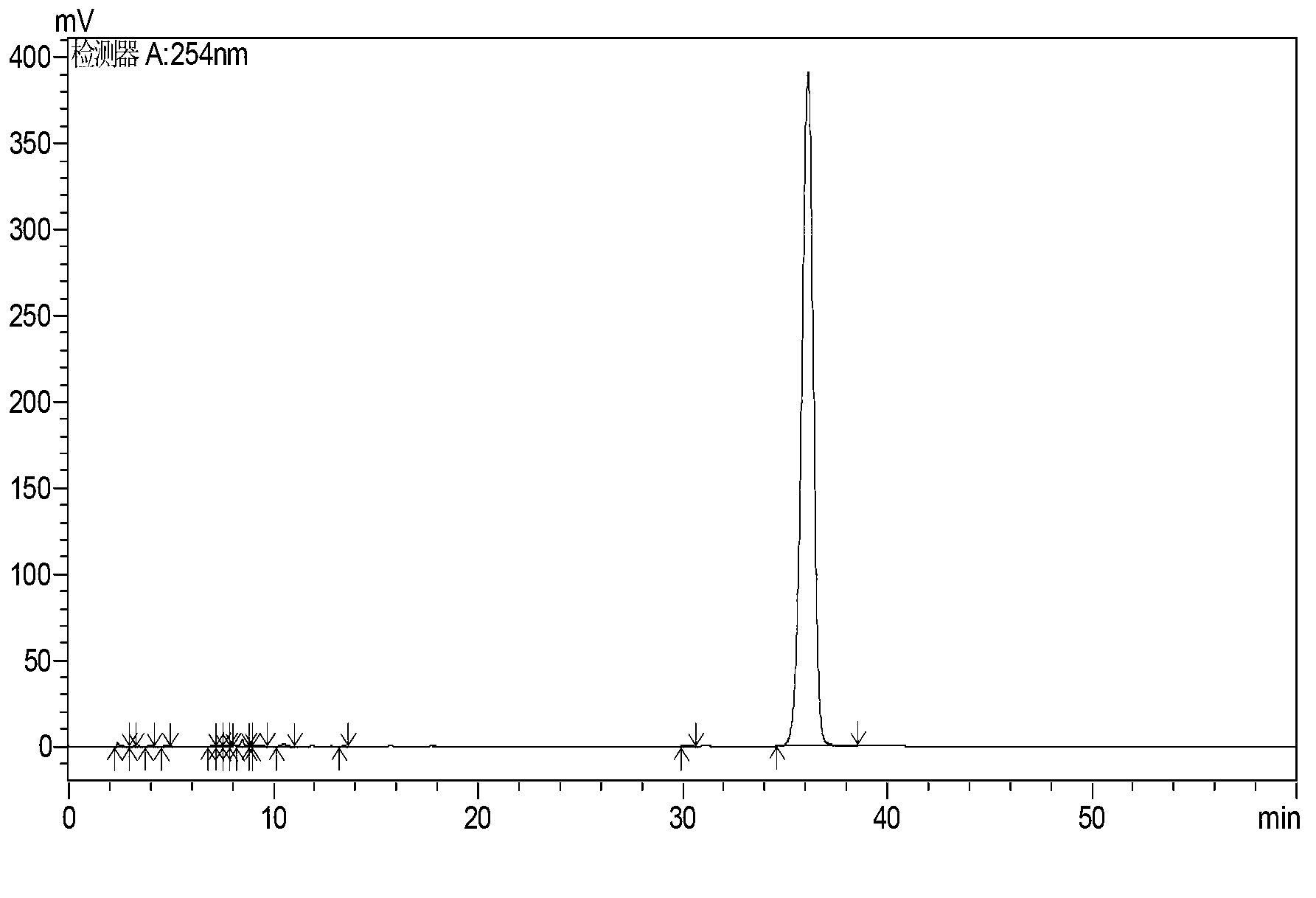

High performance liquid chromatography for measuring content of sec-butylamine

PendingCN114235991ADetermination of fitSimple and fast operationComponent separationPostcolumn derivatizationAutosampler

The invention relates to a high performance liquid chromatography method for measuring the content of sec-butylamine, and belongs to the technical field of analytical chemistry. Iodine and methanol are used for preparing a 0.01-0.05% iodine solution; the method comprises the following steps: introducing a sec-butylamine solution to be detected into a high performance liquid chromatograph through an automatic sampler, separating through a C18 chromatographic column, deriving at 60-80 DEG C by using an iodine solution at a flow rate of 0.3 ml / min, and determining at an ultraviolet wavelength of 270-330 nm. According to the present invention, the sec-butylamine content determination is achieved by using the liquid chromatography post-column derivatization method, and the method has characteristics of simple operation and low cost, and is suitable for the sec-butylamine content determination.

Owner:SHANDONG YANTAI AGRI SCI & TECH INST

Modified polycarbodiimide compound, curing agent, and thermosetting resin composition

The modified polycarbodiimide compound of the present invention is obtained by modifying a polycarbodiimide compound derived from a diisocyanate compound with at least one aliphatic amine selected from the group consisting of diethylamine, methylisopropylamine, tert-butylethylamine, di-sec-butylamine, dicyclohexylamine, 2-methylpiperidine and 2,6-dimethylpiperidine. The curing agent of the present invention comprises the modified polycarbodiimide compound of the present invention. The thermosetting resin composition of the present invention comprises a carboxyl group-containing resin having a carboxyl group in a molecule or an epoxy resin having two or more epoxy groups in one molecule, and the curing agent of the present invention. Thus, a modified polycarbodiimide compound that can allow a resin composition to be cured at a relatively low temperature and that can suppress curing of a resin composition in a drying step before a thermal curing step of a resin composition, a curing agent comprising the modified polycarbodiimide compound, and a thermosetting resin composition comprising the curing agent can be provided.

Owner:NISSHINBO CHEM

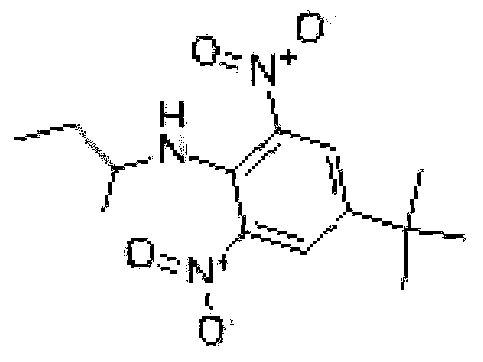

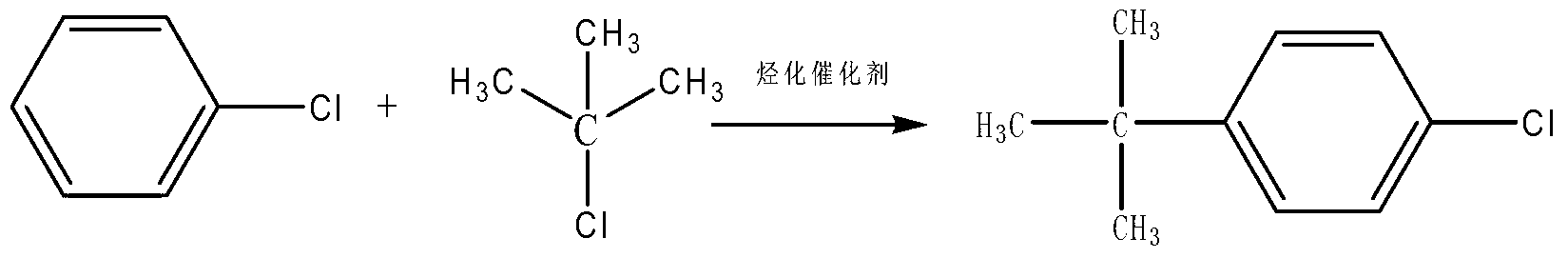

Synthesis method of high-purity butralin

InactiveCN103214378AHigh purityThe synthesis method is simpleOrganic compound preparationAmino compound preparationIce waterP-tert-Butylphenol

The invention provides a synthesis method of high-purity butralin, relates to a synthesis method of butralin, and solves the problem of the conventional synthesis method that the obtained butralin has relatively low purity. The synthesis method comprises the following steps of: 1, heating and mixing dichloroethane with p-tert-butylphenol; dropping salpeter solution; dropping concentrated nitric acid to carry out a nitratlon reaction after the upper acid water is separated; adding water; heating and refluxing; cooling through an ice-water bath; and then carrying out extraction filtration and recrystallization to obtain a nitration product; 2, adding 2-butanone, potassium iodide and potassium carbonate to the nitration product; heating; dropping dimethyl sulfate; heating to evaporate the 2-butanone; adding water to reflux; and then filtering and recrystallizing to obtain a methylate; and 3, heating and mixing the methylate with methanol; dropping sec-butylamine to react for a time; adding water; heating; and then filtering to obtain the high-purity butralin. The purity of the butralin obtained through the synthesis method is up to more than 99%; and the synthesis method is mainly applied to the synthesis of the butralin.

Owner:HEILONGJIANG UNIV

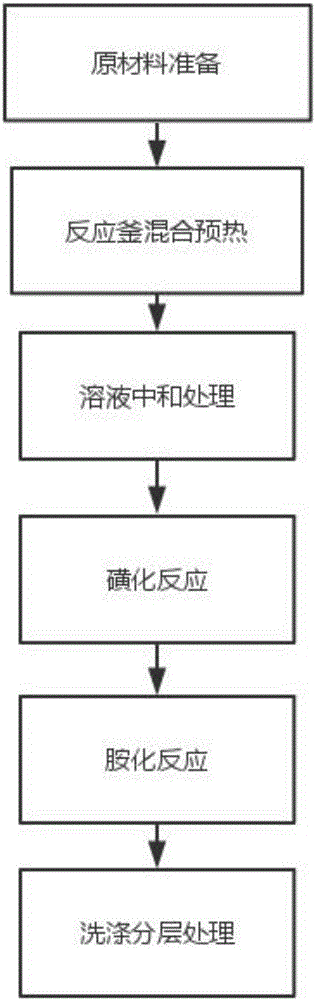

Method for synthesizing herbicide raw medicine

InactiveCN106496076AHigh puritySimple and reliable production processSulfonic acid preparationChlorobenzeneMultiple use

The invention discloses a method for synthesizing a herbicide raw medicine, and relates to the pesticide production field. The method includes six technological processes of raw material preparation, reaction kettle mixing preheating, solution neutralizing treatment, sulfonation reaction, amination reaction and washing layering treatment; with use of the sulfonation reaction of 2,6-dinitro p-tert chlorobenzene and sodium pyrosulfite and the amination reaction of 2,6-dinitro p-tert chlorobenzene and sec-butylamine, the herbicide raw medicine with relatively high purity can be prepared; moreover, with multiple use of clear water for washing, the production process is simple and reliable, recrystallization is not needed, the high-purity product can be obtained, the yield and the product purity are high, an efficient herbicide product can be obtained, and the method is worthy of promotion.

Owner:枣阳市先飞高科农药有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com