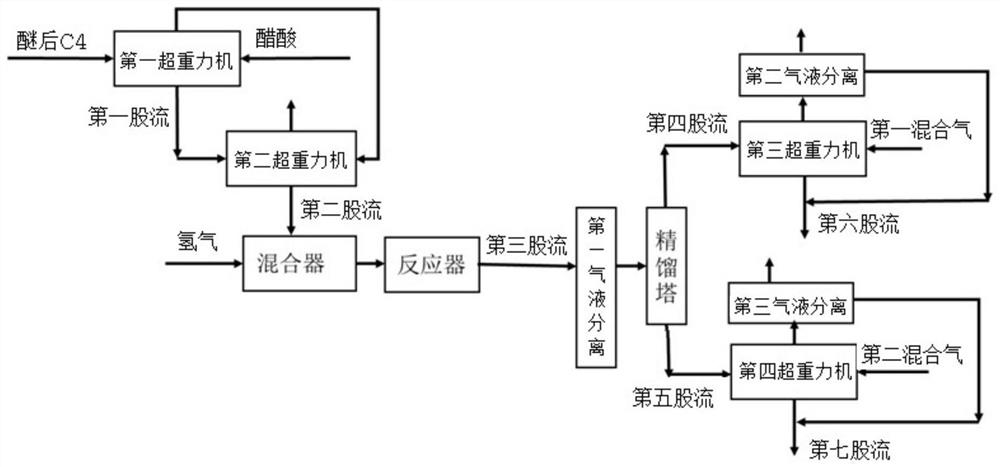

Method for co-producing monoethylamine and sec-butylamine by supergravity method

A high-gravity method and sec-butylamine technology are applied in chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., which can solve problems such as unseen co-production process methods and unseen high-gravity technology, and achieve Good social significance and economic benefits, simple process and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

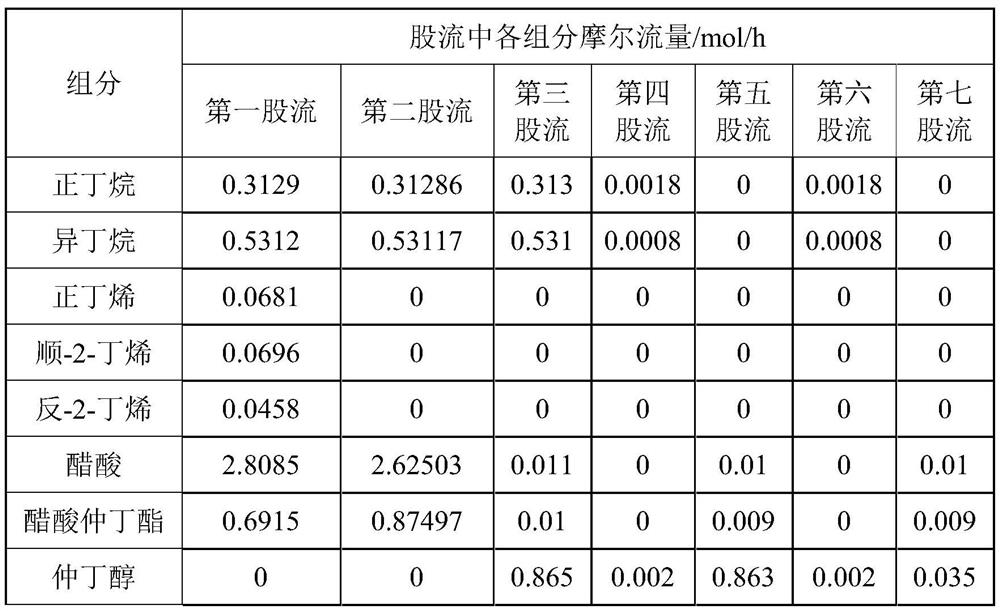

[0063] This embodiment provides a method for the coproduction of monoethylamine and sec-butylamine by the high gravity method.

[0064] The first catalyst and the second catalyst are selected to use macroporous sulfonic acid type cation exchange resin produced by Dandong Mingzhu Special Resin Co., Ltd.

[0065] The preparation method of the 3rd catalyst is as follows:

[0066] (1) Carrier molding: take 300g of alumina powder and 6g of scallop powder and mix them in a kneader, add 270g of water, knead for 20min, then extrude into a 3mm thick clover shape with an extruder, dry at 120°C, and then heat at 800°C Calcined at lower temperature for 4 hours to obtain an alumina carrier.

[0067] (2) Loading active components: take 99.3g of Ni(NO 3 ) 2 ·6H 2 O (analytically pure), 51.08g of Cu(NO 3 ) 2 ·3H 2 O (analytical pure) was dissolved in water to be 162mL solution, and the above solution was loaded on the obtained 100g carrier by spraying twice; after each spraying, it was...

Embodiment 2

[0105] This embodiment provides a method for the coproduction of monoethylamine and sec-butylamine by the high gravity method.

[0106] The first catalyst and the second catalyst are selected to use macroporous sulfonic acid type cation exchange resin produced by Dandong Mingzhu Special Resin Co., Ltd.

[0107] The preparation method of the 3rd catalyst is as follows:

[0108] (1) Carrier molding: take 300g of alumina powder and 6g of scallop powder and mix them in a kneader, add 270g of water, knead for 20min, then extrude into a 3mm thick clover shape with an extruder, dry at 120°C, and then heat at 800°C Calcined at lower temperature for 4 hours to obtain an alumina carrier.

[0109] (2) Loading active components: Take 134.1g of Ni(NO 3 ) 2 ·6H 2 O (analytically pure), 31.05g of Cu(NO 3 ) 2 ·3H 2 O (analytical pure) was dissolved in water to be 168mL solution, and the above solution was loaded on the obtained 100g carrier by spraying twice; after each spraying, it wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com