Patents

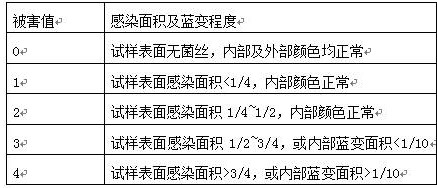

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Rubberwood" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubberwood is a light-colored medium-density tropical hardwood obtained from the Pará rubber tree (Hevea brasiliensis), usually from trees grown in rubber plantations. Rubberwood is commonly advertised as an "environmentally friendly" wood, as it makes use of plantation trees that have already served a useful function.

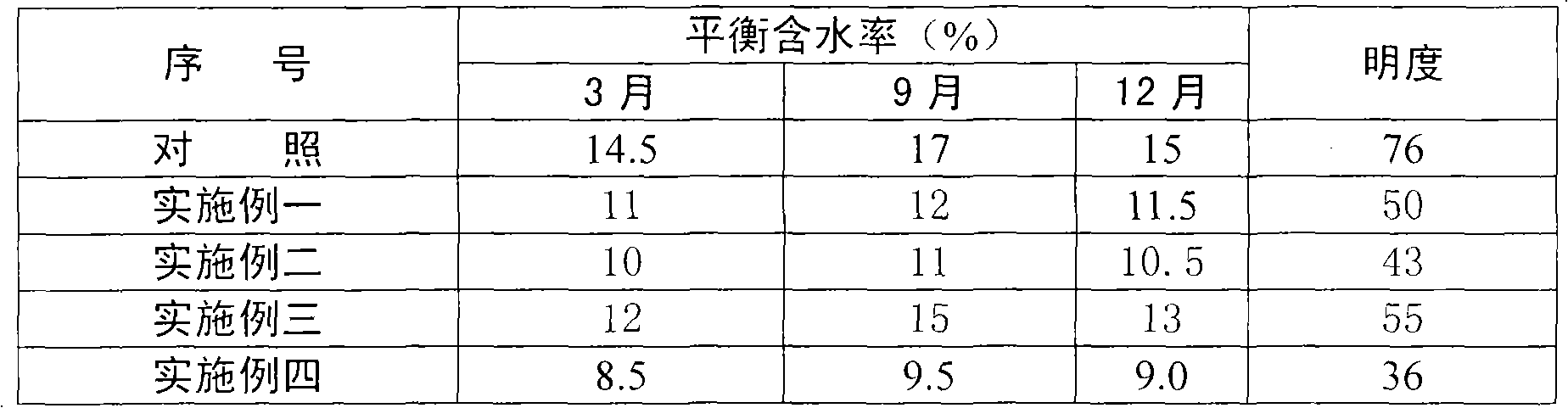

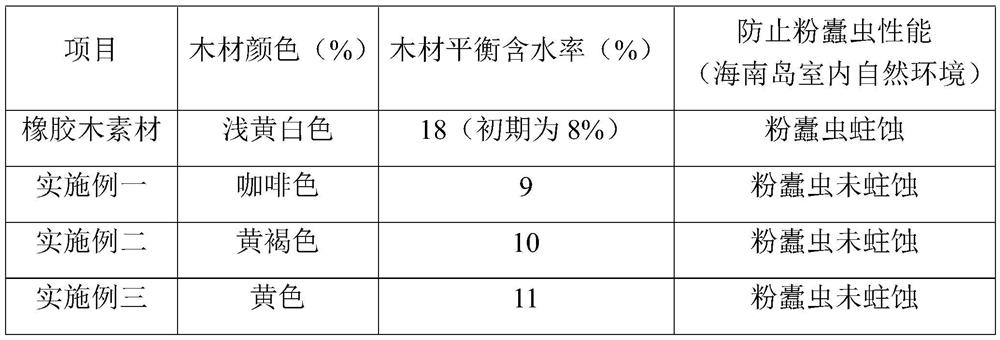

Production method for indoor integrated carbonized rubberwood

InactiveCN102581902AGood dimensional stabilityIncreased durabilityPressure impregnationWood charring/burningCarbonizationEquilibrium moisture content

The invention relates to a production method for indoor integrated carbonized rubberwood, which includes: sawing rubberwood log into specified wood, and subjecting the specified wood to termite proofing treatment, stacking, air drying and carbonizing; and subjecting the carbonized specified wood to tenoning, finger jointing, polishing, paneling and sanding to obtain the indoor integrated carbonized rubberwood. By means of combination of high-temperature carbonization and termite proofing treatment, the strength, moth and termite resistance, durability and mould proofing performance of the integrated rubberwood can be effectively improved, the integrated carbonized rubberwood has the coffee appearance, has the advantages of low variation of equilibrium moisture content, stable size, high corrosion resistance and the like, and is widely applicable to indoor furniture, floors, stair boards, decoration, fitment and the like.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Functionally-modifying method of rubber wood

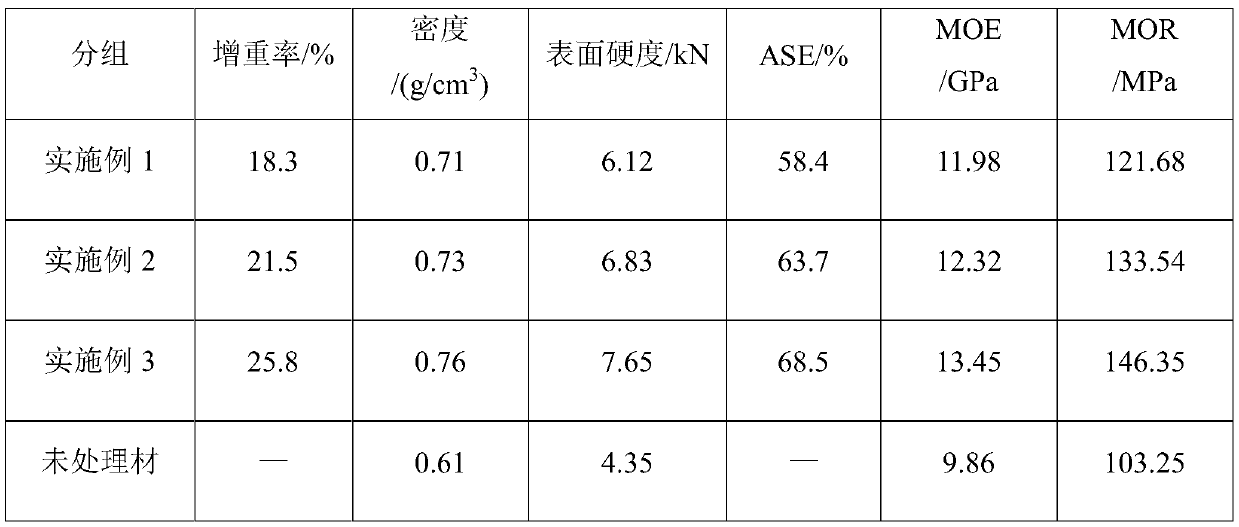

InactiveCN104647495AImprove waterproof performanceHigh hardnessWood treatment detailsPressure impregnationFiberCorrosion resistant

The invention discloses a functionally-modifying method of rubber wood. A multiple impregnation method is employed in the invention. In the method, cell walls are wrapped by an inorganic / organic glue layer formed by an impregnation solution so that an insulating layer is formed on the surface of wood fibers, thereby enabling wood to have functions of corrosion resistance, pest resistance, flame retardant and water proof and the like. The impregnation solution is not subjected to auto polymerization at a normal temperature, can adapt a production requirement and is strong in combination force with rubber wood and washing-loss-resistant performance. Modified wood is excellent in stability, is strong in waterproof performance, and is good in corrosion-resistant and flame-retardant performance. The method can increase economic value of the rubber wood.

Owner:YANGPUJIU JUTAI WOOD TECH CO LTD

Novel method for utilizing rubber wood timber brushwood and slab sawdust

The invention discloses a novel method for utilizing rubber wood timber brushwood and slab sawdust. The novel method comprises the following steps of: screening and crushing brushwood, wood shavings, slab sawdust and the like to obtain rubber wood powder, mixing the rubber wood powder with catalyst phosphoric acid according to the weight ratio of 1:(1-4), preparing active carbon with specific surface area of 1600m<2> through drying, activating, washing and stoving processes, and simultaneously recovering the catalyst; adding the wood powder to a carbonization furnace, and preparing rubber wood biomass powdered carbon by utilizing a slow-speed pyrolysis process; simultaneously, recovering combustible gas separated from pyrolysis gas in a pyrolysis process in a condensation manner so that the combustible gas is applied to an active carbon preparation process; mixing biomass oil which is liquid condensed from the pyrolysis gas with biomass powdered carbon, and carrying out extrusion forming by utilizing a mould to prepare various specifications of biomass carbon; and treating residual ash after biomass carbon combustion by utilizing recovered phosphoric acid with the concentration of 10-40% in an active carbon preparation process to obtain a liquid compound fertilizer and a grain fertilizer with adjustable proportion of potassium to phosphorus. The invention relates to a comprehensive utilization process route for producing high-specific-surface-area activated carbon, sectional carbon and compound fertilizer by taking brushwood, wood shavings and slab sawdust, generated by a rubber wood treating process, as raw materials.

Owner:闫涛 +1

Preparation method and novel using methods of carbon monolith binder

The invention discloses a preparation method and two novel using methods of a carbon monolith binder. The preparation method comprises the steps of: preparing and using biomass pyrolysis oil as a novel binder in a powdered carbon forming process from biomasses such as corn cob, rice husk, Chinese oak, rubber wood timber and the like by means of pyrolyzation and condensation. The invention also provides two using methods. One using method is mixing the binder (with moisture removed) with powdered carbon at the mass ratio of 1:1 to 1:3 at the temperature of 50-100 DEG C and then performing extrusion forming, and the other using method is directly absorbing pyrolysis gas generated by the biomass in a pyrolysis process by using the powdered carbon and then directly performing extrusion forming. The obtained carbon monolith is not broken after falling off for 10 times from the height of 1.5m, and a sample is not scattered by stirring after being combusted. The invention relates to the preparation method and the two using methods of the novel binder in the powdered carbon forming process.

Owner:JILIN UNIV

A dipping solution used for functional modification of rubberwood timber

ActiveCN104647501AEasy to modifyImprove performanceWood treatment detailsWood impregnation detailsFiberCell wall

A dipping solution used for functional modification of rubberwood timber is disclosed. The dipping solution is prepared by mixing following components by weight: 2-30% of alkaline silica sol calculated based on silicon dioxide, 2-30% of water-soluble urea-formaldehyde resin, 0.2-20% of a waterproof agent, 0.05-3% of a silane coupling agent and 1-5% of borax, with the balance being water. The dipping solution adopts combination of inorganic components and organic components. Wood cell walls are covered with an inorganic-organic glue layer formed by the dipping solution so as to form a separating layer on the surface of wood fiber, so that the timer has functions of corrosion resistance, insect prevention, flame retardance, waterproofness, and the like. Components of the dipping solution are free of self-polymerization at room temperature, thus meeting production requirements. The dipping solution is high in binding capability with rubberwood and high in loss resistance. Obtained modified timer is good in stability, high in waterproofness, good in corrosion resistance and good in flame retardance. Economic value of the rubberwood is increased.

Owner:西双版纳新宏兴木业有限责任公司

A new method for manufacturing recombined wood

The invention discloses a manufacturing method of a novel recombined wood. The process steps are: 1) Use rubber wood, poplar, Chinese fir, Chinese toon and other small-diameter logs that are prone to blue staining, branch wood, and the residues of rotary-cut veneer processing as raw materials, and then roll and decompose them into loose and non-broken longitudinally. The wood beam is a constituent unit; 2) the wood beam is tempered with a mixed solution of 0.1mol / L NaoH and sodium pyrophosphate diluted to a pH value of 9.0-11.0 with deionized water; 3) the wood beam that has been tempered The recombined wood is made through drying, dipping, hot pressing and other processes. The invention has the advantages of high raw material utilization rate, good impregnation effect and the like, and the prepared recombined wood has excellent mechanical properties and better dimensional stability. In addition, it also has the advantages of high production efficiency and low energy consumption.

Owner:LIANYUNGANG NANFANG WOOD IND CO LTD

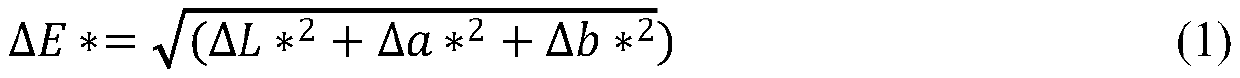

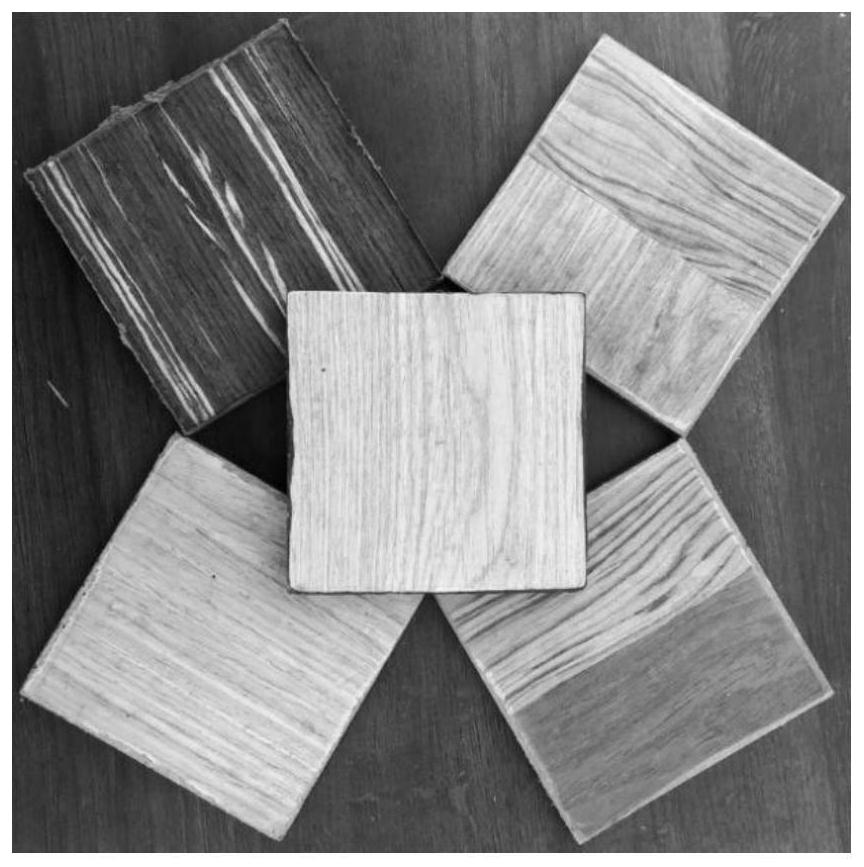

Environmentally-friendly high-strength heat-treated rubber wood and modification method thereof

ActiveCN110181628AShorten unnecessary modification timeReduce the degree of thermal decompositionWood treatment detailsThermal wood treatmentVolumetric Mass DensityMaterials science

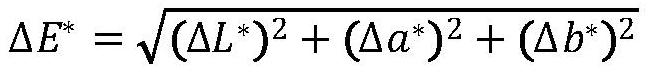

The invention discloses an environmentally-friendly high-strength heat-treated rubber wood and a modification method thereof. The environmentally-friendly high-strength heat-treated rubber wood has acolor difference of delta-E * of 18 to 30, a density of 0.62 to 0.68 g / cm3, a water content of 6% to 6.3%, a parallel-to-grain compressive strength of 38 to 45 MPa and a screw-holding power of 1800 to2200 N. The method provided by the invention comprises the following steps in six stages: drying, humidity regulation, heating, heat preservation, cooling with low loss of strength and high efficiency, and cooling. According to the invention, the loss of strength can be effectively controlled under the premise that the dimensional stability of wood is greatly improved, and a high-strength heat-treated material is prepared; meanwhile, the method has the advantages of no chemical pollution in the process of treatment, high production efficiency, low cost, simple operation, high efficiency and environmental protection; the dimensional stability and decorative performance of the wood are improved; the disadvantage of low strength of heat-treated wood is overcome at the same time; and the environmentally-friendly high-strength heat-treated rubber wood provided by the invention can be widely applied to the industry of wood products like solid wood floors, solid wood furniture and solid wooddoors.

Owner:SOUTH CHINA AGRI UNIV

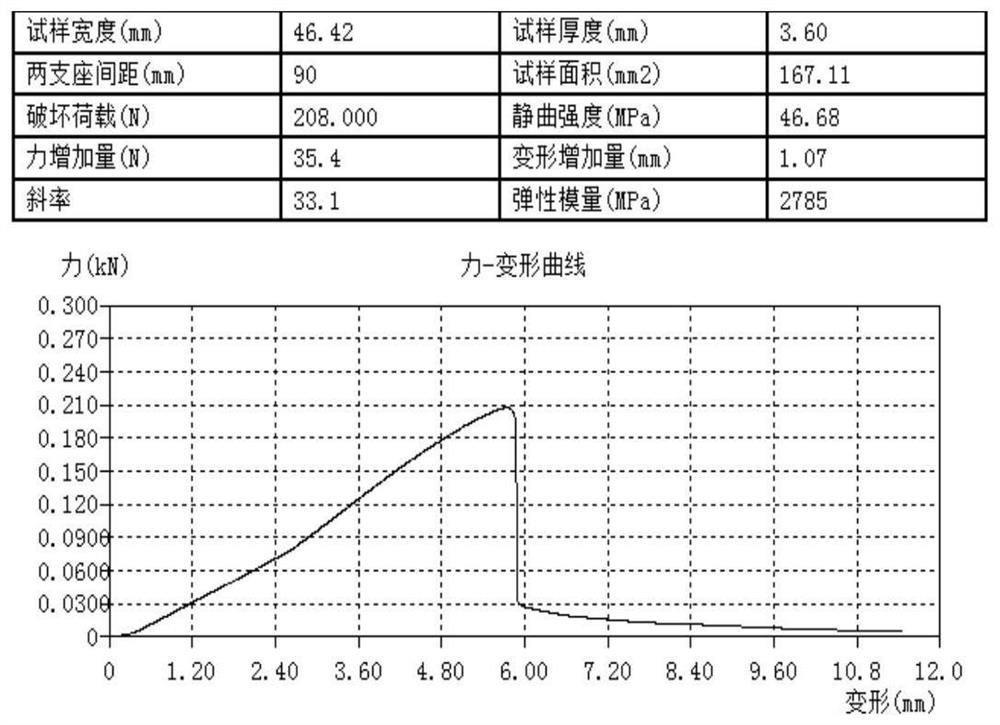

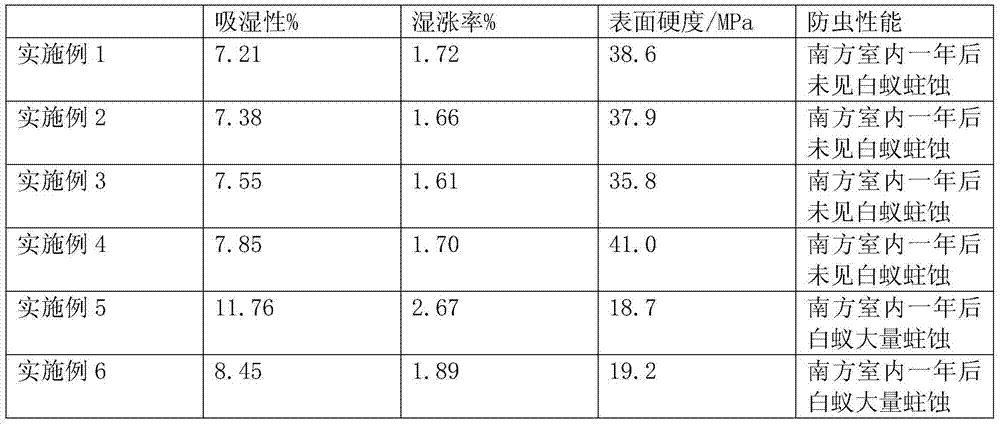

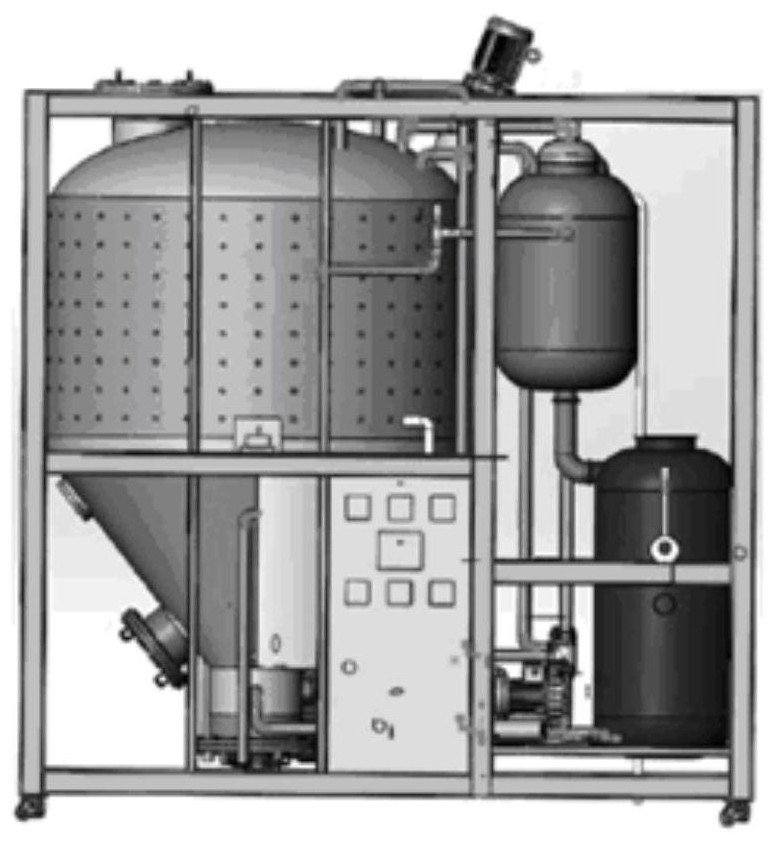

Production process for modified high-strength rubber wood floor

ActiveCN105082292AProcess environmental protectionHigh strengthWood treatment detailsPressure impregnationPolymer scienceHazardous substance

The invention discloses a production method for high-strength thermally-modified rubber wood floor. The production method comprises the following steps: sawing rubber logs into laminated timbers or blank; putting the laminated timbers or blank into a vacuum treatment tank, and carrying out impregnation in vacuum by taking boric acid and an acetic acid aqueous solution as a treating fluid; drying the laminated timbers or blank subjected to impregnation in vacuum until moisture content is 25-35%; stacking and putting the pre-dried laminated timbers or blank into carbonization treatment equipment, taking a 0.2-0.3% mycose solution as a superheated steam heat-transfer medium and a protective gas, increasing the temperature to 60-80 DEG C at a rate of 5-8 DEG C / min, and preserving the temperature for 2-3 hours, then heating the timers to 220-240 DEG C at a rate of 5-8 DEG C / min and preserving the temperature for 1-1.5 hours, stopping heating and cooling, and spraying steam to regulate humidity; and finally, preparing the wood floor. According to the production method, the process is environmentally-friendly, and hazardous substances such as resin and the like are not contained; and the obtained rubber wood floor is high in strength, good in termite resistance, stable in dimension and durable.

Owner:石家庄朗宁体育用品科技有限公司

Process for manufacturing three-ply board by means of trachycarpus martianus leaf sheath fibers

InactiveCN103862547AReduce absorptionWill not deformWood working apparatusFlat articlesFiberSolid wood

The invention discloses a process for manufacturing a three-ply board by means of trachycarpus martianus leaf sheath fibers. The process includes the steps that (1) the trachycarpus martianus leaf sheath fibers are clipped after being dried; (2) urea resin is placed in a closed container, distilled water is added to the closed container, and the mixture is uniformly stirred until no suspended matter can be observed; (3) the trachycarpus martianus leaf sheath fibers are placed in urea formaldehyde solutions, steeped and then bled to be stood, then the trachycarpus martianus leaf sheath fibers are baked and cooled; (4) the surface of a rubber wood panel is coated with resin adhesives, processed trachycarpus martianus leaf sheath fiber squares are laid on the resin adhesives in a criss-cross and overlapped mode, then the trachycarpus martianus leaf sheath fibers are covered with another rubber wood panel coated with the adhesives, and cold pressing, hot pressing and standing are carried out. The trachycarpus martianus leaf sheath fibers replace solid wood to be used for manufacturing the three-ply board, the requirements for strength and dimensional stability of artificial boards can be well met, mildewing is not prone to occurrence, a large quantity of timber resources are saved, the deficiency of existing forest resources can be relieved to some extent, and the environment is protected.

Owner:HUNAN FUXIANG WOOD

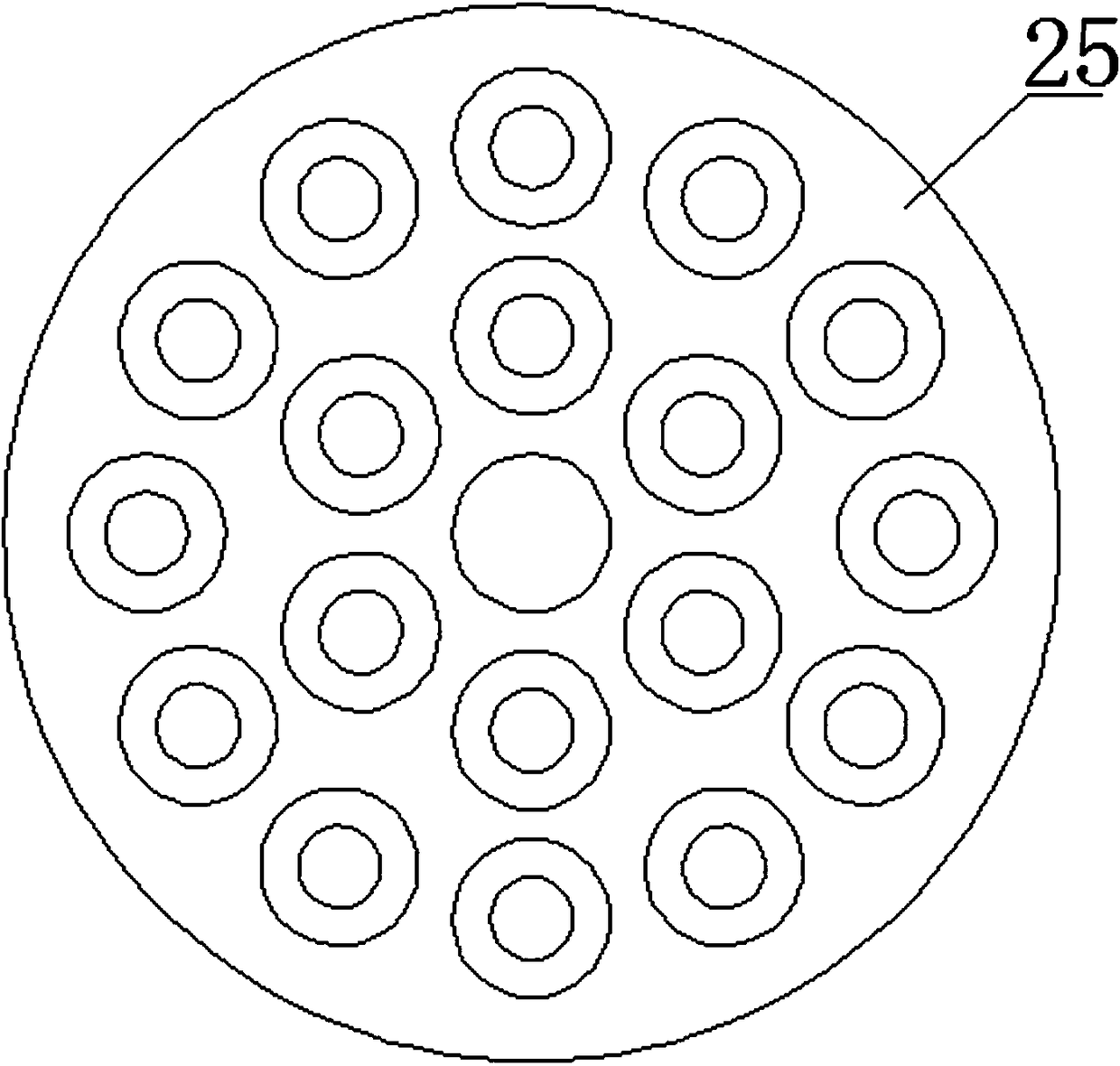

Processing method and processing system of rubber wood sliced veneer

InactiveCN109129774ADry fastGuaranteed fixed intervalWood treatment detailsVeneer manufactureComputer scienceWater content

The invention belongs to the technical field of rubber wood processing, and particularly relates to a processing method and a processing system of a rubber wood sliced veneer. The method includes thesteps: firstly, material selection; secondly, splitting; thirdly, corrosion prevention; fourthly, slicing; fifthly, drying. The technical scheme includes that placing a square wood strip into a rubberwood corrosion prevention device storing corrosion prevention liquid medicine to stew the square wood strip until water content rate of the square wood strip is 102%; spin-drying the square wood strip, enabling the water content of the square wood strip to be reduced to 50%-58% within 1-2 hours. According to the technical scheme, the square wood strip is firstly spin-dried within 1-2 hours, so that the water content of the square wood strip is reduced to 50%-58%, the wood strip is sliced into a veneer, and the veneer is dried at the medium temperature, so that the sliced veneer does not easily crack and warp when being rapidly dried.

Owner:西双版纳宏兴木制品有限责任公司

Method for manufacturing container bottom plate by using bamboo green strips to directionally reinforce, roll and flatten bamboo plates

ActiveCN114274283ASatisfy productivityFulfil requirementsBio-packagingCane mechanical workingWood veneerEngineering

The invention relates to a container bottom plate manufacturing method for directionally reinforcing a rolled and flattened bamboo plate through bamboo green strips. A radiation pine bottom plate, a radiation pine panel, a rubber wood veneer and the rolled and flattened bamboo plate are included. The bamboo filament curtain and the radial bamboo curtain are sequentially provided with the radiation pine panel, the rubber wood veneer, the rolled and flattened bamboo board, the bamboo filament curtain, the rubber wood veneer, the three layers of radial bamboo curtains, the rubber wood veneer, the three layers of radial bamboo curtains, the rubber wood veneer, the bamboo filament curtain, the rolled and flattened bamboo board, the rubber wood veneer and the radiation pine bottom board from top to bottom. The container bottom plate directionally enhanced by the bamboo green strips is reasonable in design and high in practicability, small-diameter moso bamboos or moso bamboo tips in mountainous areas are effectively utilized, the utilization rate of the moso bamboos in the mountainous areas is increased, the production cost of the bamboo container bottom plate is reduced, and the container bottom plate has the characteristics of excellent performance, high outturn percentage and moderate price; and the special requirements of container manufacturing enterprises on production and transportation of the container bottom plate can be met.

Owner:福建省闽清双棱竹业有限公司

Preparation method of flame-retardant environment-friendly high-strength board

PendingCN113910396AProtect environmentMeet environmental protection requirementsWood treatment detailsFlat articlesAdhesive cementHazardous substance

The invention discloses a preparation method of a flame-retardant environment-friendly high-strength board. Waste rubber wood which is remained in rubber wood processing enterprises and has no additional value is used as a raw material, no adhesive is used, and the flame-retardant environment-friendly board is prepared by using the characteristics of the raw material through the processes of crushing and screening, chemical pretreatment, grinding, pre-pressing, hot pressing and the like. By means of the content of the method, the flame-retardant environment-friendly high-strength board is prepared without using any adhesive on the premise of not influencing the performance of the board for the first time, toxic and harmful substances such as formaldehyde are not released, meanwhile, wastes in rubber wood processing enterprises are turned into wealth, the product additional value of the rubber wood processing enterprises is improved, and a series of problems of release of toxic and harmful substances influencing human health in home building materials and the like are solved while the economic benefit is maximized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Boards from acetylated rubberwood

Disclosed is a board made from acetylated mbberwood elements and a method for making same. The acetylated rubberwood elements have an acetyl content of at least 17% and / or are prepared by acetylating mbberwood elements using an acetylation agent in the vapour phase. The invention also pertains to acetylated rubberwood elements prepared by using an acetylation agent in the vapour phase.

Owner:TRICOYA TECH

Method for improving surface coating performance by treating rubber wood based on steam explosion method

InactiveCN111823343AGood paintabilityWon't fall offRadiation/waves wood treatmentPressure wood treatmentMetallurgyPhysical chemistry

The invention discloses a method for improving surface coating performance by treating rubber wood based on a steam explosion method, and relates to the technical field of wood product treatment. Themethod comprises the steps that oak is subjected to alkali liquor treatment, and steam explosion treatment is conducted after alkali liquor treatment, wherein the alkali liquor treatment is carried out under a microwave-assisted condition, the alkali liquor is obtained by mixing a strong alkali solution and a weak alkali solution, and the mixing mass ratio of the strong alkali solution to the weakalkali solution is 3: (1-1.5); the oak surface treated through the method has better brushing performance, the binding force between the oak surface and a coating can be greatly improved, and therefore the oak surface can be used for a longer time, and the situation that the coating on the surface falls off too early is avoided.

Owner:安徽三和工艺品有限公司

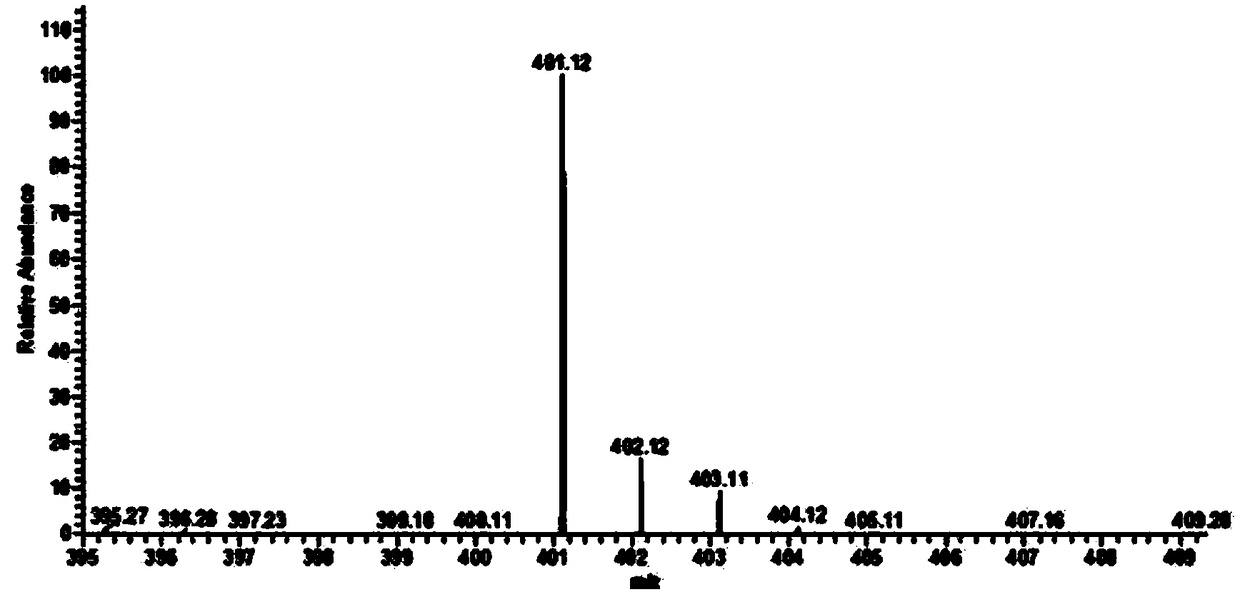

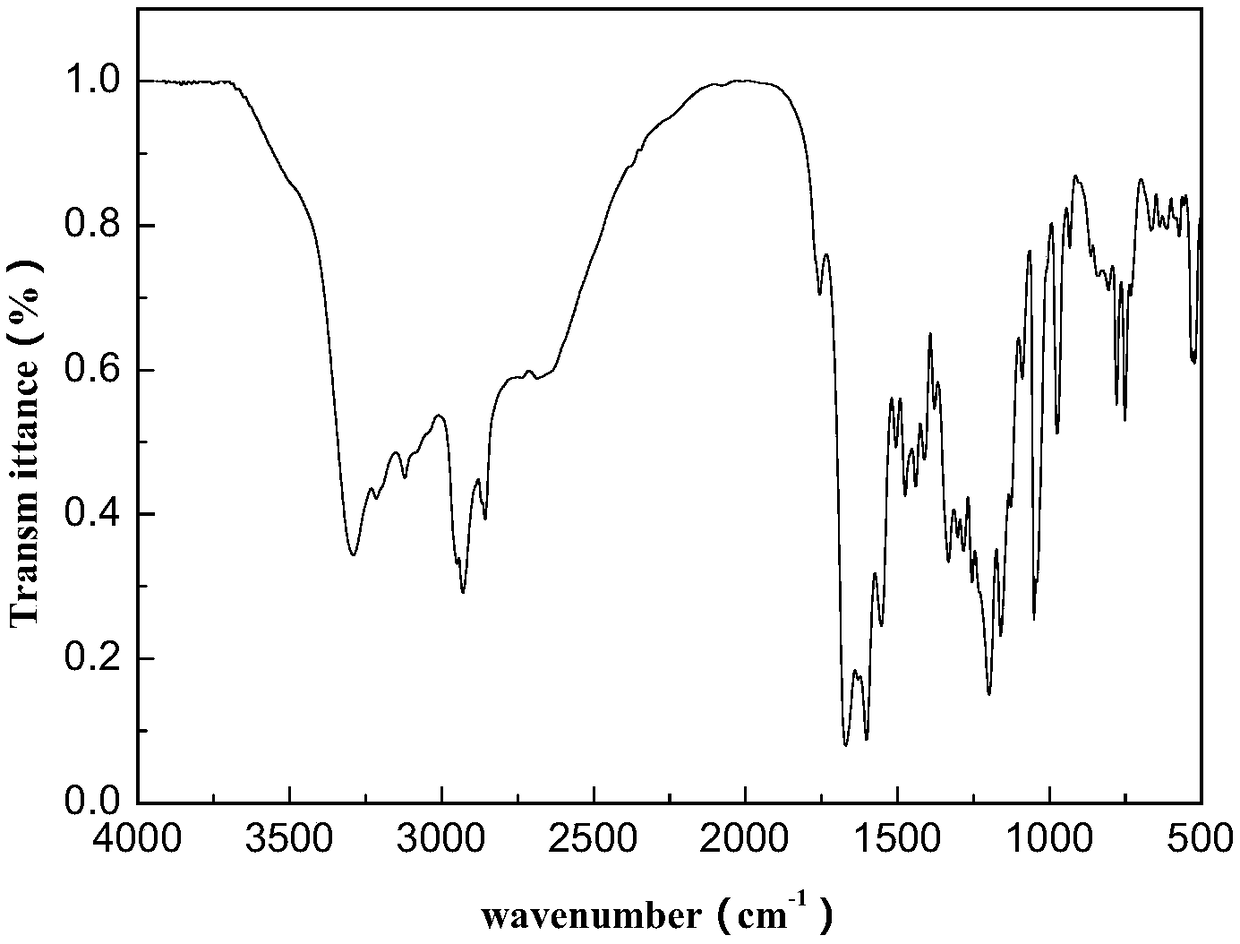

Multifunctional wood modifier and preparation method and application thereof

InactiveCN109081831AFlame retardantWith smoke suppressionOrganic chemistryWood impregnation detailsPolymer scienceFire retardant

The invention belongs to the technical field of wood modifier synthesis and provides a multifunctional wood modifier which comprises a compound I. The compound I is of a structure shown as follows. The invention further provides a preparation method of the wood modifier. The preparation method includes: using cyanuric chloride, n-hexylamine, taurine and 3-mercapto-1, 2, 4-triazole as raw materialsto synthesize the compound I through three-step reaction. The invention further provides application of the wood modifier in being impregnated in rubber wood. The multifunctional wood modifier has the advantages that a flame retardant has flame-retardant, smoke-inhibiting, bacteriostatic and moistureproof effects and is high in flame-retardant efficiency and low in cost; the modifier has high impregnation resistance when being added into the rubber wood and has no impact on using performance of the rubber wood; the modifier can form nitrogen-sulfur synergistic flame-retardant effect and is simple in synthesis process and suitable for popularization and application.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

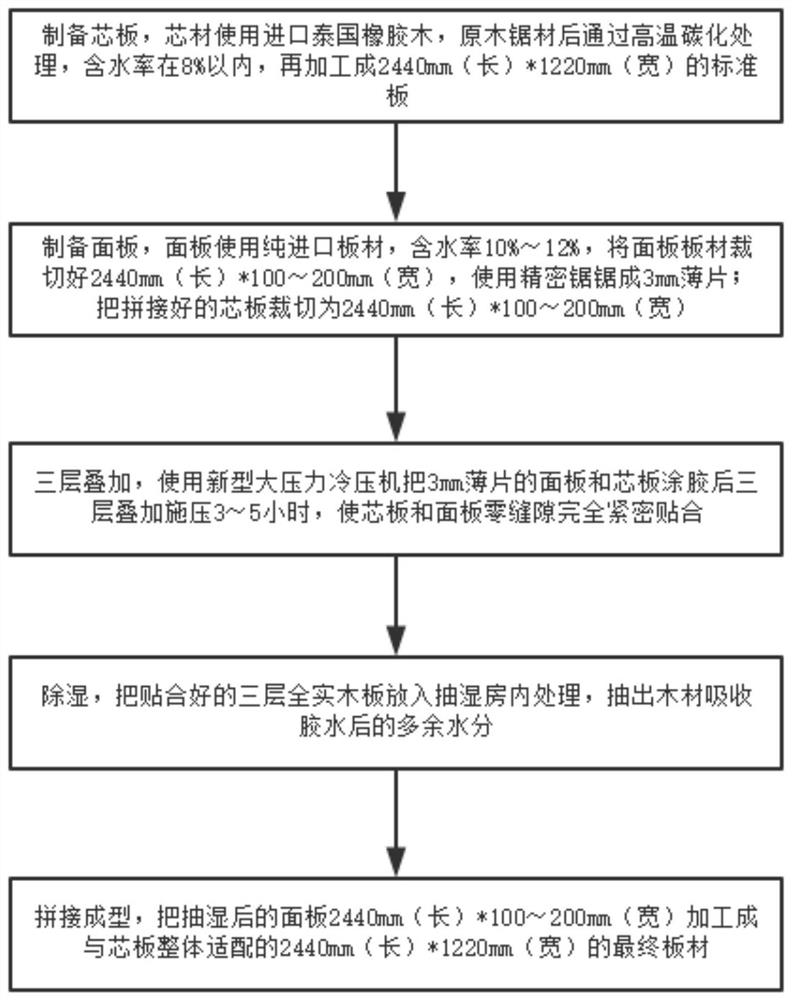

Environment-friendly waterproof and fireproof multilayer solid wood board and manufacturing process thereof

PendingCN111993503AAvoid deformationAvoid crackingWood treatment detailsWood veneer joiningSolid woodCarbonization

The invention discloses an environment-friendly waterproof and fireproof multilayer solid wood board and a manufacturing process thereof, relates to the field of processing and production of solid wood boards, and aims at avoiding material waste and improving deformation resistance, dust prevention, insect generation prevention and mildew prevention. The multilayer solid wood board comprises a core board and a panel, imported Thailand rubber wood is used as the core material of the core board, a pure imported board is used as the panel, the moisture content is 10%-12%, and the board with cleartexture and the best quality is selected; the manufacturing process specifically comprises the following steps that the core board is prepared, imported Thailand rubber wood is used as the core material, high-temperature carbonization treatment is conducted after log saw cutting, and then the log is spliced into a 2440 mm (length) * 1220 mm (width) standard board. According to the environment-friendly waterproof and fireproof multilayer solid wood board and the manufacturing process thereof, imported Thailand rubber wood is adopted as the core material, and high-temperature carbonization treatment is carried out after log sawing; the finally-prepared three-layer total solid wood board is not prone to deformation, cracking and expansion; and in addition, the board has the advantages of being low in water content and not prone to insect generation and mildewing.

Owner:郑凯

Treatment method of impregnated rubber wood

InactiveCN110815462ASolve the problem of energy consumptionSolve the costWood treatment detailsPretreatment apparatusAir compressionMaterials science

The invention discloses a treatment method of impregnated rubber wood, which comprises the following steps: putting wood to be modified into an impregnation tank, and vacuumizing at a heating state; cooling to 25 DEG C, injecting an impregnation liquid, pressurizing and maintaining the pressure for 5-6 hours, and discharging the impregnation liquid; and opening the impregnation tank, taking out the wood, putting the wood into a drying kiln, carrying out staged drying treatment, drying at 60 DEG C until the moisture content is less than 30%, drying at 70 DEG C until the moisture content is lessthan 20%, drying at 80 DEG C until the moisture content is less than 15%, and drying at 100 DEG C until the moisture content is less than 10% to obtain the impregnated rubber wood. According to the invention, the rubber wood wet plates can be directly processed; the problems of high energy consumption and high cost due to the fact that dry plates are needed for processing and treatment in conventional rubber wood processing are solved; according to the method, vacuumizing is carried out at heating state, air in the wood can be partially or completely exhausted, then cooling is conducted, theremaining air in the wood is compressed to generate a vacuum state, chemicals enter the wood by means of the pressure difference during pressurization, the impregnation effect is improved, the formaldehyde content of the impregnation liquid is low, and the method is environmentally friendly.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

A production process of modified high-strength rubber wood floor

ActiveCN105082292BProcess environmental protectionHigh strengthWood treatment detailsPressure impregnationHazardous substanceCarbonization

The invention discloses a production method for high-strength thermally-modified rubber wood floor. The production method comprises the following steps: sawing rubber logs into laminated timbers or blank; putting the laminated timbers or blank into a vacuum treatment tank, and carrying out impregnation in vacuum by taking boric acid and an acetic acid aqueous solution as a treating fluid; drying the laminated timbers or blank subjected to impregnation in vacuum until moisture content is 25-35%; stacking and putting the pre-dried laminated timbers or blank into carbonization treatment equipment, taking a 0.2-0.3% mycose solution as a superheated steam heat-transfer medium and a protective gas, increasing the temperature to 60-80 DEG C at a rate of 5-8 DEG C / min, and preserving the temperature for 2-3 hours, then heating the timers to 220-240 DEG C at a rate of 5-8 DEG C / min and preserving the temperature for 1-1.5 hours, stopping heating and cooling, and spraying steam to regulate humidity; and finally, preparing the wood floor. According to the production method, the process is environmentally-friendly, and hazardous substances such as resin and the like are not contained; and the obtained rubber wood floor is high in strength, good in termite resistance, stable in dimension and durable.

Owner:石家庄朗宁体育用品科技有限公司

A kind of environment-friendly high-strength heat-treated rubber wood and its modification method

ActiveCN110181628BShorten unnecessary modification timeReduce the degree of thermal decompositionWood treatment detailsThermal wood treatmentSolid woodCompressive resistance

The invention discloses an environmentally-friendly high-strength heat-treated rubber wood and a modification method thereof. The environmentally-friendly high-strength heat-treated rubber wood has acolor difference of delta-E * of 18 to 30, a density of 0.62 to 0.68 g / cm3, a water content of 6% to 6.3%, a parallel-to-grain compressive strength of 38 to 45 MPa and a screw-holding power of 1800 to2200 N. The method provided by the invention comprises the following steps in six stages: drying, humidity regulation, heating, heat preservation, cooling with low loss of strength and high efficiency, and cooling. According to the invention, the loss of strength can be effectively controlled under the premise that the dimensional stability of wood is greatly improved, and a high-strength heat-treated material is prepared; meanwhile, the method has the advantages of no chemical pollution in the process of treatment, high production efficiency, low cost, simple operation, high efficiency and environmental protection; the dimensional stability and decorative performance of the wood are improved; the disadvantage of low strength of heat-treated wood is overcome at the same time; and the environmentally-friendly high-strength heat-treated rubber wood provided by the invention can be widely applied to the industry of wood products like solid wood floors, solid wood furniture and solid wooddoors.

Owner:SOUTH CHINA AGRI UNIV

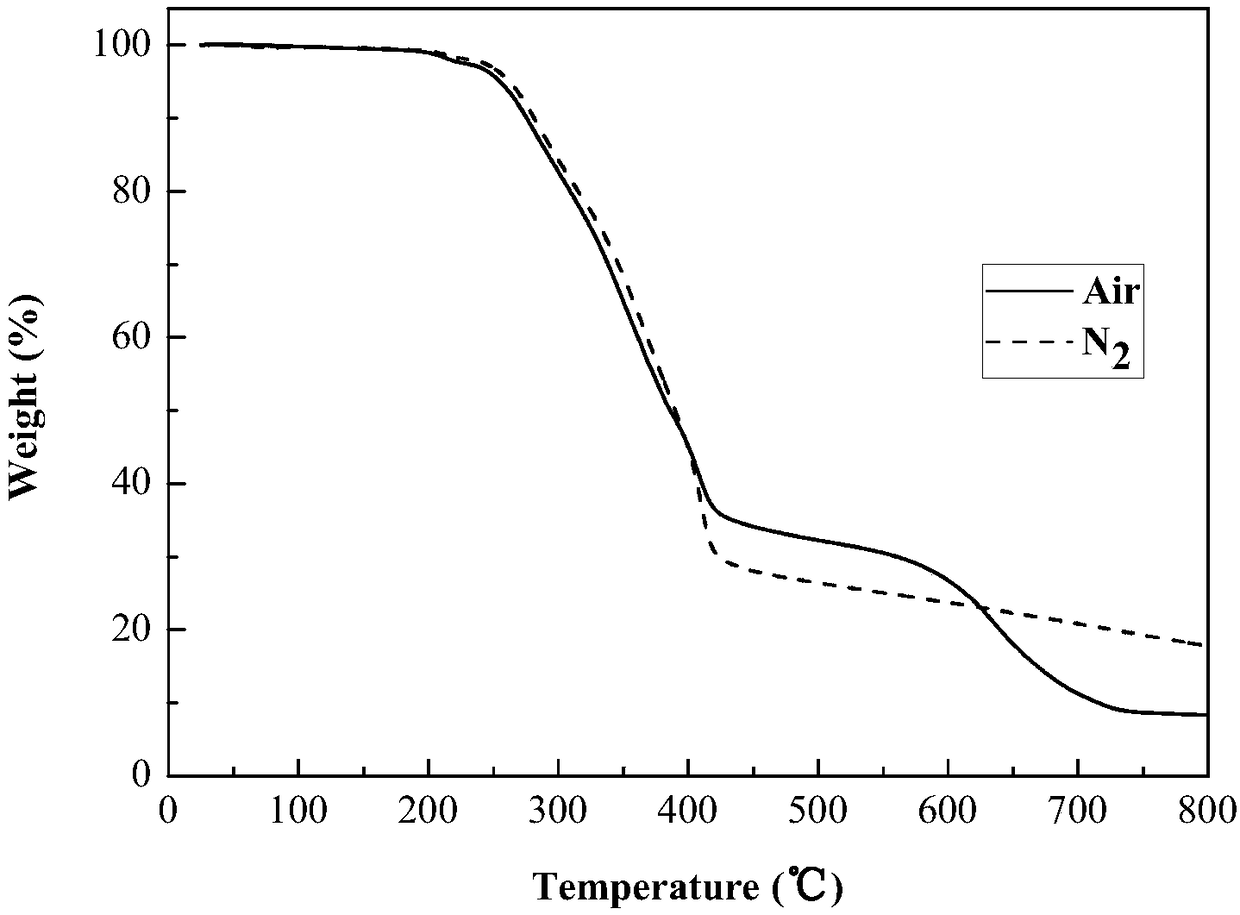

A kind of rubber wood essence and preparation method thereof

ActiveCN112869105BNo emissionsThe preparation process is environmentally friendlyClimate change adaptationNatural extract food ingredientsSmoked foodNitrogen gas

Owner:HAINAN UNIV

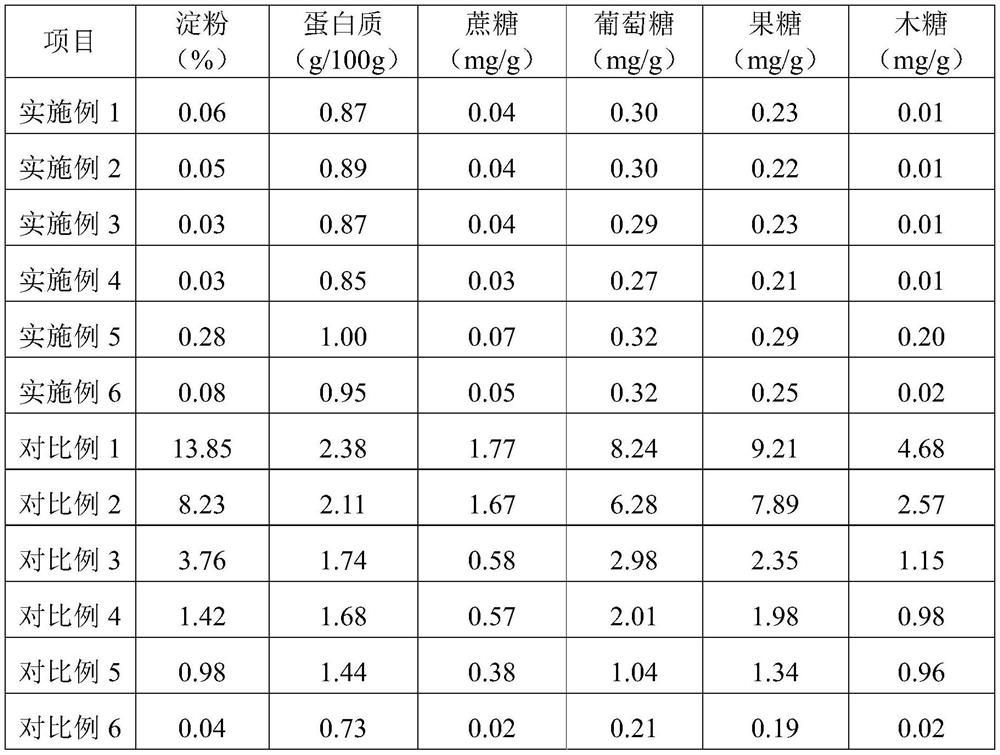

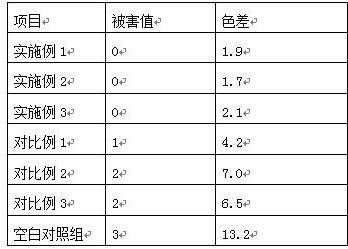

Treatment method for reducing content of starch, protein and saccharides in rubber wood

ActiveCN113858358APrevent mildewUniform colorWood treatment detailsWood impregnation detailsPulp and paper industrySodium silicate

The invention relates to a treatment method for reducing the content of starch, protein and saccharides in rubber wood. The treatment method comprises the following steps: (1) adding a weak acid solution into the rubber wood for ultrasonic acidizing treatment; (2) after ultrasonic acidification treatment, adding an alkaline nano sodium silicate solution for ultrasonic neutralization treatment; (3) stacking and air-drying the rubber wood subjected to ultrasonic neutralization treatment, and performing high-temperature drying treatment when the water content is less than 70-80%; and (4) high-temperature drying treatment comprises a heating drying stage and a cooling humidifying stage. By the adoption of the treatment method, the content of starch, protein and saccharides in the rubber wood can be greatly reduced, the color of the treated rubber wood is uniform, and the rubber wood capable of preventing mildewing of the rubber wood for a long time and keeping the natural color of the wood can be obtained.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

A kind of rubber tree log and root wood production root carving and wood pier processing method

ActiveCN113715129BNo decayReduce severe crackingWood treatment detailsThermal wood treatmentTree rootAgricultural engineering

The invention belongs to the technical field of wood processing, and relates to a processing and production method for rubber tree logs, in particular to a method for producing root carvings and wood piers from rubber tree logs and root materials. The rubber tree roots and logs are processed through a specific drying process, Not only the traditional drying defects are overcome, but also the rubber wood logs and root materials produced by the invention have the characteristics of stable wood size, not easy to deform, and are suitable for producing products such as root carvings, pen holders and wooden piers.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

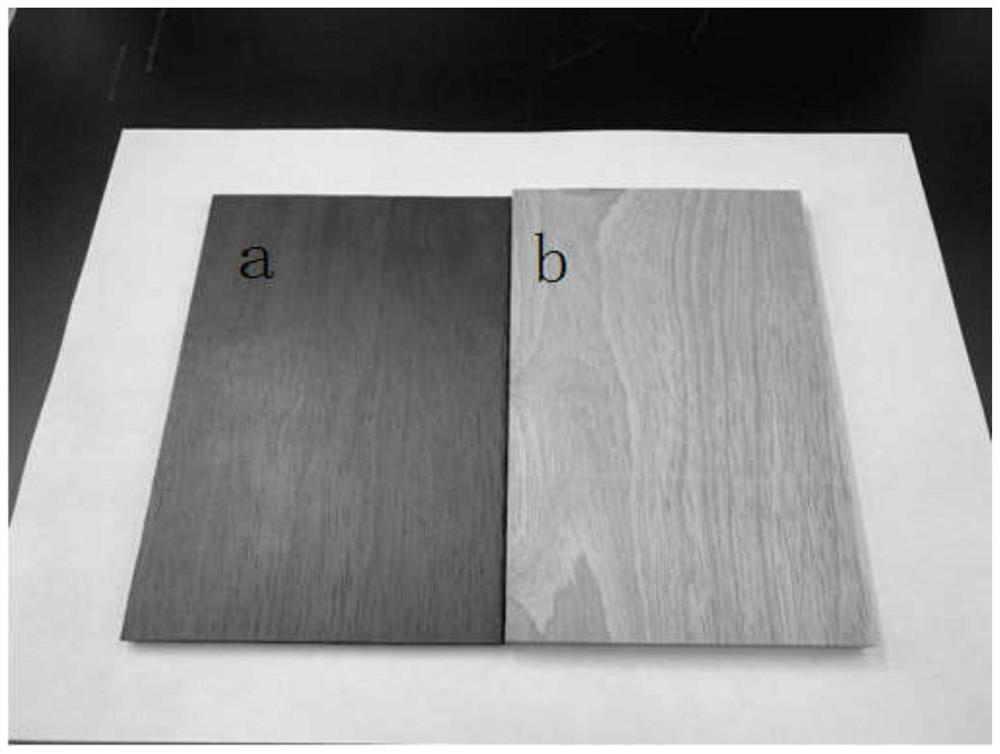

Treatment method for eliminating bluing of rubber wood

InactiveCN112497392AColor stableImprove qualityRadiation/waves wood treatmentWood treatment detailsBiotechnologyChemical treatment

The invention relates to the technical field of wood treatment, and discloses a treatment method for eliminating bluing of rubber wood. The blued rubber wood is subjected to physical and chemical treatment methods so that bluing bacteria and other accessory bacteria on the surface and in the interior can be deeply and effectively removed, and bluing spots can be well eliminated; the adopted treatment mode is simple, blue color spots in the blued rubber wood can be effectively removed, the original color of the rubber wood is stabilized, the original quality of the rubber wood is kept for a long time, the problem that the quality of the rubber wood is reduced due to the poor prevention and treatment effect caused by the high bluing infection speed is solved, the method has the advantages offavorable color spot elimination effect on the blued rubber wood and low treatment cost, and can be popularized and used in production. Economic loss and processing cost brought to rubber wood processing enterprises due to bluing are reduced.

Owner:阜阳文鼎工艺品有限公司

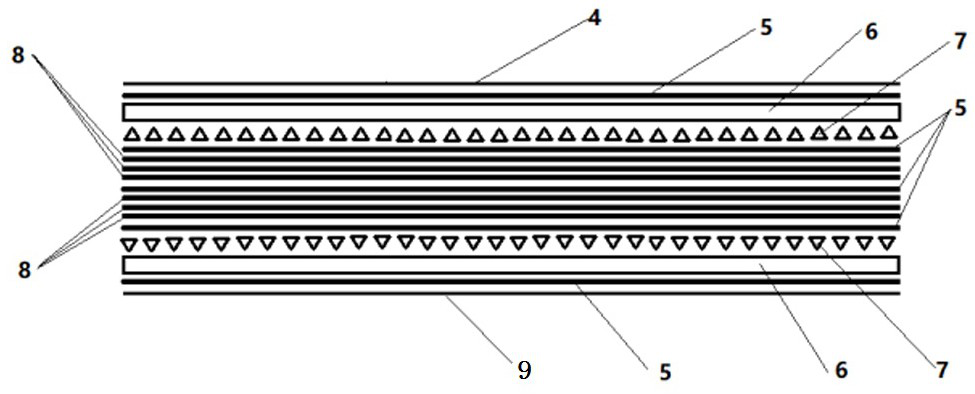

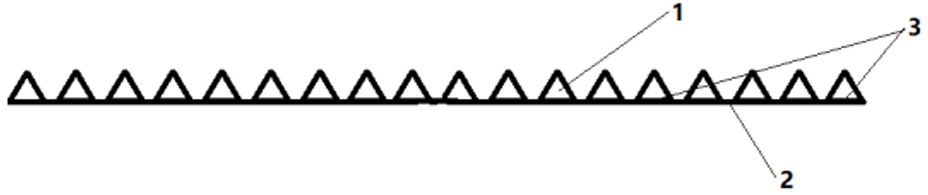

Rubber wood front core preparation process and application thereof

PendingCN110640850AFit closelyPrevent deformationAldehyde/ketone condensation polymer adhesivesWood veneer joiningPolymer scienceHot melt

The invention discloses a rubber wood front core preparation process and application thereof. The preparation process comprises the following steps: 1) rubber wood plate core assembled surfaces are machined in a sawtooth form; 2) hot melt adhesive is coated on the rubber wood plate core assembled surfaces; and more than one layers of rubber wood plate cores are pairwise assembled to form rubber wood plates after coating; 3) the assembled rubber wood plates are flatly stacked in an environment with a temperature of 25-30 DEG C and a humidity of 60-70% for 5-7 days; and 4) putty layers are coated on the surfaces of the stacked rubber wood plates, are flatly scraped, and are sanded once to obtain rubber wood front cores. The rubber wood front core preparation process and the application thereof can improve the veneer production yield, reduce the cost, and guarantee the quality.

Owner:广州市众益装饰材料有限公司

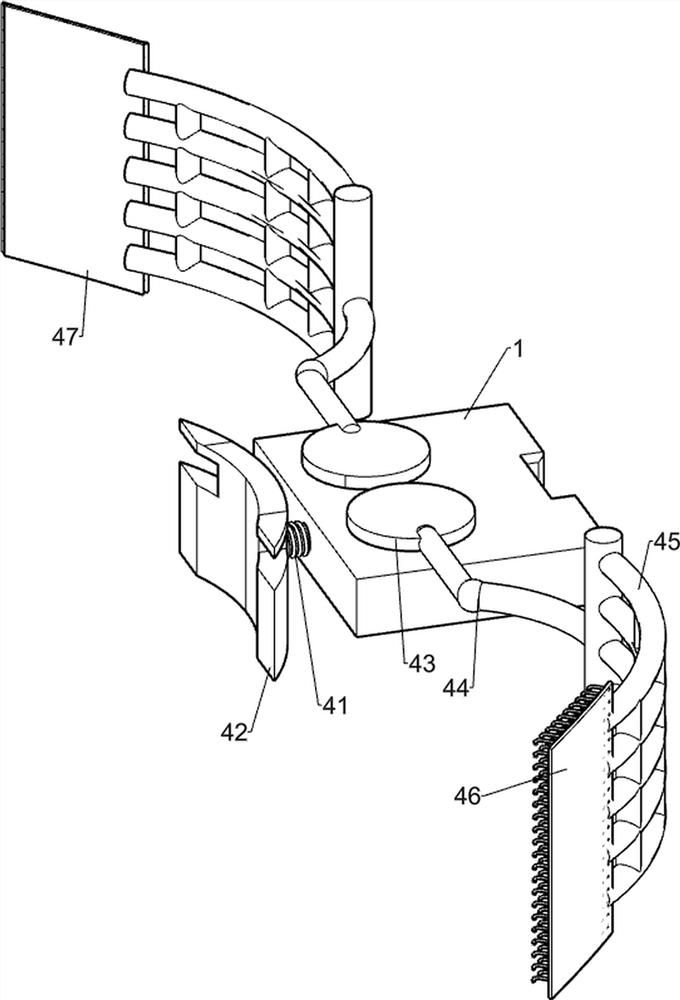

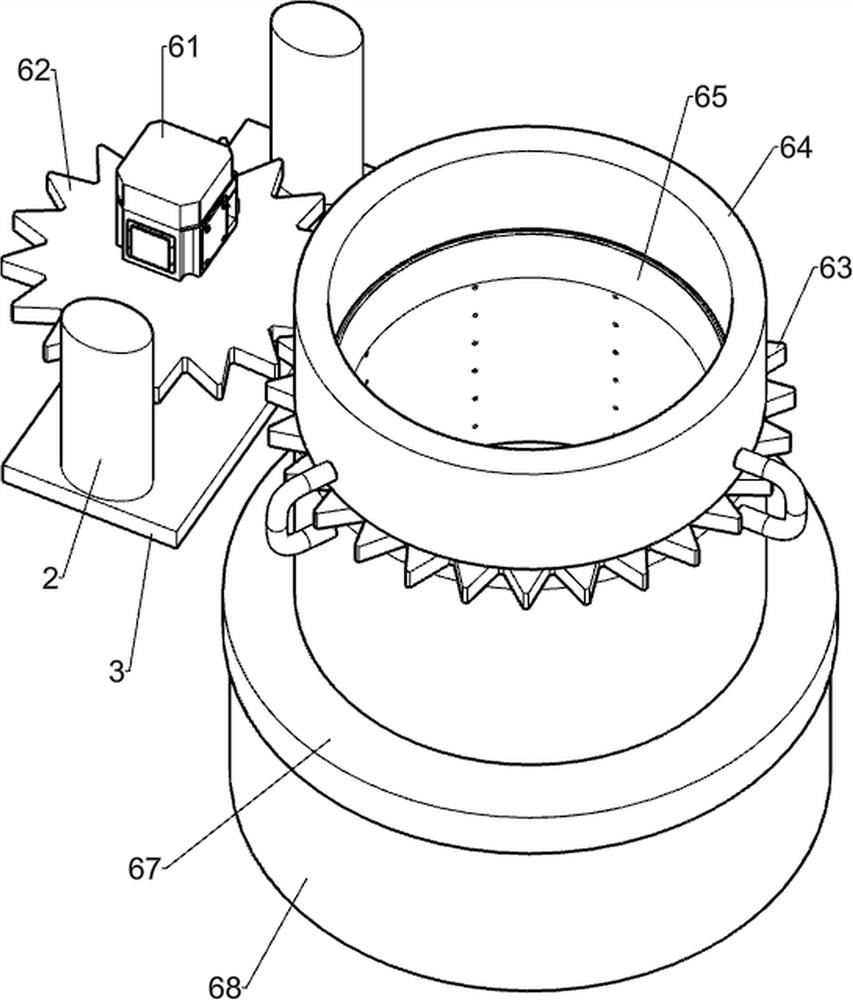

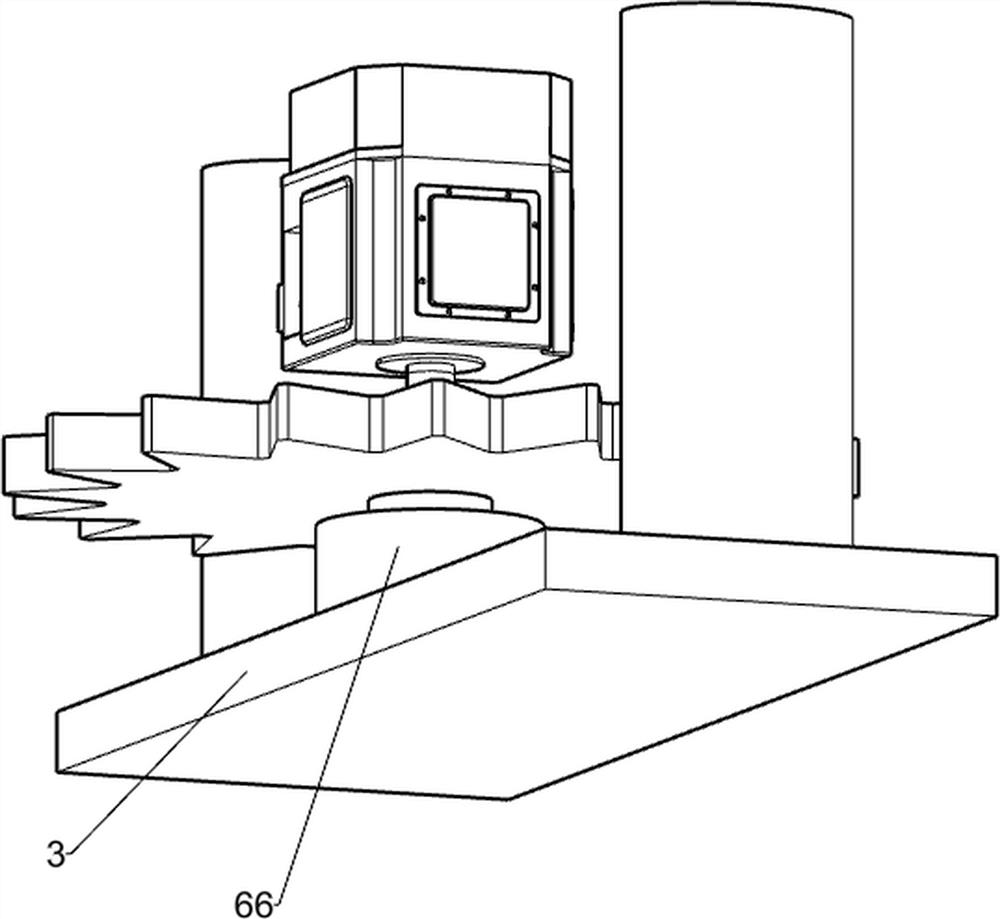

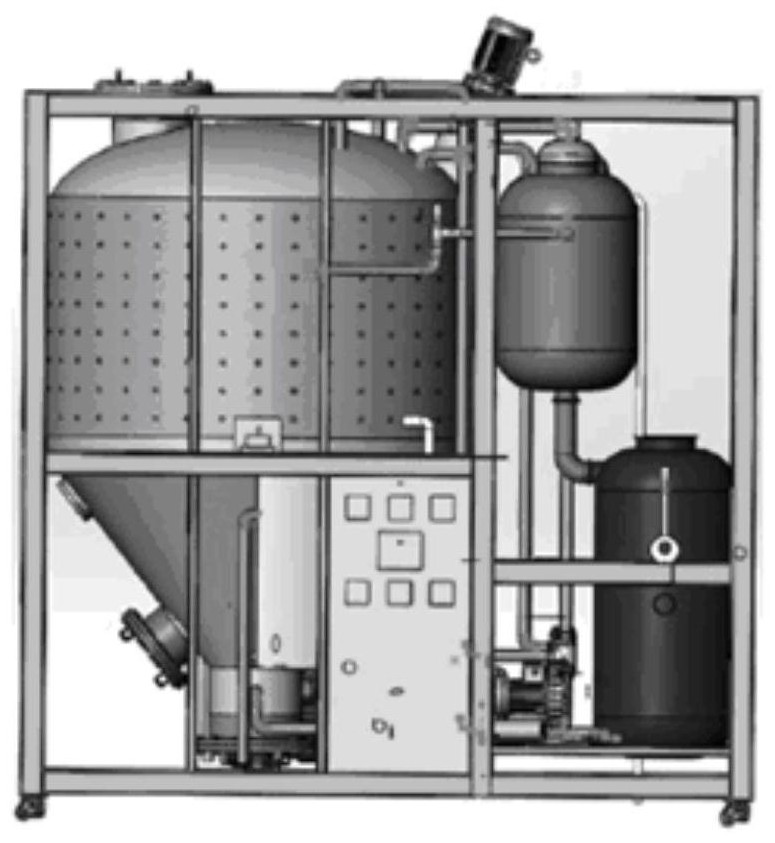

A rubber collecting device for rubber wood

The invention relates to a collection device, in particular to a rubber collection device for rubber wood. Provided is a rubber collecting device for rubber wood that is simple to operate and reduces waste. The invention provides such a rubber collecting device for rubber wood, which includes a support seat and a connecting column, the bottom of the support seat is connected with the connecting columns on both sides; the support platform is connected with the bottom of the connecting column; the guide mechanism supports the A diversion mechanism is connected in the seat; a filter mechanism is connected with the bottom of the support seat; a fixing mechanism is connected between the support seat and the diversion mechanism. Through the cooperation between the fixing mechanism, the diversion mechanism and the filtering mechanism, the device can be fixed on the rubber tree, so that the rubber juice flows into the filtering mechanism for continuous filtering, and the slag discharging mechanism can make the filtered impurities accumulate, and finally people can Take it out, this will improve the purity of the rubber juice.

Owner:佛山瓦孚材料科技有限公司

Rubber wood essence and preparation method thereof

ActiveCN112869105ANo emissionsThe preparation process is environmentally friendlyClimate change adaptationNatural extract food ingredientsPolymer scienceSmoked food

The invention discloses rubber wood essence and a preparation method thereof. The preparation method comprises the following steps that rubber wood (the tree age is 5-10 years) is crushed, the equivalent diameter is controlled to be 2-5 cm, the crushed wood blocks are subjected to nitrogen explosion treatment (50-300 MPa), laccase (0.1%-3%) is added into the wood blocks subjected to nitrogen explosion, the wood blocks subjected to laccase treatment are dried till the moisture content is 8-25%, the dried soft wood fragments and a flame retardant are mixed and placed in an environment-friendly drying furnace, the gradient heating and internal smoke generating technology is adopted, the temperature of a combustion kettle is controlled to be 150-200 DEG C, and flameless oxygen-deficient combustion is achieved. Gradient fractionation, three-stage purification, cooling and collection are performed on the cork essence to obtain the rubber wood essence. The product obtained by the invention has strong fragrance, does not contain harmful substances such as benzopyrene and the like, and can be used as an additive to develop smoked foods, feeds, medicines or other industrial products.

Owner:HAINAN UNIVERSITY

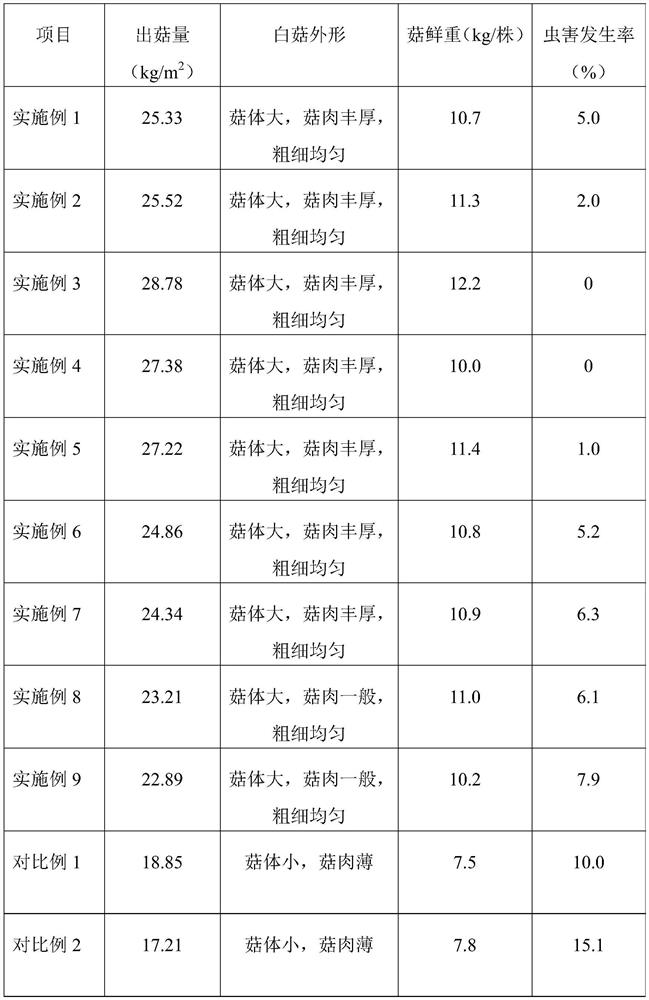

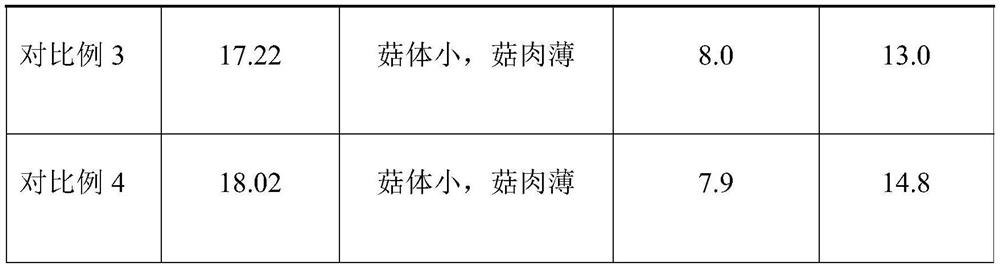

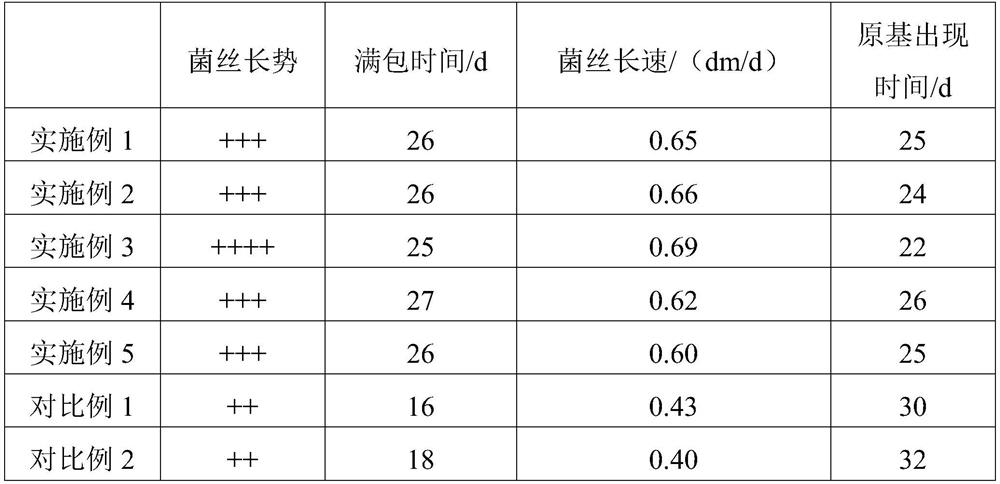

A kind of cultivation method of high-quality and high-yield white mushroom

ActiveCN110291926BImprove the cultivation effectImprove survival rateCultivating equipmentsMushroom cultivationNutritive valuesHibiscus

The invention provides a cultivation method of high-quality and high-yield white mushroom, comprising the following steps: domestication of white mushroom mother species, and cultivation of white mushroom, wherein the domestication of mother fungus is divided into domestication of three-level mother species; the cultivation of white mushroom includes: S1 Nutrient preparation, S2 cultivation management, and S3 stockpiling; wherein the nutrient includes the following raw materials in parts by weight: 50-72 parts of rubber sawdust, 44-58 parts of lychee sawdust, 45-68 parts of longan sawdust, 50-80 parts of broad-leaved wood chips, wheat bark 15 to 30 parts, 2 to 5 parts of gypsum, 3 to 8 parts of silkworm sand, 2 to 6 parts of bamboo charcoal powder, 5 to 12 parts of hibiscus bark, 4 to 11 parts of camphor wood powder, 5 to 15 parts of hematoxylin shavings, and fenxin wood 3 to 10 parts, 2 to 5 parts of sugar; the white mushroom of the invention has high yield, large mushroom body, thick and uniform mushroom flesh, high temperature resistance, high nutritional value, can effectively prevent insect damage, and increase yield.

Owner:王昌宾

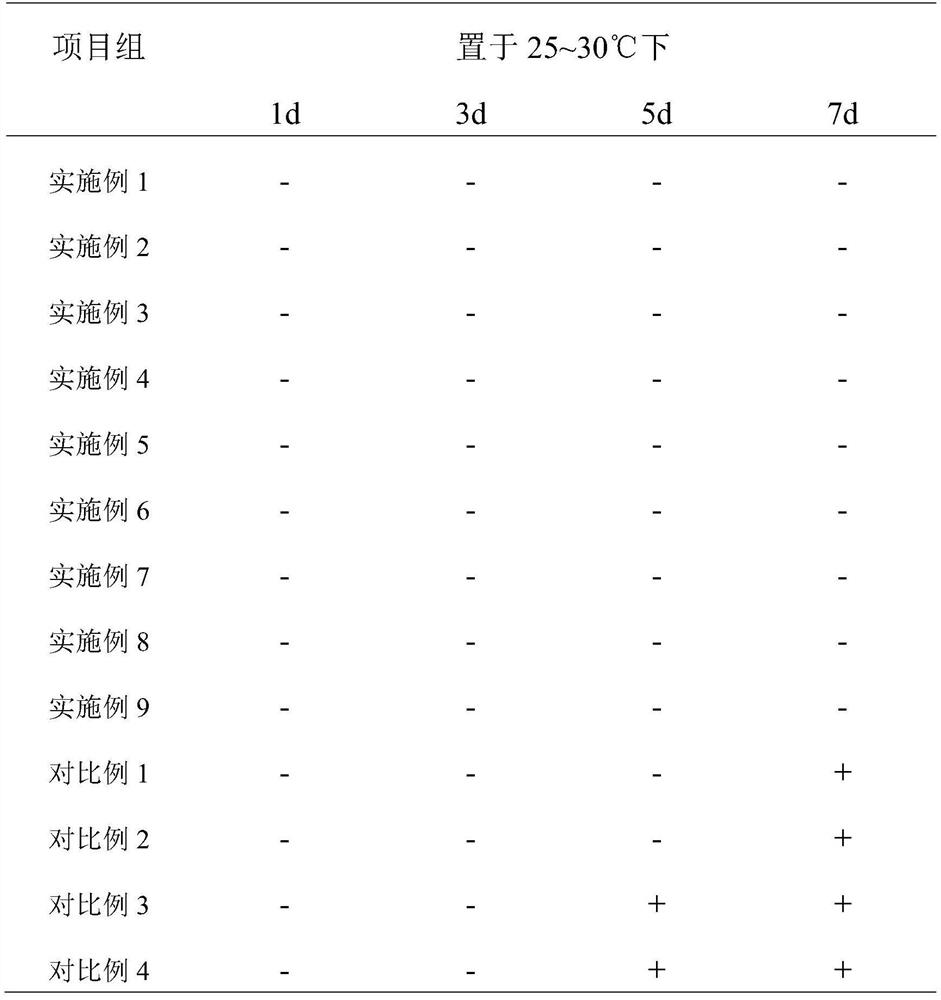

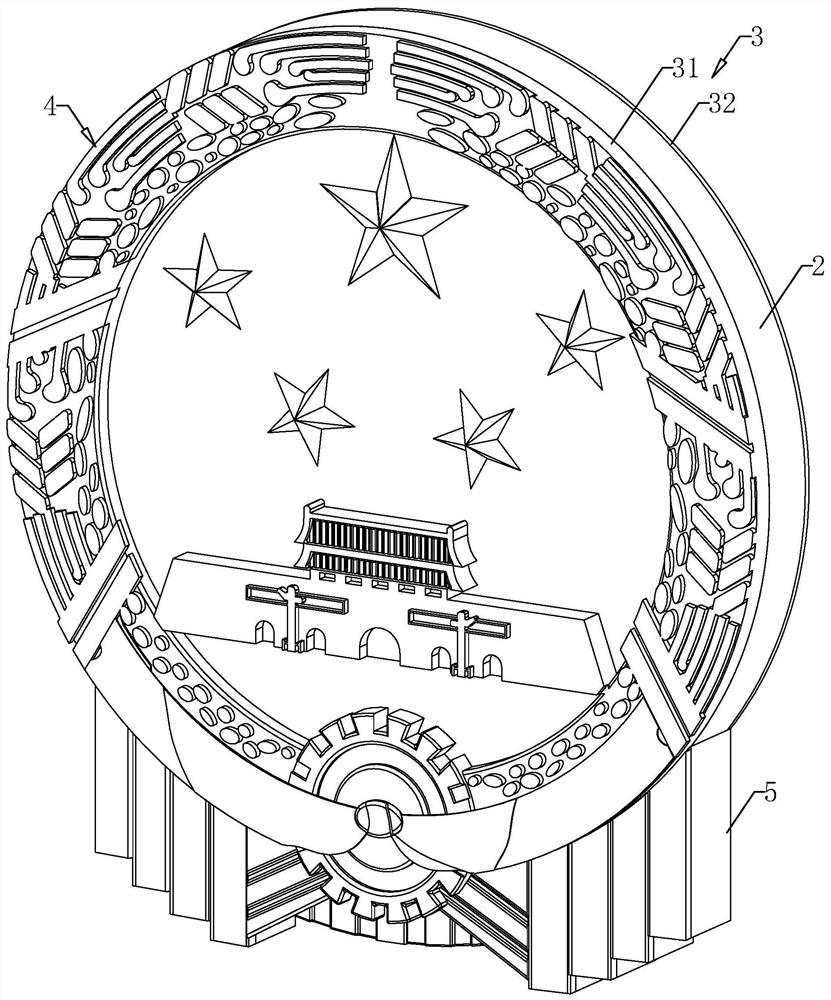

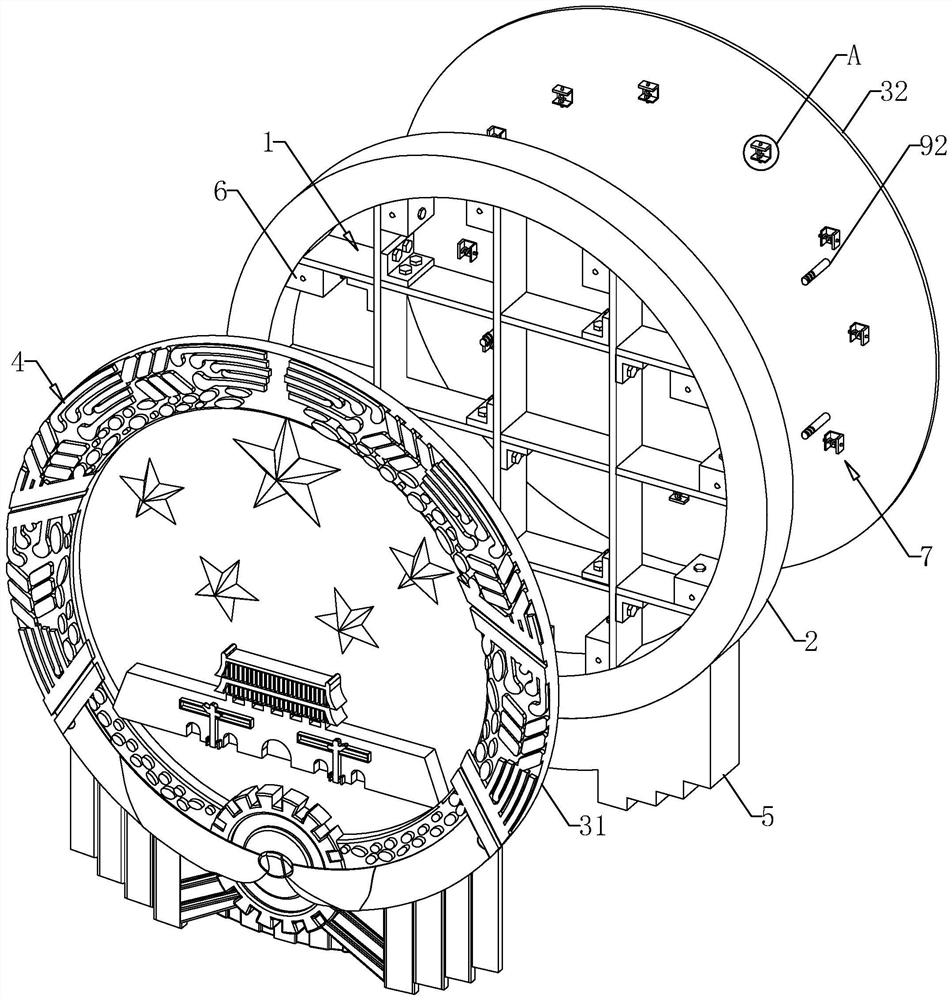

Manufacturing method of national emblem

ActiveCN112621963AMaintain a sense of heavinessMaintain a sense of dignityWood working apparatusMedalMechanical engineeringIndustrial engineering

Owner:BEIJING NO 5 CONSTR ENG GRP

A kind of cultivation method of Ganoderma lucidum

ActiveCN109769592BImprove breathabilityGood moisture permeabilityCultivating equipmentsMushroom cultivationBiotechnologyHypha

The invention discloses a method for cultivating ganoderma lucidum, which comprises the following steps: preparing a medium: including the following raw material components in parts by weight: 40-55 parts of Juncao, 20-40 parts of rubber sawdust, 15-20 parts of wheat bran, and gypsum Powder 1.5-2 parts, magnesium sulfate 0.02-0.06 parts; soil improvement in the shed; inoculation; cultivation; light management. The present invention optimizes and combines the nutritional components required for the growth of Ganoderma lucidum, so that the nutritional components can be controlled artificially, and because the nutritional components in the bag are mastered, the Ganoderma lucidum can be inserted in a reasonable and scientific manner, and the bacteria After the silk culture, after the mycelium culture is mature, the mushroom can be cultured.

Owner:儋州牧春绿色生态农业开发有限公司

Preparation method of compressed rubber wood with stable size and mildew resistance

PendingCN114633331AHigh densityGood dimensional stabilityPressure wood treatmentWood treatment detailsPolymer scienceMildew

The invention relates to a preparation method of compressed rubber wood, in particular to a preparation method of compressed rubber wood with stable size and mildew resistance. The problems that rubber wood is low in density, poor in wood property, prone to deformation and prone to mildewing and blue stain are solved. The treatment method comprises the following steps: 1, preparing a water-soluble acylated lignin solution; 2, dipping the rubber wood in a water-soluble acylated lignin solution; thirdly, hot-pressing densification treatment is conducted on the impregnated rubber wood; and 4, drying and curing. The method is used for preparing the compressed rubber wood which is stable in size and mildew-proof.

Owner:NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com