Rubber wood essence and preparation method thereof

A technology of rubber wood and essence, which is applied in the field of rubber wood essence and its preparation, can solve the problems of complex process, high cost, loss of aroma substances, etc., and achieve the effects of unique smoked flavor, environmental protection in the preparation process, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

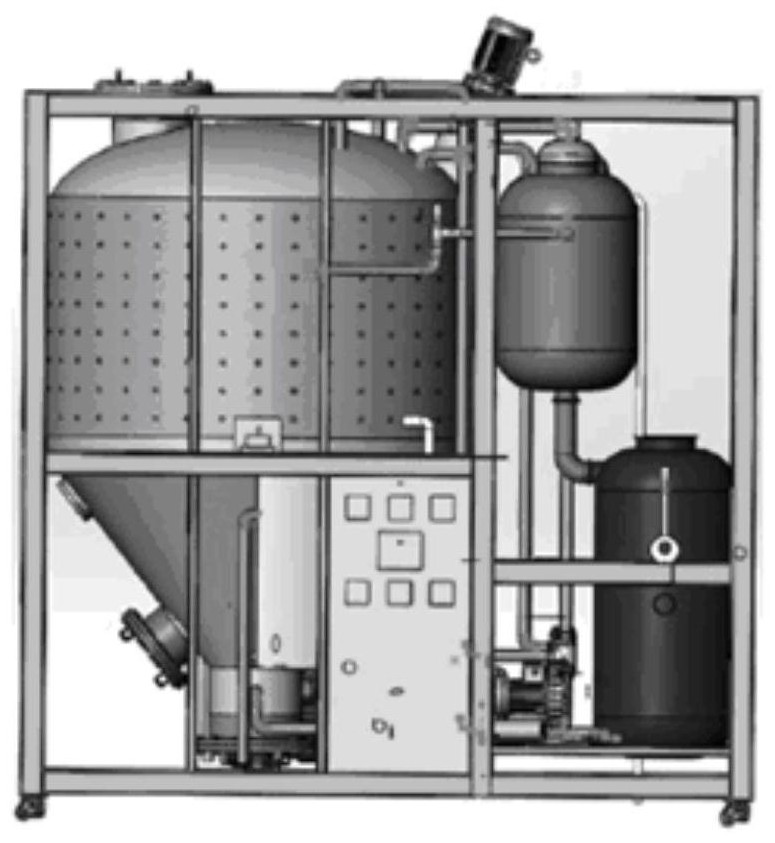

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0028] The invention provides a rubber wood essence and a preparation method thereof. Freshly felled rubber wood with a tree age of 7 years is selected, and the fresh wood is crushed so that its equivalent diameter is controlled at 3-4 cm, and the wood fragments are subjected to nitrogen blasting treatment. , the temperature was controlled at 60°C, the pressure was 100MPa, and the pressure was maintained for 4min. The blasting treatment was repeated once. Then, the wood block after the nitrogen blasting treatment was added with laccase. The mass fraction of laccase was 0.5%, and the temperature was maintained at 60°C. Keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com