Environment-friendly waterproof and fireproof multilayer solid wood board and manufacturing process thereof

An environmentally friendly technology for board production, applied in wood processing equipment, wood treatment, impregnated wood, etc., can solve the problems of easy deformation of boards, insects and mildew, and reduce the service life of boards, so as to improve the overall performance and quality, and not easy Insects and mildew, the effect of reducing the waste rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An environmentally friendly waterproof and fireproof multi-layer solid wood board, including a core board and a panel. The core material of the core board is imported Thai rubber wood, and the panel is pure imported board with a moisture content of 10% to 12%. The texture is clear and the quality is selected. The best board; the panel as a whole is 2440mm (length) * 100 ~ 200mm (width) unit boards are assembled on the surface of the core board, and finally processed into a 2440mm (length) * 1220mm (width) overall board that is compatible with the core board The splicing structure; and the thickness of the panel is 3mm, and the thickness of the core board is 15mm or 18mm or 20mm.

Embodiment 2

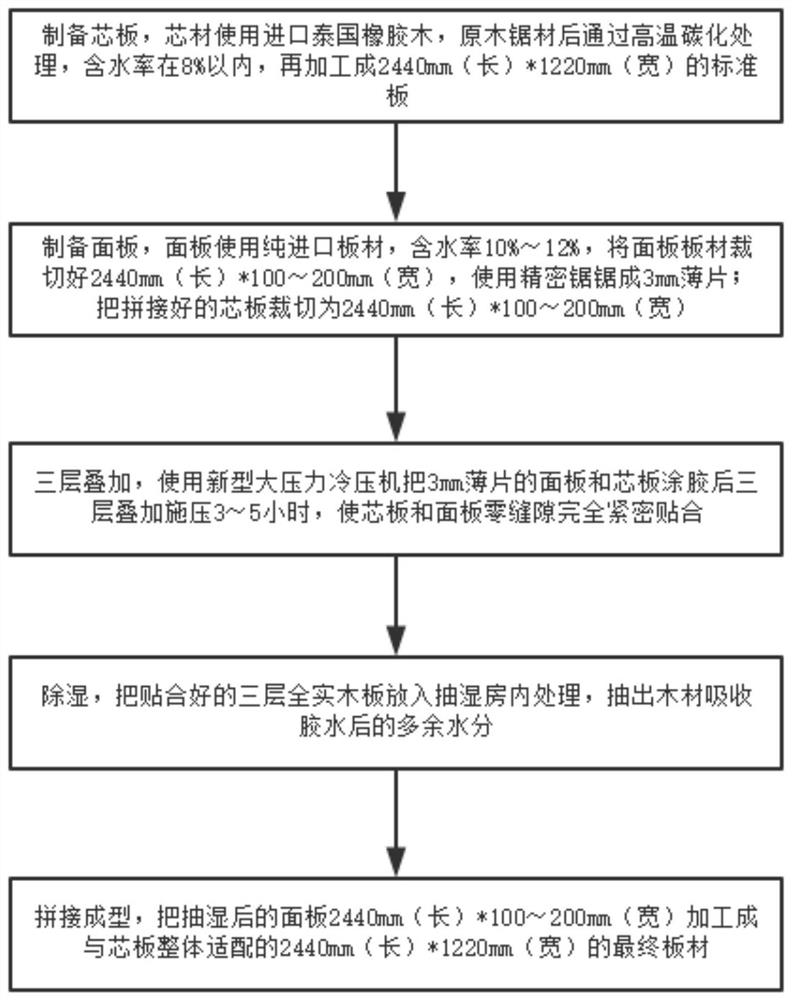

[0041] An environment-friendly waterproof and fireproof multi-layer solid wood board production process, which includes the following steps in sequence:

[0042] S1: Prepare the core board. The core material is imported Thai rubber wood. After the log is sawn, it is carbonized at high temperature, and the moisture content is within 8%, and then processed into a standard board of 2440mm (length) * 1220mm (width);

[0043] S2: Prepare the panel. The panel is made of pure imported board with a moisture content of 10% to 12%. Cut the panel to 2440mm (length) * 100 to 200mm (width), and use a precision saw to saw it into 3mm thin slices; cut the spliced core Board cut to 2440mm (length) * 100 ~ 200mm (width);

[0044] S3: Three-layer superimposition, use a new type of high-pressure cold press to apply glue to the 3mm thin panel and core board, and then press the three-layer superposition for 3 to 5 hours, so that the core board and the panel are completely tightly bonded with zer...

Embodiment 3

[0055] A manufacturing process of an environment-friendly waterproof and fireproof multi-layer solid wood board comprises the following steps in sequence:

[0056] S1: Prepare the core board. The core material is imported Thai rubber wood. After the log is sawn, it is carbonized at high temperature, and the moisture content is within 8%, and then processed into a standard board of 2440mm (length) * 1220mm (width);

[0057] S2: Prepare the panel. The panel is made of pure imported board with a moisture content of 10% to 12%. Cut the panel to 2440mm (length) * 100 to 200mm (width), and use a precision saw to saw it into 3mm thin slices; cut the spliced core Board cutting is 2440mm (length) * 100 ~ 200mm (width);

[0058] S3: Three-layer superimposition, use a new type of high-pressure cold press to glue the 3mm thin panel and core board, and then press the three layers for 4.5 hours. During cold pressing, adjust the air pressure at 2Mpa to 3.5Mpa to make the core board and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com