A rubber collecting device for rubber wood

A collection device, rubber wood technology, applied in application, separation method, filtration separation, etc., can solve the problems of waste of resources, time-consuming and laborious, and achieve the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A rubber collecting device for rubber wood, such as Figure 1-2 As shown, it includes a support base 1, a connection column 2, a support table 3, a fixing mechanism 4, a diversion mechanism 5 and a filter mechanism 6. The bottom of the support base 1 is connected with a connection column 2 on both sides, and the bottom of the connection column 2 is connected with each other. There is a support table 3 , a guide mechanism 5 is connected in the support seat 1 , a filter mechanism 6 is connected on the right side of the bottom of the support seat 1 , and a fixing mechanism 4 is connected between the support seat 1 and the guide mechanism 5 .

[0063] When a person needs to collect rubber, first cut the rubber tree bark into an arc shape, then attach the device to the rubber tree, and rotate the parts of the fixing mechanism 4 so that the parts of the fixing mechanism 4 are stuck on the rubber tree, and the fixing mechanism 4 drives the guide The components of the flow mech...

Embodiment 2

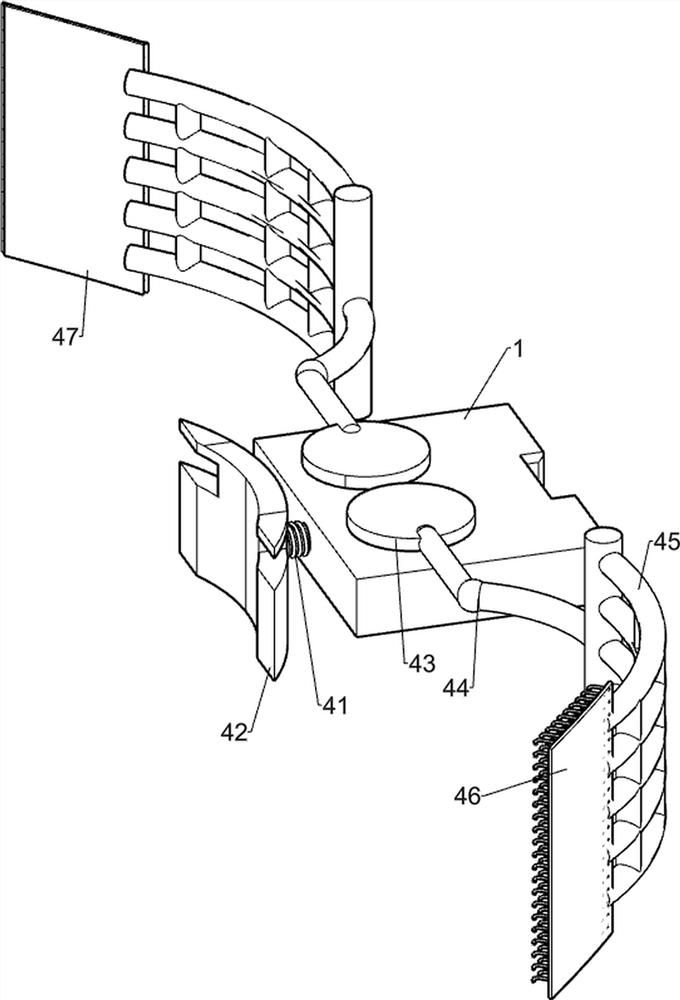

[0065] On the basis of Example 1, as Figure 3-5As shown, the fixing mechanism 4 includes a first spring 41, a pressing plate 42, a turntable 43, a fixing rod 44, a fixing rope 45, a hook surface 46 and a rough surface 47, and a pressing plate is slidably connected to the middle of the left side of the support base 1 42. A first spring 41 is connected between the right side of the extrusion plate 42 and the support base 1, the first spring 41 is sleeved on the outside of the extrusion plate 42, and the components of the guide mechanism 5 are connected with a turntable 43, and the turntable 43 is located in the support On the upper part of the seat 1, the outer side of the turntable 43 is connected with a fixing rod 44, the outer end of the fixing rod 44 is connected with a fixing rope 45, the outer side of the fixing rope 45 on the rear side is connected with a rough surface 47, and the outer side of the fixing rope 45 on the front side is connected with a hook surface 46, the...

Embodiment 3

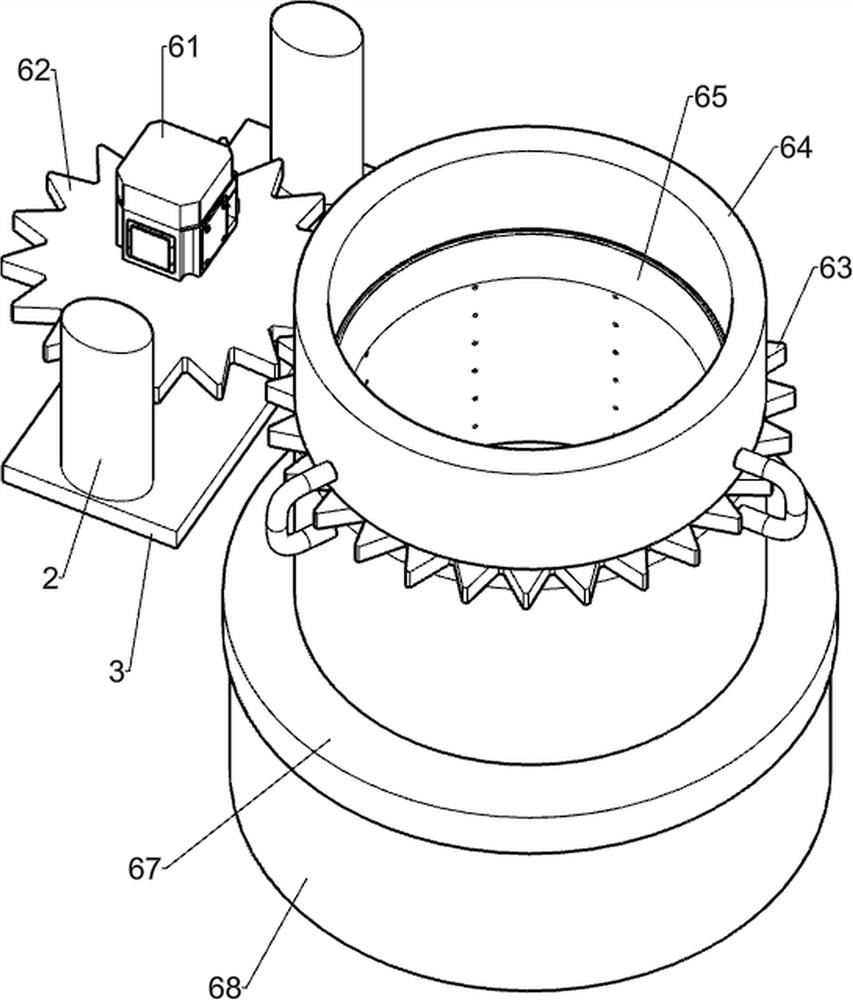

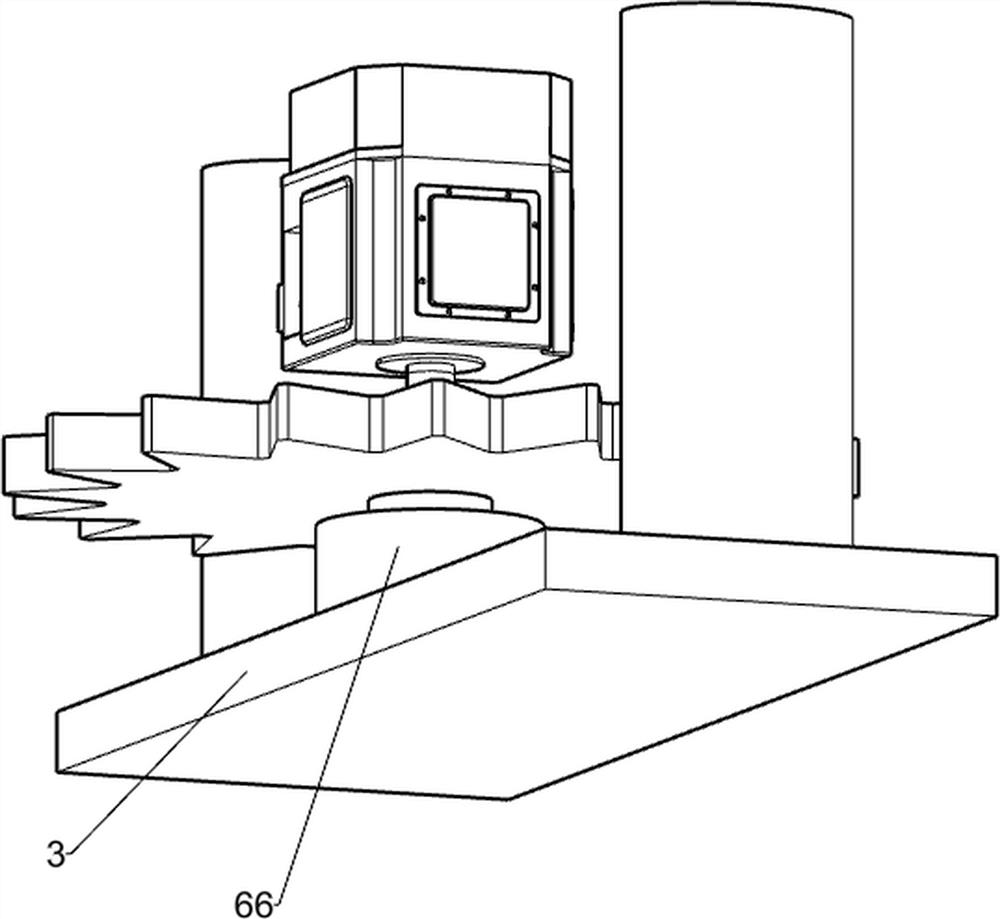

[0070] On the basis of Example 2, as Figure 6-9 As shown, the filter mechanism 6 includes a motor 61, a pinion gear 62, a large gear 63, a filter cylinder 64, a filter bucket 65, a second bearing seat 66, a snap ring 67 and a collection cylinder 68, and the top of the support table 3 is connected with a second The bearing seat 66, the middle of the bottom of the support seat 1 is connected with a motor 61, the top of the second bearing seat 66 is rotatably connected with a pinion 62, the pinion 62 is connected with the output shaft of the motor 61, and the right side of the bottom of the support seat 1 is connected with a filter cartridge 64, A filter bucket 65 is rotatably connected in the filter cartridge 64, a large gear 63 is connected to the top of the filter bucket 65, and the large gear 63 meshes with the pinion 62. A snap ring 67 is connected to the outer side of the lower part of the filter cartridge 64, and the bottom of the snap ring 67 is provided with a removable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com