Treatment method of impregnated rubber wood

A treatment method, rubber wood technology, applied in wood treatment, impregnated wood, wood treatment details, etc., can solve the problems of decay, long cycle, mildew, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

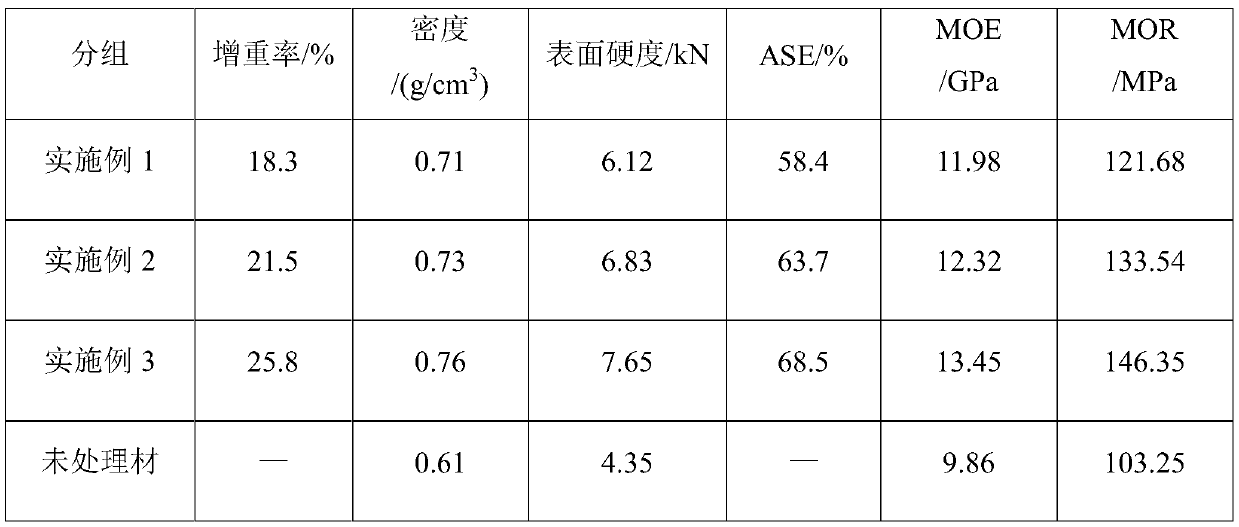

Examples

Embodiment 1

[0025] (1) Put the wood to be modified in a dipping tank, heat it to 60°C, vacuumize it to -0.1MPa, and keep it for 20-30min.

[0026] (2) When the temperature of the impregnation tank is lowered to about 25°C under vacuum, the impregnation liquid is injected, and the impregnation liquid completely submerges the wood.

[0027] (3) Pressurize to 1.2MPa, keep it for 5-6 hours, and discharge the impregnation solution.

[0028] (4) Open the impregnation tank, take out the wood and put it into the drying kiln, dry it in stages, dry at 60°C until the moisture content is <30%, dry at 70°C until the moisture content is <20%, dry at 80°C until the moisture content is <15%, 100 °C and dry until the moisture content is less than 10%.

Embodiment 2

[0030] (1) Place the wood to be modified in a dipping tank, heat to 80°C, vacuumize to -0.1MPa, and keep for 20-30min.

[0031] (2) When the temperature of the impregnation tank is lowered to about 20°C under vacuum, the impregnation liquid is injected, and the impregnation liquid completely submerges the wood.

[0032] (3) Pressurize to 1.2MPa, keep it for 5-6 hours, and discharge the impregnation solution.

[0033] (4) Open the impregnation tank, take out the wood and put it into the drying kiln, dry it in stages, dry at 60°C until the moisture content is <30%, dry at 70°C until the moisture content is <20%, dry at 80°C until the moisture content is <15%, 100 °C and dry until the moisture content is less than 10%.

Embodiment 3

[0035] (1) Place the wood to be modified in a dipping tank, heat to 120°C, vacuumize to -0.1MPa, and keep for 20-30min.

[0036] (2) When the temperature of the dipping tank is lowered to 25°C in a vacuum state, inject the dipping liquid, and the dipping liquid will completely submerge the wood.

[0037] (3) Pressurize to 1.2MPa, keep it for 5-6 hours, and discharge the impregnation solution.

[0038] (4) Open the impregnation tank, take out the wood and put it into the drying kiln, dry it in stages, dry at 60°C until the moisture content is <30%, dry at 70°C until the moisture content is <20%, dry at 80°C until the moisture content is <15%, 100 °C and dry until the moisture content is less than 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Formaldehyde emission | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com