Rubber wood front core preparation process and application thereof

A preparation process, rubber wood technology, applied in the field of rubber wood front core preparation process, can solve the problems of easy deformation of veneer, low yield rate, high cost of veneer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

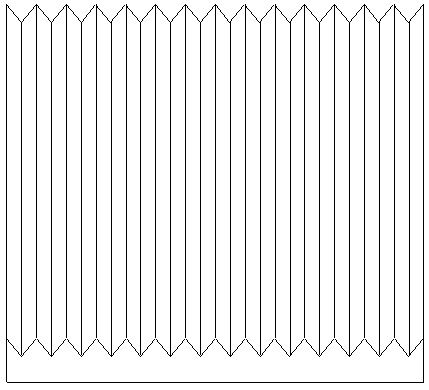

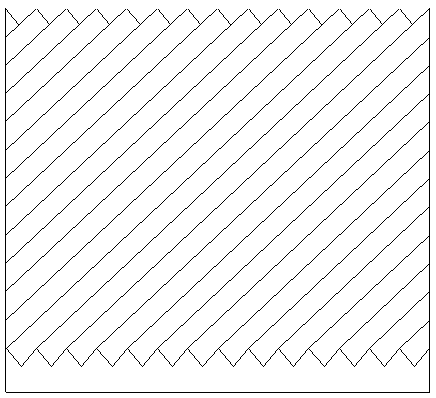

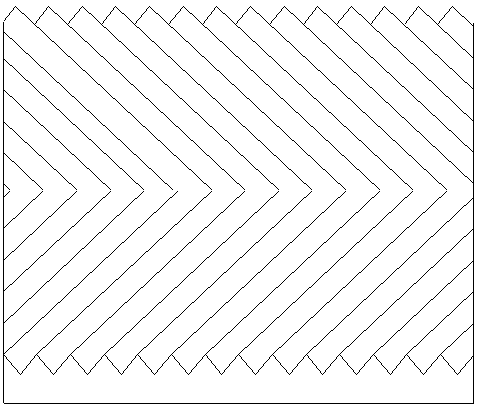

[0026] refer to figure 1 Shown, a kind of preparation technology of rubberwood front core comprises the following steps:

[0027] 1) Process the spliced surface of the rubber wood core into a straight sawtooth shape;

[0028] 2) Coat hot-melt adhesive on the spliced surface of the rubber wood board core. The coated hot-melt adhesive is composed of the following raw materials in weight percentage: 30% formaldehyde, 40% urea, 25% melamine, 1% caustic soda, polyvinyl alcohol 2%, curing agent 2%, and after coating, make more than one layer of rubber wood core two by two to form a rubber wood board;

[0029] 3) Stack the assembled rubber wood boards in an environment with a temperature of 30°C and a humidity of 70%, and place them for 5-7 days until the moisture content of the rubber wood boards is 6%;

[0030] 4) Coat the surface of the stacked rubber wood board with a layer of putty, then scrape it flat, and sand it once to get the rubber wood front core.

[0031] For the ...

Embodiment 2

[0033] refer to figure 1 Shown, a kind of preparation technology of rubberwood front core comprises the following steps:

[0034] 1) Process the spliced surface of the rubber wood core into a straight sawtooth shape;

[0035] 2) Coat hot-melt adhesive on the spliced surface of the rubber wood board core. The coated hot-melt adhesive is composed of the following raw materials in weight percentage: 36% formaldehyde, 35% urea, 24% melamine, 2% caustic soda, polyvinyl alcohol 2%, curing agent 1%, and make more than one layer of rubber wood board core two by two to form a rubber wood board after coating;

[0036] 3) Stack the assembled rubber wood boards in an environment with a temperature of 25°C and a humidity of 60%, and place them for 5-7 days until the moisture content of the rubber wood boards is 8%;

[0037] 4) Coat the surface of the stacked rubber wood board with a layer of putty, then scrape it flat, and sand it once to get the rubber wood front core.

[0038] Com...

Embodiment 3

[0040] refer to figure 1 Shown, a kind of preparation technology of rubberwood front core comprises the following steps:

[0041] 1) Process the spliced surface of the rubber wood core into a straight sawtooth shape;

[0042] 2) Coat hot-melt adhesive on the spliced surface of the rubber wood board core. The coated hot-melt adhesive is composed of the following raw materials in weight percentage: 40% formaldehyde, 35% urea, 20% melamine, 3% caustic soda, polyvinyl alcohol 1%, curing agent 1%, and after coating, make more than one layer of rubber wood core two by two to form a rubber wood board;

[0043] 3) Stack the assembled rubber boards in an environment with a temperature of 25°C and a humidity of 65%, and place them for 5-7 days until the moisture content of the rubber boards is 10%;

[0044] 4) Coat the surface of the stacked rubber wood board with a layer of putty, then scrape it flat, and sand it once to get the front core of rubber wood, and then repeatedly coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com