Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Polylactic acid preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method to reprocess polylactic acid resin and articles

InactiveUS20110244257A1Prevent degradationImprove the immunitySynthetic resin layered productsLaminationIntrinsic viscosityCopolymer

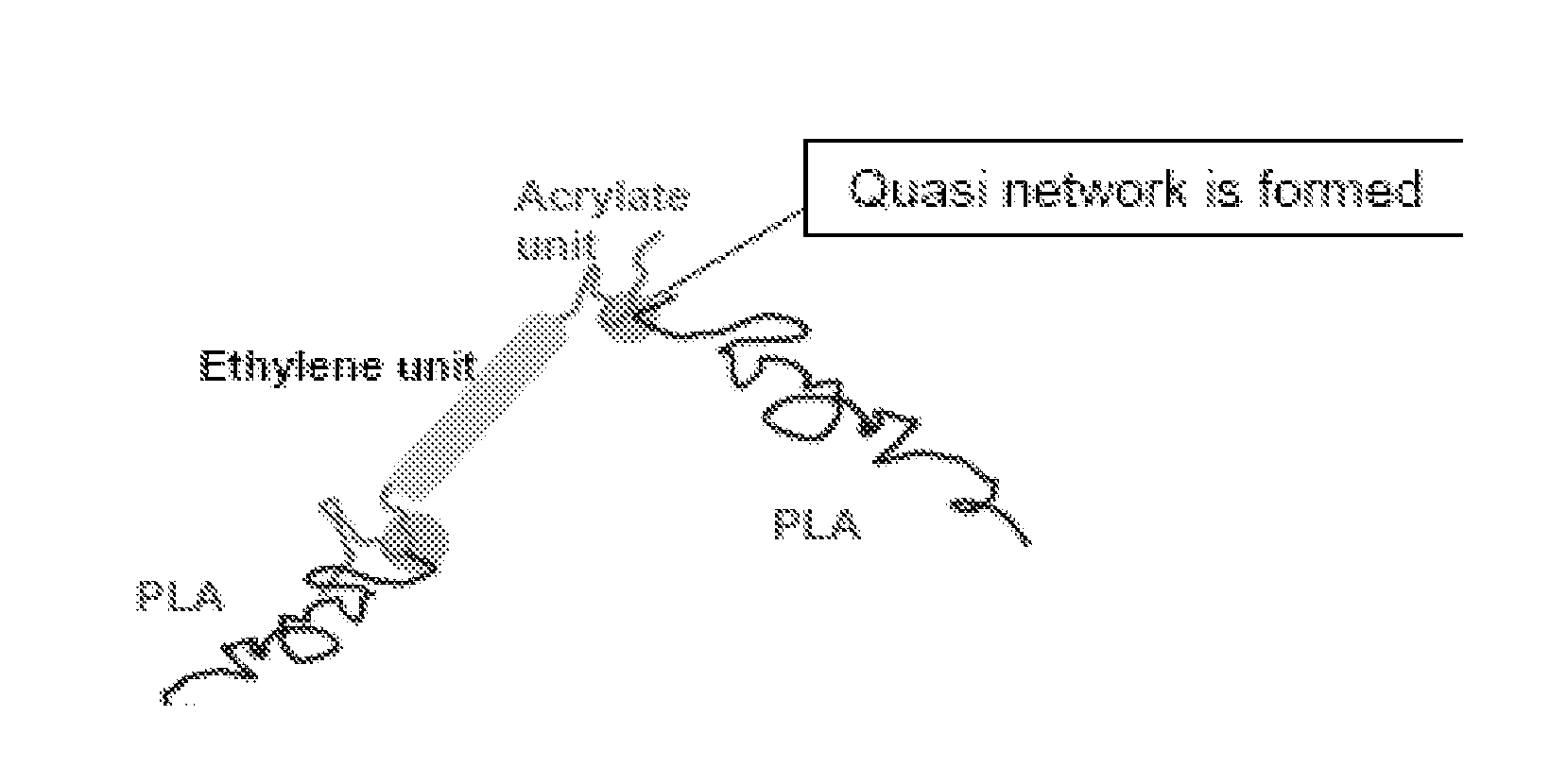

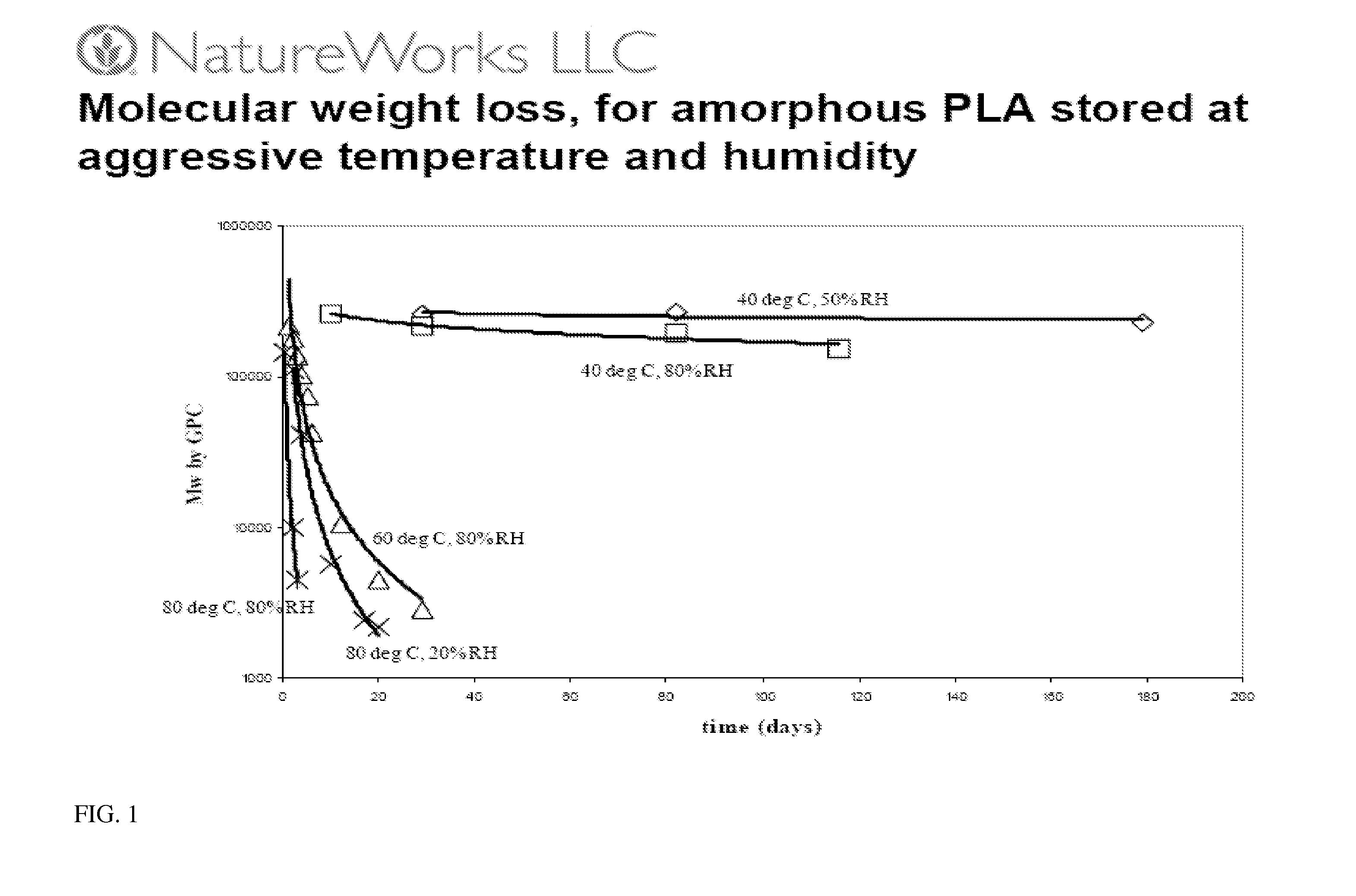

Films and formulations that include recycled polylactic acid resin are described. The films and formulations include, for example, 1-10 wt % of an ethylene-acrylate copolymer. The use of the ethylene-acrylate compolymer in the polylactic acid formulations allows for recycling of PLA-based films and articles with minimum degradation, as exhibited by changes in intrinsic viscosity and color properties.

Owner:TORAY PLASTICS AMERICA

Long chain branch polylactic acid preparation method

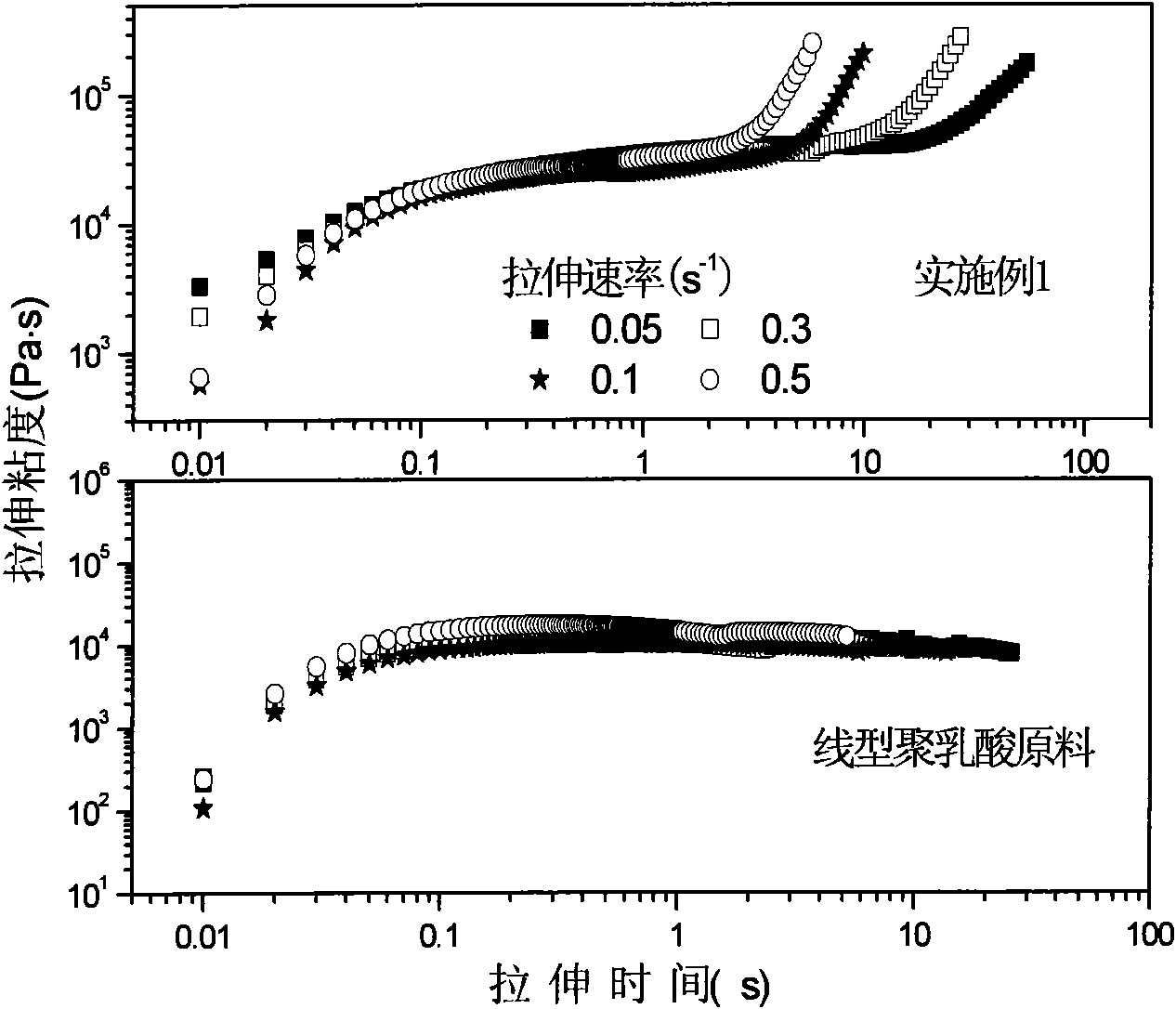

A long chain branch polylactic acid preparation method comprises the following steps: firstly, melting 100 parts of linear polylactic acid by weight at 190-210 DEG C, adding 0.5-1 part of antioxygen by weight, then adding 0.03-0.06 part of polyfunctional monomer by weight, and mixing the mixture for 10-30min to obtain the long chain branch polylactic acid; wherein, the polyfunctional monomer is one or more epoxy monomers with 3 or more of functionality. The molecular weight, the modulus and the melt strength of the product prepared by the invention are improved and the product can be used in forming processes such as foaming, film blowing and the like.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing polylactic acid by using agricultural and sideline products

InactiveCN104592500AIncrease productionStable fermentation processMicroorganism based processesFermentationEnzymatic hydrolysisRhizopus oryzae

Owner:CHONGQING HENGYUAN JINTONG TECH

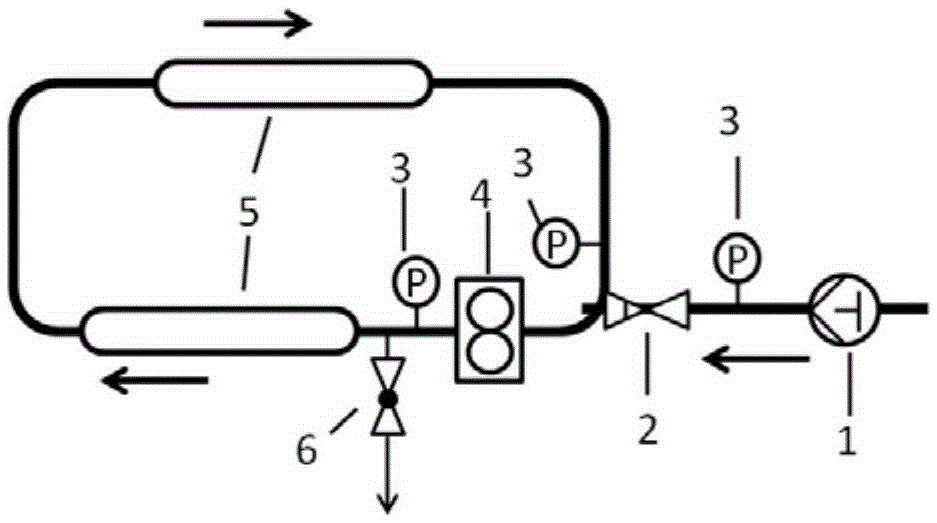

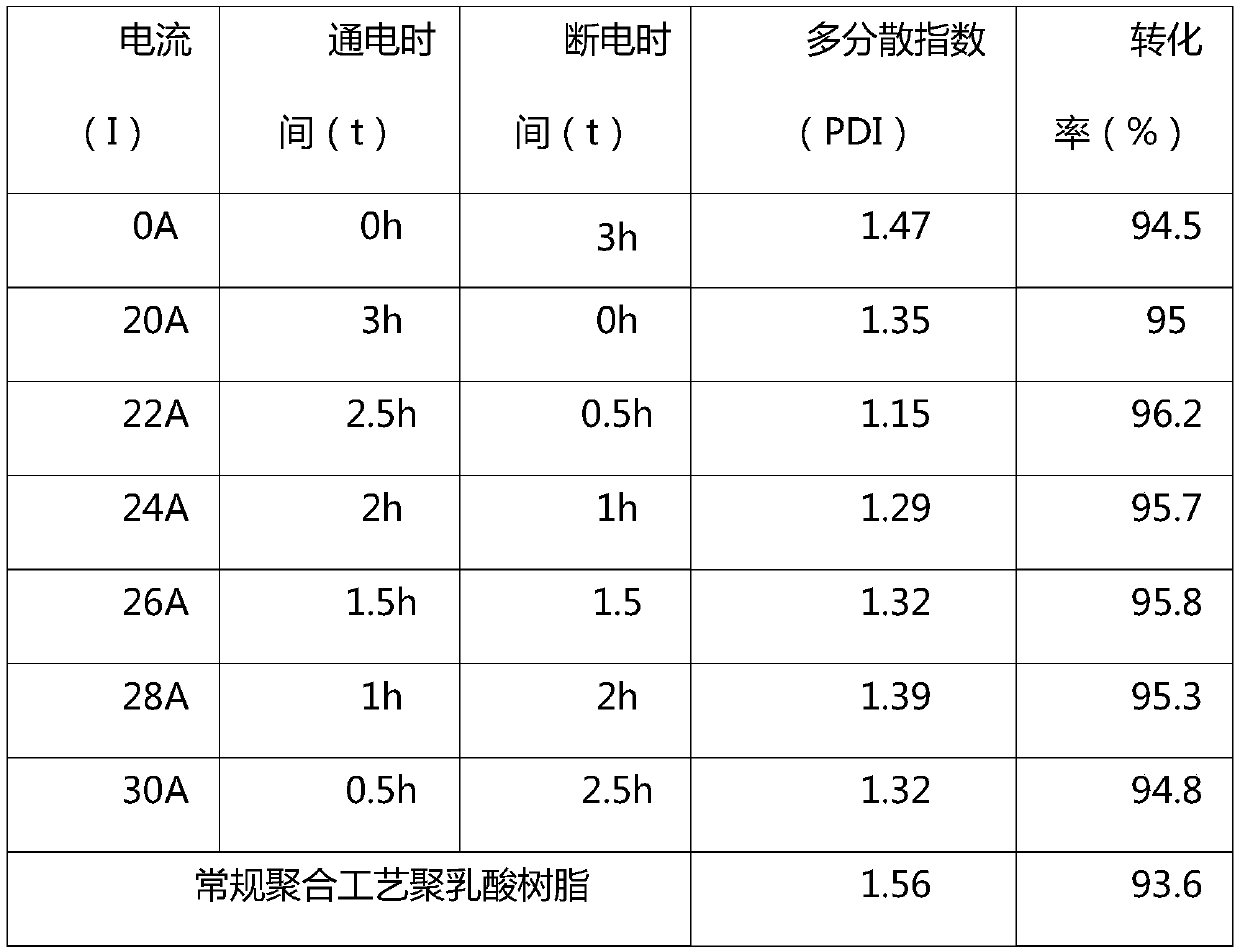

A multistage polymerization method for the preparation of polylactic acid by ring-opening polymerization of lactide

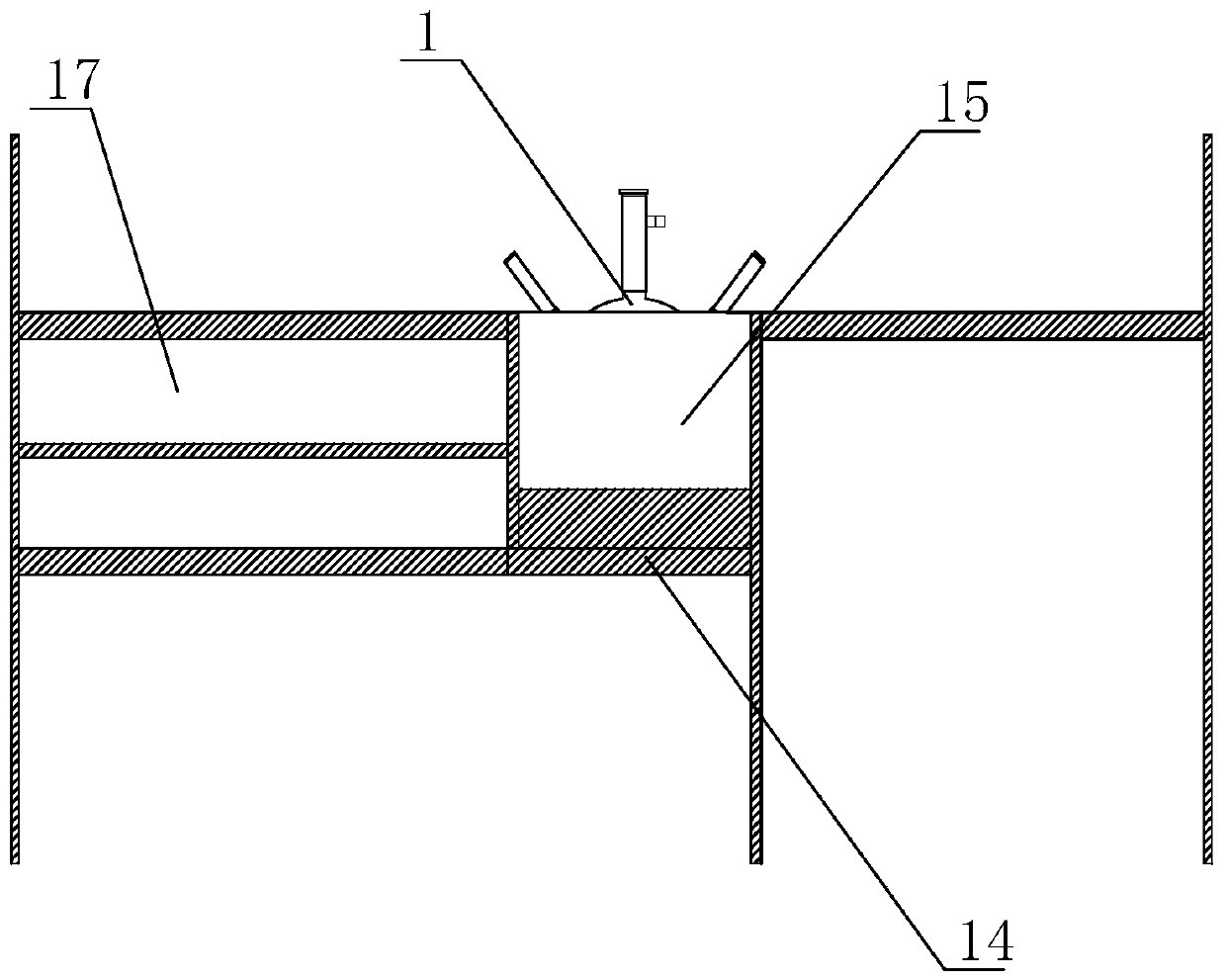

The present invention discloses a multi-stage polymerization method for polylactic acid preparation by ring-opening polymerization of lactide, the method is as follows: molten L-lactide and a composite catalyst system are fully mixed in a ring-type static mixing reaction device comprising a corrugated plate type static mixer, the reaction device temperature is raised for initial ring-opening polymerization, then the reaction device temperature is further raised for L-polylactic acid preparation. According to the multi-stage polymerization method, by adjusting of temperature and reaction time of different stages and adjusting of reaction system flow rate and shear rate, high optical purity and molecular weight polylactic acid with the distribution meeting the requirements of spinning can be obtained. Compared with the conventional polymerization method, the multi-stage polymerization method has the advantages of simple polymerization equipment, low energy consumption, low investment, short reaction time, controllable product properties, high production magnification degree and the like.

Owner:杭州聚丰新材料有限公司

Polylactic acid preparation method

InactiveCN105542154AHigh capping rateEasy to makeTert-Butyloxycarbonyl protecting groupTrifluoroacetic acid

The invention discloses a polylactic acid preparation method, belongs to the field of preparation of polylactic acid, and concretely provides an aminopolylactic acid preparation method with simple preparation process and high amino termination rate. The aminopolylactic acid preparation method comprises the following steps: reacting tert-butoxycarbonyl carbonic anhydride with aminopropanol to synthesize tert-butyloxycarbonyl aminopropanol, initiating ring-opening polymerization of L-lactide with tert-butyloxycarbonyl aminopropanol as an initiator under the catalysis of stannous octoate to synthesize tert-butyloxycarbonylamino-terminated polylactic acid, carrying out trifluoroacetic acid treatment to remove a tert-butyloxycarbonyl group to obtain amino-terminated polylactic acid, and initiating ring-opening polymerization of w-benzyloxycarbonyl-L-lysine-N-carboxylic anhydride with aminopolylactic acid as a macromolecular initiator to synthesize polylactic acid-polylysine. The method has a simple preparation process, and the polylactic acid-polylysine prepared in the invention has a high amino termination rate.

Owner:SHAANXI YUHANG ELECTRONICS

Multi-stage polymerization method for polylactic acid preparation by ring-opening polymerization of lactide

The present invention discloses a multi-stage polymerization method for polylactic acid preparation by ring-opening polymerization of lactide, the method is as follows: molten L-lactide and a composite catalyst system are fully mixed in a ring-type static mixing reaction device comprising a corrugated plate type static mixer, the reaction device temperature is raised for initial ring-opening polymerization, then the reaction device temperature is further raised for L-polylactic acid preparation. According to the multi-stage polymerization method, by adjusting of temperature and reaction time of different stages and adjusting of reaction system flow rate and shear rate, high optical purity and molecular weight polylactic acid with the distribution meeting the requirements of spinning can be obtained. Compared with the conventional polymerization method, the multi-stage polymerization method has the advantages of simple polymerization equipment, low energy consumption, low investment, short reaction time, controllable product properties, high production magnification degree and the like.

Owner:杭州聚丰新材料有限公司

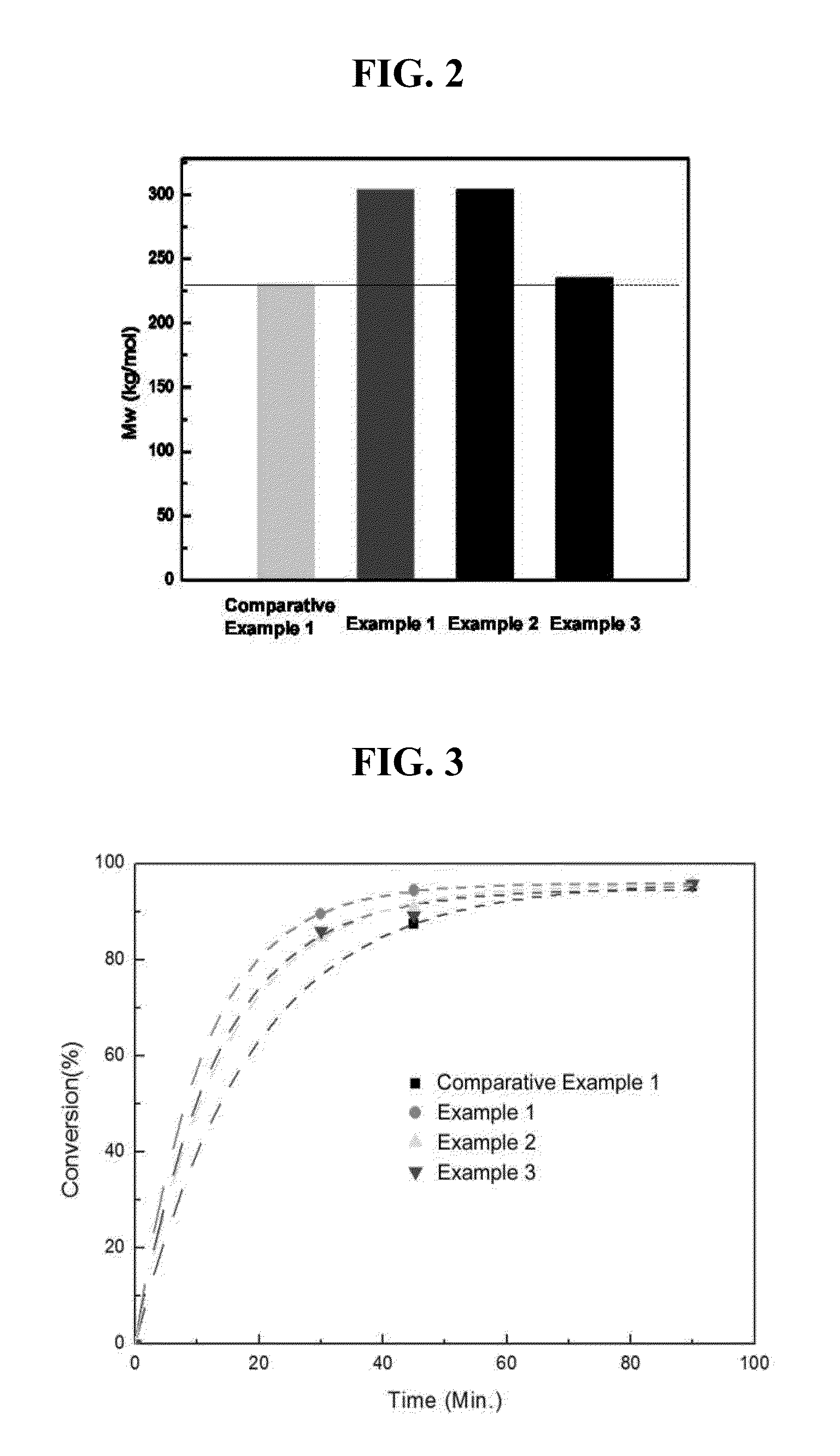

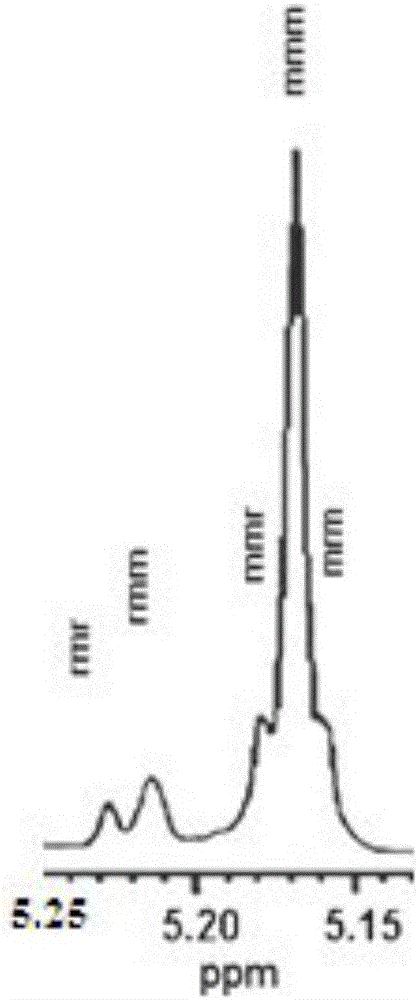

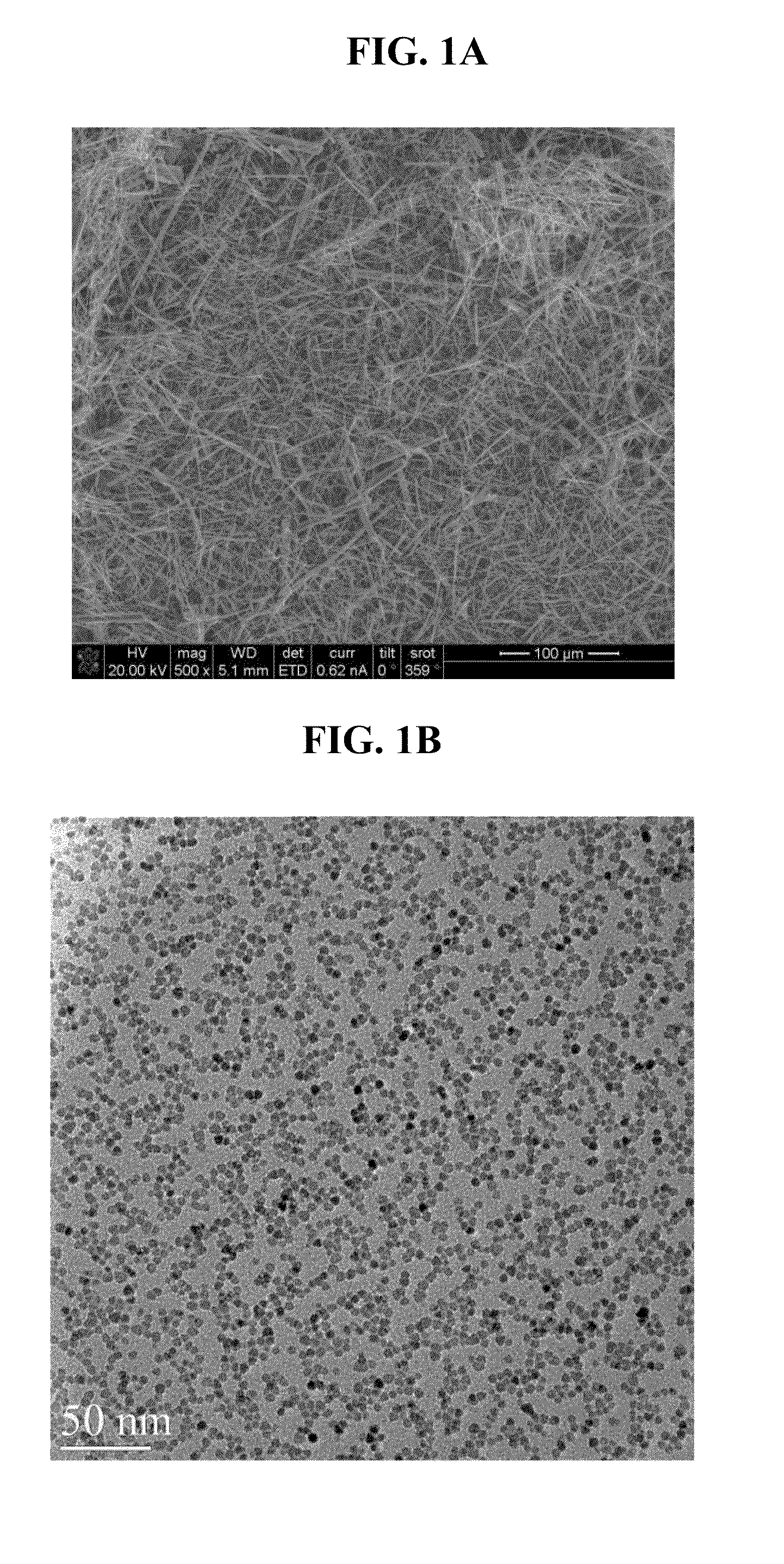

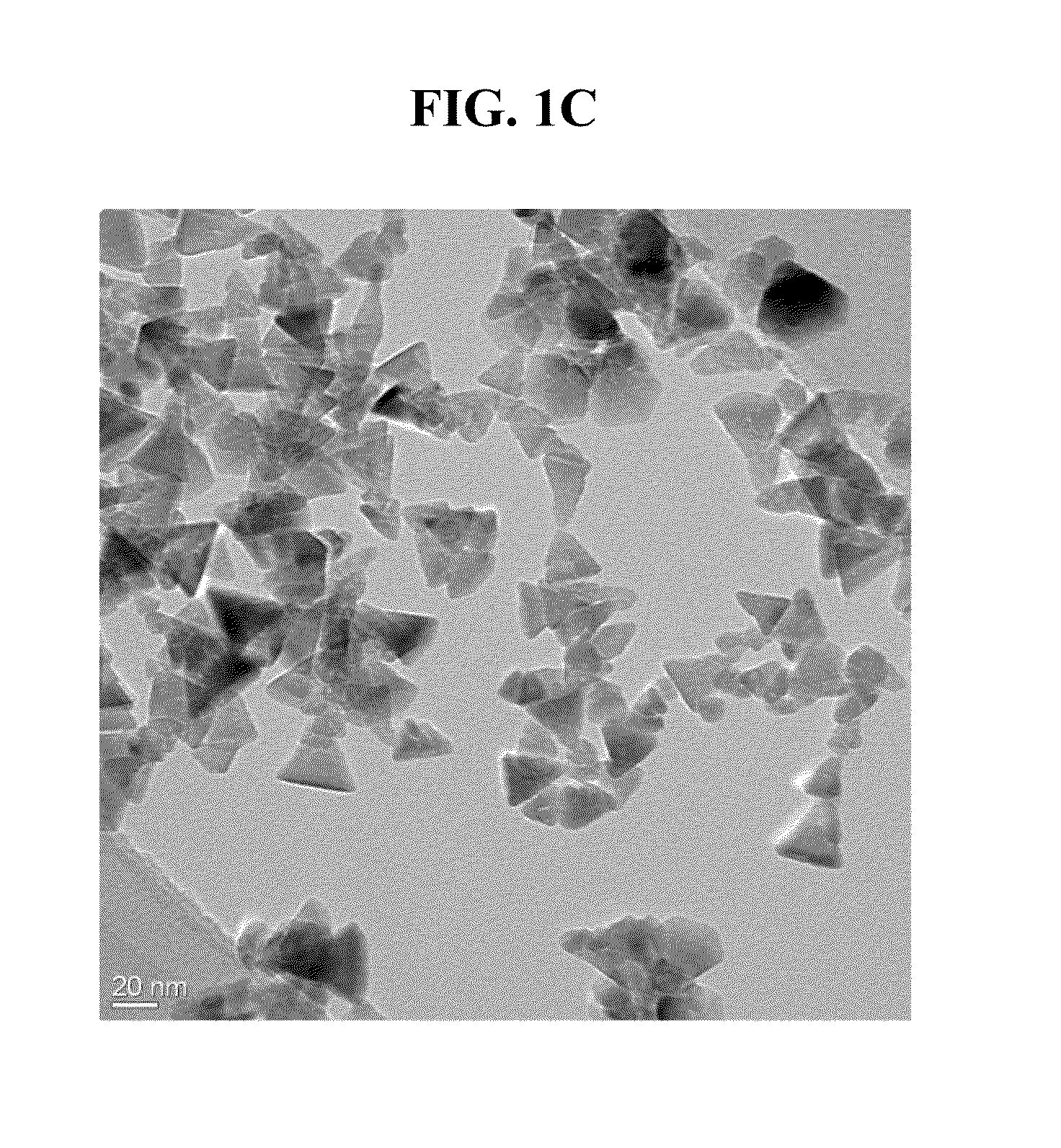

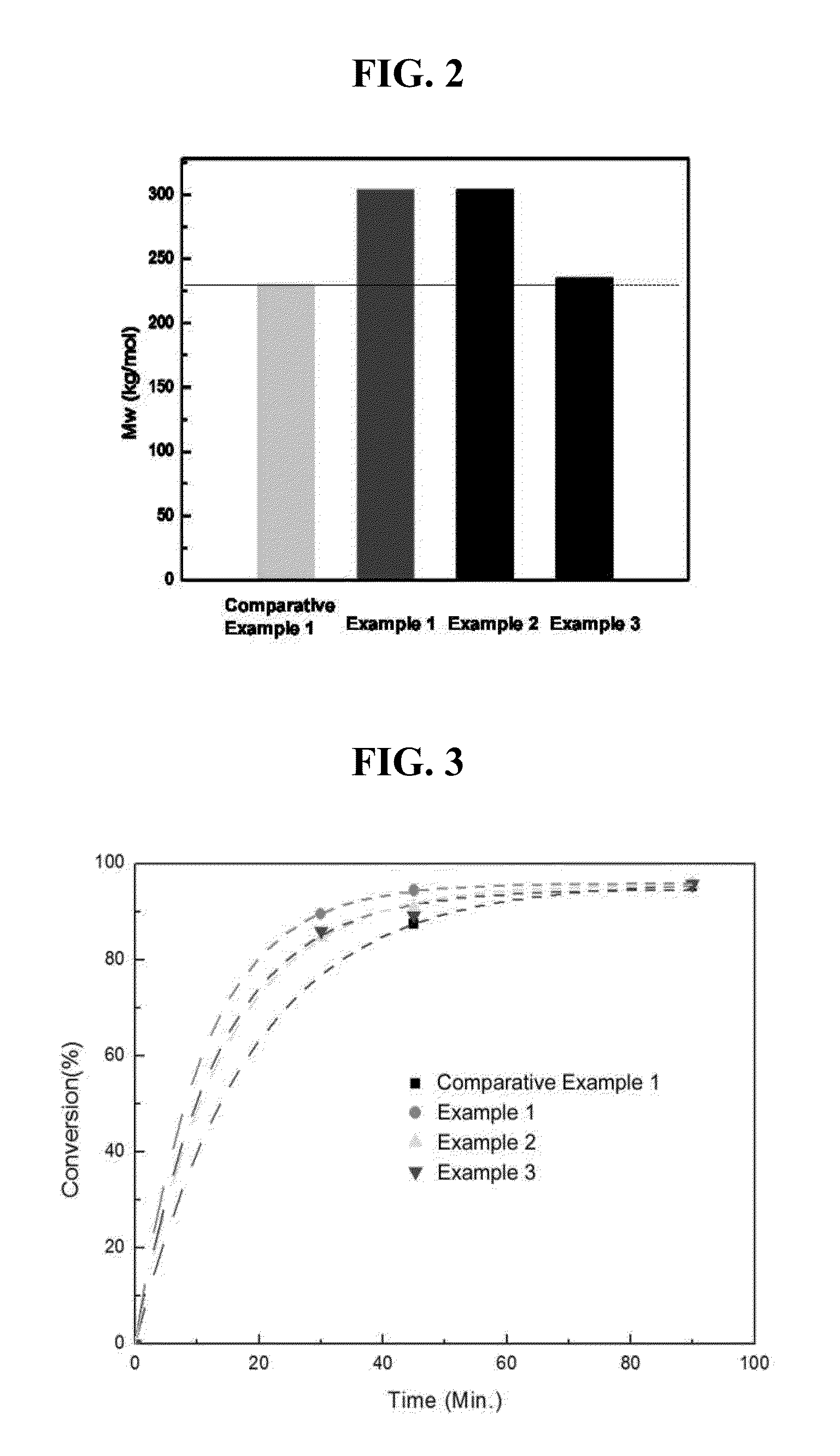

Polylactic acid preparation method, polylactic acid resin prepared using the method, resin composition comprising the polylactic acid resin, and catalyst system for preparing polylactic acid

A method of preparing polylactic acid by combining lactide with a main catalyst and cocatalyst, wherein the main catalyst includes an organometallic compound and a cocatalyst includes a nanoparticle; as well as a composition are provided.

Owner:SAMSUNG ELECTRONICS CO LTD +1

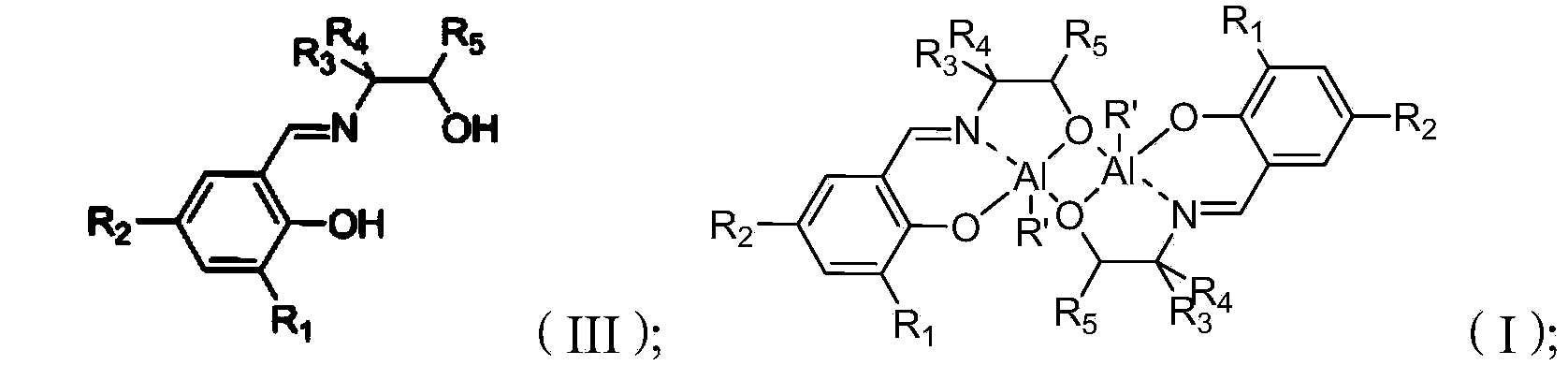

Aluminum compound based on pyrrole derivatives, preparation method of aluminum compound and polylactic acid preparation method

InactiveCN105085560AIncrease steric hindranceHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsM-xylylenediamineRing-opening polymerization

The invention provides an aluminum compound based on pyrrole derivatives, a preparation method of the aluminum compound and a polylactic acid preparation method. The molecular structure of the aluminum compound is shown as the formula (I). The aluminum compound is prepared through reaction of m-xylylenediamine and the pyrrole derivatives. On one hand, the aluminum compound serves as a catalyst with aluminum as central atoms and has high catalytic reaction activity during lactide ring-opening polymerization catalysis, and high polymerization reaction activity is obtained; on the other hand, a ligand has proper steric hindrance, an ideal stereoscopic effect is obtained, and stereoscopic selectivity of racemization lactide ring-opening polymerization is improved. The invention further provides the polylactic acid preparation method. Polylactic acid obtained by catalyzing racemic lactide through the aluminum compound is polylactic acid with isotactic heterogeneous major components, and polylactic acid with 72.0% of isotaxy components is obtained. Please see the formula in the specification.

Owner:CHANGCHUN UNIV OF SCI & TECH

Polylactic acid fiber spinning process

InactiveCN110952163AAchieve sustainable developmentHigh elongation at breakMonocomponent polyesters artificial filamentArtifical filament manufacturePolymer scienceElectrospinning

The invention relates to the field of spinning process, and specifically relates to a polylactic acid fiber spinning process. The polylactic acid fiber spinning process is characterized by comprisingthe following steps of step 1, adding polylactic acid to a mixed solvent, stirring and dissolving at room temperature, then adding tannic acid to obtain a pretreatment solution; step 2, firstly addinga plasticizer to the pretreatment solution, and then adding an initiator to obtain a spinning solution; and step 3, spinning the spinning solution using an electrostatic spinning device to obtain a polylactic acid fiber. The polylactic acid fiber spinning process provided by the invention solves the disadvantages of high polylactic acid brittleness due to high glass transition temperature of theprepared polylactic acid in the existing polylactic acid preparation process. By designing the polylactic acid fiber spinning process, the obtained polylactic acid fiber has the advantages of high temperature resistance and strong toughness.

Owner:无锡御束生物材料科技有限公司

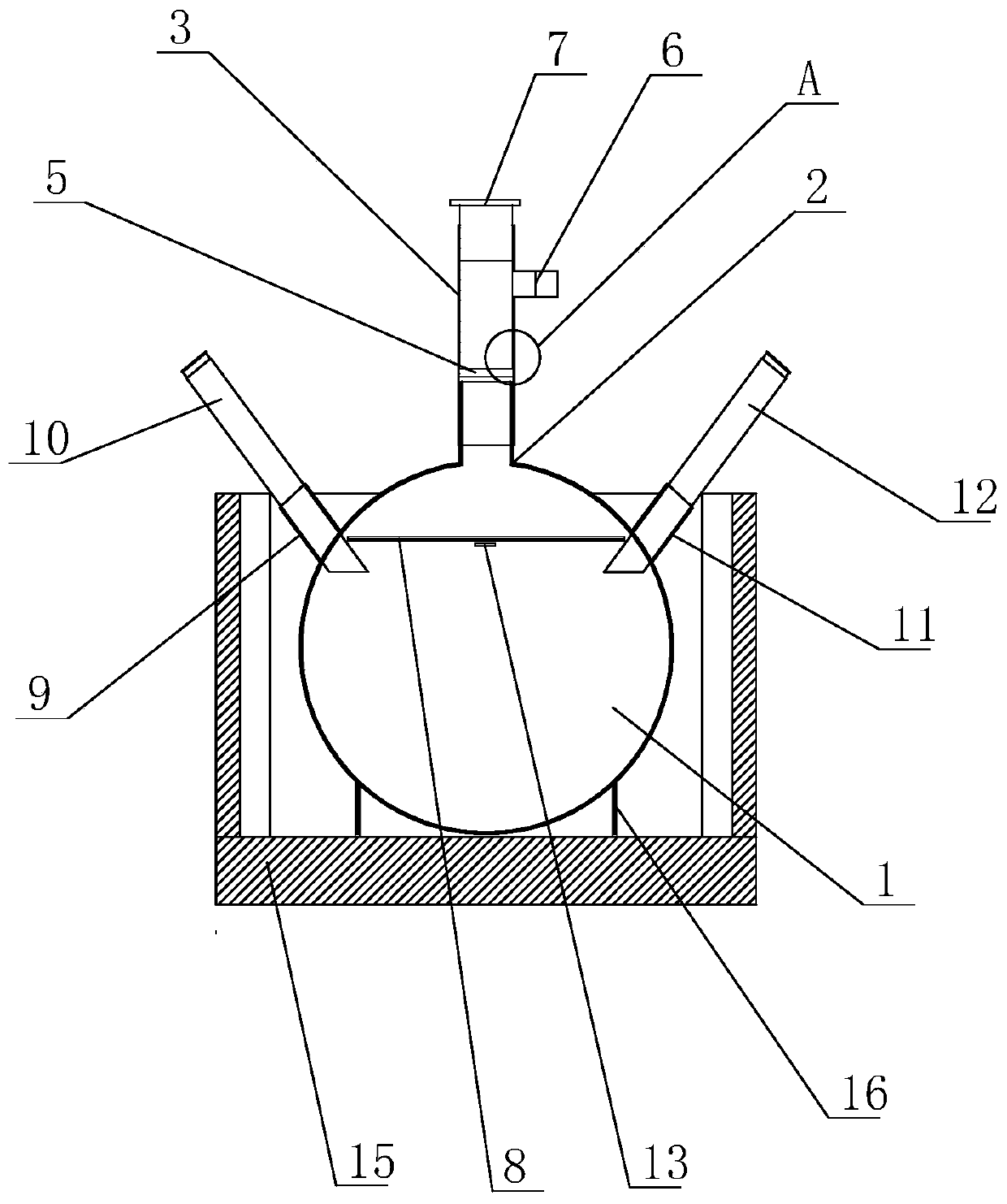

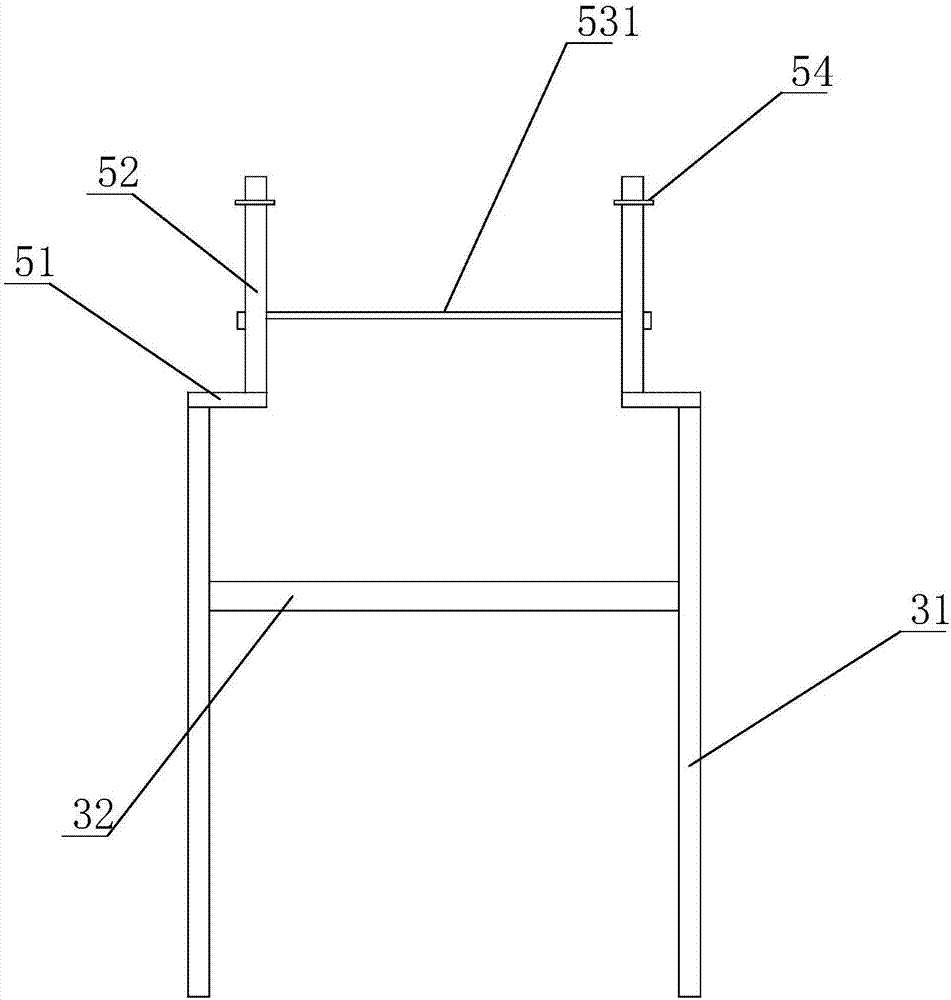

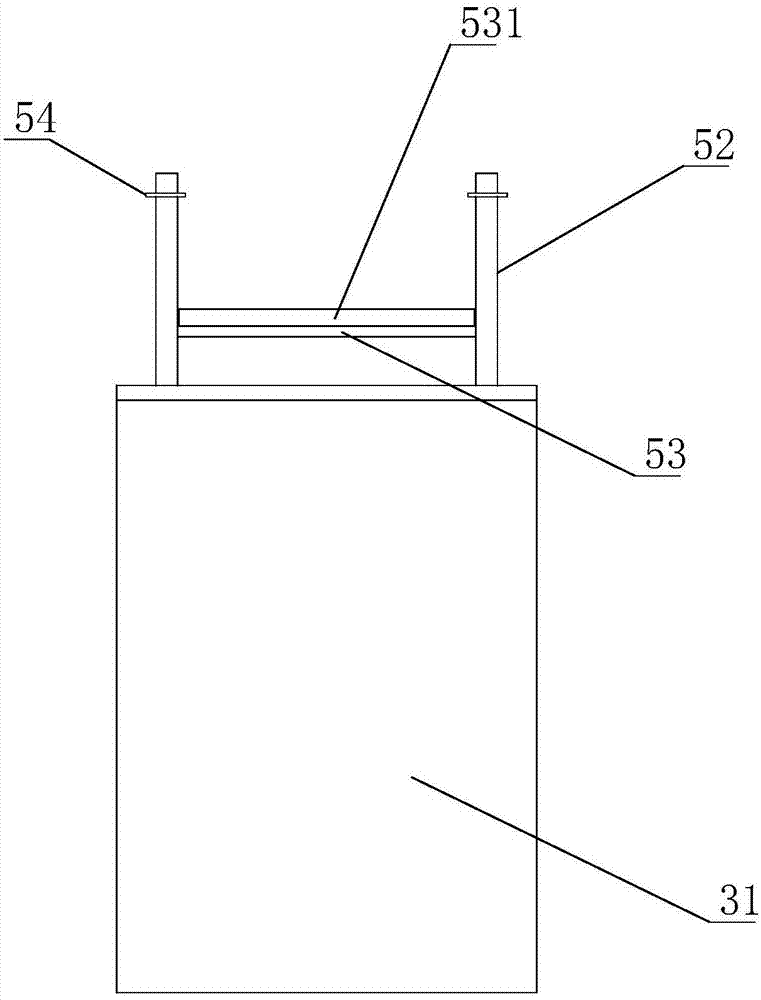

High-crystallinity heat-resistant polylactic acid preparation method and apparatus

The invention discloses a high-crystallinity heat-resistant polylactic acid preparation method and apparatus. The high-crystallinity heat-resistant polylactic acid preparation method comprises the following steps: step 1: adding dichloromethane to lactide to prepare a lactide solution, adding an initiator, and then carrying out a ring-opening polymerization reaction by using microwave irradiationunder reduced pressure conditions; step 2: adding benzoic acid to terminate the reaction to obtain a product A; step 3: dissolving the product A with dichloromethane, performing re-precipitating withmethanol, and filtering out a white solid to obtain a product B; step 4: performing melt extrusion on L-polylactic acid, D-polylactic acid, talc, and polymethacrylate according to a certain ratio by atwin-screw extruder to obtain a nucleating agent; and step 5: performing melt blending on the nucleating agent and the product B in proportion to obtain a polylactic acid compound. The beneficial effects are as follows: heat resistance is improved, thermal stability is improved, and mechanical properties are improved by adding talc and polymethacrylate.

Owner:BENGBU COLLEGE

Preparation method and application of high-melt-strength polylactic acid

The invention provides a preparation method and application of high-melt-strength polylactic acid, and belongs to the technical field of polylactic acid preparation. The preparation method of the high-melt-strength polylactic acid comprises the following steps: (1) uniformly mixing polylactic acid with dibenzoyl peroxide, acetone and trifunctional acrylate; and (2) placing the mixture in an oven for secondary drying, and carrying out extrusion molding to obtain the high-melt-strength polylactic acid blend particles. The application of the high-melt-strength polylactic acid comprises the steps: putting the high-melt-strength polylactic acid blend particles and nano calcium carbonate into a reaction kettle, introducing CO2, and reacting to obtain the polylactic acid PLA foamed beads. Benzoyl peroxide (BPO) is taken as an initiator, trifunctional acrylate is taken as a grafting monomer, the high-melt-strength polylactic acid PLA is obtained through solid-phase grafting, the prepared polylactic acid is high in melt strength, the foaming ratio during foaming reaches 19.23%, and nano calcium carbonate is taken as a foaming medium, so that the polylactic acid foamed beads with high foaming ratio are obtained.

Owner:HUBEI CHINA TOBACCO IND

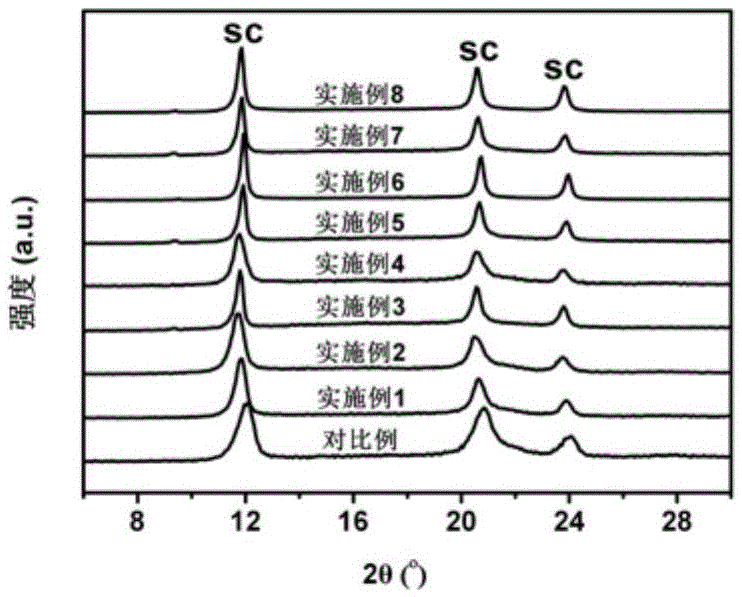

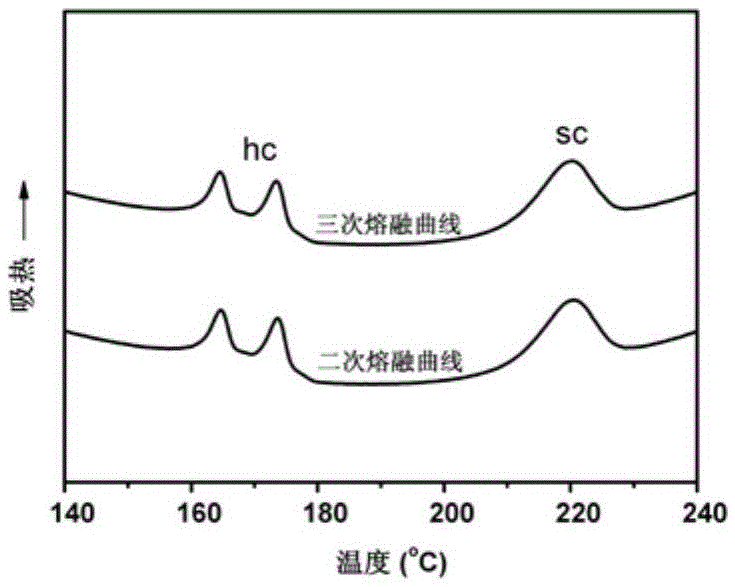

Preparation method of high molecular weight stereocomplex polylactic acid with melt stability

The invention discloses a method for preparing a high molecular weight vertical structure composite polylactic acid with melt stability characteristics. The method comprises the following steps: firstly, carrying out drying treatment on L-polylactide and dextral polylactic acid in vacuum, and then mixing an initiator which can be completely dissolved into absolute ethyl alcohol with a cross-linking agent, and then adding a mixture to a fusion mixer; melting and blending under the conditions that the temperature is 170-200 DEG C and the rotating speed is 20-120 rpm (revolutions per minute) for 2-15 minutes. The prepared high molecular weight vertical structure composite polylactic acid not only has excellent melt stability, but also has strong recrystallization ability, and can ensure that the vertical structure composite polylactic acid crystal with high purity and high content is reformed in a molten product, so as to provide excellent heat resistance and weather fastness to the product. The possibility is also provided for preparation of a PLA product with high performance by virtue of a melt processing technology. Meanwhile, the preparation method provided by the invention is simple in process, high in efficiency, and easy for realization of large-scale industrial production.

Owner:TSD (BEIJING) MEDICAL TECH CO LTD

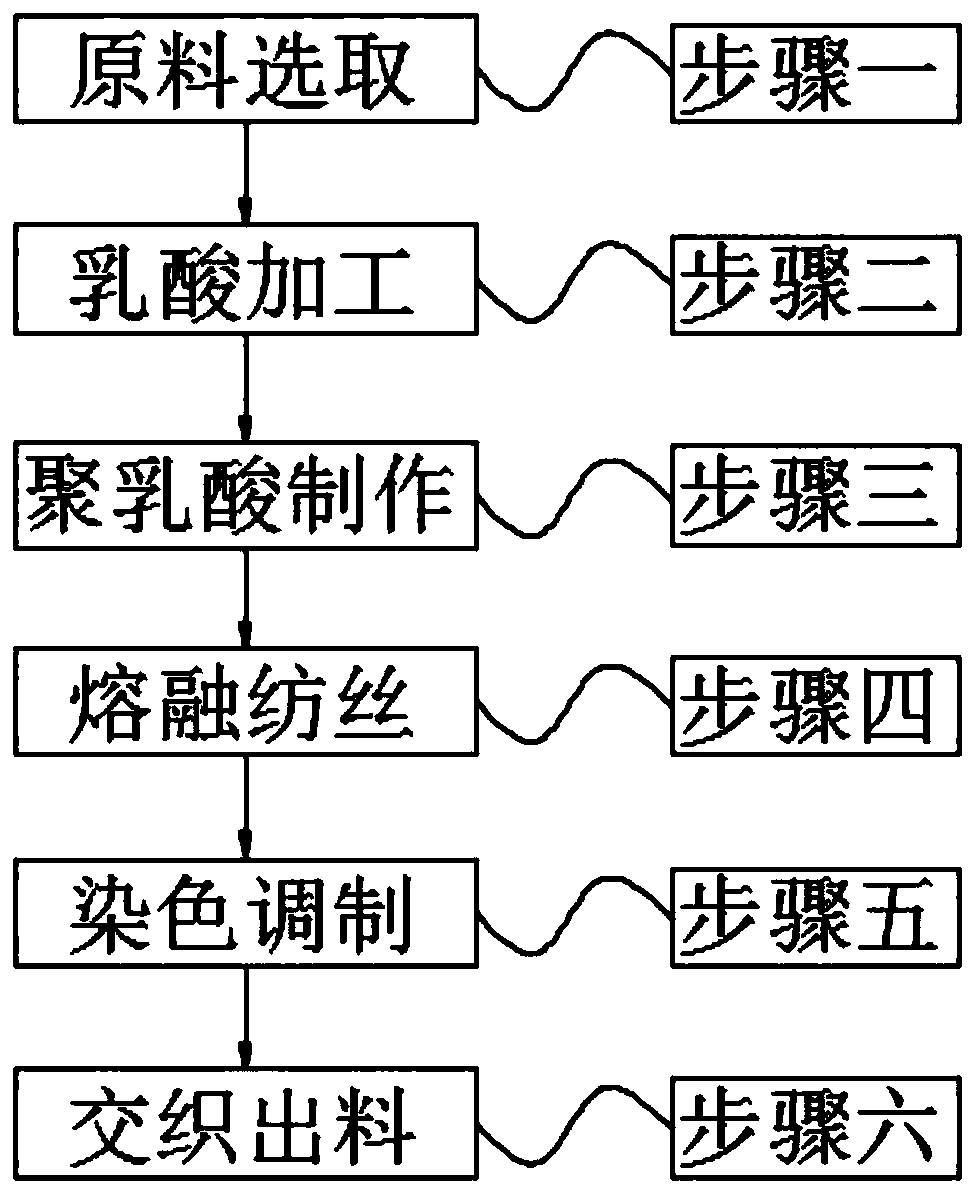

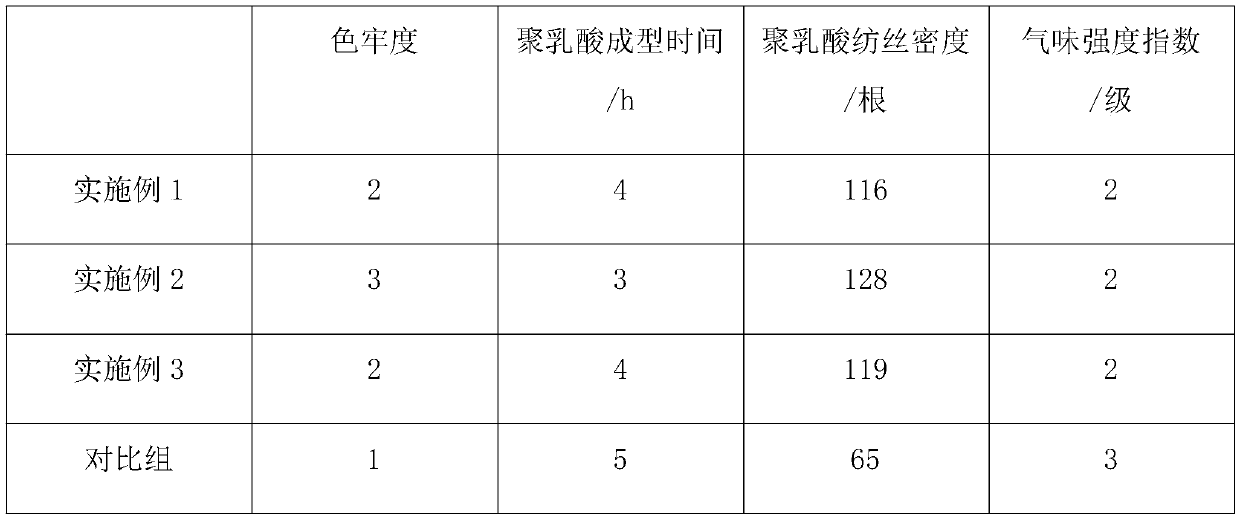

Polylactic acid based cotton interwoven fabric and processing method thereof

InactiveCN110004565APromote environmental protectionSmall smellMelt spinning methodsWoven fabricsPolyesterCellulose

The invention discloses a polylactic acid based cotton interwoven fabric and a processing method thereof. The polylactic acid based cotton interwoven fabric is prepared from, by mass, 25-35% of starch, 15-25% of cellulose, 3-8% of calcium carbonate, 10-20% of lime milk, 15-25% of polyester fibers, 5-10% of acetone, 2-5% of a dehydrating agent, 1-3% of a catalyst and 1-3% of a coloring agent according to a formula. A preparation process includes: step one, raw material selection; step two, lactic acid processing; step three, polylactic acid preparation; step four, melt spinning; step five, dyepreparation; step six, interweaving and discharging. The polylactic acid based cotton interwoven fabric and the processing method thereof have advantages that safety and reliability are realized, polylactic acid is obtained by starch fermentation and lactide ring-opening polymerization, lime milk is added for accelerating reaction to obtain polylactic acid with extremely high relative molecular weight, high polylactic acid spinning density, low manufacturing cost and cheapness of raw materials are realized, and production cost is greatly saved.

Owner:JIANGSU MINGYUAN TEXTILE

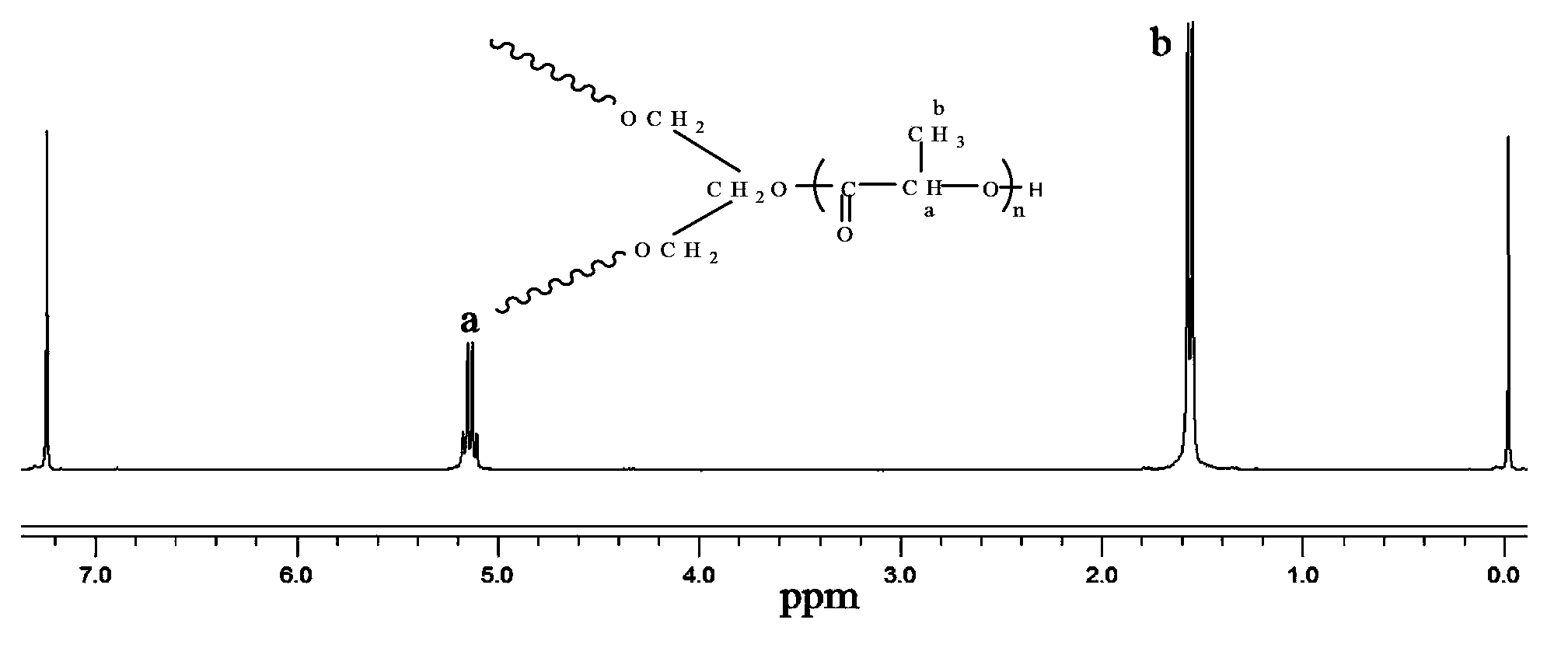

Polylactic acid segmented copolymer and modified polylactic acid preparation method

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

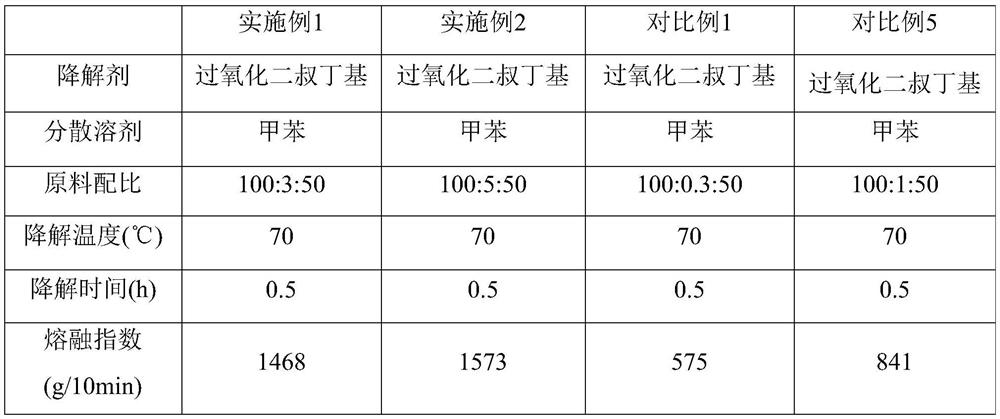

Kettle-type synthesis method of polylactic acid with high melt index and modified polylactic acid prepared thereby

ActiveCN112300417ASmall footprintReduce energy consumptionPlastic recyclingPolymer scienceMelt flow index

The invention discloses a kettle-type synthesis method of polylactic acid with a high melt index, relates to the field of polymer composite materials, and aims at solving the problems of high equipment cost, high energy consumption and low melt index of the existing polylactic acid preparation. The preparation method comprises the following steps: (1) adding polylactic acid particles, a degradation agent and a dispersing solvent into a high-temperature reaction kettle according to a mass ratio of 100:3:50-100:5:50; (2) heating the reaction kettle to 70-100DEG C, continuously performing stirring for 0.5-8.0h, and then performing cooling; and (3) filtering the mixture in the reaction kettle, and drying the solid substance to obtain the modified polylactic acid. The invention also discloses the modified polylactic acid prepared by the preparation method. Compared with a screw extruder, the kettle type production equipment is small in occupied area and low in energy consumption; the melt index of the modified polylactic acid is controlled by adjusting the reaction temperature, the reaction time and the addition amount of the degradation agent, the melt index is very stable and is 1500-2900g / 10min, and the standard of the melt index of a common melt-blown high-molecular polymer is met.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

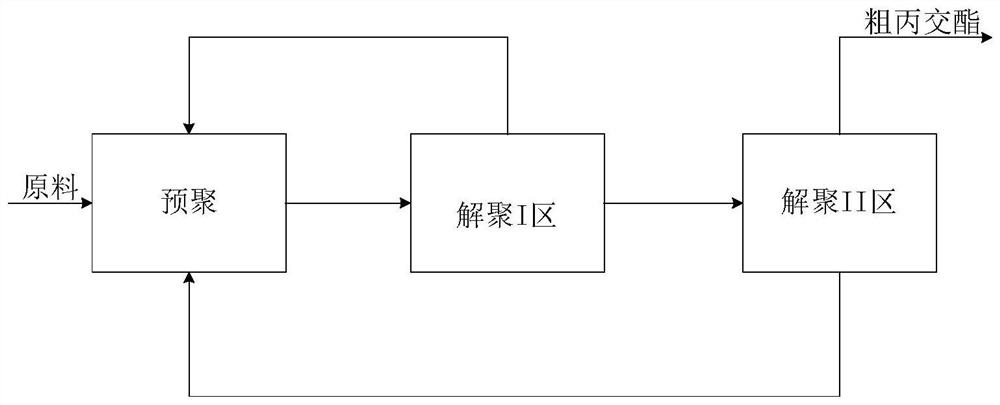

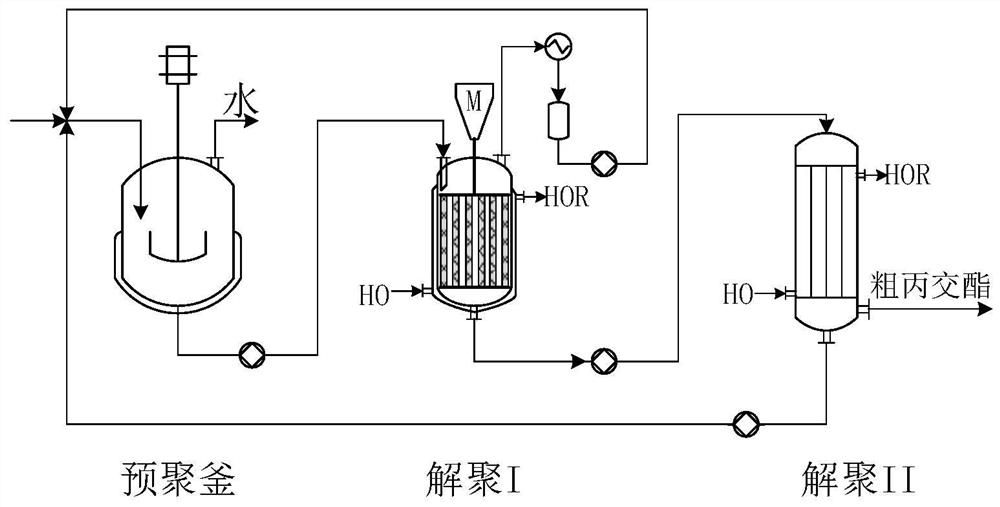

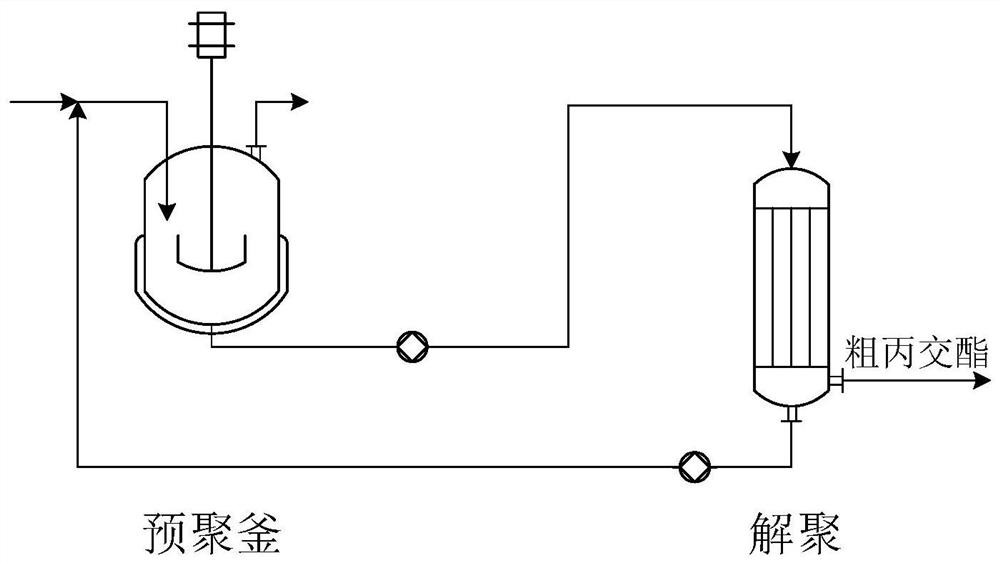

Reaction process for preparing low-acid lactide

PendingCN112480063AReduce manufacturing costQuality improvementOrganic chemistryDepolymerizationFluid phase

The invention discloses a reaction process for preparing low-acid lactide. According to the process, lactic acid is pre-polymerized and cracked to prepare lactide, the raw material polylactic acid passes through at least two depolymerization reaction zones, the single-pass conversion rate of the depolymerization reaction is controlled to be not higher than 10% in the first depolymerization reaction zone, and a gas-phase product is circulated to an upstream polylactic acid preparation procedure; and the liquid-phase product passes through a subsequent depolymerization reaction zone to obtain acrude lactide product. By adopting the process, the acid content of crude lactide can be remarkably reduced, impurities are reduced, byproducts are reduced, and downstream separation energy consumption and production cost are remarkably reduced.

Owner:WANHUA CHEM (SICHUAN) CO LTD +1

Polylactic acid preparation method, polylactic acid resin prepared using the method, resin composition comprising the polylactic acid resin, and catalyst system for preparing polylactic acid

A method of preparing polylactic acid by combining lactide with a main catalyst and cocatalyst, wherein the main catalyst includes an organometallic compound and a cocatalyst includes a nanoparticle; as well as a composition are provided.

Owner:SAMSUNG ELECTRONICS CO LTD +1

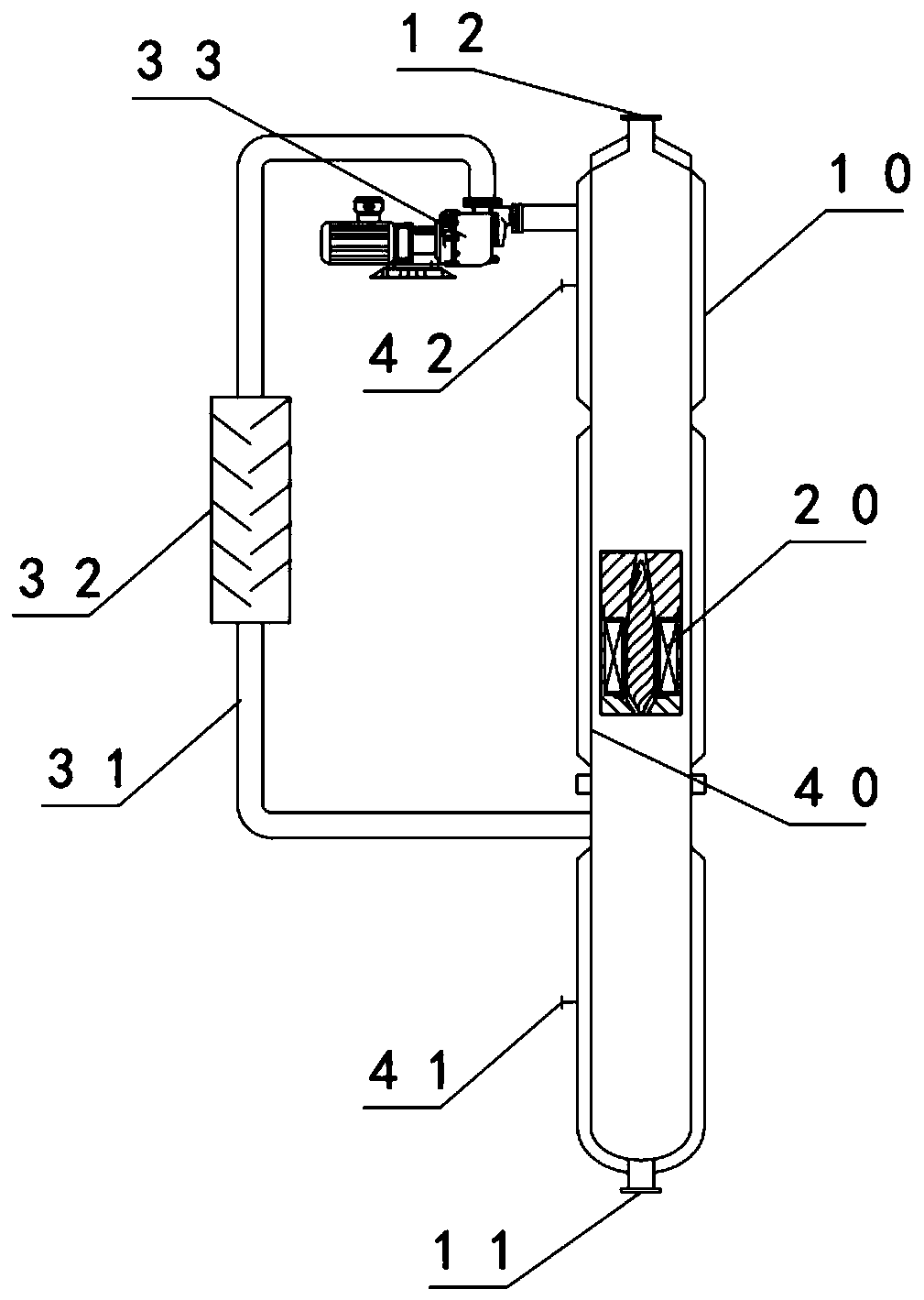

Polylactic acid polymerization reaction apparatus and system

ActiveUS11110427B1Reduce retention timeEnhance aggregation abilityFlow mixersTransportation and packagingPolymer sciencePolymer chemistry

The present invention relates to the technical field of polylactic acid preparation, and discloses polylactic acid polymerization reaction apparatus and system. The polylactic acid polymerization reaction apparatus comprises a polymerization reactor and an agitating assembly arranged in a flow channel of the polymerization reactor, wherein the agitating assembly comprises an electromagnetic winding mechanism and a magnetic induction element, the electromagnetic winding mechanism is arranged along the inner wall of the polymerization reactor around the magnetic induction element, with clearance formed between the electromagnetic winding mechanism and the magnetic induction element, so that the magnetic induction element and the electromagnetic winding mechanism can induce electromagnetic induction, and thereby the magnetic induction element can rotate around its own axis; a threaded groove is formed on the magnetic induction element. The polylactic acid polymerization reaction apparatus provided by the present invention can improve the polymerization effect and thereby improve the product conversion ratio.

Owner:JILIN COFCO BIOCHEM +2

A kind of preparation method of polylactic acid with low optical purity and high molecular weight

The invention provides a preparation method of polylactic acid with low optical purity and high molecular weight. The method comprises the following steps: enabling lactide, to be subjected to isomerization reaction under the catalysis of alcohol alkali metal salt, so as to obtain isomer mixture of meso-lactide, D-lactide and L-lactide, wherein the optical purity of L-lactide or D-lactide in lactide is 90 to 100 percent; enabling the mixture to be subjected to polymerization reaction, so as to obtain the polylactic acid with low optical purity and high molecular weight. The preparation method is simple in process route and easy to operate; the polylactic acid prepared is low in optical purity. The weight-average molecular weight of the polylactic acid prepared through the preparation method is 90 to 120 kg / mol, the molecular weight distribution index is 1.3 to 1.7, the glass-transition temperature is 53 to 57 DEG C, and the optical rotation is -125 to 120 degrees.

Owner:普立思生物科技有限公司

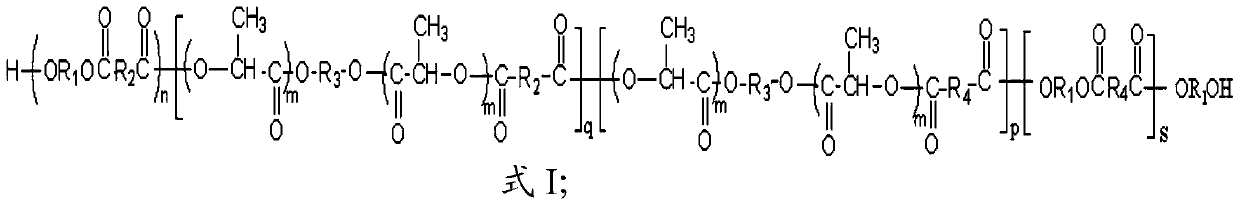

A kind of aliphatic-aromatic-polylactic acid multi-block copolymer

The invention provides an aliphatic-aromatic-polylactic acid multi-block copolymer, which is prepared by the following preparation method: double-terminated hydroxyl polylactic acid, aromatic dicarboxylic acid compounds, aliphatic dicarboxylic acid The compound and the glycol compound undergo esterification reaction and polycondensation reaction to obtain aliphatic-aromatic-polylactic acid multi-block copolymer. The aliphatic-aromatic-polylactic acid multi-block copolymer provided by the present invention contains an aliphatic-aromatic segment, which improves the flexibility of the aliphatic-aromatic-polylactic acid multi-block copolymer. The experimental results show that the elongation at break of the aliphatic-aromatic-polylactic acid multi-block copolymer provided by the present invention is 210%-600%. In addition, the preparation method of the aliphatic-aromatic-polylactic acid multi-block copolymer has simple process, mild reaction conditions, and is conducive to industrial production; no chain extender is used in the entire preparation process, which reduces environmental pollution.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

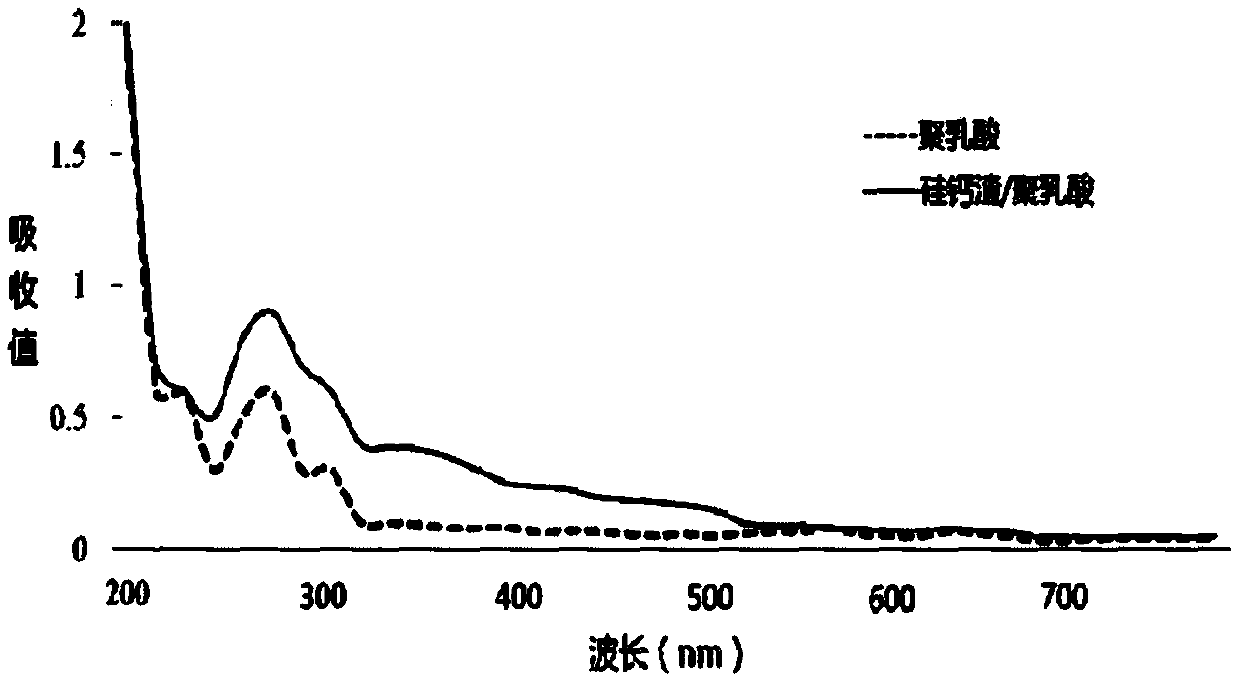

Silicon-calcium slag degradation assisted degradation polylactic acid preparation method

The invention provides a calcium silicate slag assisted degradation polylactic acid preparation method. The method comprises the following steps: 1) preprocessing calcium silicate slag: grinding and crushing calcium silicate slag through a grinding machine, and screening to obtain calcium silicate slag fine powder with a particle size of about 4-10 [mu]m; 2) modifying silicon-calcium slag: addingthe silicon-calcium slag fine powder into an ethanol solution of oleic acid, ultrasonically dispersing, heating to react, filtering and drying; 3) preparing a composite material: premixing the modified silicon-calcium slag obtained in step 2) with polylactic acid, adding the obtained mixture into a double-roller open mill, and performing melt blending to obtain a blended product; and 4) performinghot press molding to obtain the silicon-calcium slag and polylactic acid composite material. The method realizes utilization of waste slag, greatly improves the photodegradation speed of polylactic acid, and shortens the degradation period of polylactic acid.

Owner:宁波普莱斯帝金属制品有限公司

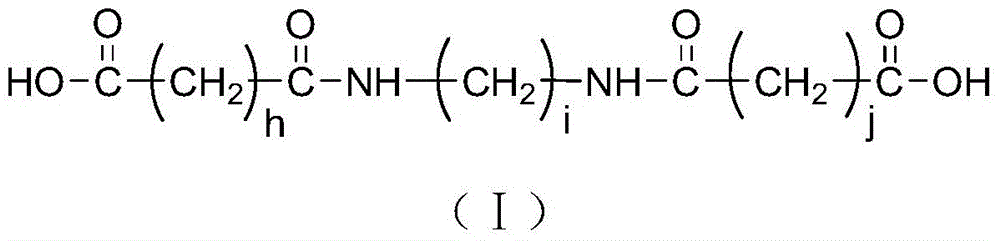

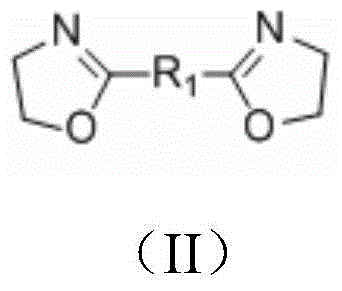

Preparation method of biodegradable polyester amide modified polylactic acid

A preparation method of biodegradable polyesteramide modified polylactic acid belongs to the technical field of polylactic acid. The method adopting a polycondensation-chain extension technology to prepare aliphatic polyesteramide modified polylactic acid comprises the following steps: carrying out melt polycondensation on aliphatic short-chain polyamide diacid and polyether diol to prepare a polyesteramide prepolymer, polycondensing the polyesteramide prepolymer, and a polylactic acid prepolymer, and carrying out chain extension by using diacylbislactame and bisoxazoline chain extender to prepare the biodegradable polyesteramide modified polylactic acid product with the molecular weight of 90290-111820. The method has the advantages of mild conditions, cheap and easily available raw materials, and environmental protection.

Owner:BEIJING UNIV OF CHEM TECH

Schiff base aluminum compound and preparation method thereof, and polylactic acid preparation method

ActiveCN103408574AIncrease steric hindranceHigh reactivityGroup 3/13 element organic compoundsHalogenBinding site

The invention provides a Schiff base aluminum compound and a preparation method thereof, and a polylactic acid preparation method. The Schiff base aluminum compound provided by the invention has a structure shown in Formula (I) or Formula (II), wherein R1 and R2 are independently selected from -H, alkyl, halogen or -NO2; R3, R4 and R5 are independently selected from -H and -CH3; R' is alkyl; and R'' is one of alkoxy and -OCH2Ph, and Ph is phenyl. The Schiff base aluminum compound provided by the invention has two metal active center binding sites, and has high reaction activity during catalytic lactide ring-opening polymerization. Besides, the Schiff base aluminum compound provided by the invention has a large molecular structure and high steric hindrance, enhances the selectivity for lactide ring-opening polymerization, and improves the space structure regularity of the polymerization product. Thus, the Schiff base aluminum compound provided by the invention has high catalytic activity and structure selectivity for lactide ring-opening polymerization, and improves the space structure regularity of polylactic acid.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

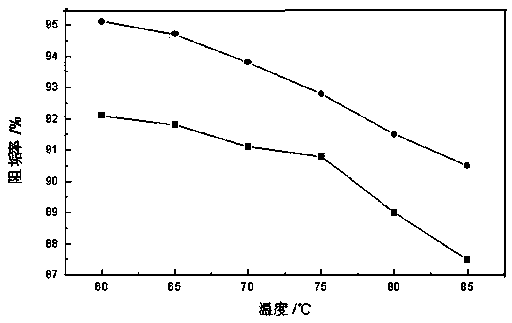

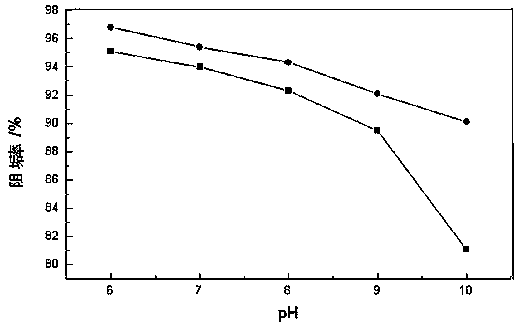

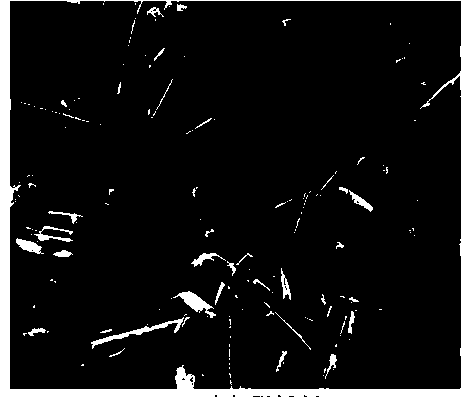

A kind of preparation and application method of polyepoxysuccinic acid derivative scale inhibitor

InactiveCN102993431BImprove complexation abilityIncrease the number of easily complexed atomsScale removal and water softeningSolubilityEcological environment

A polyepoxysuccinic acid derivative scale inhibitor, said method comprising: cyclization reaction and purification of cyclization products; preparation of polyepoxysuccinic acid products; also includes preparation of polyepoxysuccinic acid derivative Lcys-PESA , the preparation method is: put the product of polyepoxysuccinic acid PESA into a three-necked flask, add L-cysteine, put it into a methyl silicone oil bath and heat it, and when the temperature rises to 110°C-120°C, start Adjust the pH value, fully stir the reaction, and dry with a drying device to obtain L-cysteine-modified polyepoxysuccinic acid derivatives, which are finely ground and sealed for future use. The polyepoxysuccinic acid derivative scale inhibitor is applied at a temperature of 55°C-85°C, a pH value of 5.0-10.0, and a scale inhibition rate of 90%-98%. A small molecular substance is added in the synthesis, which does not contain phosphorus, is non-toxic, does not damage the ecological environment, and has good biodegradability and water solubility. Its excellent scale inhibition and dispersion properties are especially suitable for industrial water treatment.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

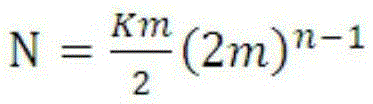

A kind of preparation method of reinforced toughened polylactic acid

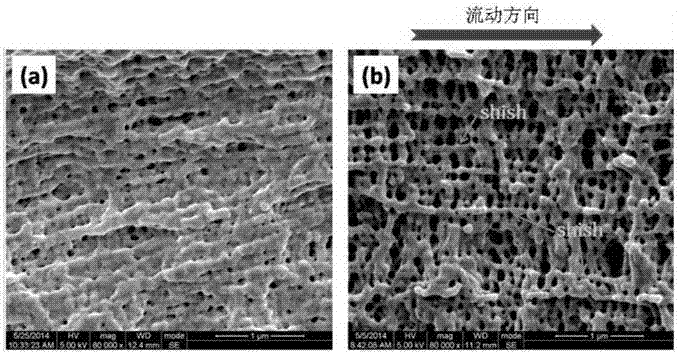

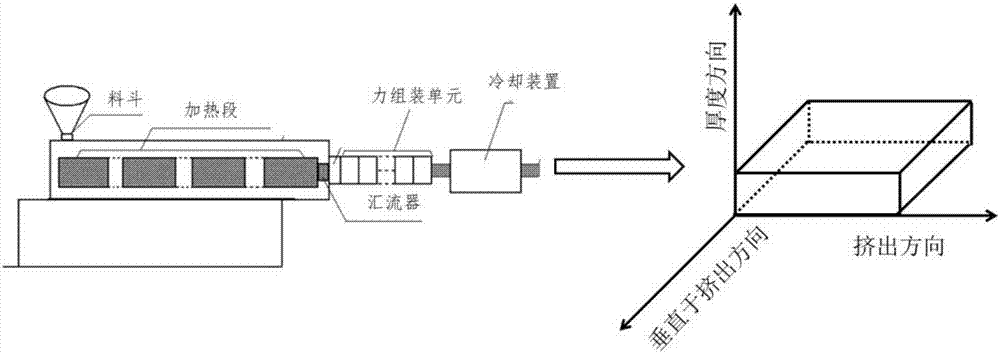

The invention discloses a preparation method of reinforced and toughened polylactic acid. The preparation method is characterized in that during the processing process, the crystallized morphology of the polylactic acid is controlled so as to improve the mechanical property of the polylactic acid. Particularly, during the processing process, certain shearing force fields and certain bidirectional drawing force fields are applied on a polylactic acid melt in different directions through the control of the number and the type of force assembling units, when the shearing and drawing action force is large enough, polylactic acid molecules are directionally arranged in the force field direction at first to form shish, then polylactic acid lamellar crystals are arranged in a direction perpendicular to the shish, and at least, an shish-kebab crystallization structure is formed; and the sizes of crystalline grains are small, besides, a large amount of interfaces are introduced in a polylactic acid material, so that the strength and the toughness of the polylactic acid material are remarkably improved. The more the number of the force assembling units with higher melt deformation degrees is, the higher the strength of the bidirectional drawing force field in the direction perpendicular to the extrusion direction is, and the smaller the mechanical strength difference of the prepared polylactic acid product in the extrusion direction and the direction perpendicular to the extrusion direction is. The preparation method has the advantages that the force assembling units are additionally arranged on a traditional extrusion device, the preparation method is simple in operation, can be produced continuously, is convenient to control, stable in quality, and high in production efficiency, has a good industrial and market prospect, can be widely applied to the preparation of a polylactic acid plate, a polylactic acid sheet and a polylactic acid film material, with high strength and toughness.

Owner:SICHUAN UNIV

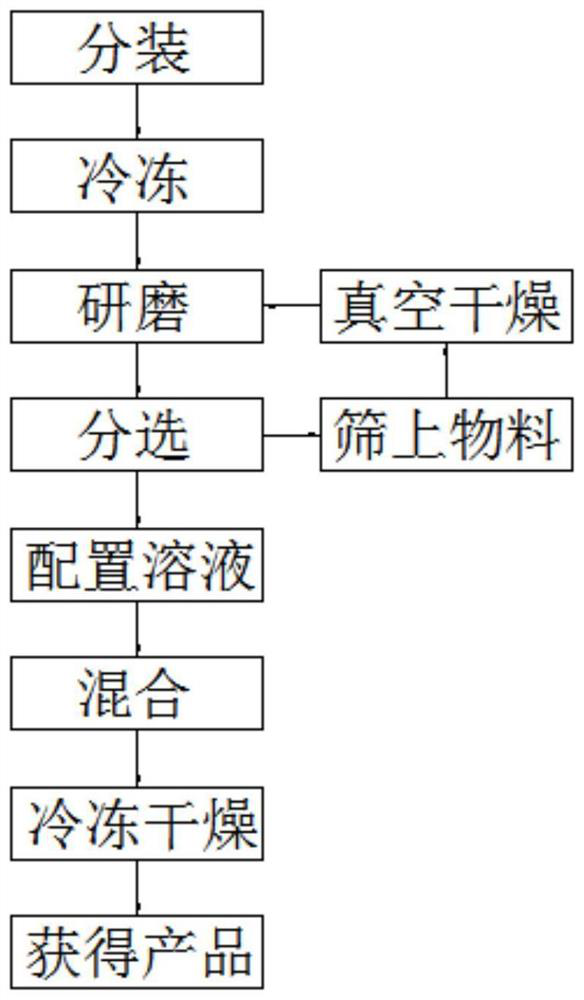

Freezing low-temperature ball-milling preparation method of polylactic acid soft tissue filled micro rice grains

PendingCN113350179AImprove refinementReduce the difficulty of productionPharmaceutical product form changeGrain treatmentsPolymer scienceFreeze-drying

The invention discloses a freezing low-temperature ball-milling preparation method of polylactic acid soft tissue filled micro rice grains. The freezing low-temperature ball-milling preparation method comprises the following steps: step a) sub-packaging; step b) freezing; step c) grinding; step d) sorting; step e) solution preparation; step f) mixing; and step g) freeze drying. The step a) sub-packaging comprises weighing a certain amount of polylactic acid raw material particles, placing the materials in a ball-milling tank, adding milling balls and sealing a cover, and the step b) freezing comprises placing the ball-milling tank filled with resin particles in a liquid nitrogen tank, and placing the liquid nitrogen tank in a refrigerator. The polylactic acid raw material particles are sub-packaged, ground and sorted, and the treated polylactic acid is improved by freezing and mixing, so that the refinement of the polylactic acid production step can be improved, the production difficulty can be reduced, and the problems that the existing polylactic acid preparation mode is relatively complicated and inconvenient to popularize, and the use requirements of the existing cosmetic and plastic surgery industry cannot be met are solved.

Owner:青岛杰圣博生物科技有限公司

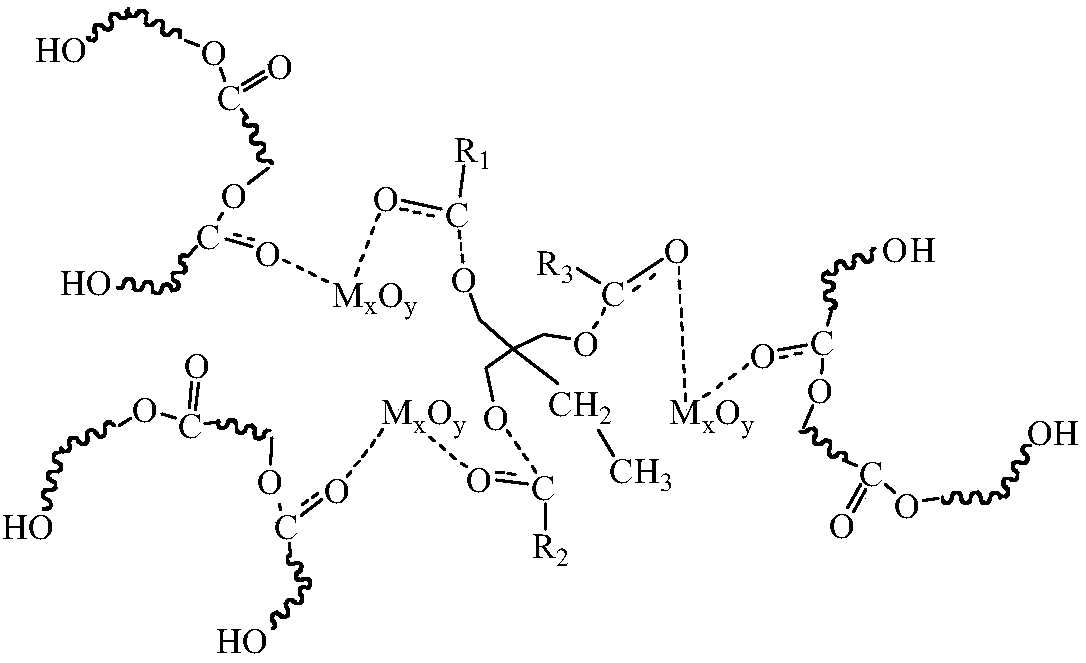

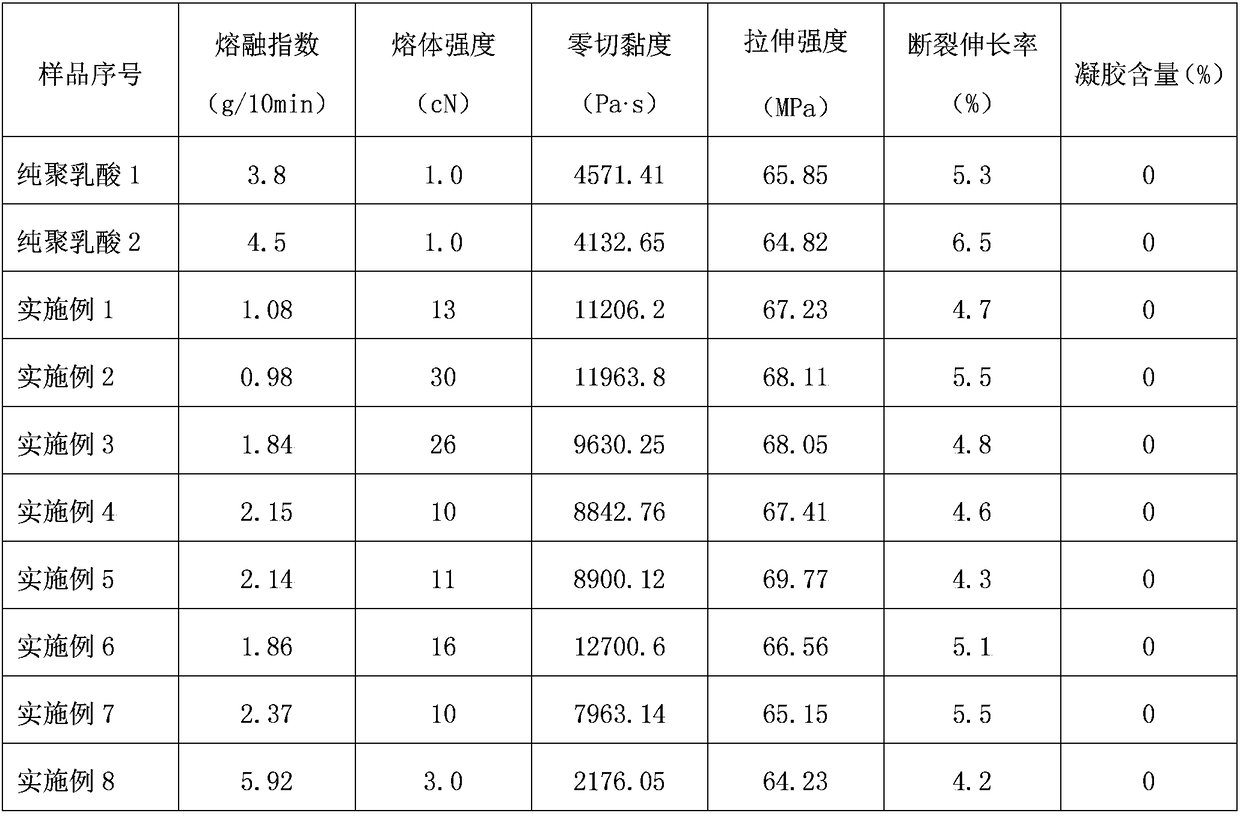

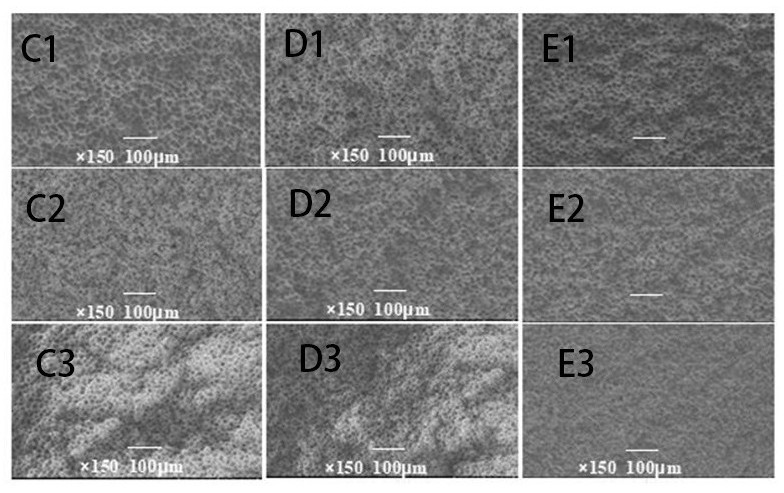

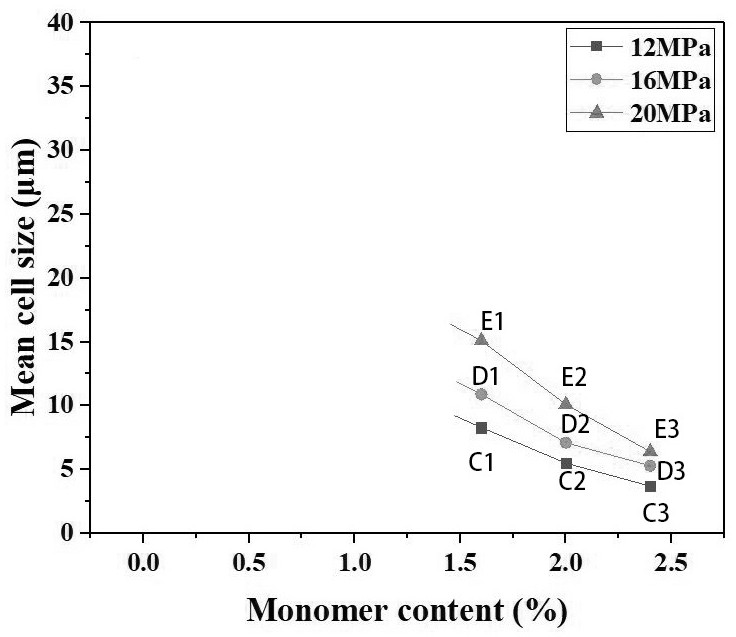

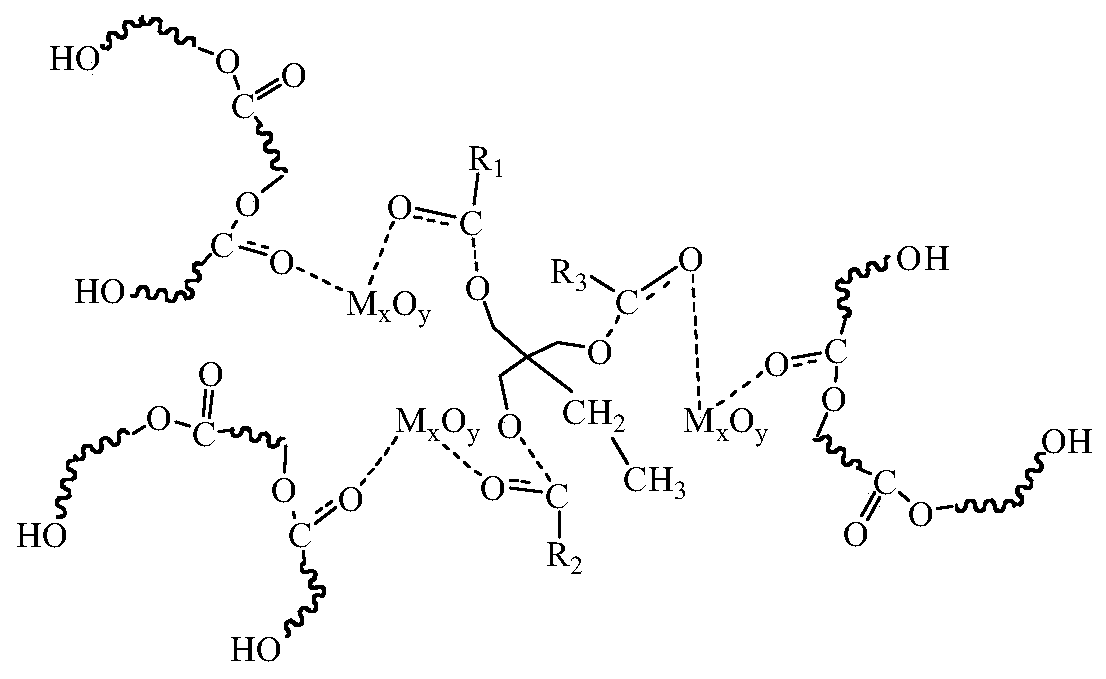

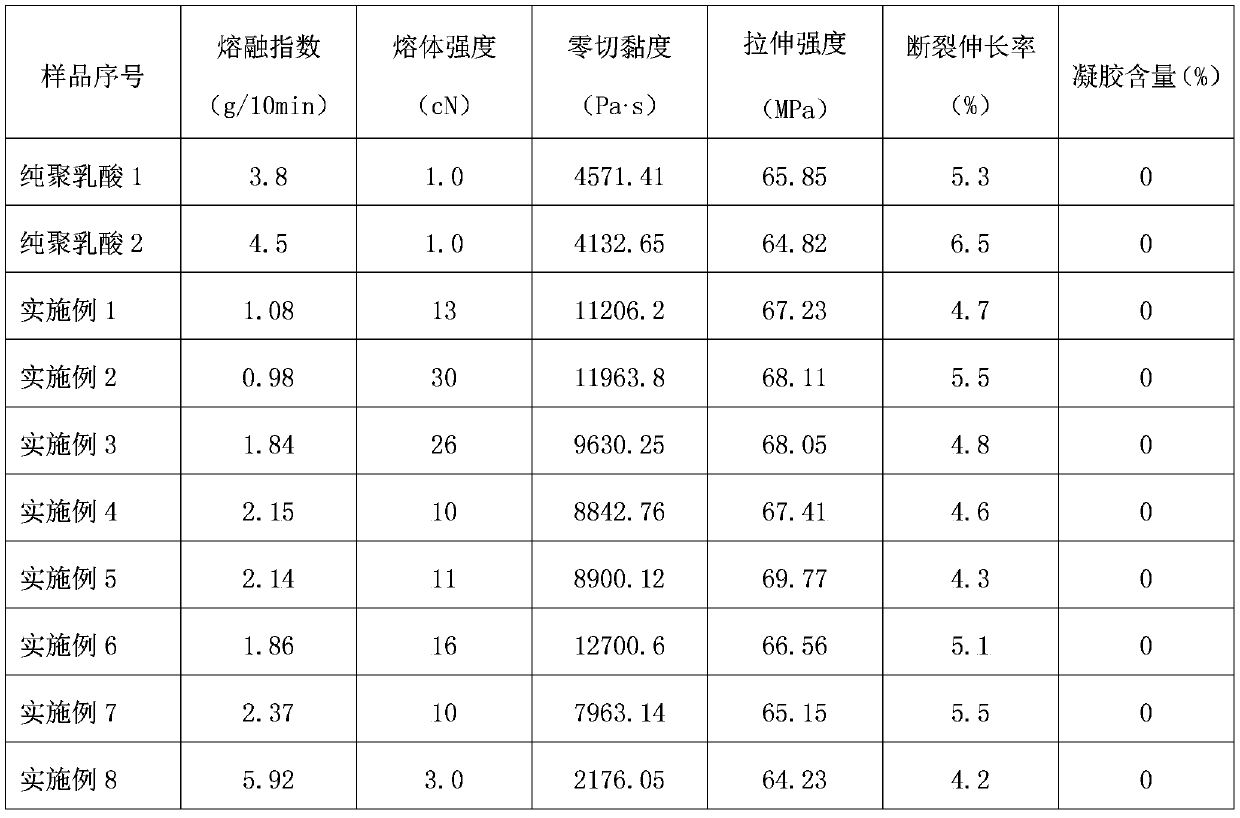

A kind of preparation method of high-efficiency gel-free long-chain branched polylactic acid

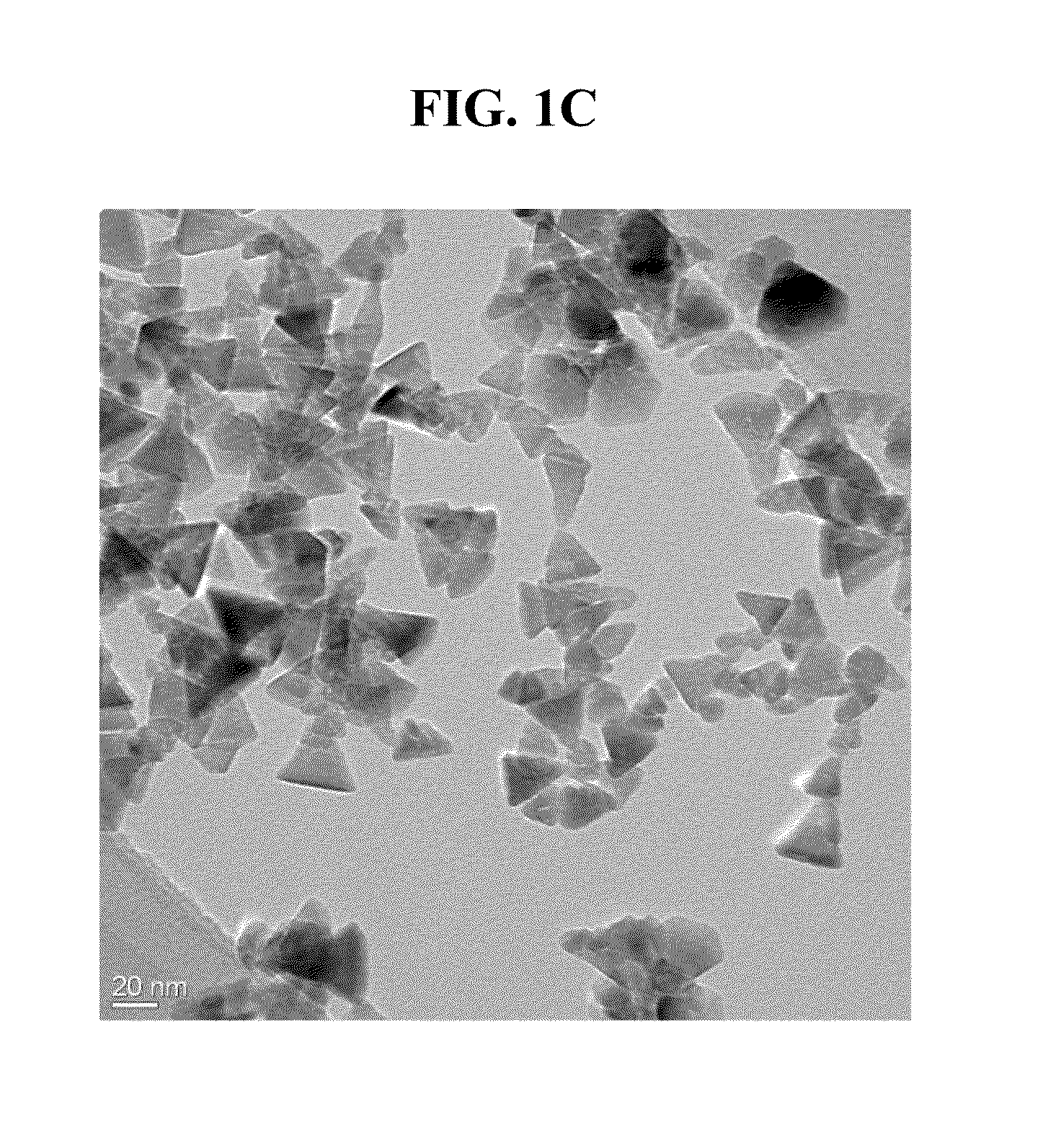

ActiveCN108341940BImprove melt strengthWide variety of sourcesTrans esterificationMetal oxide nanoparticles

The invention discloses a method for preparing high-efficient gel-free long-chain branching polylactic acid, and belongs to the technical field of high-performance polymer preparation. According to the method, metallic oxide nano particles are adopted as an accelerating agent, and the coordination between the ester group of macro molecular polylactic acid and the metallic oxide nano particle and between the ester group of a small molecular ester monomer and the metallic oxide nano particle is utilized to activate the ester groups, so that the ester exchange reaction between a polyfunctional small molecular ester monomer and a macro molecular polylactic acid is promoted to prepare the long-chain branching polylactic acid with high melt strength and significant strain hardening characteristics. The result reveals that the melt strength of the polylactic acid is increased by many folds by means of the method, the melt strength can be improved up to thirty folds, the gel content is zero, the adopted metallic oxide nano particles and the polyfunctional ester monomer are environmentally friendly, free from toxin and pollution, the source of the polyfunctional ester monomer is extensive,and most of the polyfunctional ester monomers can be used in food related industries, so that the method is a high-efficient, environmental-friendly and gel-free long-chain branching polylactic acid preparation method.

Owner:GUIZHOU UNIV

Polylactic acid polymerization reaction device and system

ActiveCN111346579AShort stayGuaranteed uniformityFlow mixersTransportation and packagingPolymer sciencePolymer chemistry

Owner:JILIN COFCO BIOCHEM +2

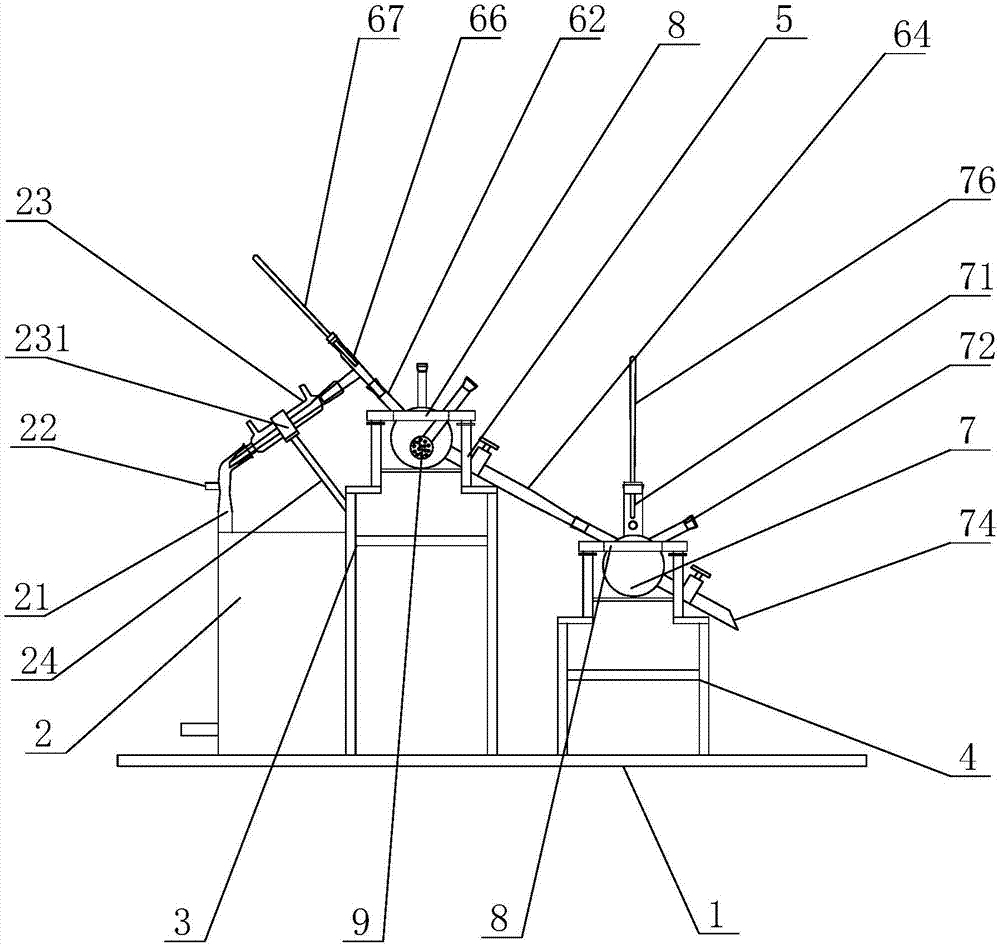

Modified polylactic acid preparation method and modified polylactic acid preparation device

The invention discloses a modified polylactic acid preparation method. The method includes: adding an appropriate amount of L-lactic acid into a container I, dehydrating, and sequentially adding dehydrated L-lactic acid and 1,4-butanediol into a container II to obtain a product A through reaction under the catalytic reaction of stannous chloride; adding the product A and 2,4-toluene diisocynate into a container III; feeding N2 into the container III to obtain a product B; dissolving with chloroform, and adding methyl alcohol to obtain a precipitate; sequentially adding chitosan and 50% NaOH solution into a container IV to obtain a product C through reaction; adding the product C and solution A into the container IV, continuously stirring for reaction for 1-5h at 90 DEG C, adopting diethyl ether for precipitating a product D obtained in reaction, and drying solid obtained by precipitating for 10h under a vacuum condition to obtain modified polylactic acid. The modified polylactic acid preparation method has advantages that the reaction process is easy to control, hydrophilcity and flexibility of polylactic acid can be improved, and medicine diffusion can be effectively inhibited to improve slow-release effect owing to a chitosan macromolecular structure.

Owner:BENGBU COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com