Reaction process for preparing low-acid lactide

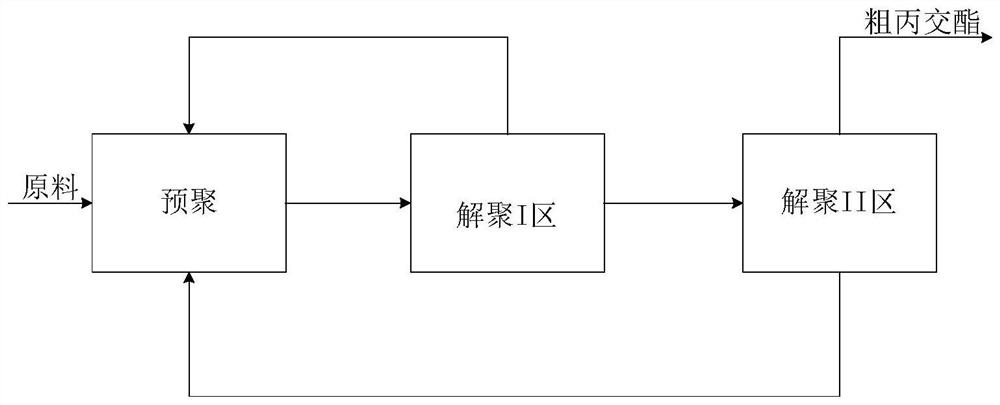

A lactide and reaction technology, which is applied in the field of reaction technology for preparing low-acid fraction lactide, can solve the problems of large equipment investment, high production cost, complicated process, etc., and achieves reduction of energy consumption and equipment investment, and reduction of production units. Consumption and production costs, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

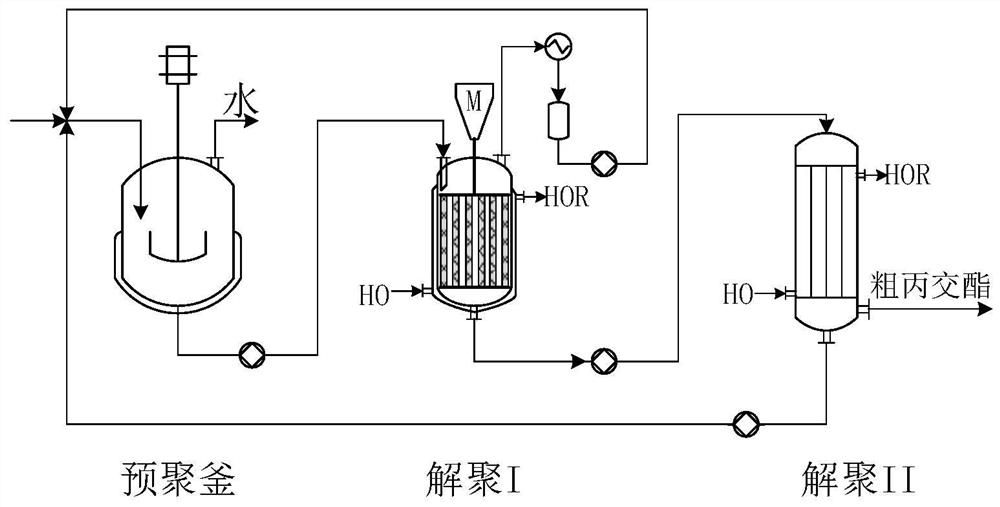

[0037] Use as attached figure 2 In the process shown, the prepolymerization adopts a batch stirred tank, lactic acid is used as raw material, the control system pressure is 1kPa, the reaction temperature is gradually increased to 150°C, and the temperature is kept for 1.5h. The reaction product lactic acid oligomer Mw=806.

[0038] The first depolymerization reactor adopts a POPE scraper evaporator, the residence time is 2s, the reaction temperature is controlled at 170°C, the pressure is 5kPa, the scraper speed is 400 rpm, the gas phase components are condensed and recycled to the prepolymerization step for use, and the liquid phase products Send to the II depolymerization reactor. The second depolymerization reactor is a tubular falling film evaporator, the reaction temperature of the second depolymerization reactor is controlled at 200°C, the pressure is 0.5kPa, the feed rate is about 3kg / h, and the crude lactide is obtained in the gas phase of the second depolymerization...

Embodiment 2

[0041] Use as attached figure 2 Shown flow process, equipment are the same as embodiment 1. The pre-polymerization adopts batch stirring tank, lactic acid is used as raw material, the pressure of the control system is 20kPa, the reaction temperature is gradually increased to 150°C, and the temperature is kept for 4h. The reaction product lactic acid oligomer Mw=810.

[0042] Depolymerization I uses a POPE scraper evaporator, the residence time is 2s, the reaction temperature is controlled at 180°C, the pressure is 1kPa, the scraper speed is 400 rpm, the gas phase components are condensed and recycled to the prepolymerization step, and the liquid phase products are sent to the second stage. Depolymerization reactor. Depolymerization II is a tubular falling film evaporator. Control the reaction temperature of the depolymerization II reactor at 200°C, the pressure of 0.5kPa, and the feed rate of about 3kg / h. The crude lactide product is obtained in the gas phase of the second ...

Embodiment 3

[0045] Use as attached figure 2 Shown flow process, equipment are the same as embodiment 1. The pre-polymerization adopts a batch stirring tank, lactic acid is used as raw material, the pressure of the control system is 2.5kPa, the reaction temperature is gradually increased to 150°C, and the temperature is kept for 2h. The reaction product lactic acid oligomer Mw=790.

[0046] Depolymerization I uses a POPE scraper evaporator, the residence time is 30s, the reaction temperature is controlled at 190°C, the pressure is 1kPa, the scraper speed is 400 rpm, the gas phase components are condensed and recycled to the prepolymerization step, and the liquid phase products are sent to the second stage Depolymerization reactor. Depolymerization II is a tubular falling film evaporator. The reaction temperature of the depolymerization II reactor is controlled at 200°C, the pressure is 0.5kPa, and the feed rate is about 3kg / h. The gas phase components are condensed and recycled to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com