Long chain branch polylactic acid preparation method

A polylactic acid and long-branched technology is applied in the preparation field of the chemical technology field, and can solve the problems of difficult processing and forming process, low melt strength, etc., and achieve the effects of low cost, high melt strength, and high modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of Long Branched Polylactic Acid

[0022] Add 100 parts of polylactic acid raw materials to the Haake internal mixer at 190°C until completely melted, then add 0.5 parts of 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl -4-Hydroxybenzyl) benzene, after mixing evenly, add 0.04 part of triglycidyl isocyanurate immediately, react blending 20min, internal mixer speed is 60rpm, obtain a kind of long branched polylactic acid material. The antioxidant can prevent thermal oxidation degradation of polylactic acid during processing. Table 1 shows the melt index results of the obtained reaction product material measured according to the ASTM D1238 standard.

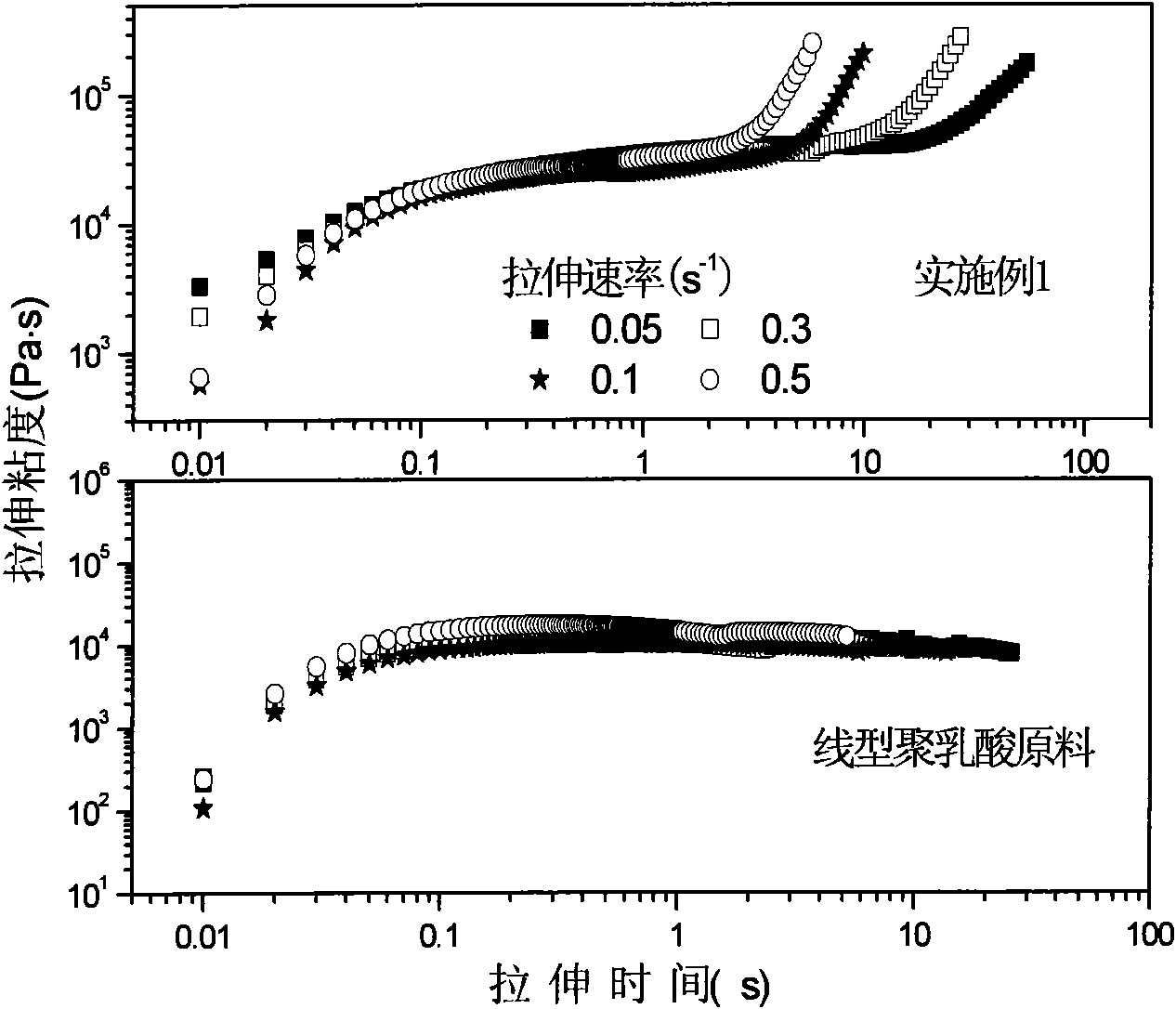

[0023] figure 1 It is the extensional rheological curve of the long-branched polylactic acid material obtained in Example 1 compared with the pure linear polylactic acid. It can be seen that the linear polylactic acid has no strain hardening phenomenon at different tensile rates, but after melting for a long time Aft...

Embodiment 2

[0027] Preparation of Long Branched Polylactic Acid

[0028] Add 100 parts of polylactic acid raw materials to the Haake mixer at 200°C until completely melted, then add 0.5 parts of 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl -4-Hydroxybenzyl)benzene, after mixing evenly, add 0.03 part of triglycidyl isocyanurate immediately, react and blend for 10min, the speed of internal mixer is 40rpm, obtain a kind of long branched polylactic acid material. The test results are shown in Table 1.

Embodiment 3

[0030] Preparation of Long Branched Polylactic Acid

[0031] Add 100 parts of polylactic acid raw materials to the Haake internal mixer at 210°C until completely melted, then add 0.5 parts of 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl -4-Hydroxybenzyl)benzene, after mixing evenly, add 0.06 part of triglycidyl isocyanurate immediately, react and blend for 30min, the speed of internal mixer is 80rpm, obtain a kind of long branched polylactic acid material. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com