A kind of preparation and application method of polyepoxysuccinic acid derivative scale inhibitor

A technology of polyepoxysuccinic acid and sodium epoxysuccinate, which can be used in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., and can solve the problems of low efficiency of scale inhibition, harmful environment, use High cost and other issues, to achieve the effect of not destroying the ecological environment, improving the linear structure, and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A. Cyclization reaction and cyclization product purification

[0024] a Add 16g NaOH to the three-necked flask, and add 36ml of water, put the three-necked flask into a magnetic stirring water bath, after fully dissolving under magnetic stirring, add 19.6g maleic anhydride, while the water bath is heated to 55°C. After the water bath was heated to 55°C, 1.2g Na catalyst was added 2 WO 4 . Then, heat the water bath to 70°C, and after the temperature is stable, use a separatory funnel to evenly add 24ml of hydrogen peroxide dropwise within 35min. At this point, the pH=6-7 was adjusted with 1:1 hydrochloric acid solution, and the mixed crude product was obtained after 1.5 hours of reaction.

[0025] b Product purification: the mixed crude product of step a is heated with an electric heating mantle, and vacuum distillation is carried out at the same time. When the residual liquid after evaporation is 1 / 2 of the original solution volume, the vacuum distillation is stoppe...

Embodiment 2

[0031] A. Cyclization reaction and cyclization product purification

[0032] a Add 13g NaOH to the three-necked flask, and add 35ml of water, put the three-necked flask into a magnetic stirring water bath, after fully dissolving under magnetic stirring, add 18g maleic anhydride, while the water bath is heated to 52 ° C. After the water bath was heated to 52 °C, 1 g of Na catalyst was added. 2 WO 4 . Then, heat the water bath to 65°C, and after the temperature is stable, add 20ml of hydrogen peroxide evenly dropwise with a separatory funnel within 30min. At this point, start to adjust pH=6-7 with 1:1 hydrochloric acid solution, and obtain mixed crude product after 1 hour of reaction.

[0033] b Product purification: the mixed crude product of step a is heated with an electric heating mantle, and vacuum distillation is carried out at the same time. When the residual liquid after evaporation is 1 / 2 of the original solution volume, the vacuum distillation is stopped. The solu...

Embodiment 3

[0039]A. Cyclization reaction and cyclization product purification

[0040] a Add 18g NaOH and 38ml to the three-necked flask, put the three-necked flask into a magnetic stirring water bath, fully dissolve under magnetic stirring, add 20g maleic anhydride, and heat the water bath to 58°C. After the water bath was heated to 58°C, 1.5g Na catalyst was added 2 WO 4 Then, heat the water bath to 75°C, and after the temperature is stable, add 26ml of hydrogen peroxide evenly dropwise with a separatory funnel within 40min. At this time, the pH=7 was adjusted with 1:1 hydrochloric acid solution, and the mixed crude product was obtained after 2 hours of reaction.

[0041] b Product purification: the mixed crude product of step a is heated with an electric heating mantle, and vacuum distillation is carried out at the same time. When the residual liquid after evaporation is 1 / 2 of the original solution volume, the vacuum distillation is stopped. The solution was poured into the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

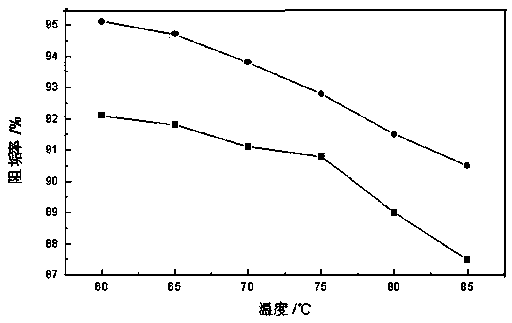

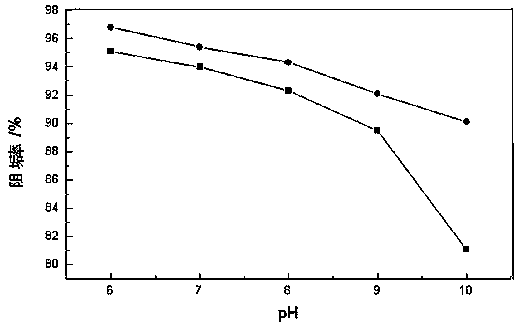

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com