Restoration agent and preparation method thereof and method using restoration agent to restore heavy metal-polluted soil

A technology of remediation agent and raw material, applied in the field of remediation of heavy metal soil pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

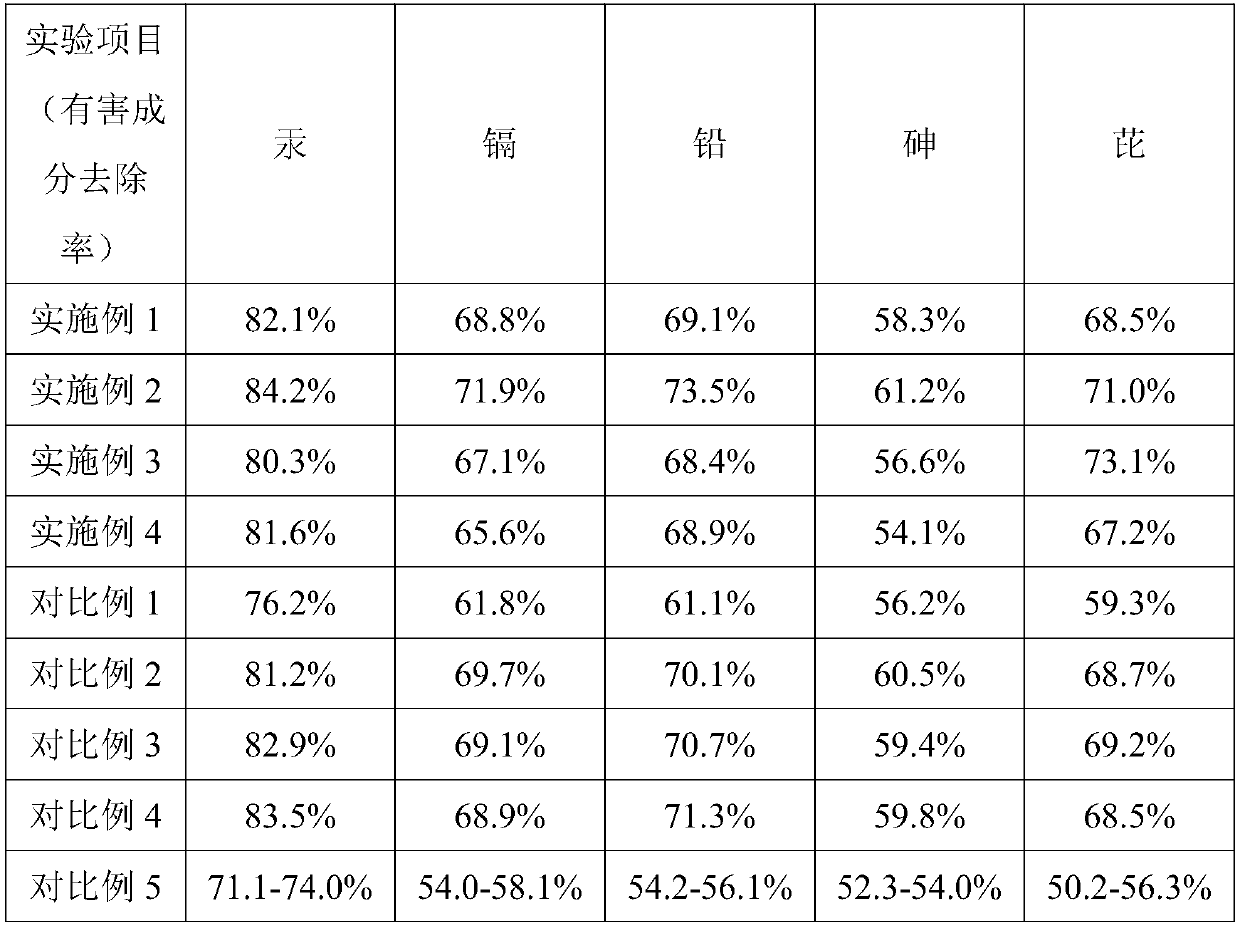

Examples

preparation example Construction

[0023] The preparation method of described restorative agent, comprises the following steps:

[0024] S1, milling: first mix and pulverize longan skin and bean root stalks by weight, pass through a 600-800 mesh sieve after pulverization, and obtain a mixed powder;

[0025] S2. Fermentation: Add the mixed powder, biochar, sepiolite, calcium dihydrogen phosphate, bagasse, lime powder, and chitosan prepared in step S1 to water in proportion by weight at a temperature of 35-50°C After stirring evenly, put it under anoxic condition to ferment for 12-18h, then add tartaric acid, hydroxyethylidene triphosphonic acid, potassium lignosulfonate, malic acid, chitosan under anaerobic environment, stir evenly and continue to ferment for 1-3h , to prepare semi-finished restorative agent;

[0026] S3. Drying and pulverizing: drying the semi-finished restorative agent prepared in step S2 for 20-35 minutes at a temperature of 50-70° C. until the moisture content of the semi-finished restorati...

Embodiment 1

[0030] A restoration agent, in parts by weight, comprising the following raw materials: 10 parts of biochar, 12 parts of sepiolite, 16 parts of calcium dihydrogen phosphate, 11 parts of bagasse, 10 parts of lime powder, 13 parts of longan skin, 30 parts of tartaric acid 53 parts of hydroxyethylidene triphosphonic acid, 25 parts of potassium lignosulfonate, 47 parts of malic acid, 5 parts of chitosan, 13 parts of bean root straw;

[0031] The bean root stalk is soybean root stalk;

[0032] The preparation method of described restorative agent, comprises the following steps:

[0033] S1, milling: first mix and pulverize longan skin and bean root stalks by weight, pass through a 600-mesh sieve after pulverizing to obtain mixed powder;

[0034] S2. Fermentation: Add the mixed powder, biochar, sepiolite, calcium dihydrogen phosphate, bagasse, lime powder, and chitosan prepared in step S1 to water in proportion by weight and stir evenly at a temperature of 35°C Finally, put it und...

Embodiment 2

[0038] A restoration agent, in parts by weight, comprising the following raw materials: 13 parts of biochar, 14 parts of sepiolite, 19 parts of calcium dihydrogen phosphate, 15 parts of bagasse, 13 parts of lime powder, 16 parts of longan skin, 33 parts of tartaric acid 57 parts of hydroxyethylidene triphosphonic acid, 29 parts of potassium lignosulfonate, 54 parts of malic acid, 7 parts of chitosan, 17 parts of bean root straw;

[0039] The legume root stalks are 8 parts of black bean root stalks and 9 parts of red bean root stalks;

[0040] The preparation method of described restorative agent, comprises the following steps:

[0041] S1, milling: first mix and pulverize longan skin and bean root stalks by weight, pass through a 700-mesh sieve after pulverization to obtain mixed powder;

[0042]S2. Fermentation: Add the mixed powder, biochar, sepiolite, calcium dihydrogen phosphate, bagasse, lime powder, and chitosan prepared in step S1 to water in proportion by weight and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com