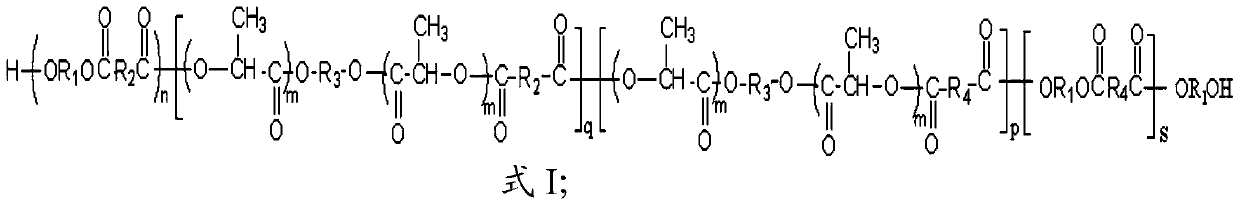

A kind of aliphatic-aromatic-polylactic acid multi-block copolymer

A multi-block copolymer and aromatic technology, applied in the field of polymers, can solve the problems of only 60% elongation at break and poor mechanical properties, and achieve the effects of facilitating industrial production, improving flexibility, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention does not have special restrictions on the source of the double-end hydroxy polylactic acid, and the double-end hydroxy polylactic acid well known to those skilled in the art can be used. For example, the commercially available products can be used, or the preparation well known to those skilled in the art can be used. The technical solution of double-end hydroxy polylactic acid is self-prepared. In the present invention, the preparation method of the double-terminal hydroxyl polylactic acid preferably includes the following steps:

[0038] In an oxygen-free environment, the glycol compound and lactide are polymerized to obtain double-end hydroxyl polylactic acid.

[0039] In the present invention, preferably, the glycol compound and lactide are polymerized in a closed and oxygen-free environment. The present invention preferably uses nitrogen or inert gas to achieve an oxygen-free environment; the inert gas is preferably argon. The present invention h...

Embodiment 1

[0088] 1.1 The 5L reactor with two vents is repeatedly evacuated and filled with inert gas to cool, then add lactide (1500g), butanediol (130g) and stannous octoate (1g) with nitrogen. The reaction system was sealed and placed in an oil bath preheated to 120°C. After stirring and reacting for 14 hours, the temperature was raised to 180°C and vacuumed to remove unreacted monomers to obtain double-terminated hydroxy polylactic acid with a relative number average molecular weight of 1kg / mol.

[0089] 1.2 Add the above-mentioned double-terminated polylactic acid (200g), terephthalic acid (320g), adipic acid (400g), butanediol (520g) and tetrabutyl titanate (1g) into the flask in sequence, and heat the flask Bring it to 150 degrees Celsius and stir the reactants while collecting the water produced by the reaction. After 6 hours, set the reaction temperature to 220 degrees Celsius and gradually increase the temperature of the system. When it reaches 220 degrees Celsius, gradually reduc...

Embodiment 2

[0095] After adding double-terminated polylactic acid (100g), terephthalic acid (320g), adipic acid (400g), butanediol (520g) and tetrabutyl titanate (1g) in Example 1.1 into the flask, Increase the temperature of the flask to 150 degrees Celsius and stir the reactants. At the same time, collect the water produced by the reaction. After 6 hours, set the reaction temperature to 290 degrees Celsius and gradually increase the temperature of the system. When it reaches 290 degrees Celsius, vacuum polycondensation reaction is gradually applied. The pressure is reduced to a high vacuum state, the polycondensation reaction is carried out, and the material is discharged for 3 hours to obtain a polybutylene adipate-polylactic acid multi-block copolymer, the relative number average molecular weight of which is 23.0 kg / mol.

[0096] The present invention tests the mechanical properties of the product according to the above technical scheme, and the test results show that the elongation at br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com