A kind of preparation method of reinforced toughened polylactic acid

A technology of strengthening and toughening, polylactic acid, which is applied in the processing field of polymer materials, can solve the problems of strength reduction, toughness reduction, strength and rigidity reduction, etc., and achieves the effect of weakening the strength difference, increasing the crystallization speed, and being beneficial to the toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Polylactic acid (PLA2003D, Nature works, USA) was selected as the experimental material, its melting index was 6g / 10min (210°C, 2.16Kg), and its weight average molecular weight was 1.85×10 5 g / cm 3 , the molecular weight distribution is 1.73. Dry in a vacuum oven at 60°C for 12 hours under vacuum.

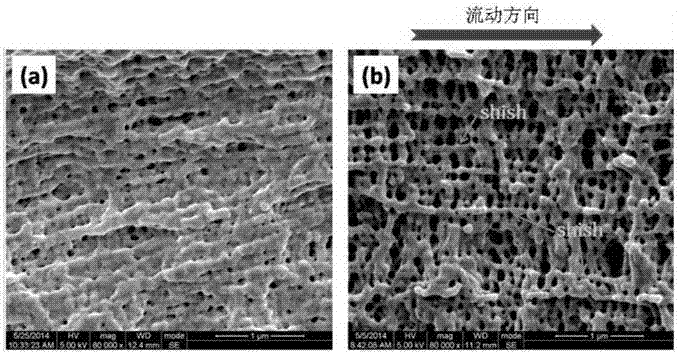

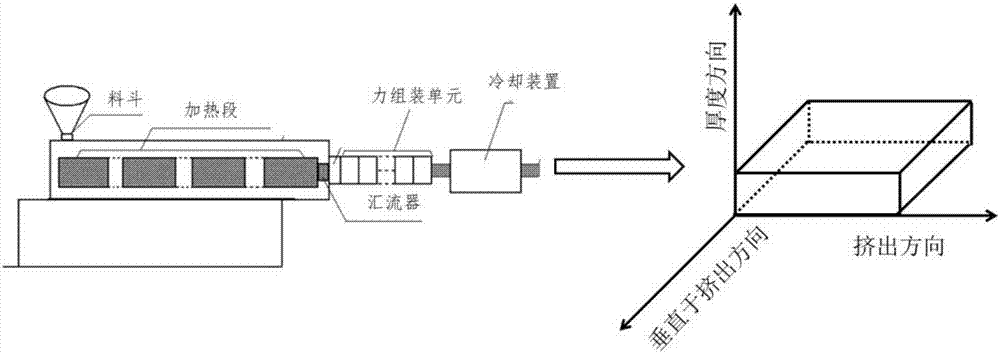

[0034] (2) Put the dried pellets into a multi-stage stretching device consisting of an extruder, a confluence, a force assembly unit, and a cooling roll (see figure 1 ) in the extruder. After the division-deformation-stacking action of the force assembly unit, it flows out from the discharge port, and after being cooled by the cooling roller, the polylactic acid material with a width and thickness of 30mm and 1.5mm respectively is obtained.

[0035] Here, the structure of the multistage stretching device will be described first. figure 1 In the process, the discharge port of the extruder is connected to the feed port of the confluence, and the discharge port of the c...

Embodiment 2

[0038] (1) Polylactic acid (PLA2003D, Nature works, USA) was selected as the experimental material, its melting index was 6g / 10min (210°C, 2.16Kg), and its weight average molecular weight was 1.85×10 5 g / cm 3 , the molecular weight distribution is 1.73. Dry in a vacuum oven at 60°C for 12 hours under vacuum.

[0039] (2) Put the dried pellets into a multi-stage stretching device consisting of a single-screw extruder, a confluence, a force assembly unit, and a cooling roll (see figure 1 ) in a single-screw extruder. After the division-deformation-stacking action of the force assembly unit, it flows out from the discharge port, and after being cooled by the cooling roller, the polylactic acid material with a width and thickness of 30mm and 1.5mm respectively is obtained. The temperatures of the feeding port, conveying section, melting section, and homogenizing section of the single-screw extruder are 125°C, 185°C, 188°C, and 185°C respectively; the temperatures of the conflue...

Embodiment 3

[0043] (1) Polylactic acid (PLA2003D, Nature works, USA) was selected as the experimental material, its melting index was 6g / 10min (210°C, 2.16Kg), and its weight average molecular weight was 1.85×10 5 g / cm 3 , the molecular weight distribution is 1.73. Dry in a vacuum oven at 60°C for 12 hours under vacuum.

[0044] (2) Put the dried pellets into a multi-stage stretching device consisting of a single-screw extruder, a confluence, a force assembly unit, and a cooling roll (see figure 1 ) in a single-screw extruder. After the division-deformation-stacking action of the force assembly unit, it flows out from the discharge port, and after being cooled by the cooling roller, the polylactic acid material with a width and thickness of 30mm and 1.5mm respectively is obtained. The temperatures of the feeding port, conveying section, melting section, and homogenizing section of the single-screw extruder are 125°C, 185°C, 188°C, and 185°C respectively; the temperatures of the conflue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com