Multi-stage polymerization method for polylactic acid preparation by ring-opening polymerization of lactide

A polymerization method and ring-opening polymerization technology, which is applied in the field of polymer material synthesis, can solve problems such as air tightness or uneven mass and heat transfer, unstable quality of final products, difficult to control the stability of conditions, etc., and achieve short reaction time , easy to control, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

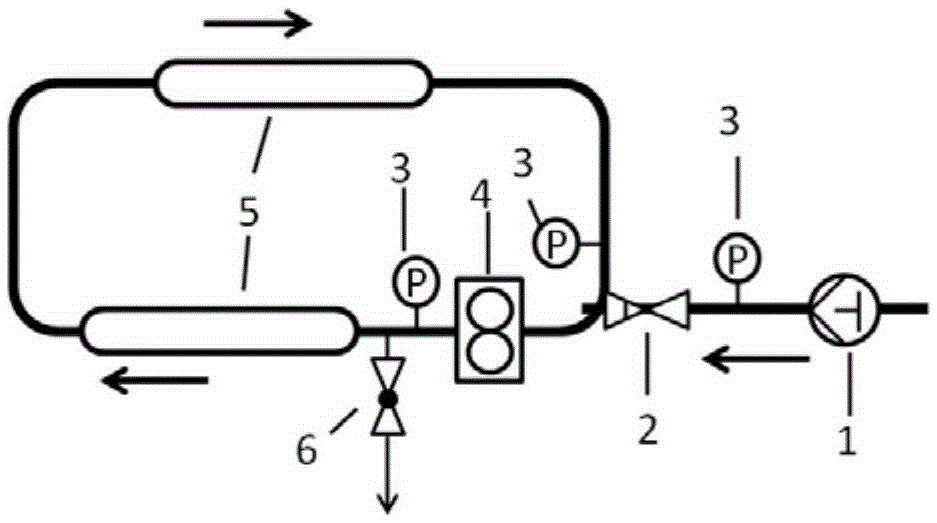

[0057] In this embodiment, the ring type static mixing reaction device such as figure 1 As shown, it is a reaction device composed of two static mixers. In the figure, 1 is a plunger metering pump, 2 is a check valve, 3 is a pressure gauge, 4 is a melt delivery pump, 5 is a static mixer, and 6 is a sampling The number of valves and discharge ports, the number of corrugated plate type mixing units in the static mixer is 30, and the corrugated plates have 9 layers in total. The radial direction between the corrugated plates and the mixer is 70°, and the angle between the top angle of the corrugated plates is 30°. The static mixers are all 500mm in length and 14mm in inner diameter. Be that the mass fraction is 95%, optical purity is 98% L-lactide and composite catalyst (composite catalyst quality is 0.05% of L-lactide, catalyst zinc powder and cocatalyst ethylene glycol molar ratio are 1:0.1 ) into the ring-type static mixing reaction device, the antioxidant is antioxidant-24, ...

Embodiment 2

[0059] In this embodiment, a ring-type static mixing reaction device consisting of 3 static mixers is used. The number of corrugated plate-type mixing units in the static mixer is 10, and the corrugated plates have 4 layers. The radial direction of the corrugated plates and the mixer is 5°, the included angle of corrugated plate top angle is 170°. The static mixers are all 500mm in length and 16mm in inner diameter. Be that 96% by mass fraction, optical purity be 98% L-lactide and composite catalyst (composite catalyst quality is 0.5% of L-lactide, catalyst tin powder and cocatalyst dodecanol mol ratio are 1: 3) Adding to the ring type static mixing reaction device, the antioxidant is Antioxidant-24, and the added amount is 0.03% of the mass of L-lactide. The mixing temperature in the first stage is 100°C, the flow rate of the reaction system is 1mm / s, and the shear rate is 1s -1 , the number of cycles in the reaction device is 5. In the second stage, the polymerization tem...

Embodiment 3

[0061] In this embodiment, a ring-type static mixing reaction device consisting of 4 static mixers is used. The number of corrugated plate-type mixing units in the static mixer is 15, and the corrugated plates have 7 layers. The radial direction of the corrugated plates and the mixer is 45°, the included angle of corrugated plate top angle is 30°. The static mixers are all 500mm in length and 18mm in inner diameter. Be that 97% by mass fraction, optical purity be 98% L-lactide and composite catalyst (composite catalyst quality is 0.7% of L-lactide, catalyst zinc oxide and cocatalyst tridecyl alcohol mol ratio are 1: 3) Adding to the ring type static mixing reaction device, the antioxidant is antioxidant-24, and the added amount is 0.05% of the mass of lactide. The mixing temperature in the first stage is 100°C, the flow rate of the reaction system is 5mm / s, and the shear rate is 40s -1 , the number of cycles in the reaction device is 8. In the second stage, the polymerizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com