Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Paper Makers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for making raw paper of heat sublimation transfer printing paper

InactiveCN102767120AEasy to useOptimize copying parametersSpecial paperWater-repelling agents additionPulp and paper industryAlum

The invention discloses a method for making raw paper of heat sublimation transfer printing paper. The method comprises the following steps of: slurrying a needle leaf wood-pulp board and a broad leaf wood-pulp board, and respectively beating the needle leaf wood-pulp board and the broad leaf wood-pulp board to 15 to 25 degrees SR and 18 to 28 degrees SR; then mixing the two beaten pulps, mixing the mixture and chemimechanical pulp (CTMP) which is beaten to 22 to 32 degrees SR in advance, and uniformly stirring the mixture with wet strength agent polyamide epoxy resin (PAE), white alum and sizing agent cation rosin size to obtain paper pulp; and putting the paper pulp onto a net, controlling the net part to be dehydrated and molded, and performing squeezing, surface sizing and drying to obtain the heat sublimation transfer printing paper. The indexes of the finished paper can meet the requirement of the heat sublimation transfer printing paper by optimizing the beating degree, the using amounts of various additives during papermaking and making parameters of a paper maker.

Owner:ZHEJIANG JINCHANG SPECIALTY PAPER CO LTD

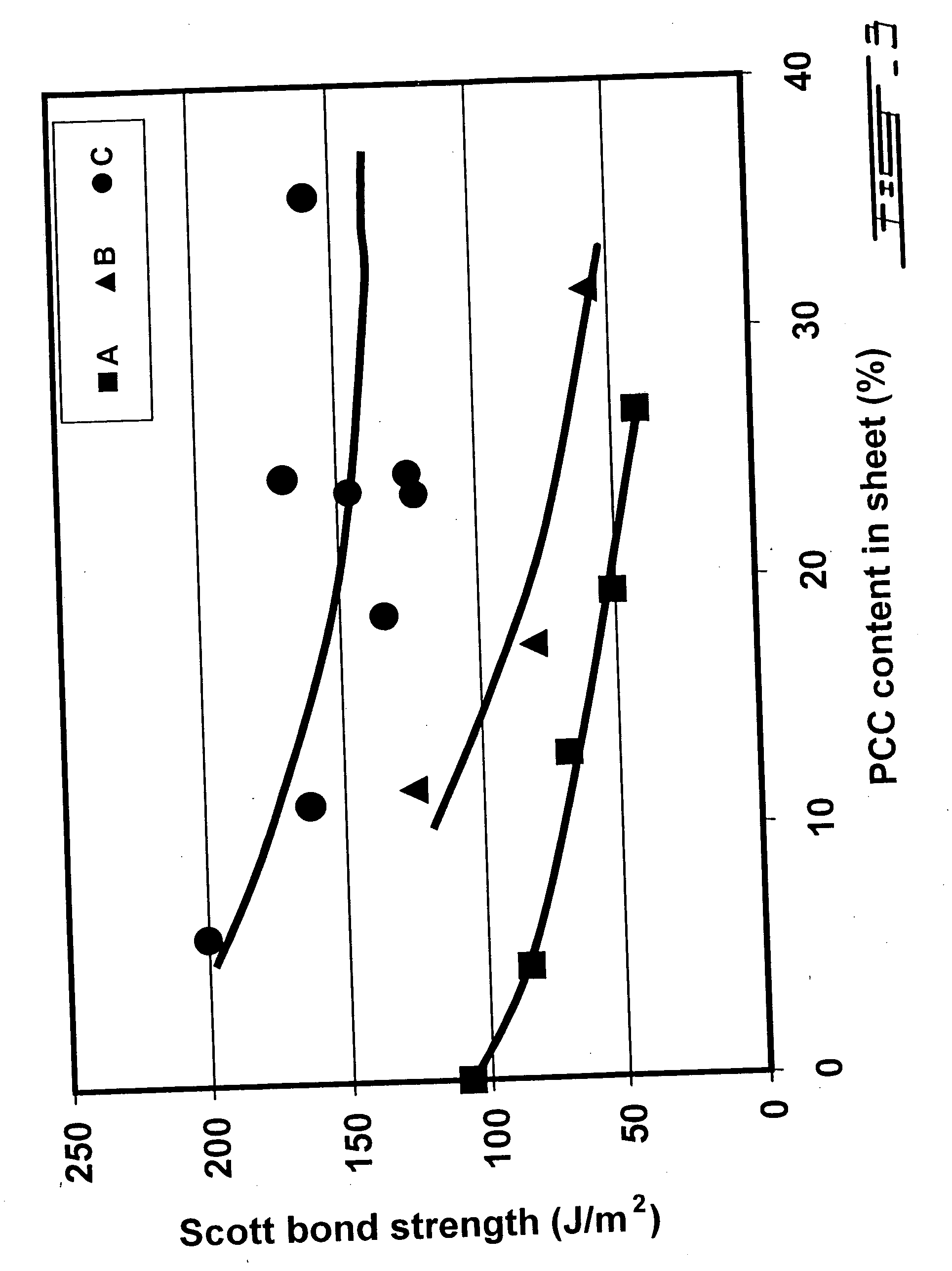

Swollen starch-latex compositions for use in papermaking

ActiveUS20050252629A1Improve filler retentionHigh retention rateNatural cellulose pulp/paperSpecial paperPapermakingPaperboard

A novel filler treatment comprising the preparation of swollen starch-latex compositions, prepared in the presence or absence of co-additives, and the addition of the said composition to a filler suspension, has been developed. Use of the treated filler during papermaking improves filler retention and produces filled papers where addition of the filler has only a minimal negative effect on strength properties. The swollen starch-latex compositions can be prepared in a batch or jet cooker, or by mixing with hot water under controlled conditions (i.e., temperature, pH, mixing, mixing time) in order to make the starch granules swell sufficiently to improve their properties as a filler additive but avoiding excess swelling leading to their rupture. The swollen starch-latex composition is then rapidly mixed with the filler slurry, preferably in a static mixer, and added to the papermaking furnish at a point prior to the headbox of the paper machine. The starch-latex composition can be used with wood-free or wood-containing furnishes. The treated filler is easily retained in the web during papermaking, improves drainage, and gives sheets having good formation. Sheets made with the treated fillers have higher bonding and tensile strengths than sheets produced using filler treated with either swollen starch alone or latex alone. Retention and drainage are further improved when conventional retention aid chemicals are added to the furnish containing the treated filler. The use of swollen starch-latex compositions could allow the papermaker to increase the filler content of the paper without sacrificing dry strength properties or increasing the amount, and hence the cost, of the retention aid added. The combination of swollen starch and latex could be used as furnish additives in the manufacture of both filled grades and grades that contain no filler such as sack papers and paperboard products.

Owner:FPINNOVATIONS INC

Production method of anti-myopia paper

ActiveCN102154925AIncrease productivityHigh mechanical strengthWater-repelling agents additionPaper coatingFiberChemical products

The invention provides a production method of an anti-myopia paper. The method comprises the steps of: impregnating a wheat straw raw material by chemical medical liquid; pretreating under a normal-pressure and low-temperature condition; separating and thinning fiber by a mechanical twisting, grinding and fiber-separating method; and copying into a paper on a paper maker. The directly-obtained color of the paper is yellow, the yellow fiber paper with different depth degrees can be produced according to the difference of the chemical products and the treatment conditions, the paper is used for the book for the school children or the reading magazine, and the paper has the function of myopia resistance without dazzling. The paper produced by the method is higher in yield and better in mechanical strength, wherein the yield of the paper is more than 60%, the rupturing length of the paper is more than 6.0km, the rupturing-resistant index is more than 4.2kPa.m<2> / g, the rupturing index is more than 3.20mN.m<2> / g, and the folding strength of the paper is more than 100 times.

Owner:SHAANXI UNIV OF SCI & TECH

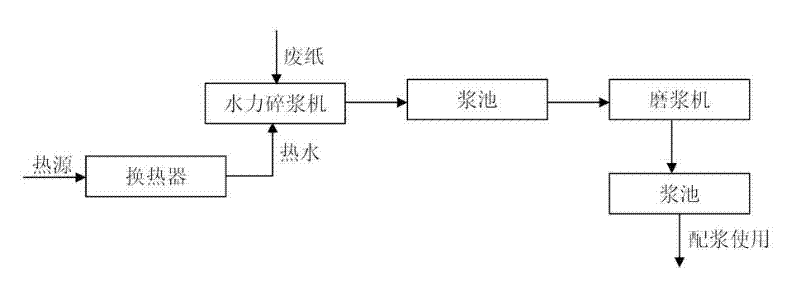

Wet strength waste paper processing method

InactiveCN102242510AReduce processing timeReduce power consumptionPaper recyclingRaw material divisionElectricityFiber

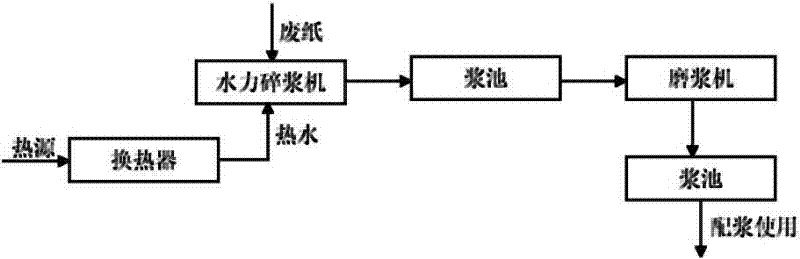

The invention provides a wet strength waste paper processing method belonging to the technical field of paper making. The method comprises the following steps of: by taking condensed water of steam of a drying part of a paper maker as a heat source, additionally providing a heat exchanger to increase the water temperature of white water for pulping from 30-35 DEG C to 60-70 DEG C; mixing with wetstrength waste paper in a pulper, and performing mild strength connection with softened fibers under a high temperature condition to easily separating the wet strength waste paper under mechanical functions. The specific processes and steps are as follows: (1) pulping; (2) grinding to form pulp; and (3) pulp proportioning to finish processing the wet strength waste paper. By adopting a heating processing method in the invention, the pulp processing time is shortened, electricity consumption during processing is reduced, the strength for breaking the fiber is reduced, the beating degree of the processed pulp is stable, and proportion of waste pulp in the blending can be properly increased as required, so that the production cost is reduced.

Owner:德州泰鼎新材料科技有限公司

Method for manufacturing mica paper by low-temperature calcining

InactiveCN103741541AHigh compressive strengthTime stablePaper/cardboardCotton clothPulp and paper industry

The invention relates to a method for manufacturing mica paper by calcining a mica material at a low temperature. The main method comprises the following steps: (1) calcining the mica material at the low temperature; (2) screening and washing the mica material which is calcined at the low temperature in step (1); (3) crushing and pulping a refined material which is obtained by screening and washing in step (2); (4) delivering the crushed pulp material to a refined pulp tank by a pipeline, and uniformly stirring; (5) allowing the mica pulp material to pass through a circular mesh cage with good drainage capacity, uniformly adsorbing mica pulp pieces on coarse cotton cloth of a paper maker, and extruding the mica pulp pieces in a main presser and a secondary presser by a uniform linear pressure, thus obtaining basically-shaped mica paper; and (6) finally drying the mica paper in drying cylinders at a high temperature, and allowing the mica paper to pass through an upper drying cylinder and a lower drying cylinder, thus obtaining various pieces of mica paper of different thicknesses. The method disclosed by the invention solves the technical problems that the mica paper has low compression strength, low tensile strength, unstable glue penetration time, unstable air permeability and the like, and has the advantages of high compression strength, high tensile strength, stable glue penetration time and stable air permeability.

Owner:湖北平安电工材料有限公司

Special iron oxide yellow pigment for tobacco and production method thereof

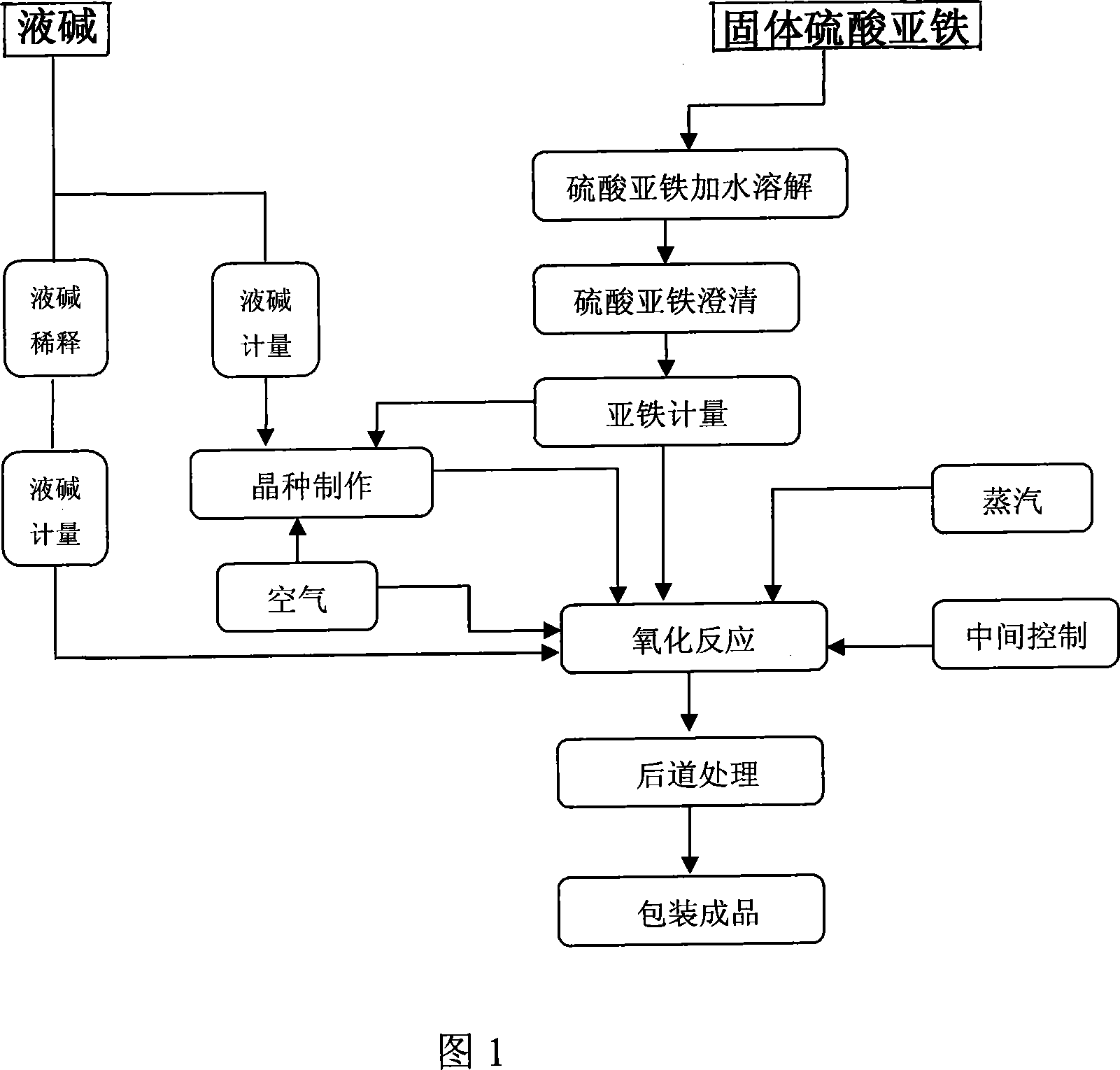

ActiveCN101225246AHigh puritySave iron resourcesPigmenting treatmentTobacco treatmentFerric oxide yellowGranularity

The invention relates to an iron oxide yellow pigment for tobacco and the production method, which resolves the technical problem and aims at providing a new liquid-liquid reacting iron oxide yellow pigment and the production method for tobacco, thus can ensure that the granularity of the product is more refined, more symmetrical and brighter than that made by iron filing method. The iron oxide yellow pigment for tobacco also aims at controlling the content of arsenic and lead in product in order to reach the requirement of tobacco industry. The production method adopts the technical proposal that the iron oxide yellow pigment is obtained by the reaction of 4500 to 5000 weight parts of solid green copperas with 80 to 88 percent content and 2500 to 300 weight parts of sodium hydroxide solution with 32 percent concentration. The production method comprises the inoculating seed preparation and the second oxidation. The an iron oxide yellow pigment can be widely used in tobacco industry, such as tipping paper makers and printing ink makers.

Owner:SHENGHUA GROUP DEQING HUAYUAN PIGMENT

Production method of hemorrhoids prevention toilet paper

ActiveCN102943413ASimple processEasy to controlNon-fibrous pulp additionInorganic boron active ingredientsFiberAmylase

The invention relates to a production method of hemorrhoids prevention toilet paper. The production method includes the following steps: 1 515 parts of ramie roots, 410 parts of Japanese dock roots, 37 parts of sophora flavescens, 37 parts of mints, 5 parts of rheum officinales, 1 part of catechu and 513 parts of rhizoma bletillae are adopted to be soaked and grinded into liquid and then are evenly mixed with 513 parts of rosin, 24 parts of boraxes, 1 part of sulphur, 0.1-0.2 part of protease, 0.1-0.5 part of amylase and 3060 parts of wood fibers to be pulped; and 2 1-2 parts of wet strength agents are filled into the pulp, large-roll toilet paper is produced by using the conventional papermaking process, and medicine toilet paper with 13-25% of moisture content is produced through copying of a paper maker; and the medicine toilet paper is subjected to slitting, bagging and sealing packaging to obtain the hemorrhoids prevention toilet paper product. The health care hemorrhoids prevention toilet paper is soft in texture and good in toughness and can be used for hemorrhoids prevention.

Owner:桐乡宏晨工业设计有限公司

Preparation for boron modified granular silicon sol

A production of boron modified particle silica sol is disclosed. It is carried out by acidizing soluble glass by strong acid cation exchange resin, alkalifying, curing, and ultra-filtering concentrating to obtain high specific superficial area particle silica sol. It can be used in various paper pulp, paper maker and paper application with pH between 4-10.

Owner:NANJING FORESTRY UNIV

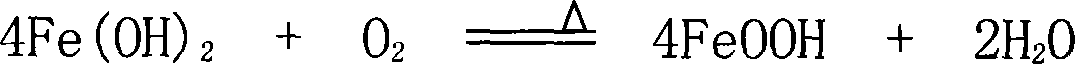

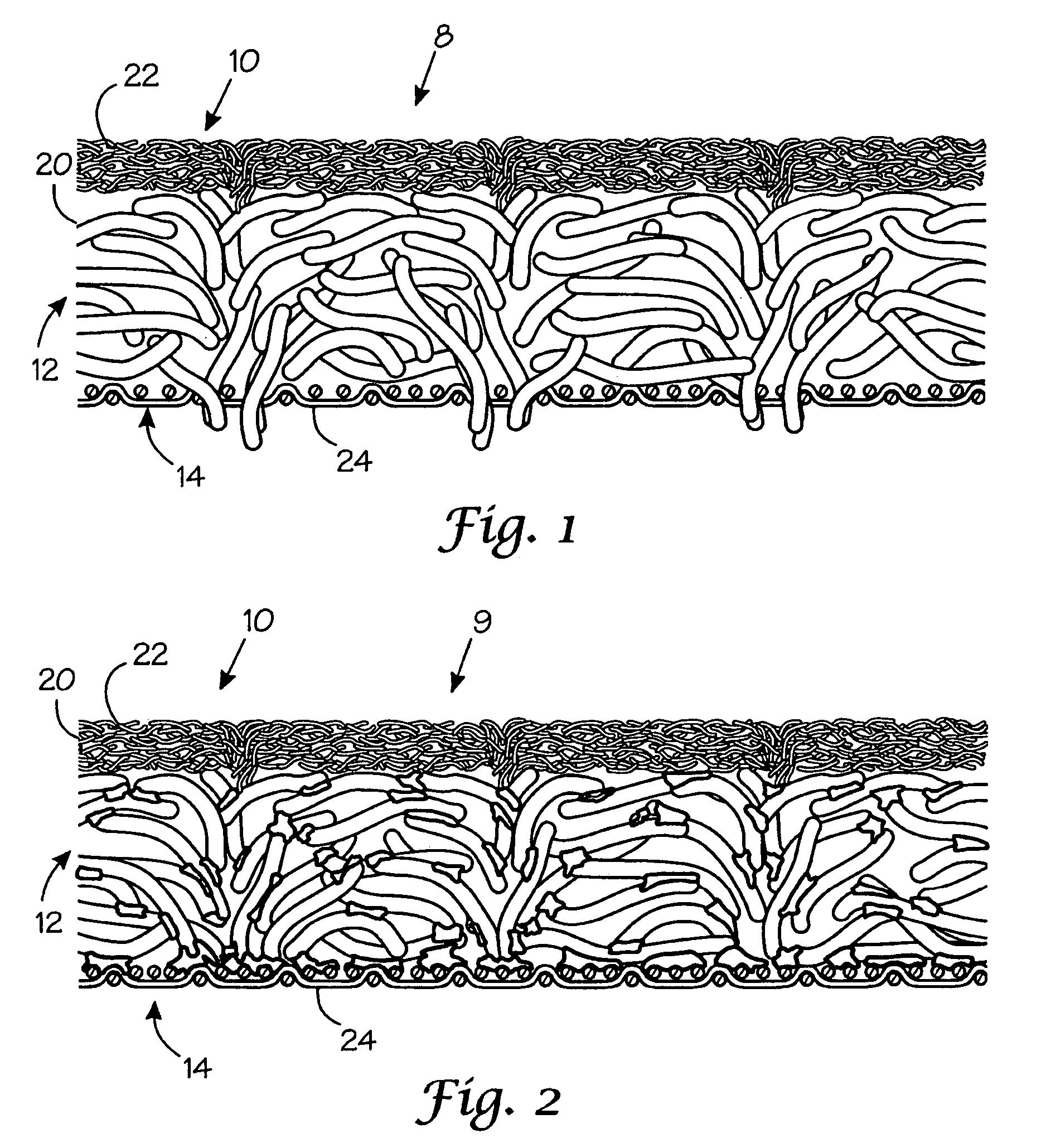

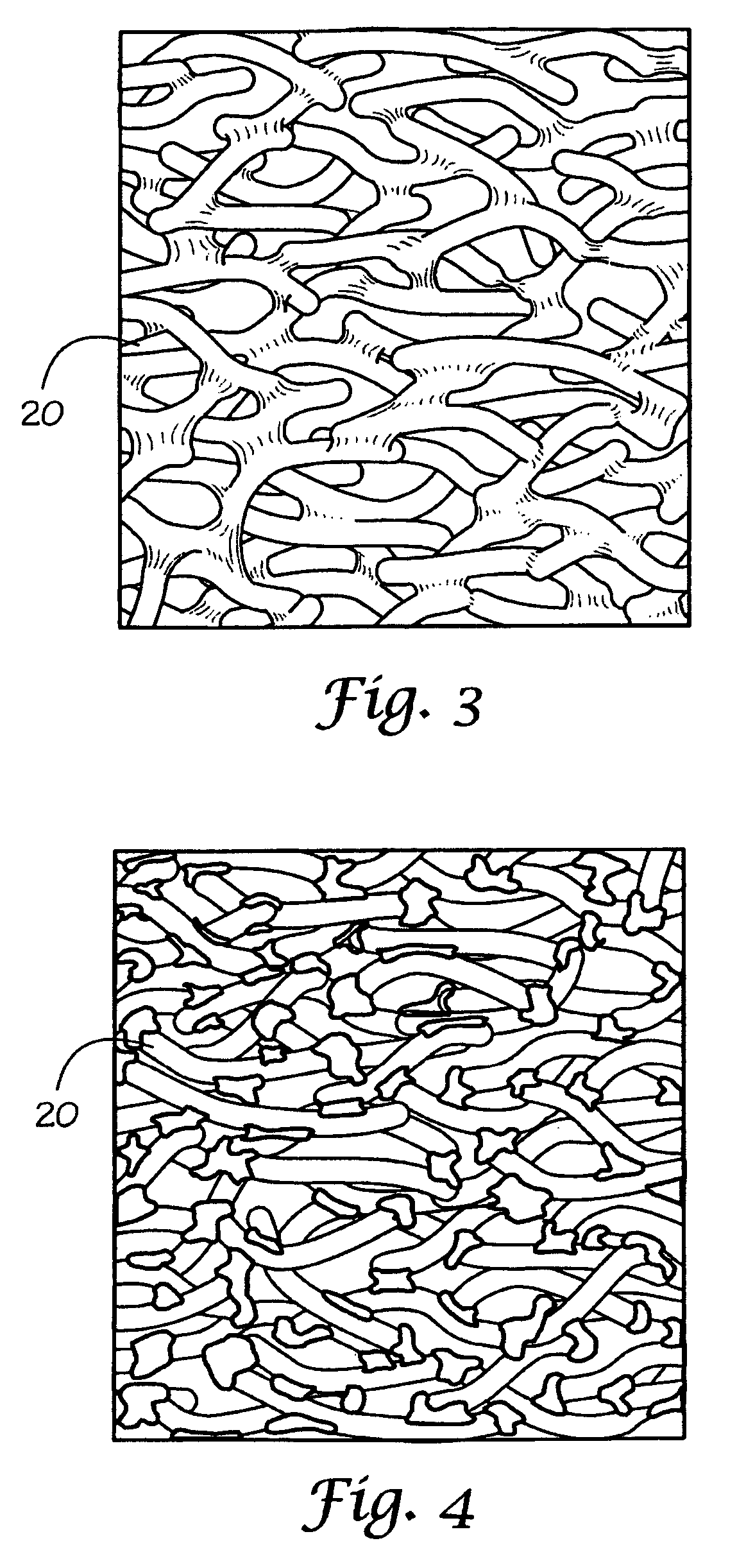

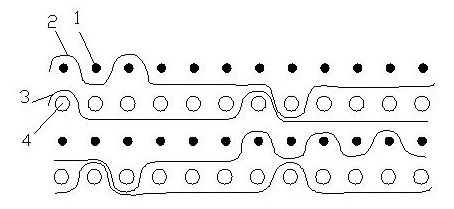

Papermakers felt having a point-bonded web layer formed of coarse fibers

InactiveUS7267745B2Improve stabilityIncrease volumeMechanical cleaningPressure cleaningEngineeringPaper Makers

A paper makers felt comprising a fibrous outer layer formed of inter-engaged fibers of between 3.0 and 67 dtex inter-engaged preferably by needling, and a web layer formed of fibers which are between 200 and 600 dtex and are inter-engaged preferably by point bonding. The outer layer is engaged with the web layer, preferably by needling, forming a composite paper makers felt.

Owner:VOITH FABRICS

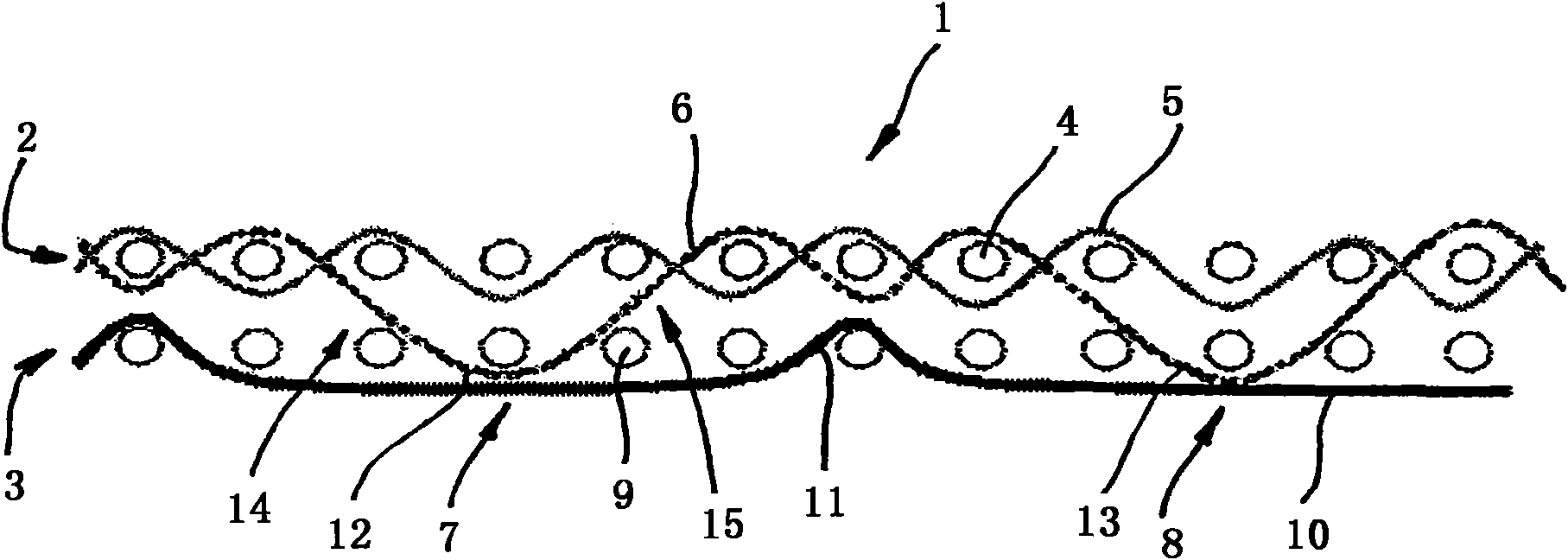

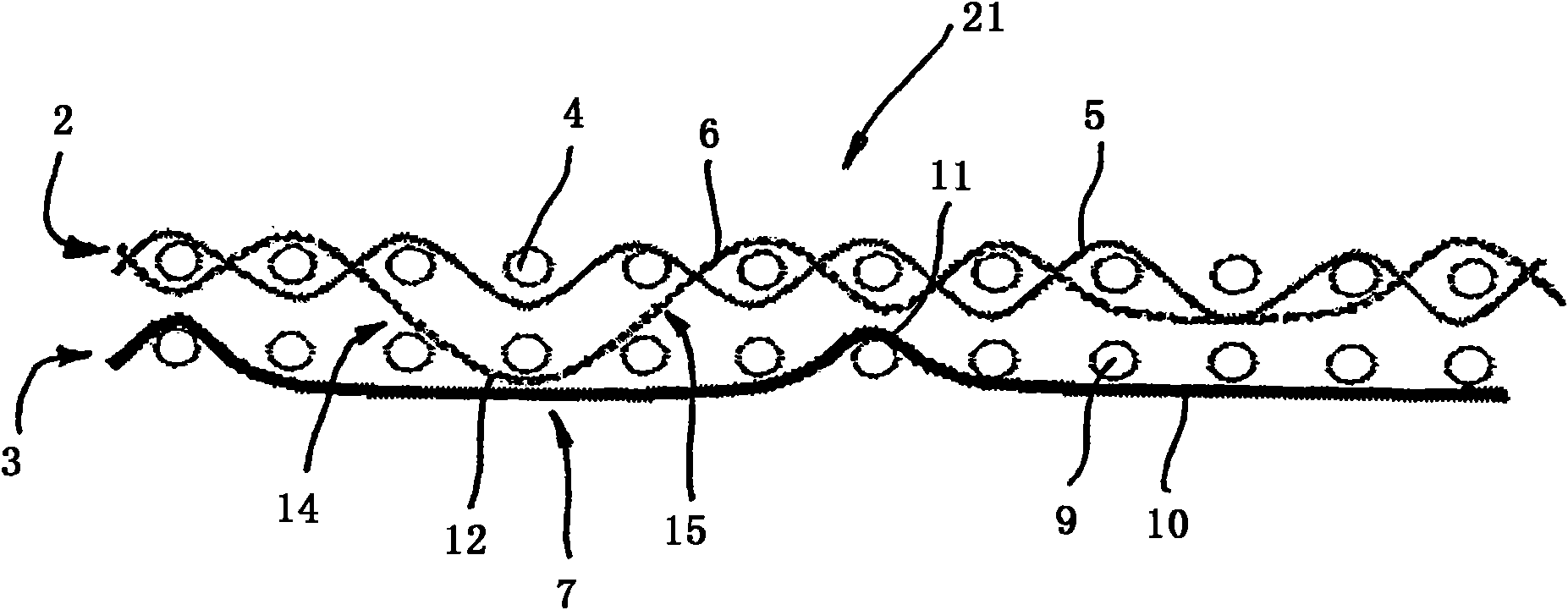

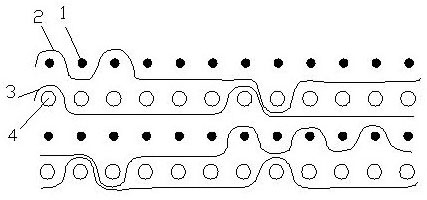

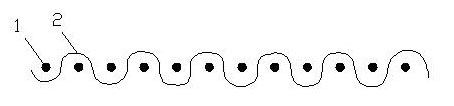

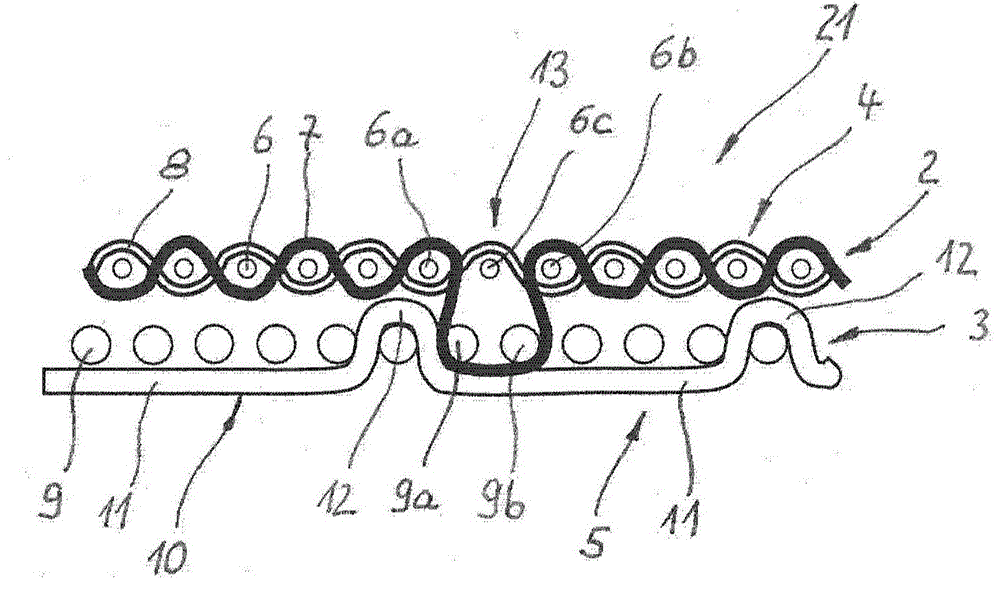

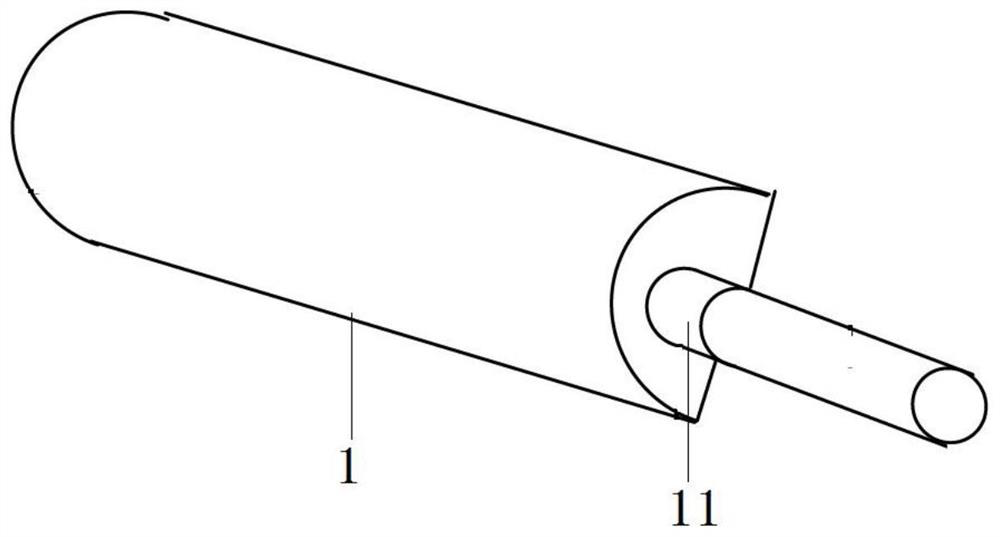

Woven paper maker fabric

The present invention relates to a woven paper maker fabric. Concretely, provided is a paper maker fabric (1, 21, 31, 41) having a first fabric layer (2) made of first threads (4, 5, 6) and a second fabric layer (3) made of second threads being connected by first binder threads (6) extending in one direction being divided into first basic threads (5) forming a plain weave with the first threads (4), and into the first binder threads (6) forming a plain weave with the first threads (4) section-wise, the first binder threads (6) bind one second thread (9) at binder points (7, 8) on the outside, wherein first threads (4) extending transversely to the first binder threads (6) are not bound at the binding points (7, 8), the number of which exceeds the number of the second threads being bound there by the number of at least two, wherein only one single binder thread (6) is provided between two adjacent first basic threads (5) respectively.

Owner:HEIMBACH GMBH & CO KG

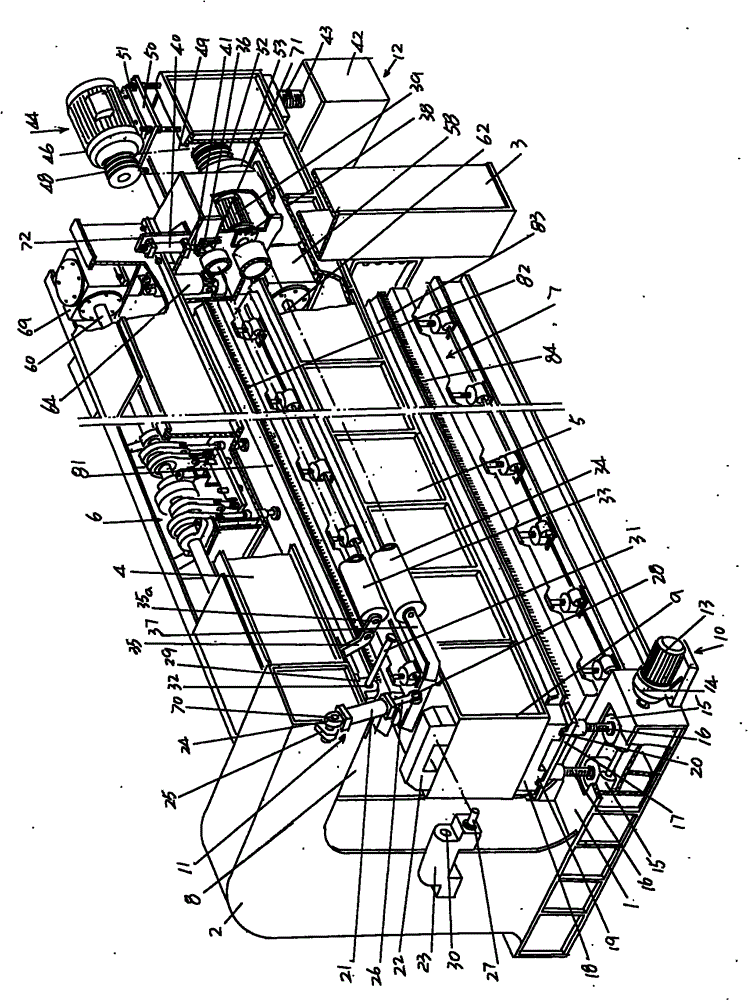

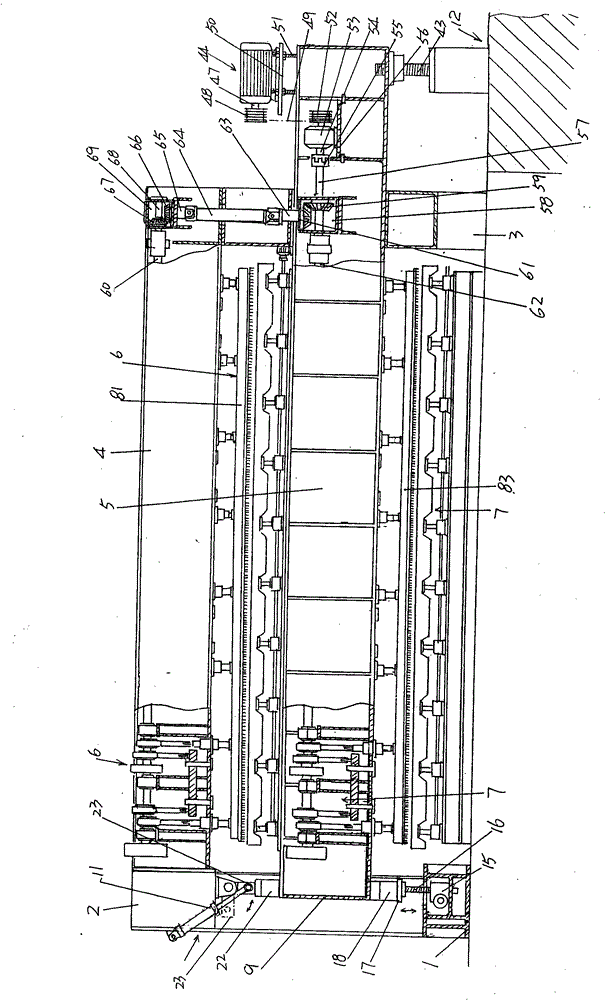

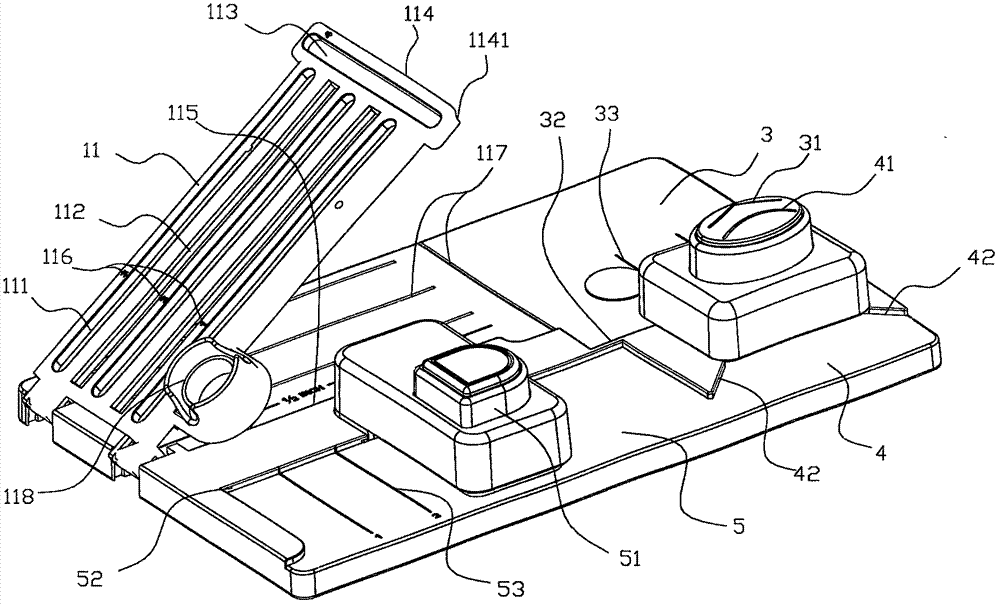

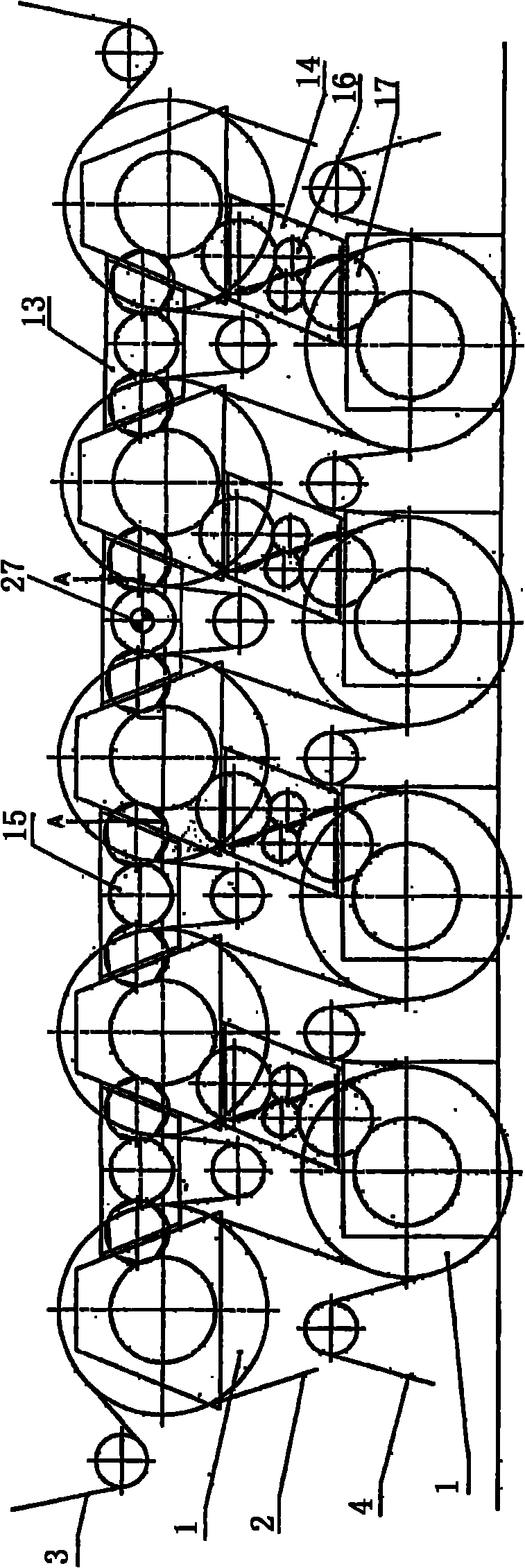

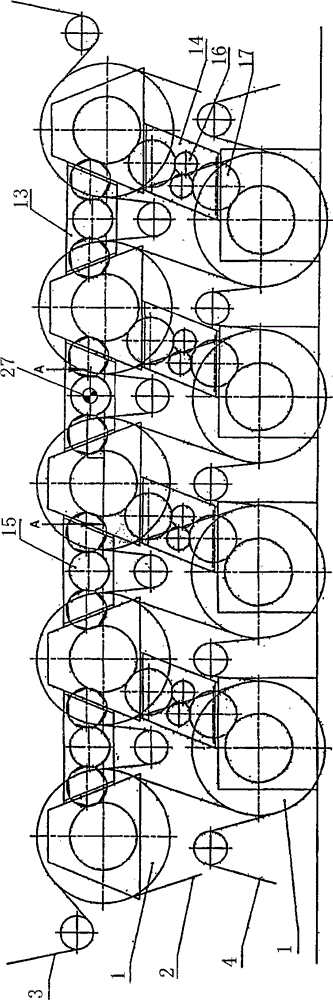

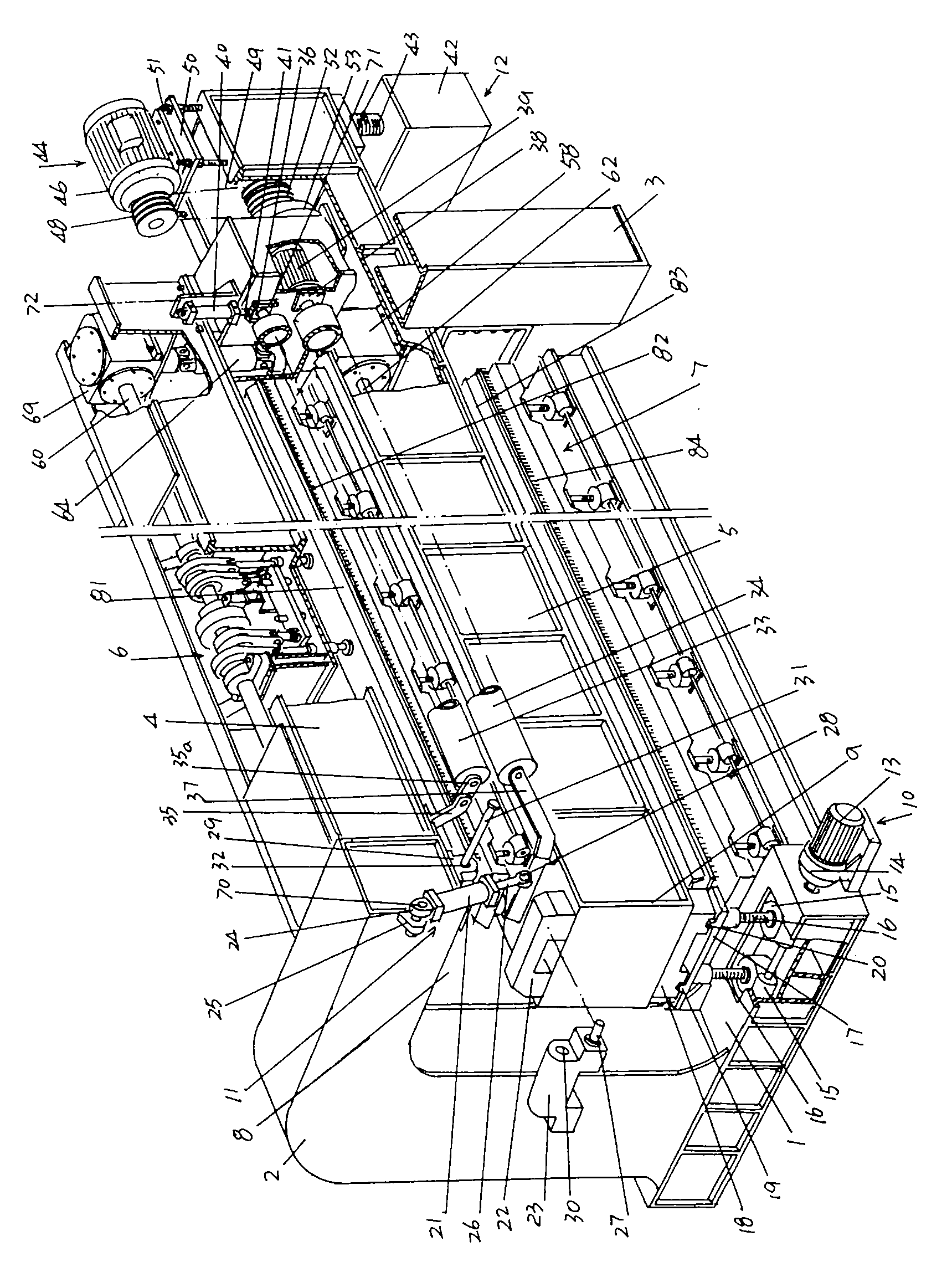

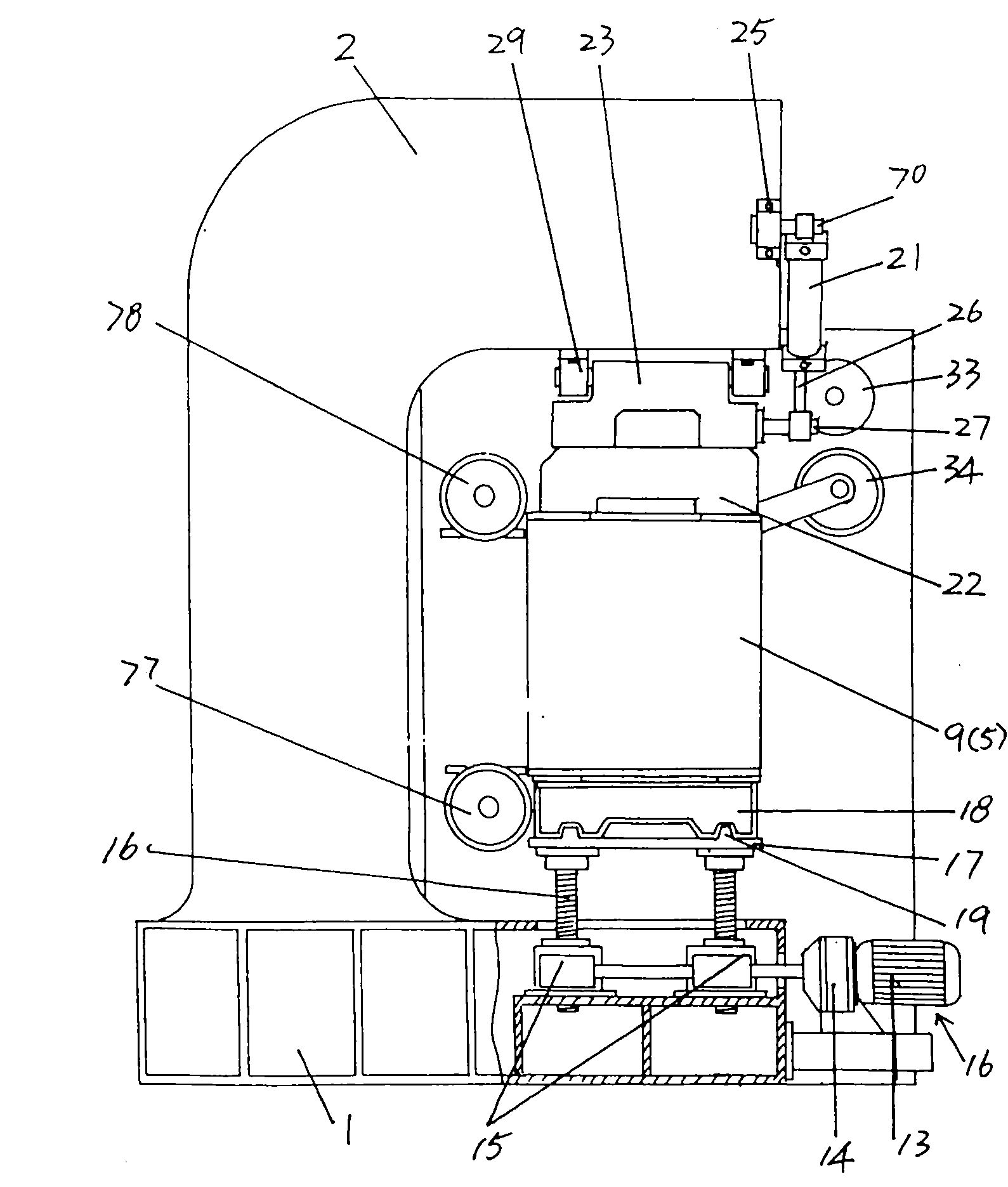

Formed felt collecting device of paper maker felt needling machine without end points

InactiveCN102134788BReduce labor intensityImprove work efficiencyNeedling machinesEngineeringUltimate tensile strength

A formed felt collecting device of a paper maker felt needling machine without end points belongs to the technical field of non-textile machinery. The paper maker felt needling machine without end points comprises an upright pillar, a support, a first cross beam, a second cross beam, an outer needling mechanism, an inner needling mechanism and a driving mechanism. The formed felt collecting device comprises a pressing roll, a felt guide roll, a first acting cylinder and a first motor, wherein one end of the pressing roll, toward the upright pillar, is arranged on a rotating arm; the rotating arm is arranged on a pivot arm of the pressing roll; the pivot arm of the pressing roll is fixed at the bottom of the first cross beam; one end of the pressing roll, toward the support, is arranged ona pressing roll shaft seat; one end of the felt guide roll, toward the upright pillar, is provided with a pivot arm of the felt guide roll; one end of the felt guide roll, toward the support, is arranged on a felt guide roll shaft seat and connected with the first motor in a transmission way; the felt guide roll shaft seat is arranged on the support; the first motor is arranged on the support; the first acting cylinder is arranged at the top of the support; and a piston rod of the first acting cylinder is connected with the pressing roll shaft seat. The formed felt collecting device can not only reduce the labor intensity of operators and human input, but also improve the working efficiency.

Owner:常熟市天顺无纺设备有限公司

Three-layer paper making forming net with high lateral stiffness

InactiveCN101906731AStrong resistance to deformationResistant to high vacuum suctionMachine wet endPolyesterLateral stiffness

The invention discloses a three-layer paper making forming net with high lateral stiffness, which comprises a surface net and a bottom net that are formed by crosswise weaving warps and wefts, wherein the surface net and the bottom net are connected and compounded by connecting lines; the surface net adopts a two-dimensional plain weaving structure; the bottom net adopts a six-dimensional broken satin weaving structure; the warps comprise surface net warps and bottom net warps; the diameters of the surface net warps and the bottom net warps are respectively 0.18 mm and 0.22 mm; the weaving density of the surface net warps and the bottom net warps is 24 unit / cm; the wefts comprise surface net wefts and bottom net wefts, wherein the surface net wefts comprise surface net nylon wefts and surface net polyester wefts respectively with a diameter of 0.18 mm; and the surface net nylon wefts are used as the connecting lines and connected with the compound surface net and the bottom net in an asymmetric connecting mode. The invention enhances the lateral stiffness of the forming net, strengthens deformation resistant capability in use, and is more suitable for a high-speed paper maker to operate.

Owner:HENAN HUAFENG FABRIC TECH

Technology for making paper without sewage drainage and apparatus and adhesives

InactiveCN1560358AAvoid discharge pollutionAvoid wastingPulp de-wateringWater dischargePolyvinyl alcohol

The invention relates to a paper making process, device and adhesive. Its process: pulping-milling pulp-storing pulp-batching-desanding and deslagging-flowing pulp-wet-making paper-dehydrating-drying, where the batching working procedure adds the adhesive in a batching tank, the flowing pulp working procedure makes the paper pulp in a flowing pulp box formed into wet-made paper, and its main character: the sewage water circulating and recycling working procedure is behind the dehydrating working procedure. The conveyer belt of the paper maker adopts nylon net, and does need washing in running course, avoiding the pollution caused by washing water; the adhesive is prepared of starches, polyvinyl alcohol and polystyrene,has good flocculating effect on paper pulp, and thoroughly separates paper pulp from water, thus able to directly circulate and reuse the sewage water, and avoiding the pollution caused by sewage water discharge.

Owner:厉龙松

Environment-friendly shoe insole board production process

The invention discloses an environment-friendly shoe insole board production process. The environment-friendly shoe insole board production process includes production steps: feeding, by weight, 38-42% of mug-long fiber paper pulp, 28-30% of wood powder and 28-30% of toilet paper pulp into a hydrapulper for mixing, and using a pulp pump to pump the mixed pulp into a pulp tank; feeding the mixed pulp into a heat dispersion system for heating at 80-100 DEG C for secondary defibering, so that paper pulp fibers can be saturated in water absorption, and speed increase of a production line is facilitated; feeding paper pulp processed by the heat dispersion system into a pressure screen system for third-time defibering; dyeing the paper pulp processed by the pressure screen system, uniformly mixing dye and pulp, and feeding the paper pulp into a paper maker for conventional production to obtain a shoe insole board. Finished paper sheets made by the process are free of impurity dots on the surfaces so as to be more attractive than traditional paperboards with residual ink dots.

Owner:庄财亿

Production technology for high-wet modulus cotton pulp

The invention relates to a production technology for a high-wet modulus cotton pulp, which comprises the following steps: preparing raw materials: taking cotton linters as the raw materials, opening, removing impurities, sending to a cyclone separator by air, fully mixing the raw materials with alkali liquor, and then extruding and dewatering; digesting: feeding slurry soaked with the alkali liquor into a spherical digester for digesting; chloridizing: chloridizing the digested slurry; bleaching: feeding the chloridized slurry into a bleaching tank for bleaching, and concentrating the slurry by using a concentrator before bleaching at the feeding moment; performing acid treatment: performing the acid treatment on the bleached cotton pulp and feeding hydrochloric acid into the bleaching tank in a spraying mode; and obtaining an end product: making by using a paper maker and packing into the end product of the cotton pulp. According to the production technology provided by the invention, a dry impurity-removing machine is firstly utilized to fully separate, scatter and purify the slurry, and then the slurry enters into a spiral sieve drum type extruder, and the cotton fibers are more uniformly soaked in the alkali liquor; the digesting uniformity is increased; the cost of the raw materials is low; the processing process is simple; the operation is convenient; the purchasing scope of the raw materials is wide and is unlimited; the output of modal fiber products is increased; and the development of the modal fiber industry is boosted.

Owner:TANGSHAN SANYOU GRP DONGGUANG PULP CO LTD

Production process of non-heat-seal type tea filter paper

InactiveCN106283895AHigh strengthAvoid breakingReinforcing agents additionChemical/chemomechanical pulpFiberCross-link

The invention discloses a production process of non-heat-seal type tea filter paper. The production process comprises the steps that S1, plant fibers soaked with sulfite are added into a beater, when the beating degree of slurry ranges from 15 SR to 25 SR, beating is stopped, an enhancer is added into the beater, slurry A is obtained, and the slurry is discharged for use; S2, a cross-linking agent and starch are added into the slurry A prepared in S1, the oven dry ratio of the cross-linking agent to the starch ranges from 1:120 to 45:120, then stirring is carried out for 25 min to 35 min, the materials are fully mixed to be uniform, and slurry B is obtained; S3, 5-6% flocculant is added into the slurry B prepared in S3, the mass concentration of paper pulp ranges from 0.14% to 0.16%, the materials are mixed and stirred to be uniform, then net feeding and paper manufacturing are carried out, press polishing and rolling are carried out through a paper maker, and the finished paper is made. The non-heat-seal type tea filter paper made through the process contains no harmful chemical additive, is environmentally friendly and practical, has wide market popularization value and can be widely applied and popularized.

Owner:丽水兴昌新材料科技股份有限公司

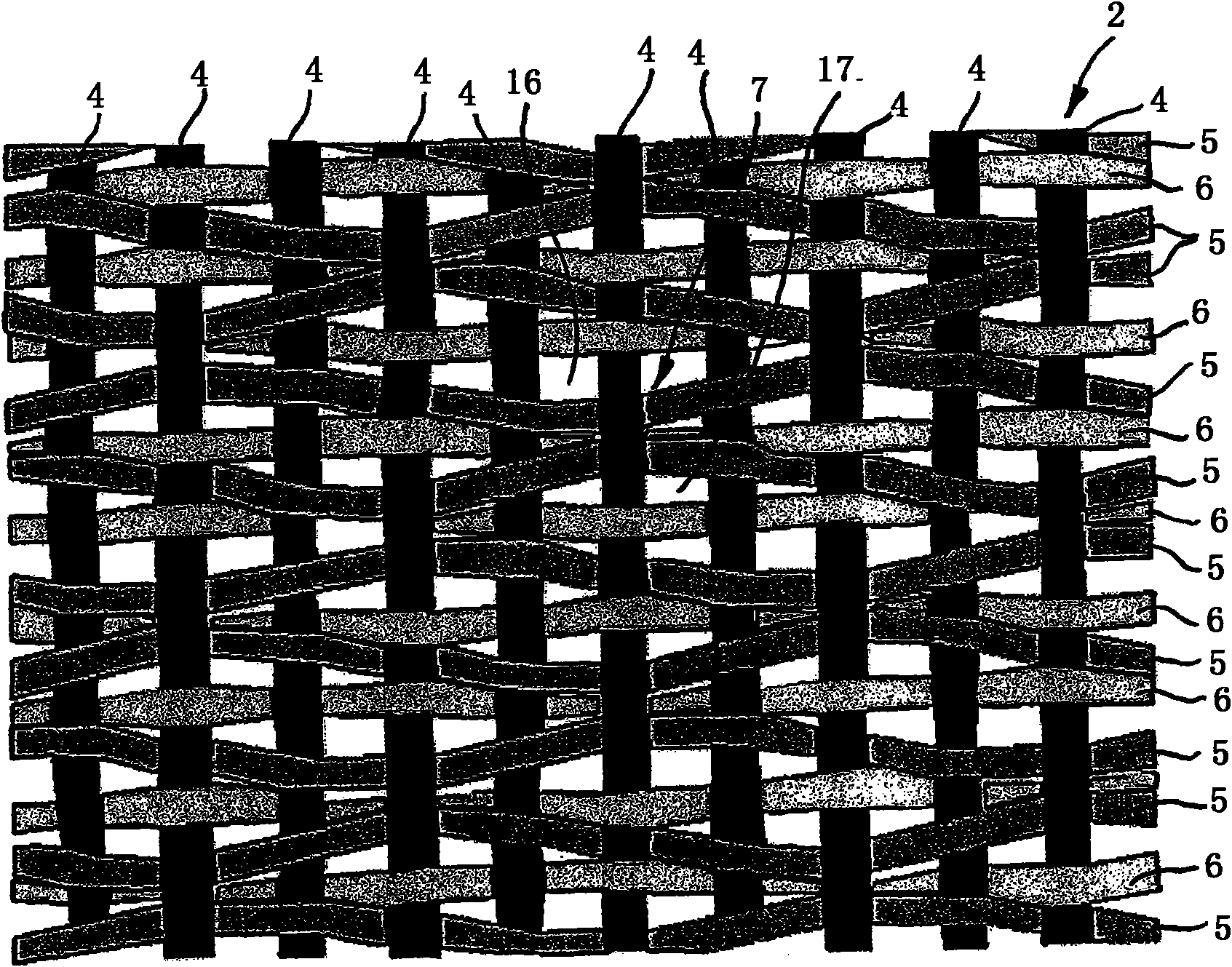

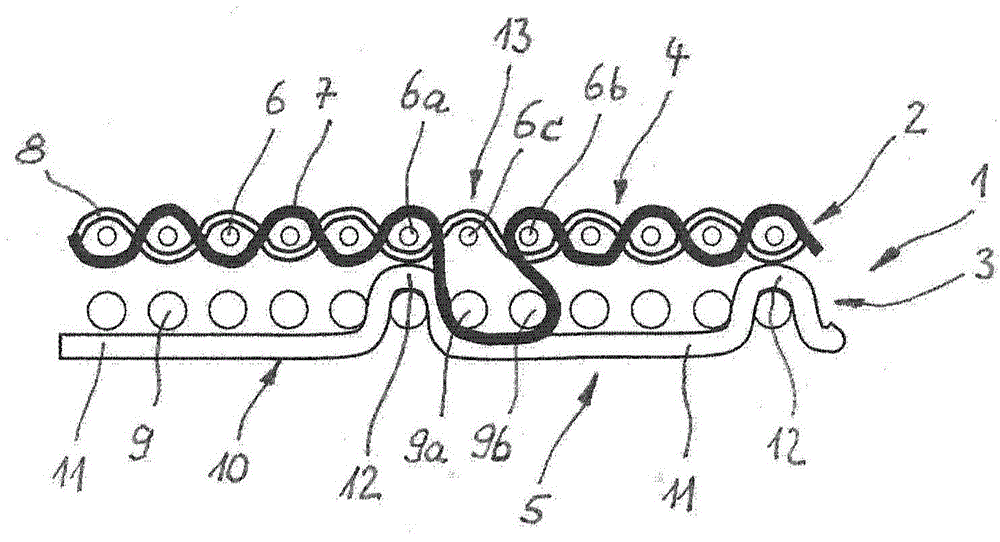

Paper maker fabric

ActiveCN104805725ADecreasing Marking TrendSave operating timeMachine wet endMulti-ply fabricsEngineeringPaper Makers

The invention relates to a fabric (1, 21) having a first woven fabric layer (2) forming a paper side and made of first threads (6, 7, 8), and a second woven fabric layer (3) made of second threads (9, 10), the two woven fabric layers (2, 3) being connected by binder threads (7) belonging to the first woven fabric layer (2) such that at binding points (13) the respective binder thread (7) binds with one first thread (6a) on the paper side, then changes to the second woven fabric layer (3) and binds with at least two second threads (9a, 9b) and then returns to the first woven fabric layer (2) again and binds with a first thread (6b) on the paper side, wherein at binding points (13) only one first thread (6c) is not bound by the said binder thread (7).

Owner:HEIMBACH GMBH & CO KG

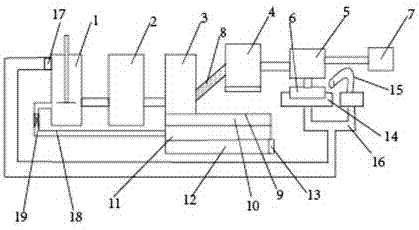

Environment-friendly paper making equipment

PendingCN106948206AReduce manufacturing costReduce wastePaper recyclingMachine wet endWater flowPulp and paper industry

Environment-friendly paper making equipment comprises a paper scrap pulper, a fiberizer, a paper maker, a dryer, a calender, a paper cutter, a paper reeling machine, a perforated pipe, a sewage sedimentation tank, a filtering layer, a clear water layer, a sedimentation layer, a drain outlet, a waste paper scrap recovery tank, exhaust equipment, a conveyor belt, a delivery port, a water pipe and a valve, wherein the paper scrap pulper is connected with the fiberizer; the fiberizer is connected with the paper maker; the paper maker and the dyer are connected through the perforated pipe; the sewage sedimentation tank is arranged below the paper maker and the perforated pipe; the sewage sedimentation tank is divided into the filtering layer, the clear water layer and the sedimentation layer; the drain outlet is formed in the sedimentation layer; the dryer is connected with the calender; the calender is connected with the paper cutter; the waste paper scrap recovery tank is arranged on the paper cutter; the exhaust equipment is arranged on one side of the paper cutter; the conveyor belt is arranged on the waste paper scrap recovery tank and the exhaust equipment; waste paper scraps are connected with the delivery port through the conveyor belt; the delivery port is formed in the paper scrap pulper; the water pipe is arranged on the clear water layer on the sewage sedimentation tank; and the valve is arranged on the water pipe.

Owner:安徽金兄弟环保科技股份有限公司

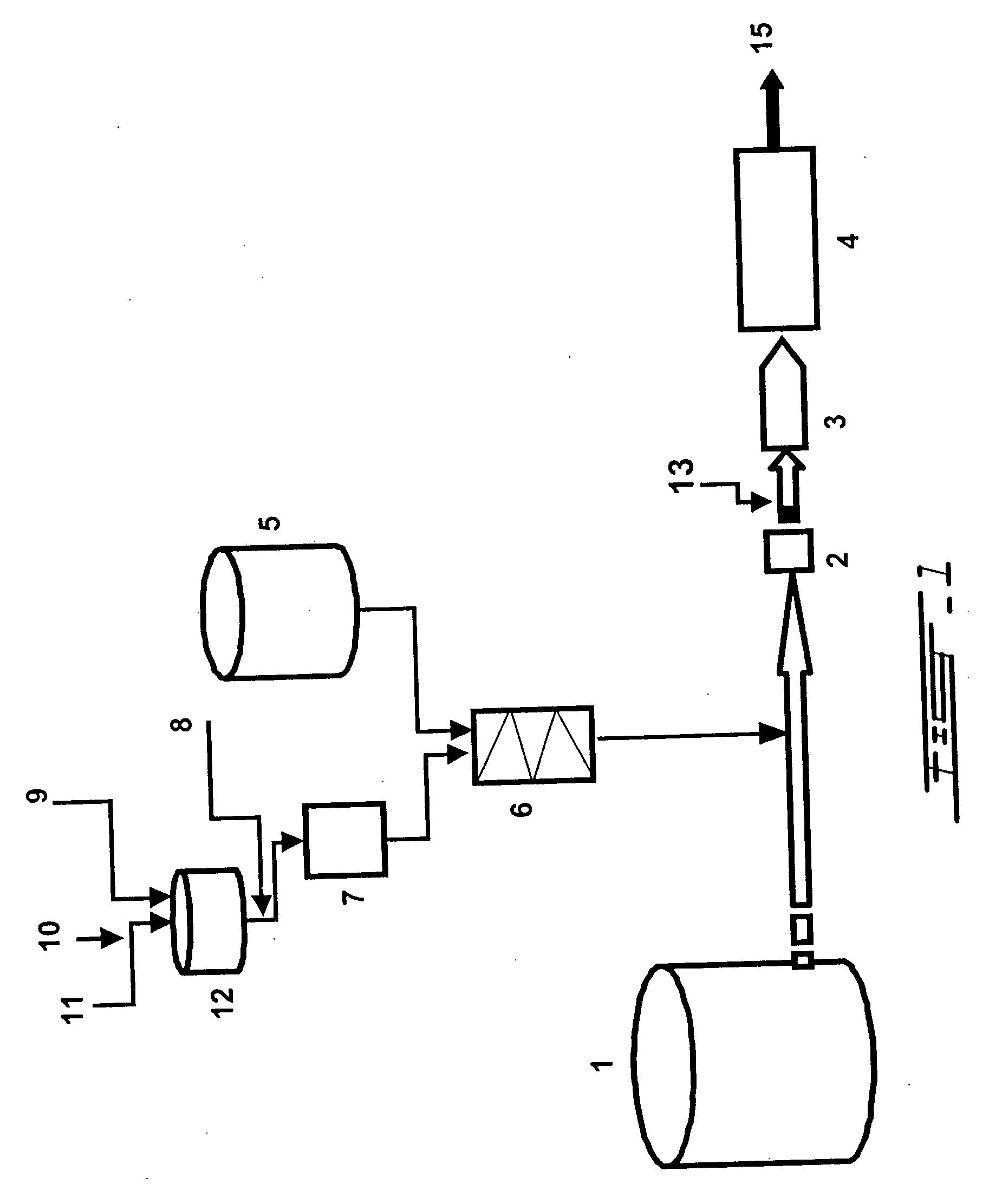

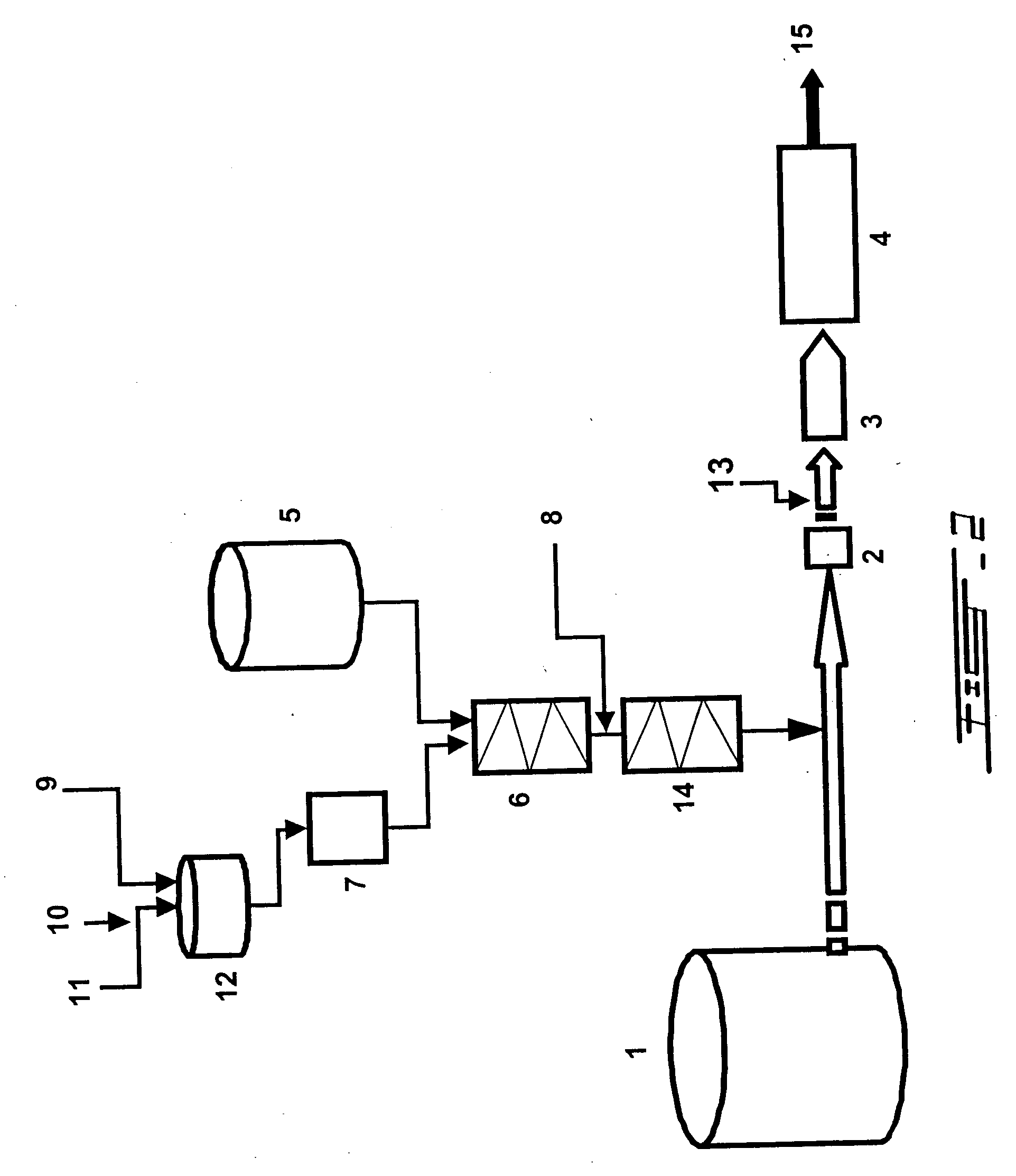

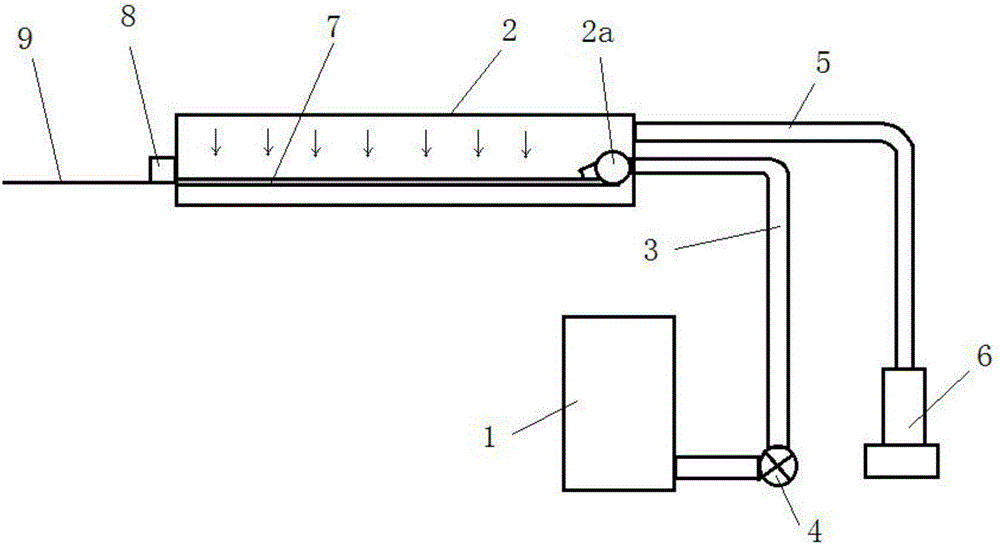

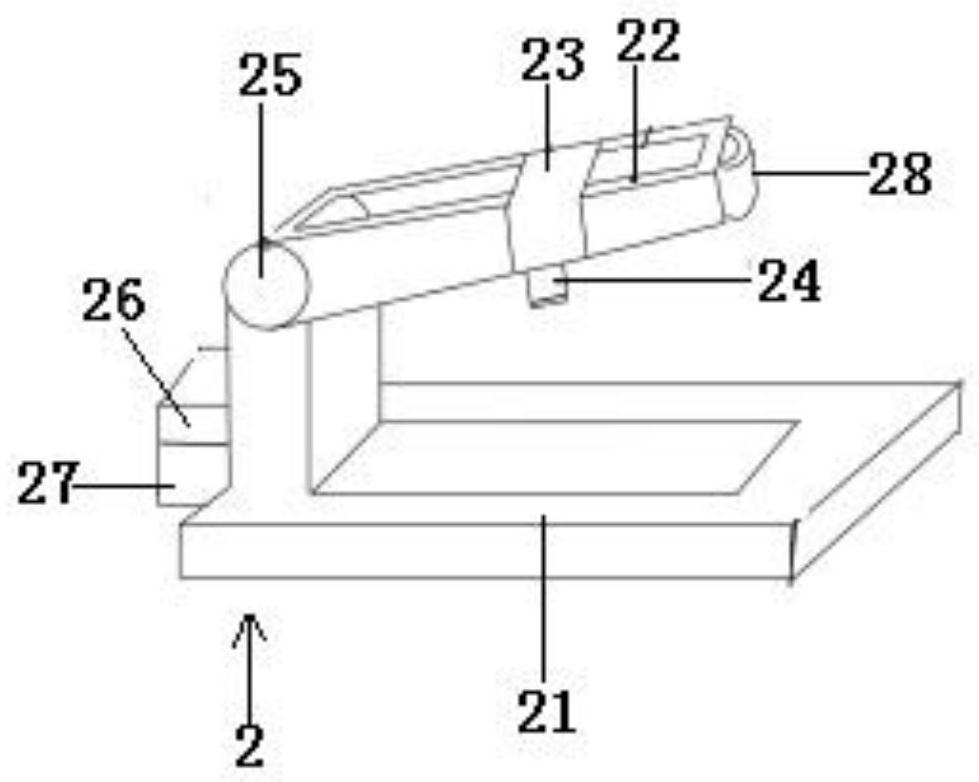

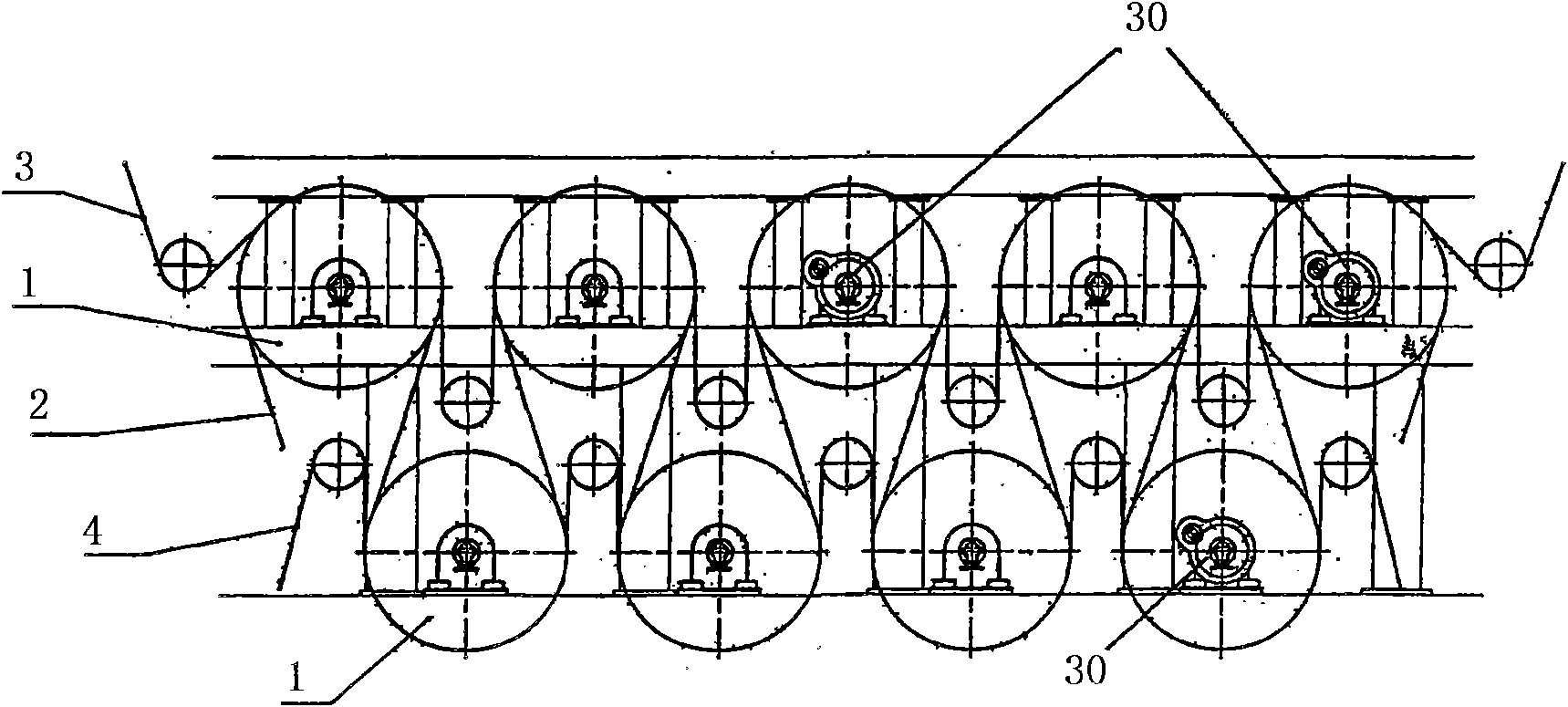

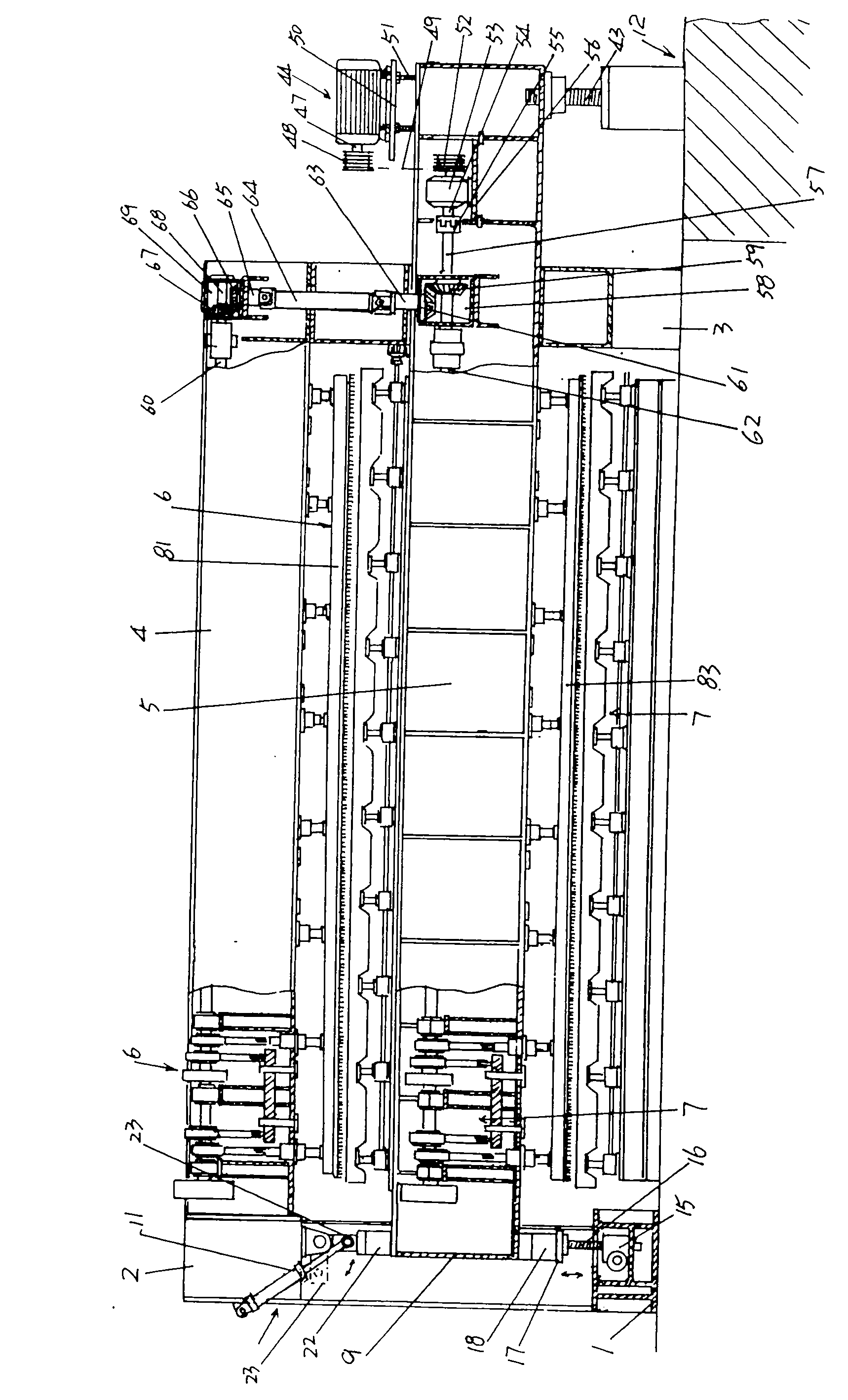

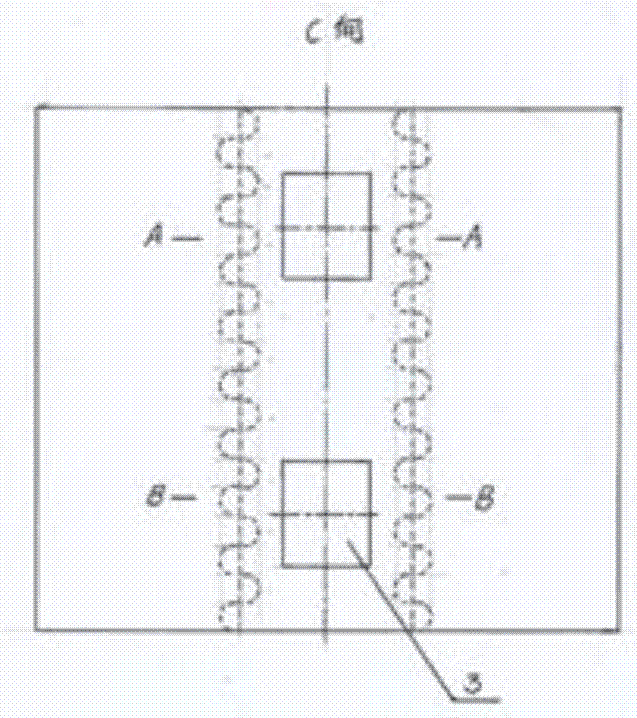

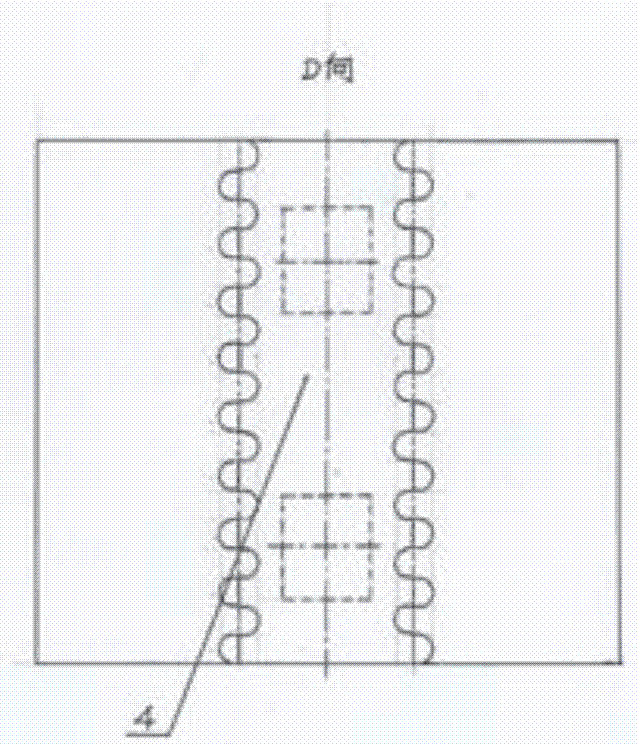

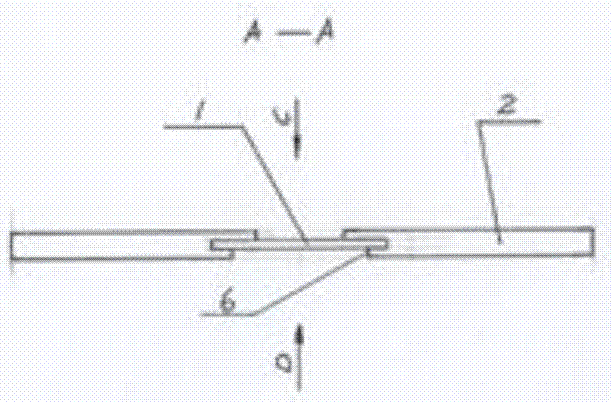

Method and device for enabling slurry in slurry flow box of forming part of paper maker to be evenly distributed

InactiveCN107177998ASpread evenlyUniform thicknessMachine wet endPulp and paper industryPaper Makers

A method and device for uniformly distributing slurry water in the headbox of the forming part of a paper machine, the method is to blow wind into the top of the closed headbox box, and apply uniform wind to the top of the box full of slurry Press to make the slurry water evenly distributed in the headbox of the forming section of the paper machine. The device comprises a slurry tank (1), a closed headbox (2), a slurry feeding pipe (3) connecting the slurry tank (1) and the closed headbox (2), and is arranged on the slurry feeding pipe The slurry inlet pump (4), the air inlet pipe (5) blowing to the top of the headbox box body and the low-pulsation Roots blower (6) installed on the air inlet pipe. The invention can evenly distribute the pulp water in the head box of the forming part of the paper machine, so as to obtain a paper base with uniform thickness.

Owner:建水春秋纸业有限公司

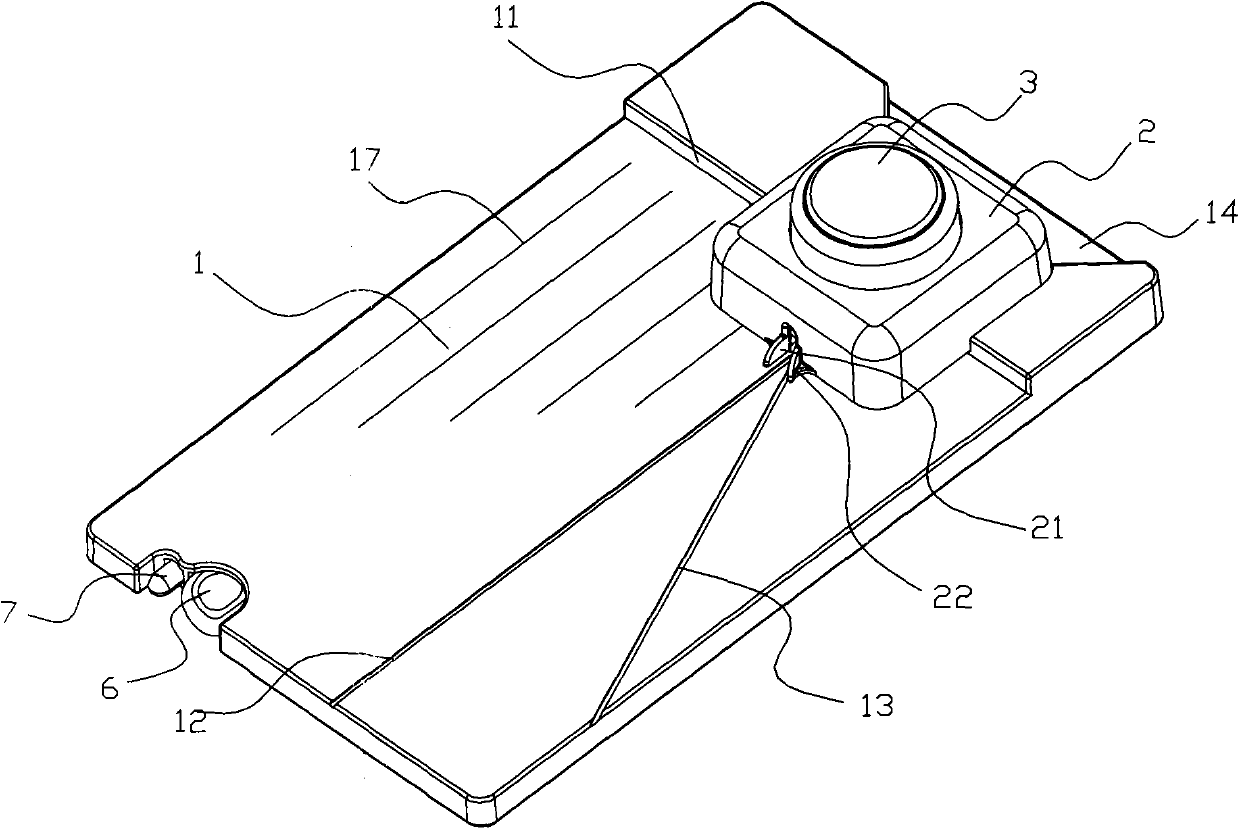

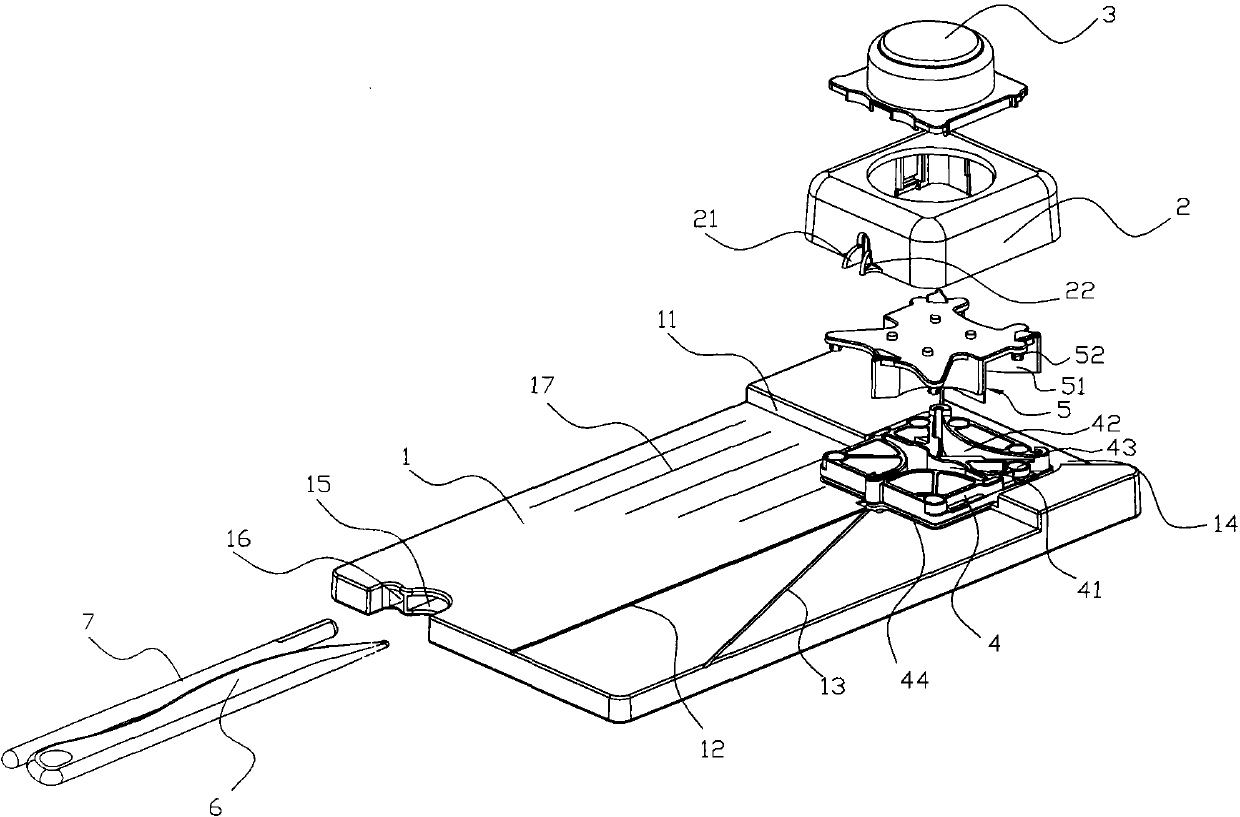

A paper English character and number maker

The invention discloses a paper English character and number maker which comprises a manufacturing plate and cutters, wherein the manufacturing plate is a plate body structure with zones which are respectively a linear joint-cutting zone, a trimming zone, a corner cutting zone and an opening cutting zone; each zone is provided with a paper positioning guiding rule or a positioning ruler or a combination of the positioning guiding rule and the positioning ruler; the linear joint-cutting zone is further provided with a linear guide rail which is arranged along the surface of the plate body; and the cutters comprise a linear cutter, a trimming cutter, a corner cutting cutter and an opening cutting cutter, which are respectively arranged in the linear joint-cutting zone, the trimming zone, the corner cutting zone and the opening cutting zone correspondingly for cutting the positioned paper in each zone into an opening, a side, a corner and an opening with an English character or a number. The paper English character and number maker can be used for quickly completing modeling of English characters and numbers, so that the structure of a making tool is simplified, and the manufacturing cost is reduced; meanwhile, the manufacturing plate is small in size, is convenient to carry and quick to place to carry out work, and is relatively low in requirements on an operation environment.

Owner:PARRIC NINGBO STATIONERY & GIFTS MFG

Preparation method of asbestos or non-asbestos rubber latex sheet by paper making process

The invention discloses a method for preparing asbestos or non-asbestos latex copy plate, which comprises: first, mixing and dispersing asbestos or non-asbestos fiber to be beaten, and adding calcium carbonate or convex-concave rod powder and carbon black into water, or first adding calcium carbonate or convex-concave rod powder and carbon black before beating; adding latex, sulfuration agent and anti-aging agent into mixture; at last, adding silicane coupler, silicane cross-linker, or titanic acid ester coupler into mixture; using caustic soda or sodium carbonate to adjust the pH valve of mixture to 7.5-8.5; adding sodium fluoride; feeding the mixture via the feeding system of paper maker, to be molded and dried to attain asbestos or non-asbestos latex copy plate. The invention adds silicane coupler, silicane ross-linker or titanic acid ester, and sodium fluoride into slurring beating process, to significantly improve the strength of product.

Owner:SHAANXI UNIV OF SCI & TECH

Repair paper maker and repairing method suitable for ancient calligraphy and painting cultural relics

The invention discloses a repair paper maker suitable for ancient calligraphy and painting cultural relics, and relates to the technical field of calligraphy and painting repairing. The repair paper maker comprises a scanner and a repair paper maker body. The scanner is used for scanning and measuring the damaged part of the cultural relics and measuring the size of the damaged part and the thickness of each part of the peripheral edges of the damaged part, and the scanner is in radio connection with the repair paper maker body. According to the size of the damaged part detected by the scanner and the thicknesses of the edges, the repair paper maker body makes repair paper matched with the size of a gap and the thicknesses of the edges of the gap in the paper. The invention further provides a method for repairing the ancient calligraphy and painting cultural relics. The method comprises the following steps: first, the damage part and the thickness of each part of the peripheral edge of the damage part are measured with the scanner; second, the repair paper maker body makes repair paper matched with the gap according to the size of the damage part detected by the scanner and the thicknesses of the edges; and third, the repair paper is fixed to the gap. With there repair paper maker and repairing method suitable for the ancient calligraphy and painting cultural relics, the calligraphy and painting cultural relics can be repaired without gap scraping.

Owner:NANJING MUSEUM

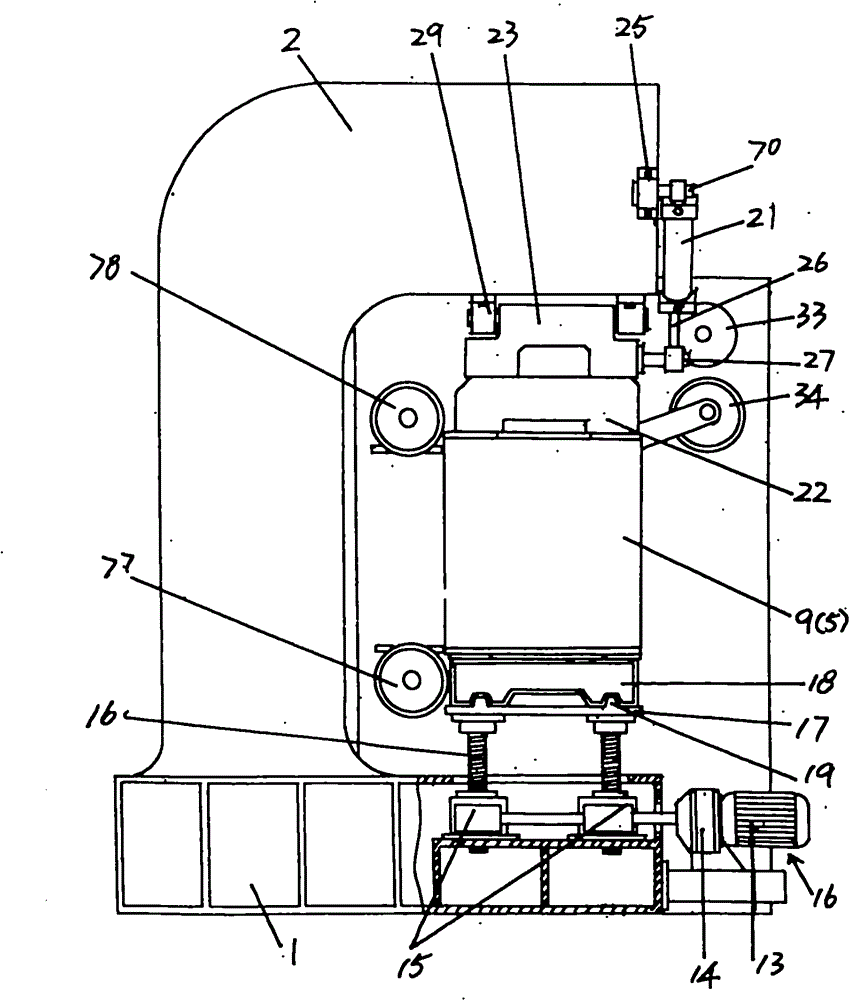

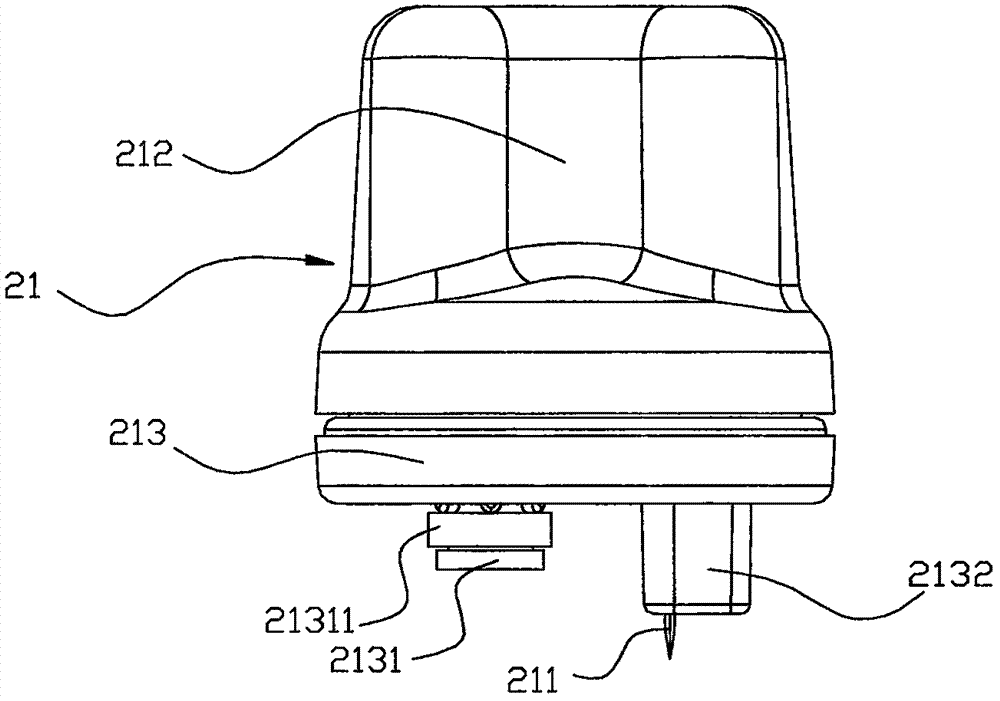

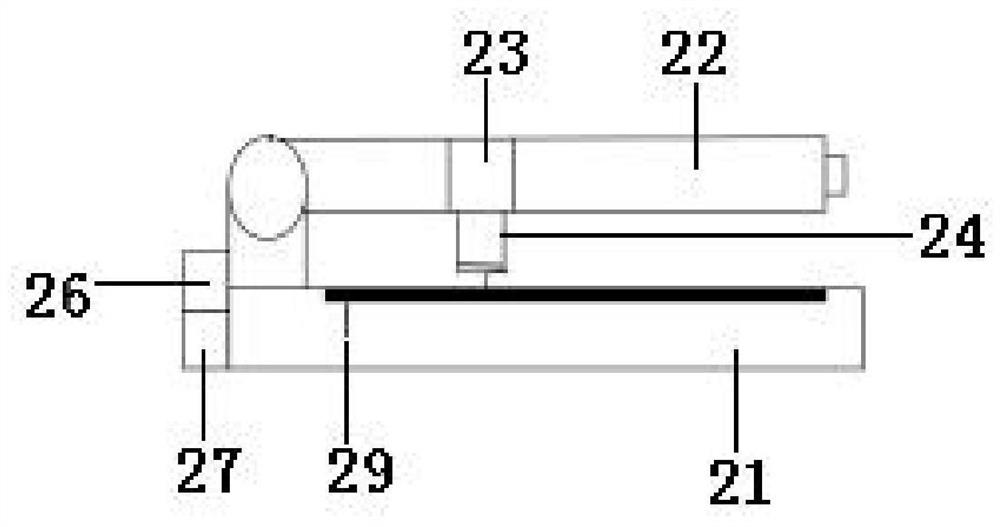

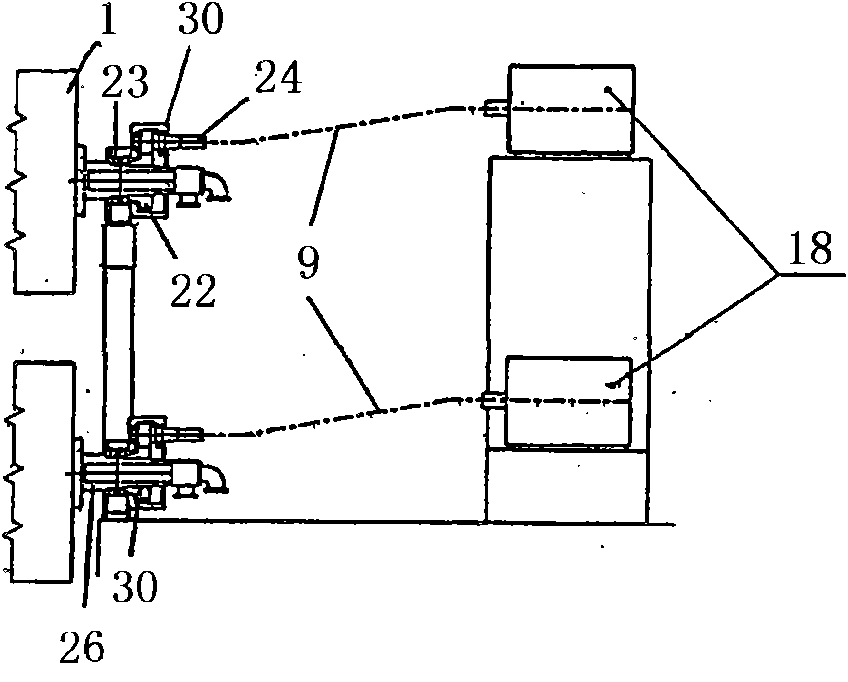

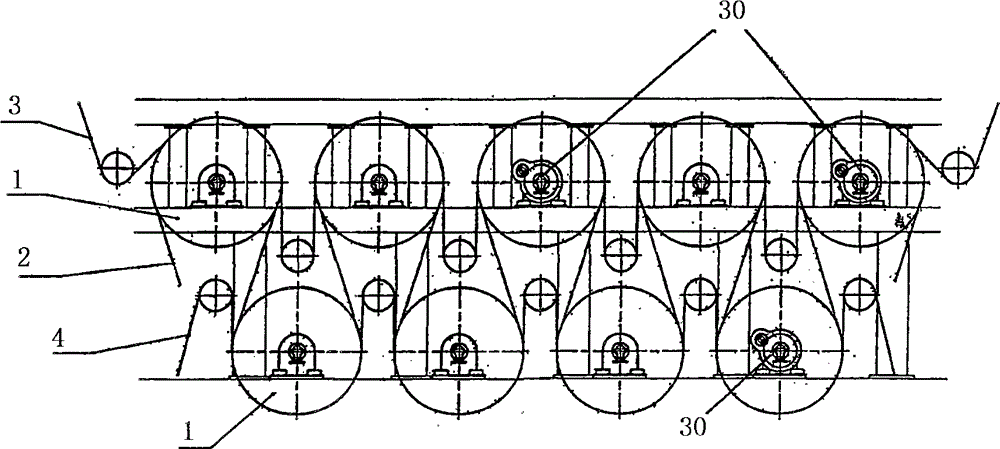

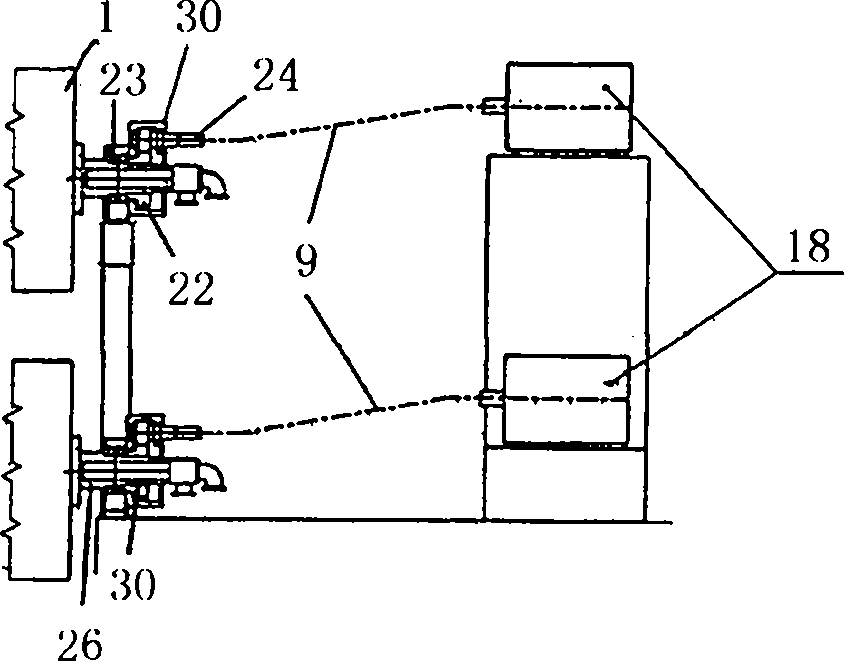

Bearing gear unit for paper maker or carton machine

The invention relates to a bearing gear unit (30) as a drive and support assembly of a drying cylinder (1) or a suction roller (25) of a paper maker or carton machine, which has a bearing (23) for storage of a pivot (26) of the drying cylinder (1) or the suction roller (25), a gear wheel (22) connected with the pivot in a fixed manner and a driving pinion (28), wherein the bearing (23), gear wheel (22) and the pinion (28) are arranged in a housing (21). The bearing is arranged between the cylinder (1) and / or the roller (25) and the gear wheel (22). The invention also relates to a drier part having the bearing gear unit (30) therein.

Owner:ANDRITZ AG

Preparation method of asbestos latex sheet

Owner:SHAANXI UNIV OF SCI & TECH

Bearing gear unit for paper maker or carton machine

The unit has a bearing (23) for storage of a pivot (26) i.e. hollow shaft, of a drying cylinder (1) or a suction roller (25), and a gear wheel (22) connected with the pivot in a fixed manner. A driving pinion (28) is provided for driving the gear wheel, where the bearing, gear wheel and the pinion are arranged in a housing (21). The bearing is arranged between the cylinder and / or the roller and the gear wheel, and the pinion is connected with a drive shaft (24) in a fixed manner, where the drive shaft is arranged in the housing.

Owner:ANDRITZ AG

Production method of anti-myopia paper

ActiveCN102154925BIncrease productivityHigh mechanical strengthWater-repelling agents additionPaper coatingFiberPulp and paper industry

The invention provides a production method of an anti-myopia paper. The method comprises the steps of: impregnating a wheat straw raw material by chemical medical liquid; pretreating under a normal-pressure and low-temperature condition; separating and thinning fiber by a mechanical twisting, grinding and fiber-separating method; and copying into a paper on a paper maker. The directly-obtained color of the paper is yellow, the yellow fiber paper with different depth degrees can be produced according to the difference of the chemical products and the treatment conditions, the paper is used forthe book for the school children or the reading magazine, and the paper has the function of myopia resistance without dazzling. The paper produced by the method is higher in yield and better in mechanical strength, wherein the yield of the paper is more than 60%, the rupturing length of the paper is more than 6.0km, the rupturing-resistant index is more than 4.2kPa.m<2> / g, the rupturing index is more than 3.20mN.m<2> / g, and the folding strength of the paper is more than 100 times.

Owner:SHAANXI UNIV OF SCI & TECH

A paper flower-shaped maker that is symmetrical around the axis

ActiveCN104802456BImprove production efficiencyReduce error rateMechanical working/deformationPaper/cardboard articlesAxis of symmetryPetal

The invention discloses a paper flower-shaped maker symmetrical around an axis, which comprises a scribing board and a cutter; There are double-folded grooves that are perpendicular to the reference side and angled grooves that maintain an angle with the double-folded grooves, and the angle between the folded grooves and the double-folded grooves is half of the average angle corresponding to the number of petals that make up the flower shape; The cutting knife cuts off the edge of the petals and the paper between the adjacent petals one by one; by setting the cutting board and the cutting knife, the processing of the flower-shaped crease and the flower-shaped edge contour can be completed at the same time, which improves the efficiency of flower-shaped production and reduces errors. Moreover, by arranging the second cutting knife on the scribing board, the independent auxiliary flower leaf production can be quickly completed, so that the auxiliary flower leaf forms auxiliary decoration for the paper flower shape symmetrical around the axis, and saves tool costs.

Owner:PARRIC NINGBO STATIONERY & GIFTS MFG

Formed felt collecting device of paper maker felt needling machine without end points

InactiveCN102134788AReduce labor intensityImprove work efficiencyNeedling machinesElectric machineryEngineering

A formed felt collecting device of a paper maker felt needling machine without end points belongs to the technical field of non-textile machinery. The paper maker felt needling machine without end points comprises an upright pillar, a support, a first cross beam, a second cross beam, an outer needling mechanism, an inner needling mechanism and a driving mechanism. The formed felt collecting device comprises a pressing roll, a felt guide roll, a first acting cylinder and a first motor, wherein one end of the pressing roll, toward the upright pillar, is arranged on a rotating arm; the rotating arm is arranged on a pivot arm of the pressing roll; the pivot arm of the pressing roll is fixed at the bottom of the first cross beam; one end of the pressing roll, toward the support, is arranged ona pressing roll shaft seat; one end of the felt guide roll, toward the upright pillar, is provided with a pivot arm of the felt guide roll; one end of the felt guide roll, toward the support, is arranged on a felt guide roll shaft seat and connected with the first motor in a transmission way; the felt guide roll shaft seat is arranged on the support; the first motor is arranged on the support; the first acting cylinder is arranged at the top of the support; and a piston rod of the first acting cylinder is connected with the pressing roll shaft seat. The formed felt collecting device can not only reduce the labor intensity of operators and human input, but also improve the working efficiency.

Owner:常熟市天顺无纺设备有限公司

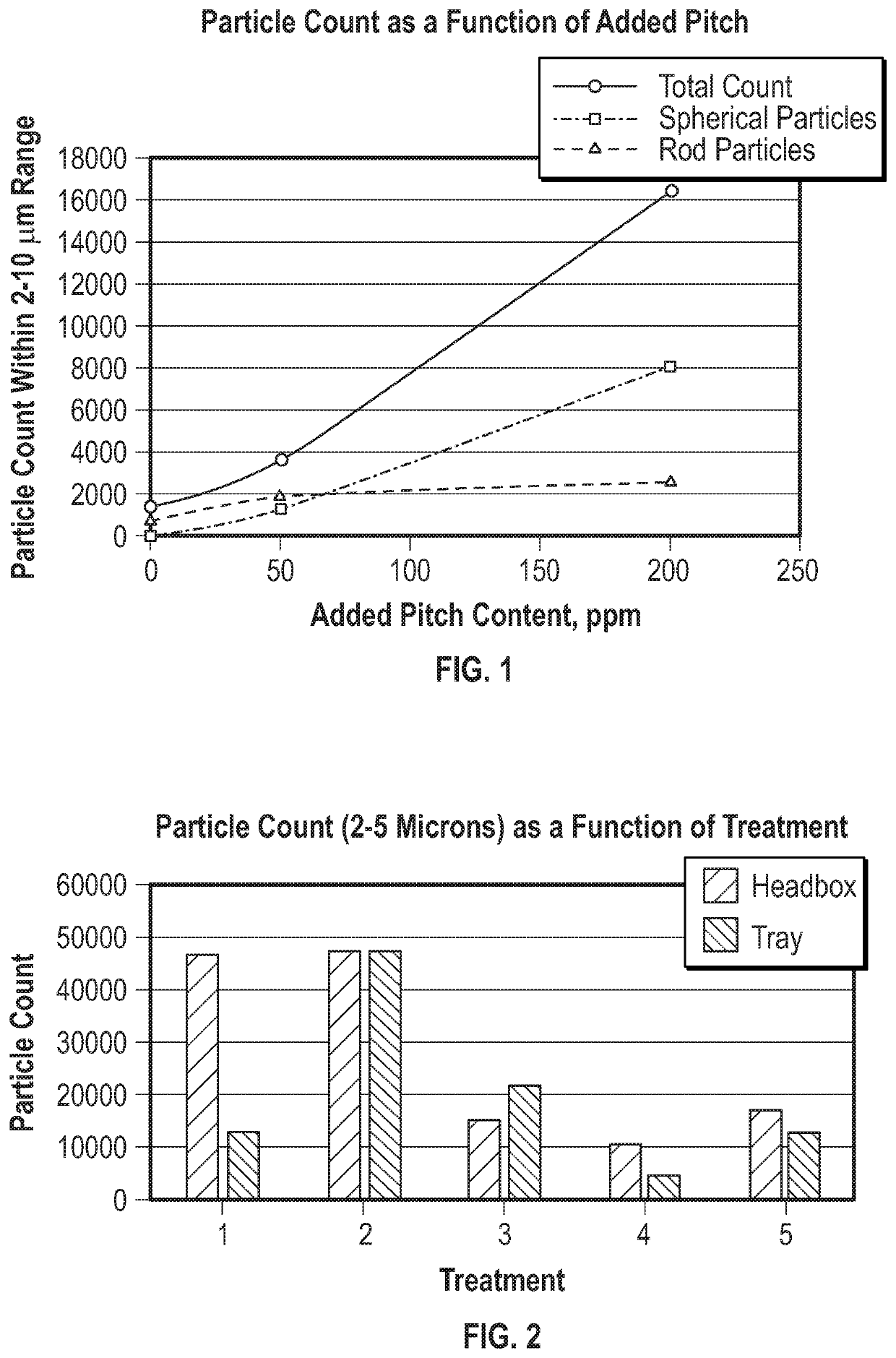

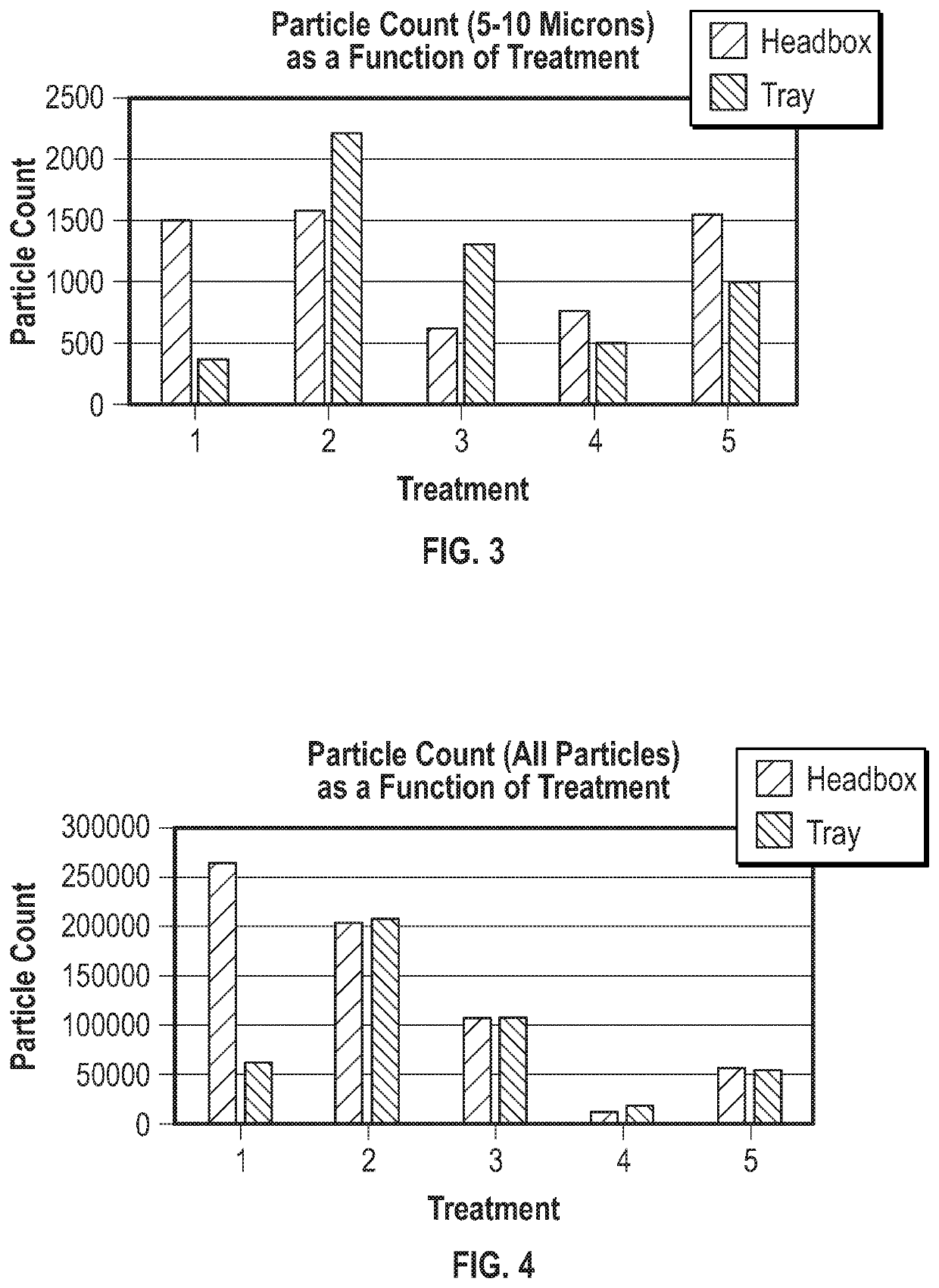

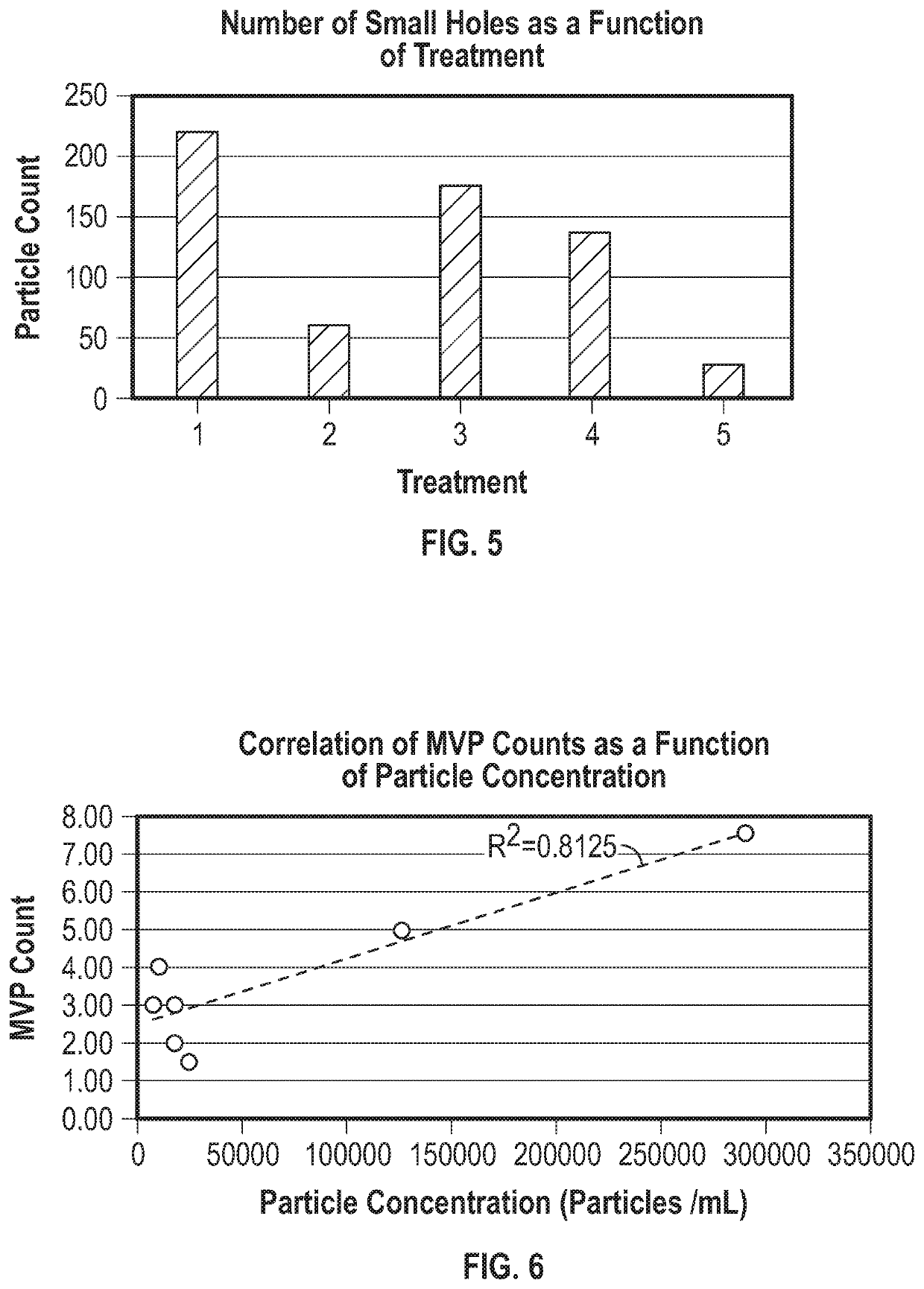

Method of measuring hydrophobic contaminants in a pulp slurry or a papermaking system

A method of measuring hydrophobic contaminants in a pulp slurry or a papermaking system includes the steps of providing an aqueous paper mill sample, filtering the aqueous paper mill sample to produce a filtrate comprising particles, and collecting an image of the particles in a measured volume of the filtrate. The method also includes the steps of analyzing the image to determine a size and morphology of the particles in the measured volume of filtrate, identifying spherical particles having a size of from about 1 micron to about 20 microns in the measured volume of filtrate, and quantifying a number of the spherical particles having the size of from about 1 micron to about 20 microns in the measured volume of filtrate. This method is useful for papermakers for deposition diagnostics, prevention, and contaminant control treatment optimization.

Owner:SOLENIS TECH CAYMAN

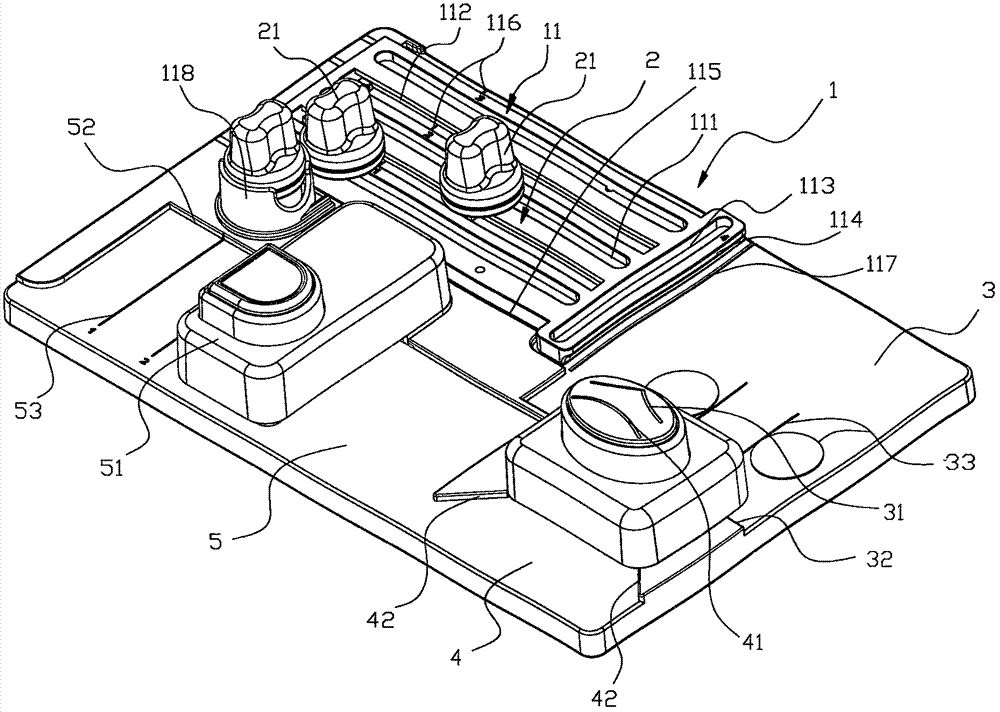

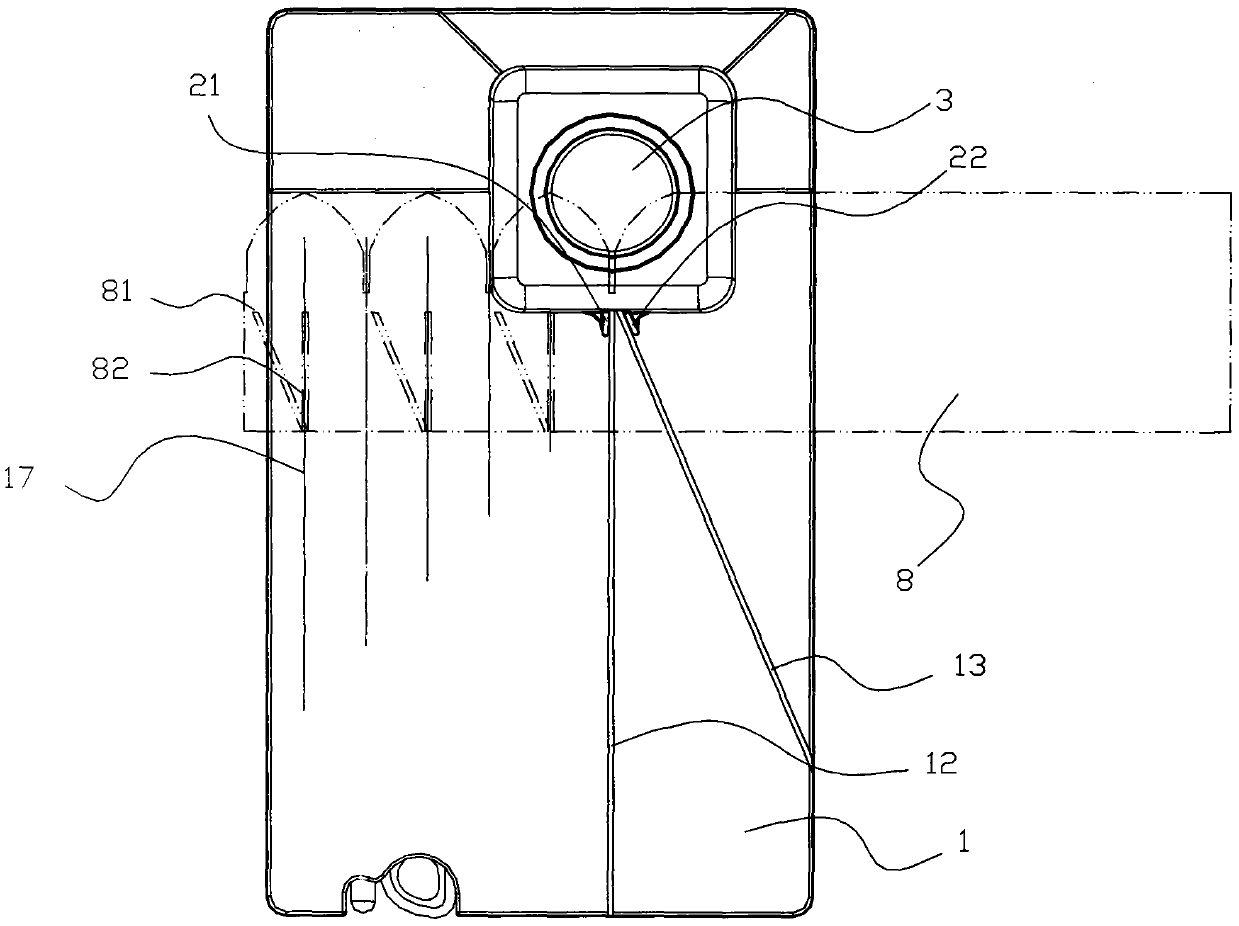

Security paper to which safety film is added through open hole and full window combined forming technology and manufacturing method

InactiveCN107326718AWith second-line anti-counterfeitingEasy to identify first-line anti-counterfeitingSpecial paperPaper/cardboardPapermakingPaper manufacturing

The invention provides security paper to which a safety film is added through the open hole and full window combined forming technology and a manufacturing method and belongs to the field of security paper manufacturing. Firstly, a wet paper sheet with an open hole is made, then a wet paper sheet with a full window is made, meanwhile, the wet paper sheet with the open hole and the wet paper sheet with the full window are attached, the open hole and the full window are superposed together and located in the front face and the rear face of the paper respectively, the safety film is applied between the two wet paper sheets, and the safety film is compounded in the open hole and full window region; finally squeezing and drying are carried out to obtain security paper dry sheet paper in which the open hole and the full window are combined and to which the safety film is added. The security paper and the manufacturing method have the advantages that the open hole (window) and adding of the safety film are completed at a time in the papermaking process of a paper maker, the full window anti-counterfeiting technology is added and integrated with the former technology, the manufacturing difficulty is greatly increased, meanwhile, the counterfeiting difficulty is also increased, and the anti-counterfeiting performance of the paper is greatly improved.

Owner:天津环球磁卡科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com