Method and device for enabling slurry in slurry flow box of forming part of paper maker to be evenly distributed

A technology of uniform distribution and headbox, applied in paper machine, wet end of paper machine, paper making, etc., can solve the problems of changing, affecting sizing uniformity, pressure instability, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

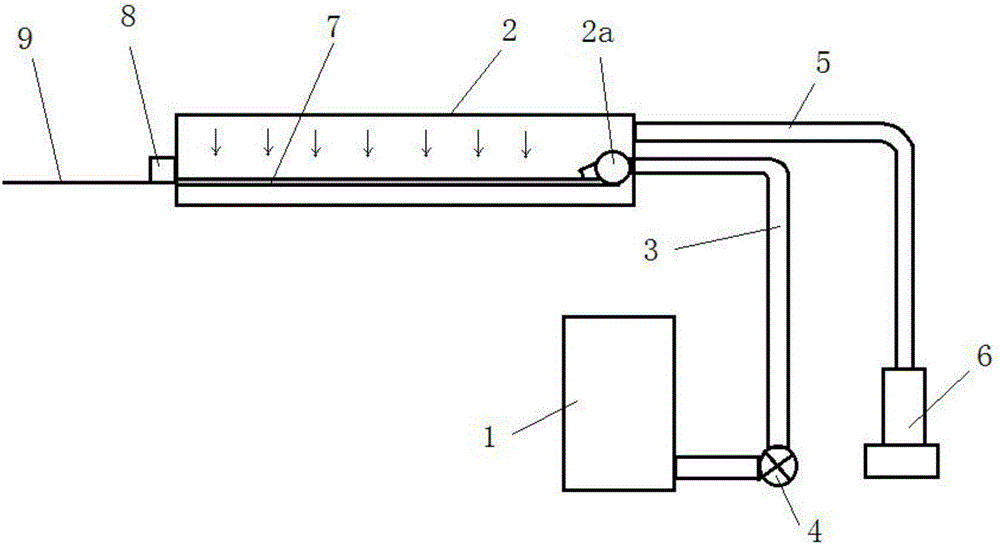

[0009] The method of the present invention to uniformly distribute the slurry water in the headbox of the forming part of the paper machine is to blow wind into the top of the closed headbox box, and apply uniform wind pressure above the slurry covered with the box, so that the paper machine The slurry water is evenly distributed in the headbox of the forming section.

[0010] Such as figure 1 As shown, the device for realizing the method of the present invention includes a slurry tank 1, a closed headbox 2, a slurry feeding pipe 3 connecting the slurry tank 1 and the closed headbox 2, and a slurry feeding pipe 3 arranged on the slurry feeding pipe 3. The pump 4, the air inlet pipe 5 blowing air to the top of the headbox box and the low-pulsation Roots blower 6 installed on the air inlet pipe.

[0011] When the device of the present invention is in operation, the pulp feed pump 4 pumps the finished pulp in the pulp tank 1 into the closed headbox 2 through the pulp delivery pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com