Woven paper maker fabric

A technology of weaving fabrics and fabrics, applied in the direction of textiles and papermaking, papermaking, paper machines, etc., can solve the problems of weakening the quality of sheets, woven structures destroying plain weaving structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

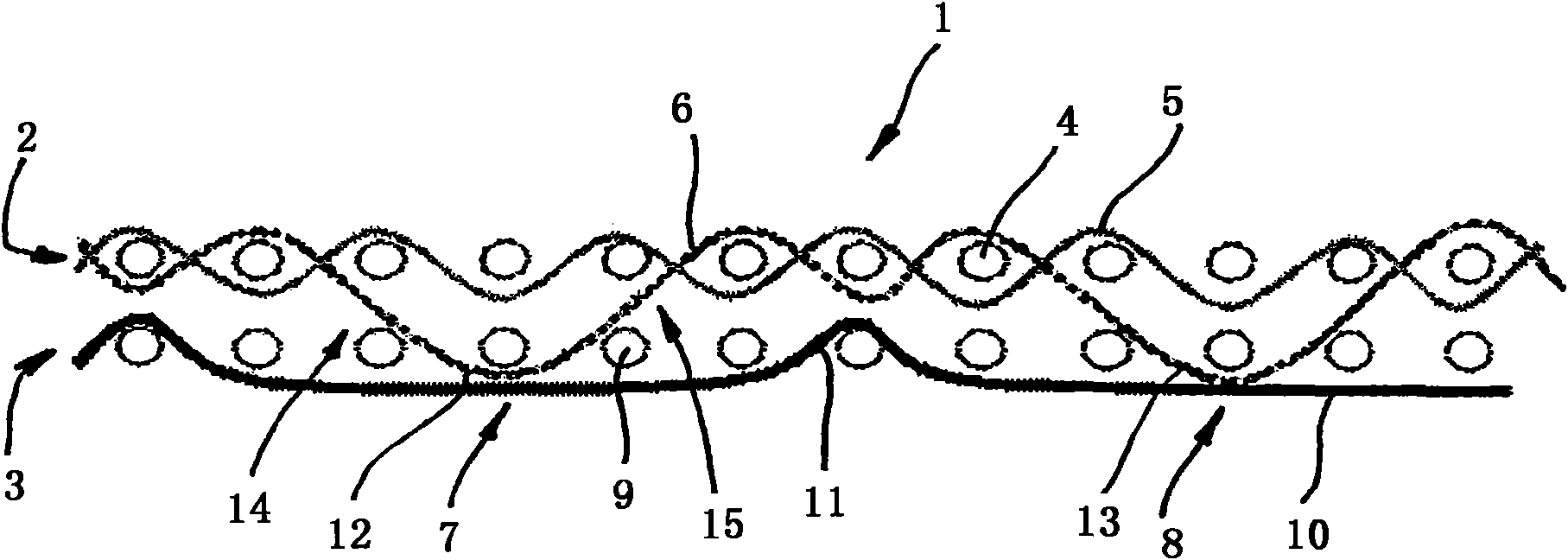

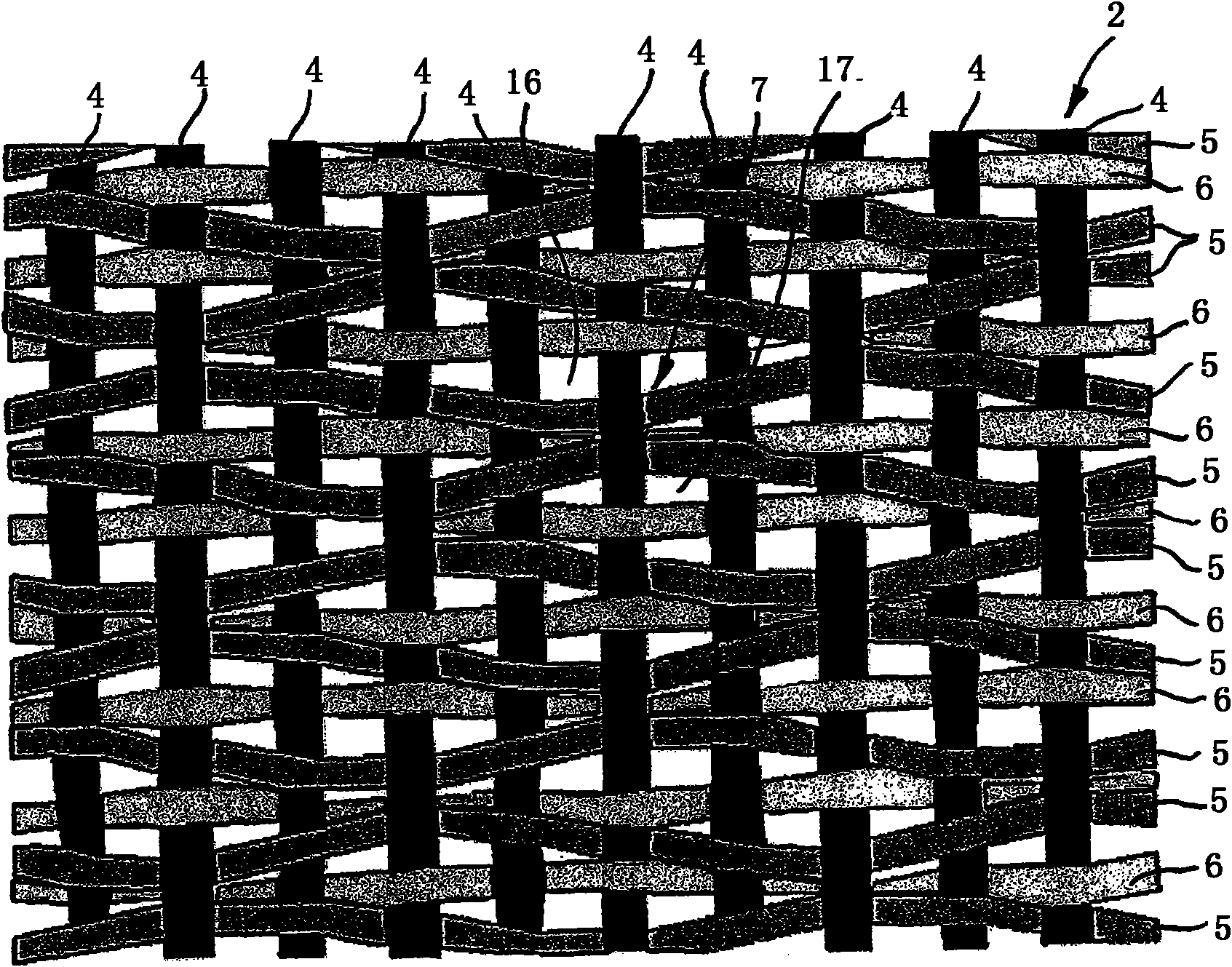

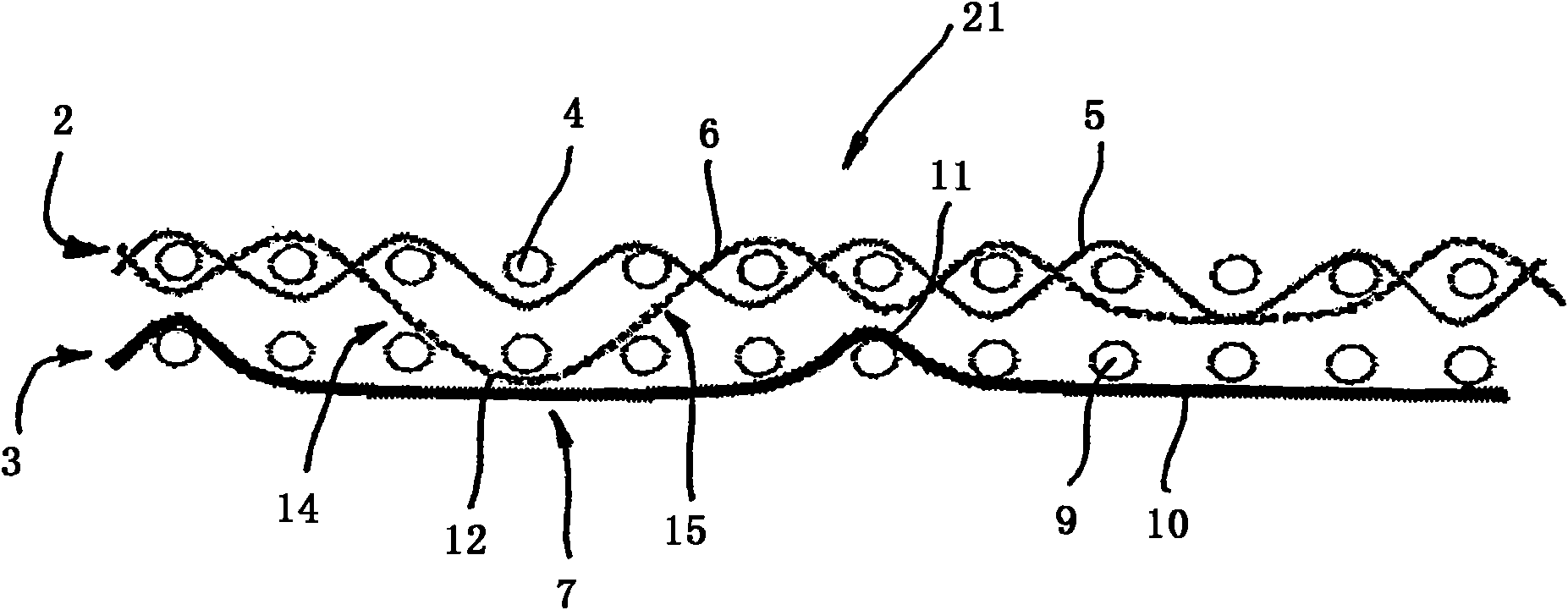

[0027] figure 1 The woven papermaker's fabric 1 shown in has: the paper side and thus the first woven fabric layer 2 ; and the machine side and thus the second woven fabric layer 3 . The two woven fabric layers 2, 3 are placed on top of each other.

[0028] The first woven fabric layer 2 consists of first longitudinal threads (identified for example by 4) extending in the direction of travel of the paper machine woven fabric 1 and first transverse threads extending transversely to the first longitudinal threads, both threads Has a circular cross section. The first transverse thread is composed of a first transverse base thread 5 and a first transverse binding thread 6 . These two kinds of threads 5 , 6 alternate with each other in the direction of the first longitudinal thread 4 . The first transverse base line 5 and the first longitudinal thread 4 are interwoven with a plain weave, but the first binding transverse thread and the first longitudinal thread 4 are only in a cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com