Security paper to which safety film is added through open hole and full window combined forming technology and manufacturing method

A technology of safety film and anti-counterfeiting paper, which is applied in paper, papermaking, paper machines, etc., can solve the problems of poor anti-counterfeiting, easy to counterfeit, and no mature technology, and achieve the effect that it is not easy to imitate and difficult to produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

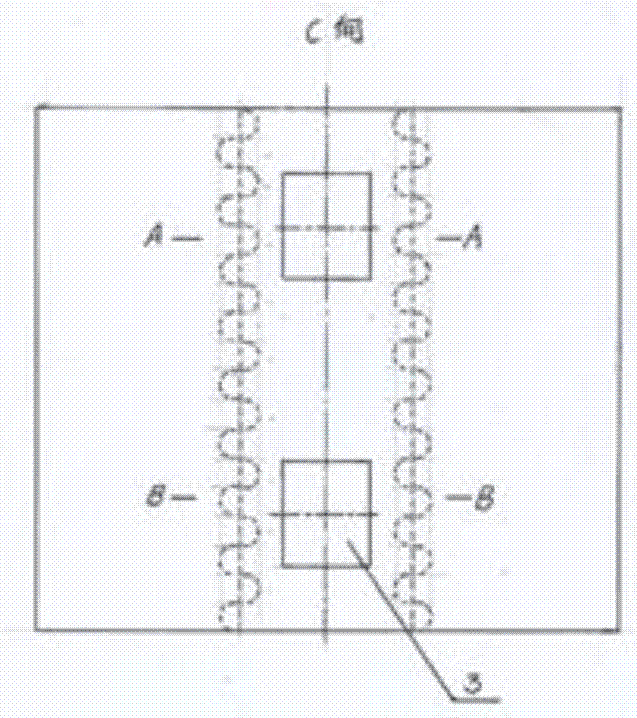

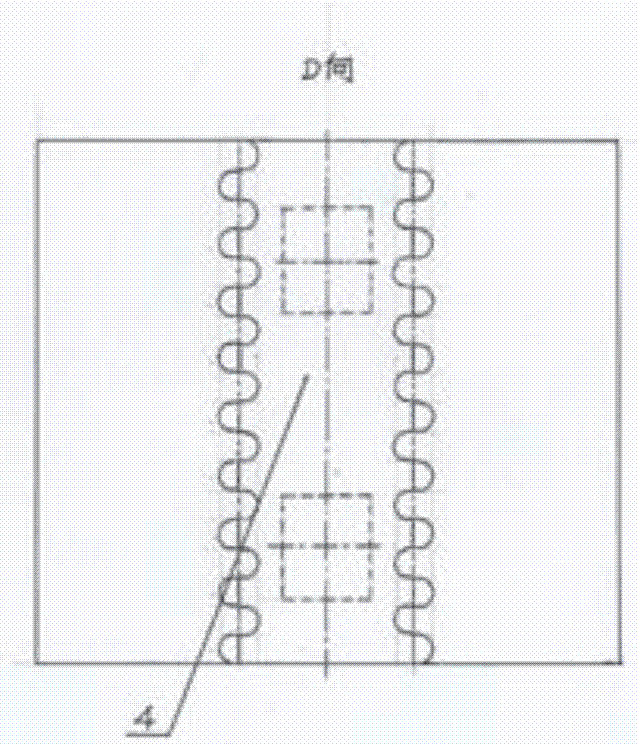

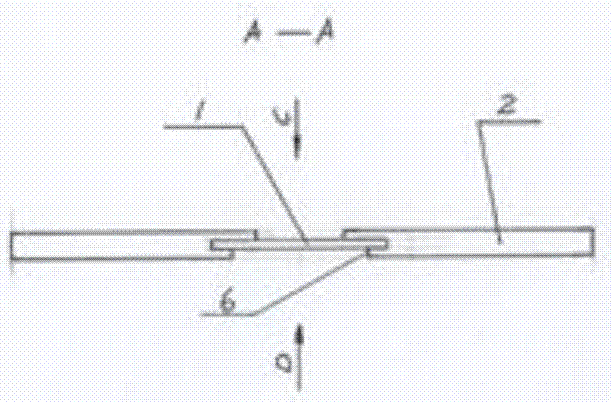

[0037] Embodiment: As shown in the figure, a combination of opening and full window forming technology is added to the security film anti-counterfeiting paper, the anti-counterfeiting paper has an opening 3 with a length of 12mm and a width of 6mm, and a width of 9-15mm. The tooth top is 15mm, and the full opening window 4 is 9mm on both sides, and also has a safety film 1 with a width of 12mm sandwiched between the paper sheets 2. The opening 3, safety film 1, and full opening window 4 are in the same The centerlines are superimposed together, the opening 3 and the fully open window 4 are respectively located on the front and back of the paper sheet 2, the safety film 1 can be observed through the opening 3, and the safety film 1 can also be observed through the fully open window 4 , the edge portion 6 of the opening 3 and the fully opened window 4 has irregular burrs 6, and the thickness of the burrs is lower than the sheet thickness of the anti-counterfeiting paper.

[0038...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com