Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92 results about "Mercuric ammonium chloride" patented technology

Efficacy Topic

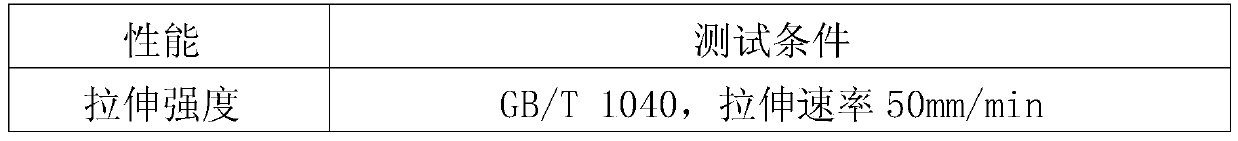

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-mercury catalyst for acetylene hydrochlorination

InactiveCN102380407AEasy to makeLow costPhysical/chemical process catalystsPreparation by halogen halide additionO-Phosphoric AcidPtru catalyst

Disclosed is a low-mercury catalyst for acetylene hydrochlorination. Mercuric chloride is carried on activated carbon. Raw materials comprise, by weight, 100 parts of activated carbon, 4-5 parts of mercuric chloride, 8-10 parts of total essential assistant, 1-5 parts of total non-essential assistant, wherein the essential assistant comprises 2-5 parts of bismuth chloride, 1-5 parts of cerium chloride, 1-5 parts of barium chloride and 2-5 parts of copper chloride; and the non-essential assistant comprises at least one of potassium chloride, phosphoric acid, zinc chloride and cuprous chloride. After being subjected to surface subtraction and drying on acid and oxidizing conditions, activated carbon is in reflux treatment with urea solution; and the catalyst can be prepared by soaking the treated activated carbon with HgC12 dissolved in hydrochloric acid and assistant solution sufficiently after urea is removed by steps of heating, washing the activated carbon with hydrochloric acid and finally drying the same. The carrying capacity of mercuric chloride in the catalyst is lower so that cost for the catalyst is reduced and consumption of mercury resources is decreased. Furthermore, activity and stability of the low-mercury catalyst are much higher than those of the existing high-mercury catalyst, and reforming rate and selectivity of reaction of vinyl chloride can be 99.7% and be higher than 99.8%. Accordingly, the low-mercury catalyst for acetylene hydrochlorination is suitable for industry production and is environment-friendly.

Owner:CHENGDU HUIEN FINE CHEM

Low-mercury catalyst used for synthesizing vinyl chloride

InactiveCN102962082APlay a fixedActivePhysical/chemical process catalystsPreparation by halogen halide additionPtru catalystCopper chloride

The invention discloses a low-mercury catalyst used for synthesizing vinyl chloride. The low-mercury catalyst takes mercuric chloride as a main active component, one or more of precious metals such as Au, Pd, Pt, Ru, Rh, Os and Ir salts or complexes thereof as active regulators, and one or more of potassium chloride, ferric chloride, zinc chloride and copper chloride as cocatalysts. By adding trace amount of precious metal salt into the mercuric chloride, the low-mercury catalyst forms a stable composite metal compound, plays a role in fixing and activating mercuric chloride, and still maintains very high catalytic activity and stability when the load capacity of the mercuric chloride is reduced to 0.1-2%.

Owner:DALIAN RES & DESIGN INST OF CHEM IND

Method for recycling waste mercury catalyst

InactiveCN103803638AEfficient use ofEasy to reusePhysical/chemical process catalystsChemical recyclingActivated carbonMercuric ion

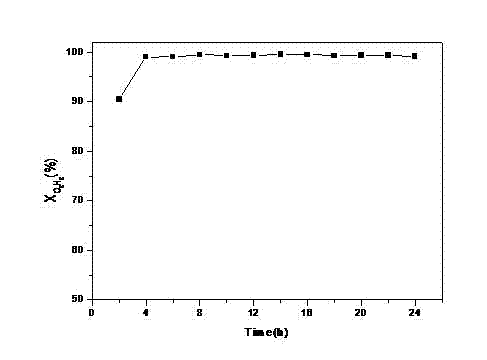

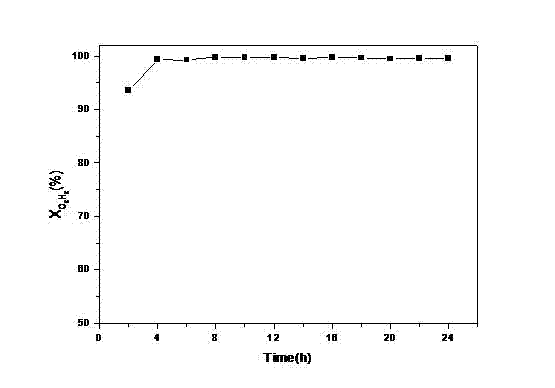

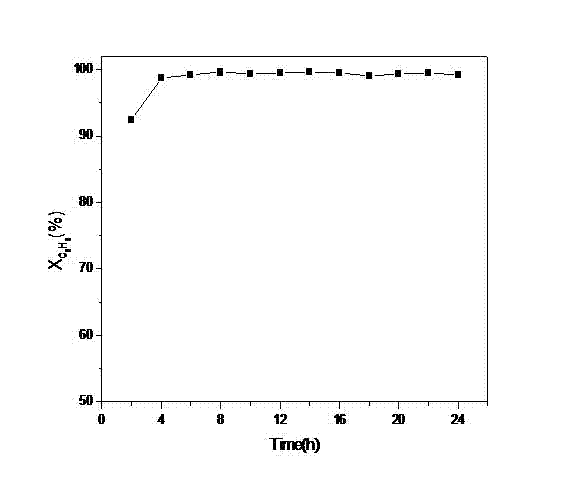

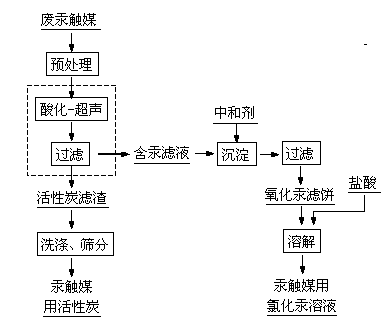

The invention discloses a method for recycling a waste mercury catalyst. The method comprises the steps of adding the waste mercury catalyst into water, controlling the temperature at 70-95 DEG C, carrying out hot dissolution pretreatment while stirring, regulating the pH value to 1-3, and filtering after carrying out ultrasonic treatment for 10-60min or filtering in an ultrasonic field to separate mercuric chloride and phosphorus and sulfur impurities from activated carbon in time, wherein the mercuric chloride and the phosphorus and sulfur impurities are separated from the surface of the activated carbon; after filtering, washing the obtained activated carbon and sieving to prepare a mercury catalyst; controlling the temperature of mercury-contained filtrate at 50-90 DEG C, adding a neutralizing agent to regulate the pH value to 6-8, and reacting for 30-90min, wherein mercury ions in the solution are completely converted into mercuric oxide sediments, and toxic substances, namely phosphorus and sulfur in the mercury catalyst still remain in the solution; filtering to obtain a mercuric oxide filter cake, and dissolving with hydrochloric acid to obtain a mercuric chloride solution for preparing the mercury catalyst. According to the invention, the waste mercury catalyst is recycled through acidification-ultrasonic synergistic desorption, coupling and filtration, therefore, the method is simple in process, high in efficiency and low in energy consumption.

Owner:CENT SOUTH UNIV

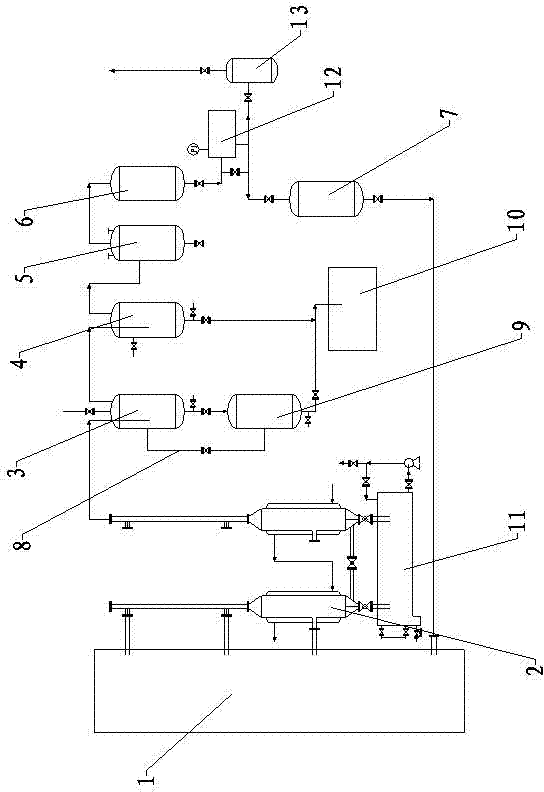

Waste mercury catalyst recovery technology and waste mercury catalyst recovery device

ActiveCN103693676ARealize the comprehensive utilization of resourcesAvoid Mercury LossNitrogen purification/separationCarbon compoundsChemistryActivated carbon

The invention discloses a waste mercury catalyst mercuric chloride recovery technology. The technology comprises the following steps: putting a waste mercuric chloride catalyst of which the mercury content is 2.5-4% into a dry distillation furnace; introducing nitrogen from the bottom of the dry distillation furnace; swapping out air inside the dry distillation furnace, and then controlling the pressure inside the dry distillation furnace at -0.09 to 0MPa; heating and warming the dry distillation furnace to reach the temperature being 500-600 DEG C so as to obtain recycled activated carbon, and a mixed gas containing mercuric chloride and nitrogen; introducing the mixed gas into a cooler; cooling to obtain mercuric chloride powder. Oxidation of the activated carbon by an inert gas is protected and avoided by adopting the principle that the boiling point of the mercuric chloride is lower than the coking temperature of the activated carbon; simultaneous recovery of the HgCl2 and the activated carbon is achieved under a negative-pressure closed environment; the recovery rate of mercuric chloride can be up to 70%; the overall recovery technology is a closed circulating technology; closed circulation of a waste residue, an exhaust gas and a wastewater can be achieved; the pollution to the environment is avoided.

Owner:NINGXIA JINHAI CHUANGKE CHEM TECH

Sorbents for removal of mercury from flue gas cross reference to related applications

InactiveUS7771700B2Solid waste managementUsing liquid separation agentParticulatesAlkaline earth metal

Owner:CHEM PROD CORP

Method for preventing and controlling tissue culture seedling pollution

InactiveCN101627727AInhibitoryBactericidalHorticulture methodsPlant tissue cultureFungicideGrowing season

The invention relates to a method for preventing and controlling tissue culture seedling pollution by mercuric chloride. In the method for preventing and controlling tissue culture seedling pollution, the pollution of a polluted tissue culture seedling can be eliminated by a plurality of transfer periods, wherein each transfer period comprise the following two steps: (1) adding mercuric chloride into a culture medium of the tissue culture seedling; and (2) transferring the polluted tissue culture seedling on the culture medium containing the mercuric chloride. The mercuric chloride adopted by the invention is spectrum fungicide, has the effects of inhibition and sterilization on the polluted tissue culture seedling culture medium, has less dosage, can be directly added into the culture medium, carries out high pressure sterilization along with the culture medium and does not reduce the sterilizing effect; the pollution rate is reduced below 5 percent, the production cost can be effectively reduced, and economic benefits are improved; and as for some tissue culture seedlings rushing for a growing season, when the seedlings for production are polluted, the invention can eliminate the pollution, supplement the seedling dosage and reduce loss. In addition, the used culture medium carries out chemical processing so as to prevent pollution and be beneficial to environmental protection.

Owner:SHANDONG YANTAI AGRI SCHOOL

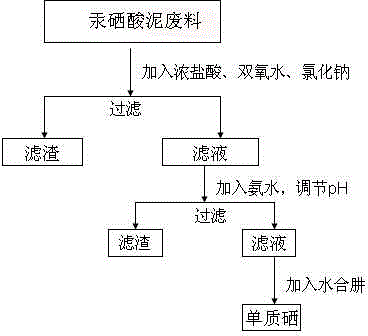

Method for extracting selenium from mercury-selenium acid mud waste

InactiveCN104828788AComplete restorationHigh recovery rateSolid waste disposalElemental selenium/telluriumEnvironmental engineeringReagent

The invention discloses a method for extracting selenium from mercury-selenium acid mud waste; elemental selenium is refined by a wet method under the condition of normal temperature, impurities in the mercury-selenium acid mud are removed, equipment is simple in requirements and easy to operate, and used chemical reagents basically have no pollution to the environment. Strong oxidability of hydrogen peroxide makes selenium oxidized into high-valence ions to go into a solution system, and a lot of heat is released for the system; addition of sodium chloride provides chlorine ions for the reaction system; a main impurity mercury is removed in a manner of a white precipitate ammoniated mercuric chloride; strong reducibility of hydrazine hydrate makes the high-valence selenium sufficiently reduced into elemental selenium. Results show that the content of elemental selenium reaches 90% or more and the recovery rate also reaches up to 90% or more.

Owner:XIANGTAN UNIV

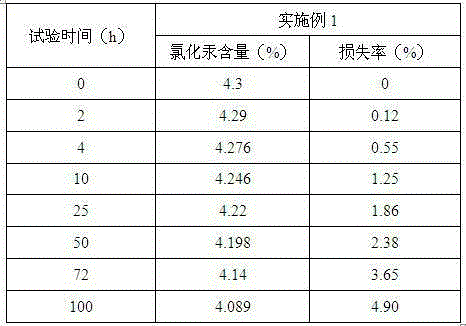

Method for low-mercury catalyst with good heat stability

ActiveCN105195224AImprove thermal stabilityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystPhenylphosphine

A provided method for low-mercury catalyst with good heat stability comprises preparation of active carbon, preparation of an adsorption solution, and adsorption processing. The adsorption processing steps comprises ultrasonic assisted adsorption, microwave assisted adsorption and vacuum penetration adsorption. The prepared low-mercury catalyst comprises, in percent by weight, 4.3% of mercuric chloride, 8.6% of zinc chloride, 8.6% of palladium chloride, 2.87% of platinum chloride, 2.87% of tetrabutyl ammonium chloride, 2.87% of tripotasium triphenylphosphine-3,3',3''-trisulfonate, and 0.18% of water. The low-mercury catalyst possesses the mechanical strength of 98.6%, the granularity of 3-6 mm (98%), the bulk density of 460 g / L, and the mercuric chloride ignition loss of 0.39%. The prepared low-mercury catalyst is good in heat stability and low in mercuric chloride loss rate. When the low-mercury catalyst is applied to vinyl chloride synthesis reaction, the acetylene conversion rate is 99.93%, the vinyl chloride selectivity is close to 100%, and the vinyl chloride yield is 95.2%.

Owner:NINGXIA JINHAI CHUANGKE CHEM TECH

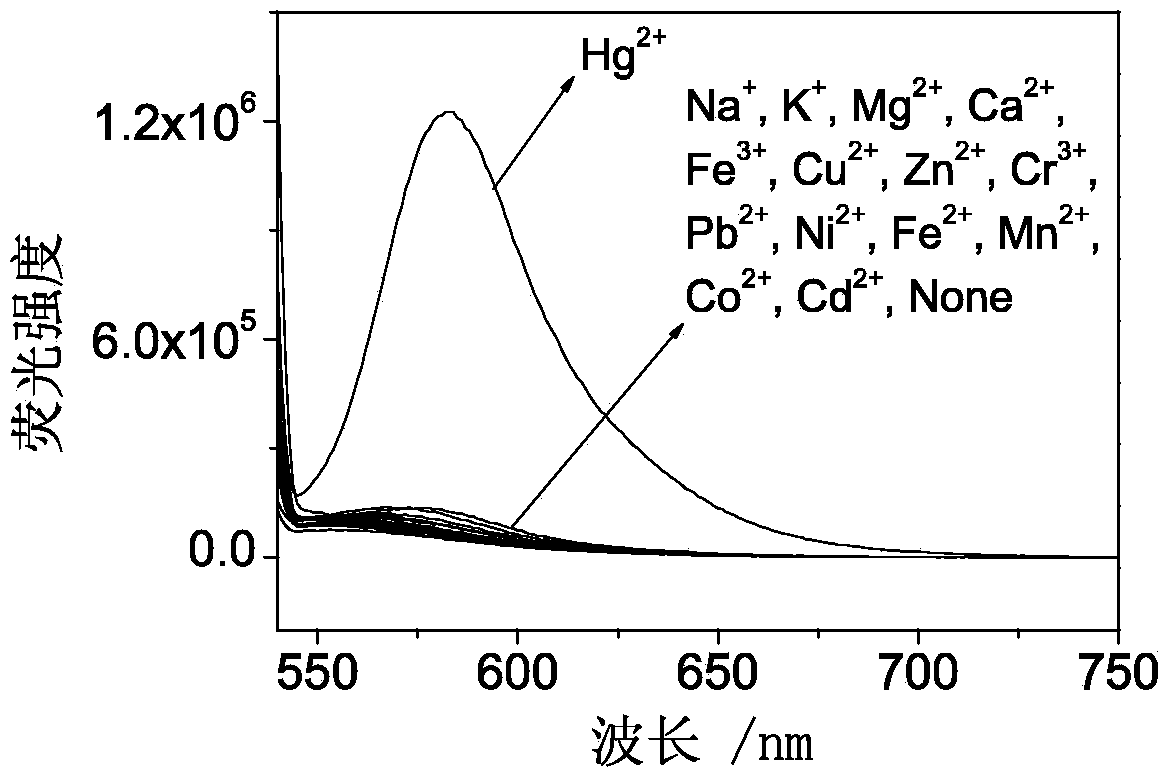

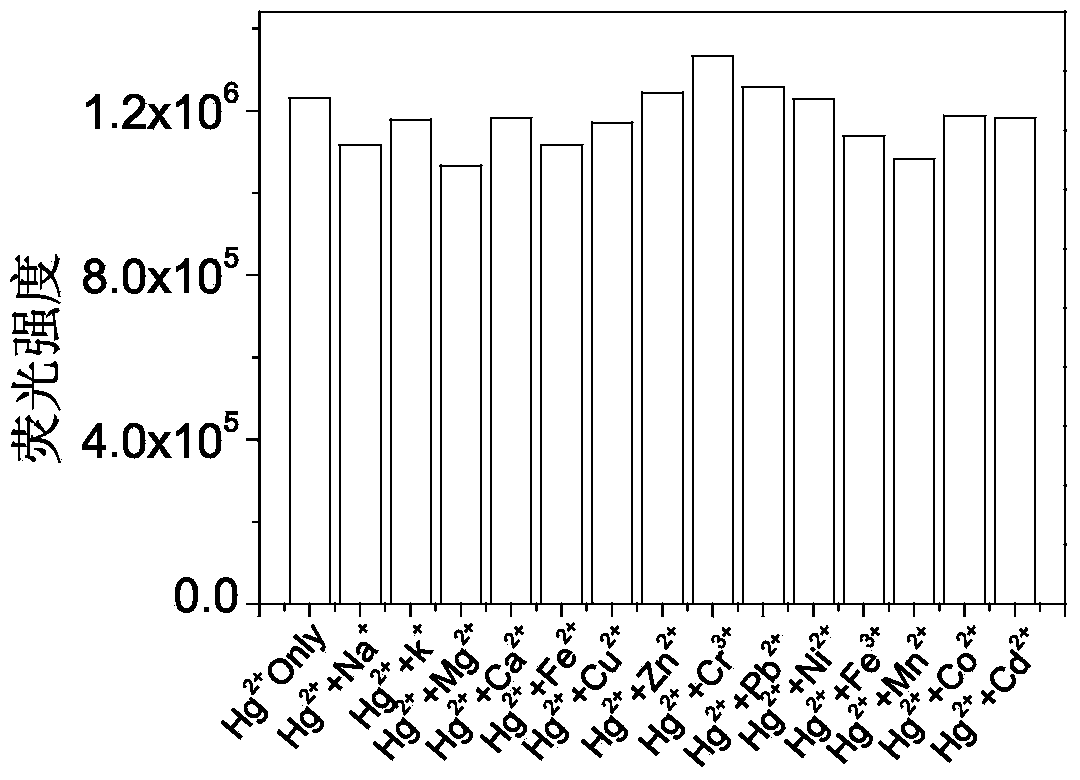

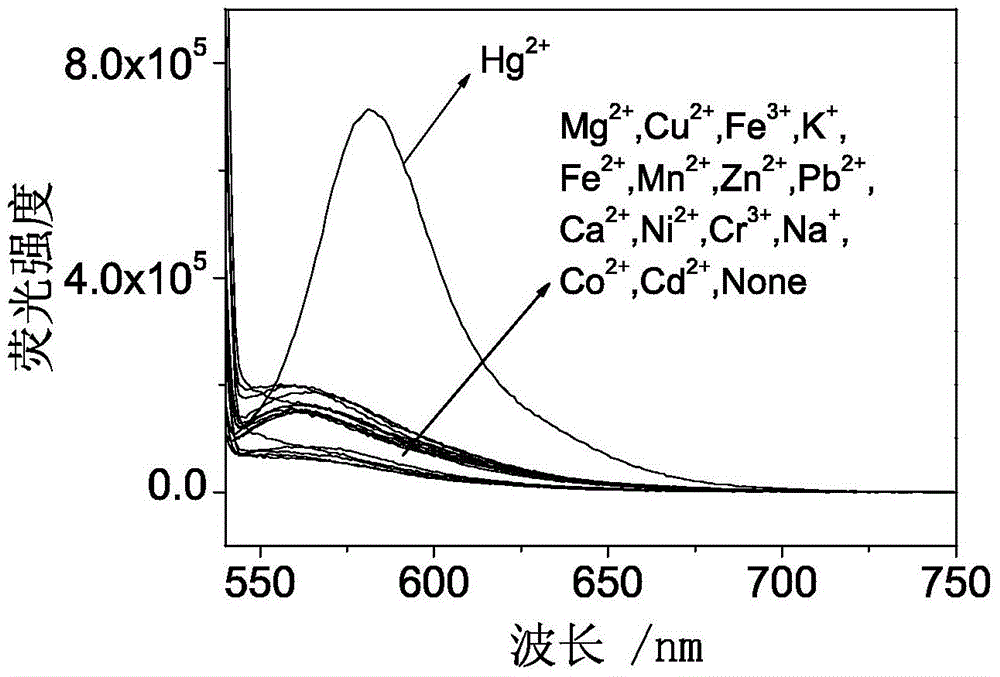

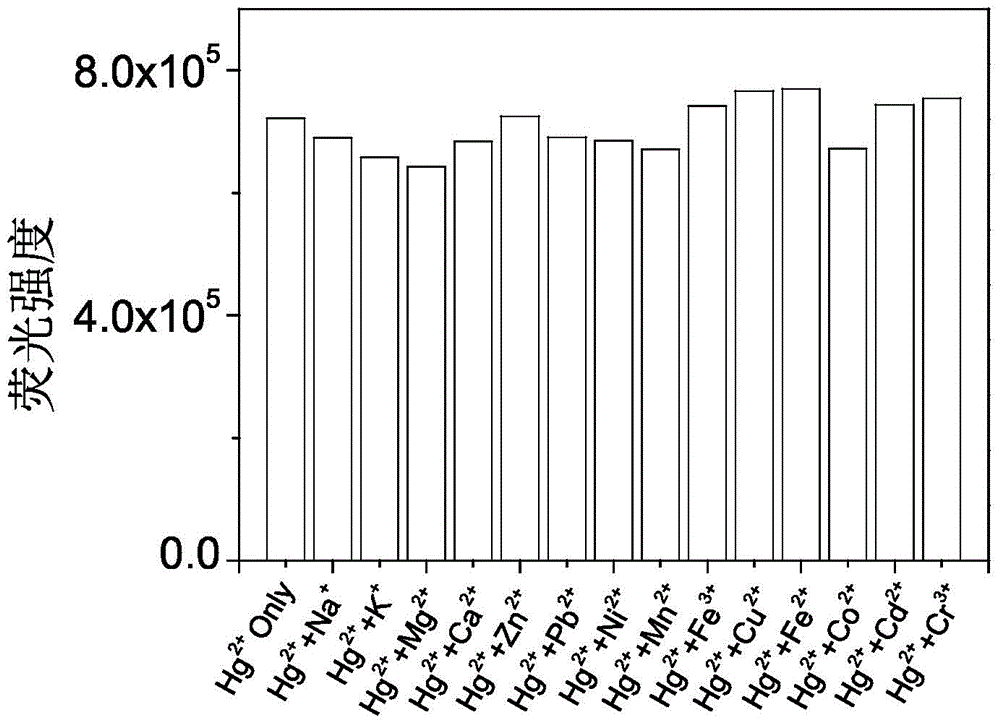

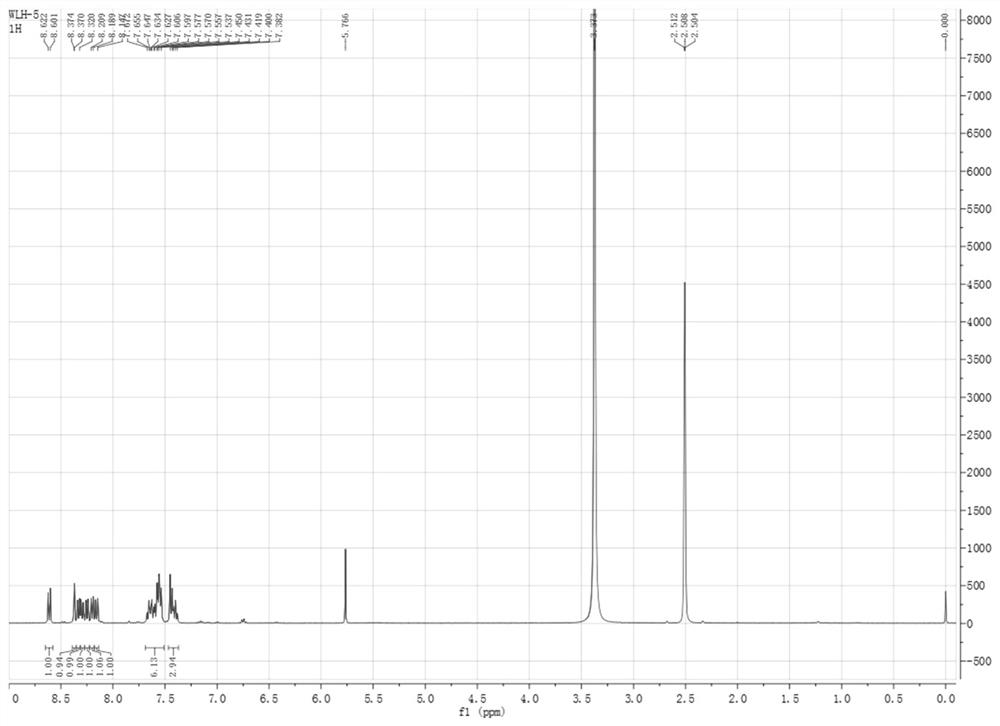

Fluorescent probe synthesized by rhodamine B, triethylene tetramine and phenyl isothiocyanate and preparing method and application thereof

ActiveCN104140432ANo need for separation and purificationThe synthesis method is simpleOrganic chemistryFluorescence/phosphorescenceFluoProbesMercuric ion

The invention discloses a fluorescent probe synthesized by rhodamine B, triethylene tetramine and phenyl isothiocyanate and a preparing method and application thereof. Specifically, firstly, the rhodamine B reacts with the triethylene tetramine to form a spirocyclic amide structure which is stable in property, nitrogenous bridged segments are introduced in, and the rhodamine B reacts with the phenyl isothiocyanate, so that sulphur atoms are introduced in. By means of the thiophil property of mercury ions, each molecule in an obtained novel rhodamine B-phenylthiourea derivative RTTU can be combined with three mercury ions, and therefore high selectivity and detection sensitivity are achieved. Fluorescent probe molecules can conduct detection in a neutral buffer solution, especially an aqueous phase and can also detect the mercury ions from mercuric chloride, and higher practicability is achieved. In addition, the fluorescent probe molecules can be directly precipitated out in the preparing process, further separation and purification are not needed, and the synthesizing method is simple and convenient and easy to implement.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Catalyst for acetylene hydrochlorination and preparation method and application thereof

PendingCN111389441ALarge specific surface areaSimple preparation processPhysical/chemical process catalystsPreparation by halogen halide additionActivated carbonPtru catalyst

The invention discloses a nitrogen-phosphorus co-doped metal-free catalyst for acetylene hydrochlorination reaction and a preparation method and application of thereof, and belongs to the field of material synthesis technology and application. The nitrogen-phosphorus co-doped metal-free catalyst is prepared by blending acid-washed activated carbon with a precursor solution of nitrogen and phosphorus, dipping, drying and roasting and is applied to preparation of vinyl chloride monomers by hydrochlorination of acetylene. The prepared porous activated carbon metal-free catalyst is large in specific surface area and contains nitrogen and phosphorus at the same time and is simple in preparation process and can replace a toxic mercuric chloride catalyst. The metal-free catalyst is applied to fixed bed acetylene hydrochlorination to prepare vinyl chloride and has good catalytic activity and selectivity and good industrial application prospect.

Owner:鄂尔多斯市瀚博科技有限公司

Method for measuring total iron

InactiveCN104459017ANo dischargeReaction is easy to controlChemical analysis using titrationTest sampleWater chlorination

The invention relates to a method for measuring total iron, and belongs to the field of analysis and detection. The method comprises the following steps: S1, fusing an iron-containing test sample at high temperature by using alkali, and then leaching by using acid; S2, heating a leaching solution to be nearly boiled, dropping tin chloride (50-150g / L) to until the light yellow color appears, and cooling; S3, dropping a titanium trichloride solution until the tungsten blue color appears by taking sodium tungstate as an indicator; S4, dropping several drops of copper solutions, and shaking to fade the tungsten blue color; S5, adding a right amount of sulfuric-phosphorous mixed acid (2+3), and titrating until the purple color as an end point appears by taking sodium diphenylamine sulfonate (4-10g / L) as an indicator and using a standard potassium dichromate solution. The method disclosed by the invention substitutes that the traditional total iron measurement in which mercuric chloride needs to be applied, so that the environmental pollution is reduced, the reaction is easily controlled by adding the copper solution and mixed sulfuric acid, end point discoloration is relatively obvious, and the method is relatively accurate, fast, simple and convenient.

Owner:工信华鑫科技有限公司

Fluorescence probe based on RB (rhodamine B), TEPA (tetraethylenepentamine) and PITC (phenyl isothiocyanate) as well as preparation method and application of fluorescence probe

ActiveCN104098582AHigh selectivityHigh detection sensitivityOrganic chemistryFluorescence/phosphorescenceMercuric ionThiourea

The invention discloses a fluorescence probe based on RB (rhodamine B), TEPA (tetraethylenepentamine) and PITC (phenyl isothiocyanate) as well as a preparation method and an application of the fluorescence probe. The preparation method comprises specific steps as follows: RB and TEPA react firstly to form a spiro amide structure with a stable property, a nitrogenous bridged fragment is introduced, and the mixture reacts with PITC to introduce sulfur atoms. By virtue of thiophilicity of mercuric ions, each molecule of a novel RB-phenylthiourea derivative RPTU obtained through the scheme can be bound with four mercuric ions, so that higher selectivity and detection sensitivity are achieved; and the fluorescence probe molecules can perform detection in a neutral buffer solution particularly an aqueous phase, can be further used for detecting the mercuric ions of mercuric chloride, and has better practicability.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Processing method of chlorine-containing tail gas produced by mercuric chloride production

ActiveCN104084026APromote decompositionGood catalyticDispersed particle separationMercury halidesChlorine dioxideReduction treatment

The invention discloses a processing method of chlorine-containing tail gas produced by mercuric chloride production. The processing method comprises the following steps: producing a sodium hypochlorite solution from tail gas which contains chlorine and mercuric chloride vapor, and then adding nickel chloride (or nickel oxide or nickel hydroxide) for nickel oxide hydroxide generating reaction; mixing sodium hypochlorite with nickel oxide hydroxide in a decomposition reaction kettle for two to three hours; performing coexistence of a solution from the decomposition reaction kettle with nickel oxide hydroxide in a continuous decomposition tank for three to five days, wherein when the pH value approaches to seven to eight, decomposition is completed; then putting a sodium chloride solution into a soluble alkali trough, adding alkali until the concentration of sodium hydroxide reaches 5% to 10%, and then returning to an absorption reaction kettle to be used again; sucking chlorine dioxide, chlorine and hydrochloric acid gas which are decomposed everywhere into a reduction treatment tower by negative pressure generated by a fan to enable the gases to contact with alkali liquor, wherein sodium chloride returns to an alkali liquor precipitation tank, and gases are exhausted by an induced draft fan. With the processing method, stable by-products can be obtained, highly toxic mercury chloride can be recycled, and the up-to-standard release of tail gas can be realized.

Owner:贵州重力科技环保股份有限公司

Isolated culture method for peony ovules

InactiveCN102511395ASolve the problem of hybrid abortionPlant tissue cultureHorticulture methodsOvaryCulture mediums

The invention relates to an isolated culture method for peony ovules. After peony ovaries which are fertilized for 15 to 90 days are disinfected by mercuric chloride, the ovules are taken out and divided into a 15-to-48-day ovule group and a 49-to-90-day ovule group; the 15-to-48-day ovule group is inoculated into MS culture medium, cultured in the dark for 3 to 15 days, then inoculated into MS culture medium II, cultured in the dark for 10 days and then cultured in light for 7 to 27 days; afterwards, the 15-to-48-day ovule group is inoculated into the MS culture medium II again and cultured in light for 8 to 28 days, so that mature peony seeds I are obtained; and after being first cultured in the dark for 10 days, the 49-to-90-day ovule group is cultured in light for 7 to 27 days, then inoculated in the MS culture medium II again and cultured in light for 8 to 28 days, so that mature peony seeds II are obtained. The isolated culture method for peony ovules can be used in the isolatedresearch on peony embryo development, and solves the problems of the early abortion of the embryos of good-looking peony varieties and the abortion of distant somatic hybrid peonies, and by way of ovule culture, the improved research on peony varieties can be carried out as well.

Owner:HENAN UNIV OF SCI & TECH

Method for preparing low-mercury catalyst by employing high/middle-porosity active carbon

ActiveCN105195184AImprove thermal stabilityShorten activation timePhysical/chemical process catalystsPreparation by halogen halide additionPtru catalystReaction temperature

A provided method for preparing a low-mercury catalyst by employing high / middle-porosity active carbon comprises preparation of an adsorption liquid and adsorption processing. The adsorption processing step comprises ultrasonic assisted adsorption and microwave assisted adsorption. The prepared low-mercury catalyst comprises, in percent by weight, 4.2% of mercuric chloride, 8.4% of barium chloride, 8.4% of potassium chloride, 4.2% of platinum(II)-ammonium chloride, 4.2% of tetraammineplatinum(II) chloride, and 0.19% of water. The catalyst possesses the mechanical strength of 98.8%, the granularity of 3-6 mm (98.7%), and the bulk density of 475 g / L. The prepared low-mercury catalyst is low in mercuric chloride ignition loss and good in heat stability. When being applied to synthetic reaction of vinyl chloride, the prepared low-mercury catalyst is good in catalysis effect, and helps to reduce reaction time and shorten activation time of hydrogen chloride.

Owner:NINGXIA JINHAI CHUANGKE CHEM TECH

Preparation method for ethyne hydrochlorination homogeneous complex catalyst

ActiveCN104987439AOvercome reunionExtended use timeBulk chemical productionDispersityActivated carbon

The invention discloses a preparation method for an ethyne hydrochlorination homogeneous complex catalyst. According to the method, the ethyne hydrochlorination homogeneous complex catalyst is prepared by using mercuric chloride and potassium chloride as a precursor to synthesize a potassium mercuric chloride complex under the acidic condition and the high potassium ion concentration condition, using activated carbon as a carrier, and adopting a dipping and drying process. The prepared catalyst is high in thermal stability, uniform in distribution of active ingredients, high in dispersity, large in number of active points, and good in catalytic conversion effect.

Owner:贵州重力科技环保股份有限公司 +1

Culture method for directly obtaining plant by pepper anther and culture medium

ActiveCN103444542APromote formationIncrease release ratePlant tissue cultureHorticulture methodsPlant cellEmbryo

The invention relates to a culture method for directly obtaining a plant by a pepper anther and a culture medium, and belongs to the field of plant cell engineering. The culture method comprises the steps: (1), selecting a flower bud with microspores in a mid-late uninucleate stage; (2), soaking the flower bud by alcohol with the concentration being 70 percent for 0.5-1min and mercuric chloride with the concentration being1.2 percent for 8-15min, washing for 3-5 times by using sterile water, sucking water to be dry by using sterile filter paper to obtain a sterile anther in the mid-late uninucleate stage; (3), floating the sterile anther in the mid-late uninucleate stage in the liquid culture medium, carrying out dark shake culture for 20-25 days, and then carrying out illumination shake culture; (4), after carrying out illumination shake culture for 10-20 days, transferring a formed cytoledon-stage embryo to an MSO solid culture medium for being cultured, and growing into a normal plant. The culture method disclosed by the invention has the advantages that (1), the induction frequency of a normal embryo is greatly increased, the regeneration frequency of the normal plant is remarkably increased; (2), the operation process is simple, and the plant can be directly obtained from microspores freely dispersing in the liquid culture medium; (3), the culture method is suitable for multiple types of peppers such as cow-horn peppers, capsicum, line peppers and sweetbell redpeppers.

Owner:北京海花生物科技有限公司 +1

Method for reproducing purple yam seedlings by tissue culture

InactiveCN104115753AGrow fastReduce browning depthPlant tissue cultureHorticulture methodsBiotechnologyForest yam

The invention provides a method for reproducing purple yam seedlings by tissue culture. The method takes a purple yam tender stem tip of 1.0cm as an explant and comprises the following steps: sterilizing the explant by 75% alcohol and a 0.1% mercuric chloride solution; inoculating the explant on an initial culture medium MS0; after the stem tip is survived, treating a regenerated tender stem tip of 0.5-1.0 mm; carrying out stem tip induction culture, stem tip subculture multiplication culture and rooting culture with different culture media at different periods to obtain a purple yam bottle seedling; after the seedling height is about 2cm, transplanting the bottle seedling into a nutrition bowl substrate for hardening; and culturing for 50-60 days till the seedling grows to be as high as 10cm, thereby obtaining the purple yam seedling. A stem tip induction multiplication culture medium is formed by MS, 0.5mg / L of 6BA and 0.1mg / L of NAA; a rooting culture medium is formed by 1 / 2MS, 0.2mg / L of NAA and 0.2g / L of Ac; each culture medium contains 45g / L of edible sugar and 6g / L of agar, and the pH of each culture medium is 5.7. According to the method, a germination accelerating manner is simple and convenient and the germination speed is high; a detoxification manner is simple and rapid and the detoxification rate is high; the variety is high in quality and pure; with the method, the industrialized production of purple yam tissue culture seedlings and the popularization of breed improvement can be realized.

Owner:INST OF BIOLOGICAL RESOURCES JIANGXI ACAD OF SCI

Method for preparing low mercury catalyst by using activated carbon with high carbon tetrachloride adsorption value

ActiveCN105413719AShorten activation timeReduce sublimation speedCatalyst activation/preparationPtru catalystPhenylphosphine

The present invention provides a method for preparing a low mercury catalyst by using activated carbon with a high carbon tetrachloride adsorption value. The method comprises gas phase adsorption, absorption solution preparation and microwave absorption. The microwave absorption comprises first-stage microwave absorption. The first-stage microwave absorption is performed at the temperature of 60 DEG C, the microwave wavelength is 139 mm, the frequency is 2650 MHz, the power is 310 w, and the adsorption treatment lasts for 10 minutes. The method has the beneficial effects that the low mercury catalyst prepared by the method provided by the present invention comprises the following components in percentages by weight: 4.91% of chlorinated mercury, 4% of zinc chloride, 2% of palladium chloride, 2% of platinum chloride, 2% of tetrabutyl ammonium chloride, 2% of triphenylphosphine sulfonic acid potassium and 0.20% of water; the mechanical strength is 99.6%, the particle size is 3-6 mm (99.8%), and the bulk density is 516 g / L; and In the synthesis reaction of vinyl chloride, the conversion rate of acetylene reaches 99.98%, and the yield of the vinyl chloride reaches 97.3%.

Owner:NINGXIA JINHAI CHUANGKE CHEM TECH

Preparation method for CdHgTe/CdS core-shell quantum dot

ActiveCN104927868ARich sourcesLow priceNanoopticsLuminescent compositionsQuantum yieldPotassium borohydride

The invention provides a preparation method for a CdHgTe / CdS core-shell quantum dot. The preparation method comprises the following steps: A, preparing a potassium tellurium hydride solution which is prepared by reducing tellurium powder through potassium borohydrate; B, weighing a certain proportion of cadmium chloride and mercuric chloride crystal, dissolving the mixture with deionized water, and performing metered volume to obtain a mixed solution of cadmium chloride and mercuric chloride; C, adding quantified thioglycolic acid into the mixed solution; D, adjusting the solution with a potassium hydroxide solution to enable the solution to have a specific pH value; E, after inert gas is introduced for oxygen removal, adding the new prepared potassium tellurium hydride solution; F, irradiating through a UV light, and detecting through fluorescence spectrum analysis; G, adding isopropanol for purification, and drying through a freezer dryer to obtain CdHgTe / CdS core-shell quantum dot solid powder. According to the preparation method, the process is relatively simple; process parameters are easy to control; raw materials are inexpensive, the synthesized quantum dot is small in particle size and relatively uniform in particle size distribution, and the fluorescence quantum yield is relatively high.

Owner:湖北荆楚理工资产经营管理有限公司

Application of mercuride in preparing antivenom medicaments

InactiveCN101879186AAvoid damageSave livesHeavy metal active ingredientsAntinoxious agentsBiotechnologyTreatment effect

The invention discloses application of mercuride in preparing antivenom medicaments, aiming at solving the problems of unobvious treatment effect, high death rate and the like in the prior art, wherein the mercuride is one of mercuric sulfide, mercuric oxide, mercuric sulfate, mercuric chloride and the like. Because the main component in the mercuride is heavy metal which has the characteristic of inactivating all proteins, the mercuride has fatal destructive effect on all the proteins; and snake venom is formed by mixing dozens of poisonous proteins, therefore, the mercuride can inactivate the poisonous proteins in the snake venom so as to enable the poisonous proteins to lose activity (toxicity), thereby achieving the purpose of resisting the snake venom.

Owner:丁新侃

Low-mercury catalyst for synthesizing vinyl chloride and preparation method of low-mercury catalyst

InactiveCN104785285AReduce contentReduce mercury useMolecular sieve catalystsMolecular sieveMagnesium

The invention discloses a low-mercury catalyst for synthesizing vinyl chloride and a preparation method of the low-mercury catalyst. The low-mercury catalyst comprises the following components in percentage by weight: 2-6.5% of mercuric chloride, 2.2-2.5% of copper chloride, 3-7% of barium chloride, 1-9% of zinc chloride, 2.1-3.5% of nickel chloride, 1.75-6% of potassium chloride, 0.5-6% of magnesium chloride, 0.65-1.25% of strontium chloride, 1.2-1.3% of cadmium chloride, 1-9% of rare earth chloride and the balance of a molecular sieve. The low-mercury catalyst has the beneficial effects that firstly, the content of mercuric chloride is low, namely, only 2-6.5%, the use amount of mercury is reduced, and the production cost is lowered; secondly, the activity and the stability of the low-mercury catalyst are respectively improved by 15% and 20% when being compared with those of a conventional high-mercury catalyst; thirdly, the service life of the low-mercury catalyst is prolonged, namely, is 8000-9000 hours; fourthly, the low-mercury catalyst is simple in preparation method and good in sealing environment-friendly property, and the environment pollution caused by mercury loss can be avoided.

Owner:JIAOZUO WENXIAN SANLING CHEM PLANT

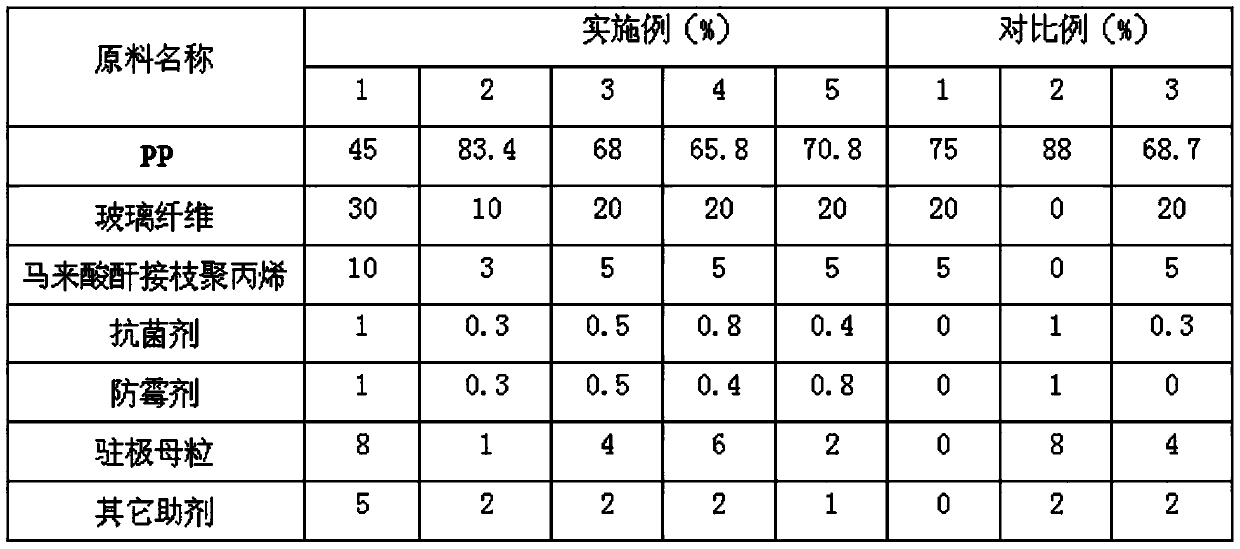

Antibacterial and mildew-proof reinforced polypropylene composite material for fan blades and preparation method thereof

InactiveCN111499975AImprove electrostatic adsorption capacityAbsorb firmlyPentachlorophenolQuinoline

The invention relates to an antibacterial and mildew-proof reinforced polypropylene composite material for fan blades and a preparation method thereof; the polypropylene composite material comprises PP, a reinforcing agent, a first compatilizer, an auxiliary agent, an inorganic antibacterial agent, an organic mildew preventive and electret masterbatch; the inorganic antibacterial agent takes silver, copper and zinc as antibacterial main bodies, and takes permutite, silicon, apatite, titanium oxide and zirconium phosphate as antibacterial carriers; the organic mildew preventive is one or a compound of two or more of tetrachloroisophthalonitrile, diclofenac, phenol, pentachlorophenol, phenyl mercury oleate, 8-hydroxyquinoline copper, mercuric chloride and sodium fluoride; the electret masterbatch comprises the main components: 0-100 parts of polypropylene, 8-50 parts of an electret agent, 0-3 parts of a second compatilizer, 0.05-0.35 part of a first antioxidant and 0-3 parts of an anti-aging agent. According to the invention, a compound system of the inorganic antibacterial agent and the organic mildew preventive is adopted, so that the material plays a synergistic mildew-proof rolein the organic mildew preventive and the antibacterial agent.

Owner:广东顺威赛特工程塑料开发有限公司

Low-cost method for preparing high-crystallinity high-viscosity pseudo-boehmite

InactiveCN110255593ALow cost of preparationLow costSolid waste disposalAluminium oxides/hydroxidesBoehmiteIndustrial waste

The invention discloses a low-cost method for preparing high-crystallinity high-viscosity pseudo-boehmite. The method comprises the following steps: (1) carrying out a reaction on an industrial waste aluminum raw material of 2N-4N with an alcohol under the catalytic action of mercuric chloride or aluminum chloride to obtain an aluminum alkoxide, carrying out distilling purification on the obtained aluminum alkoxide for 6-24 hours, mixing the purified aluminum alkoxide with an alcohol solution, and carrying out hydrolyzing to obtain a completely hydrolyzed pseudo-boehmite wet product; and (2) adding water, carrying out washing at a temperature of 50-60 DEG C, continuously carrying out stirring, adding an auxiliary agent, and carrying out aging to obtain the high-crystallinity high-viscosity pseudo-boehmite. According to the method, waste aluminum products with relatively low purity are adopted, so that preparation cost is low, energy is saved, and the environment is protected. The purity of the produced pseudo-boehmite is in a range of 99.9-99.95% and meets the requirements of the catalytic industry on pseudo-boehmite. Meanwhile, 90-95% of the alcohol can be recovered in the process, so that cost is greatly reduced.

Owner:广西玉林市思达粉体技术有限公司

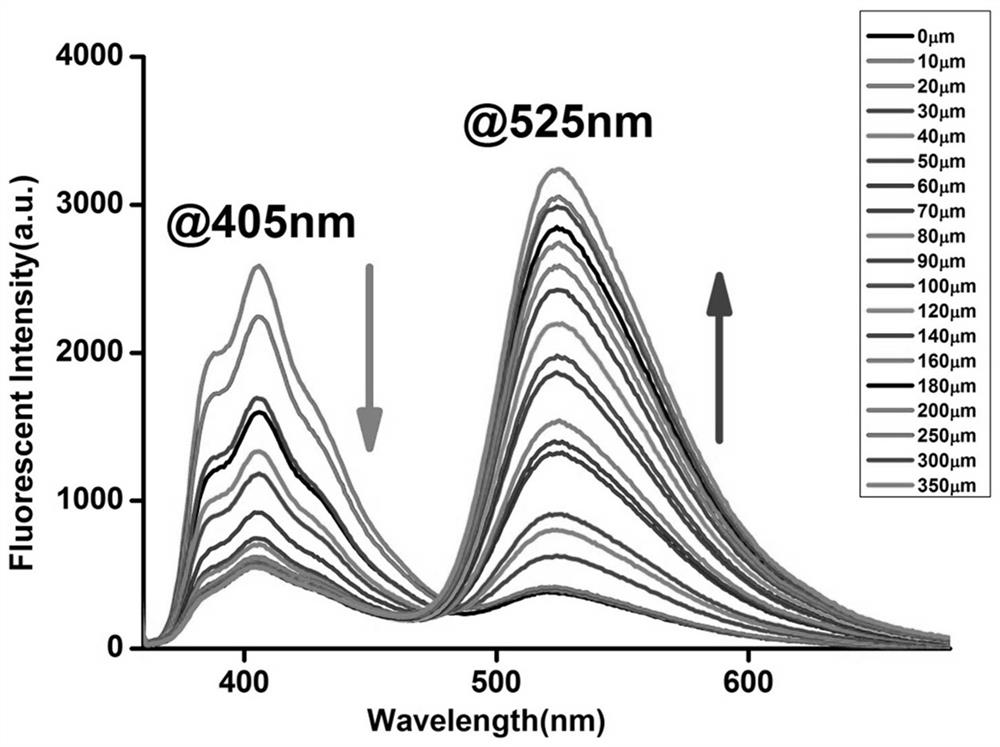

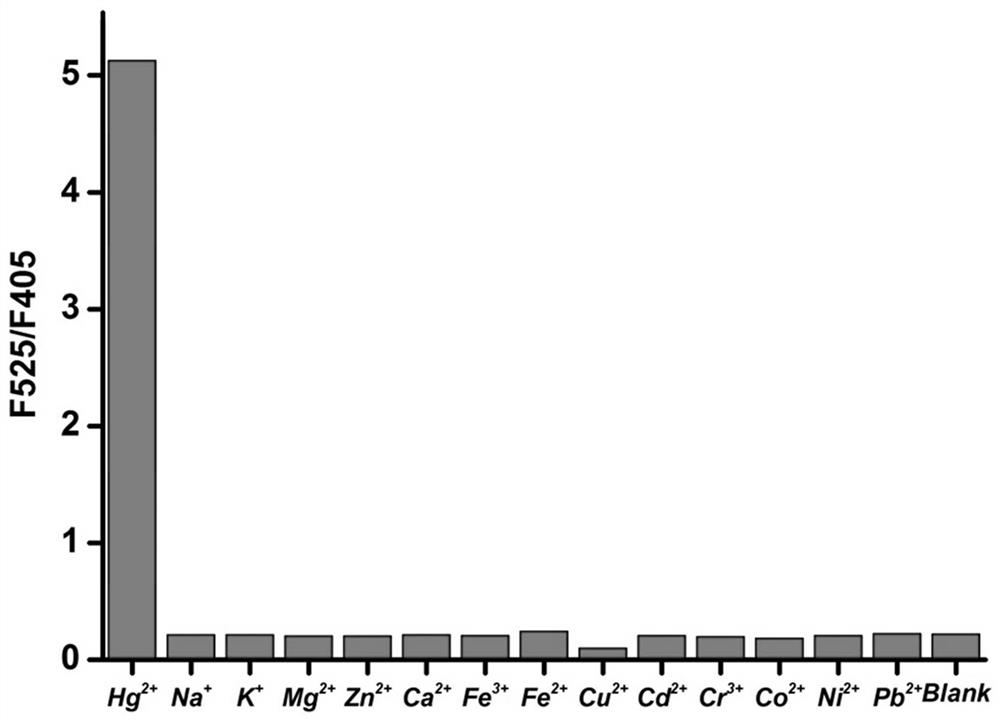

Mercury-responsive fluorescent probe and preparation method thereof

PendingCN111777573AGood choiceHigh sensitivityOrganic chemistryFluorescence/phosphorescenceFluoProbesFluorescence

The invention discloses a preparation method and application of a ratio type divalent mercury fluorescent probe. The structural formula of the divalent mercury fluorescent probe is shown in the specification. The invention also provides a preparation method of the probe. The fluorescent probe shows blue fluorescence in a buffer solution and can carry out a specific reaction with mercuric chlorideto generate a product emitting yellow fluorescence, so that specific response to mercury is realized, and the probe also has good selectivity on divalent mercury.

Owner:CHINA THREE GORGES UNIV

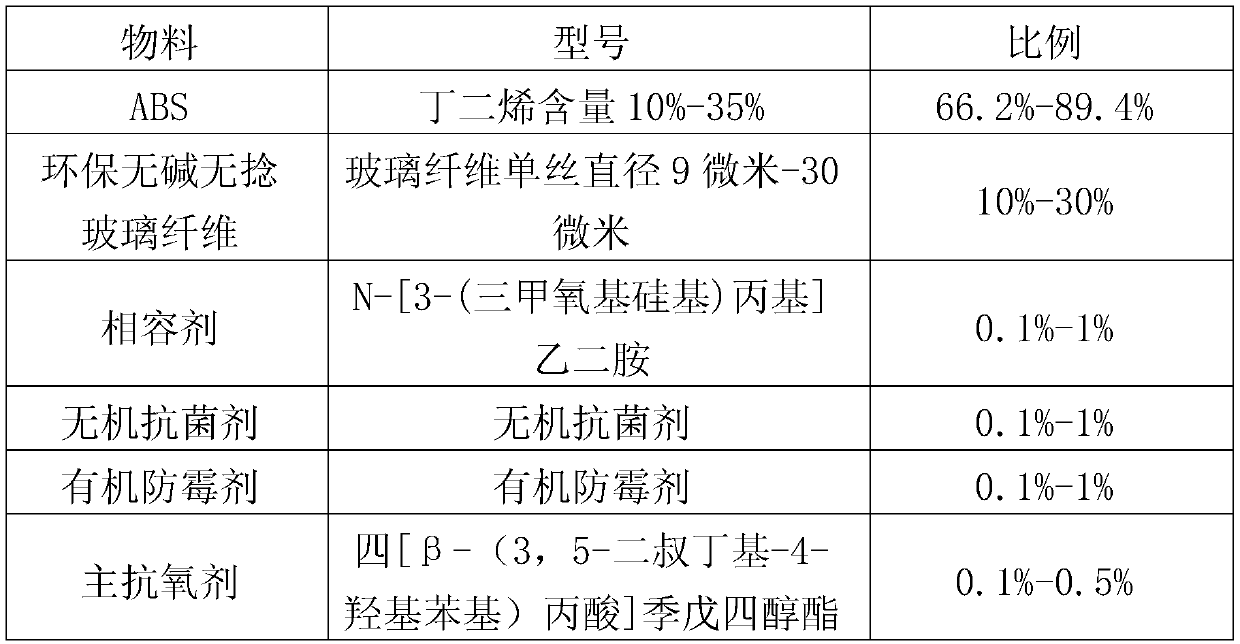

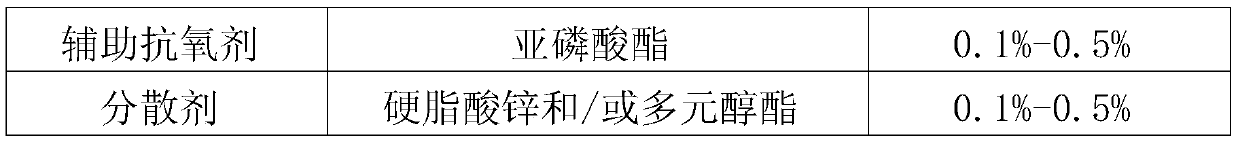

Antibacterial mildew-proof reinforced ABS composite material for fan blades and preparation method thereof

The invention relates to an antibacterial mildew-proof reinforced ABS composite material for fan blades and a preparation method thereof. The ABS composite material comprises ABS, environment-friendlyalkali-free untwisted glass fibers, a compatilizer, a main antioxidant, an auxiliary antioxidant and a dispersing agent, and is characterized by further comprising an inorganic antibacterial agent and an organic mildew preventive; the inorganic antibacterial agent takes silver, copper and zinc as antibacterial main bodies, and takes permutite, silicon, phospholime, titanium oxide and zirconium phosphate as antibacterial carriers; the organic mildew preventive is one or a compound of two or more of tetrachloroisophthalonitrile, diclofenac, pentachlorophenol, phenyl mercury oleate, 8-hydroxyquinoline copper, mercuric chloride and sodium fluoride. The environment-friendly alkali-free untwisted glass fibers are adopted, the diameter of glass fiber monofilaments ranges from 9 [mu]m to 30 [mu]m, and it is guaranteed that the material has enough strength after being reinforced through the glass fibers; a compound system of the inorganic antibacterial agent and the organic mildew preventive is adopted, so that the material has a synergistic mildew-proof effect on the organic mildew preventive and the antibacterial agent.

Owner:广东顺威赛特工程塑料开发有限公司

High-activity environment-friendly low-mercury composite catalyst

InactiveCN103521246AImprove catalytic performanceImprove bindingPhysical/chemical process catalystsActivated carbonBarium dichloride

The invention belongs to the technical field of chemical materials and discloses a high-activity environment-friendly low-mercury composite catalyst. The high-activity environment-friendly low-mercury composite catalyst comprises the following components according to the product specification weight: 4-6% of mercuric chloride, 0.2-0.6% of barium chloride, 0.2-1% of strontium chloride, 0.2-1% of copper chloride, 0.2-0.5% of calcium chloride, 0.2-0.6% of aluminum chloride and 85-95% of activated carbon. The total weight of the barium chloride, the strontium chloride, the copper chloride, the calcium chloride and the aluminum chloride is 1-3.7%. The high-activity environment-friendly low-mercury composite catalyst has the advantages that expensive mercuric chloride is replaced with a chloride blending agent with relatively low price, and the synthesized high-activity environment-friendly low-mercury composite catalyst is good in stability, low in price and free of pollution to the environment so as to be an ideal high-activity environment-friendly low-mercury composite catalyst.

Owner:刘金朝

Method for rapidly identifying purity of rape hybrids indoors

PendingCN113040048ARapid identificationImprove the efficiency of purity identificationLeaf crop cultivationPlant genotype modificationHybrid seedVernalization

The invention discloses a method for rapidly identifying the purity of rape hybrids indoors. The method comprises the following step of sterilizing rape seeds, specifically, soaking the hybrid seeds with a 0.1% mercuric chloride solution for 10-15 minutes, cleaning the seeds with ddH2O for 2-3 times, carrying out low-temperature vernalization in a bud stage, putting the sterilized seeds into a culture dish paved with three layers of wet filter paper, putting the culture dish into an artificial climate chamber, placing the seeds at normal temperature for 1-2 days until the seeds germinate, putting the germinated seeds exposing white buds into an incubator at 2 DEG C or 4 DEG C, and carrying out low-temperature treatment for 2-3 weeks; and through artificial low-temperature vernalization, increase of the planting density in a seedling stage and increase of the temperature, sunshine duration and illumination intensity in the growth stage, the growth process is effectively accelerated, and the purpose of rapidly identifying the purity of the hybrids is achieved. The method has the beneficial effects that the growth process is effectively accelerated and the purity of the rape hybrids is rapidly identified through artificial low-temperature vernalization treatment of the rape seeds, coordinated control over the temperature, illumination time and illumination intensity and technical measures such as the increase of the planting density, topping and branch reduction.

Owner:HENAN ACAD OF AGRI SCI

Distillation recovery method of waste mercury catalyst

InactiveCN112251606AImprove cleanlinessImprove adsorption capacityProcess efficiency improvementActivated carbonDistillation

The invention discloses a distillation recovery method of a waste mercury catalyst. The method includes the following steps that the waste mercury catalyst is placed in a sodium hydroxide solution, heating is performed to enable mercuric chloride in the waste mercury catalyst to react with sodium hydroxide to convert the mercuric chloride into mercuric oxide, and pretreated waste is obtained; thepretreated waste is placed in a distillation furnace, and heating is performed to decompose mercury oxide in the pretreated waste into mercury vapor; the mercury vapor is introduced into an air condenser for indirect condensation, most of the mercury vapor forms liquid metal mercury, the liquid metal mercury falls into a mercury collecting box at the lower part for storage, and liquid metal mercury and mercury soot are obtained through condensing of the residual mercury vapor by the aid of a multi-tube condenser and enter a mercury collecting tank at the lower part; the tail gas is adsorbed bymodified activated carbon, and the adsorbed tail gas is washed by a sodium sulfide solution and is discharged. Compared with the prior art, the modified activated carbon is adopted to adsorb the tailgas generated after distillation of the waste mercury catalyst, the mercury absorption capacity of the activated carbon can be improved, and thus the cleanliness of the tail gas can be greatly improved.

Owner:新晃鲁湘钡业有限公司

Method for decomposing sodium hypochlorite

InactiveCN104085904APromote decompositionGood catalyticAlkali metal chloridesSodium chlorateWater chlorination

The invention discloses a method for decomposing sodium hypochlorite. The method comprises the following steps: carrying out gas and liquid mixing and absorbing reaction on exhaust gas which contains chlorine and mercuric chloride vapor and comes from a mercuric chloride synthesis working procedure by using a sodium hydroxide solution with the weight concentration of 5-10%, so as to produce a sodium hypochlorite solution, cooling and dissolving the mercuric chloride vapor into the sodium hypochlorite solution, enabling air to escape from the surface of the solution, when the pH value of the solution is 10.5-11, adding nickel chloride (or nickel oxide or nickel hydroxide) according to the ratio that 25kg of nickel chloride (or nickel oxide or nickel hydroxide) is added into every 1-1.5t of sodium hypochlorite solution, stirring and mixing uniformly, and completing decomposition when the pH value is 7-8; separating nickel oxyhydroxide from the solution, thereby obtaining a sodium chloride solution. The method has the advantages that the decomposition of the sodium hypochlorite solution can be accelerated, the recycling of materials can be realized, and the method is safe and environment-friendly.

Owner:GUIZHOU DALONG MERCURY SILVER STAR IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com