Antibacterial and mildew-proof reinforced polypropylene composite material for fan blades and preparation method thereof

An antibacterial, antifungal, and composite material technology, applied in the field of composite materials, can solve the problems of easy deformation of fan blades, low strength of polypropylene resin, and influence on air volume, and achieve the effects of stable operation, increased air volume, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

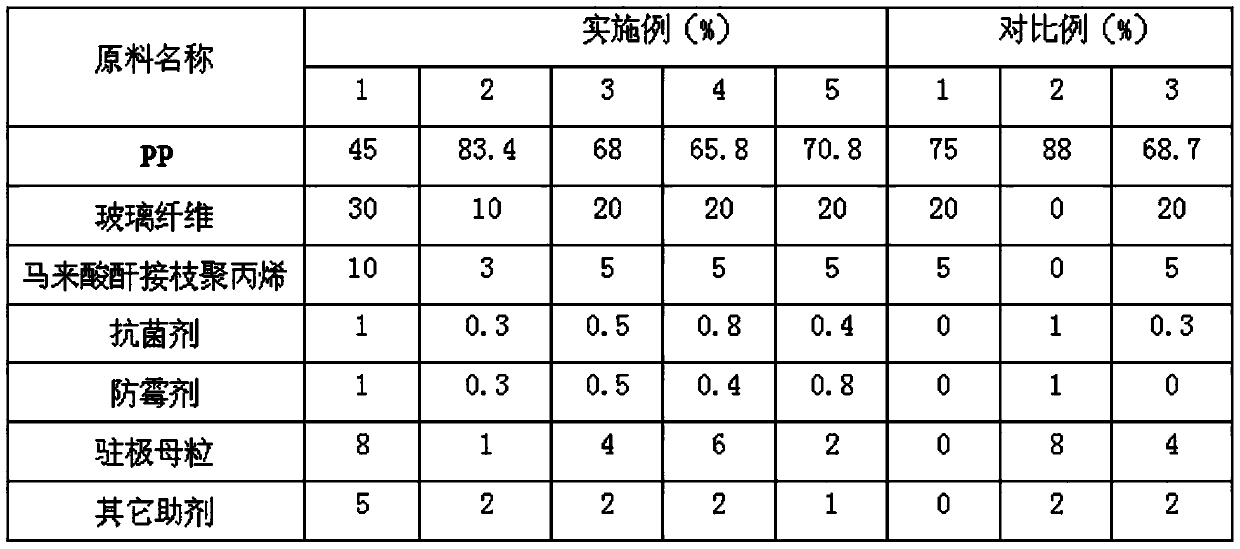

[0019] A kind of antibacterial and antifungal reinforced polypropylene composite material for wind leaf, the composition ratio of which is calculated by mass percentage as shown in the following table

[0020] materials Proportion PP 45-84.4% Enhancer 10%-30% first compatibilizer 3-10% Inorganic antibacterial agent 0.1%-1% Organic mildew inhibitor 0.1%-1% Electret Masterbatch 1-8% Auxiliary 1-5%

[0021] Among them, the inorganic antibacterial agents use silver, copper, and zinc as the main antibacterial agents, and use zeolite, silicon, apatite, titanium oxide, and zirconium phosphate as the antibacterial carriers; the organic antifungal agents are tetrachloroisophthalonitrile, diclofen, A compound of one or more of pentachlorophenol, phenylmercury oleate, 8-hydroxyquinoline copper, mercuric chloride and sodium fluoride.

[0022] The reinforcing agent is glass fiber; the first compatibilizer is maleic anhydride grafted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com