Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66 results about "Low energy laser" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

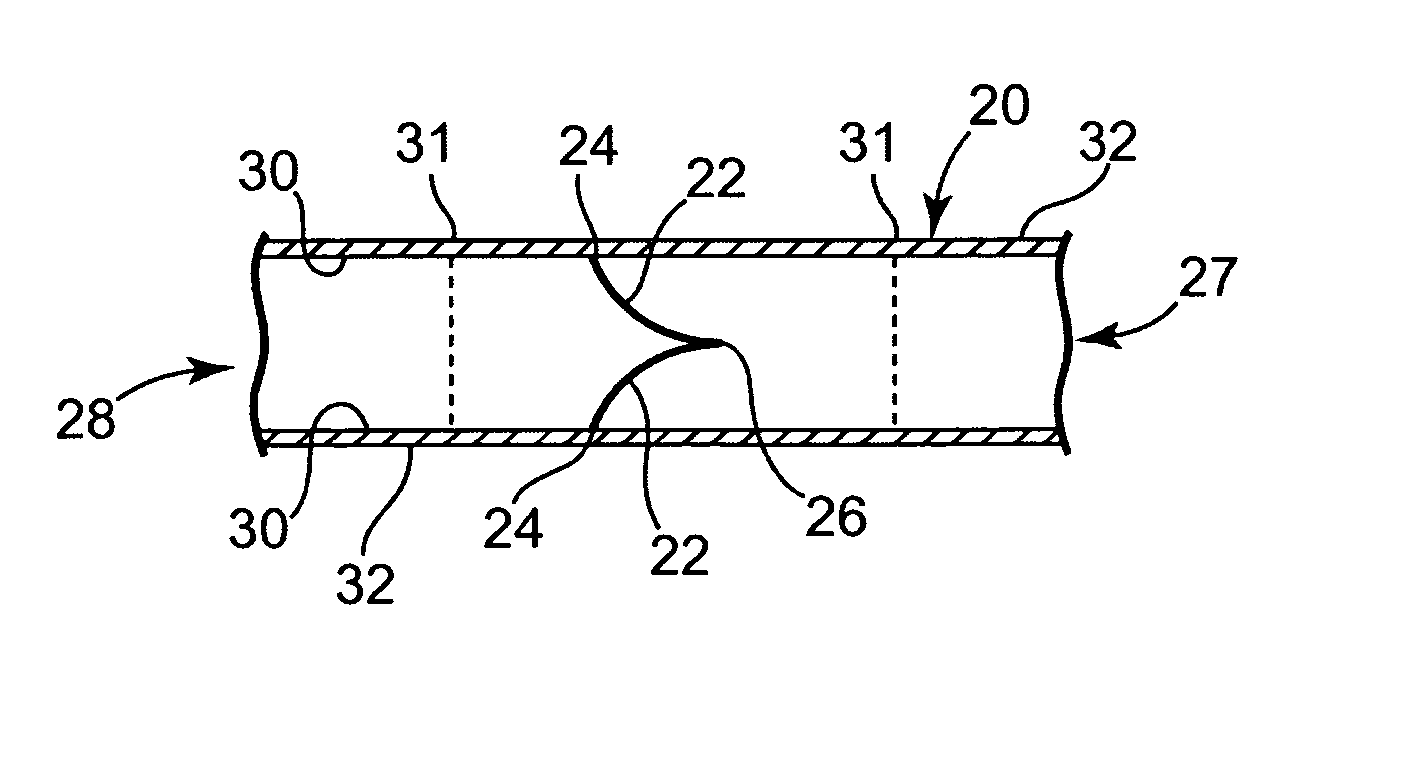

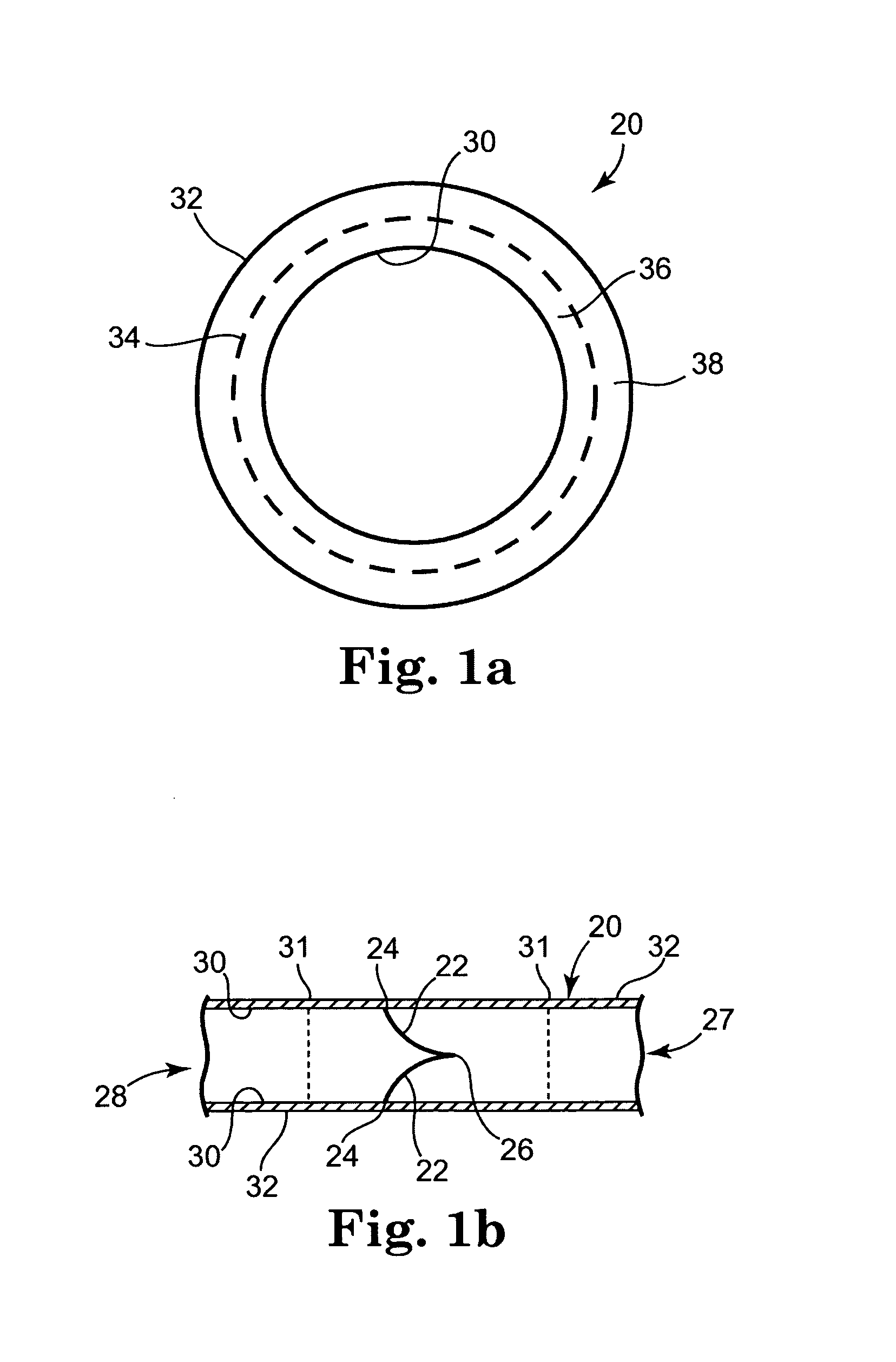

Composite heart valve apparatus manufactured using techniques involving laser machining of tissue

ActiveUS20070073392A1Modifies tissue much fasterLow scrap rateTubular organ implantsVenous valvesVeinLaser processing

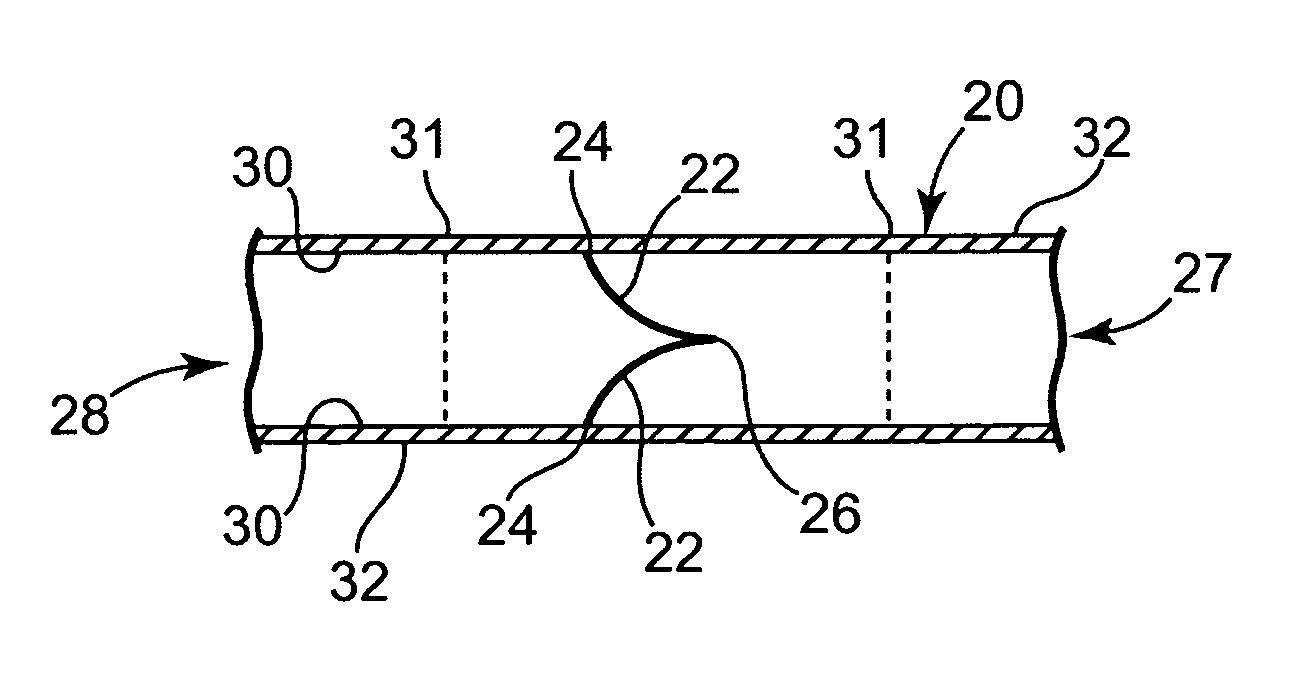

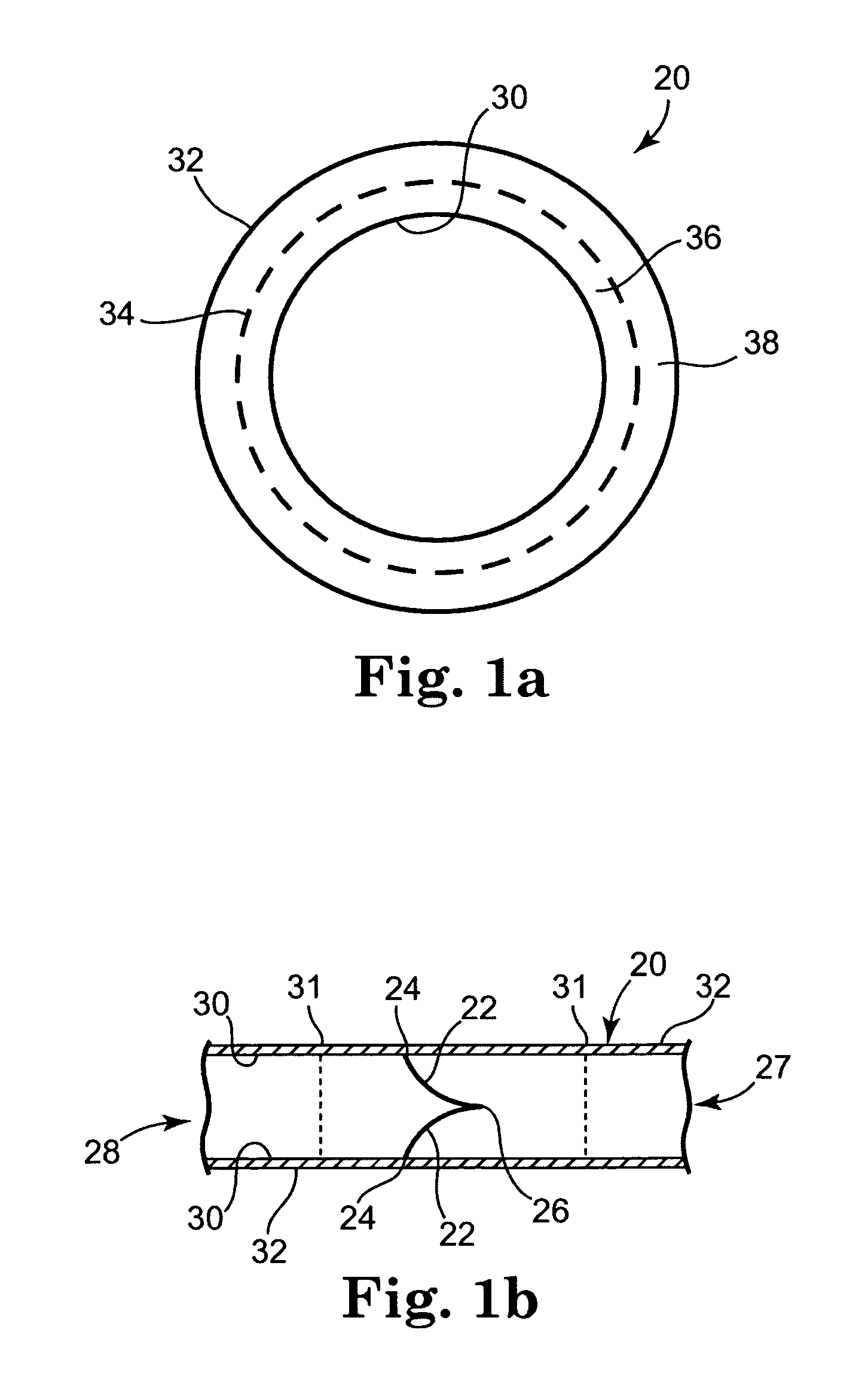

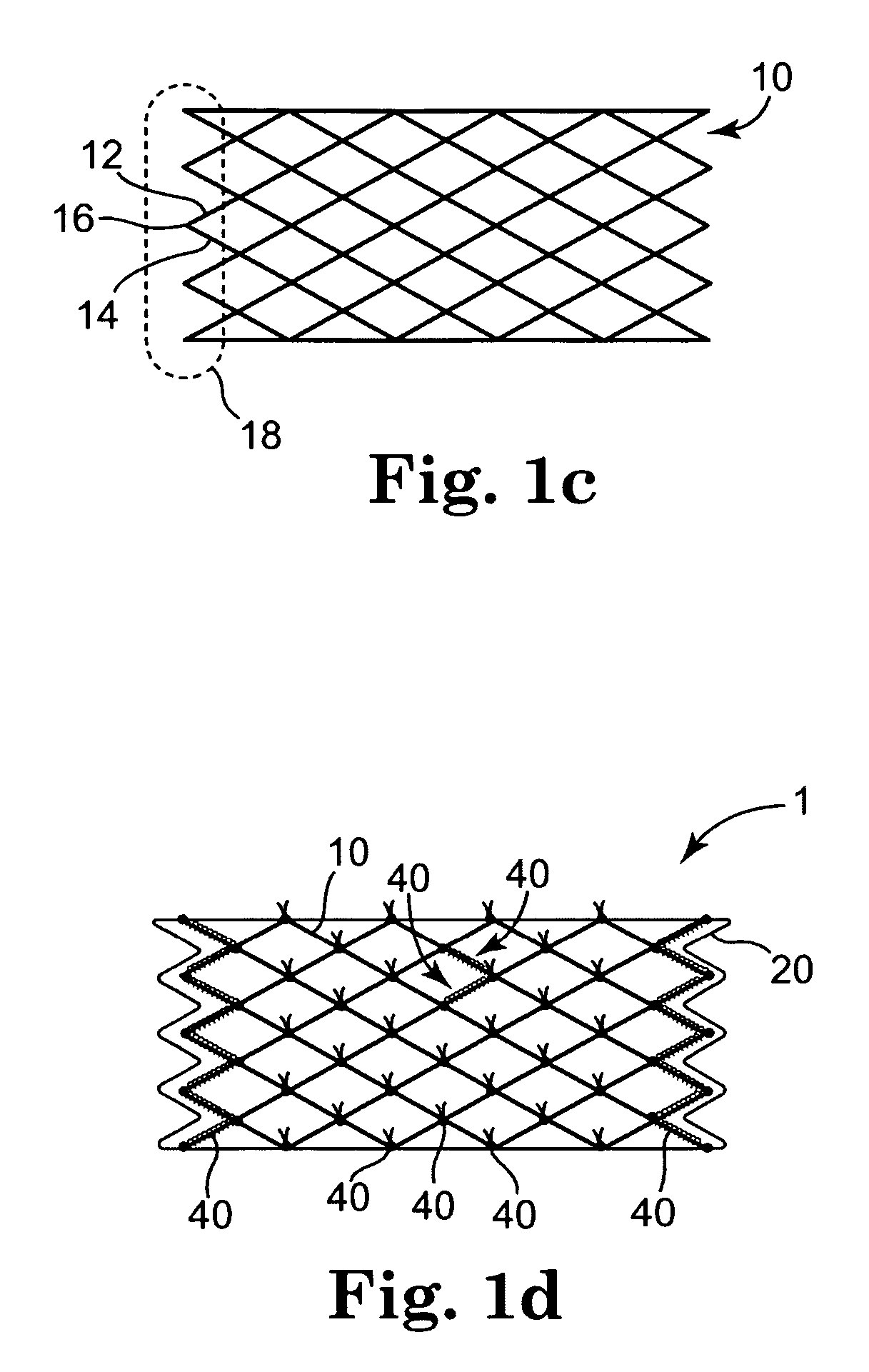

Methodology for using laser machining techniques to modify a tissue for use in a medical device. In a representative mode of practice, relatively low energy laser machining is used to thin down at least a portion of a valved jugular vein. The thinned down vein may then be sutured to, or otherwise integrated with, a corresponding stent to make a percutaneous heart valve.

Owner:MEDTRONIC INC

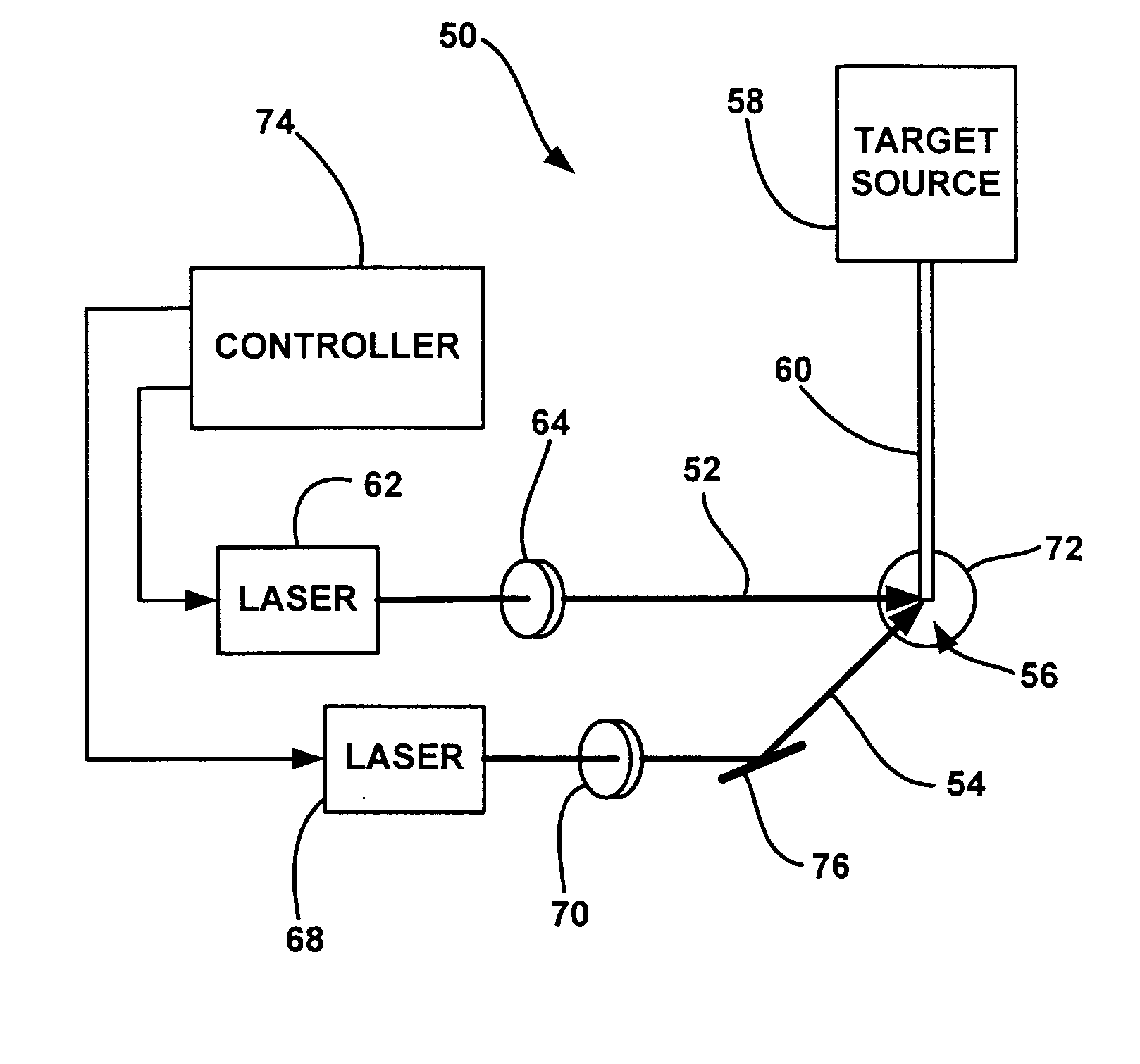

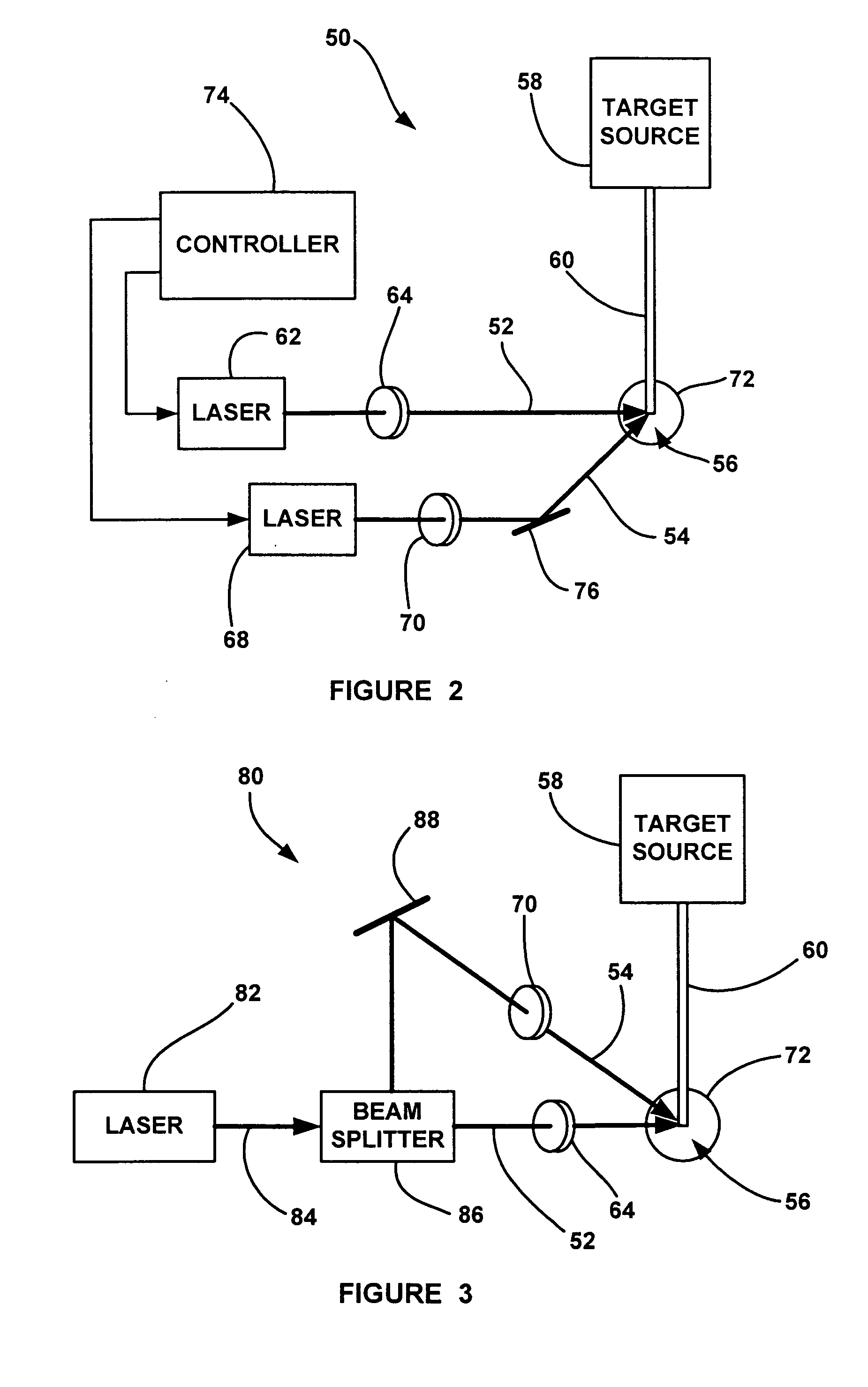

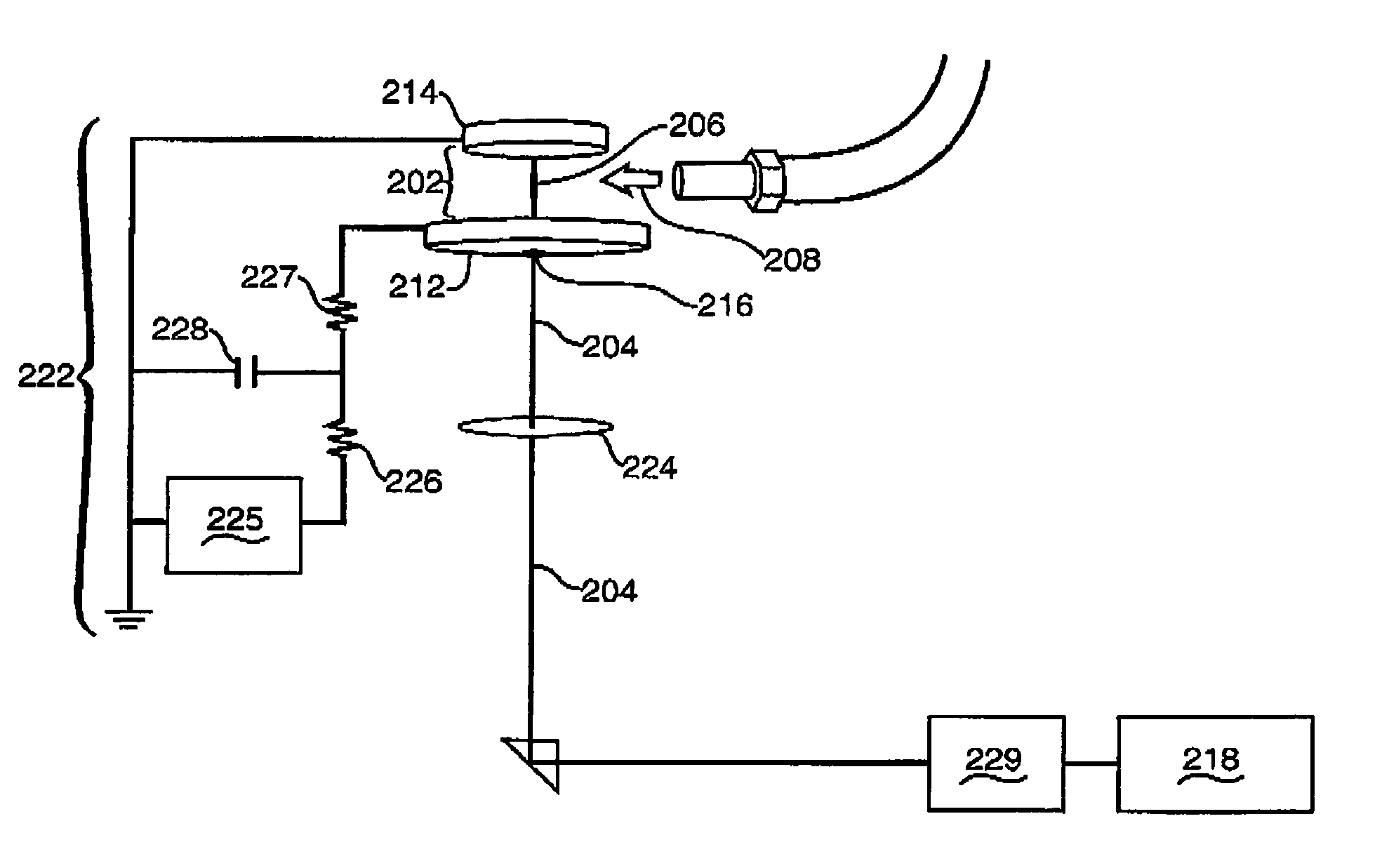

Laser-produced plasma EUV light source with pre-pulse enhancement

InactiveUS20040264512A1Laser using scattering effectsSemiconductor/solid-state device manufacturingBeam splitterHigh energy

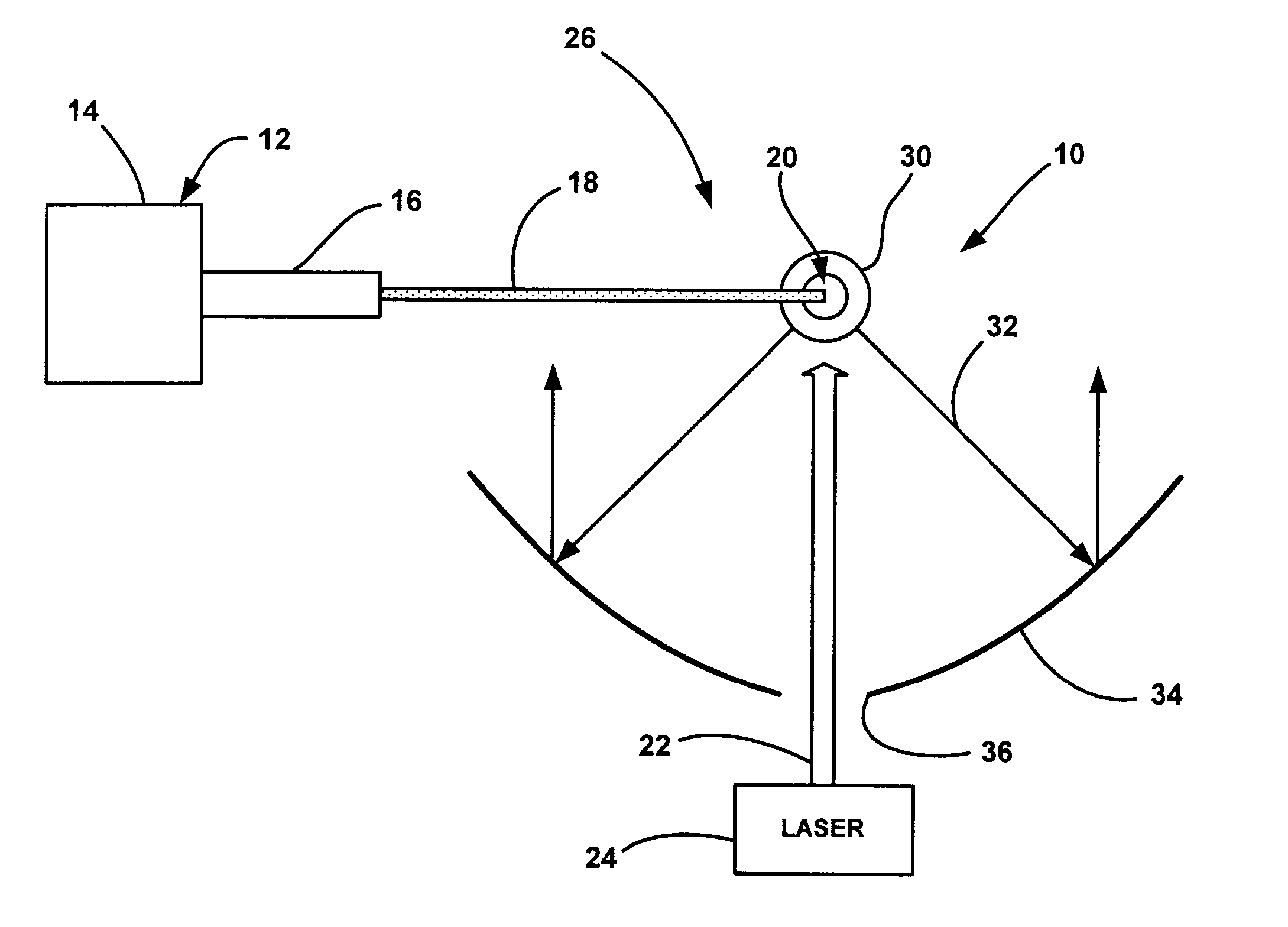

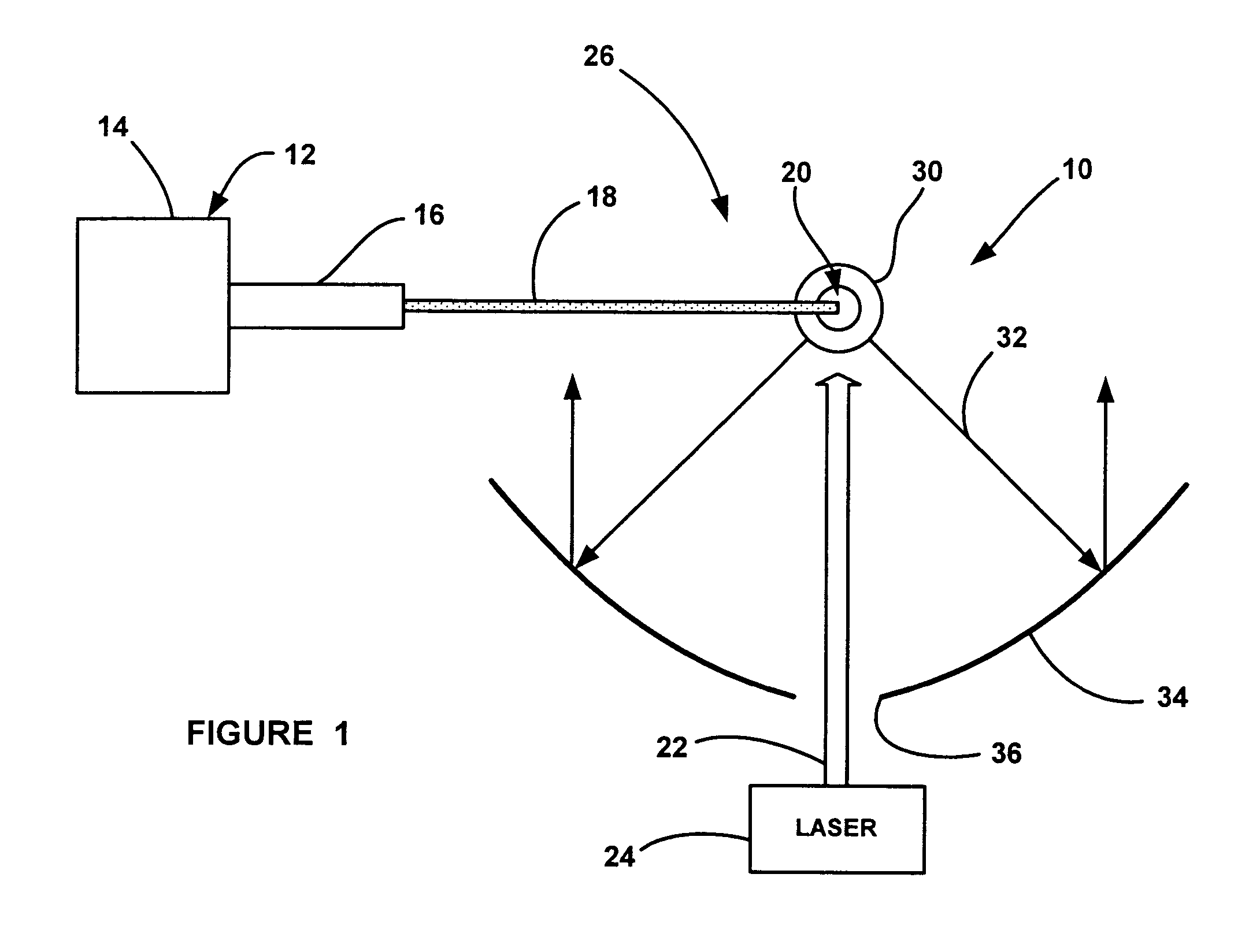

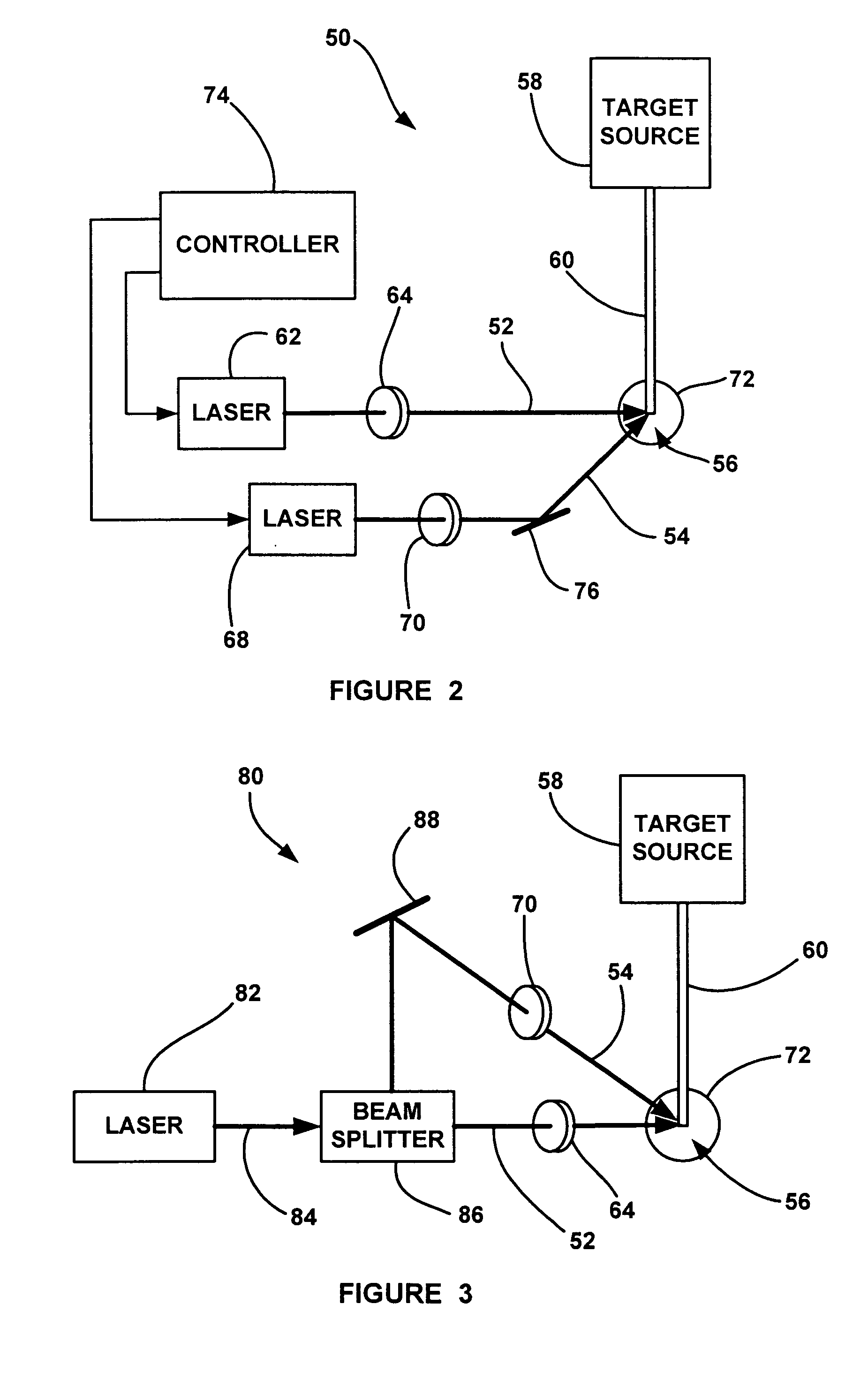

An EUV radiation source that employs a low energy laser pre-pulse and a high energy laser main pulse. The pre-pulse generates a weak plasma in the target area that improves laser absorption of the main laser pulse to improve EUV radiation emissions. High energy ion flux is reduced by collisions in the localized target vapor cloud generated by the pre-pulse. Also, the low energy pre-pulse arrives at the target area 20-200 ns before the main pulse for maximum output intensity. The timing between the pre-pulse and the main pulse can be reduced below 160 ns to provide a lower intensity of the EUV radiation. In one embodiment, the pre-pulse is split from the main pulse by a suitable beam splitter having the proper beam intensity ratio, and the main pulse is delayed to arrive at the target area after the pre-pulse.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

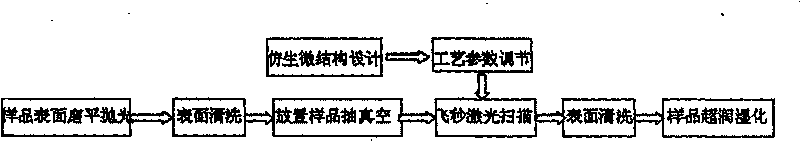

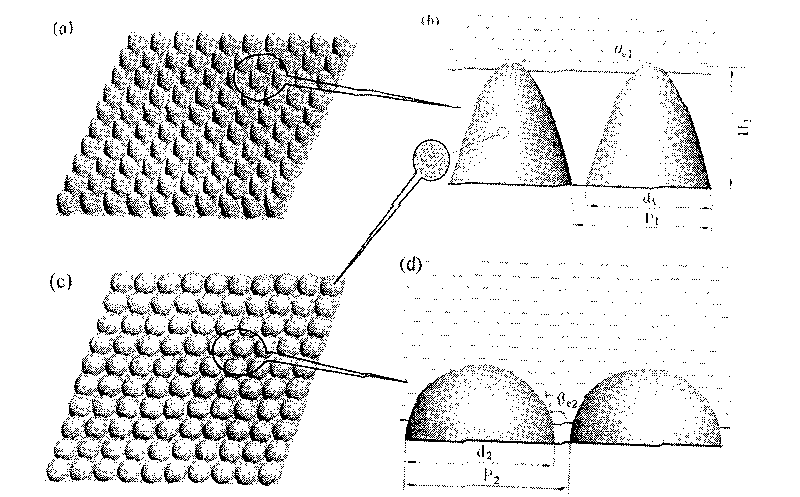

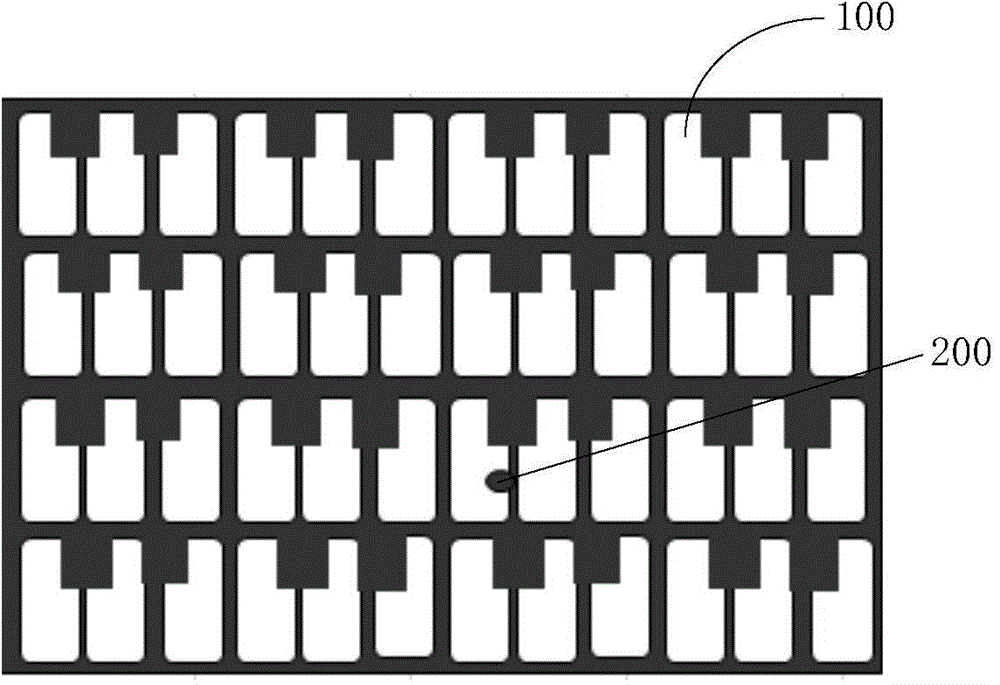

Bionic metal ultra-wetting trans-scale structure design method and preparation method

InactiveCN101712102AEasy to analyze and calculateIdeal wettability structureLaser beam welding apparatusMacroscopic scaleScale structure

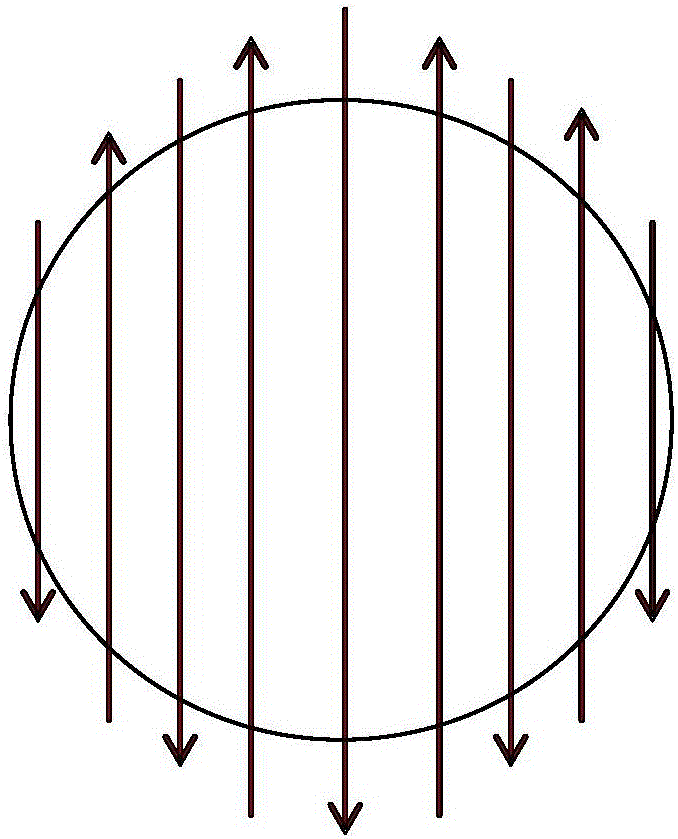

The invention relates to the technical field of laser microprocessing, in particular to a method for obtaining a metal-based ultra-wetting surface by designing the trans-scale structure of a metal surface, preparing a laser microstructure on the metal surface and carrying out necessary ultra-wetting decoration to the metal surface. The method comprises the following steps: firstly, designing a macroscopical large-area superficial periodical mastoid structure which simulates a locus leaf surface; constructing a micronano periodical structure on the microstructure of the mastoid structure to obtain a macroscopical-micronano trans-scale geometric model; adjusting laser parameters and a laser scanning path according to geometric parameters acquired after the bionic metal ultra-wetting trans-scale structure is designed; scanning the plane first time; rotating a sample 90 degrees; and scanning the plane again with low-energy laser. The trans-scale microstructure approaches to the surface appearance of a natural organism, is easy to calculate and analyze a contact angle and has a simple and controllable preparation process.

Owner:JIANGSU UNIV

Laser-produced plasma EUV light source with pre-pulse enhancement

InactiveUS6973164B2Improves laser absorption of laserLess likely to damageLaser using scattering effectsSemiconductor/solid-state device manufacturingBeam splitterVapor cloud

An EUV radiation source that employs a low energy laser pre-pulse and a high energy laser main pulse. The pre-pulse generates a weak plasma in the target area that improves laser absorption of the main laser pulse to improve EUV radiation emissions. High energy ion flux is reduced by collisions in the localized target vapor cloud generated by the pre-pulse. Also, the low energy pre-pulse arrives at the target area 20–200 ns before the main pulse for maximum output intensity. The timing between the pre-pulse and the main pulse can be reduced below 160 ns to provide a lower intensity of the EUV radiation. In one embodiment, the pre-pulse is split from the main pulse by a suitable beam splitter having the proper beam intensity ratio, and the main pulse is delayed to arrive at the target area after the pre-pulse.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

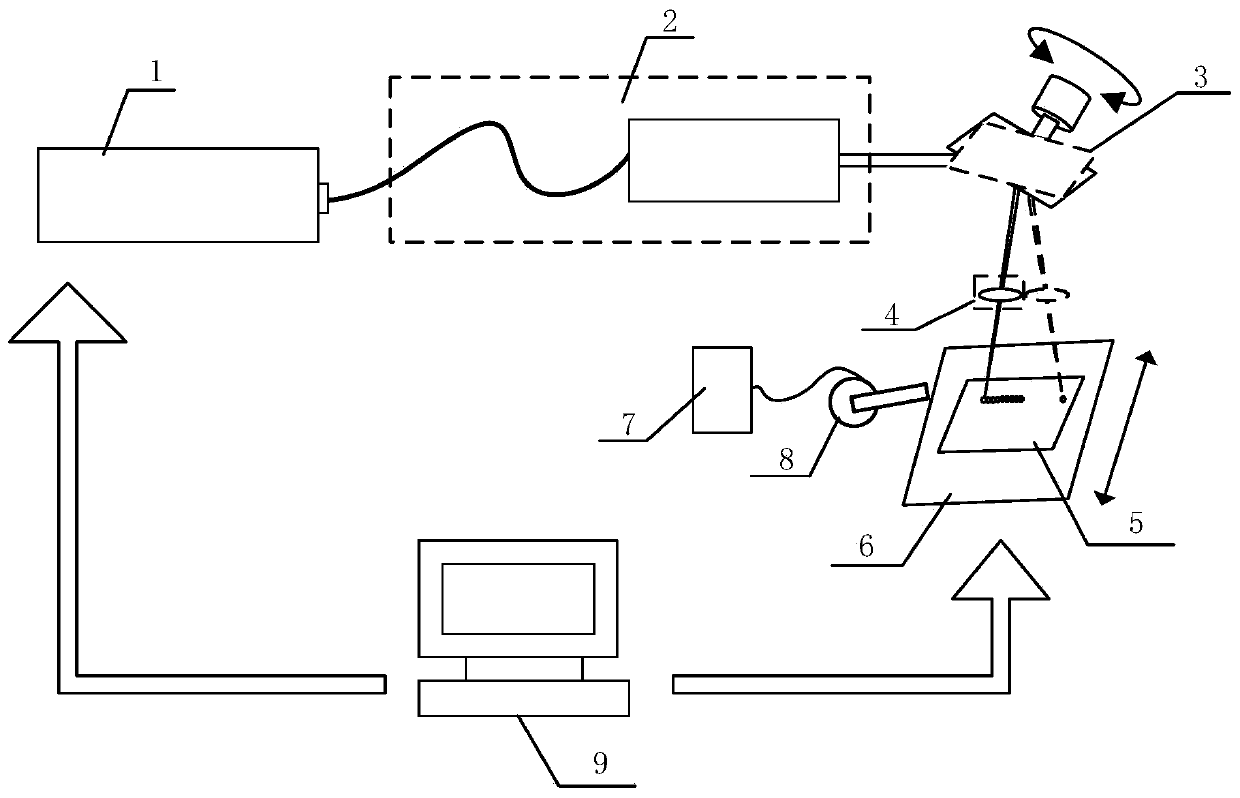

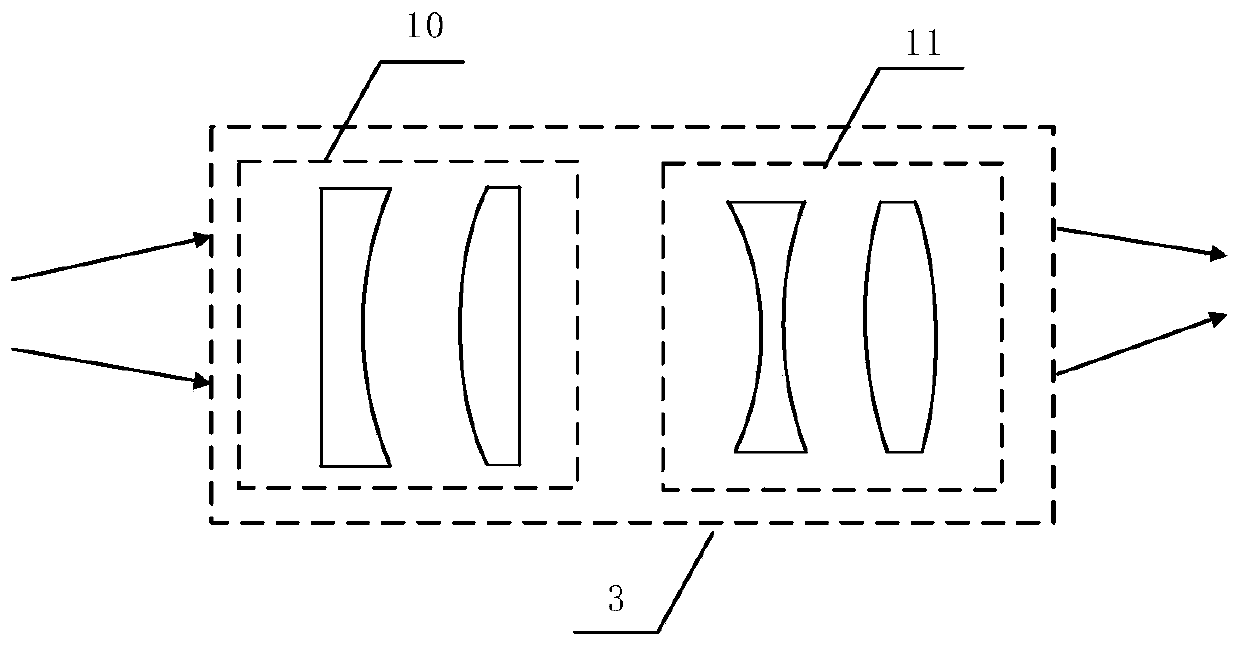

Passive imaging system with distance measuring function and distance measuring method thereof

ActiveCN103760567ARealize rangingRealize functionElectromagnetic wave reradiationDigital imageAnalog-to-digital converter

The invention discloses a passive imaging system with a distance measuring function and a distance measuring method of the passive imaging system. The passive imaging system comprises a high-frequency low-energy pulse laser emitting device, a photodiode array detector imaging device, a video amplifying and analog-digital converting device and a digital processing device for digital image processing and timing sequence occurrence. The high-frequency low-energy pulse laser emitting device is used for emitting high-frequency low-energy laser pulses and expanding bundles and shaping to reach a long distance; the photodiode array detector imaging device is used for receiving laser spots and background images reflected by a target and obtaining a distance value by adjusting integral time; the video amplifying and analog-digital converting device is used for converting photogenerated charges of the photodiode array detector imaging device into voltage and digitizing analog images through a analog-digital converter; the digital processing device for digital image processing and timing sequence occurrence is used for preprocessing digital images input by the video amplifying and analog-digital converting device and extracting the target. According to the passive imaging system, high-performance passive imaging and the distance measuring function are combined.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Composite heart valve apparatus manufactured using techniques involving laser machining of tissue

ActiveUS7682304B2Modifies tissue much fasterLow scrap rateTubular organ implantsVenous valvesVeinMedical device

Methodology for using laser machining techniques to modify a tissue for use in a medical device. In a representative mode of practice, relatively low energy laser machining is used to thin down at least a portion of a valved jugular vein. The thinned down vein may then be sutured to, or otherwise integrated with, a corresponding stent to make a percutaneous heart valve.

Owner:MEDTRONIC INC

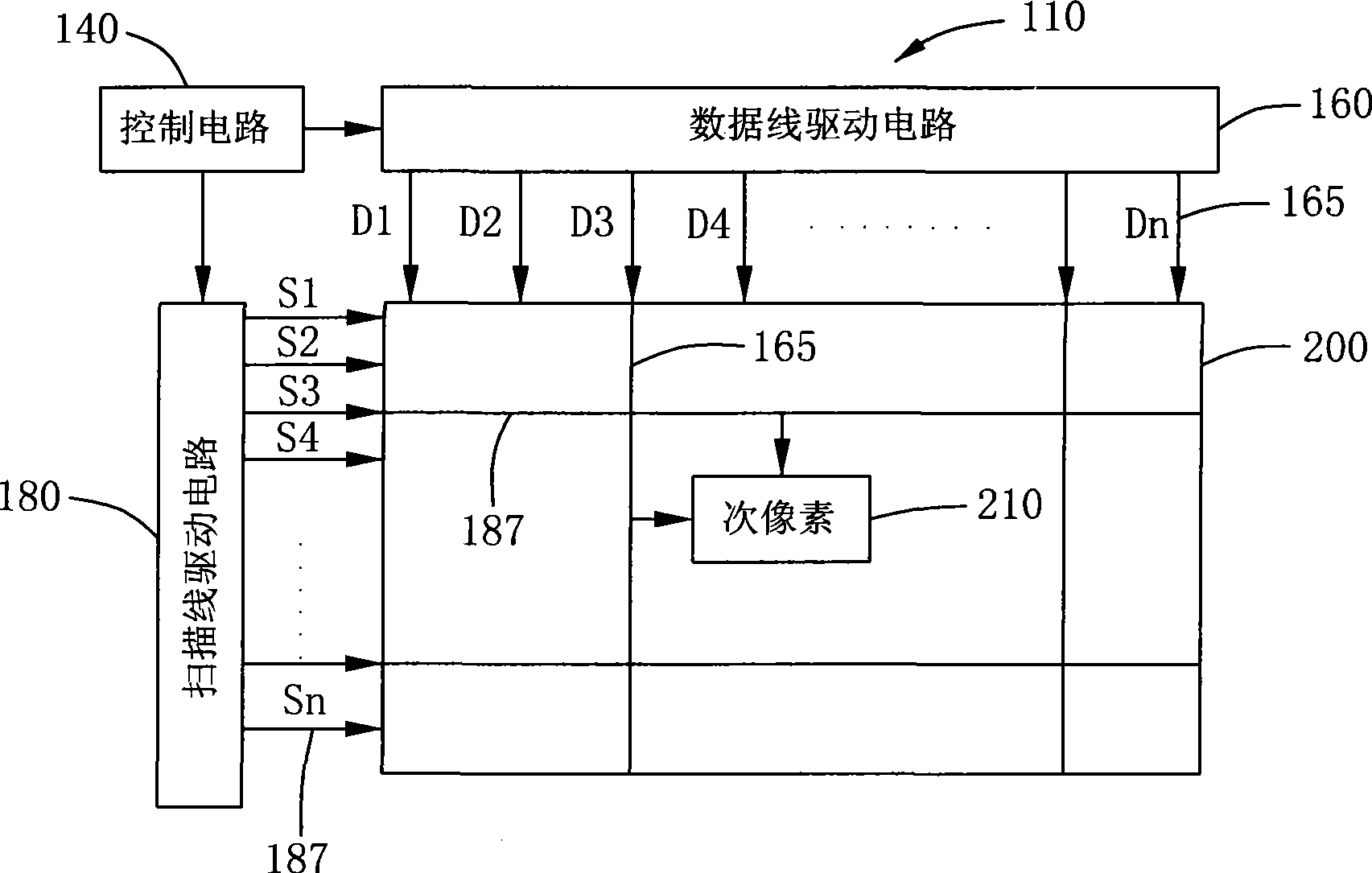

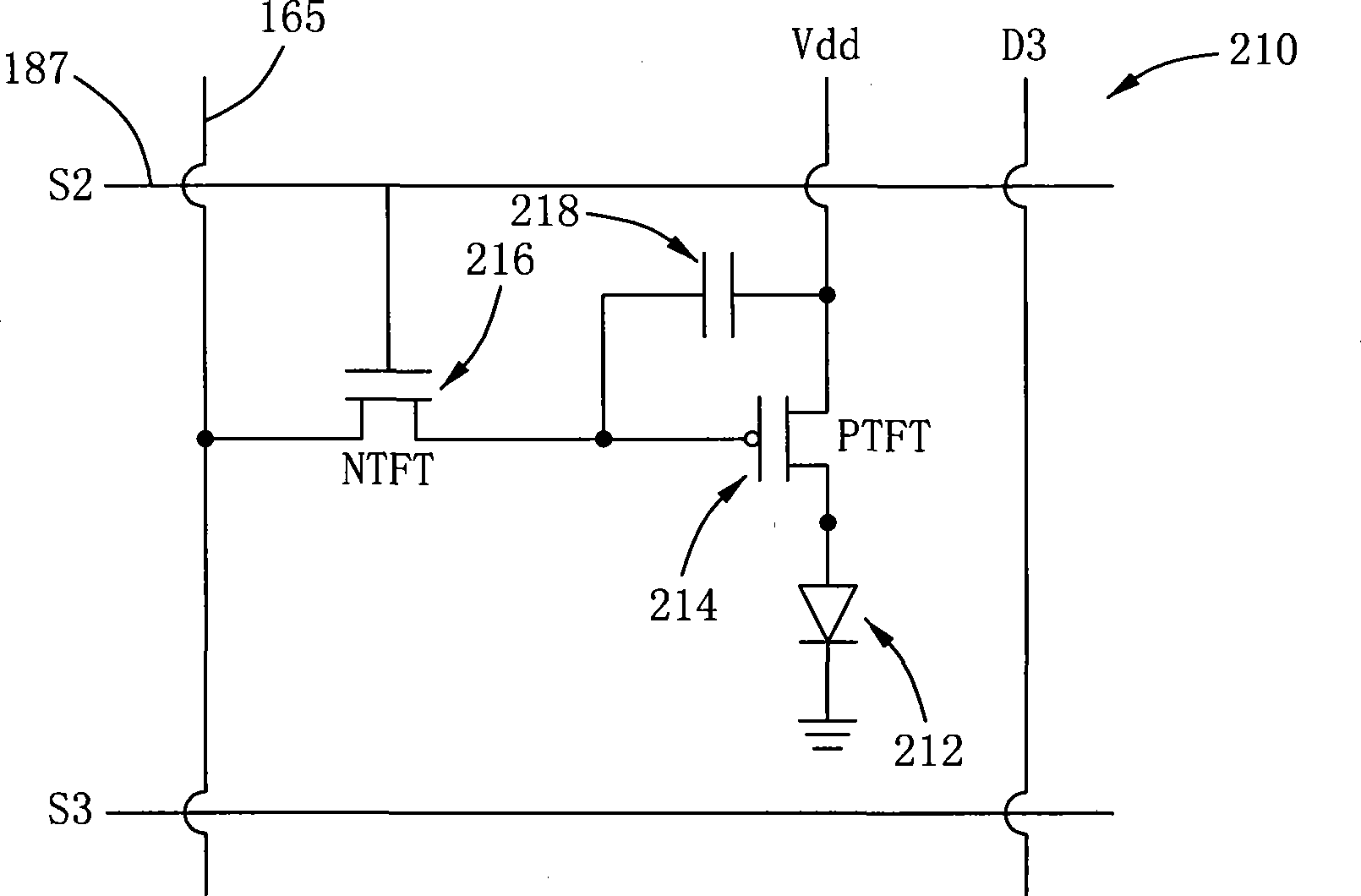

Method for manufacturing thin film transistor (TFT) and OLED display having tfts manufactured by the same

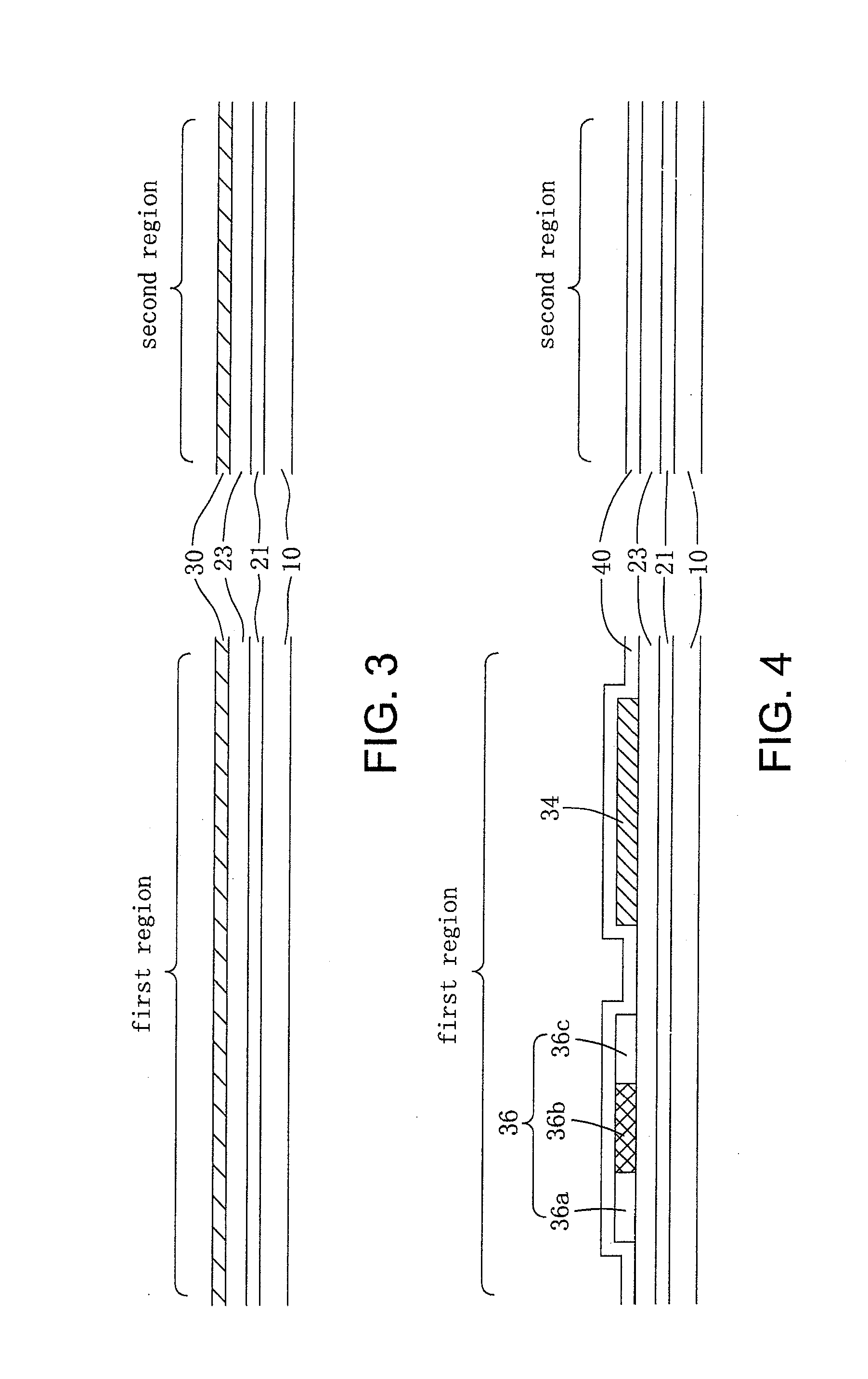

ActiveUS20090146927A1Improve electrical performanceHigh carrier mobilityStatic indicating devicesSolid-state devicesDisplay deviceCharge carrier mobility

An organic light emitting diode (OLED) display and thin film transistor (TFT) manufacturing method thereof are disclosed. According to the present invention, poly-silicon layers for forming active areas of non-driving TFT (e.g. peripheral circuit TFT and switch TFT) and driving TFT used in the OLED display are respectively made by using standard laser crystallization method and non-laser crystallization method or low energy laser crystallization method. Therefore, the peripheral circuit TFT has excellent electrical performance such as high carrier mobility, while the OLED-driving TFT has good stability so that the resultant display can operate with improved luminance uniformity.

Owner:INNOLUX CORP

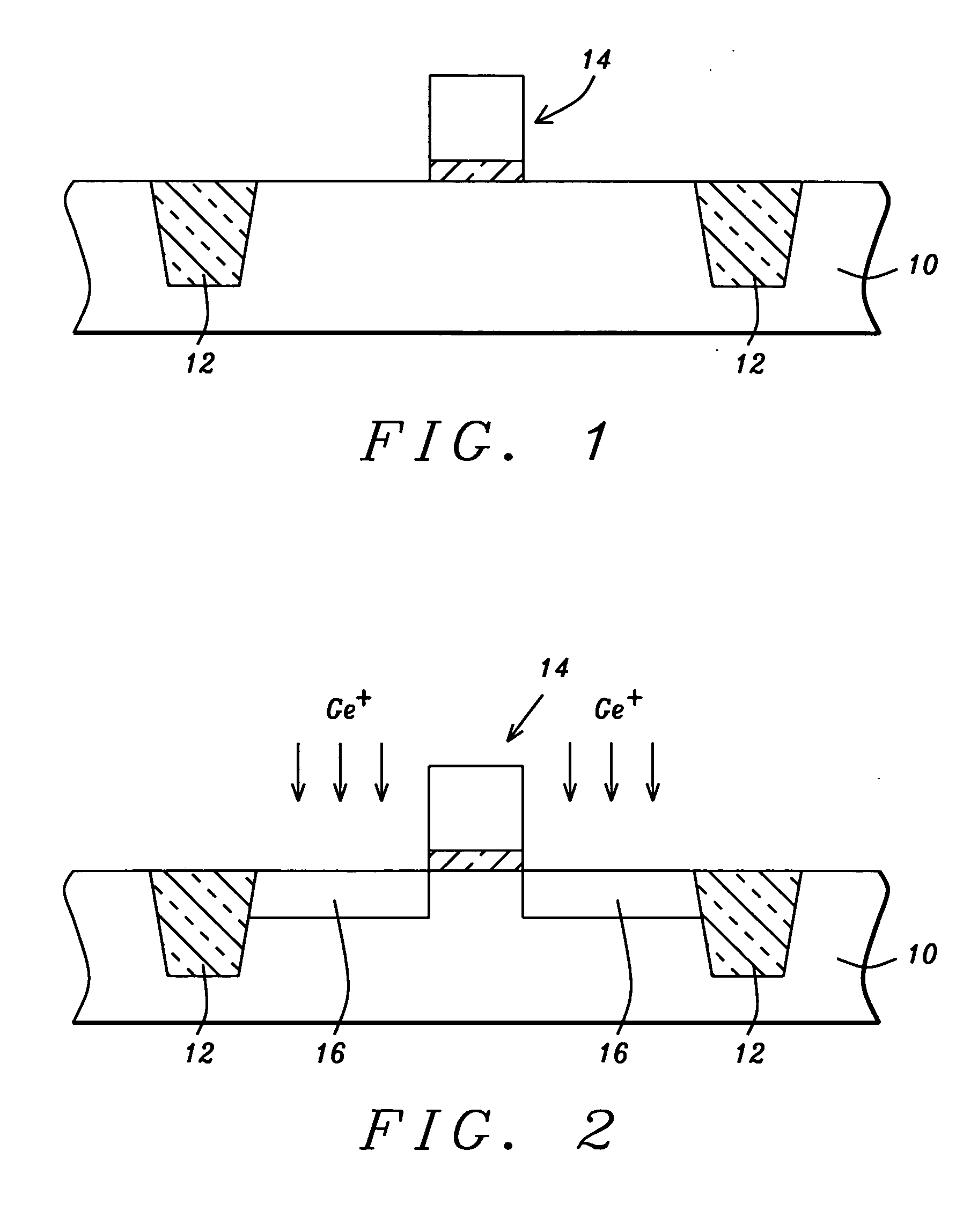

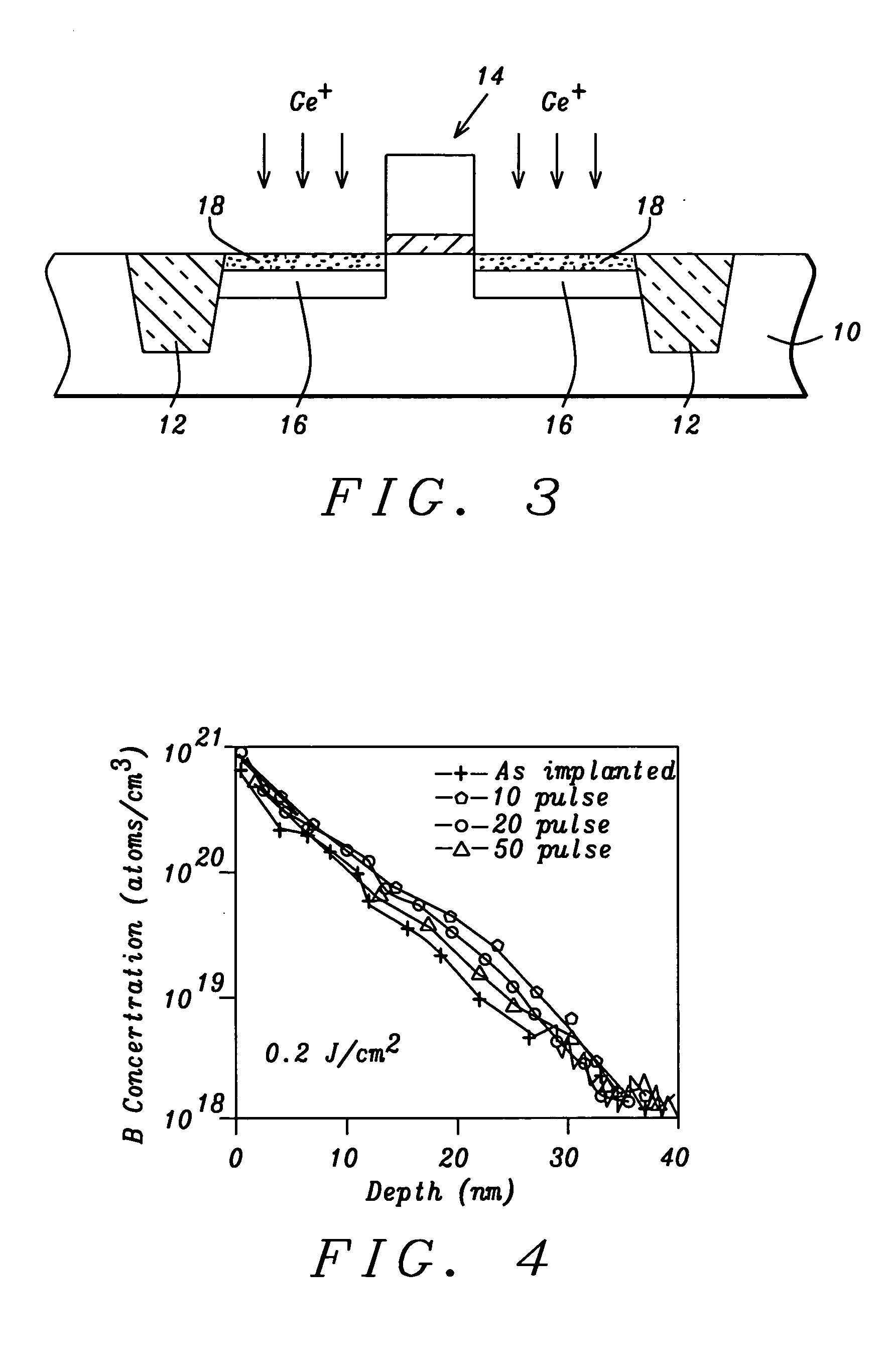

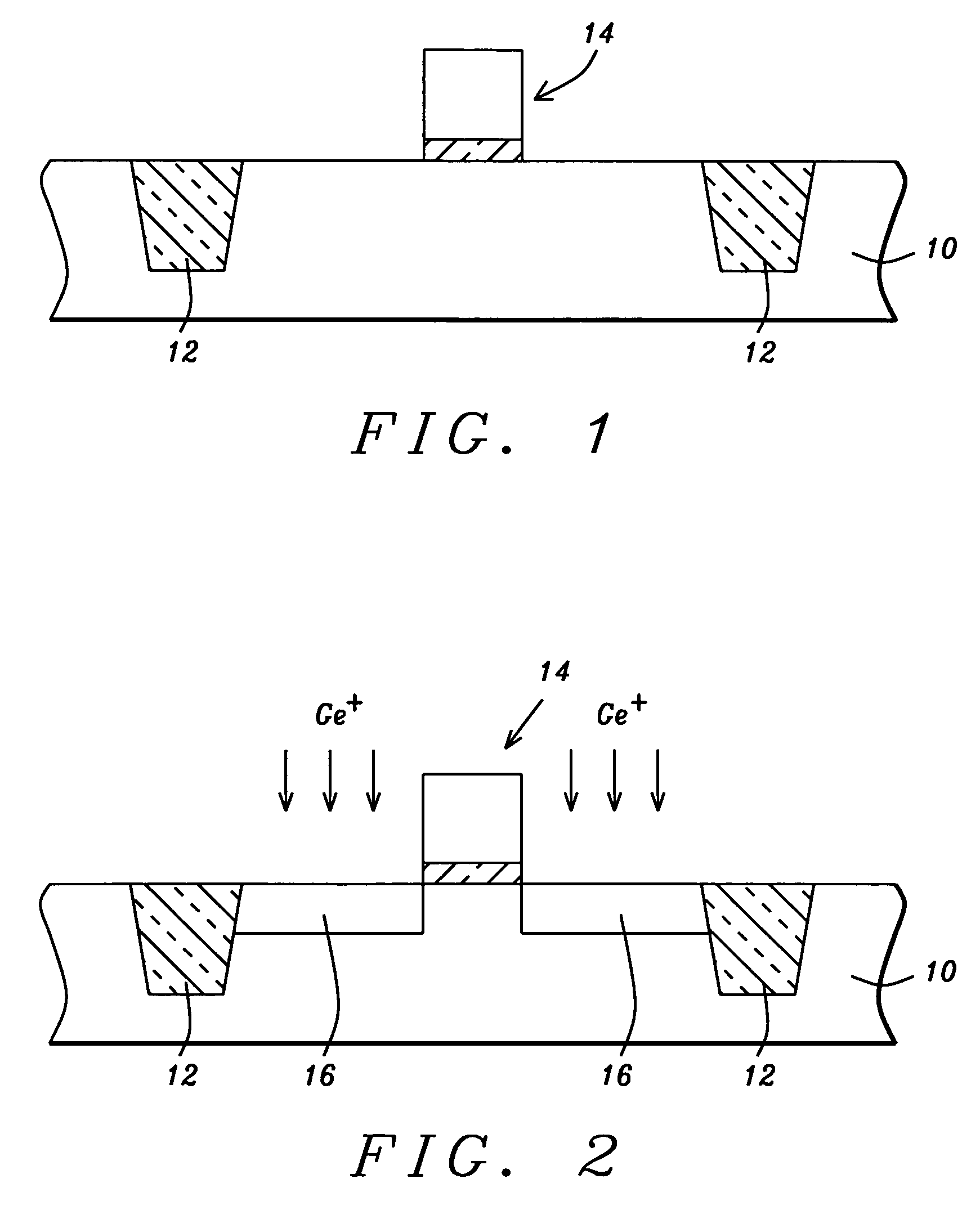

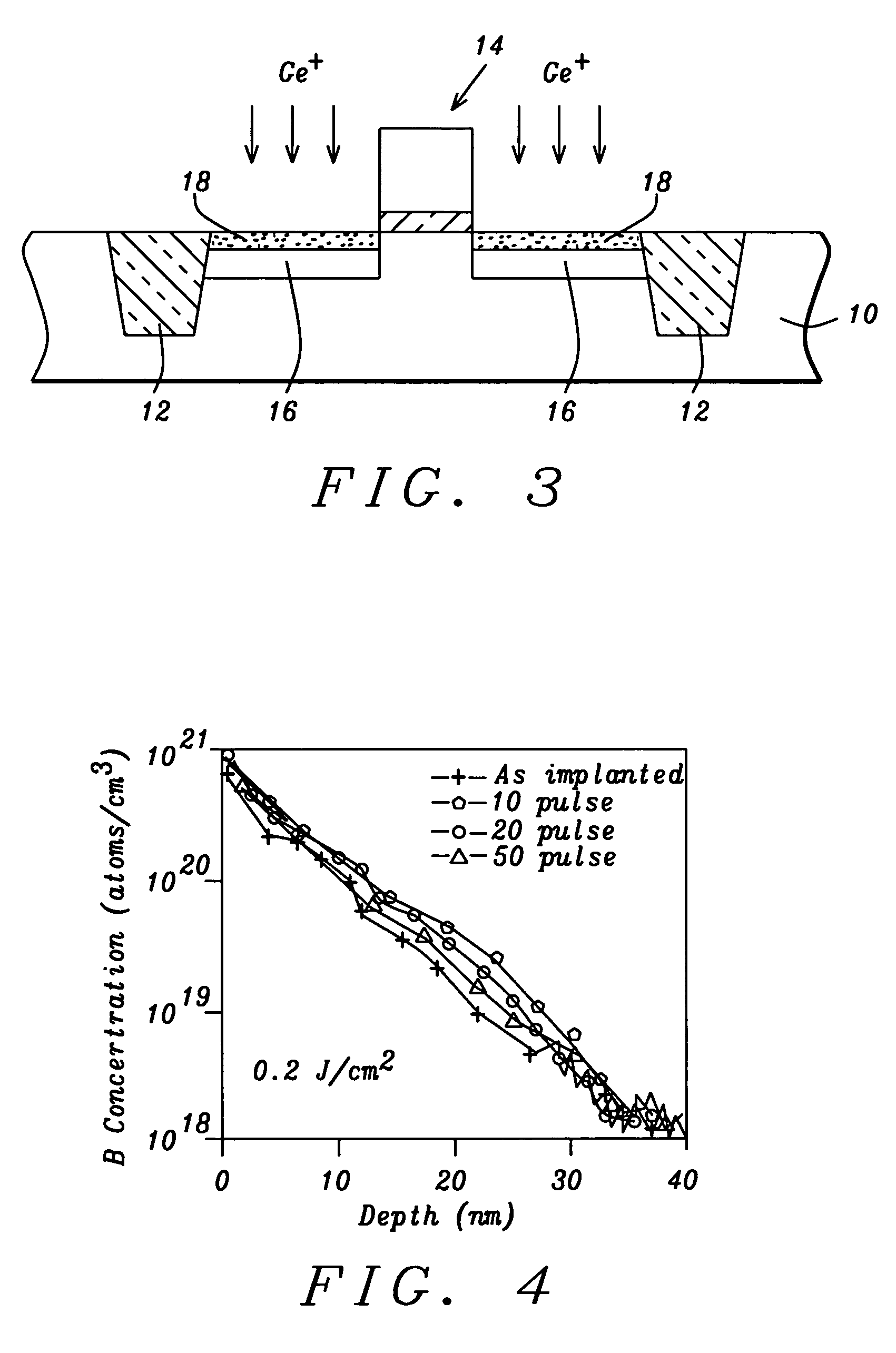

Dual step source/drain extension junction anneal to reduce the junction depth: multiple-pulse low energy laser anneal coupled with rapid thermal anneal

InactiveUS20050158956A1Reduce sheet resistanceShallow junctionSemiconductor/solid-state device manufacturingMOSFETDevice material

A process is described to form a semiconductor device such as MOSFET or CMOS with shallow junctions in the source / drain extension regions. After forming the shallow trench isolations and the gate stack, sidewall dielectric spacers are removed. A pre-amorphizing implant (PAI) is performed with Ge+ or Si+ ions to form a thin PAI layer on the surface of the silicon regions adjacent to the gate stack. B+ ion implantation is then performed to form source / drain extension (SDE) regions. The B+ implant step is then followed by multiple-pulsed 248 nm KrF excimer laser anneal with pulse duration of 23 ns. This step is to reduce the sheet resistance of the junction through the activation of the boron dopant in the SDE junctions. Laser anneal is then followed by rapid thermal anneal (RTA) to repair the residual damage and also to induce out-diffusion of the boron to yield shallower junctions than the just-implanted junctions prior to RTA.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

Method for modifying high-toughness surfaces of metal materials

The invention discloses a method for modifying the high-toughness surfaces of metal materials, relating to a surface modification technique for materials. The method comprises the following main steps: 1) pretreating the surface of a metal material; 2) carrying out laser shot blasting treatment on the pretreated surface of the material; 3) carrying out magnetic field nitriding on the surface subjected to laser shot blasting treatment; 4) carrying out magnetic field quenching on the surface subjected to nitriding; 5) carrying out low-energy laser shot blasting treatment on the surface subjected to magnetic field quenching; 6) carrying out magnetic field quenching again on the surface subjected to low-energy laser shot blasting treatment, so that a flat high-toughness surface is obtained. According to the invention, the grain structure of a surface can be effectively refined, the thickness of a nitriding layer can be increased, the nitriding time can be shortened, the brittleness of the nitriding layer can be reduced, and the toughness of the surface can be improved. The method disclosed by the invention is simple in technological process, easy in operation, high in efficiency, and suitable for mass production in a large scale.

Owner:常熟市通顺纺织有限责任公司

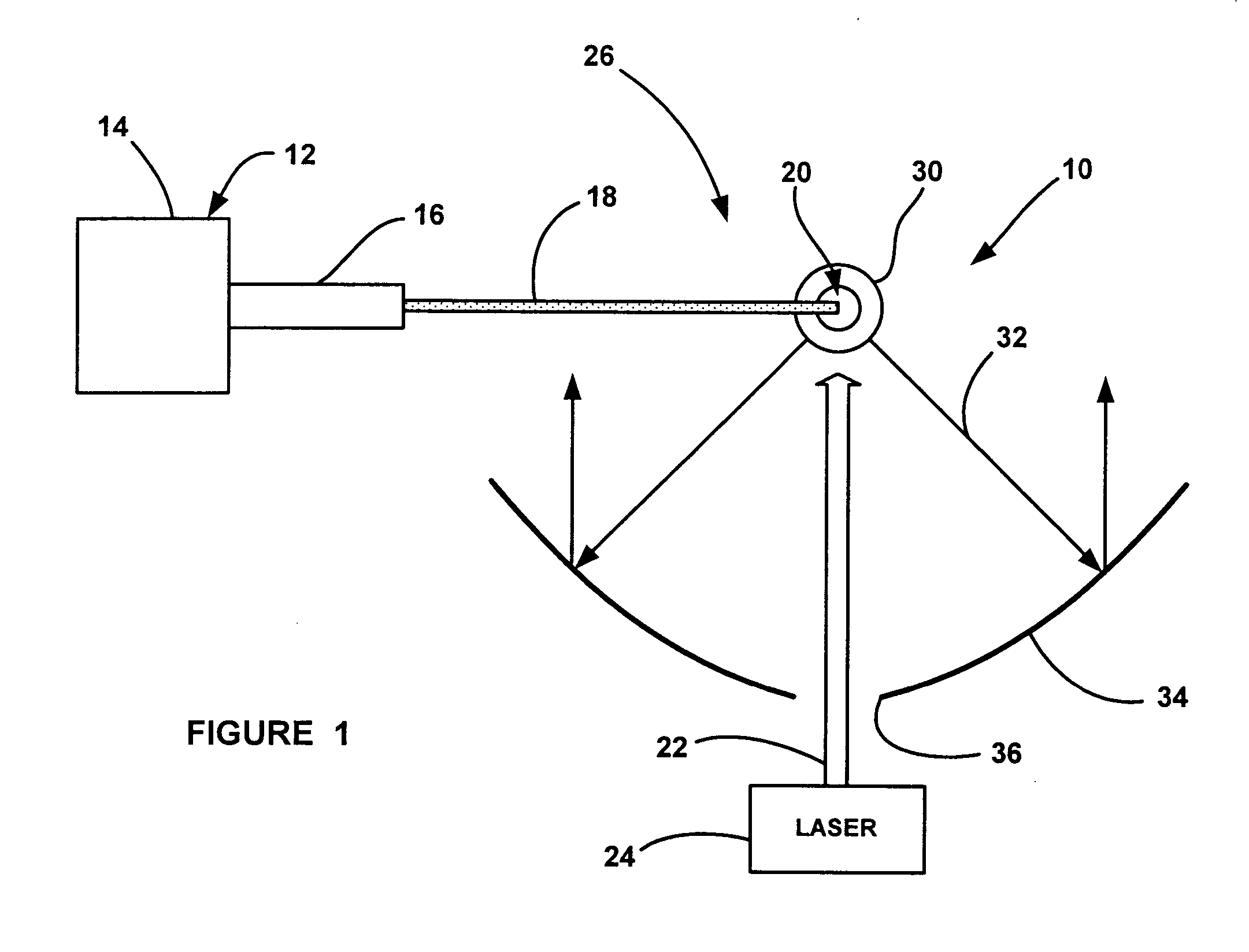

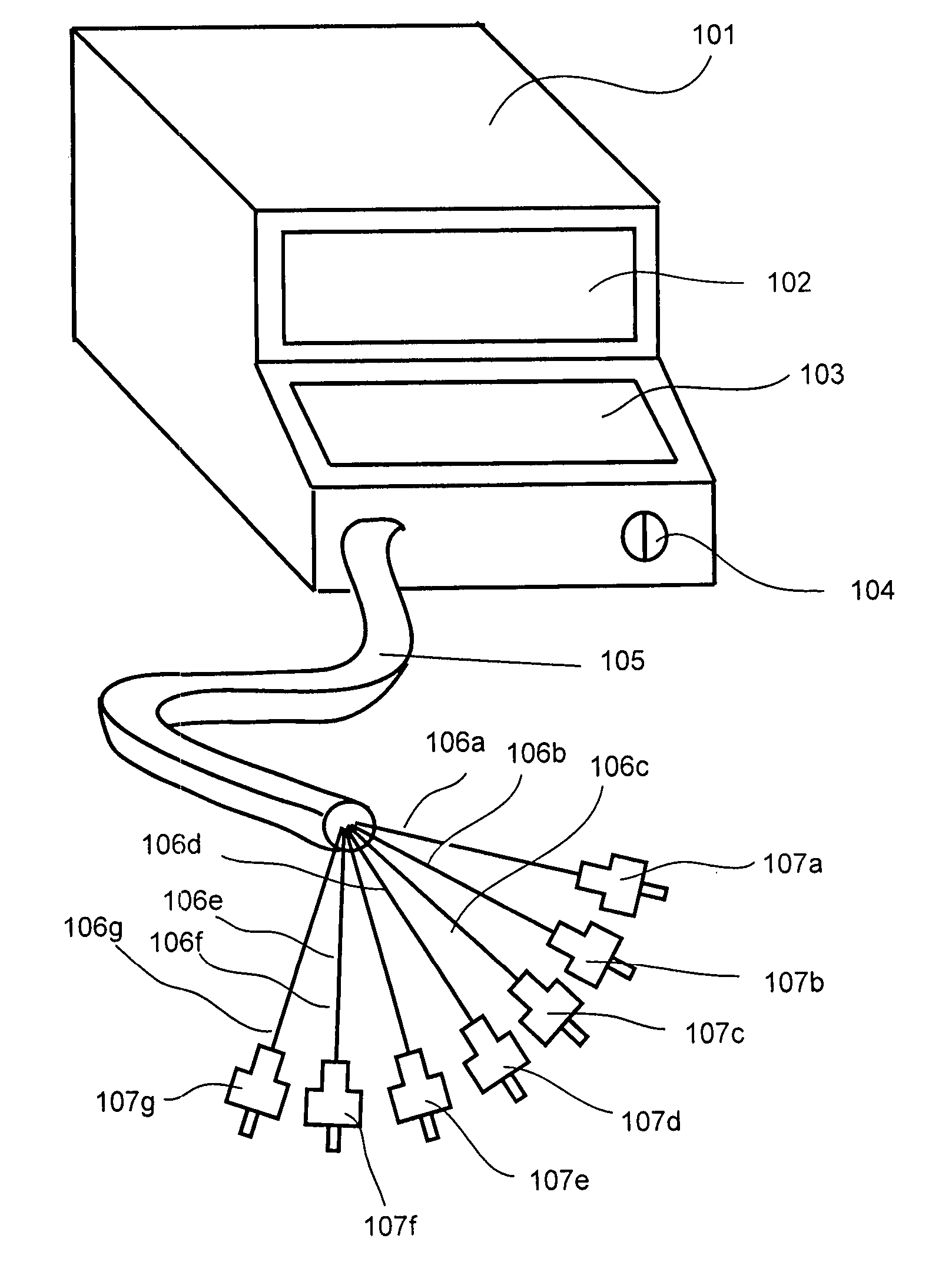

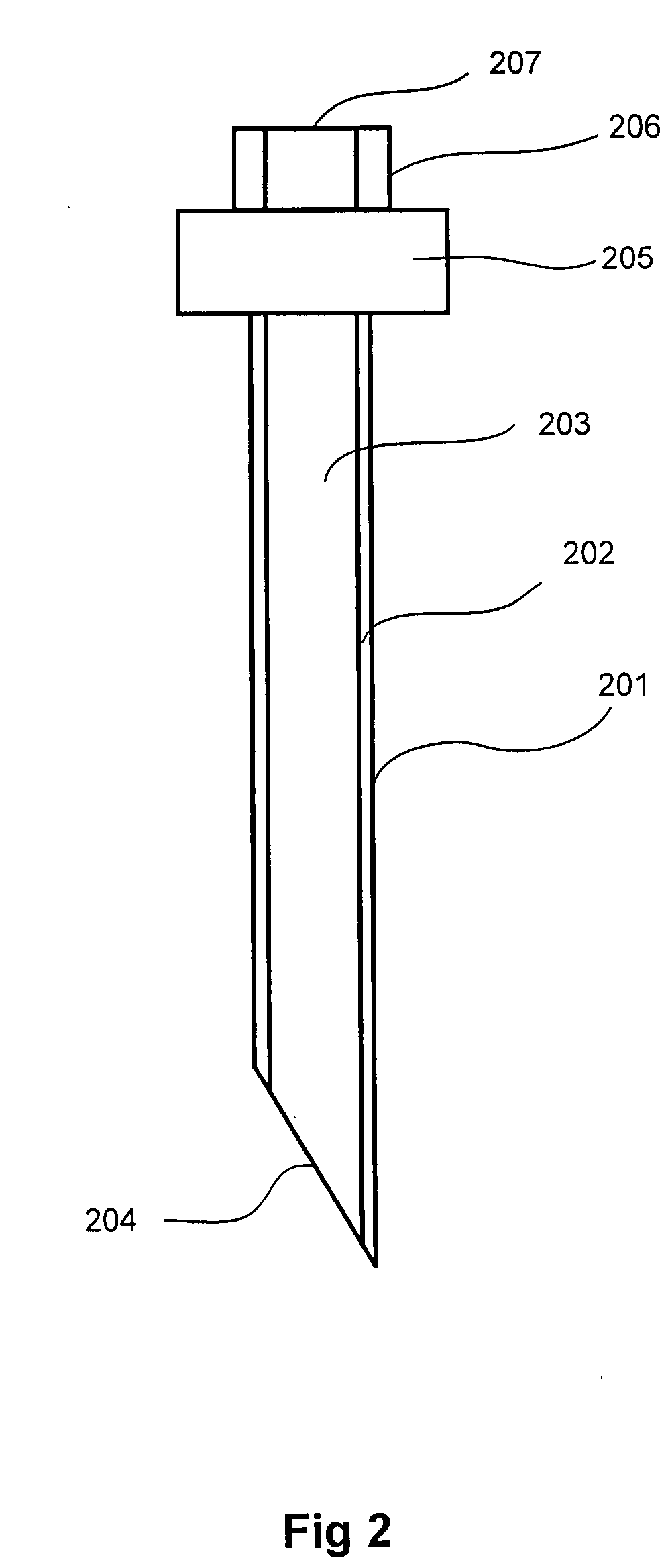

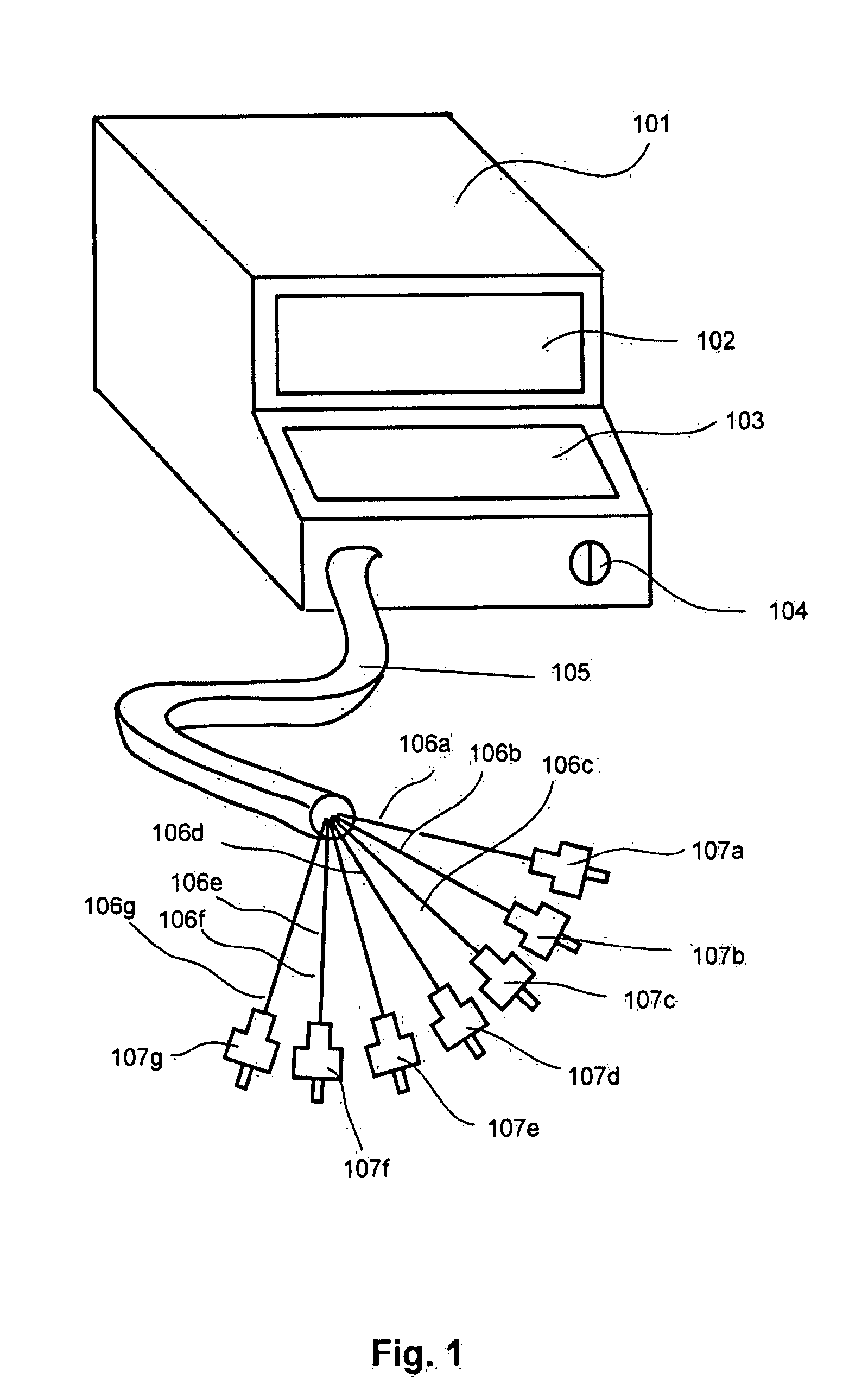

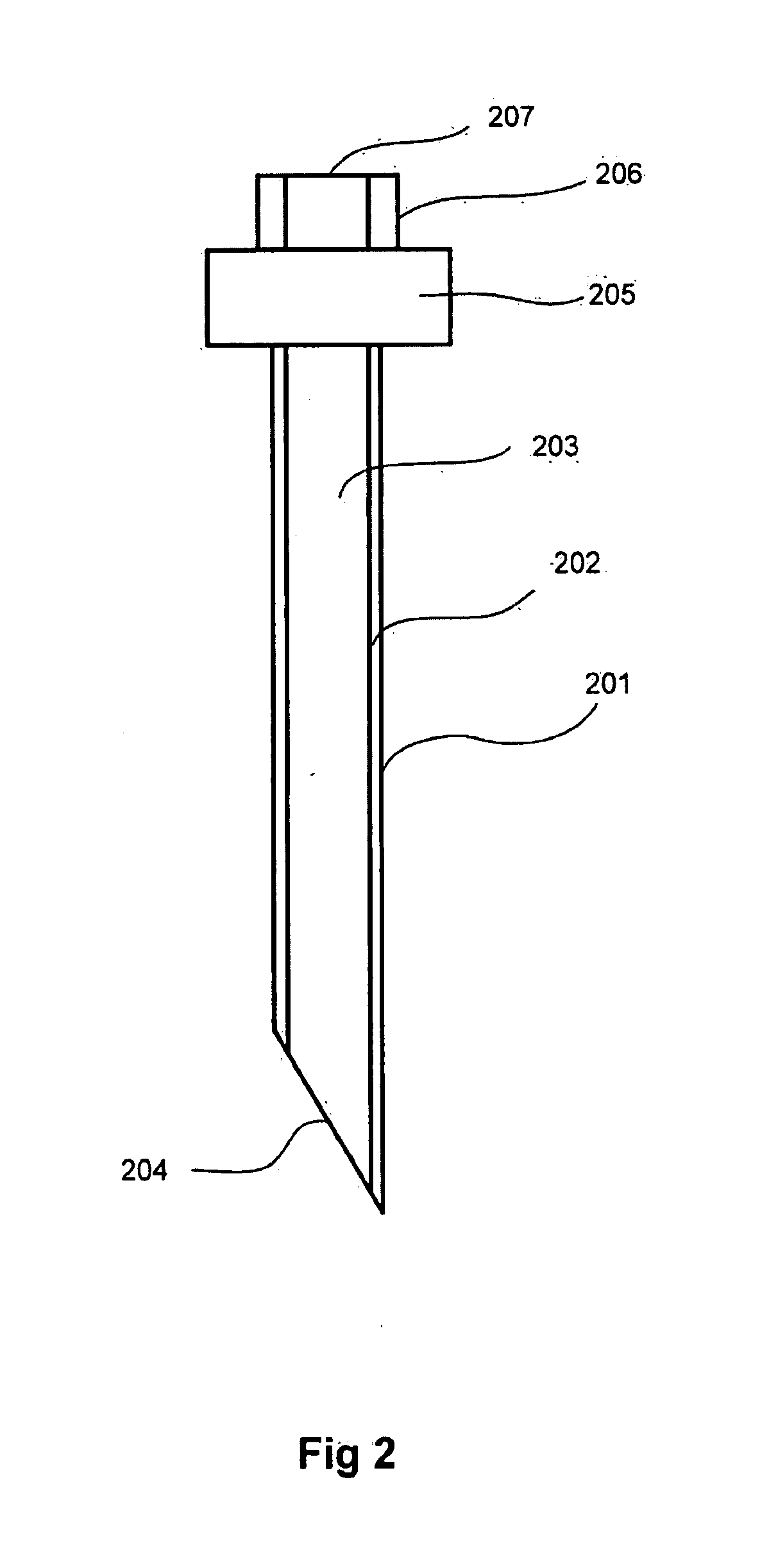

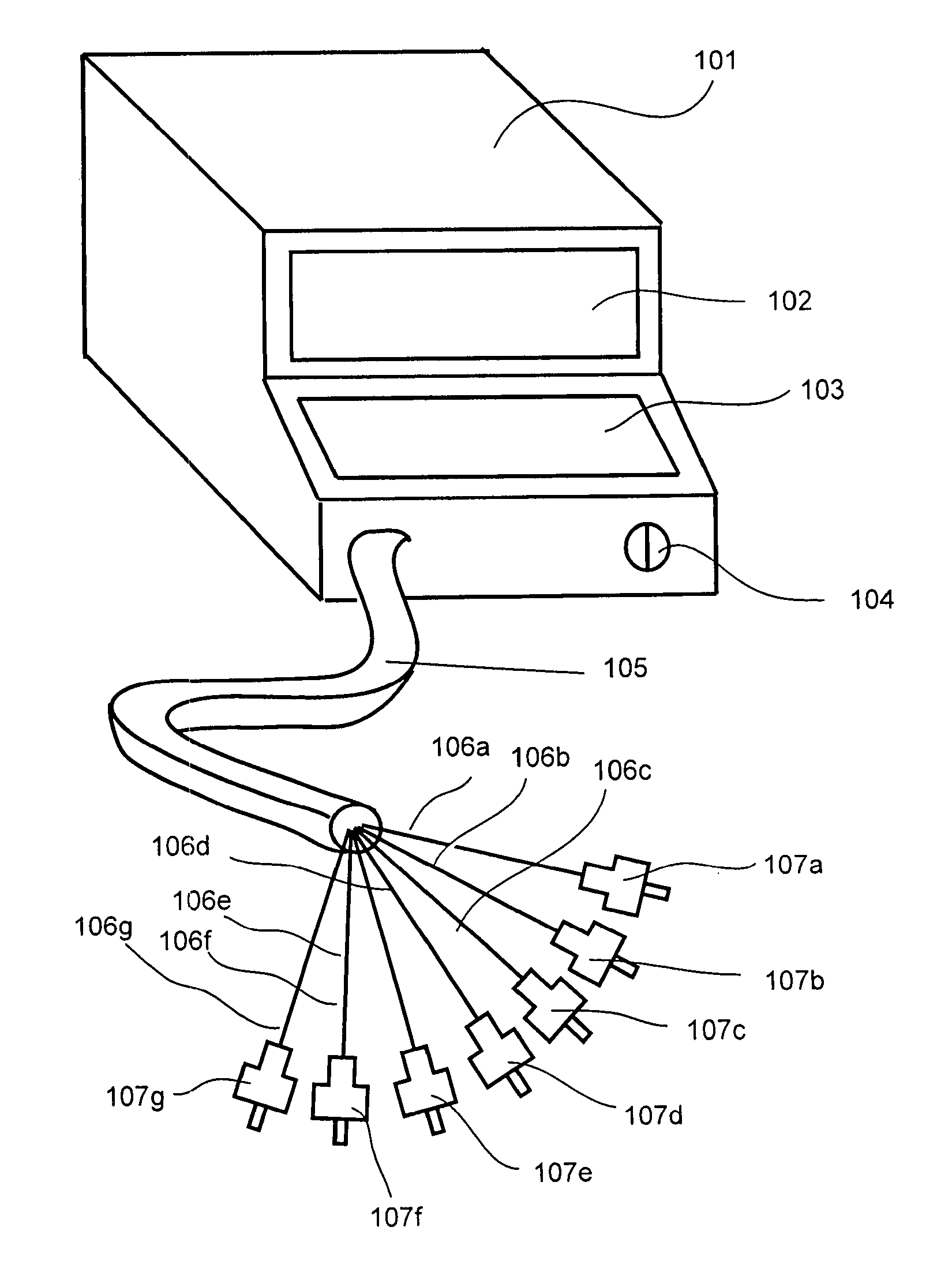

Cancer treatment using low energy lasers

A method and apparatus for destroying cancerous cells or tumors includes placing fiber needles into the human body adjacent cancerous cells or tumors that have been biologically dyed and exposing the cells or tumors to low-energy laser energy light emitted through the fiber needles so that the laser energy destroys the cancer cells or tumors through ablation without destruction of surrounding healthy tissue.

Owner:CAO DENSEN +1

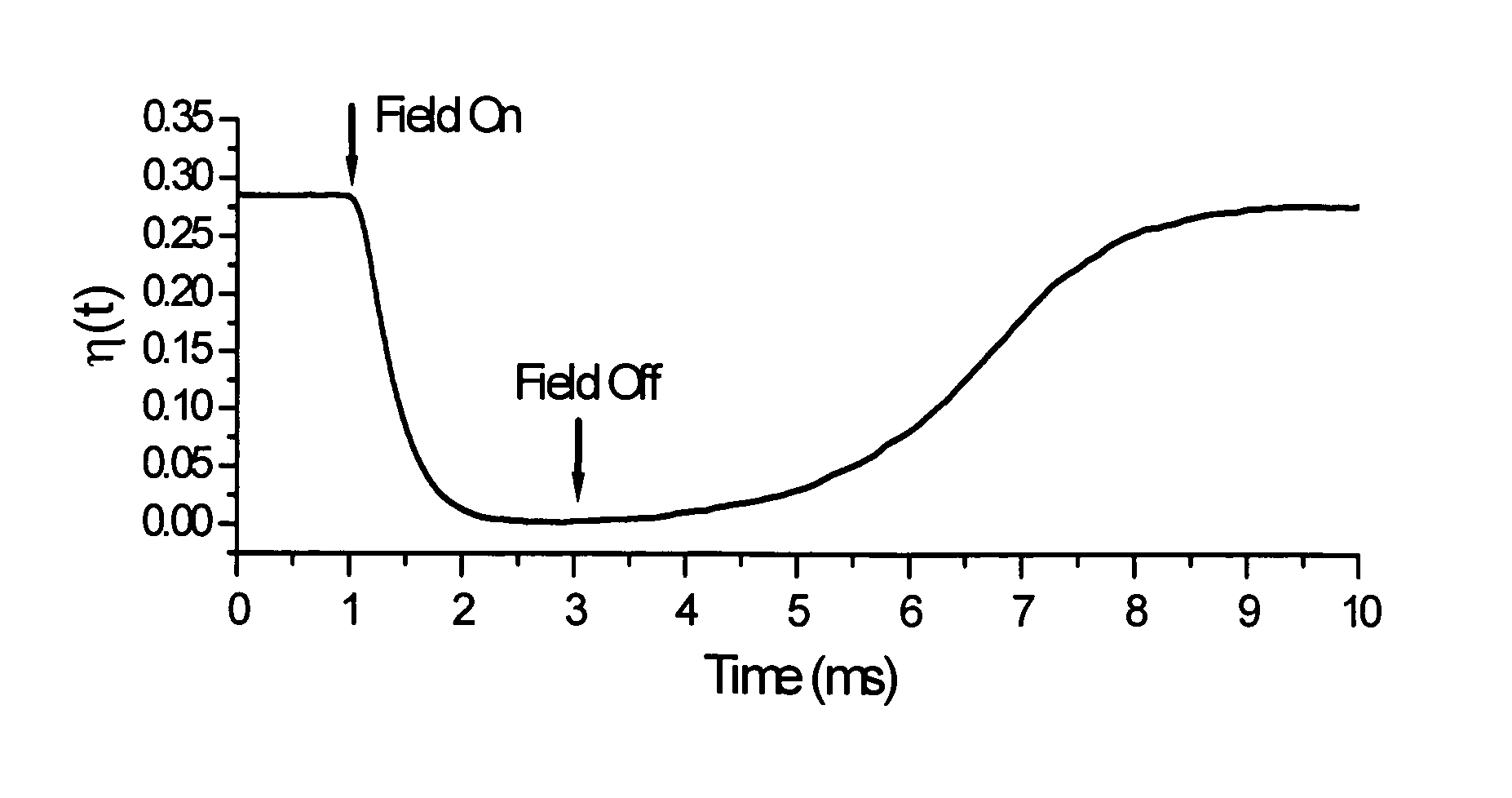

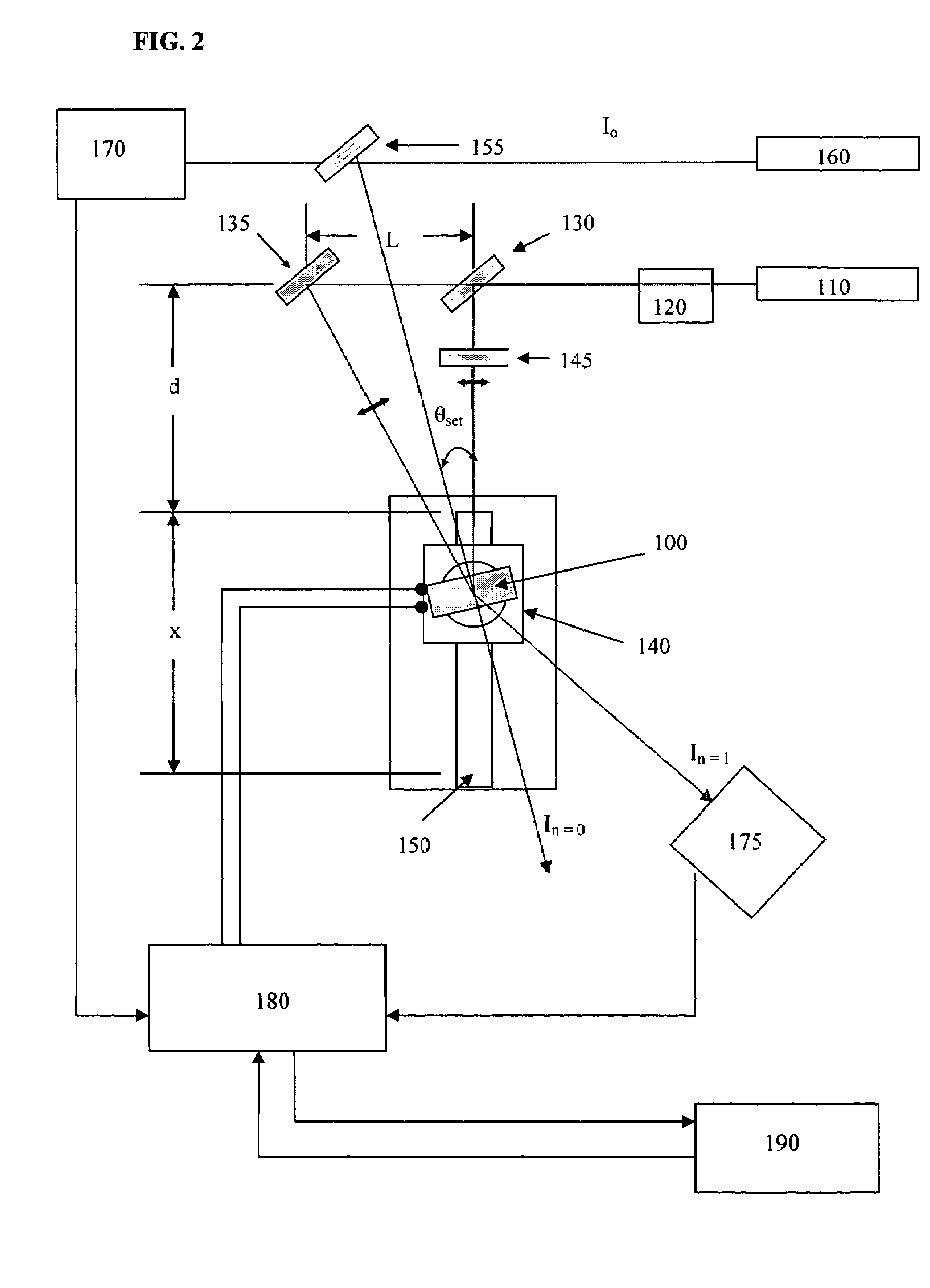

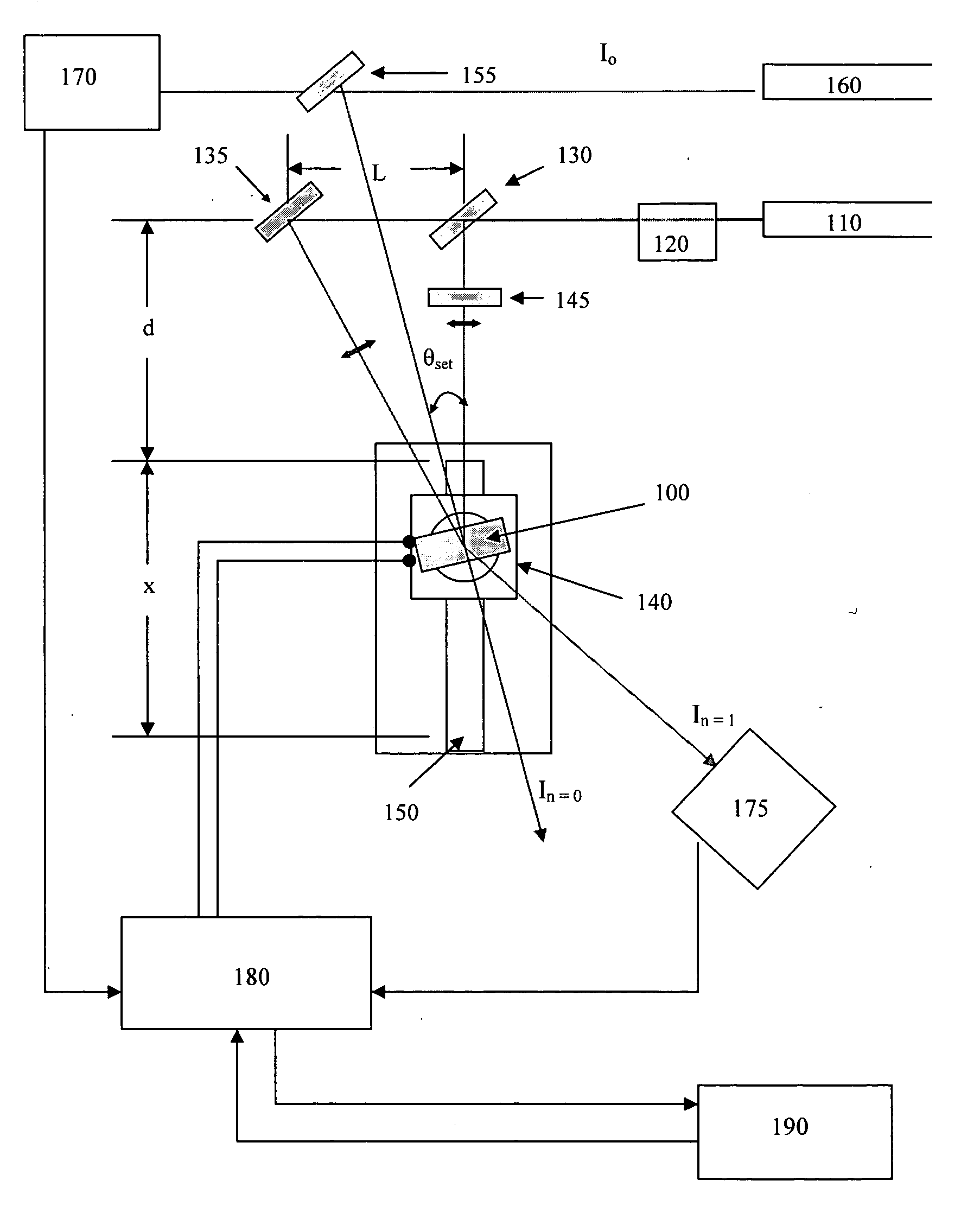

Switchable holographic gratings

InactiveUS7625674B2Efficient manufacturingLow costPhotosensitive materialsRadiation applicationsLight beamLaser beams

The present invention includes systems and compositions of holographic grating structures devices and methods for fabricating such holographic grating structures. The method comprises the steps of preparing a composite mixture comprising a polymerizable matrix, a liquid crystal, and a photo-oxidant dye, producing an interference pattern from two interference beams, wherein the two interference beams originate from a recording laser beam directed by a low energy laser, and projecting the interference pattern on the composite mixture to form a holographic grating structure. As described, the holographic grating structure yields a first-order diffraction efficiency of at least about 30% diffraction efficiency which may be adjusted by the application of an electric field.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Cancer treatment using low energy lasers

A method and apparatus for destroying cancerous cells or tumors includes placing fiber needles into the human body adjacent cancerous cells or tumors that have been biologically dyed and exposing the cells or tumors to low-energy laser energy light emitted through the fiber needles so that the laser energy destroys the cancer cells or tumors through ablation without destruction of surrounding healthy tissue.

Owner:CAO DENSEN +1

Preparation method of cobaltosic-oxide nitrogen-doped graphene synthesized by laser and with adjustable oxygen vacancies

InactiveCN109590008AImprove OER/ORR catalytic performanceSimple processPhysical/chemical process catalystsDoped grapheneOxygen vacancy

The invention discloses a preparation method of cobaltosic-oxide nitrogen-doped graphene synthesized by laser and with adjustable oxygen vacancies. The preparation method comprises the following stepsof: using oxidized graphene to ultrasonically disperse in absolute ethyl alcohol, preparing into 0.33mg / ml suspension, taking 24ml suspension, adding 1.2ml 0.2M cobaltous acetate solution, 0.5ml NH4OH solution with the concentration of 30% and 0.7ml deionized water, and carrying out oil bathing for 10 hours at a temperature of 80 DEG C; pouring the solution into a reaction kettle, and reacting for 3 hours at a temperature of 150 DEG C; then carrying out high-speed centrifugation at a speed of 12000-20000r / m, then repeatedly cleaning for 3-4 times by using the deionized water, obtaining precipitates and carrying out freezing and drying; mixing a sample and the deionized water into a test tube according to the mass ratio of 1:2-1:5, and under magnetic stirring, using 15-97mJ energy of nanosecond parallel pulse laser to irradiate the solution for 5-25 minutes; carrying out centrifuging, freezing and drying to obtain the cobaltosic-oxide nitrogen-doped graphene with the adjustable oxygenvacancy. The preparation method disclosed by the invention has the beneficial effects that by adjustment for the irradiation energy and time of low-energy laser, the concentration of the oxygen vacancies in the composite system is adjusted and the unchanged structure of the composite system is maintained.

Owner:TIANJIN UNIV

Cancer Treatment Using Lasers

A method and apparatus for destroying cancerous cells or tumors includes placing fiber needles into the human body adjacent cancerous cells or tumors that have been biologically stained and exposing the cells or tumors to low-energy laser energy light emitted through the fiber needles so that the laser energy destroys the cancer cells or tumors through carbonization and / or vaporization without destruction of surrounding healthy tissue. The stain is specifically selected to have an absorption efficiency of greater than 90% for energy emitted by a given laser such that it greatly enhances absorption of the laser energy over surrounding unstained tissue. Appropriate stain and laser selection can allow treatment through an intact column of living tissue as laser energy to which living tissue is transparent may be used in combination with a stain that makes targeted tissue opaque to that energy.

Owner:CAO GROUP

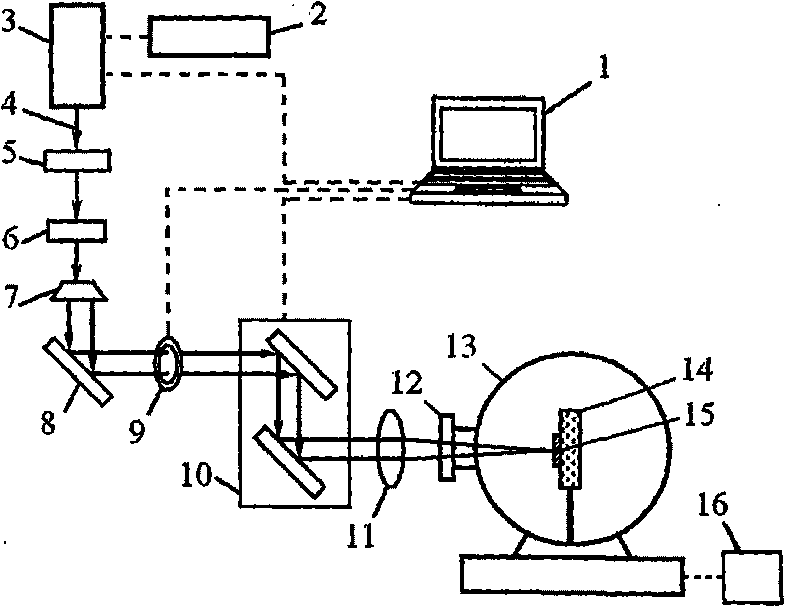

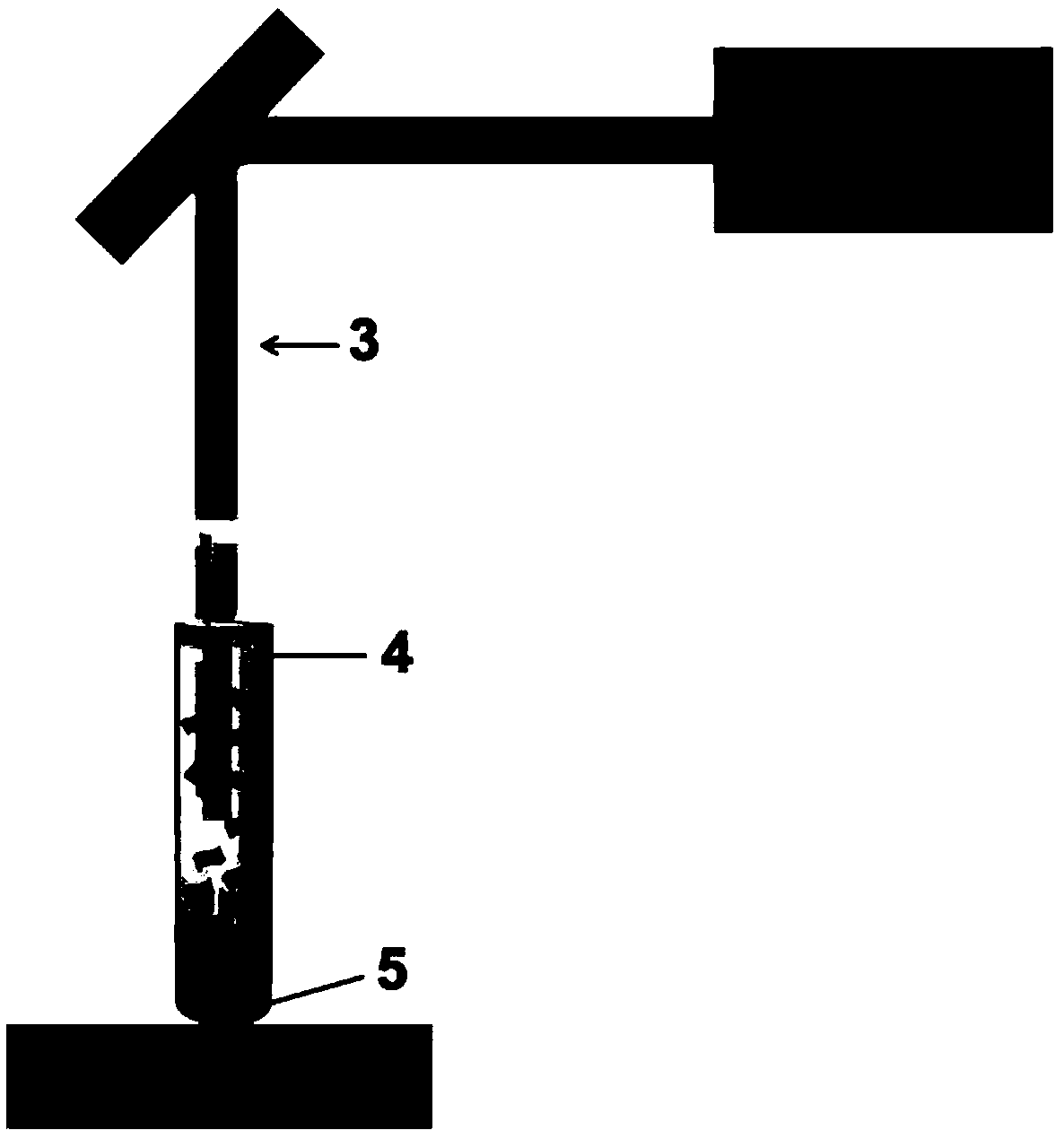

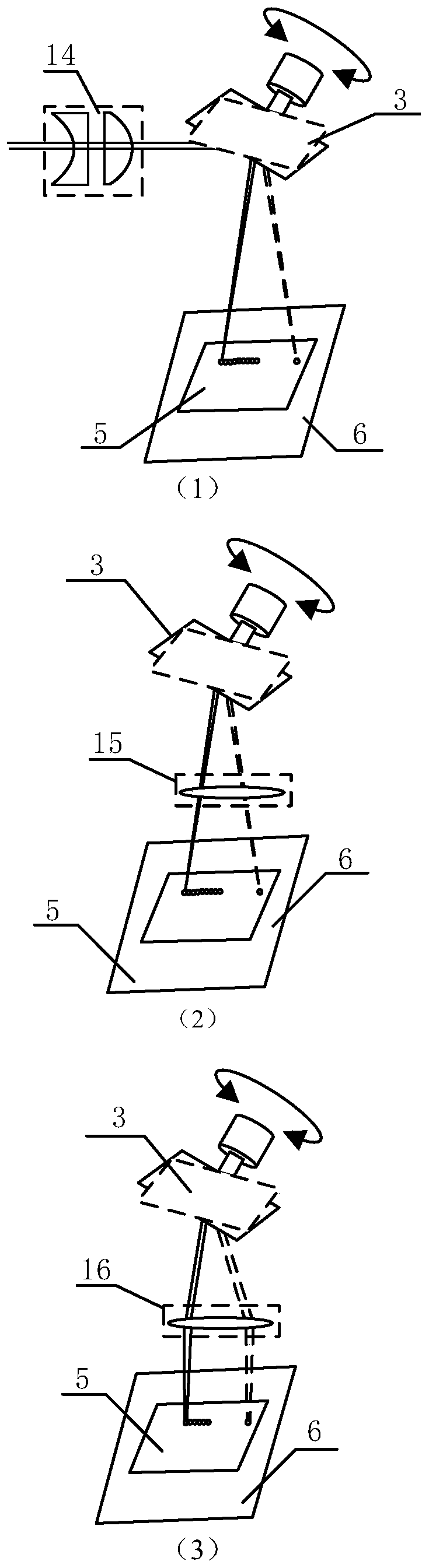

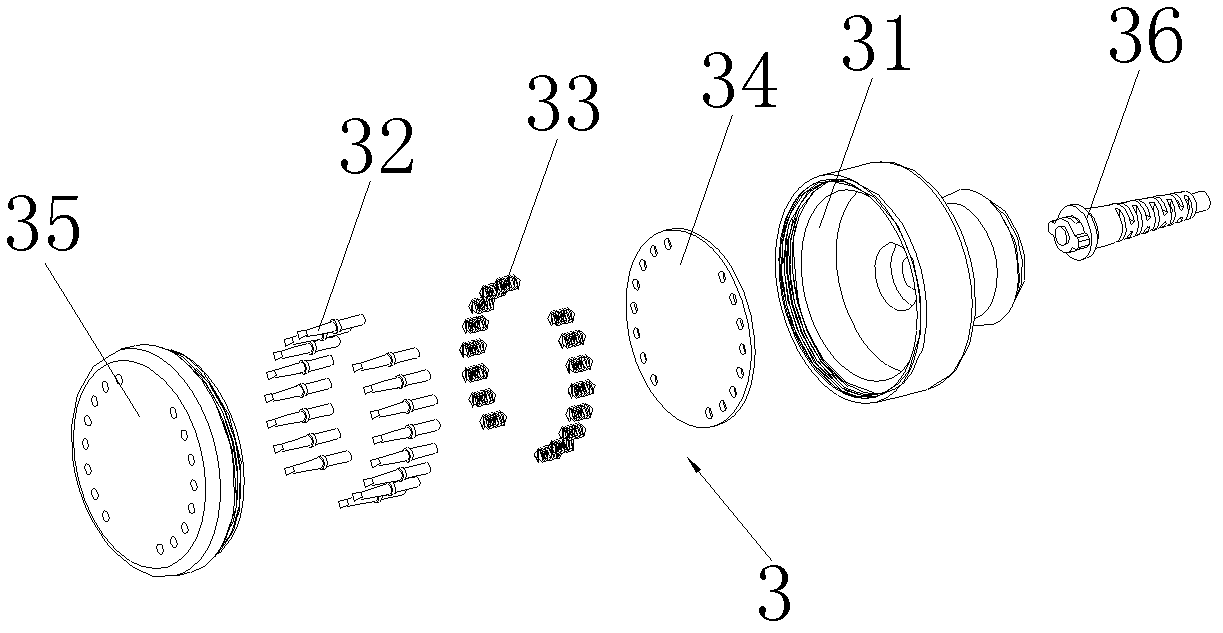

Scanning type laser shock peening device

PendingCN110205478ARealize one-dimensional high-speed scanningExpand the scope of actionLight guideGalvanometer

The invention relates to metal surface treatment, in particular to a scanning type laser shock peening device. The scanning type laser shock peening device comprises a laser, a light guide device, a restraint layer loading device, a one-dimensional scanning galvanometer and a focusing device. The light guide device is arranged between the laser and the one-dimensional scanning galvanometer. A metal part is located on an output light path of the one-dimensional scanning galvanometer. The metal part is provided with a restraint layer and a motion clamping device. The focusing device is arrangedon a light path between the light guide device and the metal part. A high-repetition-frequency low-energy laser shock peening method is high in frequency, and the machining efficiency is greatly improved.

Owner:西安天瑞达光电技术股份有限公司

Substrate repairing device and repairing method

ActiveCN104880841ARepair protrusion defectsAvoid wastingNon-linear opticsLaser transmitterOptoelectronics

The invention provides a substrate repairing device and a repairing method. The device comprises a laser emitter and an imaging unit. Being located on one side of a substrate, and with a preset height from the surface of the substrate, the laser emitter emits a first laser which is in parallel with the surface of the substrate and is used for detecting protruded defects of the substrate, and emits a second laser which is used for repairing the protruded defects requiring repair. The imaging unit is used for imaging the substrate; when it is detected that the first laser is scattered by certain protruded defects, the protruded defects are judged to be the protruded defects requiring the repair. By using the low-energy laser to detect the protruded defects and using the high-energy laser to repair the protruded defects, the substrate repairing device can efficiently repair the protruded defects of the substrate.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

Dual step source/drain extension junction anneal to reduce the junction depth: multiple-pulse low energy laser anneal coupled with rapid thermal anneal

A process is described to form a semiconductor device such as MOSFET or CMOS with shallow junctions in the source / drain extension regions. After forming the shallow trench isolations and the gate stack, sidewall dielectric spacers are removed. A pre-amorphizing implant (PAI) is performed with Ge+ or Si+ ions to form a thin PAI layer on the surface of the silicon regions adjacent to the gate stack. B+ ion implantation is then performed to form source / drain extension (SDE) regions. The B+ implant step is then followed by multiple-pulsed 248 nm KrF excimer laser anneal with pulse duration of 23 ns. This step is to reduce the sheet resistance of the junction through the activation of the boron dopant in the SDE junctions. Laser anneal is then followed by rapid thermal anneal (RTA) to repair the residual damage and also to induce out-diffusion of the boron to yield shallower junctions than the just-implanted junctions prior to RTA.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

Switchable holographic gratings

InactiveUS20060073393A1Efficient manufacturingLow costPhotosensitive materialsRadiation applicationsLight beamLaser beams

The present invention includes systems and compositions of holographic grating structures devices and methods for fabricating such holographic grating structures. The method comprises the steps of preparing a composite mixture comprising a polymerizable matrix, a liquid crystal, and a photo-oxidant dye, producing an interference pattern from two interference beams, wherein the two interference beams originate from a recording laser beam directed by a low energy laser, and projecting the interference pattern on the composite mixture to form a holographic grating structure. As described, the holographic grating structure yields a first-order diffraction efficiency of at least about 30% diffraction efficiency which may be adjusted by the application of an electric field.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Thin film transistor manufacturing method and display having the same

ActiveCN101546732AImprove uniformity of light emissionImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingCharge carrier mobilityDisplay device

An organic light emitting diode (OLED) display and thin film transistor (TFT) manufacturing method thereof are disclosed. According to the present invention, poly-silicon layers for forming active areas of non-driving TFT (e.g. peripheral circuit TFT and switch TFT) and driving TFT used in the OLED display are respectively made by using standard laser crystallization method and non-laser crystallization method or low energy laser crystallization method. Therefore, the peripheral circuit TFT has excellent electrical performance such as high carrier mobility, while the OLED-driving TFT has goodstability so that the resultant display can operate with improved luminance uniformity.

Owner:INNOLUX CORP

Method for manufacturing printed circuit board

ActiveUS20140053397A1Lower performance requirementsAvoid it happening againPrinted circuit aspectsInsulating layers/substrates workingContact padPrinted circuit board

A method for manufacturing a PCB includes certain steps. A printed circuit board sheet is provided. The printed circuit board includes an unwanted portion and a printed circuit board unit which includes a plurality of contact pads. An imaginary boundary line is defined between the printed circuit board unit and the unwanted portion. Each of the contact pads defines an outline. A nearest distance between the outline and the imaginary boundary line is less than 4 millimeters. The printed circuit board sheet is punched along the imaginary boundary line, forming one hollow portion or a plurality of through slots. A plurality of burrs is generated on an inner surface of the hollow portion or the through slots. The burrs are removed using a low-energy laser cutting process, thereby obtaining a printed circuit board. A laser power used in the low-energy laser cutting process is 5-8 watts.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Optical-fiber-guiding weak-laser coaxial composite welding gun

InactiveCN105127594AOvercome installation challengesEasy to igniteWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSilicon dioxide

The invention discloses an optical-fiber-guiding weak-laser coaxial composite welding gun, and relates to the field of laser-TIG composite welding guns. The optical-fiber-guiding weak-laser coaxial composite welding gun aims at solving the problems that in traditional single-welding-wire and single-heat-source welding, weld joints are wide, welding deformation is big, the welding speed is low, and the fusion depth is small. An electric arc is directly generated through induction of laser, a tungsten electrode is manufactured by being divided into multiple segments, an optical fiber is arranged in the tungsten electrode, and the laser is introduced into the tungsten electrode through the optical fiber and focused through a collecting lens; the length of the tungsten electrode and the length of the optical fiber are regulated through a tungsten electrode length regulator and an optical fiber regulator, the exterior of the optical fiber is provided with a silicon dioxide heat insulation coating, and a spiral cooling water channel is lathed on an inner sleeve of the composite welding gun. According to the optical-fiber-guiding weak-laser coaxial composite welding gun, the theory that low-energy laser assists electric arc welding is utilized, the laser-TIG coaxial composite design is adopted, the structure is simple and practical, not only can the basic requirements of a common welding gun be met, but also the high-precision welding electric arc very easy to ignite can be obtained, the welding production efficiency is improved, and the production and maintenance cost is lower.

Owner:QINGDAO UNIV OF SCI & TECH

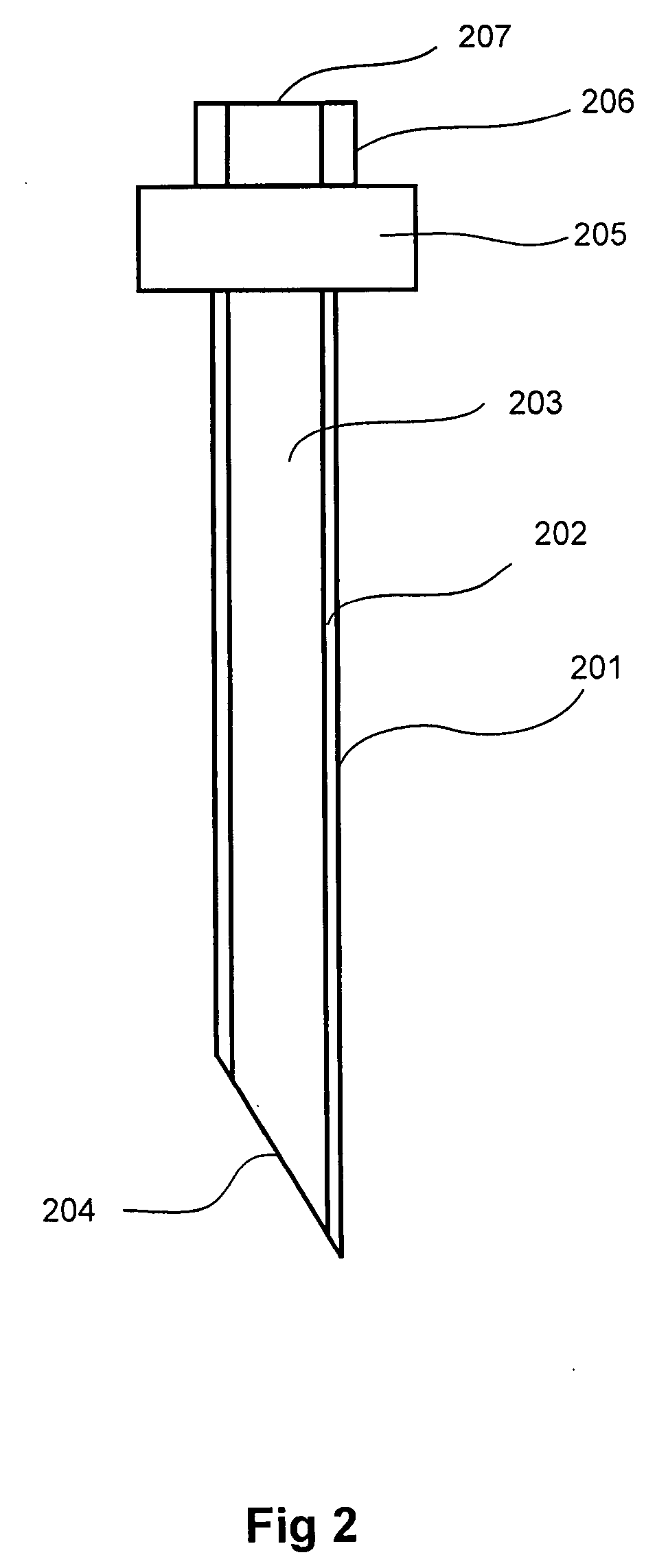

Method for modifying mechanical surface of sintered nd-fe-b magnet based on plastic constraint

ActiveCN103646776AImprove corrosion resistanceReduce impact brittlenessInductances/transformers/magnets manufactureGrain boundaryAbsorption layer

The invention discloses a method for modifying a mechanical surface of a sintered nd-fe-b magnet based on plastic constraint, and relates to surface modification technologies of permanent magnet materials. The method mainly comprises the steps that 1) the surface, to be processed, of the sintered nd-fe-b magnet is pretreated; 2) an absorption layer and a restraint layer are arranged on the surface, to be processed, of the sintered nd-fe-b magnet; 3) the unprocessed surface of the sintered nd-fe-b magnet is covered with plastic tough metal; 4) low-energy laser shock treatment is carried out on the covered surface, to be processed, of the sintered nd-fe-b magnet; 5) laser surface heat treatment is carried out on the cleaned surface of the sintered nd-fe-b magnet after the shock treatment; 6) the steps 2)-5) are repeated, the low-energy laser shock treatment and the laser surface heat treatment are carried out many times, and the sintered nd-fe-b magnet with the modified surface is obtained. The surface crystalline grains of the sintered nd-fe-b magnet can be effectively refined, surface layer grain boundary rich neodymium phase distribution can be homogenized, and the corrosion resisting performance of the sintered nd-fe-b magnet can be improved obviously. The method is simple in process, easy to operate, and suitable for large-scale and mass production.

Owner:东台城东科技创业园管理有限公司

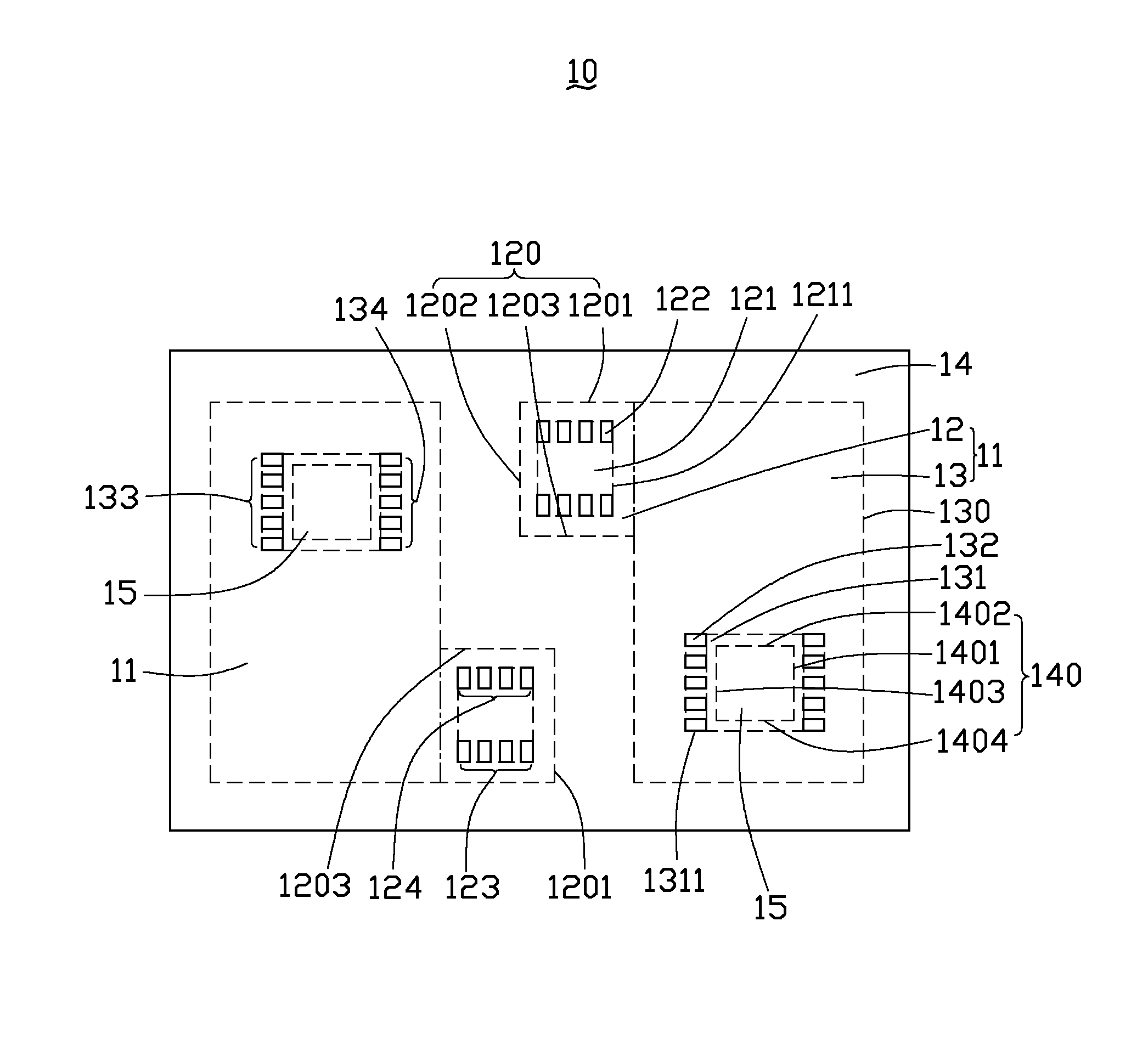

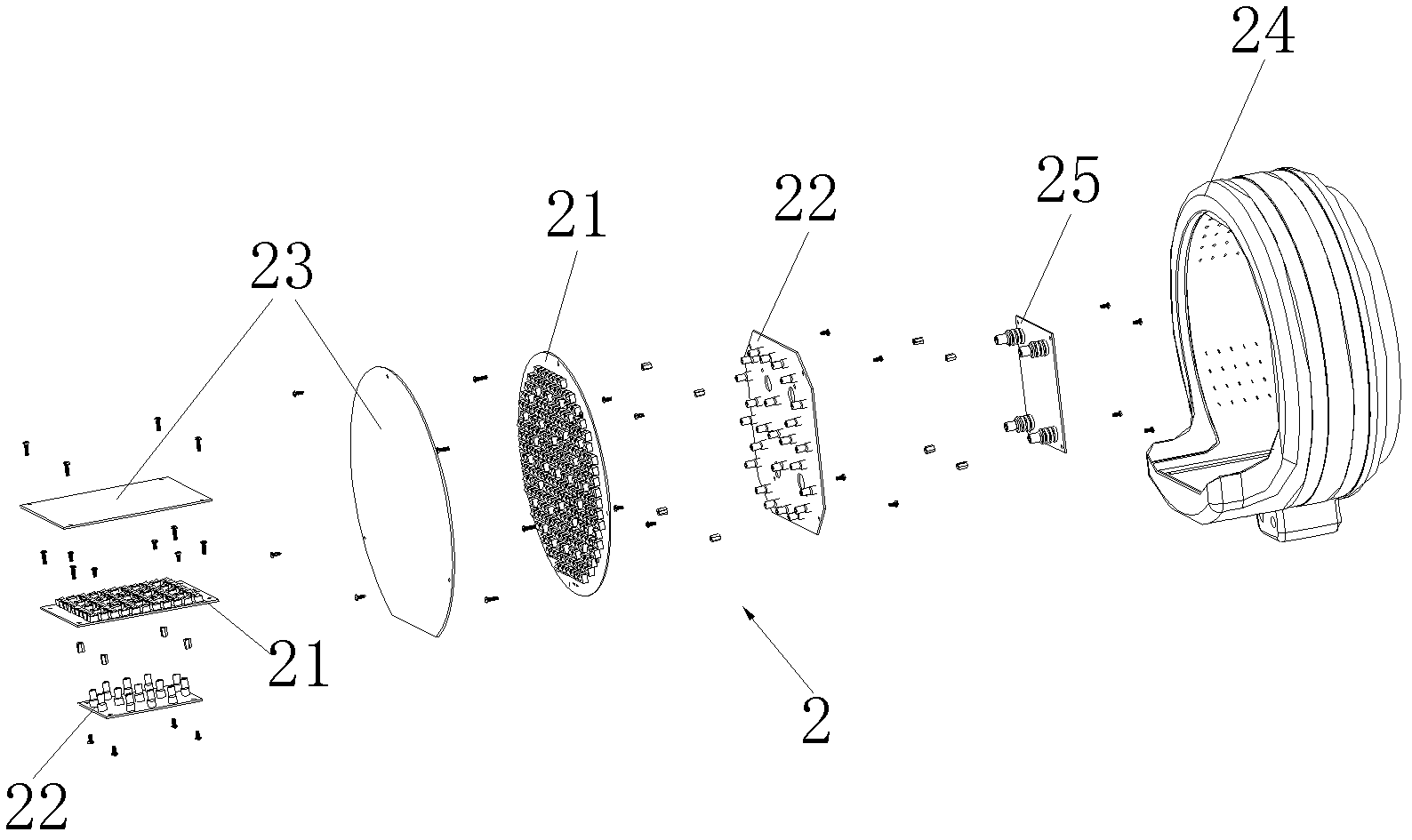

Irradiation method for hair growth

ActiveCN102488973AGood for growth and developmentTo achieve the purpose of comprehensive synergistic treatmentElectrotherapyBathing devicesElectrical impulseEngineering

The invention discloses an irradiation device for hair growth. The irradiation device comprises a machine body, a pressure swing absorption oxygen-making unit and a controller which are arranged in the machine body as well as a hair care cover and a PDT (Photon Dynamic Treatment) micro electric hair comb which are arranged outside the machine body; the pressure swing absorption oxygen-making unit absorbs external air and makes oxygen of the concentration of more than 96%; a 808-nm laser generation unit, a 650-nm laser generation unit and a first narrow spectrum cold light generation unit which are electrically connected with the controller are arranged in the hair care cover; a plurality of oxygen outlets communicated with the output end of the pressure swing absorption oxygen-making unit are formed in the hair care cover; and the PDT micro electric hair comb comprises a plurality of flexible metal probes electrically connected with the controller as well as a second narrow spectrum cold light generation unit. Compared with the prior art, the irradiation device adopts narrow spectrum cold light with three wavelengths, two kinds of low-energy laser, high purity oxygen and low frequency electric pulse to apply to the head part of a patient at the same time, thereby achieving the purpose of comprehensive co-therapy and facilitating hair growth of patients.

Owner:广州美锐健康产业股份有限公司

Perpendicular LED chip structure and preparation method therefor

ActiveCN105742417ASave energyIncrease overlapSemiconductor/solid-state device manufacturingSemiconductor devicesQuantum wellOptoelectronics

The invention provides a preparation method for a perpendicular LED chip structure. The preparation method comprises the steps of 1) providing a growth substrate, and forming an epitaxial layer on the growth substrate; 2) forming a metal electrode layer and a bonding substrate on the epitaxial layer in sequence; and 3) peeling off the growth substrate by low-energy laser, wherein the overlapping ratio of adjacent two small light spots is greater than 50%. The invention also provides the perpendicular LED chip structure, wherein the perpendicular LED chip structure comprises the bonding substrate, and the metal electrode layer, a P-GaN layer, a multi-quantum-well layer and an N-GaN layer which are positioned on the bonding substrate in sequence, and a passivation layer and an N electrode which are positioned on the surface of the N-GaN layer in sequence. By adoption of the preparation method, the problem of cracking or severe deformation of the bonding substrate easily caused by high wafer stress after bonding in the perpendicular process of the large-dimensional LED chip is solved; and meanwhile, the problems of severe electric leakage and extremely low rate of finished products directly caused by severe microcosmic influence of the epitaxial layer structure and the performance are also solved.

Owner:ENRAYTEK OPTOELECTRONICS

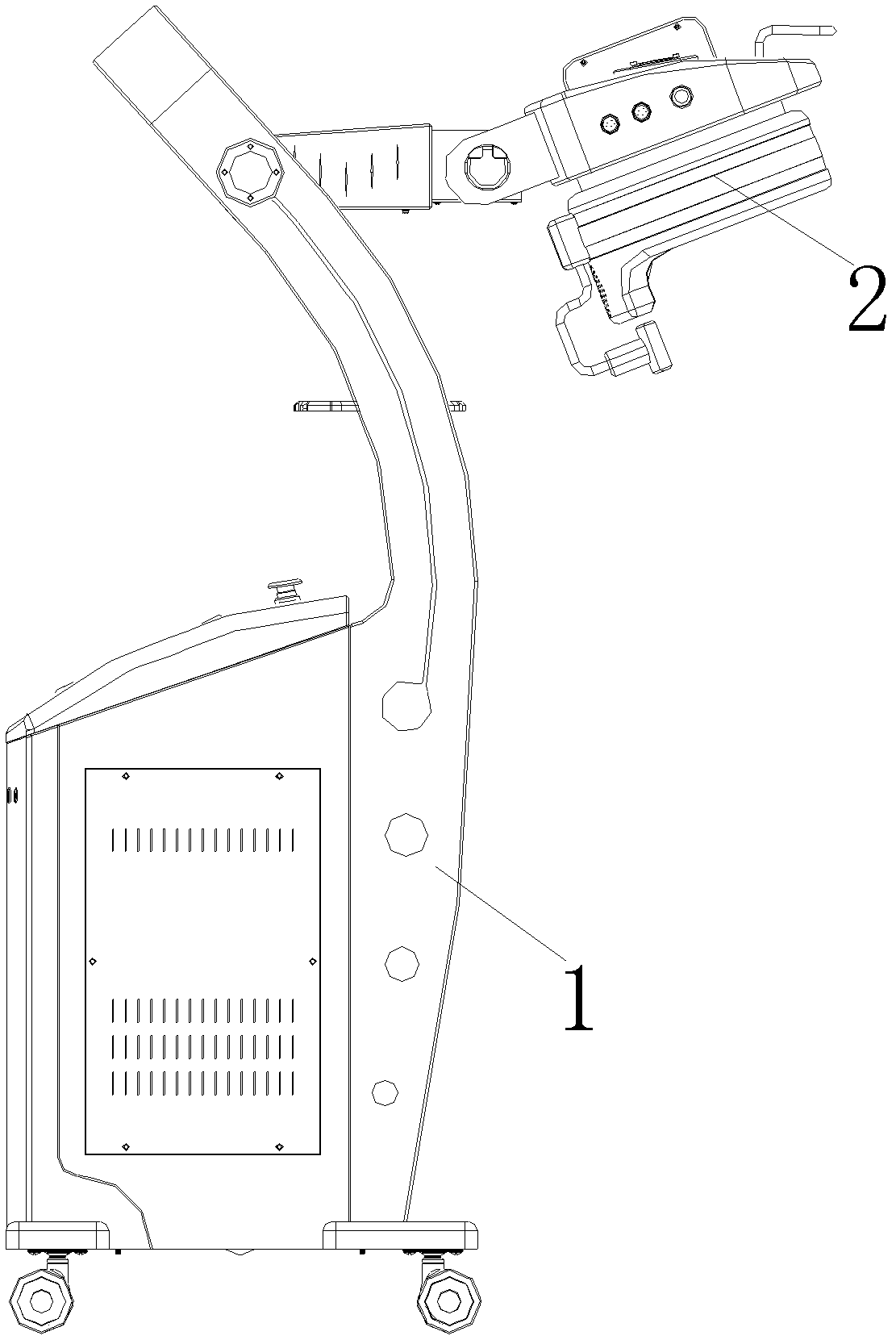

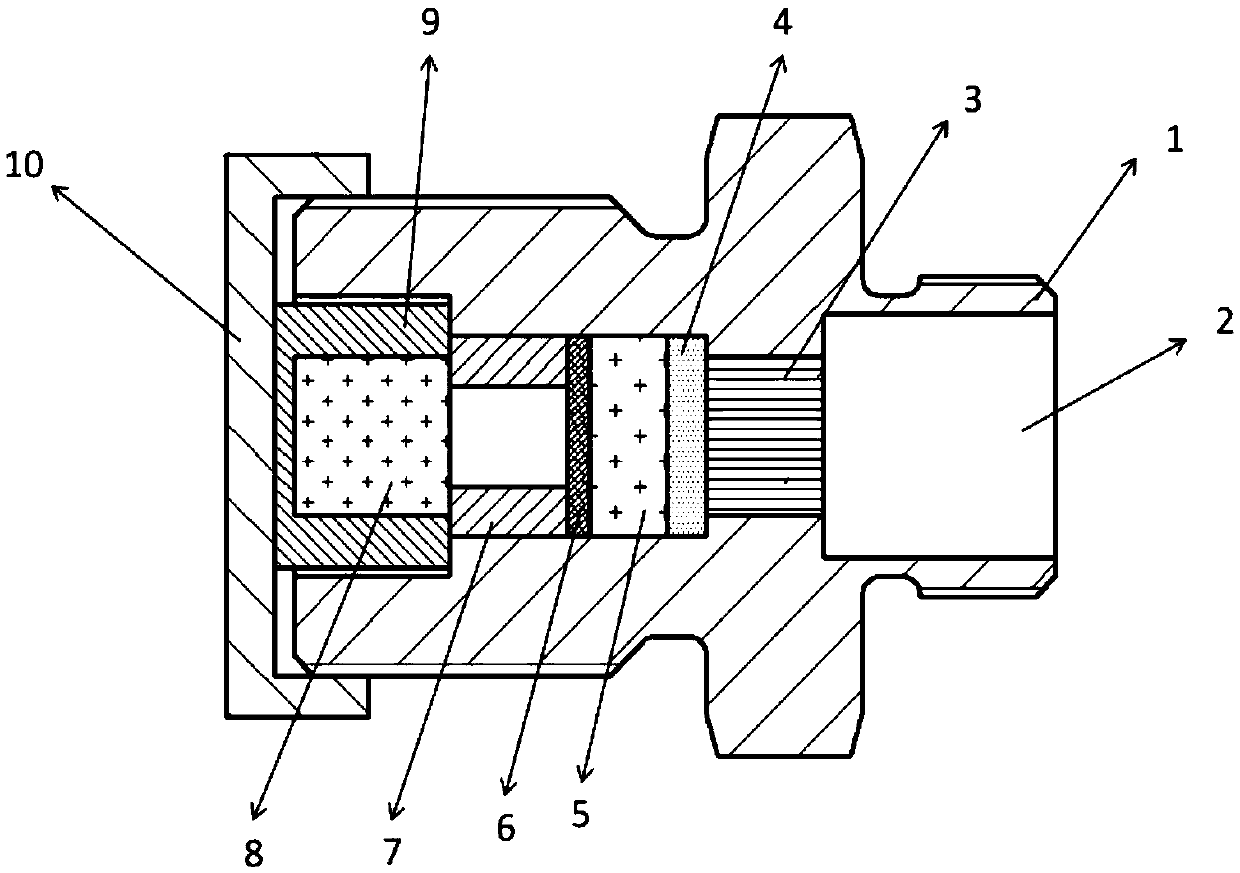

Laser shock peening device and method

The invention relates to the field of metal surface treatment, in particular to a laser shock peening device. The laser shock peening device comprises a high-repetition-frequency low-energy laser, a light guide device, a focusing device, a constrained layer loading device and a metal part, wherein one end of the light guide device is connected with the high-repetition-frequency low-energy laser, and the other end of the light guide device is connected with the focusing device; the constrained layer loading device forms a constrained layer on the surface of the metal part; a light spot output by the focusing device penetrates through the constrained layer and act on the surface of the metal part. According to the laser shock peening device, the high-repetition-frequency low-energy laser shock peening method is adopted, the frequency is relatively high, and the processing efficiency is greatly improved.

Owner:西安天瑞达光电技术股份有限公司

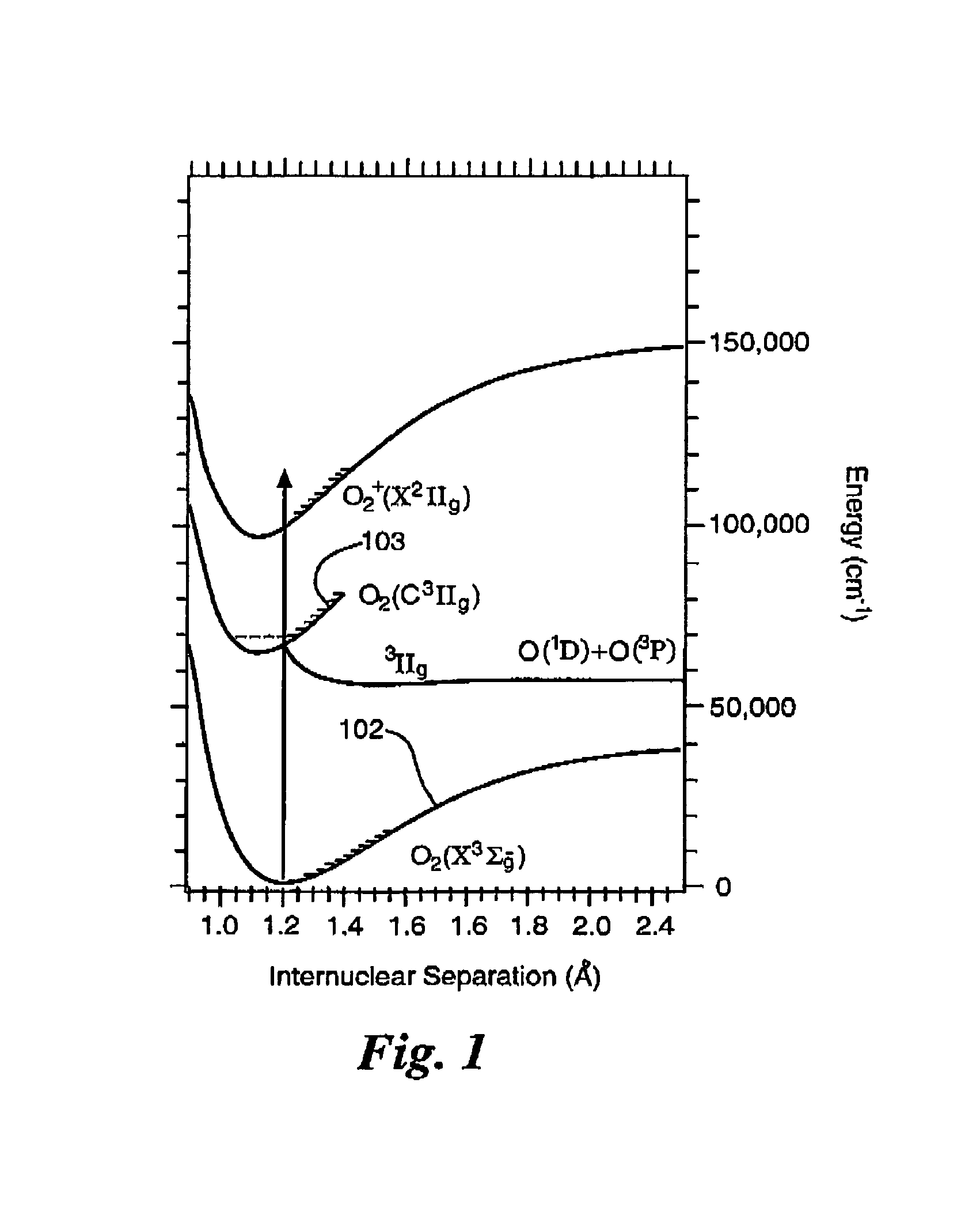

Low energy laser-induced ignition of an air-fuel mixture

ActiveUS8858222B1Eliminate needImprove directionPulsating combustionIncandescent ignitionUltravioletEngineering

A new approach for igniting an air-fuel mixture in a turbine or other engine is disclosed. Resonance-enhanced multiphoton ionization (REMPI) is used to generate volume ionization within an air-fuel flow and induce an ignition arc. The output of a relatively low energy single pulsed ultraviolet laser is aimed across an electric field inside a volume of air to create a pre-ionized channel so that a smaller voltage electric field is sufficient to create an electrical arc that follows the pre-ionized channel and will ignite an air-fuel mixture. Because the arc follows the pre-ionized channel, it can be directed to an optimal location inside an ignition volume for igniting the air-fuel mixture. A specific example embodiment is described using a 287.5 nm wavelength pulsed ultraviolet laser to excite ground state oxygen molecules to a specific excited state having a coincident term energy with a specific nitrogen molecule excited state.

Owner:AIR FORCE UNITED STATES OF AMERICA AS REPRESETED BY THE SEC OF THE THE

Method for reducing laser detonation energy

The invention discloses a method for reducing laser detonation energy. The method is realized based on a low-energy laser detonator, laser is transmitted to ignition powder through an optical fiber, and the ignition powder is ignited; combustion to detonation design is utilized, initiating explosive is ignited by the ignition powder, the initiating explosive generates a combustion rotary detonation process, and the detonation output of the initiating explosive is realized; then metal flying sheet is driven through the initiating explosive detonation, so that the metal flying sheet hits at highspeed and detonates insensitive explosive, thereby achieving the low energy detonation of the insensitive explosive. According to the method for reducing laser detonation energy, full-fiber transmission can be realized in the whole detonation process, and the safety and reliability of weapons can be greatly improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Metal material toughening treatment method

InactiveCN107794364AImprove toughnessImprove surface qualitySolid state diffusion coatingHigh power lasersIsomerisms

The invention discloses a metal material toughening treatment method comprising the following steps that grinding, polishing, washing and drying pretreatment are conducted on the surface of metal material; selective-area strengthening and toughening treatment is conducted on the pretreated metal material through a high-power laser beam or an electron beam or an ion beam, and a heterogeneous isomerism type reinforcement phase is obtained on the surface of a base material; boriding treatment is conducted on the surface of the metal material obtained after selective-area strengthening and toughening treatment; magnetic field nitriding treatment is conducted on the surface of the boronized metal material; then low-energy laser shot blasting treatment is conducted on the surface obtained aftermagnetic field nitriding; and then magnetic field quenching is conducted on the surface obtained after low-energy laser shot blasting treatment, and the flat high-strength-toughness surface is obtained. Through the metal material toughening treatment method, strength and toughness of the surface of the metal material can be improved significantly, service life of the metal material is prolonged, and the needs of practical application are met.

Owner:XIAN AERONAUTICAL POLYTECHNIC INST

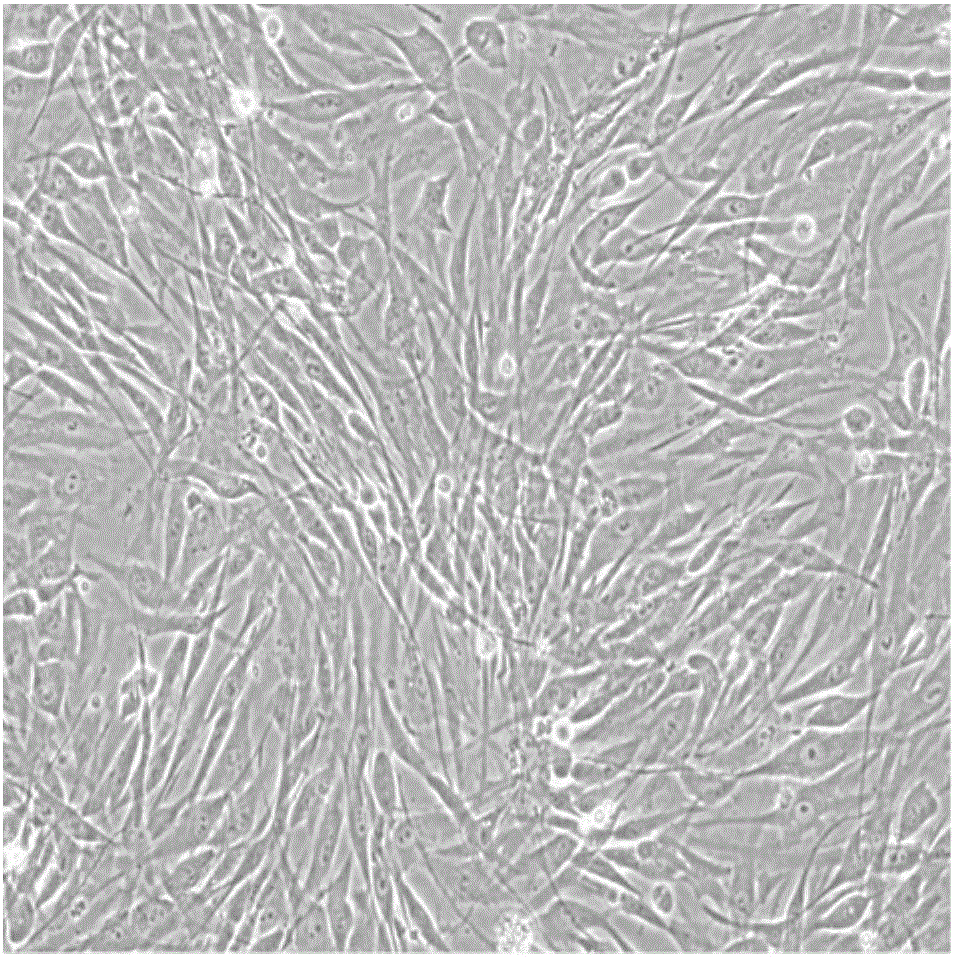

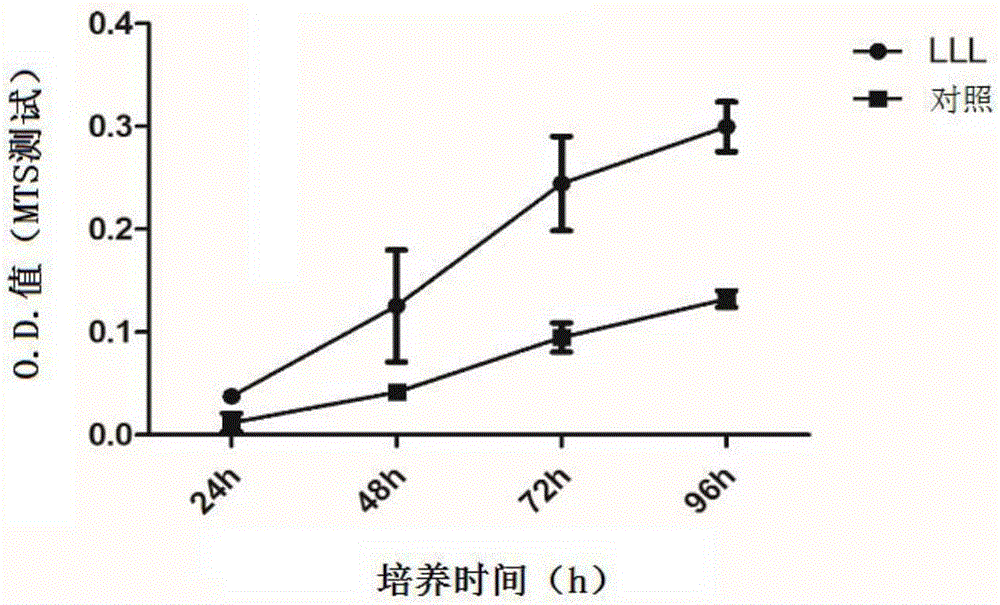

Pretreatment method of human adipose-derived mesenchymal stem cells

InactiveCN106801035AIncreased proliferationImprove migration abilitySkeletal/connective tissue cellsUnknown materialsPretreatment methodMesenchymal stem cell

The invention provides a pretreatment method of human adipose-derived mesenchymal stem cells. The pretreatment method comprises the steps of (a) providing the human adipose-derived mesenchymal stem cells; (b) carrying out primary culture on the human adipose-derived mesenchymal stem cells; (c) carrying out secondary culture on the human adipose-derived mesenchymal stem cells; (d) adopting low energy laser with a wavelength of 660nm+ / -20nm to irradiate the human adipose-derived mesenchymal stem cells in a process of the secondary culture, wherein the irradiation dose is 11-16J / cm<2>; (e) obtaining the treated human adipose-derived mesenchymal stem cells. The method can maintain the cytological characteristics of the human adipose-derived mesenchymal stem cells (hAD-MSCs) and effectively improve the proliferation ability and transfer ability of the hAD-MSCs by means of radiation treatment, thus being used for a pretreatment scheme of stem cell transplantation.

Owner:THE INST OF BASIC MEDICAL SCI OF CHINESE ACAD OF MEDICAL SCI

Process for obtaining metal oxides by low energy laser pulses irradiation of metal films

InactiveUS20130171373A1Short laser irradiation timeShort timeRadiation applicationsVacuum evaporation coatingAlloyMaterials science

The present invention relates to processes for obtaining metal oxides by irradiation of low energy laser pulses of metal layers, wherein said metals can be formed as simple metals, alloys, or multilayers. The present invention performs the oxidation of a thin metal film deposited on a substrate; e.g., glass (SiO2) or silicon (Si) by a laser-irradiation time of a few nanoseconds to femtoseconds at high repetition rate, time necessary to achieve a stoichiometry and a well-defined microscopic structure. Through the processes of the invention, it is possible to obtain complex structures and metal oxides at room temperature in a very short time and with very low energy consumption.

Owner:CENT DE INVESTIGACION CIENTIFICA Y DE EDUCACION SUPERIOR DE ENSENADA BAJA CALIFORNIA CICESE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com