Substrate repairing device and repairing method

A substrate repair and substrate technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of abrasive belt breakage, long repair time, and low efficiency, and achieve the effects of avoiding waste, reducing loss rate, and improving repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

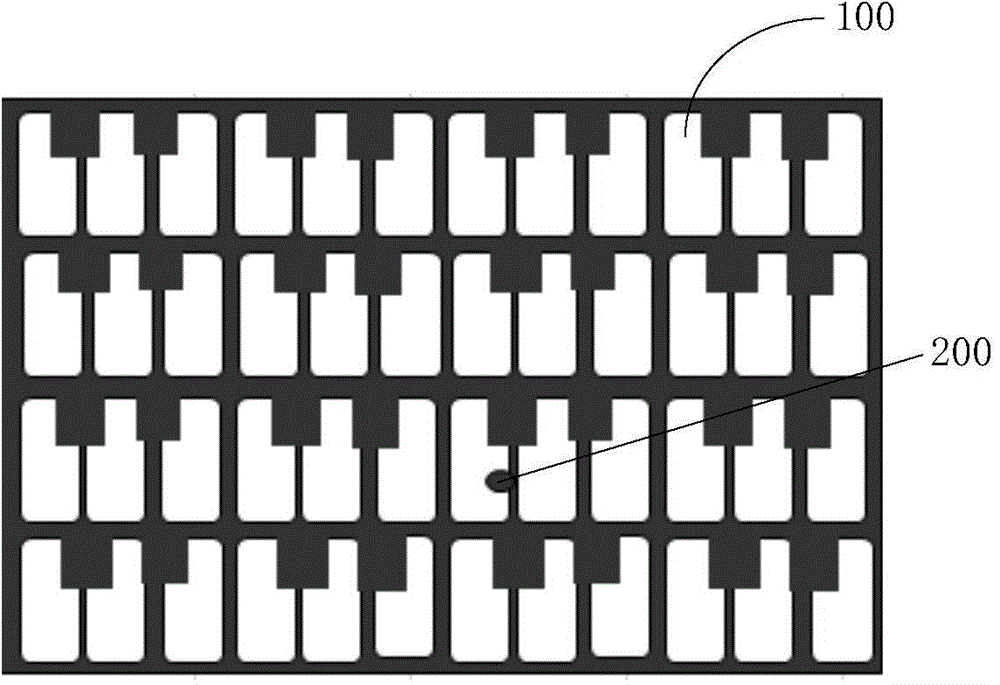

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0031] In one embodiment of the present invention, a substrate repairing device is provided.

[0032] Figure 4 A schematic diagram of the substrate repairing device of the present invention is shown. Figure 5 A schematic diagram showing the repairing of the substrate by the first laser of the substrate repairing device of the present invention.

[0033] refer to Figure 4 and Figure 5 , the substrate repairing device provided by the present invention specifically includes a laser emitter 201 and an imaging unit 202 .

[0034] In this embodiment, the laser emitter 201 is located on one side of the substrate, and the laser emitter 201 can emit a first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com