Thin film transistor manufacturing method and display having the same

A thin-film transistor and display technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of low yield rate of AMOLED products, uneven stripe-like light emission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical content of the present invention will be described in detail below with reference to the drawings.

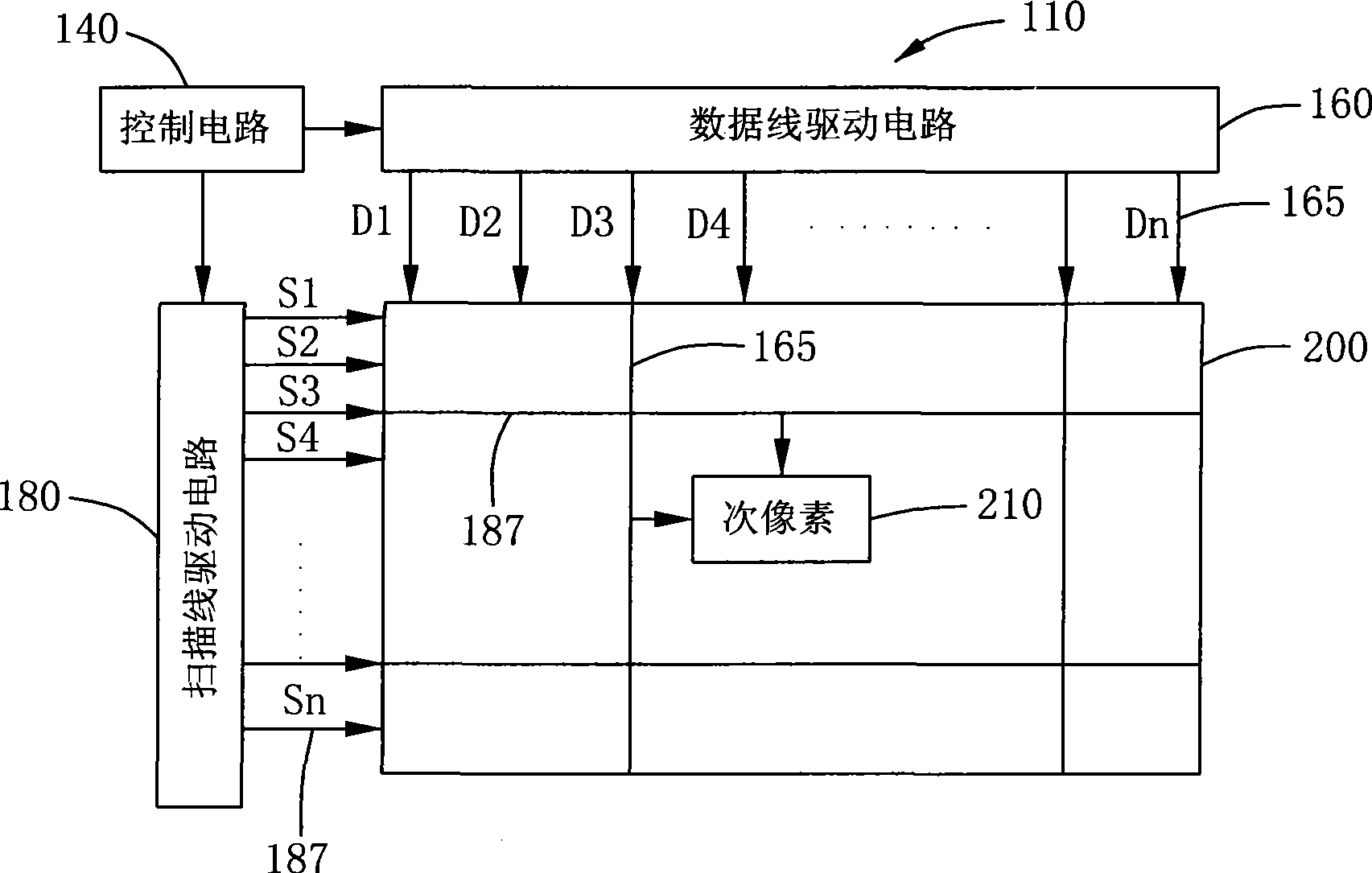

[0016] figure 1 The basic circuit structure of an active matrix organic light emitting diode (AMOLED) display 110 is shown. The OLED display 110 includes a control circuit 140 , a data line driving circuit 160 , a scanning line driving circuit 180 and a display panel 200 . The display panel 200 has a plurality of sub-pixels 210, and each pixel 210 is connected to a data line (D1 to Dn) 165 and a scan line (S1 to Sn) 187 to form a matrix. The sub-pixel 210 receives the image data signal of the data line driving circuit 160 and the switching / addressing signal of the scanning line driving circuit 180 via the data line 165 and the scanning line 187 . The data line driving circuit 160 and the scanning line driving circuit 180 are controlled by the control circuit 140 .

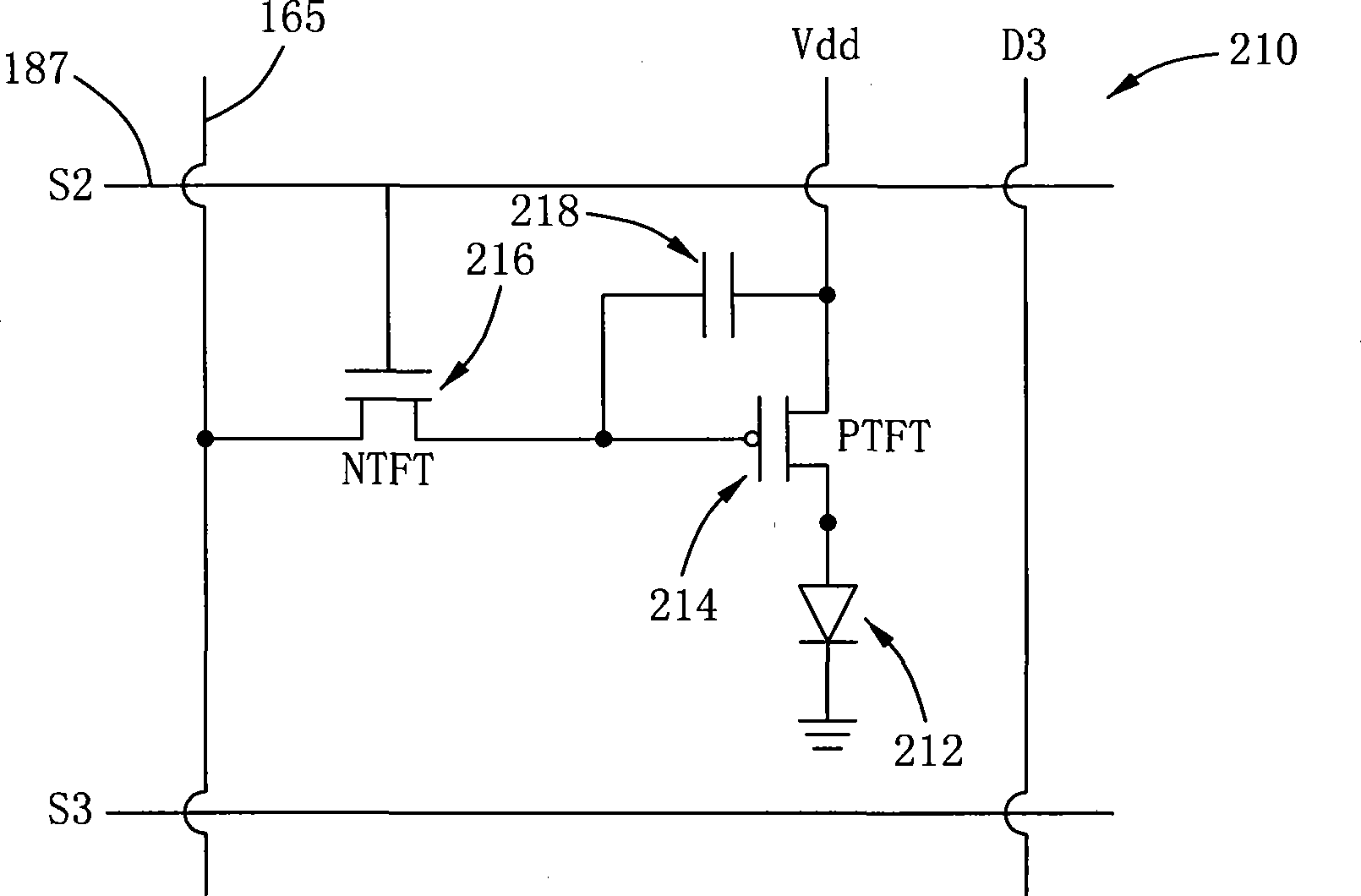

[0017] The circuit design of a sub-pixel may include a plurality of thin film transistors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com