Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

160 results about "Germanium tetrachloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Germanium tetrachloride is a colourless, fuming liquid with a peculiar, acidic odour. It is used as an intermediate in the production of purified germanium metal. In recent years, GeCl₄ usage has increased substantially due to its use as a reagent for fiber optic production.

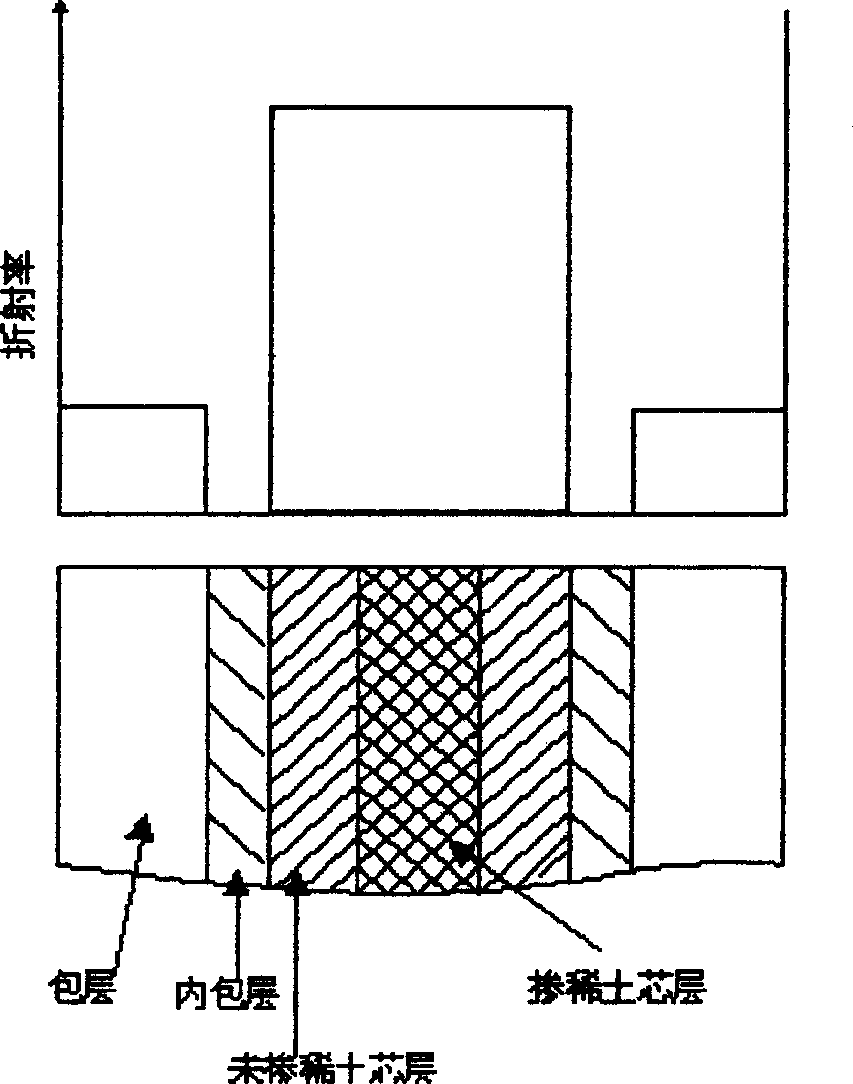

Method for manufacturing rare earth extended fibre-optical prefabricated bar

InactiveCN1490267APrecise control of doping amountImprove performanceGlass shaping apparatusGlass deposition burnersGas phaseRare earth

A process for preparing the prefabricated RE-doped optical-fibre rod features that the chemical gas-phase deposition of plasma is used to deposit the doped SiO2 layer on the inner surface of liner quartz tube and the evaporator is used to directly deliver the RE compound and other codoping agent into reaction tube for direct deposition without pollution.

Owner:FENGHUO COMM SCI & TECH CO LTD

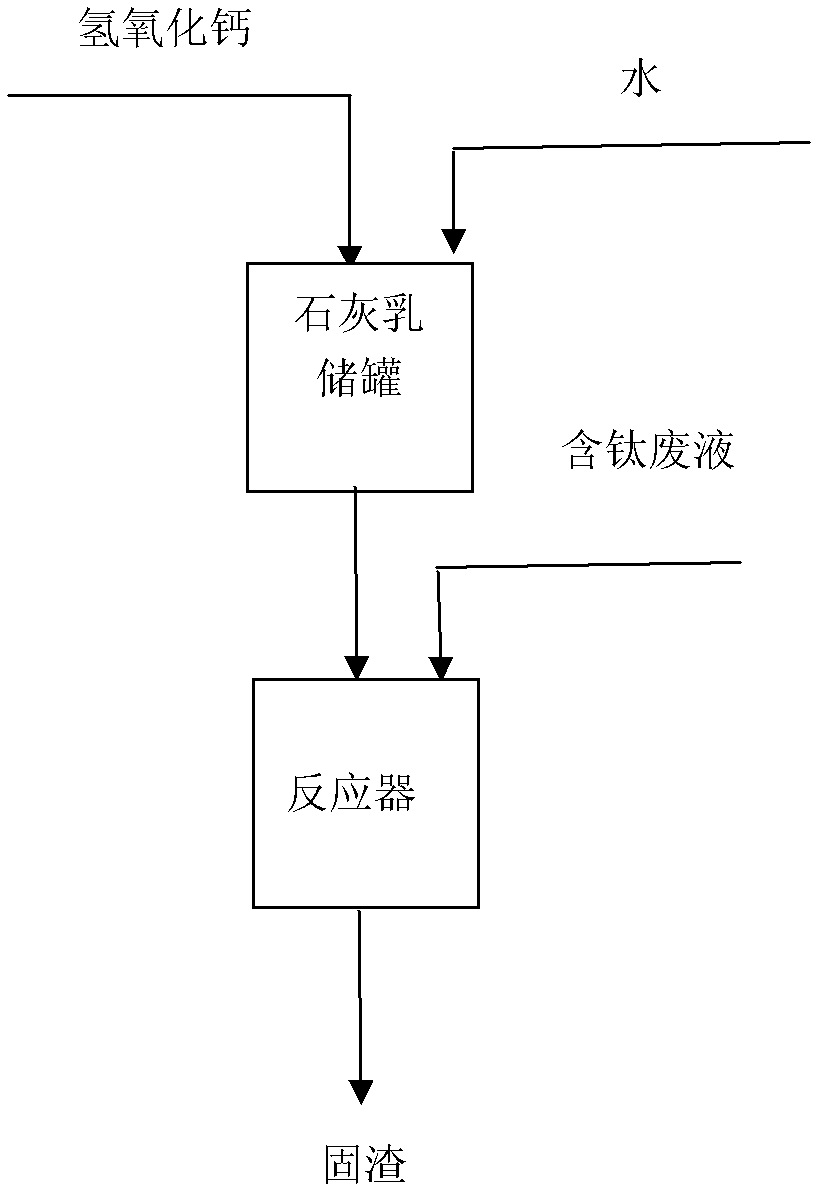

Method for treating titanium tetrachloride-containing waste liquid

InactiveCN103028224AEasy to follow upReduce the amount of waterChemical protectionLiquid wasteReaction temperature

The invention discloses a method for treating a titanium-containing waste liquid, which belongs to the field of treatment of industrial waste liquids. The method comprises the following process steps of: preparing white lime (Ca(OH)2) and water into lime milk according to a certain proportion in a lime milk storage tank; putting a certain amount of the prepared lime milk into a reactor; and directly adding a certain amount of titanium-containing waste liquid into the reactor, controlling the adding speed of the titanium-containing waste liquid, keeping the reaction temperature below or equal to 90 DEG C, and finally reacting to form solid waste residues TiO2 / CaCl2.nH2O. White lime is taken as an alkali neutralizing agent, and the titanium-containing waste liquid directly undergoes a hydrolysis neutralizing reaction with lime milk without a hydrolysis reaction, so that the amount of water needed in the conventional method is saved, and solid waste residues are taken as a final treatment product and are convenient to transport; and moreover, conventional measures such as burning and landfilling can be adopted in a subsequent treatment way, so that the treatment cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

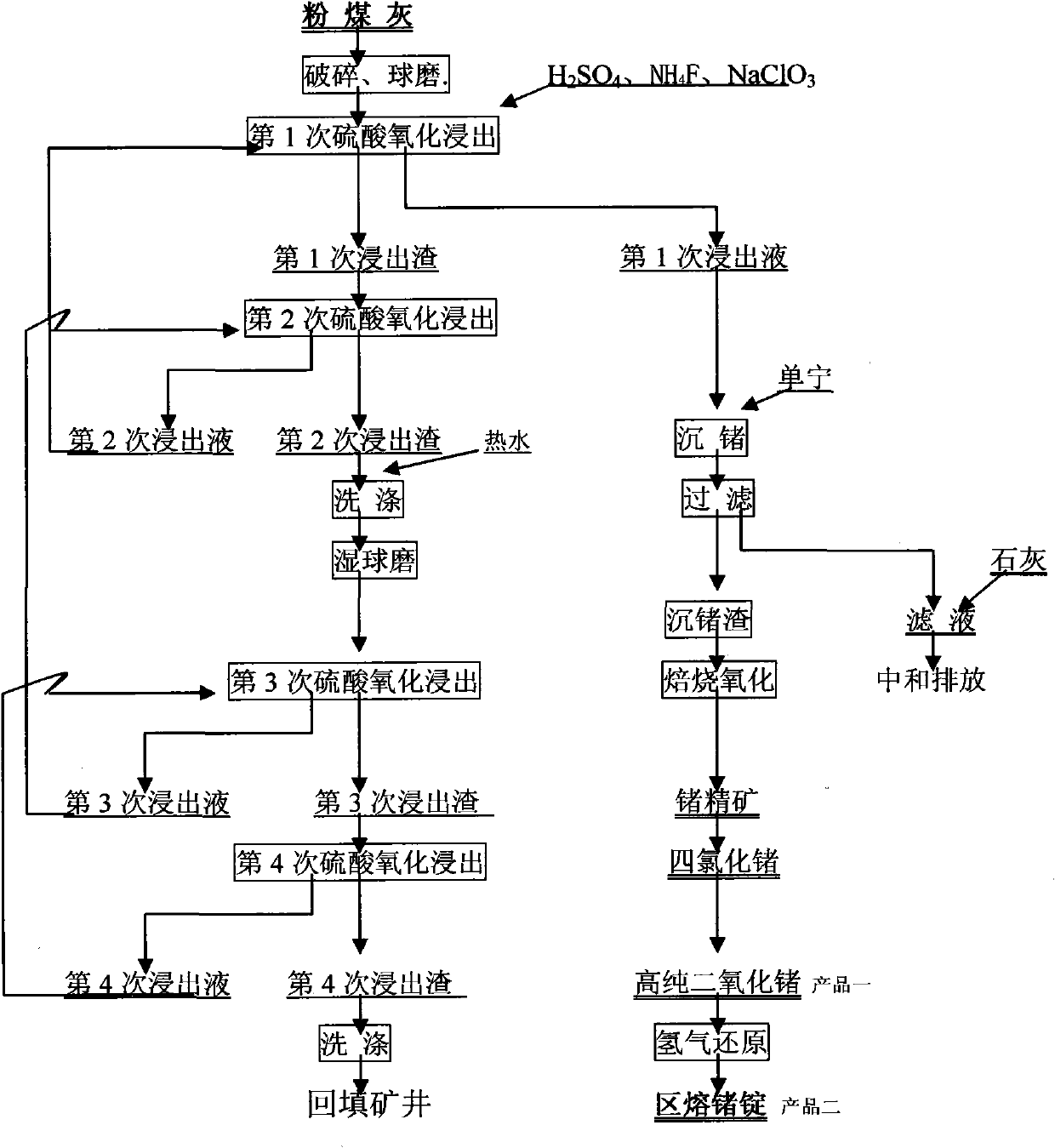

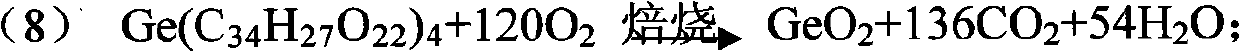

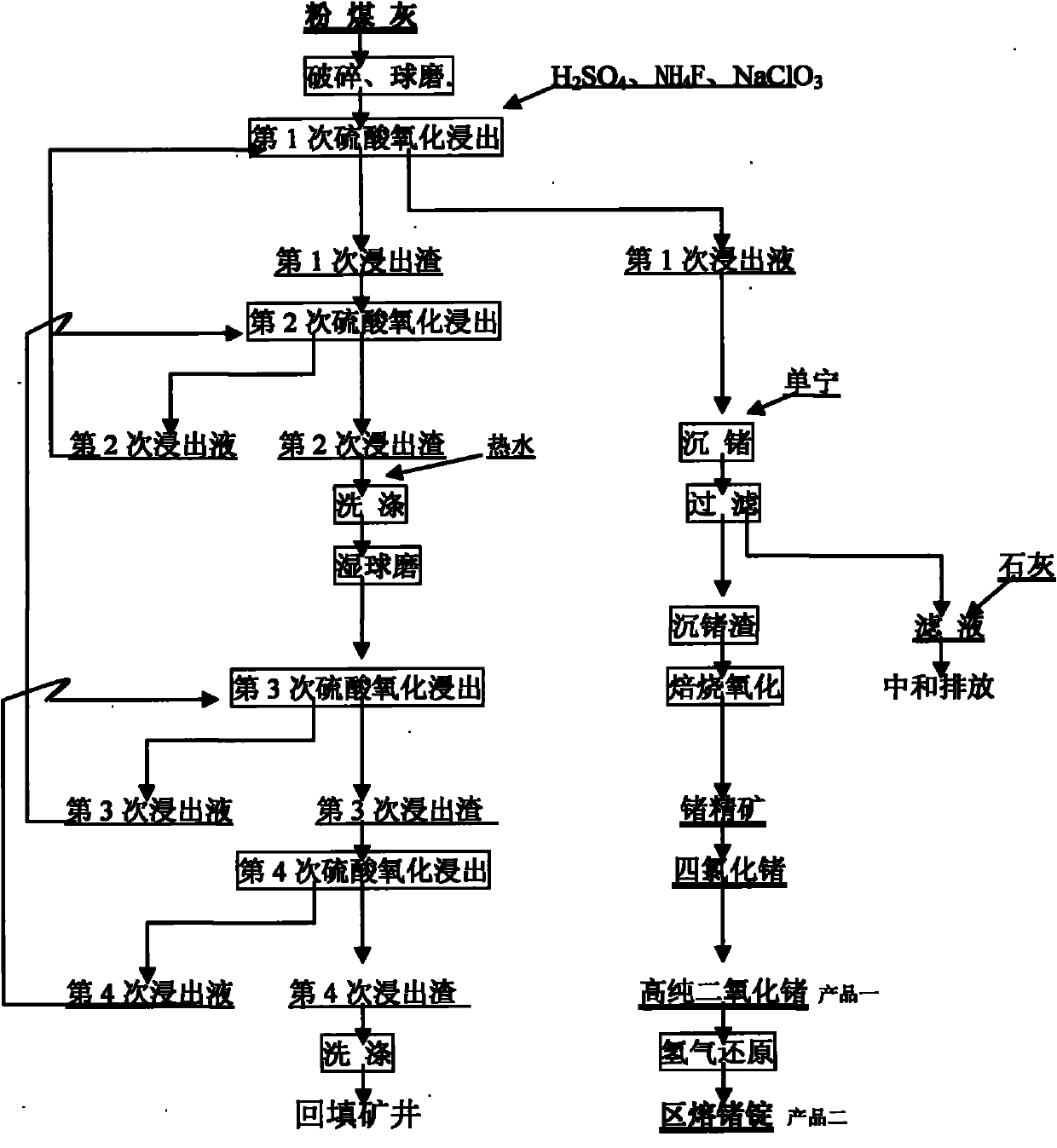

Method for recovering germanium from flyash by wet process

InactiveCN101906542ATake advantage ofReduce pollutionProcess efficiency improvementSodium chlorateHydrometallurgy

The invention relates to a method for recovering germanium from flyash by a wet process, belonging to the technical field of wet-process metallurgy. The method comprises the following steps of: (1) crushing flyash to more than 200 meshes by a wet process; (2) carrying out oxidizing leaching twice on wet flyash by using a sulfuric acid solution, sodium chlorate and ammonium fluoride; (3) crushing the flyash to 200-400 meshes for a second time; (4) leaching 3 or 4 times by using the same condition as that of the first leaching; (5) regulating the pH value of the first leached liquid to 2-2.5 by using ammonia water, and then precipitating and leaching out germanium in the liquid by using tannin with a weight percentage content of 80-99 percent; (6) drying and roasting the germanium precipitate to prepare a germanium concentrate; distilling the germanium concentrate with hydrochloric acid by using a conventional method to obtain germanium tetrachloride; and redistilling, rectifying, purifying and hydrolyzing to obtain high-purity germanium dioxide. The invention is used for flyash after recovering germanium by a fire process, sufficiently utilizes rare germanium metal, reduces the pollution of tailings to the environment, and has the advantages of low cost and high recovery rate.

Owner:JIUJIANG BAIDUN VANADIUM TECH TRADING

Method for recovering germanium from zinc dross

ActiveCN101760653ANo pollution in the processSolve the technical problems of recyclingProcess efficiency improvementIndiumEvaporation

Then invention relates to a method for recovering germanium from zinc dross, belonging to the technical field of non-ferrous metallurgy. After the secondary extracted zinc is leached by adopting the wet method, and the leached dross can be pre-treated, the germanium can be converted into the germanic from the low-valence in metal or germanium monoxide. Namely, hydrogen peroxide is used for oxidizing germanium, lead, indium, arsenic and other elements in the hydrochloric acid medium, so that the elements can be oxidized from low valence to high valence; the lead, indium, arsenic, gallium and the like react into solution, the low-valence germanium wrapped by the elements can be exposed and oxidized to be the germanic by the hydrogen peroxide under the acid condition into hydrochloric acid solution, and the germanic can escape in a form of germanium tetrachloride by evaporation, so as to realize the separation with other purities; and then, the separated germanium tetrachloride is purified and hydrolyzed, so as to prepare germanium dioxide. In the zinc dross with the germanic being more than 2.0%, the recovery rate of the germanic can reach more than 98%; in the zinc dross with the germanic being more than 1.0-2.0%, the recovery rate of the germanic can reach more than 95%; and in the zinc dross with the germanic being 0.1-1.0%, the recovery rate of the germanic can reach more than 90%.

Owner:YUNNAN WUXIN IND

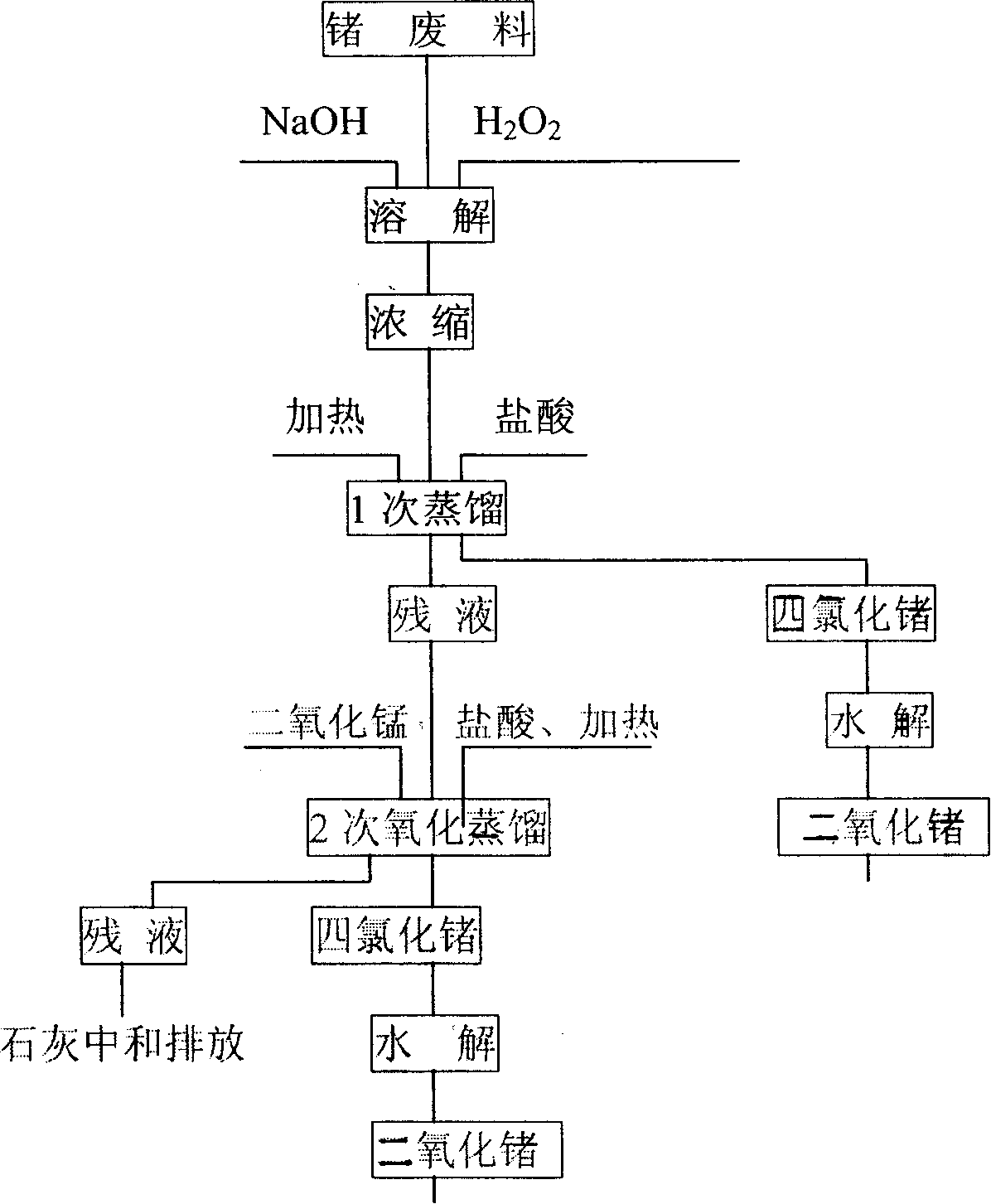

Reclamation of germanium from chromium-germanium alloy waste material by wet method

ActiveCN101186973ASolve the problem of low recovery rate of extracted germaniumDistillationMetal impurities

Provided is a process of germanium wet-recovery from chromium-germanium alloy waste. The invention provides a process for recovering germanium aiming at that chromium-germanium alloy contains multiple metallic impurities, and germanium waste material is mixed with a vast amount of organic materials due to the employment of organic solvent in process of mutually wrapping and cutting of the chromium-germanium. A dissolution system of NaOH-H2O2 is employed to destroy organic matters in the waste material, which enables the organic matters to be saponified in NaOH, H2O2 is employed to oxygenize the bare metal germanium in the waste material, which enables the metal germanium to turn into ions which enter solution, then hydrochloric acid is employed to neutralize excessive alkali and distill out dissolved germanium, further hydrochloric acid in hydrochloric acid-MnO2 system is employed to react with chromium and part of metal impurities to enter the solution, the other part of the metal impurities which do not react with the hydrochloric acid is oxidized by chlorine gas to enter the solution, the chlorine gas is generated by the reaction of MnO2 and the hydrochloric acid, germanium wrapped by the impurities is released to react with the chlorine gas to form Ge4+ ions, the Ge4+ ions are combined with chloride ions to form germanium tetrachloride which then escapes after secondary distillation, thereby being separated from the other impurities. The recovery ratio by employing the germanium recovering process reaches above 99%.

Owner:YUNNAN LINCANG XINYUAN GERMANIUM IND +1

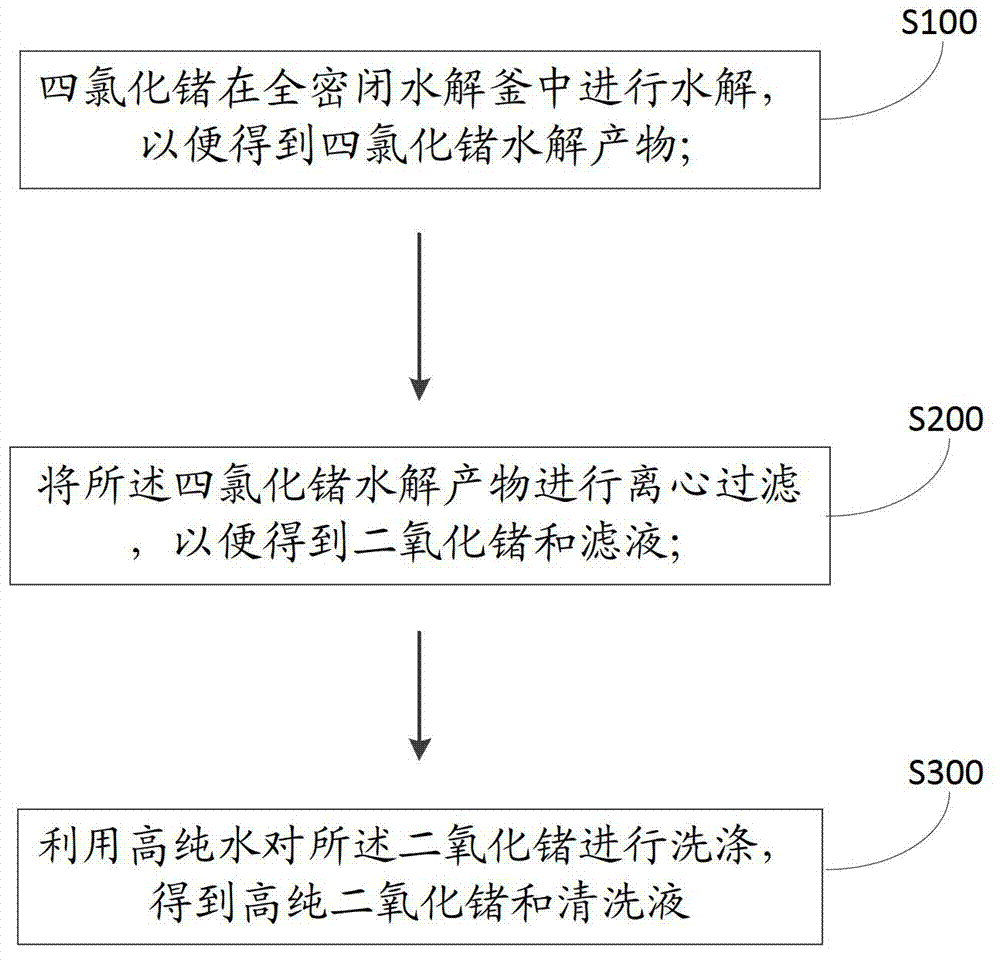

Novel process for preparing germanium dioxide (GeO2)

ActiveCN102774877AReduce lossesHigh degree of automationGermanium dioxideGermanium dioxideHydrolysis

The invention provides a method for preparing germanium dioxide (GeO2). According to the embodiment of the invention, the method comprises the following steps: hydrolyzing the germanium tetrachloride(GeCl4) in a fully-closed hydrolysis reactor to obtain the hydrolysis product of the GeCl4, centrifuging and filtering the hydrolysis product of the GeCl4 to obtain the GeO2 and the filtrate, and cleaning the GeO2 by high-purity water to obtain the high-purity GeO2 and the cleaning solution. According to the embodiment of the invention, the GeO2 hydrolyzing, filtrating and washing method and device have the advantages of high degree of automation, high GeO2 hydrolysis yield, good solid-liquid centrifugal separation effect, low production costs, less metal loss and environment friendliness.

Owner:云南驰宏国际锗业有限公司

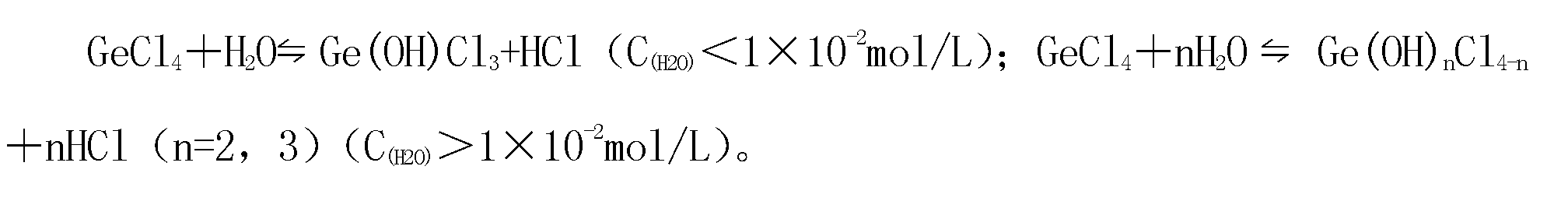

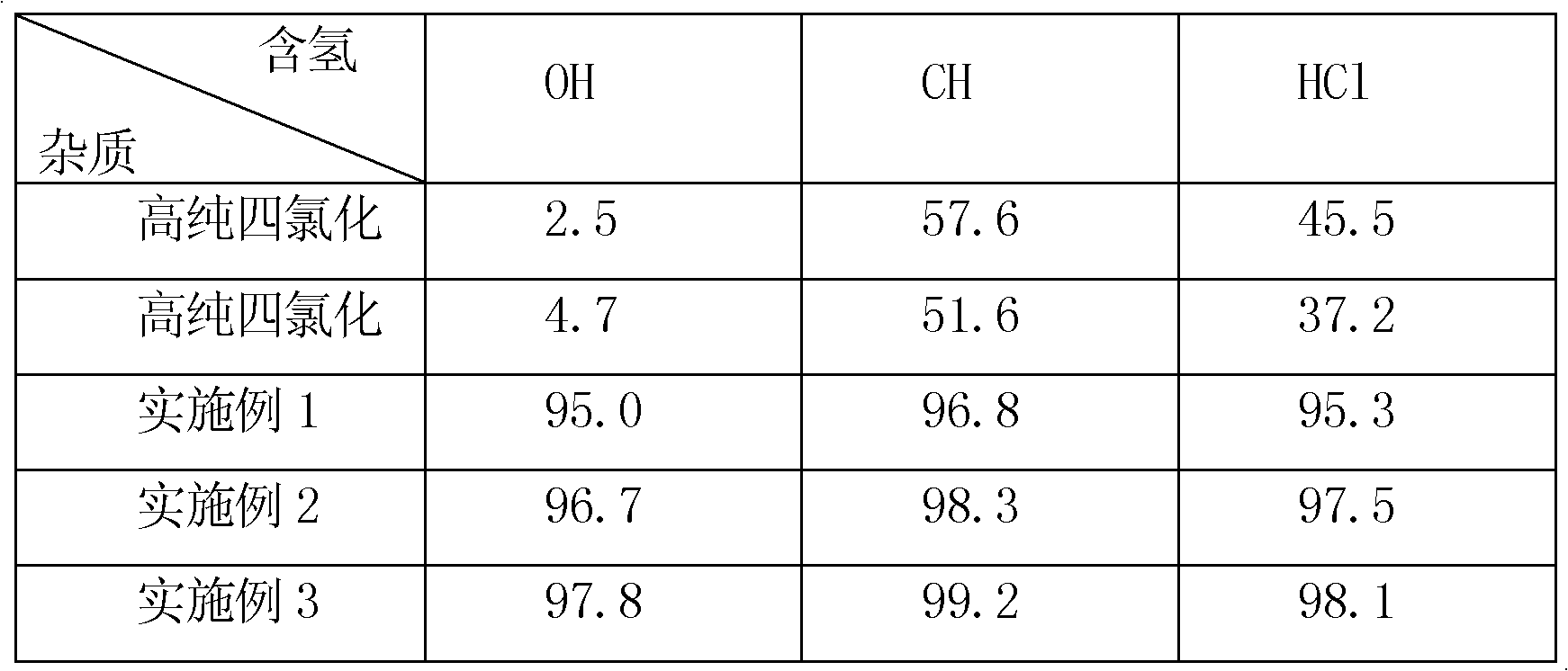

Preparation purification method of germanium tetrachloride for optical fiber

InactiveCN103183375AMeet the requirements of germanium tetrachlorideSuitable for mass production applicationsGermanium halidesPurification methodsDistillation

The invention provides a preparation purification method of germanium tetrachloride for optical fibers, which adopts germanium concentrate as a raw material; hydrochloric acid, sulfuric acid, and ferric trichloride are added into a chlorination reaction vessel according to a certain proportion for reaction to prepare crude germanium tetrachloride; the crude germanium tetrachloride is fully mixed with hydrochloric acid and manganese dioxide according to a certain proportion in a repeated distillation reaction vessel for distillation and purification to obtain preliminarily purified germanium tetrachloride; the germanium tetrachloride after repeated distillation purification is processed in a quartz rectifying tower in inert atmosphere by controlling a tower bottom temperature to be 75-95 DEG C, a tower column temperature to be 30-95 DEG C, and a reflux ratio of 4:1-14:1, so as to obtain high-purity germanium tetrachloride. The high-purity germanium tetrachloride prepared through three procedures of chlorination distillation, repeated distillation, and rectification purification, has a content of transition metal impurities of less than 3 ppb, a content of hydrogen-containing impurities of less than 1 ppm, and meets the requirements for perform rod germanium tetrachloride for optical fibers.

Owner:GRINM ELECTRO OPTIC MATERIALS

Preparation method of low-chloride high-purity germanium dioxide

InactiveCN106564933ALow chlorine contentAvoid insufficient hydrolysisGermanium dioxideFiltrationNitrogen

Owner:YUNNAN LINCANG XINYUAN GERMANIUM IND +1

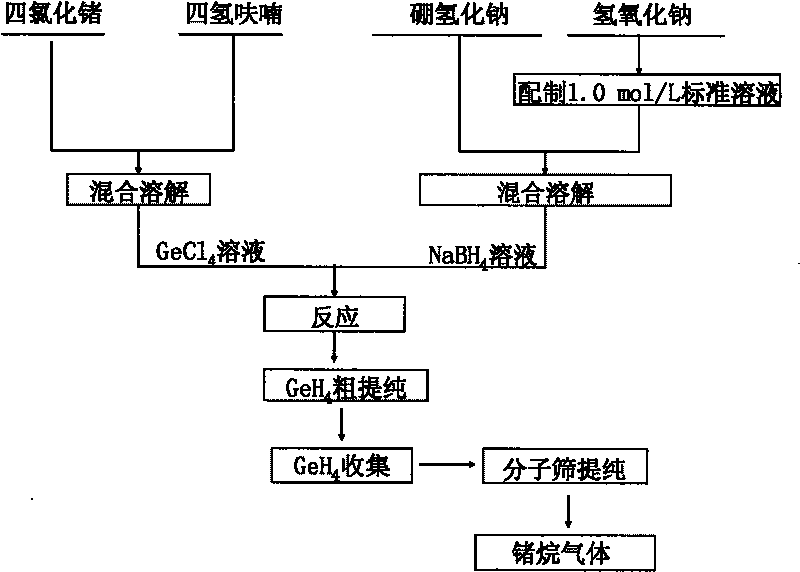

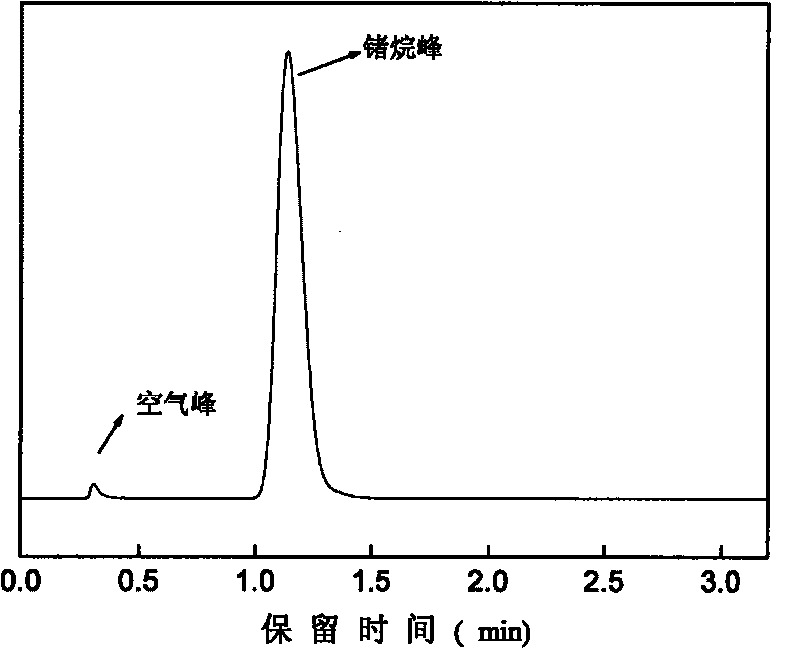

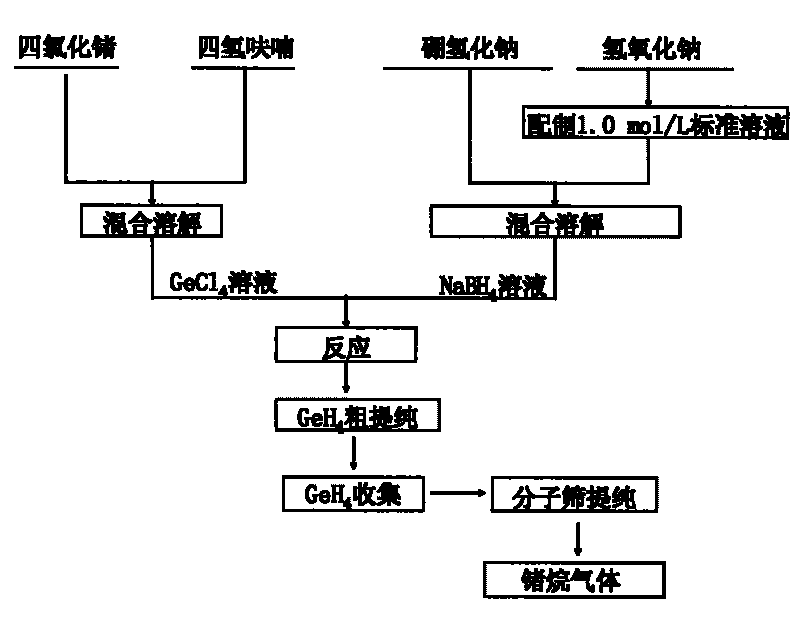

Preparation method of germane

InactiveCN101723326AEasy to separate and purifyImprove conversion rateMetal hydridesSodium borohydrideGermane

The invention discloses a preparation method of germane, comprising dripping tetrahydrofuran solution of germanium tetrachloride into sodium hydroxide solution of sodium borohydride to react, and preparing the germane; wherein the molar ratio between the germanium tetrachloride and the sodium borohydride is 1:1-10. The reaction is carried out according to the equation: GeCl4+NaBH4+3NaOH=GeH4+B(OH)3+4NaCl. The method is simple in technique and lower in cost; and the prepared germane has high yield and less impurity content, and is easy to purify.

Owner:ZHEJIANG SCI-TECH UNIV +1

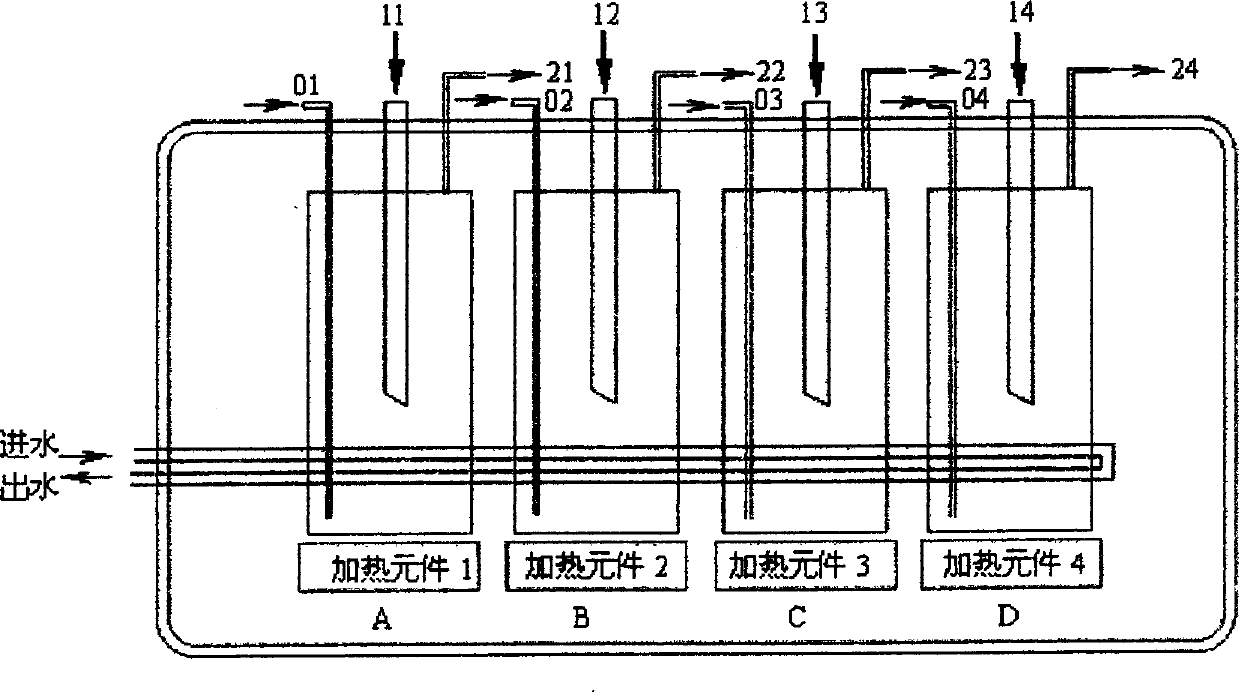

PCVD method for making large-diameter fibre-optical mandrel

ActiveCN101182113AImprove uniformityQuality improvementGlass making apparatusHigh frequency powerEngineering

The invention relates to a PCVD manufacturing method for an optical fiber mandrel with large diameter. The external diameter of a quartz liner is determined to be 36-46mm, the inner diameter to be 32-40mm and the length of the liner to be 1.45-1.85m for the process of PCVD. Parameters of a processing technology are that the high frequency power of a microwave resonator is controlled to be 6KW-15KW and the deposition temperature is 1080-1130 degree Celsius. The variety of mixed air flowing through the liner includes silicon tetrachloride vapor, germanium tetrachloride vapor, high-purity oxygenand Freon. The inside pressure of the liner is 10-15millibar. The air flow rate inside the liner is 30-80m / s. the air volumetric flow rate is 4400-8800SCCM. The invention solves a technical problem of unstable plasma caused by the fast air flow rate. The uniformity of the liner deposition is improved. The effective length of the liner deposition mandrel is increased, which increases the wire drawing length of a single mandrel. The working efficiency and the equipment utilization ratio are improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Condensed materials

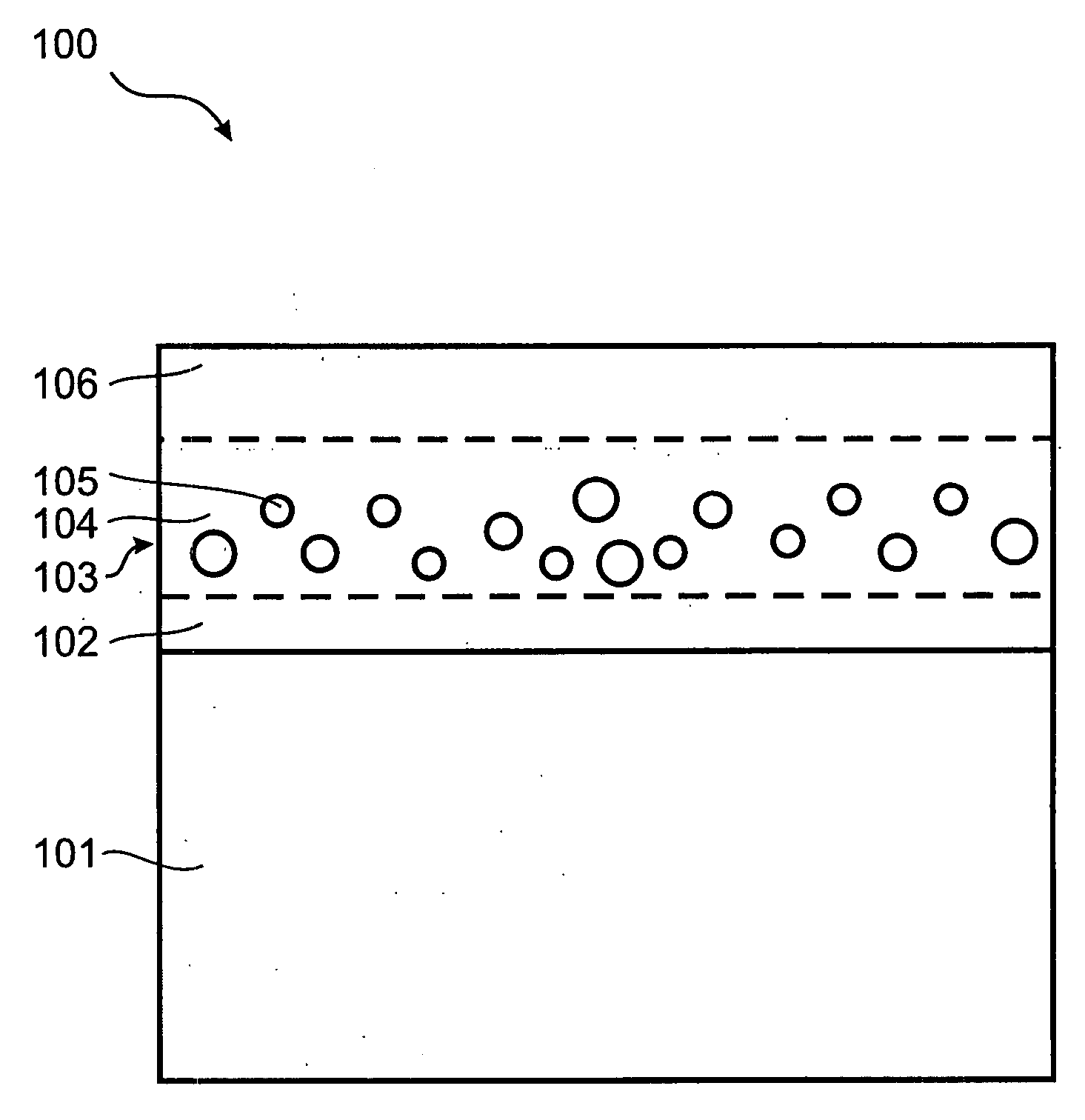

InactiveUS20100068505A1Prevents unwanted electron flowShorten the construction periodMaterial nanotechnologyLayered productsNanoparticleSilicon dioxide

A method for synthesis of germanium nanoparticles in thin SiO2 films comprising: preparing a solution comprising silicon esters, germaniumtetrachloride (GeCl4) or germanium esters, methyl- or higher alcohols, and water; applying the solution to a surface of a substrate; consolidating the solution on the surface of the substrate, thereby obtaining a glass comprising silicon dioxide and germanium dioxide; selectively reducing the germanium dioxide to form germanium nanoparticles.

Owner:WESTFALISCHE WILHELMS UNIV MUNSTER

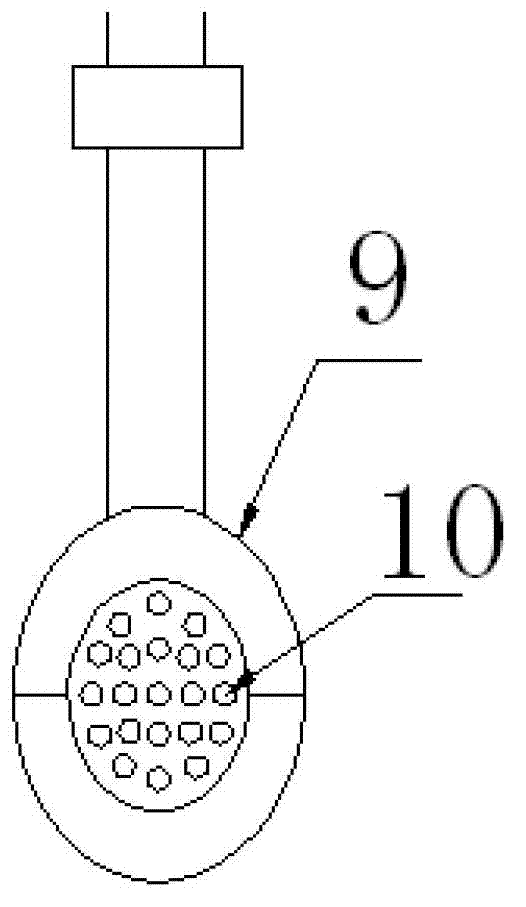

Method and device for removing hydrogen-containing impurities from germanium tetrachloride

The invention discloses a method and a device for removing hydrogen-containing impurities from germanium tetrachloride. The method comprises the steps of: using rectified germanium tetrachloride as raw materials, adding germanium tetrachloride with the purity being 4N-5N into a rectifying kettle for rectification, increasing the temperature of the kettle to 75-83 DEG C for rectification, keeping the germanium tetrachloride to be in a sub-boiling state and feeding in nitrogen with the flow rate being 30-40L / h to exhaust HCl gas, wherein exhaust time is no less than 6 hours; after the HCl gas is exhausted, continuously increasing the temperature of the kettle, and when all sieve plates of a rectifying column are in a boiling state, starting to calculate total reflux time, wherein the total reflux time is no less than 3 hours; and after total reflux is completed, turning on a switch of an electromagnetic valve to adjust the reflux ratio to be 8:1 to 12:1, taking products at a front section, detecting the distilled germanium tetrachloride, if the detected products satisfy the production requirement of the germanium tetrachloride for optical fibers, putting the electromagnetic valve on the side with the products being taken, and finally shifting to a filling process after the obtained germanium tetrachloride products are detected as acceptable. The method and the device for removing the hydrogen-containing impurities from the germanium tetrachloride have the advantages that the technological process is simple, the operation is simple, the hydrogen-containing impurities can be well removed from the germanium tetrachloride, and the industrial use value is very high.

Owner:云南驰宏国际锗业有限公司 +1

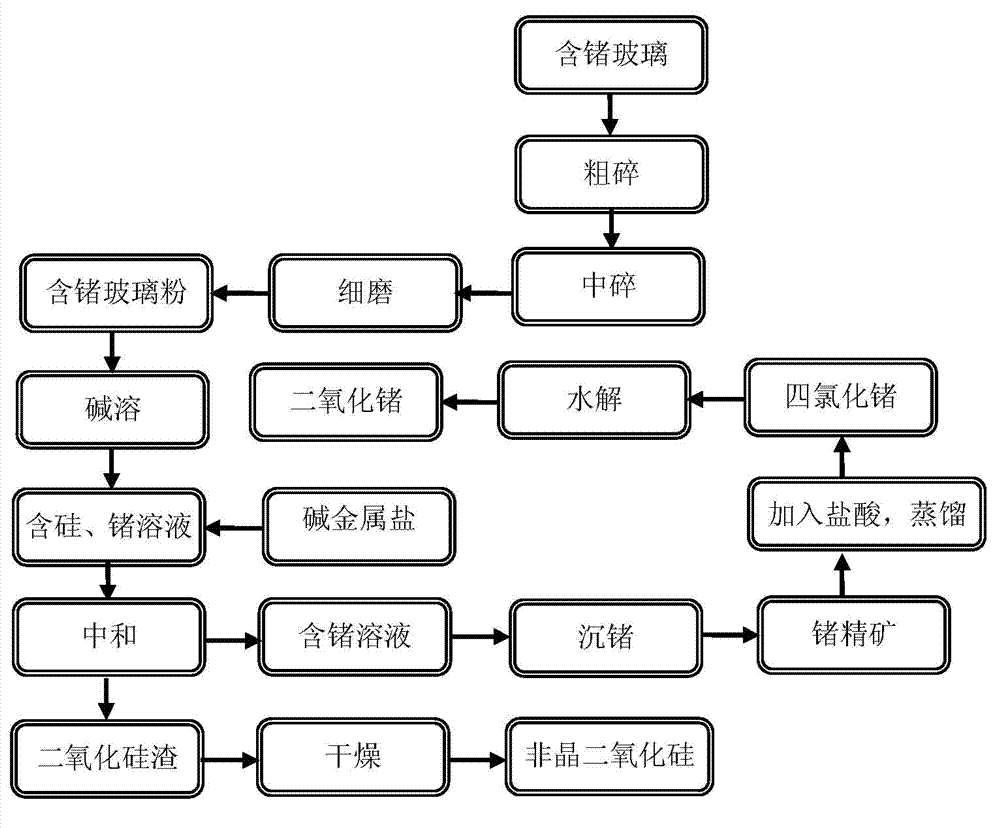

Method for recycling germanium from germanium-containing glass

The invention discloses a method for recycling germanium from germanium-containing glass, which comprises the following steps: 1) pulverizing germanium-containing glass into germanium-containing glass powder, adding an alkali solution into the germanium-containing glass powder, heating to 120-300 DEG C, and keeping the temperature for 1-10 hours to obtain a water solution containing sodium silicate and sodium germanate; 2) adding an alkali metal salt into the water solution containing sodium silicate and sodium germanate obtained in the step 1), regulating the pH value to 6-9, aging, carrying out solid-liquid separation, drying the solid to obtain amorphous silicon dioxide, and recycling; 3) adding magnesium chloride into the solution obtained by solid-liquid separation in the step 2) to obtain a precipitate containing magnesium germanate; and 4) mixing the precipitate containing magnesium germanate with hydrochloric acid, carrying out chlorination distillation, condensing to collect germanium tetrachloride, and hydrolyzing the germanium tetrachloride to obtain germanium dioxide. The method abandons the pyrogenic process for recycling high-silicon germanium-containing waste, lowers the energy consumption, reduces the environmental pollution, and has the advantages of simple technique, high germanium recycling rate and low recycling cost.

Owner:湖北拓材再生资源有限公司

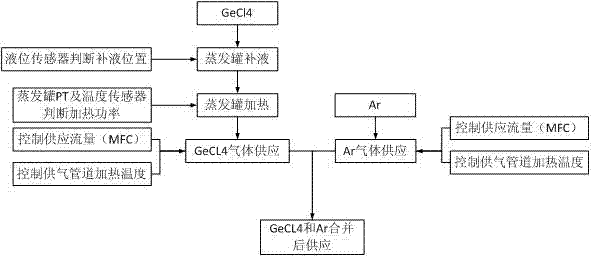

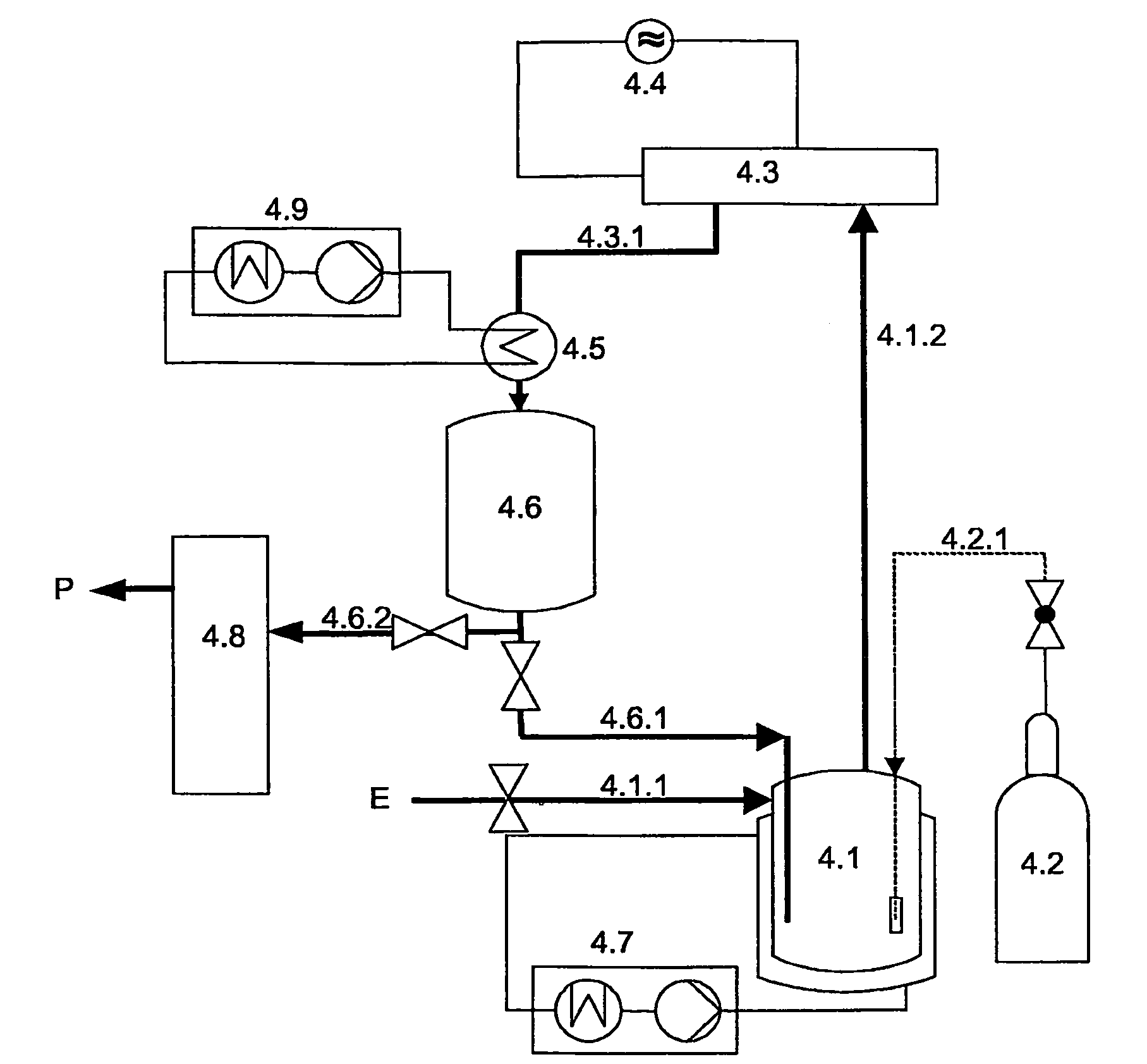

High-precision germanium tetrachloride (GeCl4) supplying method and high-precision germanium tetrachloride supplying equipment

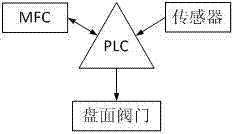

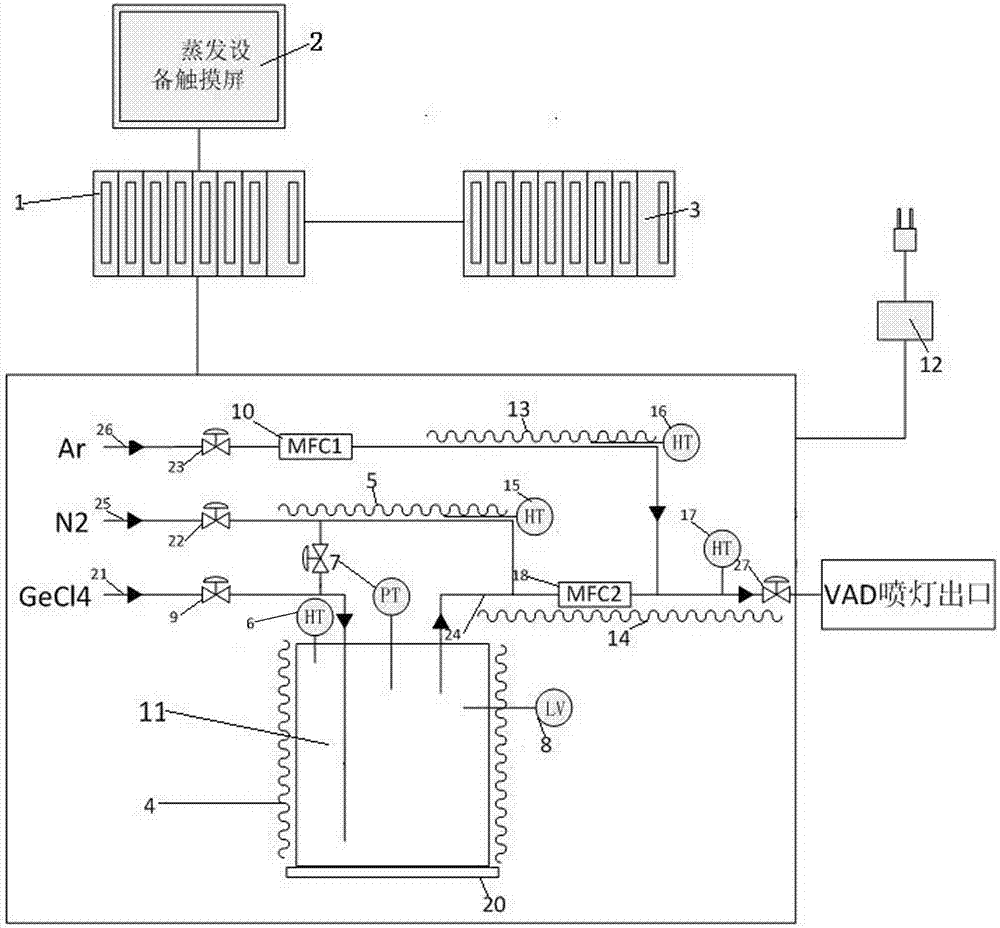

ActiveCN103803790AReal-time monitoring and control of refractive index profilesPrecise control of the refractive index profileGlass making apparatusProgrammable logic controllerEngineering

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +1

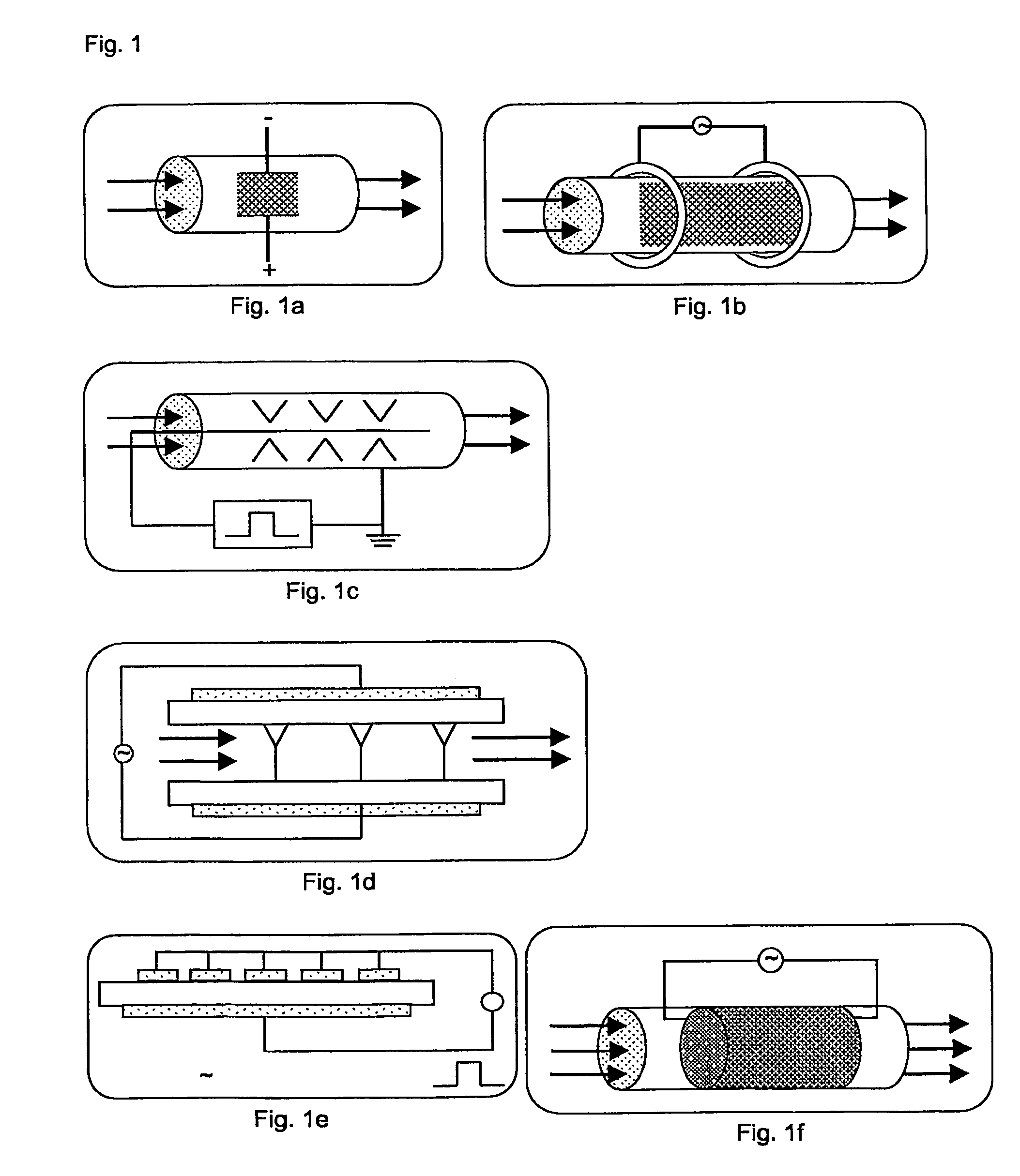

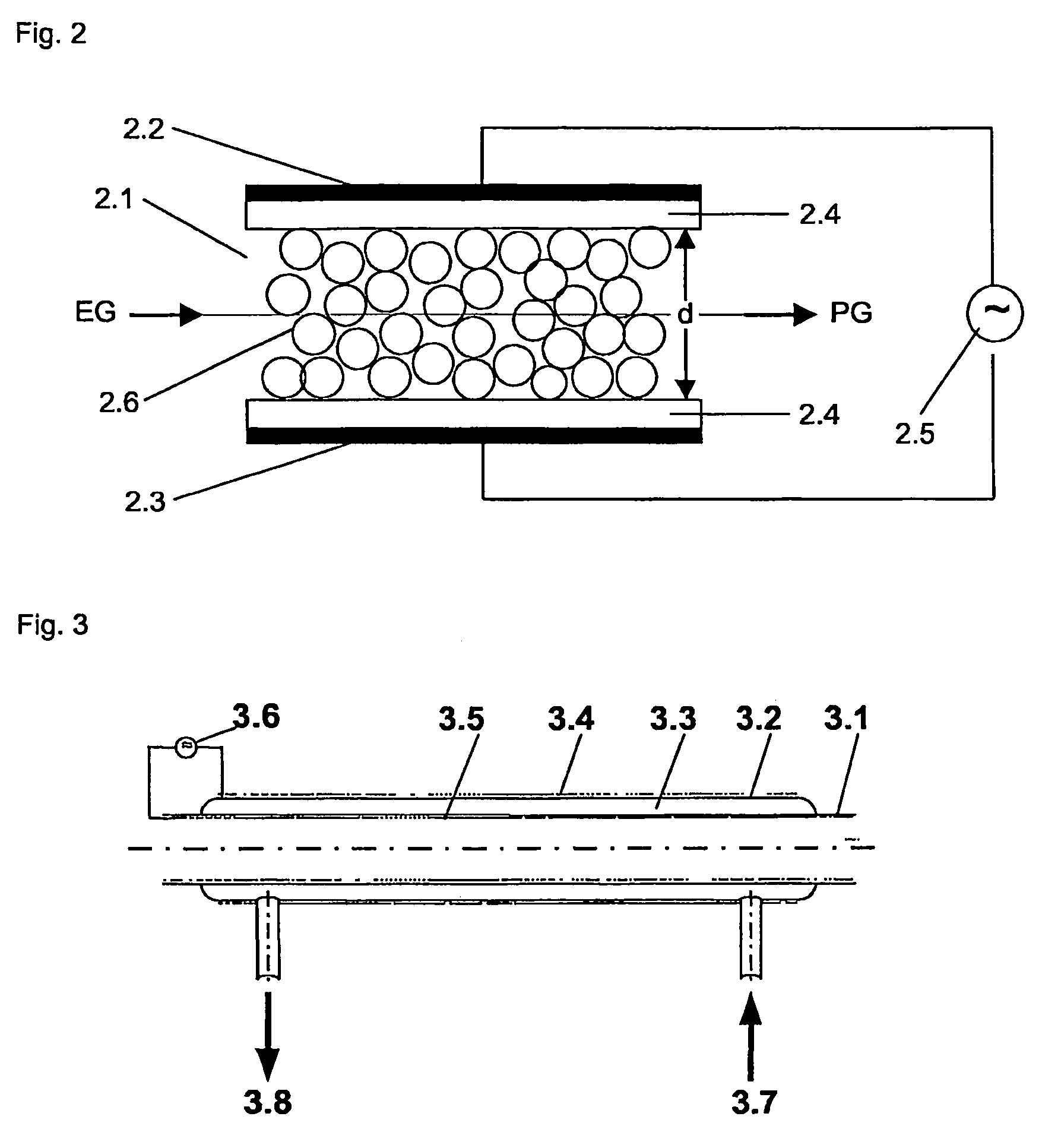

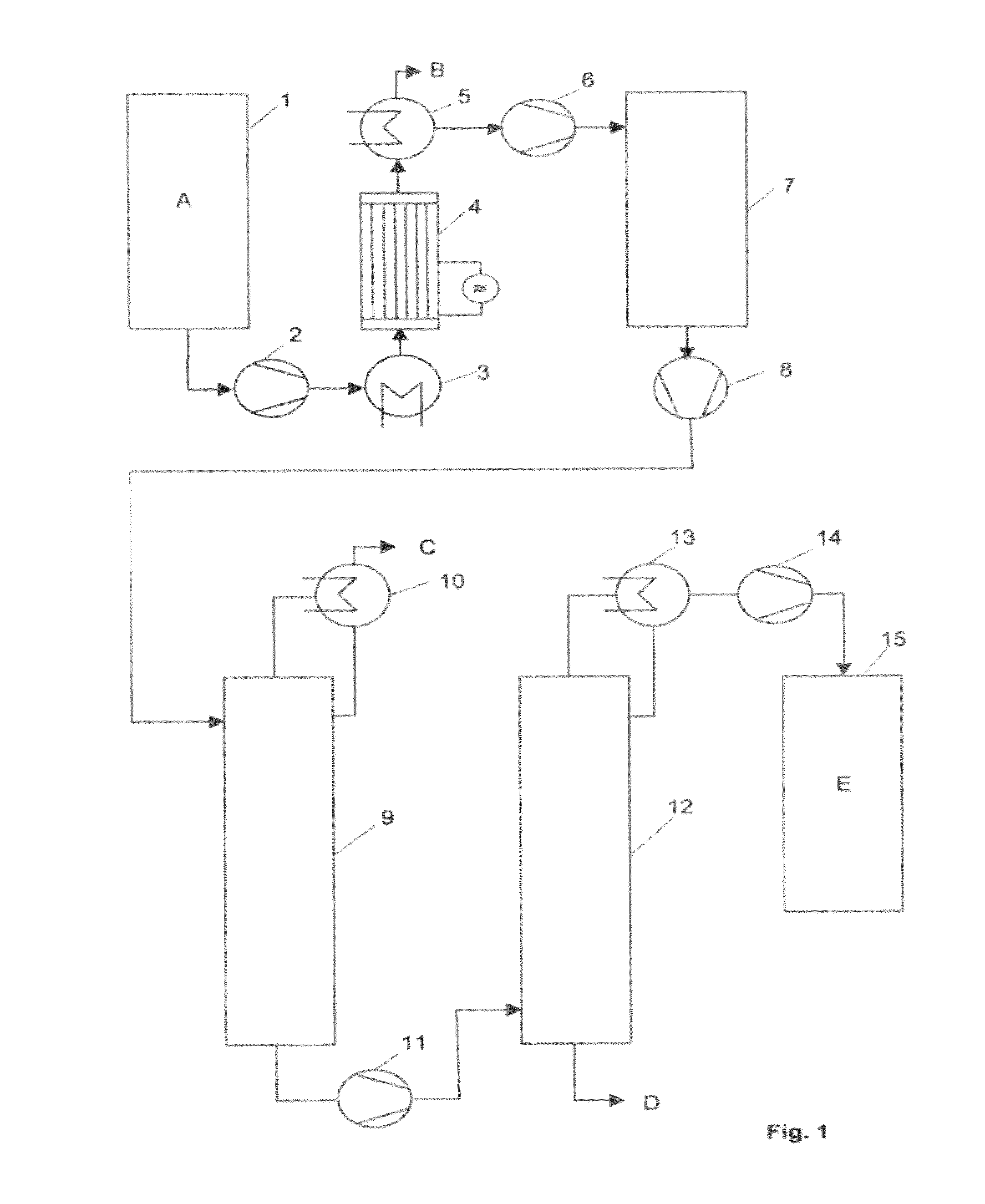

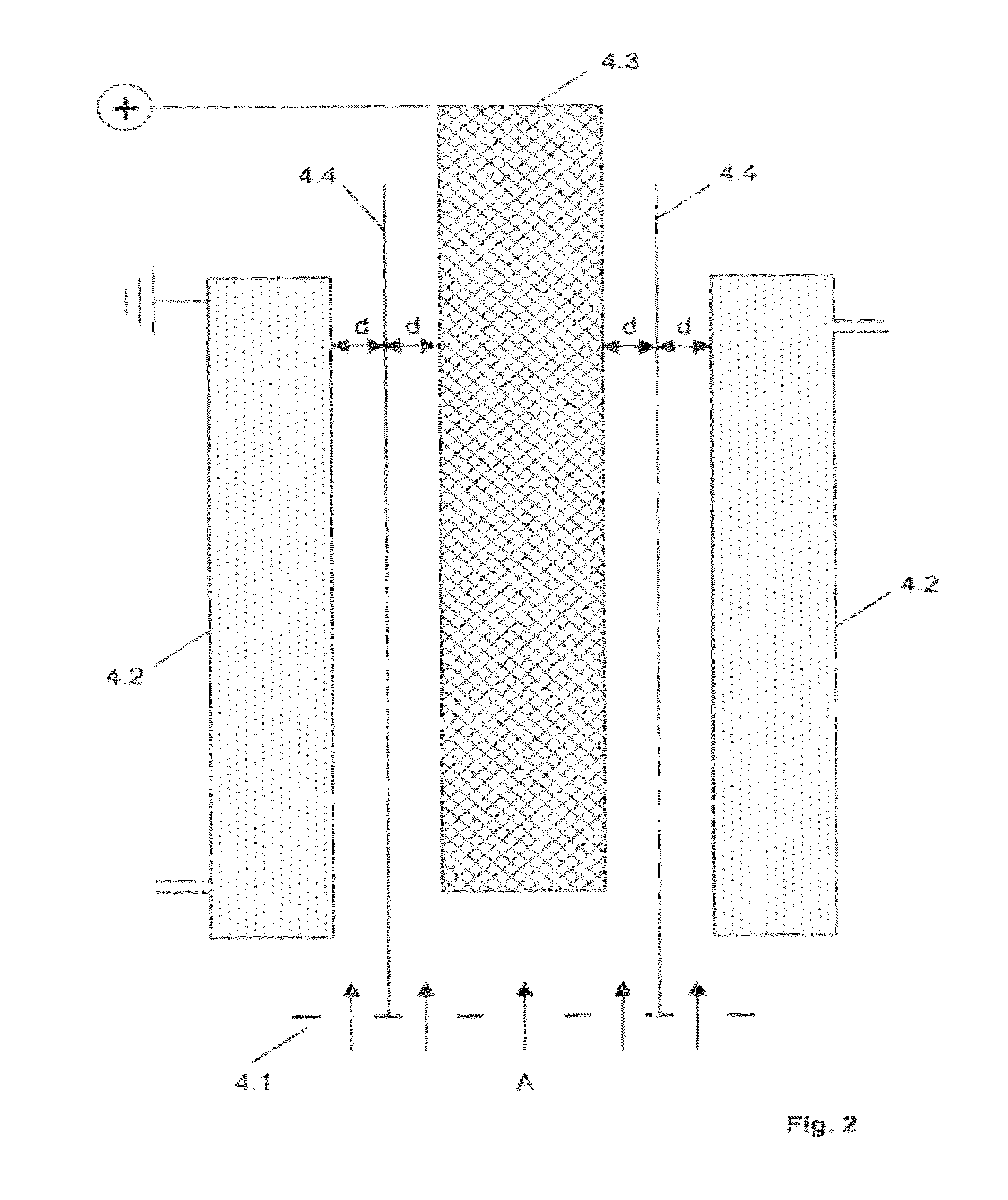

Process and apparatus for purifying silicon tetrachloride or germanium tetrachloride containing hydrogen compounds

ActiveUS8002954B2Germanium halidesEnergy based chemical/physical/physico-chemical processesHydrogenDistillation

The invention relates to a process for the purification's of silicon tetrachloride or germanium tetrachloride contaminated with at least one hydrogen-containing compound, in which the silicon tetrachloride or germanium tetrachloride to be purified is treated in a targeted manner by means of a cold plasma and purified silicon tetrachloride or germanium tetrachloride is isolated from the phase which has been treated in this way. The present invention further relates to an apparatus for carrying out the process of the invention, which comprises a stock and vaporization unit for silicon or germanium tetrachloride (4.1 or 5.1) which is connected via a connecting line with the inlet of the reactor (4.3 or 5.3) with control unit (4.4 or 5.4) for producing the dielectrically hindered discharges whose outlet leads via a pipe either directly or indirectly via at least one further reactor (5.5) to a condensation unit (4.5 or 5.11) with downstream collection vessel (4.6 or 5.12) which is connected via an offtake line (4.6.2 or 5.12.1) to a distillation unit (4.8 or 5.13) and, if appropriate, is equipped with a feed line (4.6.1) to the unit (4.1).

Owner:EVONIK OPERATIONS GMBH

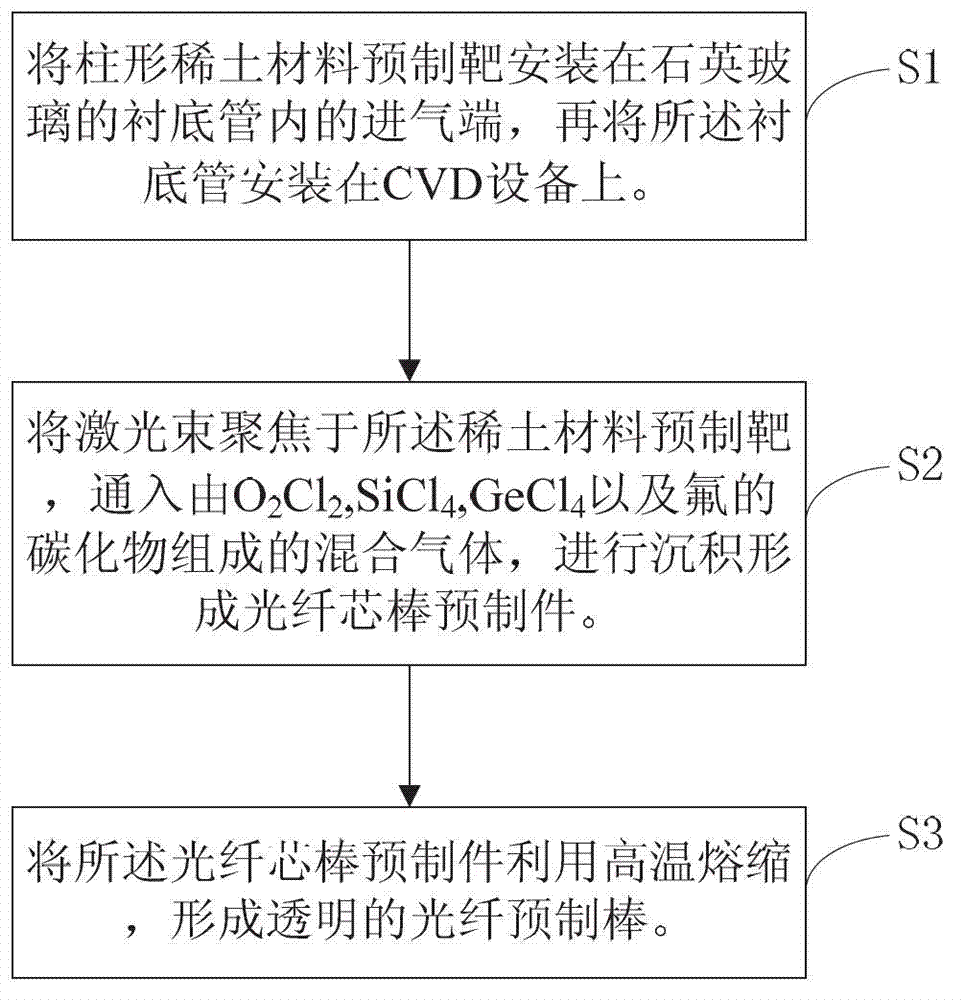

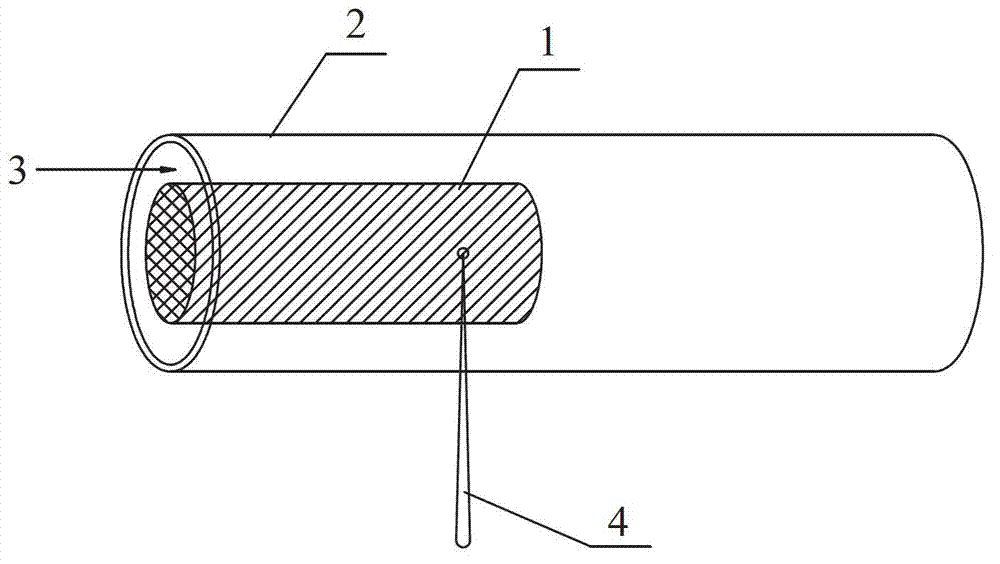

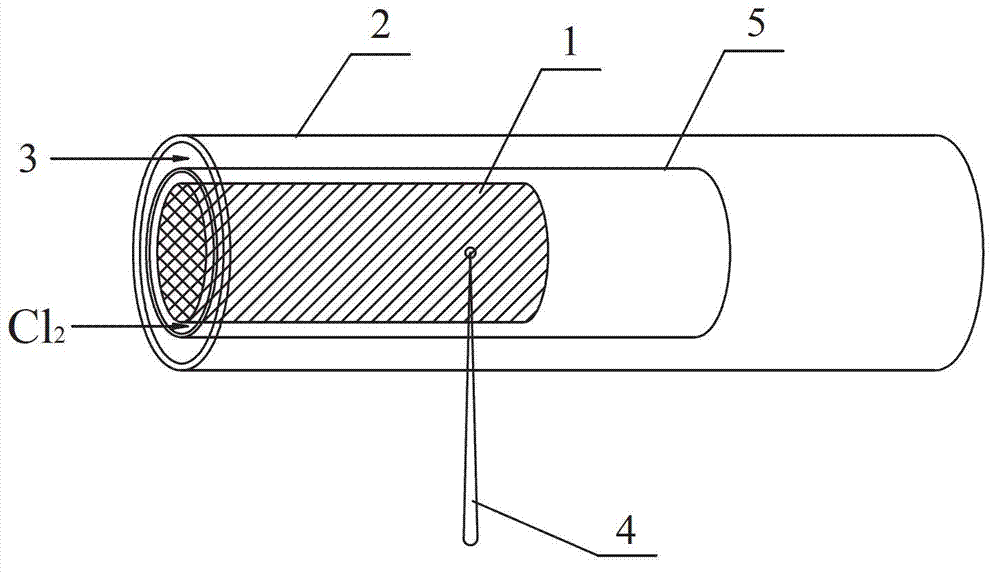

Manufacturing method of rare earth-doped optical fiber preformed rod

A manufacturing method of a rare earth-doped optical fiber preformed rod relates to the field of optical fiber preformed rods, and comprises the following steps: S1, mounting a cylindrical rare earth material preformed target rod at a gas inlet end in a quartz glass substrate tube, mounting the substrate tube on a chemical vapor deposition device; S2, focusing laser on the rare earth material preformed target rod, introducing mixed gas composed of oxygen, chlorine, silicon tetrachloride gas, germanium tetrachloride gas, and carbides of fluorine, performing deposition to form an optical fiber core rod preform; S3, melting the optical fiber core rod preform for contraction at a high temperature to form the transparent optical fiber preformed rod. The method increases the diameter of the optical fiber preformed rod, greatly improves the production manufacturing efficiency and the rare earth ion doping uniformity of the rare earth-doped optical fiber preformed rod, reduces the content of ineffective impurities of the optical fiber preformed rod, also reduces the production cost, and is suitable for popularization of large-scale production.

Owner:RUIGUANG TELECOMM TECH CO LTD

Method for comprehensively recovering valuable metals from complex alloys containing stibium, tellurium, indium, germanium and silver

InactiveCN101705378ASimple processGood effectPhotography auxillary processesProcess efficiency improvementAutomatic controlIndium

The invention discloses a method for comprehensively recovering valuable metals from complex alloys containing stibium, tellurium, indium, germanium and silver. The method comprises the following steps of: alkaline roasting and transformation: mechanically and uniformly stirring smashed and ball milled alloy powder and caustic soda flakes according to a weight ratio of 1:2, loading into an automatic control electric roasting furnace and heating to a temperature of 850 DEG C for 10 hours and taking out of the furnace and then smashing for later use; production of germanium: acidizing roasted powder through sulfuric acid, then obtaining germanium tetrachloride through a process for distilling and extracting the germanium and producing high-purity germanium ingots through rectification, hydrolysis, reduction and zone-melting; recovery of tellurium and silver: washing and filter-pressing acid sludge mixed liquor in the kettle after distilling the germanium to obtain residues; recovery of indium and stibium: neutralizing filter-pressed acid liquor by using alkali liquor to have the pH value of 5 to obtain an indium-stibium mine, and leaching by using dilute sulphuric acid, wherein a final pH value is 1.0-1.5, the content of stibium in leached residues is 30 percent; and extracting, replacing, fusion casting, electrolyzing and refining leach liquor through P204 to obtain 4N high-purity indium ingots.

Owner:南京中锗科技有限责任公司

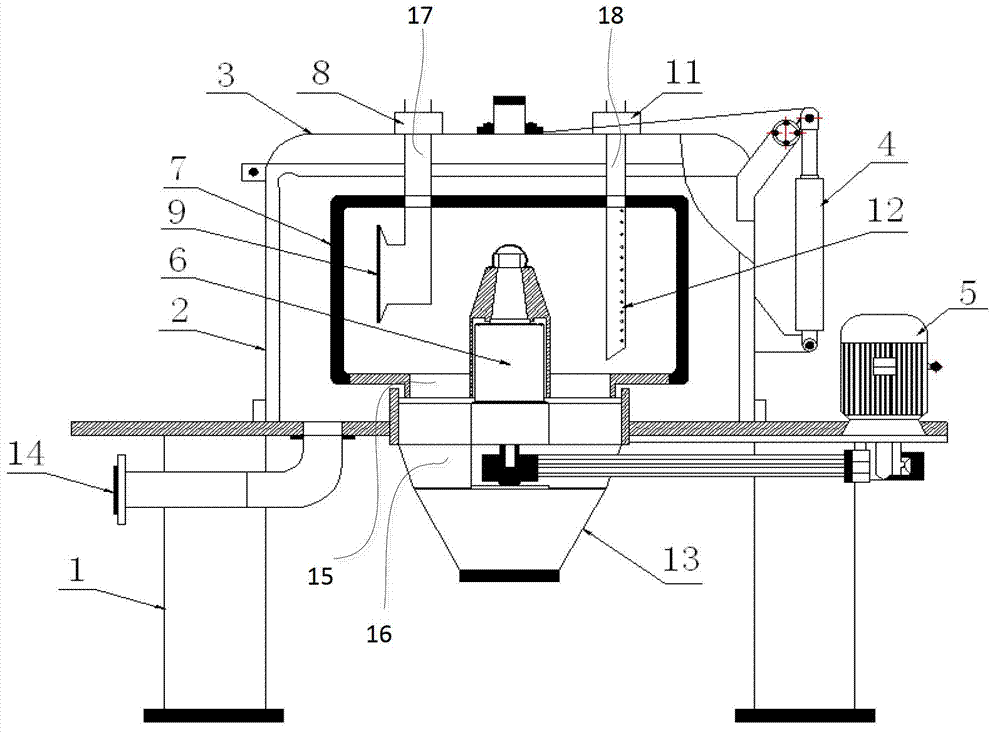

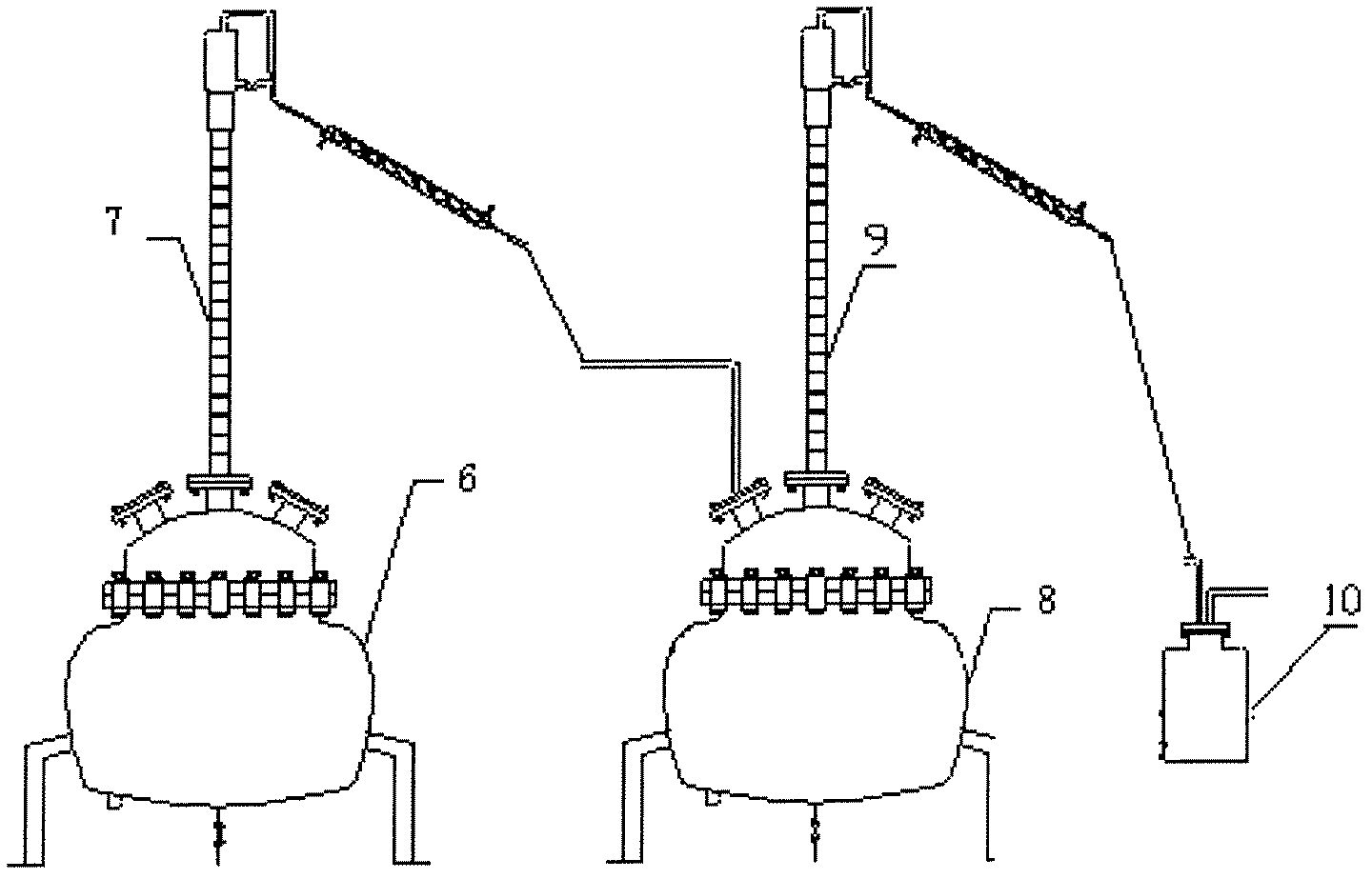

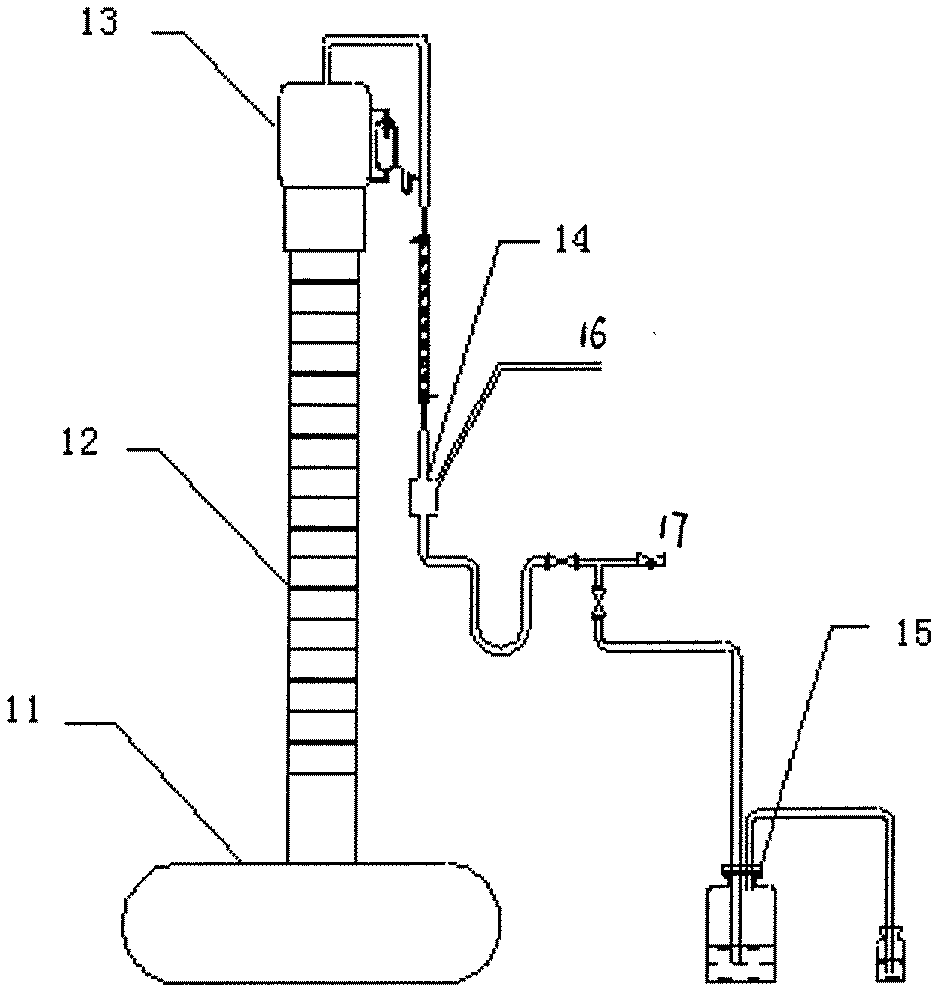

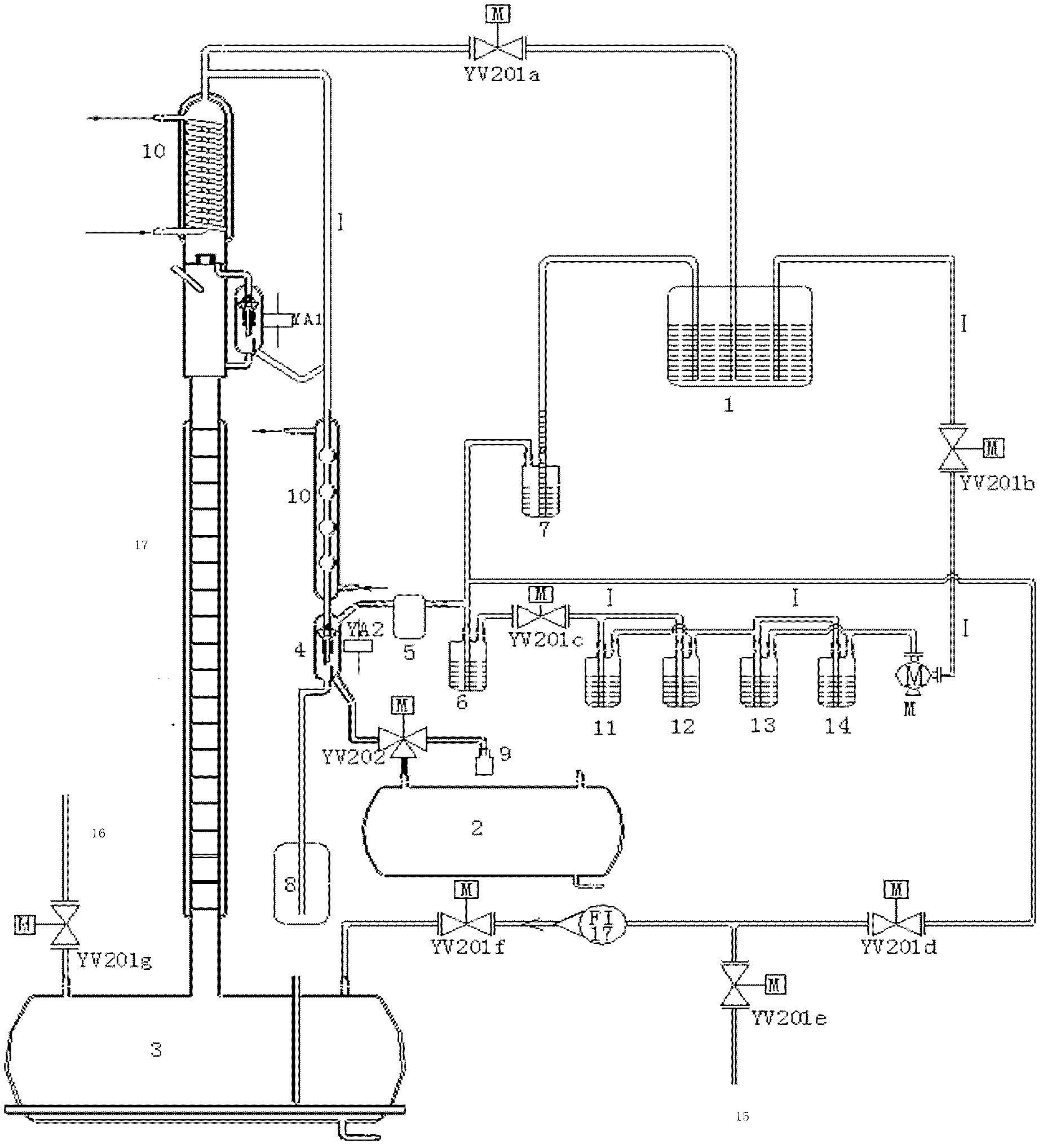

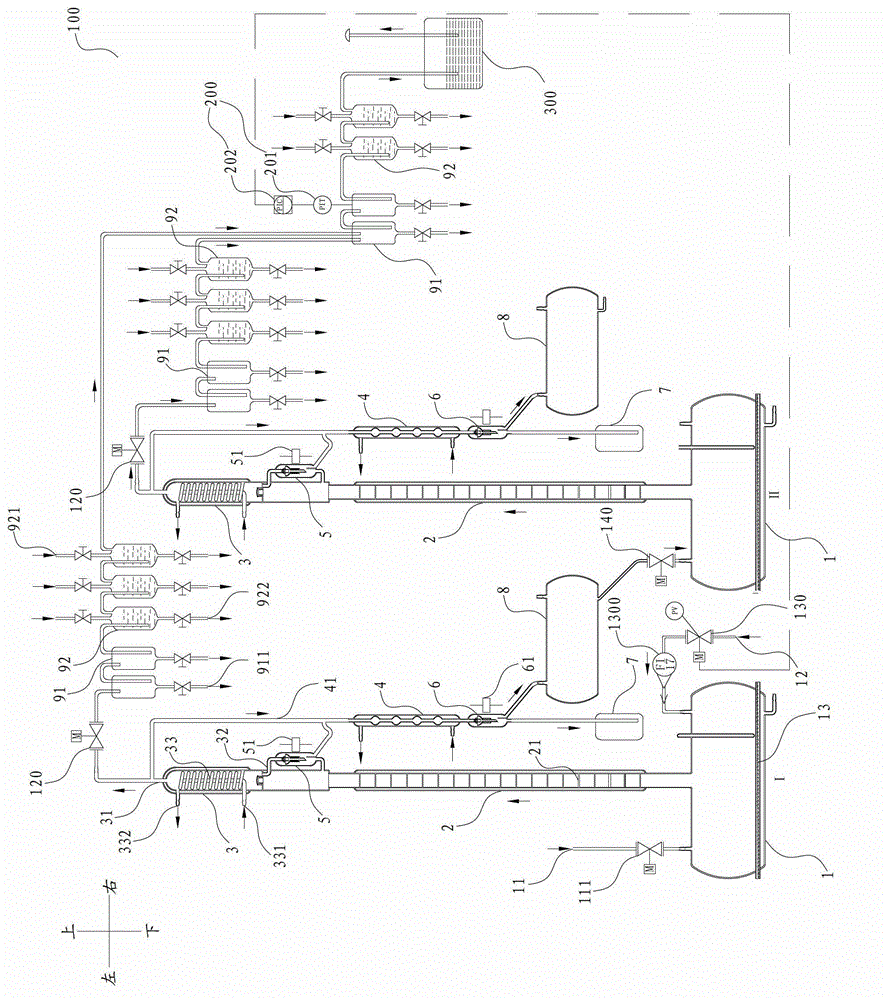

Production system of germanium tetrachloride for optical fiber

ActiveCN102976395AImprove distillation purityIsolated entryGermanium halidesEngineeringProcess engineering

The invention provides a production system of germanium tetrachloride for optical fiber. The production system of germanium tetrachloride for the optical fiber comprises at least two rectification units. The rectification units are connected with each other in series. Each of the rectification units comprises a rectifying still, a rectifying tower, a primary condensing tower, a secondary condensing tower, a discharging head, a primary exhaust gas absorption device, a secondary exhaust gas absorption device and a exhaust gas treatment device. The secondary exhaust gas absorption device is communicated with the primary exhaust gas absorption device. The exhaust gas treatment device is communicated with the secondary exhaust gas absorption device. The production system of germanium tetrachloride for the optical fiber improves the rectifying purity of the germanium tetrachloride for the optical fiber enormously by arranging a plurality of rectification units and improves the reliability of the sealing and maintains the pressure balance in the system by arranging the primary exhaust gas absorption device and the secondary exhaust gas absorption device and can evacuate the exhaust gas finally produced by the production system through the exhaust gas treatment device by arranging the exhaust gas treatment device.

Owner:云南驰宏国际锗业有限公司

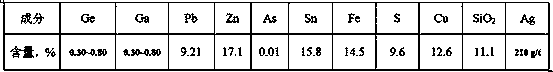

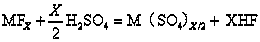

Method for recovering germanium from germanium-containing multi-metal material

A method for recovering germanium from a germanium-containing multi-metal material belongs to a germanium extracting method in the technical field of metallurgy, in particular to a technical method for recovering germanium from the multi-metal material containing the germanium, gallium, tin, copper, silver and the like. The method comprises the following steps: as for the germanium-containing multi-metal material of which the germanium content is higher than 0.1%, carrying out oxidation pretreatment on the material by water, hydrochloric acid, ammonium fluoride and potassium permanganate, then recovering the germanium with a distillation separation method, hydrolyzing obtained germanium tetrachloride containing part of fluoride into germanium dioxide, and carrying out secondary distillation and purification after removing fluorine by sulfuric acid to prepare high-purity germanium dioxide. According to the technical method, the recovery rate of germanium can reach more than 95%.

Owner:YUNNAN DONGCHANG METAL PROCESSING

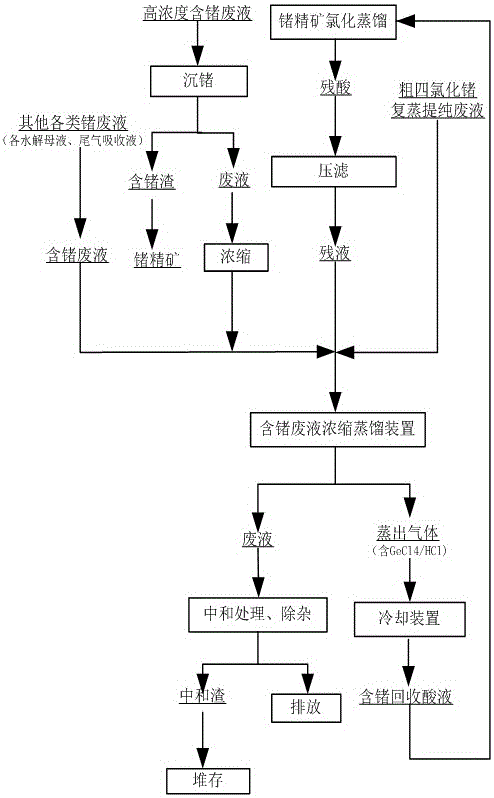

Technological method for recovering germanium from low-concentration germanium-containing waste liquid

InactiveCN106756126AHigh recycling costHigh outputProcess efficiency improvementLiquid wasteDistillation

The invention relates to the field of hydrometallurgy, in particular to a technological method for recovering germanium from low-concentration germanium-containing waste liquid. The method comprises the following steps that reacted acid generated through chloridizing distillation of the low-concentration germanium-containing waste liquid and germanium concentrate is combined into a distillation still, the germanium-containing waste liquid is subjected to heating distillation, the temperature of heating distillation is 110-120 DEG C, distilled germanium tetrachloride and hydrogen chloride are cooled firstly and then subjected to reverse absorption through hydrochloric acid, recovered germanium-containing acid liquid is transferred to a germanium concentrate chloridizing distillation working section, and the recovered germanium-containing acid liquid and the newly added hydrochloric acid are used for extracting germanium in the germanium concentrate through chloridizing distillation. By adopting the technological method, 90% of germanium in the germanium-containing waste liquid can be effectively recovered in an energy-saving mode, the using amount of new hydrochloric acid can be reduced by 80% or more by the germanium concentrate chloridizing distillation working section, germanium metal recovered each year can reach 500-1200 kg, and wastewater processing and discharging can be reduced by 90% or more. The efficient recovery of germanium is achieved, and circulation recycling of the hydrochloric acid is also achieved.

Owner:YUNNAN LINCANG XINYUAN GERMANIUM IND +1

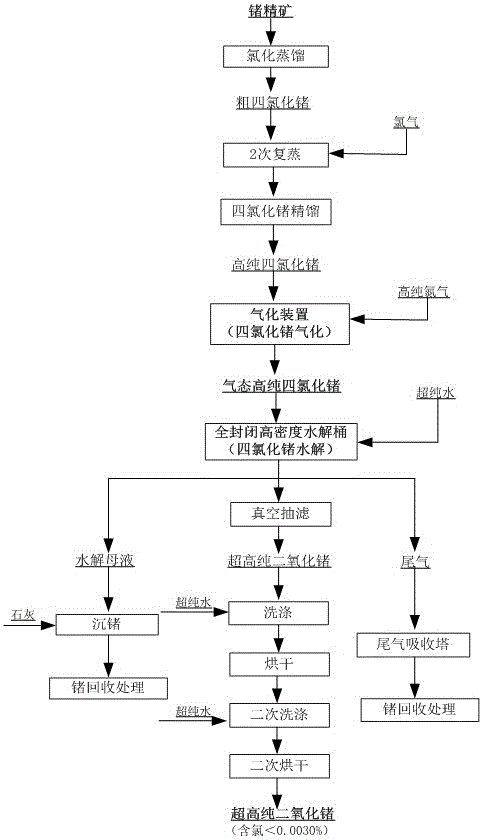

Preparation method of germanium dioxide

InactiveCN109319827AOvercome the problem of not being able to effectively extract and recycleReduce productionGermanium dioxidePhysical chemistryHydrolysis

The invention discloses a preparation method of germanium dioxide, and relates to the field of rare metal metallurgy. The preparation method sequentially includes the steps of chlorinating and distilling germanium ore, re-steaming the germanium ore, rectifying and purifying the germanium ore to obtain germanium tetrachloride, hydrolyzing the germanium tetrachloride to prepare germanium dioxide andhydrolysis supernatant, precipitating the hydrolysis supernatant to prepare magnesium germanate filter residues, and distilling the magnesium germanate filter residues to obtain the germanium tetrachloride for reutilization. The preparation method has the advantages of high recovery rate, low use cost, less residual liquid, energy conservation and environment protection.

Owner:衡阳恒荣高纯半导体材料有限公司

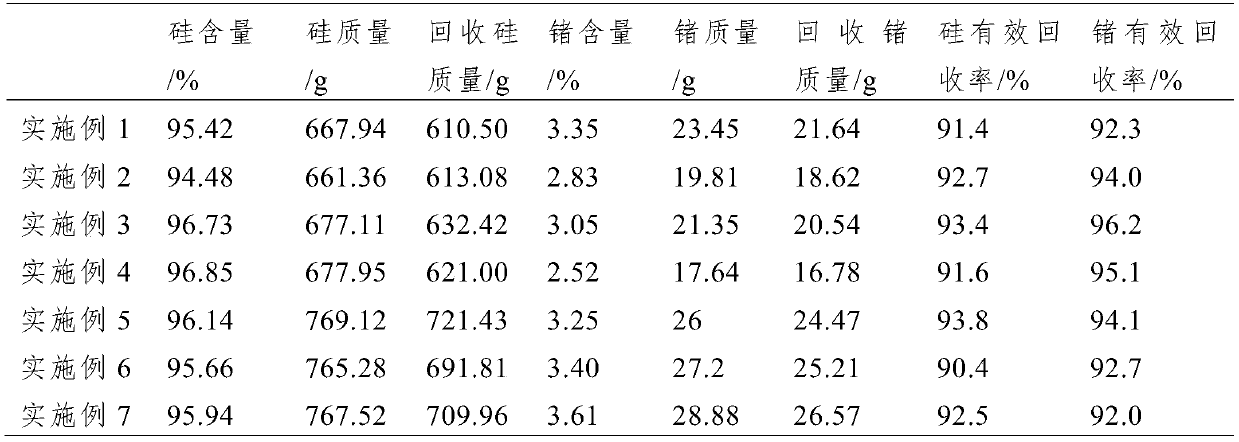

Method for recovering silicon and germanium from germanium-containing optical fiber waste

InactiveCN110386606AFull recoveryAchieve separationSilicaSolid waste disposalMagnesium saltGermanium dioxide

The invention discloses a method for recovering silicon and germanium from germanium-containing optical fiber waste. The method comprises the following steps: 1, the crushed germanium-containing optical fiber waste is screened, and powder is obtained; 2, the powder and water are mixed to be beaten, soluble alkali is added, under the vacuum condition, after microwave heating, the temperature keepsconstant, and leachate containing the silicon and the germanium is obtained; 3, an alkali metal salt is added into the leachate containing the silicon and the germanium, the pH is regulated, stirring,aging and solid-liquid separation are conducted, and a solid and liquid are obtained; 4, the solid is dried, and amorphous silicon dioxide is obtained; 5, a magnesium salt is added into the liquid, stirring for germanium sedimentation, aging and filtering are conducted, and residue and filtrate are obtained; 6, ferric chloride is added into the filtrate, precipitation adsorption reaction, aging and filtering are conducted, and precipitation is obtained; and 7, the residue and the precipitation are mixed with water to be beaten, the mixture is mixed with hydrochloric acid to be distilled, germanium tetrachloride is obtained and hydrolyzed, and germanium dioxide is obtained. According to the method, the silicon and the germanium in the waste can be effectively recovered, and the silicon andthe germanium are separated.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

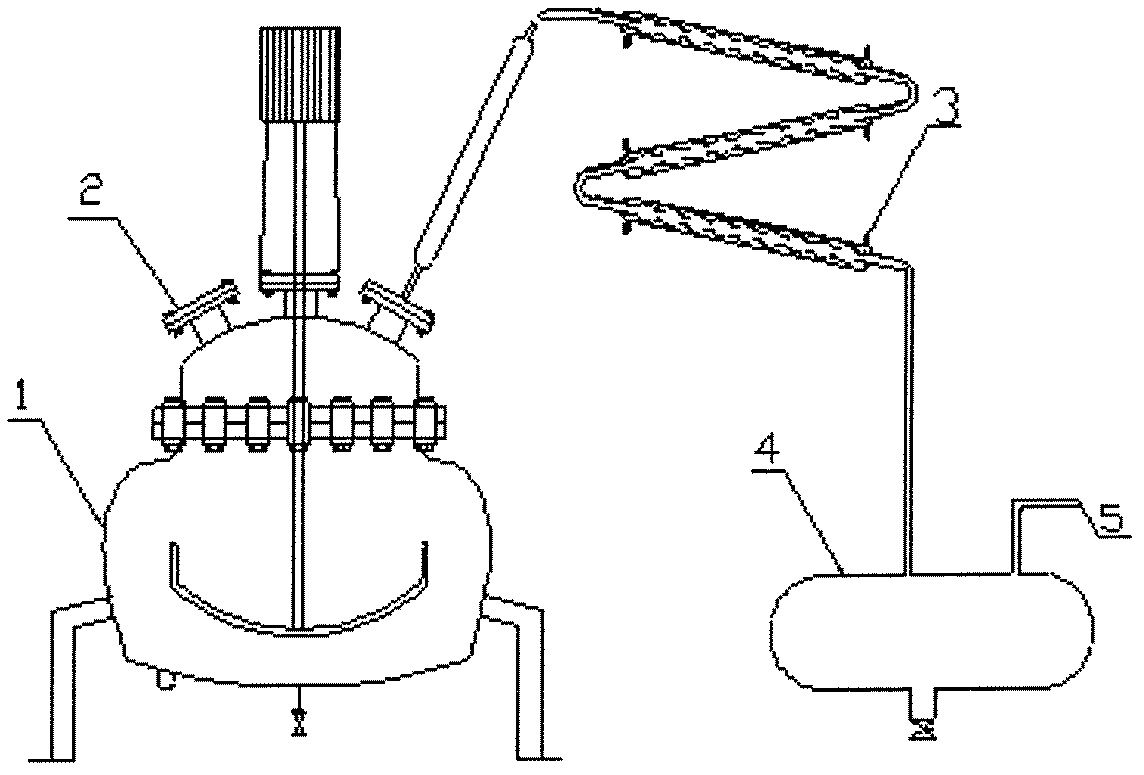

Method for producing germanium tetrachloride for optical fibre

InactiveCN101234780AGood removal effectSimple processGermanium halidesPhysical chemistryNitrogen gas

The invention discloses a method for producing germanium tetrachloride for optical fibers, which includes the steps: hydrochloric acid and germanium tetrachloride with a volume ratio of 0.25-2.0: 1 are added into a distiller to be distilled; or while separately distilling the germanium tetrachloride, HCI gas is pumped in until the distilling is finished with the distilling temperature of 76-80 DEG C; after the distilled solution is separated by a hydrochloric separator, the germanium tetrachloride solution is stored in a storage tank to be discharged to an empty tower distiller for 36-72 hours of standing; temperature of the germanium tetrachloride solution is raised to 70-75 DEG C; while continuous pumping nitrogen for 12-36 hours, an ultraviolet lamp is adopted for lighting; finally, distillation operation is carried out at 76-80 DEG C and the product is transferred. The method for producing the germanium tetrachloride for optical fibers has the advantages of simple process course and convenient operation which can remove the impurity containing hydrogen in the germanium tetrachloride with high value for industrial use.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Reactor, plant and industrial process for the continuous preparation of high-purity silicon tetrachloride or high-purity germanium tetrachloride

ActiveUS8221593B2Chemical/physical/physico-chemical microreactorsGermanium halidesHydrogenMetallurgy

A reactor, a plant, and a continuous, industrial process carried out therein for preparing high-purity silicon tetrachloride or high-purity germanium tetrachloride by treating the silicon tetrachloride or germanium tetrachloride to be purified, which is contaminated by at least one hydrogen-containing compound, by a cold plasma and isolating purified high-purity silicon tetrachloride or germanium tetrachloride from the resulting treated phase by fractional distillation. The treatment is carried out in a plasma reactor in which longitudinal axes of a dielectric, of a high-voltage electrode, and of a grounded, metallic heat exchanger are oriented parallel to one another and at the same time parallel to the force vector of gravity.

Owner:EVONIK OPERATIONS GMBH

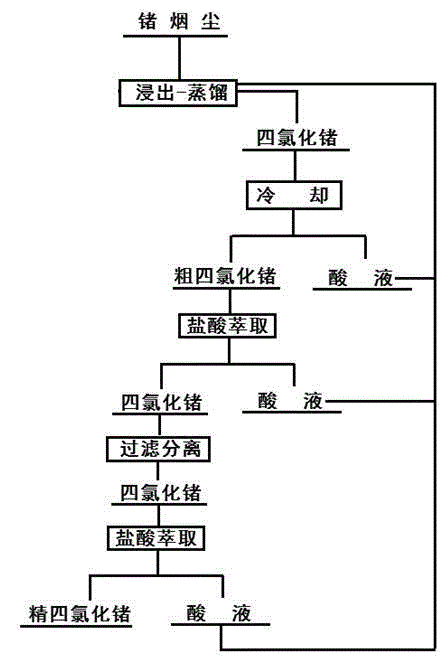

Method for extracting germanium from germanium-containing smoke dust

ActiveCN104789785AStable recoveryHigh purityProcess efficiency improvementRefining (metallurgy)Distillation

The invention relates to a method for extracting germanium from germanium-containing smoke dust, and belongs to the technical field of chemical metallurgy. The method adopts the germanium-containing smoke dust, which is obtained by dry distillation of lignite and has the germanium content of 8.0-30.0wt%, as a raw material to perform extraction, and comprises the following steps: performing leaching distillation on the germanium-containing smoke dust; cooling the obtained gas containing germanium tetrachloride to obtain a crude germanium tetrachloride solution; performing first-time extraction on the crude germanium tetrachloride solution; filtering the germanium tetrachloride solution obtained by the first-time extraction by using a separating column; performing second-time filtration on the obtained germanium tetrachloride solution to obtain a refined germanium tetrachloride solution; and hydrolyzing the obtained refined germanium tetrachloride solution into germanium dioxide, and reducing the germanium dioxide to obtain germanium. According to the method provided by the invention, the technological process is easy to control and strong in operability, the germanium recovery rate is stable, the cost is significantly reduced relative to that of a continuous distillation or continuous extraction process, the purity of germanium can reach more than 99.999%, and the resistivity of germanium is more than 15 ohm cm.

Owner:HEBEI UNIV OF ENG

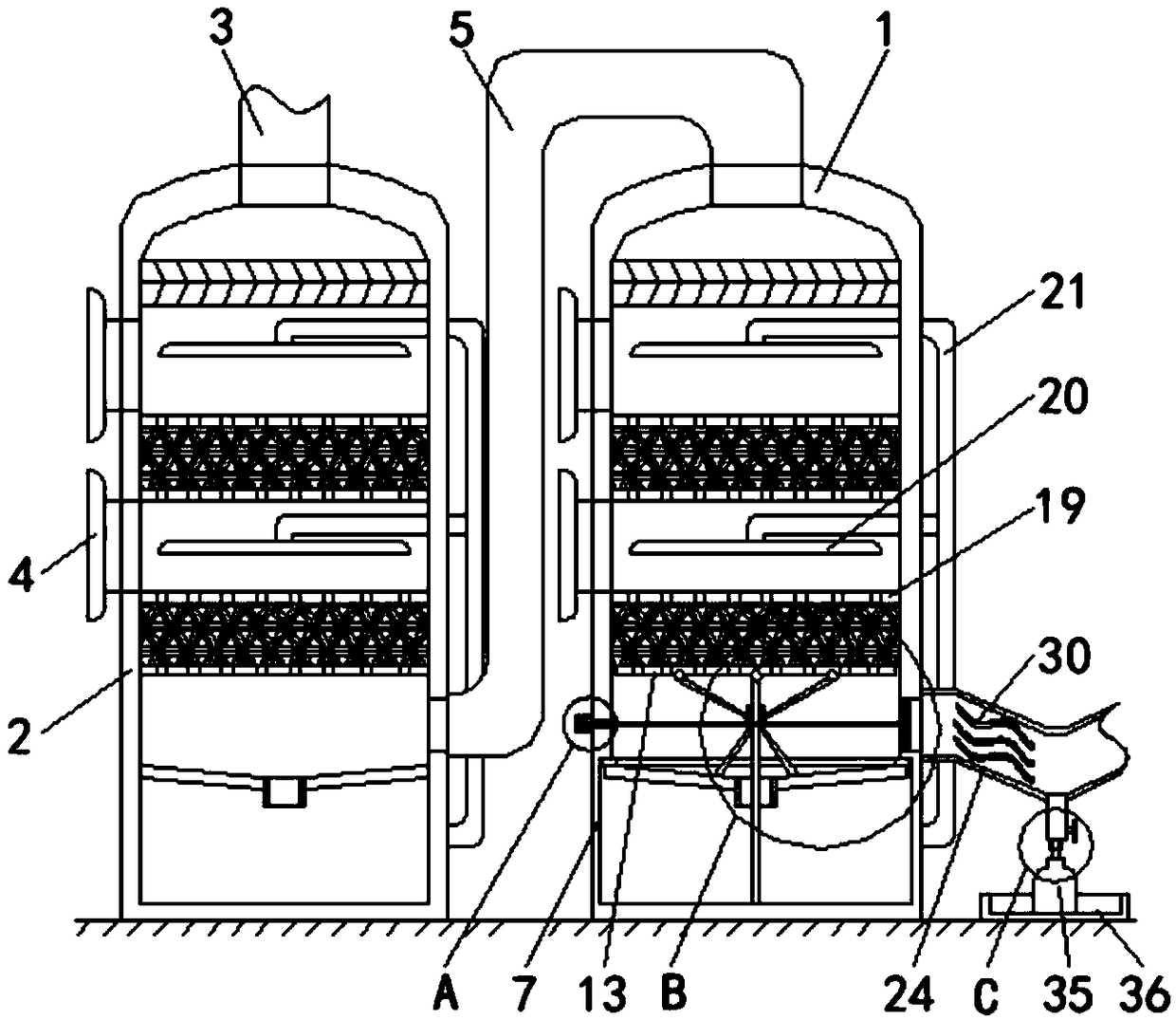

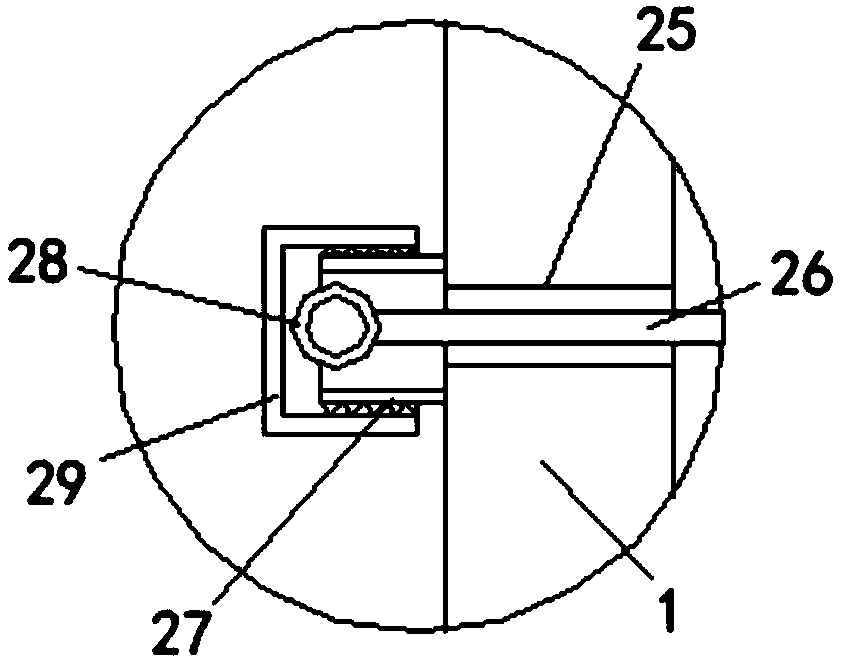

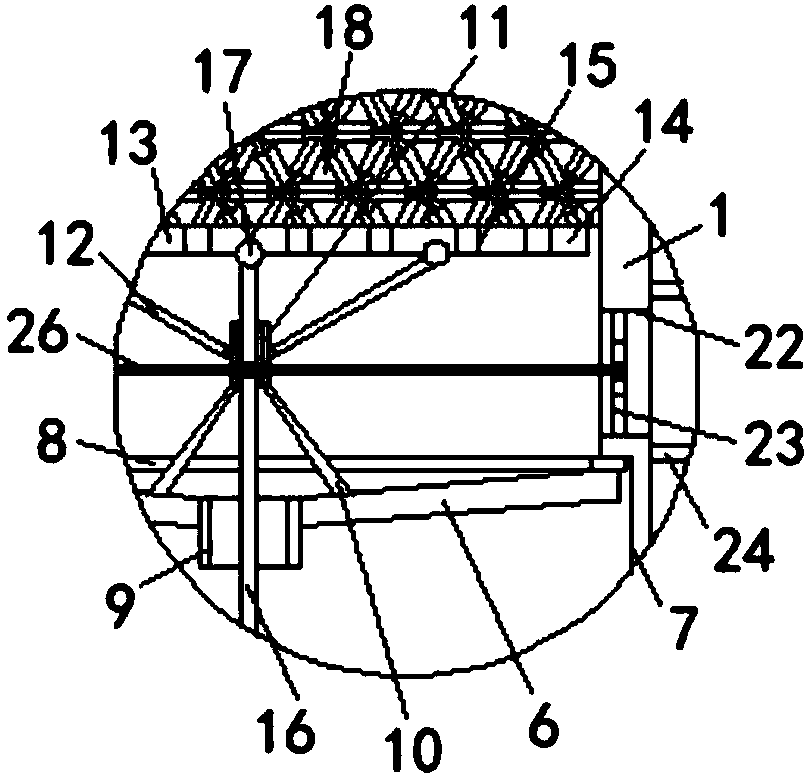

Anti-blocking emergency operation type alkali liquid spraying tower for purifying germanium tetrachloride

InactiveCN108211756AExtended service lifeReduce entryDispersed particle separationEngineeringSpray tower

The invention relates to the technical field of chemical production and discloses an anti-blocking emergency operation type alkali liquid spraying tower for purifying germanium tetrachloride. The anti-blocking emergency operation type alkali liquid spraying tower comprises a first-grade spraying tower, wherein the bottom of the first-grade spraying tower is fixedly connected with the ground; the top of the first-grade spraying tower is fixedly connected with an adapting pipe; one end, far away from the first-grade spraying tower, of the adapting pipe is fixedly connected with a second-grade spraying tower; an exhausting pipe is fixedly connected with the top of the second-grade spraying tower; the left side face of the first-grade spraying tower and the left side face of the second-grade spraying tower are fixedly connected with maintenance windows. According to the anti-blocking emergency operation type alkali liquid spraying tower for purifying the germanium tetrachloride, a slidinggroove is arranged so that a liquid receiving plate can slide downward in the sliding groove under the action of gravity; finally, a filler layer at the bottom of the first-grade spraying tower can rapidly fall down to the top of the liquid receiving plate through setting an inserting hole, a safety rod and a pull ring, so that the aim of providing a spraying tower blocking emergency measure is realized.

Owner:重庆熵臻科技有限公司

Regeneration utilization method of germanium in infrared chalcogenide glass waste material

PendingCN109385540AAchieve recyclingRealize recyclingProcess efficiency improvementDistillationZone melting

The invention more specifically relates to a regeneration utilization method of germanium in infrared chalcogenide glass waste material. According to the regeneration utilization method of germanium in infrared chalcogenide glass waste material, germanium is extracted from infrared chalcogenide glass waste material, and the method principles are that: the oxidation performance of H2O2 is adopted to destroy Ge-Se, Ge-As, Ge-Sb bonds in infrared chalcogenide glass waste material, germanium is oxidized into GeO, a single GeO layer is formed on the surface, GeO is oxidized into GeO2, GeO2 is dissolved in water to form germanic acid; when an obtained solution contains an alkali, germanic acid is reacted with the alkali to produce sodium germinate, so that germanium dissolving is accelerated; concentrated sulfuric acid is adopted to neutralize excess sodium hydroxide solution and adjust and control the concentration of hydrogen ions in the solution; FeCl3 is adopted to oxidize As<3+> into As<6+>, and sufficienct chloride ions are provided; concentrated hydrochloric acid is adopted for distillation of germanium tetrachloride from the solution, and AsCl6 is left in a distillation raffinate; the germanium tetrachloride obtained through distillation is subjected to traditional technology including secondary distillation, rectification, hydrolysis, reduction, and zone melting so as to obtain high purity zone-refined germanium ingot.

Owner:YUNNAN KIRO CH PHOTONICS

Method for producing germanium dioxide by utilizing germanium-containing wastes

InactiveCN107324376ASave acidSave hydrogen peroxideGermanium dioxideGermanium halidesHydrolysateDistillation

The invention provides a method for producing germanium dioxide by utilizing germanium-containing wastes. The method is characterized by comprising the following steps: directly adding the germanium wastes into a concentrated hydrochloric acid containing ferric trichloride; using chlorine as a shielding gas and adopting a rectifying column for distilling and purifying germanium tetrachloride; preparing germanium dioxide by performing totally closed hydrolysis reaction on the purified germanium tetrachloride; washing the hydrolysate and drying, thereby acquiring dry germanium dioxide; and adding the germanium wastes into a return fluid after completing distillation, thereby continuously producing. The germanium tetrachloride can be continuously produced in the manner of adding the germanium wastes into the concentrated hydrochloric acid containing ferric trichloride, and then adding chlorine for oxidizing, distilling and preparing germanium tetrachloride and adding the germanium wastes after completing the distillation; the usage of acid and hydrogen peroxide can be saved; the distilling return fluid can be repeatedly reused; and no distilling waste acid is generated.

Owner:KUNMING HUIQUAN HIGH PURITY SEMICONUCTING MATERIALS CO LTD

Preparation method of germane gas

ActiveCN102249188AImprove conversion rateReduce generationMetal hydridesPresent methodSodium borohydride

The invention provides a preparation method of germane gas. According to the method, a sodium hydroxide solution of sodium borohydride is prepared; polyether with a volume of 0.5% to 5% of that of the solution is added to the solution; and a tetrahydrofuran solution of germanium tetrachloride is added to the solution for preparing germane gas. Compared to previously disclosed methods, according to the present method, polyether is added to the reaction solution, such that a substantial effect is brought in, generation of yellow precipitate is greatly reduced, and a conversion rate of germane is improved by approximately 7%.

Owner:中锗科技有限公司

Method for recycling germanium from high-silicon-content optical fiber production waste

PendingCN109439909AImprove evaporation efficiencyHigh transmittance to microwave radiationProcess efficiency improvementDistillationGermanium dioxide

The invention discloses a method for recycling germanium from high-silicon-content optical fiber production waste. The method comprises the following steps that (1) the high-silicon-content and germanium-containing optical fiber production waste is ground till the number of holes is 100 or above,, and then a vulcanizing agent is added and uniformly mixed to prepare particles with the diameters of1-5 mm; (2) sulfidingvolatilization is carried out on the germanium, and the germanium sulfide volatilization smoke dust is collected, or the mixed volatilization smoke dust of the germanium sulfide and germanium dioxide is collected; (3) the obtained germanium-containing smoke dust is subjected to microwave oxidation roasting or oxidation roasting in other forms, or is subjected to sulfuric acidoxidation leaching directly; (4) the high-germanium-content microwave oxidation roasting product is directly subjected to hydrochloric acid chlorination distillation so as to obtain germanium tetrachloride to be subjected to hydrolyzation, and thus a germanium dioxide concentrate is obtained; and (5) sulfuric acid oxidation leaching is carried out on the low-germanium-content materials in the step(2) and the step (3), wherein a leaching solution adopts tannin or an organic solvent to precipitate or extract the enriched germanium and to produce the germanium concentrate. The method can be usedfor extracting and separating the germanium and the silicon from the materials containing 95% or above of the silicon at high efficiency and low cost.

Owner:六盘水中联工贸实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com