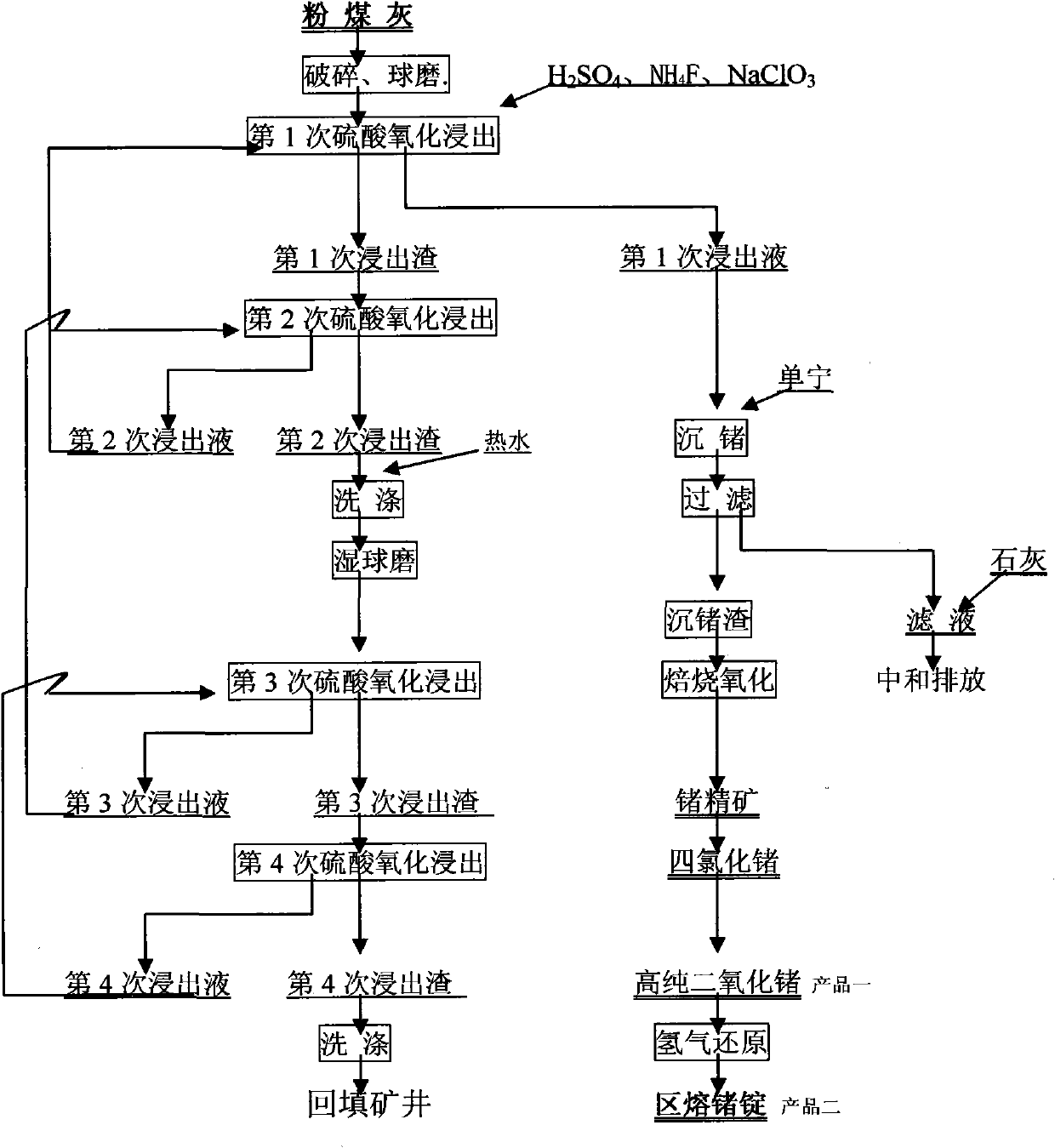

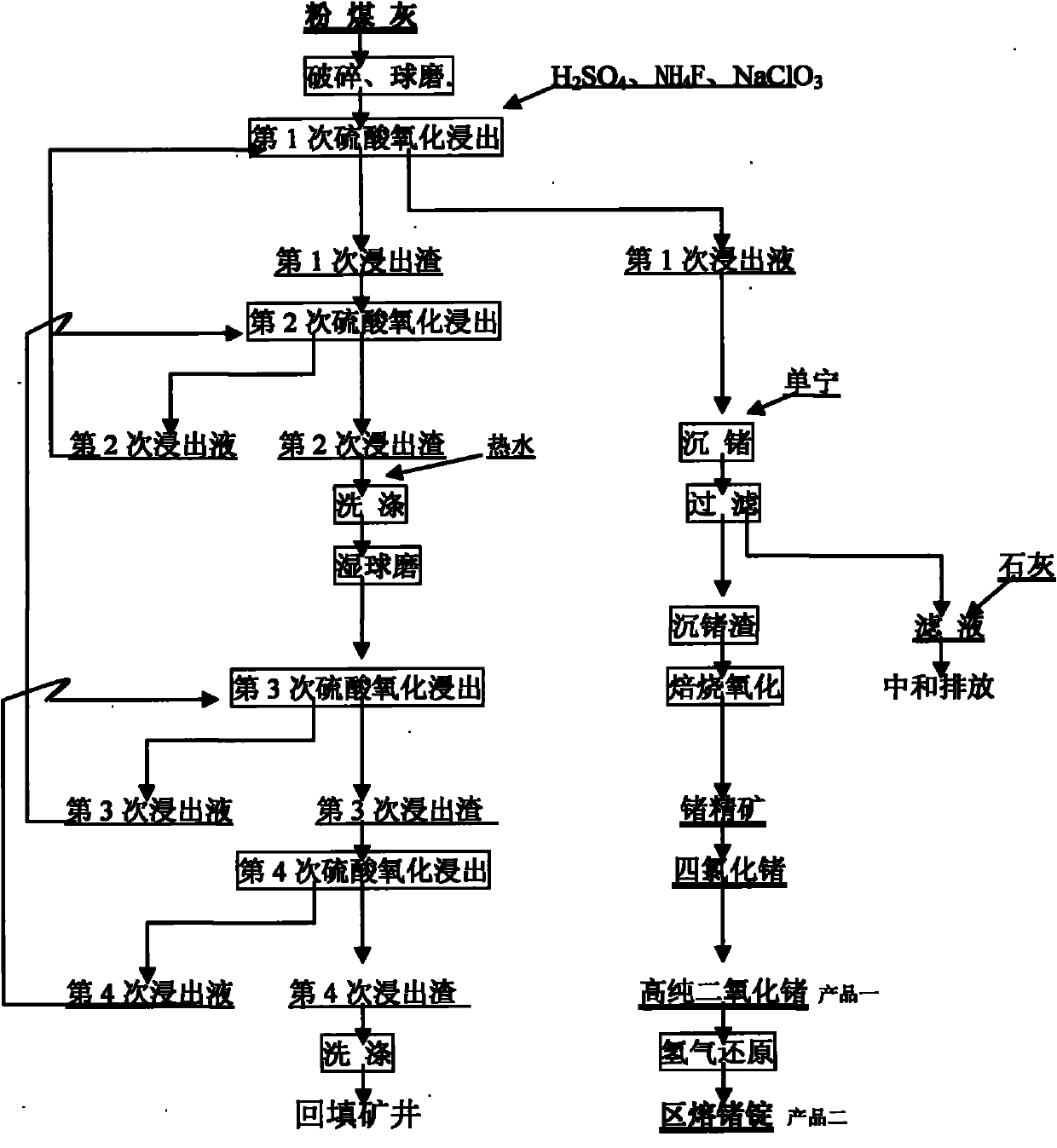

Method for recovering germanium from flyash by wet process

A technology of fly ash and wet method, applied in the field of wet recovery of germanium and secondary recovery of germanium by wet method, can solve the problems of low recovery rate, high recovery cost, occupation of large land, etc., to reduce pollution, low cost, The effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

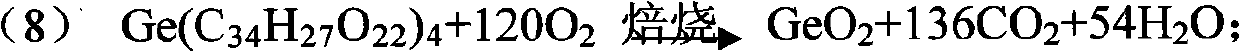

[0030]Embodiment 1: Take 1000g of wet fly ash which is pulverized to 200 mesh by ball milling and place it in a 3000mL beaker. The moisture mass percentage in the wet fly ash is 25.1%. The mass percentage of silicon is 70.23%, the mass percentage of calcium oxide is 0.57%, and the mass percentage of magnesium oxide is 0.52%. Add 0.5mol / L sulfuric acid of 1000g, add 4g sodium chlorate, 25g ammonium fluoride, After stirring and mixing, raise the temperature to 80°C and keep the temperature at 80-85°C, start the mechanical stirring at a speed of 110-120 revolutions per minute, perform the first stirring and leaching for 3 hours, and then filter to obtain a leaching solution 980mL, the germanium content is 126mg / L, adopt the same conditions as the first leaching, and then carry out the second oxidation leaching, after liquid-solid separation, wash the acid solution in the fly ash with 400g hot water, and use pH test paper Check the washing water so that the pH of the washing water...

Embodiment 2

[0031] Example 2: Take 1000 g of wet fly ash crushed by ball milling to 200 mesh and place it in a 3000 mL beaker. The moisture mass percentage in the wet fly ash is 29.3%, the germanium content is 380 g / t, and the silica mass percentage is 69.31%, the mass percentage of calcium oxide is 4.07%, and the mass percentage of magnesium oxide is 0.61%. Add 1500 g of 0.5 mol / L sulfuric acid, add 5 g of sodium chlorate, and 30 g of ammonium fluoride. After stirring and mixing, Raise the temperature to 80°C and keep the temperature at 80-85°C, start mechanical stirring at a speed of 110-120 revolutions per minute, stir and leach for 4 hours, and then filter to obtain 1550mL of leaching solution with a germanium content of 81mg / L. Under the same conditions as the first leaching, carry out the second oxidative leaching of the fly ash after the first leaching. After liquid-solid separation, wash the acid in the fly ash with 400g of hot water, and then use a ball mill to crush it to 200-400...

Embodiment 3

[0032] Example 3: Take 1000g of wet fly ash crushed to 200 mesh by ball milling in a 3000mL beaker, the moisture mass percentage in the wet fly ash is 20.70%, the germanium content is 212g / t, and the silica mass percentage is 66.57 %, the mass percentage of calcium oxide is 38.82%, the mass percentage of magnesium oxide is 0.64%, add the sulfuric acid of 2000g0.5mol / L, add 2.5g sodium chlorate, 20g ammonium fluoride, after stirring and mixing, heat up to 80°C, and keep the temperature at 80-85°C, start mechanical stirring at a speed of 110-120 revolutions per minute, stir and leach for 5 hours, and then filter to obtain 1980mL of primary leachate with a germanium content of 68mg / L, using the conditions of primary leaching Carry out the second oxidative leaching of the fly ash after the first leaching, and after the liquid-solid separation, wash the acid solution in the fly ash with 400g hot water, then crush it to 200-400 mesh with a ball mill, and put it into the In the origi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com