Preparation method of low-chloride high-purity germanium dioxide

A technology of germanium dioxide and high-purity germanium tetrachloride, which is applied in directions such as germanium dioxide, can solve the problem that germanium dioxide cannot meet the demand of low-chlorine and high-purity germanium dioxide, and achieves the improvement of the direct yield of hydrolysis and the improvement of hydrolysis. rate, the effect of reducing chlorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

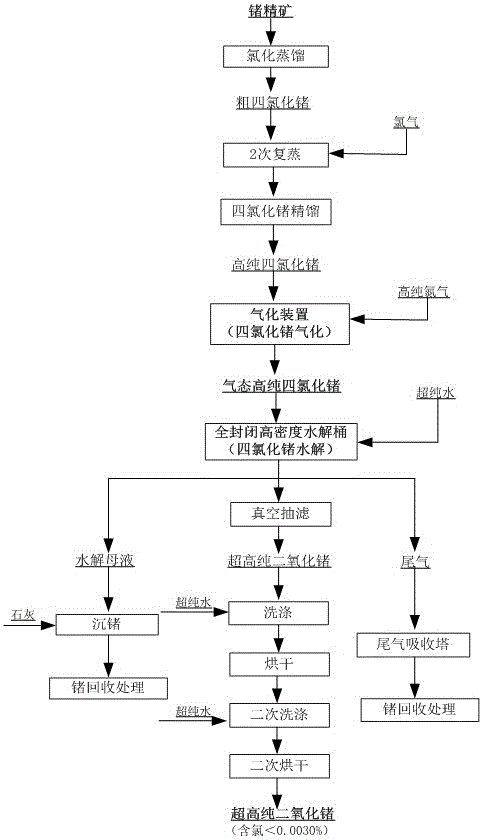

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the preparation of low-chlorine high-purity germanium dioxide, concrete method is as follows:

[0025] (1) Secondary re-distillation of crude germanium tetrachloride: take the crude germanium tetrachloride produced by the chlorination distillation of germanium concentrate, add it to a 500 L enamel still, and then add a volume equal to the volume of crude germanium tetrachloride 2 times of analytically pure hydrochloric acid and feed into the chlorine gas whose volume is 0.5 times of the volume of thick germanium tetrachloride, start to heat up and re-steam the thick germanium tetrachloride, the main effect of chlorine gas is to oxidize the impurities close to the boiling point of germanium tetrachloride; The germanium tetrachloride produced by the first re-evaporation is added to another 500 L enamel for the second heating and re-evaporation. Also add analytical pure hydrochloric acid and chlorine gas whose volume is 0.25 times the volume of germanium tetra...

Embodiment 2

[0032] Embodiment 2: the preparation of low-chlorine high-purity germanium dioxide, concrete method is as follows:

[0033] (1) Secondary re-distillation of crude germanium tetrachloride: take the crude germanium tetrachloride produced by the chlorination distillation of germanium concentrate, add it to a 500 L enamel still, and then add a volume equal to the volume of crude germanium tetrachloride 1.5 times of analytically pure hydrochloric acid and feed into the chlorine gas whose volume is 2 times of the volume of thick germanium tetrachloride, start to heat up and re-steam the thick germanium tetrachloride, the main effect of chlorine is to oxidize the impurities close to the boiling point of germanium tetrachloride; The germanium tetrachloride produced by the first re-evaporation was added to another 500 L enamel for the second heating and re-evaporation, and analytically pure hydrochloric acid and chlorine gas with a volume twice the volume of germanium tetrachloride were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com