Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63 results about "Food coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating is an industrial process that consists of applying a liquid or a powder onto the surface of an edible product to convey new (usually sensory) properties. Coating designates an operation as much as the result of it: the application of a layer and the layer itself. Coating takes different meanings depending on the industry concerned.

Methods and compositions for enhancing palatability of animal feed using tetrapotassium pyrophosphate

InactiveUS20050037108A1Improve palatabilityLow production costAnimal feeding stuffAccessory food factorsPotassiumTetrapotassium pyrophosphate

Compositions and methods for enhancing the palatability of dry and semi-dry animal feed compositions, particularly extruded cat food compositions, are described. In one embodiment, the palatability enhancer is a dry cat food coating including tetrapotassium pyrophosphate at about 0.1% to about 1.0% by weight of the finished pet food product. In the case of extruded pet food products, the palatability enhancer is applied after the extrusion process to the extruded particles or pieces of pet food.

Owner:MEOW MIX CO THE

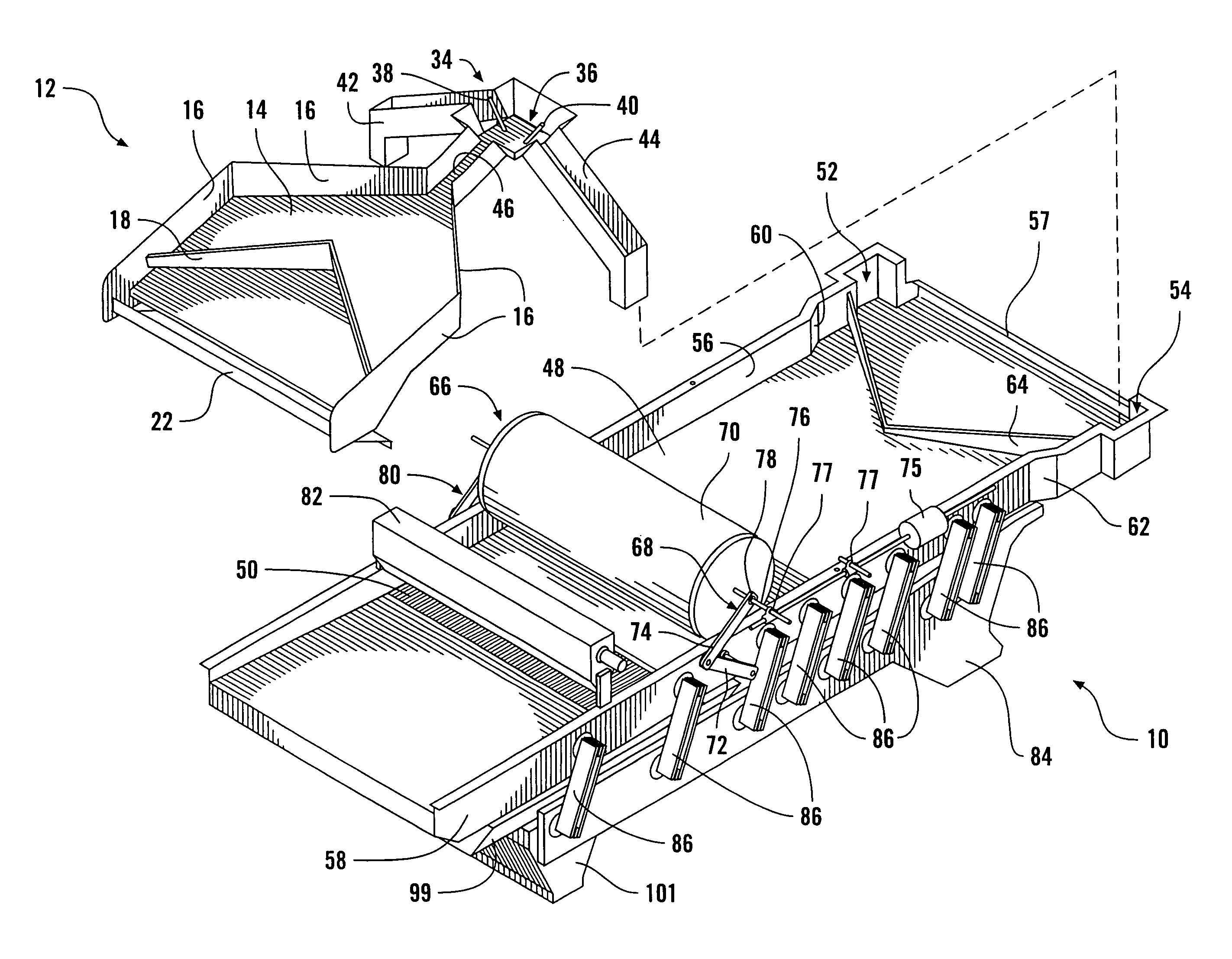

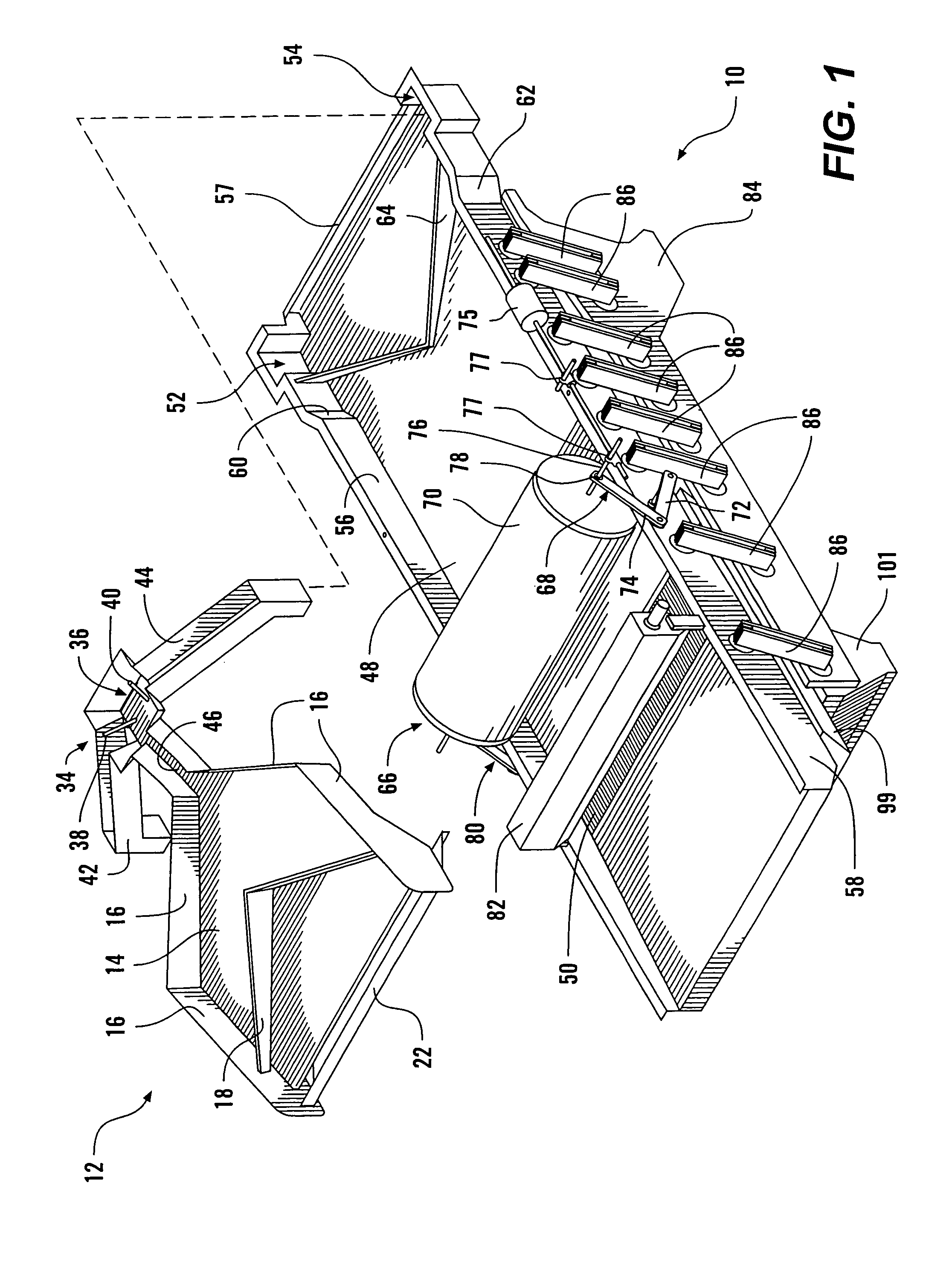

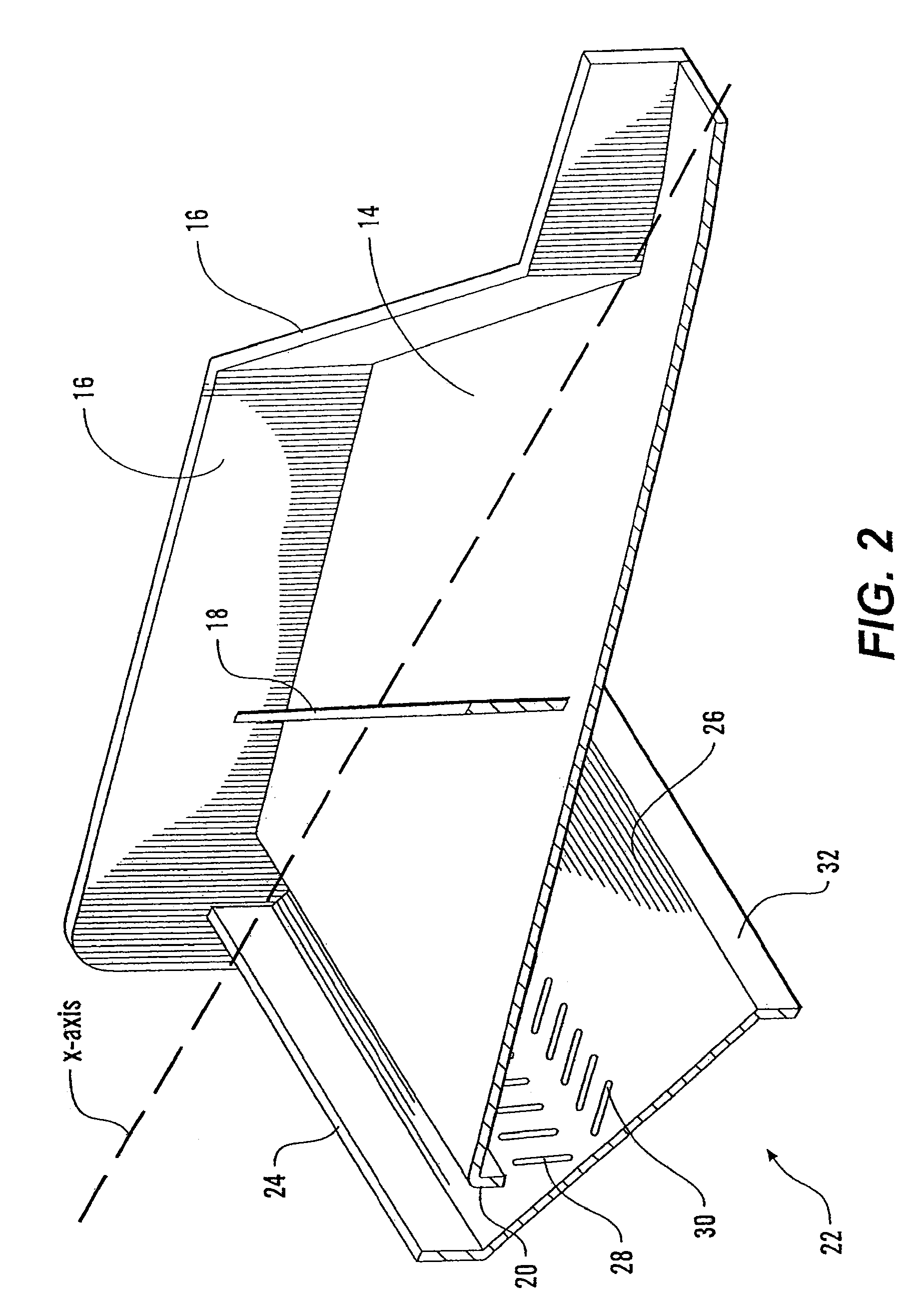

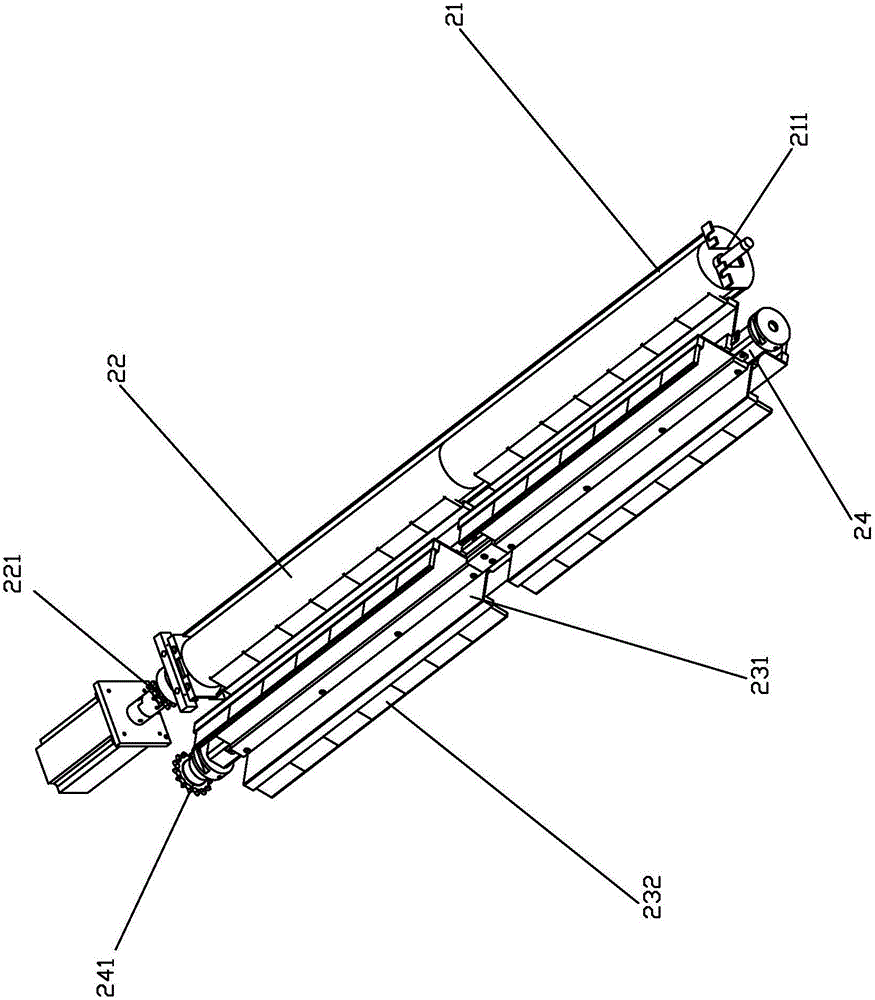

Food Coating and Topping Applicator Apparatus and Methods of Use Thereof

Apparatuses and methods for coating, topping, and conveying foods. The apparatus includes a first frame, spring assemblies, a vibrating assembly including an upper pan, a middle pan, a lower pan, and a second frame mounted to the lower pan with the spring assemblies. The second frame is an excited frame and the upper pan, the middle pan, the lower pan are vibrationally connected. The apparatus also includes a vibratory drive unit mounted and adapted to impart energy to the second frame. In addition, the apparatus has a wire conveyor belt assembly including a wire conveyor belt, and a housing that receives the wire conveyor belt. The wire conveyor belt assembly is suspended inside of the vibratory assembly by the first frame such that the wire conveyor belt assembly is isolated from the vibratory assembly.

Owner:VIBRATORY SOLUTIONS

Process for preparing a hand-held snack item, and a product thereof

A method for preparing a hand-held snack item, said method comprising: (a) applying a first edible, heat-sensitive food material to an initial formed hand-held food item, thereby forming a preliminary coated hand-held food item; (b) applying a second edible food coating material to said preliminary coated hand-held food item, thereby forming a secondary coated hand-held food item, wherein said second edible food material is applied to said preliminary coated hand-held food item in such a manner as to substantially completely coat said first edible, heat-sensitive food material, and wherein said second edible food material is selected from a material which possesses sufficient physical characteristics to act as a protective medium for said first edible, heat-sensitive food material when said secondary coated hand-held food item is subjected to a temperature in the range of from about 35° C. to about 350° C. for a period of time in the range of from about 10 hours to about 30 seconds.

Owner:THE QUAKER OATS CO

Protein-containing food product and coating for a food product and method of making same

A composition comprising about 10-65 weight % of a protein particulate material, about 35-90 weight % of a lipid-containing material, and no more than small amounts of an emulsifier, can be used as a coating composition for a food product, or as an ingredient in a coating composition for a food product. When used as a coating for a snack food item such as a protein-containing energy bar, the coating can add to the nutritive value of the bar, and maintain the moisture content of the bar. A method for making the composition includes the steps of adding finely ground particulate protein matter to a fat composition with heat and high shear, then cooling the composition.

Owner:BUNGE OILS INC

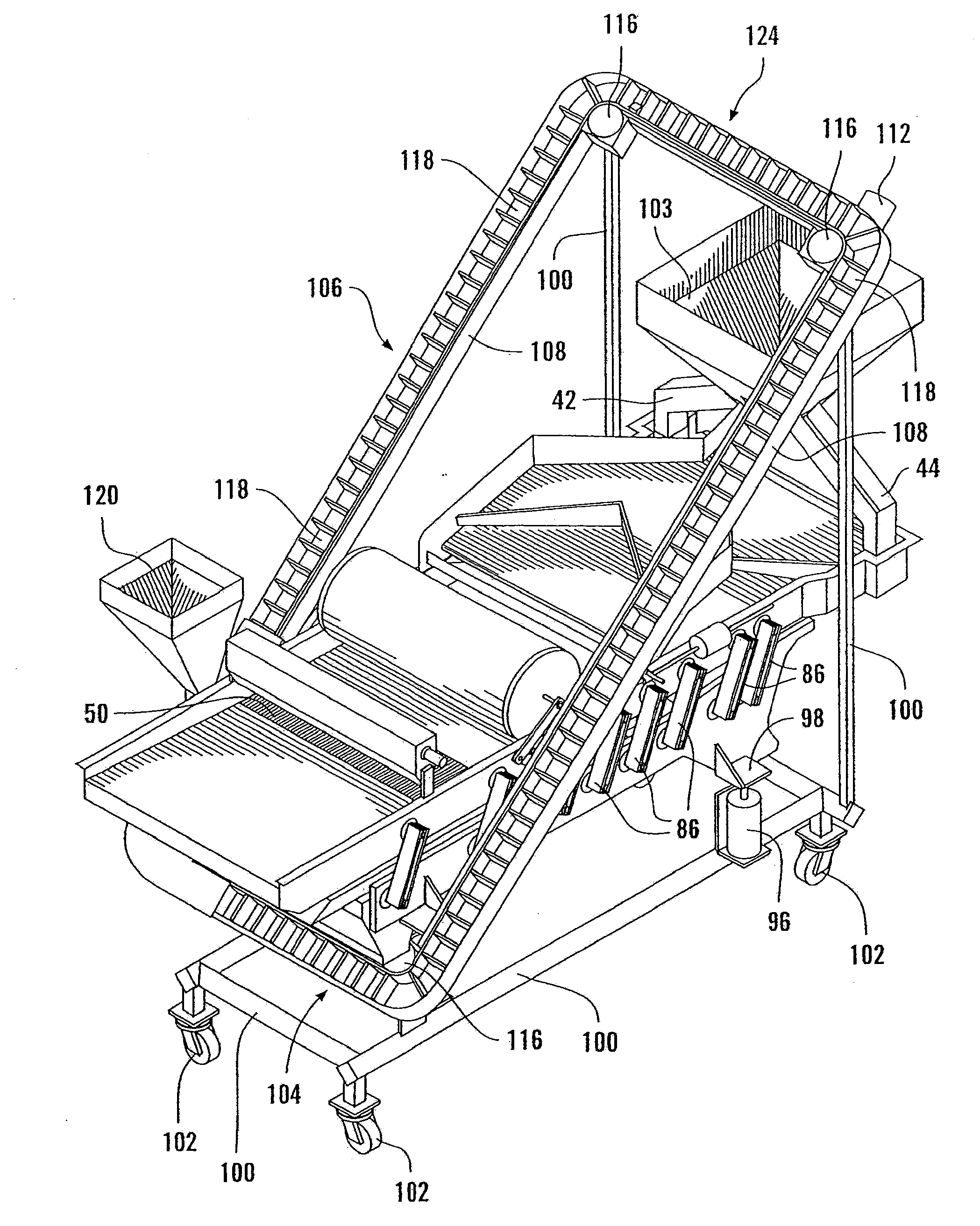

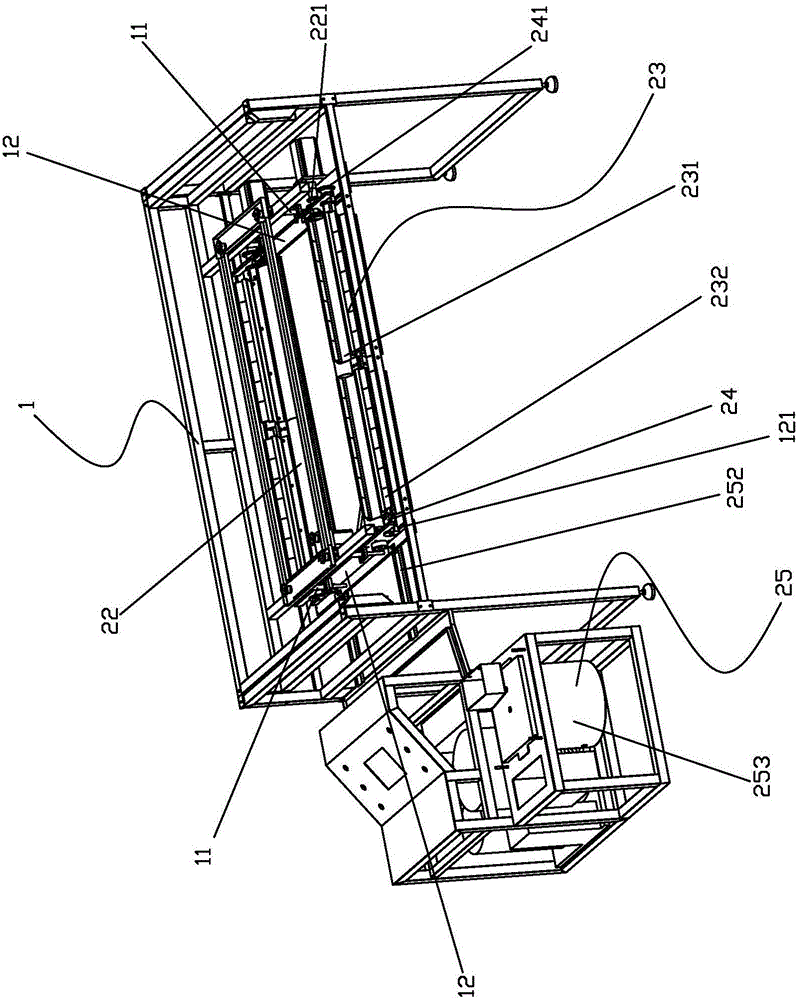

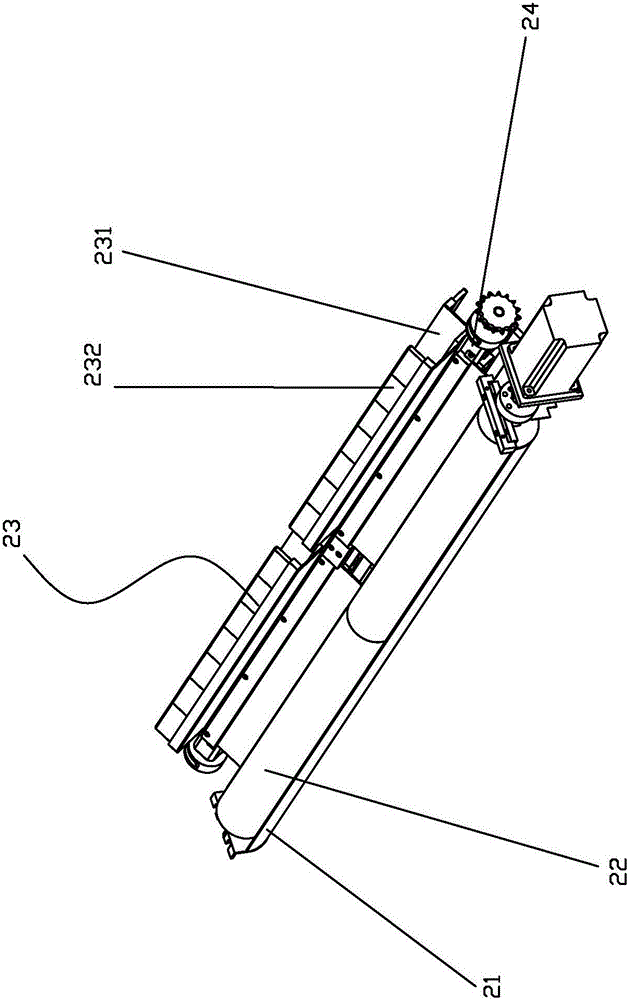

Vibrational excited frame food coating apparatus and methods of use thereof

The present invention is directed to an excited apparatus for coating food product with a coating. The apparatus includes an elongate pan having proximal and distal portions; a screen located in the distal portion and adapted to screen coating; an elongate frame; a motorized vibrator adapted to impart energy to the elongate frame at an angle β below horizontal; a plurality of springs mounting the elongate pan to the elongate frame, the springs being mounted at an angle θ above horizontal; another elongate frame; a plurality of dampeners mounting the two elongate frames; another elongate pan having proximal and distal portions, the elongate pan mounted to the other elongate pan and adapted to feed coating to the other elongate pan; a soft roller rotationally actuated by a ratchet assembly, the ratchet assembly engaged by the elongate pan; and, a recycle assembly for transferring screened coating to the elongate pans, wherein the elongate pan's vibrations have longitudinal and vertical vector components at a predetermined amplitude and frequency. The excited apparatus further includes a waterfall distributor member mounted to the elongate pan, the waterfall distributor including one or more transverse rows of a plurality of angular slots.

Owner:VIBRATORY SOLUTIONS

Food coating and topping applicator apparatus and methods of use thereof

Apparatuses and methods for coating, topping, and conveying foods. The apparatus includes a first frame, spring assemblies, a vibrating assembly including an upper pan, a middle pan, a lower pan, and a second frame mounted to the lower pan with the spring assemblies. The second frame is an excited frame and the upper pan, the middle pan, the lower pan are vibrationally connected. The apparatus also includes a vibratory drive unit mounted and adapted to impart energy to the second frame. In addition, the apparatus has a wire conveyor belt assembly including a wire conveyor belt, and a housing that receives the wire conveyor belt. The wire conveyor belt assembly is suspended inside of the vibratory assembly by the first frame such that the wire conveyor belt assembly is isolated from the vibratory assembly.

Owner:VIBRATORY SOLUTIONS

Water-soluble soybean polysaccharide coating preservative

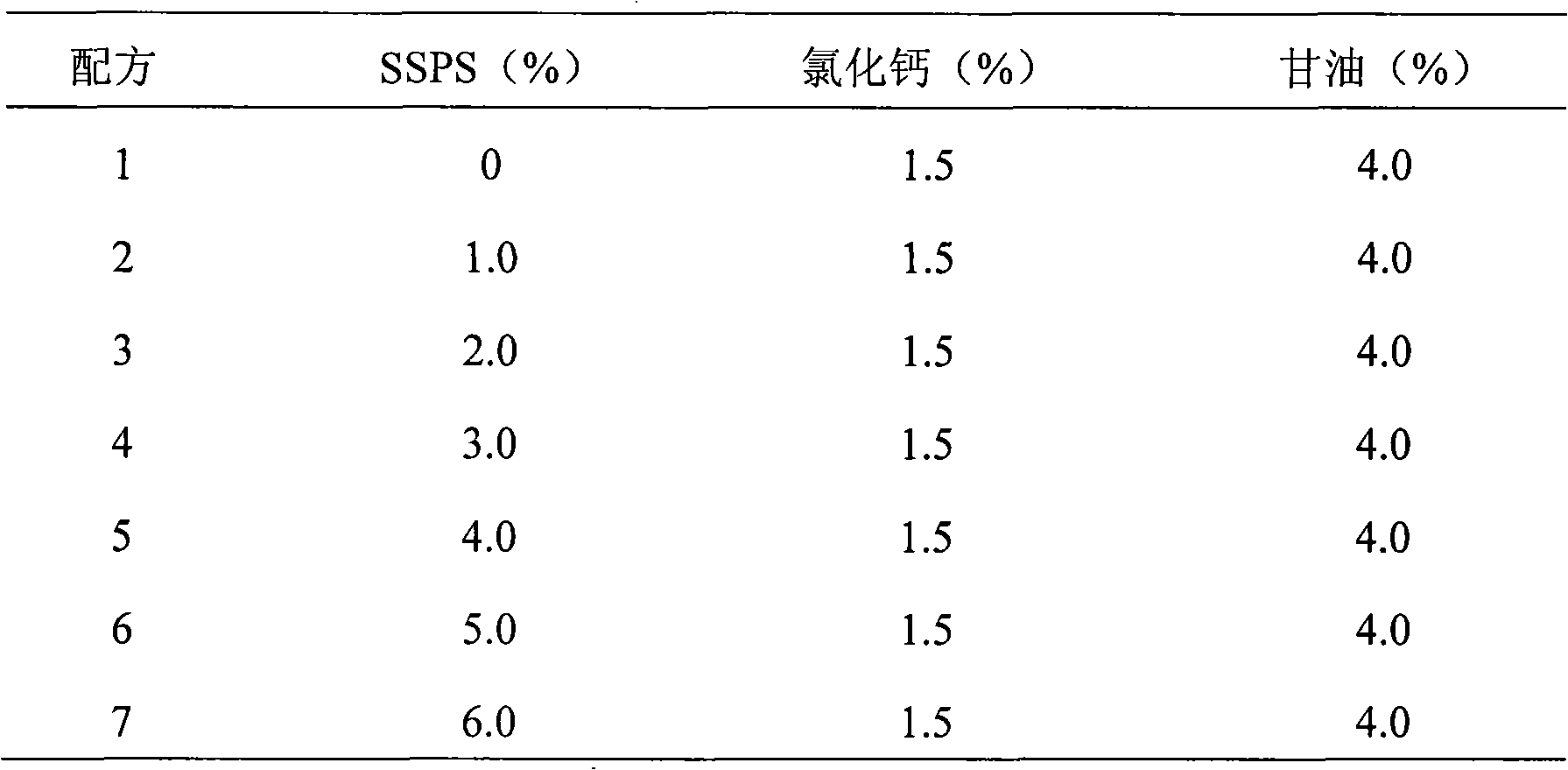

InactiveCN101637294AReduce water permeabilityGood film formingEggs preservation by coatingFruits/vegetable preservation by coatingChitosan coatingAdditive ingredient

The invention relates to a food coating preservative containing water-soluble soybean polysaccharides. The preservative can also contain an enhancer, a plasticizer and other auxiliary components. Thepreservative has good film-forming property and antibacterial property, compared with the coating preservation for eggs which is carried out by using chitosan coating liquid and paraffin coating liquid, a water-soluble soybean polysaccharide coating has the advantages of lower water permeability rate, better preservation effect, a wide range of sources of raw materials, low production cost and edible safety.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

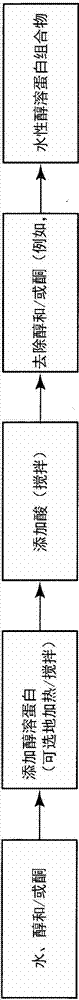

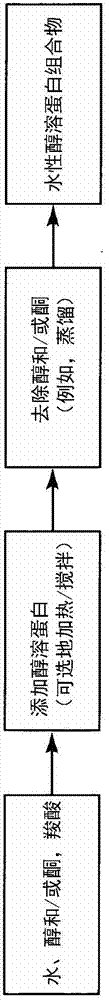

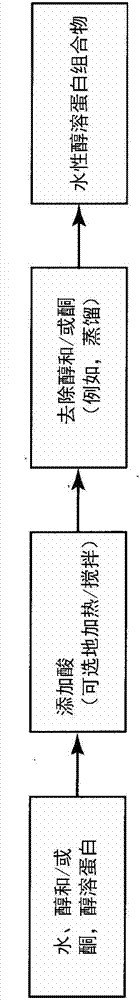

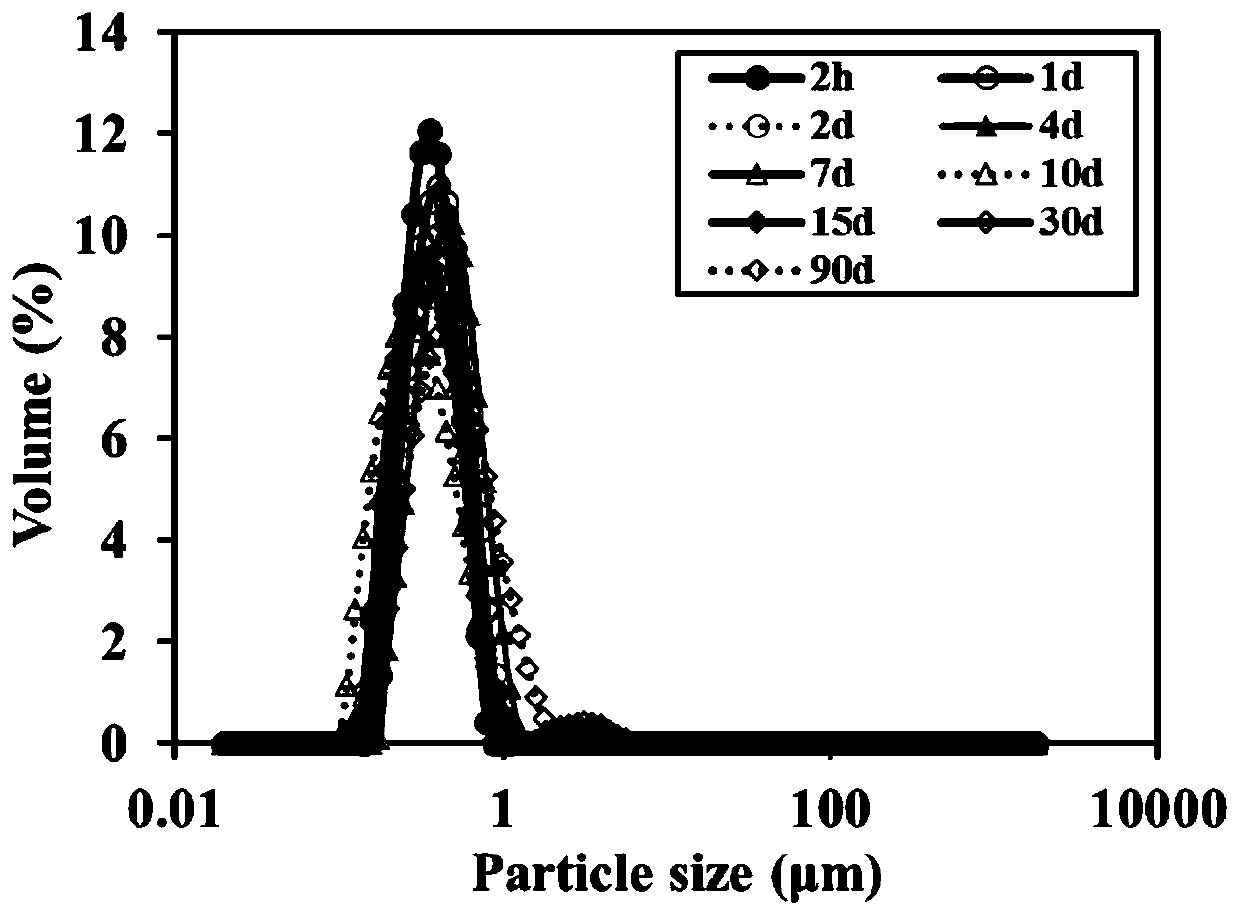

Water-based prolamin compositions, methods of making water-based prolamin compositions, and applications thereof

Owner:POET RES INC

Stable aqueous dispersions of hydrophilic phenolic resins having low xylenol and bisphenol-A content

Storage stable aqueous dispersions of a heat-reactive hydrophilic phenolic resin (e.g., phenol / formaldehyde) are disclosed. The dispersions comprise a base resin that is the reaction product of an aromatic alcohol and an aldehyde, and an etherified resin component selected from the group consisting of an etherified phenol / aldehyde resin, an etherified cresol / aldehyde resin, and mixtures thereof. The dispersions further comprise a protective colloid (e.g., polyvinyl alcohol). The addition of the etherified resin component in an amount of at least about 20% by weight of the base resin provides storage stability, but does not adversely affect the desirable physical and chemical characteristics (e.g., chemical resistance) of end products made from such dispersions. Moreover, the dispersions of the present invention can avoid the use of etherified resin components derived from bisphenol-A and / or xylenols, which present heath concerns in food coating applications.

Owner:GEORGIA PACIFIC CHEM LLC

Process for preparing a hand-held snack item

InactiveUS6375998B1Prevents and limits degradationSeed preservation by coatingFood coatingSnack foodHand held

The present invention relates to a method for preparing a hand-held snack item, said method comprising: (a) applying a first edible, heat-sensitive food material to an initial formed hand-held food item, thereby forming a preliminary coated hand-held food item; (b) applying a second edible food coating material to said preliminary coated hand-held food item, thereby forming a secondary coated hand-hold food item, wherein said second edible food material in applied to said preliminary coated hand-held food item in such a manner as to substantially completely coat said first edible, heat-sensitive food material, and wherein said second edible food material is selected from a material which possesses sufficient physical characteristics to act as a protective medium for said first edible, heat-sensitive food material when said secondary coated hand-held food item is subjected to a temperature in the range of from about 35° C. to about 350° C. for a period of time in the range of from about 10 hours to about 30 seconds; and (c) subjecting said secondary coated hand-held food item to a temperature in the range of from about 35° C. to about 350° C. for a period of time in the range of from about 10 hours to about 30 seconds, thereby producing a final, coated hand-held snack item wherein said first edible, heat-sensitive food material is substantially intact. The present invention further relates to a hand-held snack item prepared by such method.

Owner:THE QUAKER OATS CO

Stable aqueous dispersions of hydrophilic phenolic resins having low xylenol and bisphenol-A content

Storage stable aqueous dispersions of a heat-reactive hydrophilic phenolic resin (e.g., phenol / formaldehyde) are disclosed. The dispersions comprise a base resin that is the reaction product of an aromatic alcohol and an aldehyde, and an etherified resin component selected from the group consisting of an etherified phenol / aldehyde resin, an etherified cresol / aldehyde resin, and mixtures thereof. The dispersions further comprise a protective colloid (e.g., polyvinyl alcohol). The addition of the etherified resin component in an amount of at least about 20% by weight of the base resin provides storage stability, but does not adversely affect the desirable physical and chemical characteristics (e.g., chemical resistance) of end products made from such dispersions. Moreover, the dispersions of the present invention can avoid the use of etherified resin components derived from bisphenol-A and / or xylenols, which present heath concerns in food coating applications.

Owner:GEORGIA PACIFIC CHEM LLC

Antibacterial emulsion with pure essential oil, preparation method and application of emulsion

InactiveCN110236070AHigh antibacterial activityGood antibacterial effectClimate change adaptationFood preservationEscherichia coliFresh food

The invention belongs to the technical field of food coating film protection compositions and particularly relates to an antibacterial emulsion with pure essential oil, a preparation method and application of the emulsion. The antibacterial emulsion is prepared from plant essential oil, flavor aldehyde, chitosan, a surfactant and the like. The antibacterial activity of the prepared emulsion to escherichia coli and staphylococcus aureus is superior than that of single plant essential oil, the content of the surfactant is low, the emulsion does not contain edible fat and oil, the preparation conditions are mild, and the emulsion is safer to use and stable, has a long storage period, is used after being diluted and can be widely applied to rot prevention and fresh preservation of fresh food.

Owner:HUAZHONG AGRI UNIV

Automatic food coating apparatus

ActiveCN105010450AGuarantee the right amountUniform thicknessPreservation by coatingDough processingSlurryEngineering

The present invention discloses an automatic food coating apparatus, which includes a frame. According to the present invention, the key points of the technical scheme are as follows: an automatic coating mechanism for coating the food surface with an egg slurry or oily food is arranged on the frame, and comprises a bottom groove for holding the egg slurry or oily food, a material roller for adhering the egg slurry or oily food in the bottom groove onto the roller surface through rotation is arranged above the bottom groove, at least one material brush for dipping the adhered egg slurry or oily food from the material roller is positioned beside the material roller, and a side of the bottom groove close to the material brush is equipped with a blocking sheet so as to control the dipping amount of the egg slurry or oily food dipped from the material rollers by the material brush. According to the present invention, an automatic food coating apparatus is provided, wherein the egg slurry or oily food is adhered onto the material roller through rotation of the material roller, and then is dipped from the material roller by the material brushes, the material brushes are scrapped with the blocking sheet of the bottom groove so as to control an appropriate dipping amount of egg slurry or oily food, then the dipped egg slurry or oily food is spread onto the surface of the food to be baked, such that automatic coating of egg slurry or oily food and an uniform coating thickness can be achieved.

Owner:SHANDONG GELANDE BIO TECH

Process for preparing a hand-held snack item, and the product thereof

InactiveUS20020015765A1Prevents and limits degradationBaking mixturesConfectioneryBiotechnologySnack food

The present invention relates to a method for preparing a hand-held snack item, said method comprising: (a) applying a first edible, heat-sensitive food material to an initial formed hand-held food item, thereby forming a preliminary coated hand-held food item; (b) applying a second edible food coating material to said preliminary coated hand-held food item, thereby forming a secondary coated hand-held food item, wherein said second edible food material is applied to said preliminary coated hand-held food item in such a manner as to substantially completely coat said first edible, heat-sensitive food material, and wherein said second edible food material is selected from a material which possesses sufficient physical characteristics to act as a protective medium for said first edible, heat-sensitive food material when said secondary coated hand-held food item is subjected to a temperature in the range of from about 35° C. to about 350° C. for a period of time in the range of from about 10 hours to about 30 seconds; and (c) subjecting said secondary coated hand-held food item to a temperature in the range of from about 35° C. to about 350° C. for a period of time in the range of from about 10 hours to about 30 seconds, thereby producing a final, coated hand-held snack item wherein said first edible, heat-sensitive food material is substantially intact. The present invention further relates to a hand-held snack item prepared by such method.

Owner:THE QUAKER OATS CO

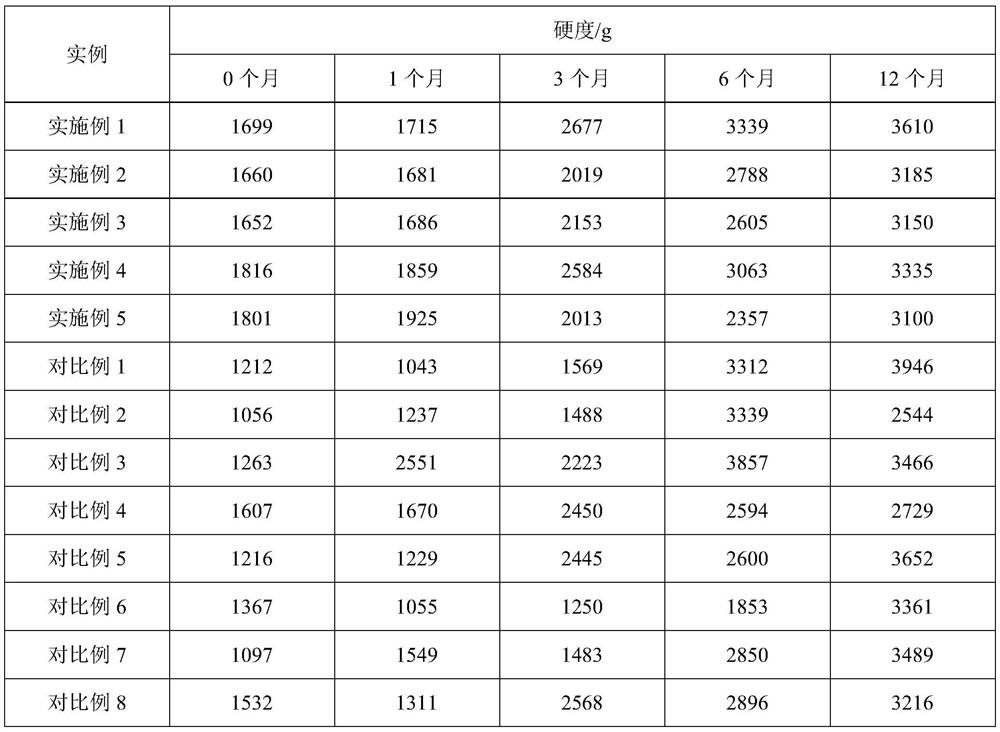

Heat-proof chocolate coating

ActiveCN106615501AImprove liquiditySolve technical problems of high temperature deformationSugar food ingredientsCocoaFlavorHeat resistance

The invention provides a heat-proof chocolate coating. The heat-proof chocolate coating contains low-melting-point carbohydrate and is prepared through baking and agglomeration, wherein the melting point of the low-melting-point carbohydrate is 80-150 DEG C, can be 80-120 DEG C and also can be 80-110 DEG C or 90-100 DEG C. The heat-proof chocolate coating is prepared through the baking and the agglomeration, and the consumption of the low-melting-point carbohydrate is not less than 10%. The heat-proof chocolate coating provided by the invention has good heat resistance and fluidity and can serve as a food coating layer. After being baked under a high temperature, the low-melting-point carbohydrate can be completely melted and does not produce peculiar smell. Compared with the prior art, the heat-proof chocolate coating has the advantages that on one hand, the technical problem of the high-temperature deformation of chocolate is effectively solved, and on the other hand, the original flavor is maintained.

Owner:阿胡斯卡尔斯油脂(张家港)有限公司

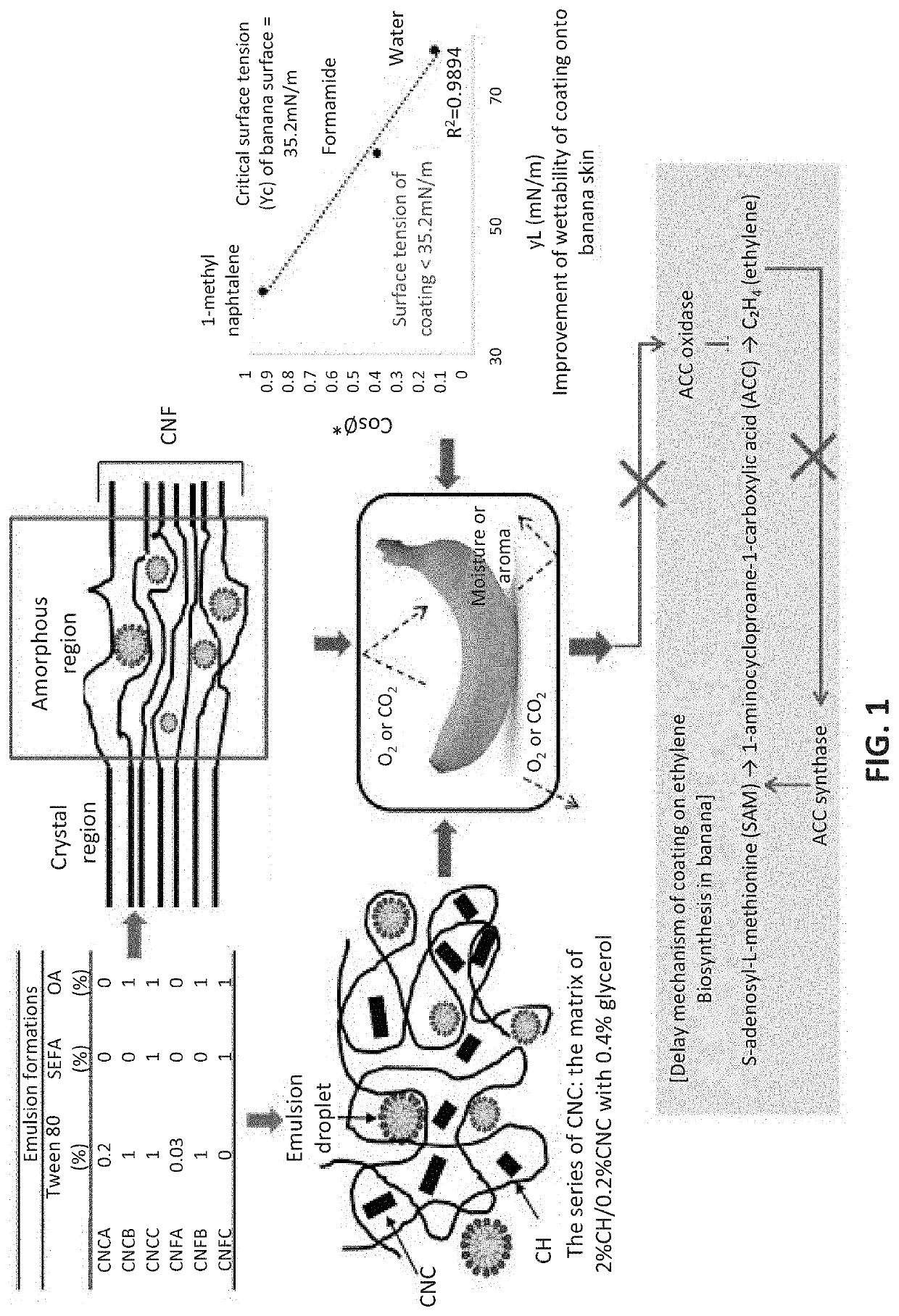

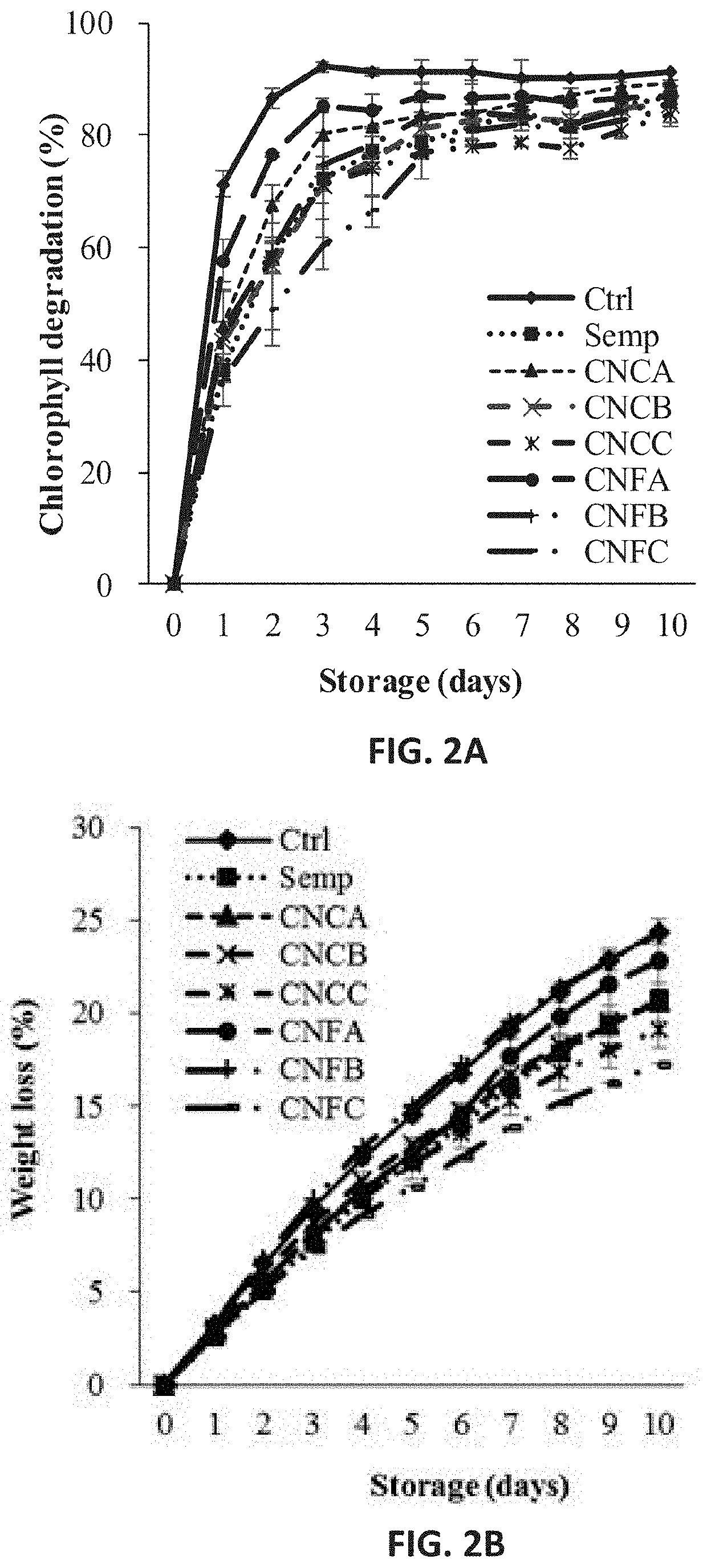

Food product coatings

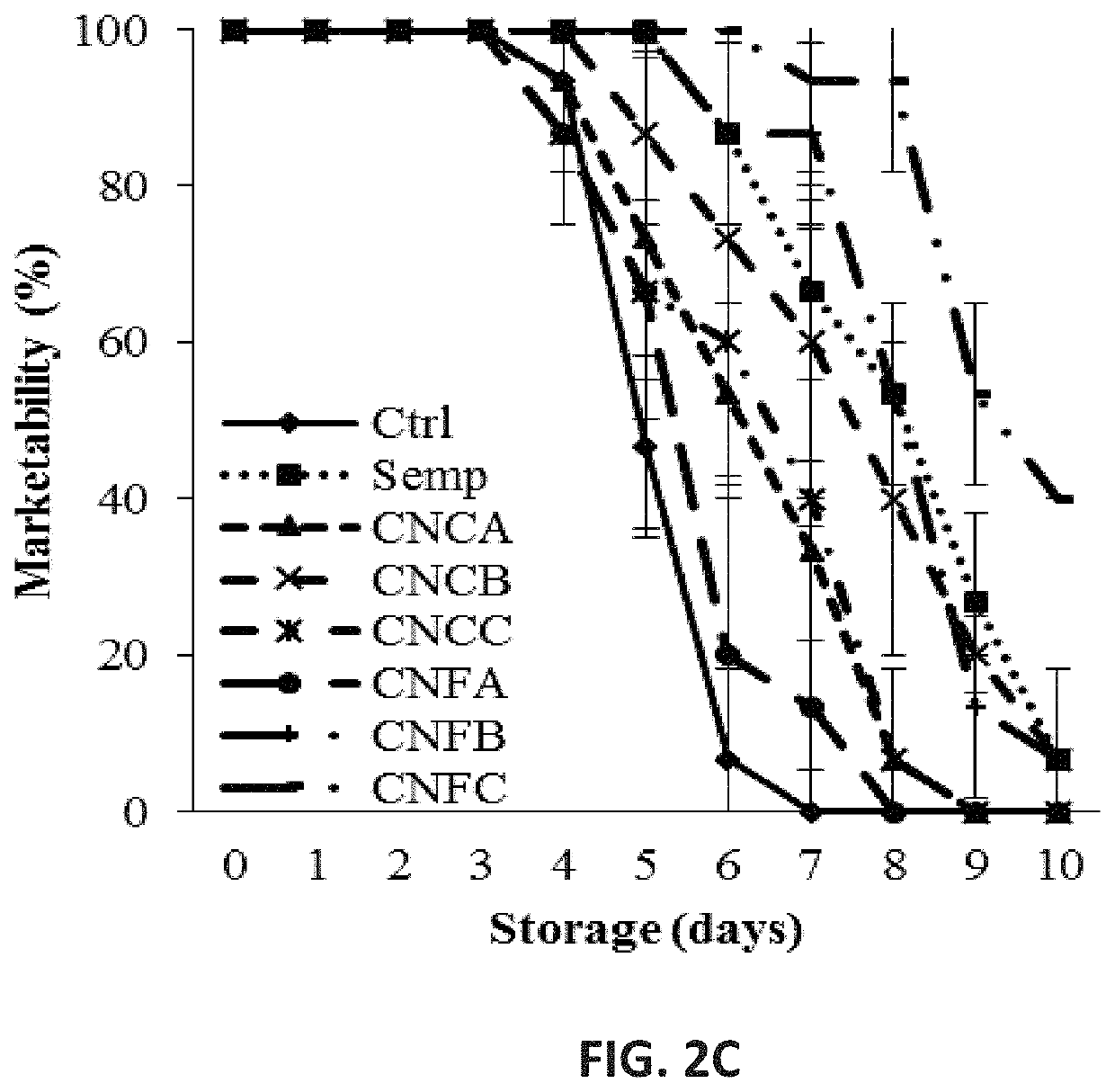

Disclosed herein are embodiments of a coating composition comprising cellulose nanomaterials and emulsion systems. The coating compositions provide improved moisture barrier and wettability onto fruit surfaces and can control physiological activity and enhance storability of food products, such as fruits during ambient storage. Also disclosed herein are embodiments of dried and substantially dried coatings, films, products made with the coating compositions, and methods of making and using the coating compositions described herein.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

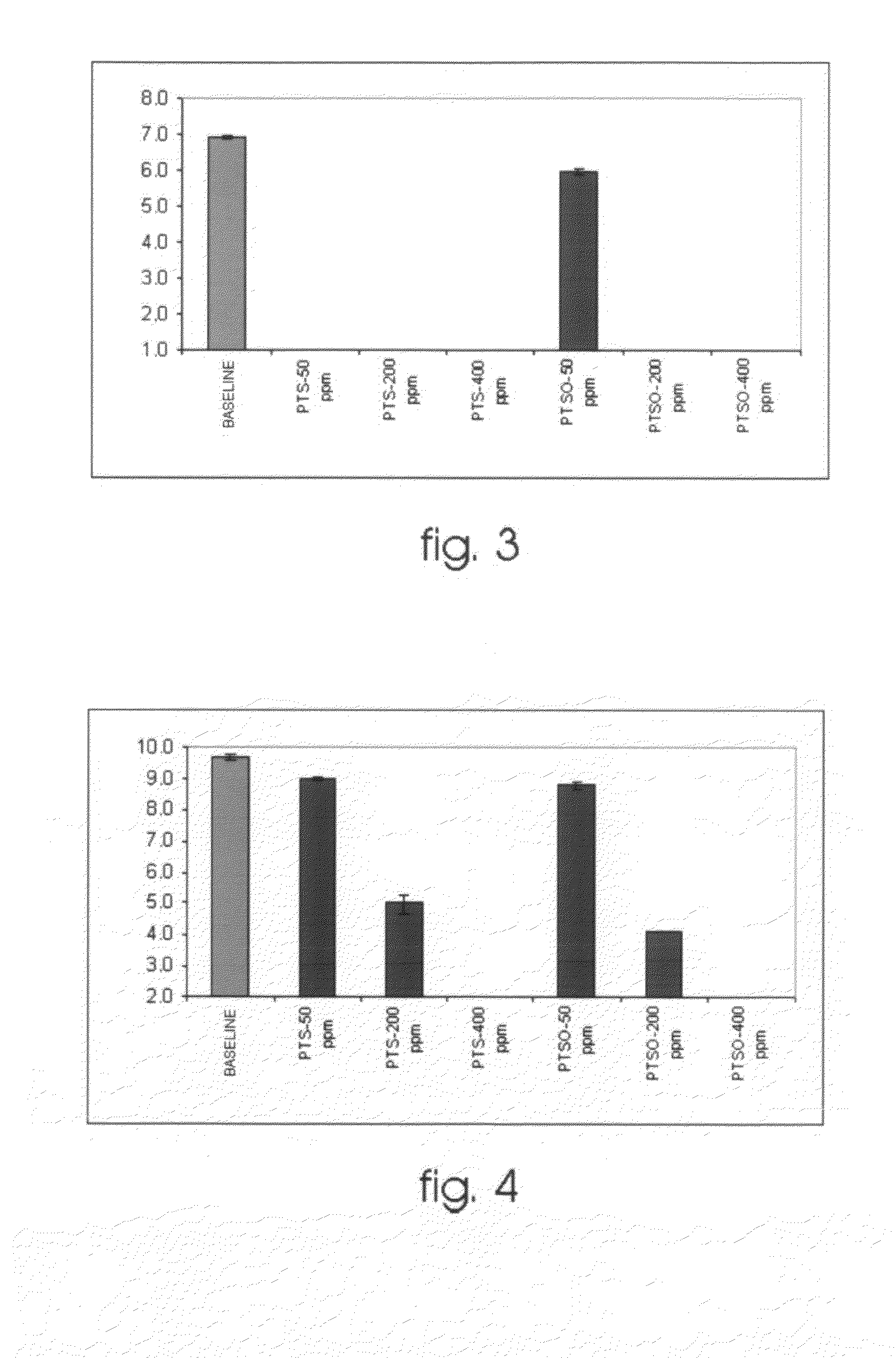

Use of an antibacterial compound which is derived from alliaceae, as a natural additive in animal feed

The invention relates to the use of an antibacterial compound, which is derived from alliaceae, as a natural additive in animal feed, intended as an antimicrobial agent in animal feed, and as an alternative, due to its antibacterial nature, to the use of antibiotics as growth promoters, proposing the use of the compound separately (purity greater than 95%), and encapsulated or supported on different inert materials or food coatings, and in that said compound preferably consists of propyl propylthiosulfinate and, in an alternative variant, of propyl propylthiosulfonate.

Owner:DMC RES CENT

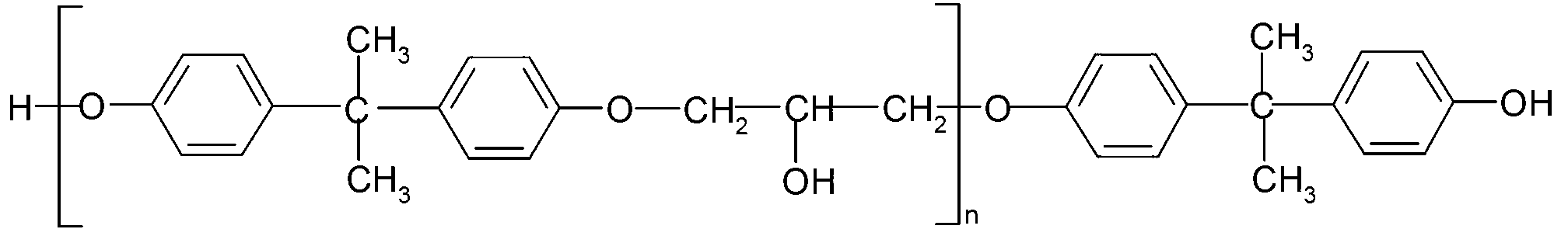

Special decorative powder coating for glass wine bottle and ceramic vessel and application

InactiveCN103289524AImprove adhesion performanceOvercoming featurePowdery paintsEpoxy resin coatingsMetallurgySolvent

The invention relates to a special decorative powder coating for a glass wine bottle and a ceramic vessel. The raw material comprises the following components in parts by weight: 500-900 parts of special resin, 80-300 parts of special curing agent, 50-100 parts of pigment, 100-300 parts of filler and 30-50 parts of auxiliary. The special decorative powder coating provided by the invention has the characteristics of high decoration, alcohol solvent resistance, scratch resistance, high temperature and low temperature resistance and the like, and is suitable for the cold storage and cellar storage of wines; and moreover, the special decorative powder coating is energy-saving and environment-friendly, replaces the traditional paint or waterborne coating spraying technology, prevents pollution and harmful substances, and improves the safety and sanitation level. The product provided by the invention is only applied to exterior decoration and does not contact with things contained inside, and passes the detection of the state health standard GB / T5009.69-2008 for the food coating.

Owner:TIANJIN XIANGSHENG NEW MATERIALS CO LTD

Easy-to-pulping die-cutting high-barrier food coating paperboard and preparation method thereof

ActiveCN111379189AReduce intensityImprove mechanical propertiesNon-fibrous pulp additionClimate change adaptationPolyvinyl alcoholPaperboard

The invention relates to an easy-to-pulping die-cutting high-barrier food coating paperboard and a preparation method thereof. The coated paper comprises a paperboard base material, wherein the surface of the paperboard base material is coated with two layers of water-based composite coatings, and each water-based composite coating is composed of a film coating layer compounded by a polyvinyl alcohol aqueous solution and polyacrylate emulsion with low glass-transition temperature and a film coating layer of emulsion with high barrier property, which are sequentially coated on the paperboard base material; during preparation, a polyvinyl alcohol aqueous solution and polyacrylate emulsion compound solution with low glass-transition temperature coat one surface of a paperboard base material for one time, then the paperboard base material is dried and is coated with a high-barrier emulsion for the second time, and the paper is dried and cooled to obtain the coated paper. Compared with theprior art, the coating disclosed by the invention is small in molecular elongation, relatively crisp in texture, low in strength, easy to naturally crush, convenient for waste paper recycling, pulpingand reusing, and beneficial to ecological balance and environmental protection.

Owner:SHANGHAI ZIDAN FOOD PACKAGING & PRINTING CO LTD +1

Complementary food nutrient supplementing food coating containing nuts for infants and children

The invention provides a complementary food nutrient supplementing food coating containing nuts for infants and children and relates to the technical field of complementary food nutrient supplementing foods for the infants and the children. The formula of the complementary food nutrient supplementing food coating contains following components in percentage by mass: 80-90% of nut jam, 6-8% of edible oil and / or DNA (Deoxyribose Nucleic Acid) algae oil, 0.05-0.1% of a multivitamin premix and 2-5% of a multi-mineral-substance premix, wherein the multivitamin premix comprises lipid-soluble vitamin and water soluble vitamin; the apparent viscosity of the coating is 20000-80000 centipoises and the content of fat is 8-40%. According to physiological functions of the infants and the children and a knowing and diet principle of growth and development, many vitamins and mineral substances which have high density are added into the nut jam and are used as the nutrient supplementing food for the infants and the children, so as to improve the nutrition and the health of the infants and the children.

Owner:天添爱(江苏)生物科技有限公司

Pearly-lustre type coating premix and preparation method thereof

The invention discloses a dry powder coating premix which is composed of a macromolecule film-forming material and a pearly-lustre pigment, and belongs to the technical field of medicines and food coatings. A pearly-lustre type coating premix is characterized by comprising the component of the dry powder coating premix which is composed of the macromolecule film-forming material, such as hydroxypropyl methyl cellulose, and the pearly-lustre pigment in a physically mixing manner, the premix is sprayed on surfaces of solid particles, pill cores, tablets and candies after being dissolved, and the surface of the premix has the pearl-like high-glossiness gorgeous color.

Owner:AILEYI MEDICINE MATERIAL SCI & TECH TIANJIN CITY

Wrapping material for food

InactiveCN101279661AExtended shelf lifeLong storage timeFlexible coversWrappersFood flavorPollution prevention

The invention discloses a food coating material, comprising the materials with the following weight proportion: 10 to 80 parts of flour, 20 to 90 parts of plant powder and 10 to 25 parts of water. The invention adds various plant powders with good smell or medical value, such as the powder of grinded dried seeds, fruits, flowers, leaves, stems and roots of plants or crops, to the flour to make a food wrapping material. The wrapping material of the invention can not only coat meet, but also coat bean products, eggs and even fruits and vegetables to bake and then get the food with unique flavor. The coating material of the invention can not only coat meet, but also coat bean products, eggs and even fruits and vegetables to bake and then get the food with unique flavor. The food wrapping material has the advantages of anti-oxidation, bacterial refraining, scent adding, fresh keeping and secondary pollution prevention.

Owner:严凤权

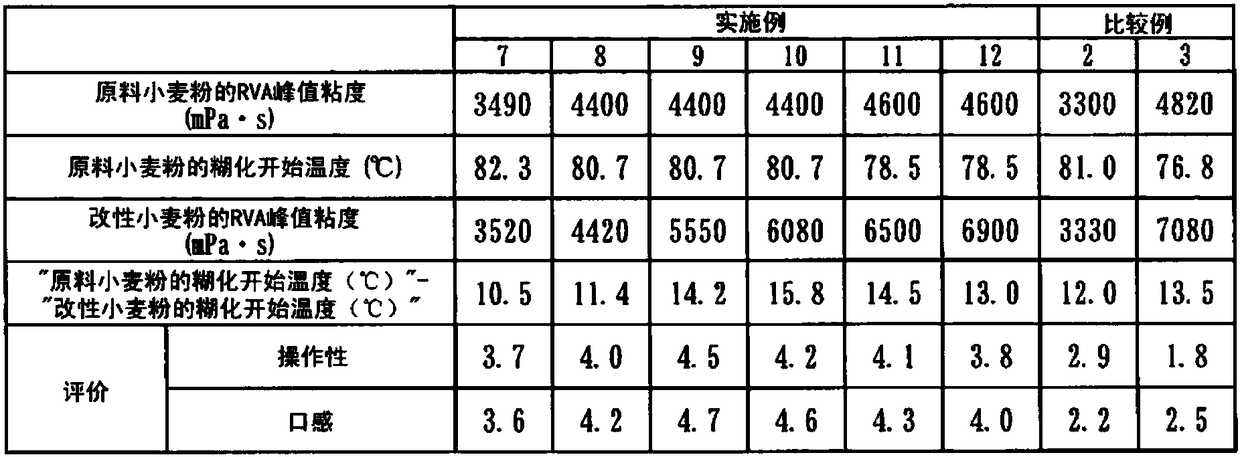

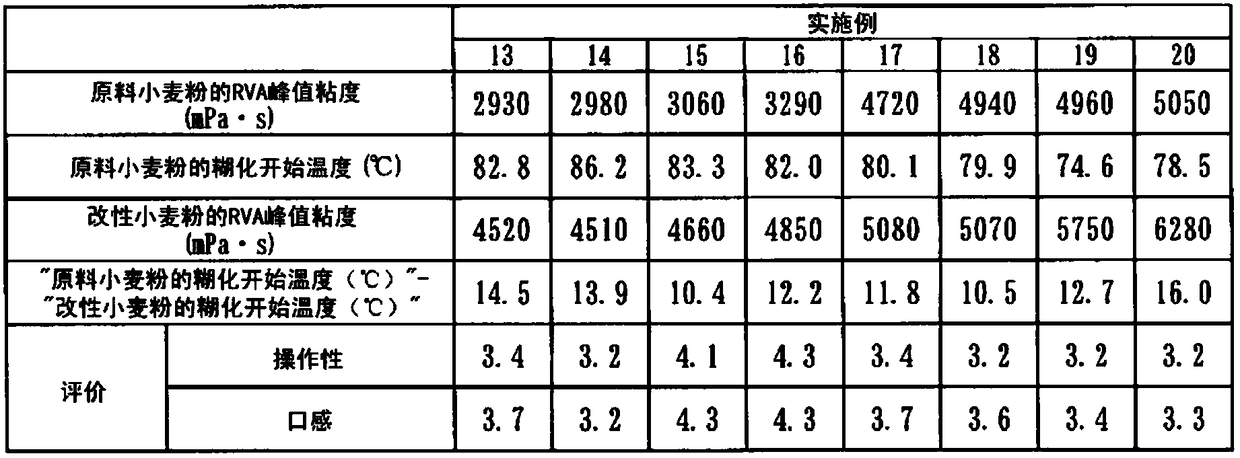

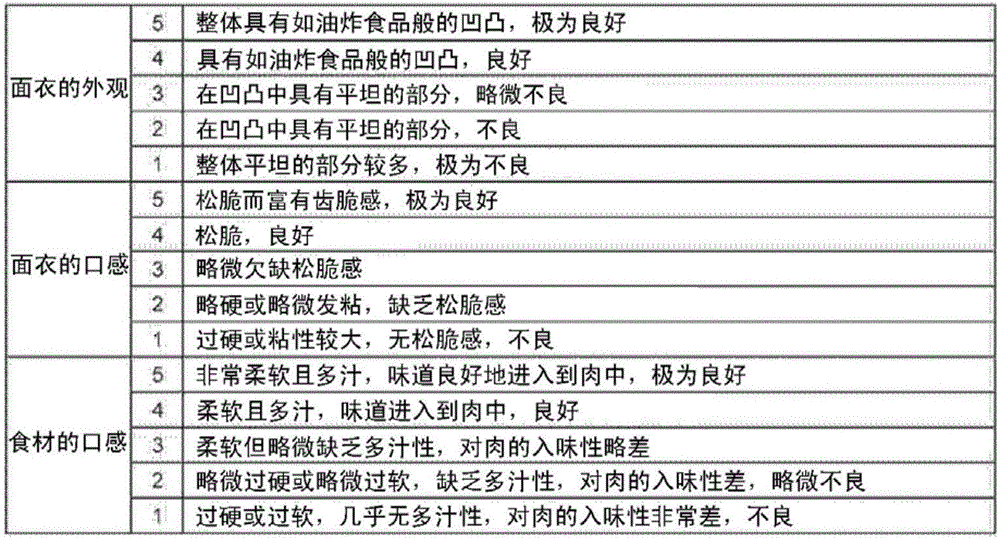

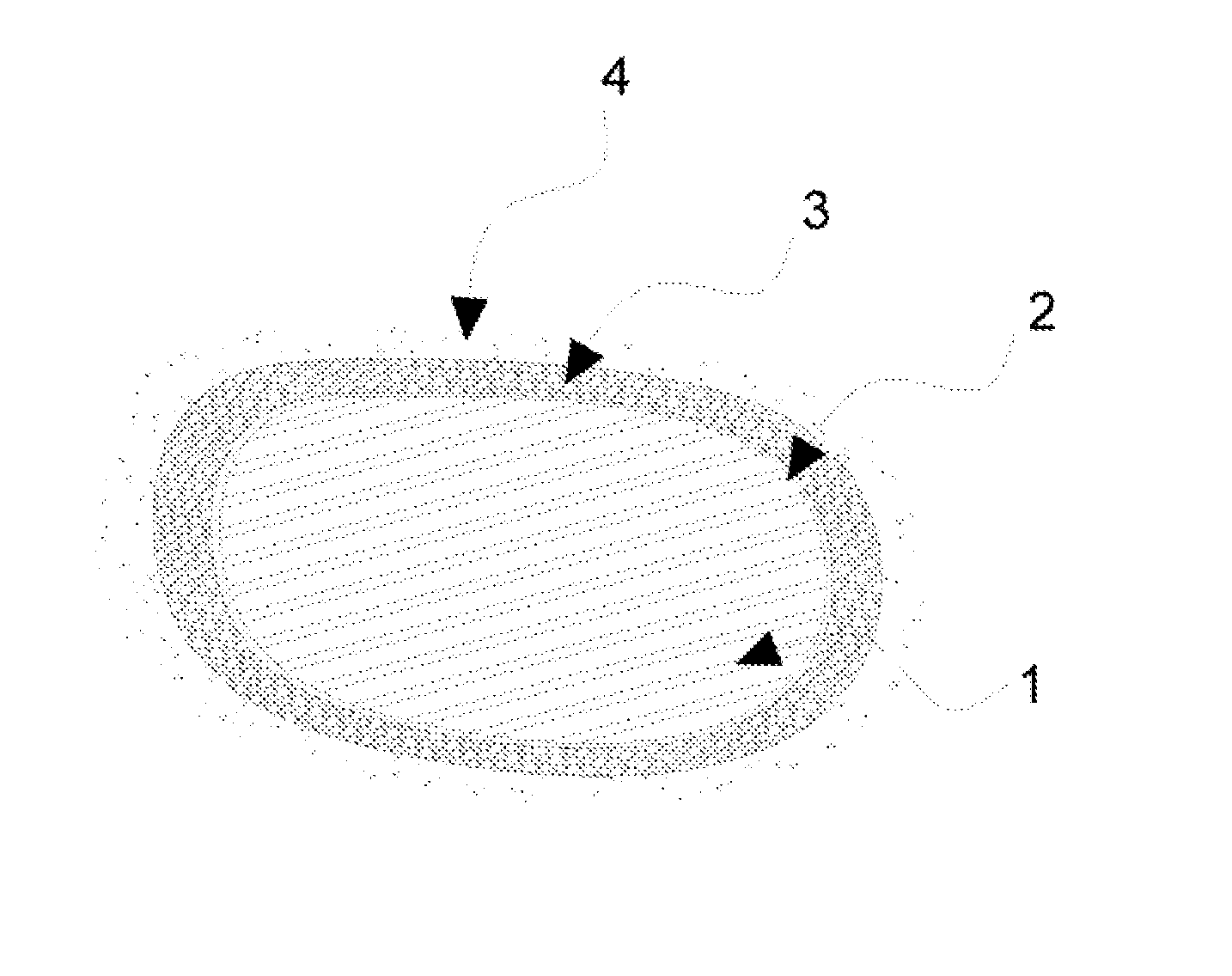

Modified wheat flour for fried food coating

This modified wheat flour for fried food coating is formed from the heat treatment product of a starting wheat flour; the RVA peak viscosity is 3,500 to 7,000 mPa s; and the gelatinization start temperature is at least 10DEG C lower than that of the starting wheat flour. The gelatinization start temperature of the starting wheat flour is preferably 70 to 86DEG C. The RVA peak viscosity of the starting wheat flour is preferably 3,000 to 5,000 mPa s. This modified wheat flour for fried food coating has good dispersibility in water and excellent workability, and is capable of producing a fried food coating having a crispy texture.

Owner:NISSIN YORK

Mix for fried food coating

A mix for a fried food coating according to the present invention is characterized by containing waxy potato starch. Preferably, the added amount of waxy potato starch is 15-50 mass% with respect to the total weight of the mix. Preferably, 15-50 parts by mass of waxy potato starch and 10-85 parts by mass of non-waxy potato starch are also contained. Also, the waxy potato starch preferably has 85 mass% or more of amylopectin content. Further, preferably, a swelling agent is contained in an amount of 0.3-3 mass% with respect to the total weight of the mix and also sugars are contained in an amount of 2-8 mass% with respect to the total weight of the mix.

Owner:NISSIN YORK

Edible Anti-microbial food coating materials

InactiveUS20070031543A1Reduce microbial countImprove protectionConfectionerySweetmeatsAdditive ingredientAnti bacteria

The invention discloses edible anti-microbial food coating materials whose application to foods such as meat, poultry, seafood, vegetables, cheese, or mushrooms results in a significant reduction in the population of microbial contaminants on the surface of the food product. In addition, the edible anti-microbial food coating materials protect the coated food from further microbial growth or contamination. These edible anti-microbial food coating materials contain materials that impart the anti-microbial characteristics. Ingredients that lower the pH of the coating materials result in coating materials that are anti-bacteria, while ingredients that are preservatives or mold inhibitors result in coating materials that are anti-mold and anti-yeast, The edible anti-microbial coating materials are applied to the surface of the food product in layers which are comprised of one or more of the following: adhering material, predust, batter, and crumbs. In addition, the edible anti-microbial coating materials can be manufactured to have a high water activity which also results in a breading product that browns more evenly and eliminates the known frostiness problem inherent in extruded crumb products.

Owner:PHRESH TECH

Food coating prepared from raw milk as well as preparation method and application of food coating

ActiveCN112244293AIncrease profitMake up for the lossFood coatingFood ingredient as taste affecting agentBiotechnologyCellulose

The invention belongs to the technical field of food raw material processing, and particularly relates to a food coating prepared from raw milk as well as a preparation method and application of the food coating. The food coating comprises the following components of whole milk powder, polydextrose, raw milk and other mixed materials including edible essence, phospholipid, vegetable oil, anhydrouscream, maltitol and isomaltooligosacharide; carrageenan, xanthan gum and sodium carboxymethyl cellulose in a certain mass ratio are added in the preparation process, heating and emulsification is performed, and then cutting molding is performed. The prepared food coating is good in stability and high in purity, the pleasant smell can be kept, and the protein content can be effectively protected.

Owner:浙江衡美健康科技股份有限公司

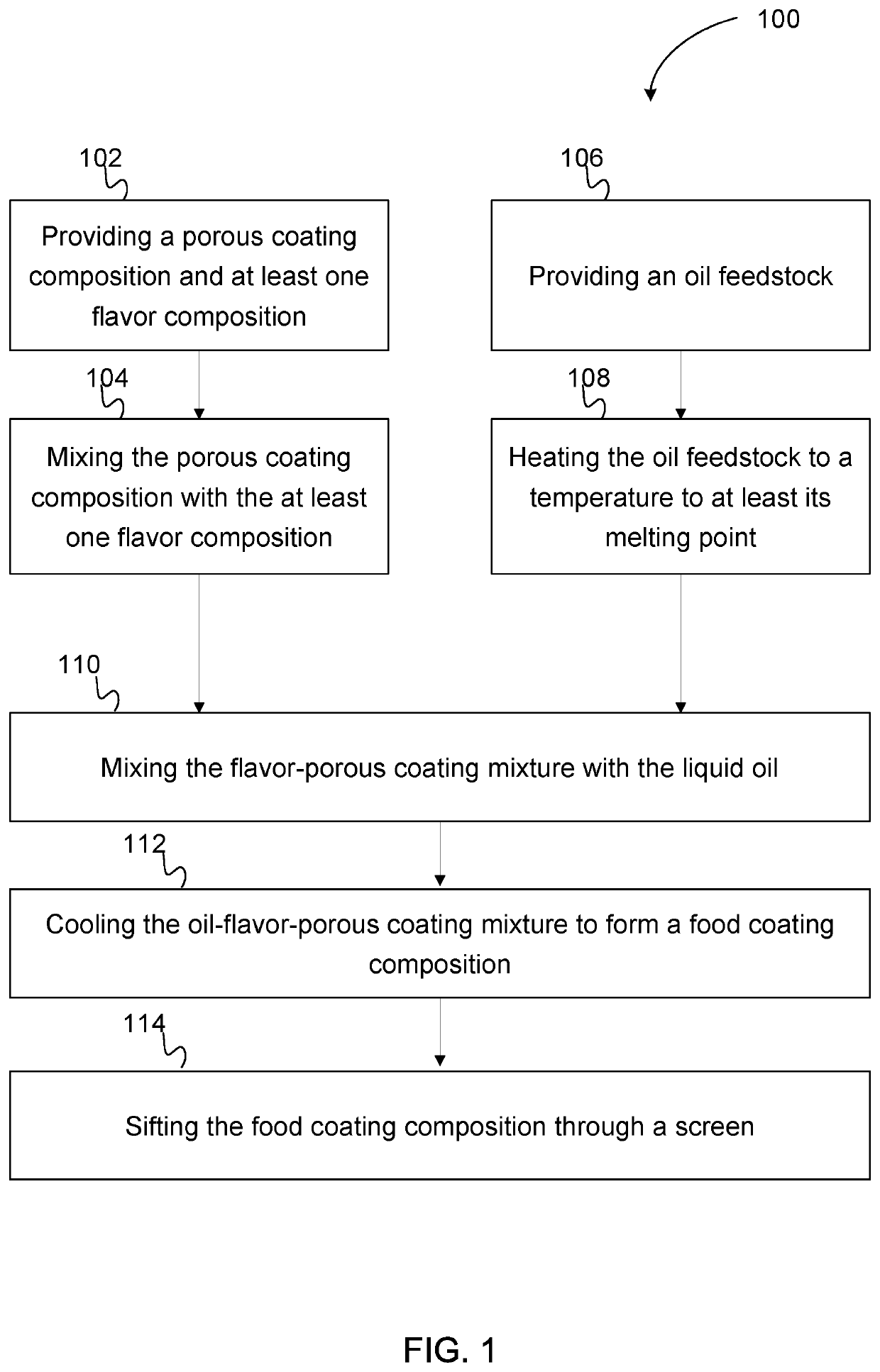

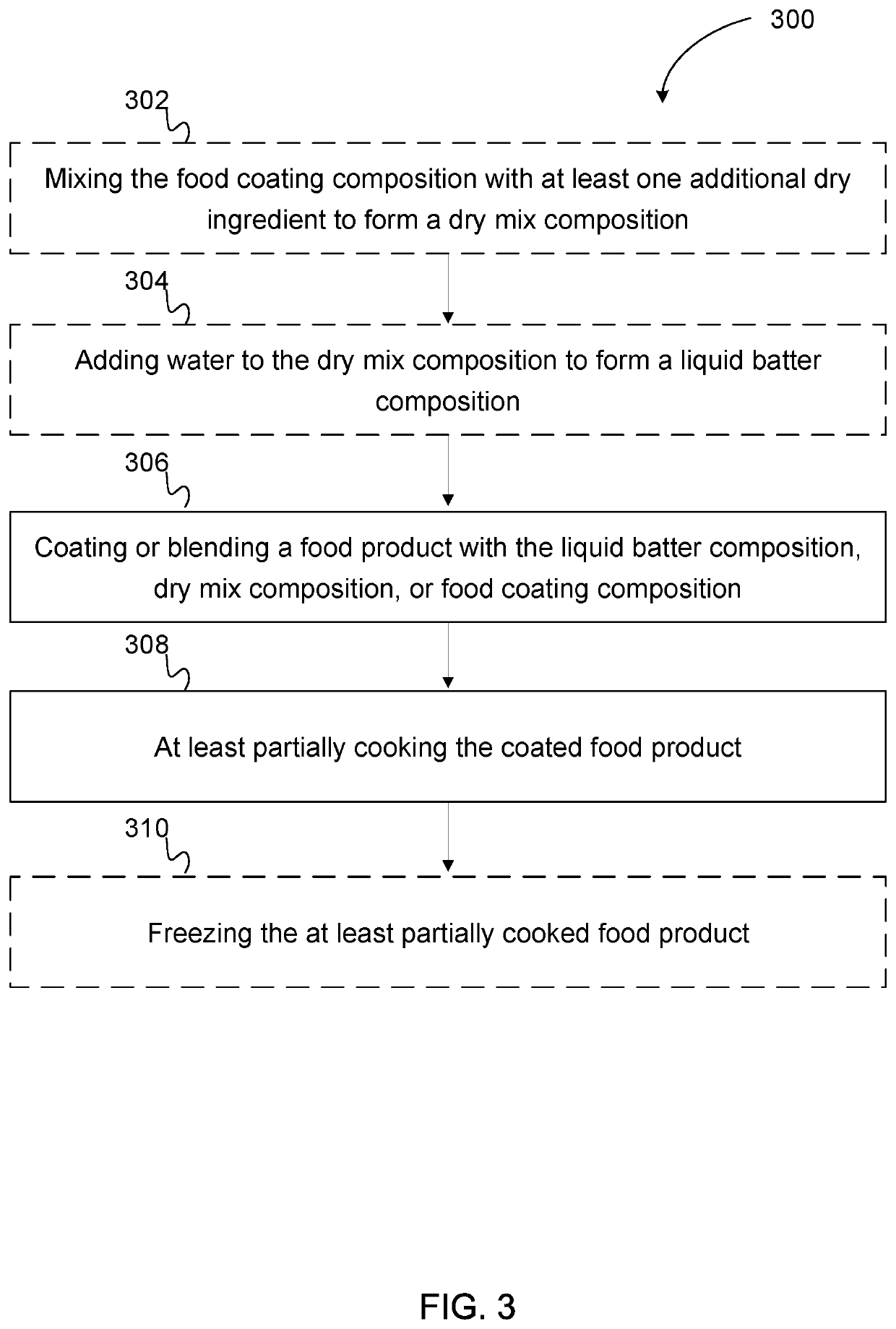

Food coating compositions and methods of making food coating compositions

InactiveUS20200288766A1Food thermal treatmentFood mechanical treatmentPorous coatingOrganic chemistry

Food coating compositions and their methods of making are disclosed herein. In one embodiment, the method includes mixing a porous coating composition with at least one flavor composition, wherein at least a portion of the at least one flavor composition is absorbed into pores of the porous coating composition; heating an oil feedstock to a temperature greater than the melting point of the oil feedstock to form a liquid oil; mixing the liquid oil with the at least one flavor composition prior to, contemporaneous with, or after the at least one flavor composition is mixed with the porous coating composition to provide an oil-flavor-porous coating mixture; and cooling the oil-flavor-porous coating mixture to 25° C. or less to form a food coating composition, wherein the liquid oil solidifies as an exterior coating for the porous coating composition and the flavor composition absorbed within the pores of the porous coating composition.

Owner:THE EDLONG CORP

Coating method of chocolate temperature-sensitive food coating film and coating system for implementing method

The invention provides a coating method of a chocolate temperature-sensitive food coating film and a coating system for implementing the method. Kiss coating is adopted in bottom coating and surface coating, and less wax emulsion and silicon dioxide anti-sticking agent are added in a surface coating oxygen barrier type PVDC (Polyvinyl Dichloride) emulsion in a first surface coating procedure and a surface coating low-temperature heat seal material in a second surface coating procedure. The coating film has the characteristics of high barrier, heat seal properly and capability of being compounded with a paper body through a UV (ultraviolet) adhesive, is smooth in surface, walks on coating equipment easily without larger tension, and has no remarkable shrinkage deformation after being heated by an oven without influencing the property of a product.

Owner:HAINAN SHINER IND

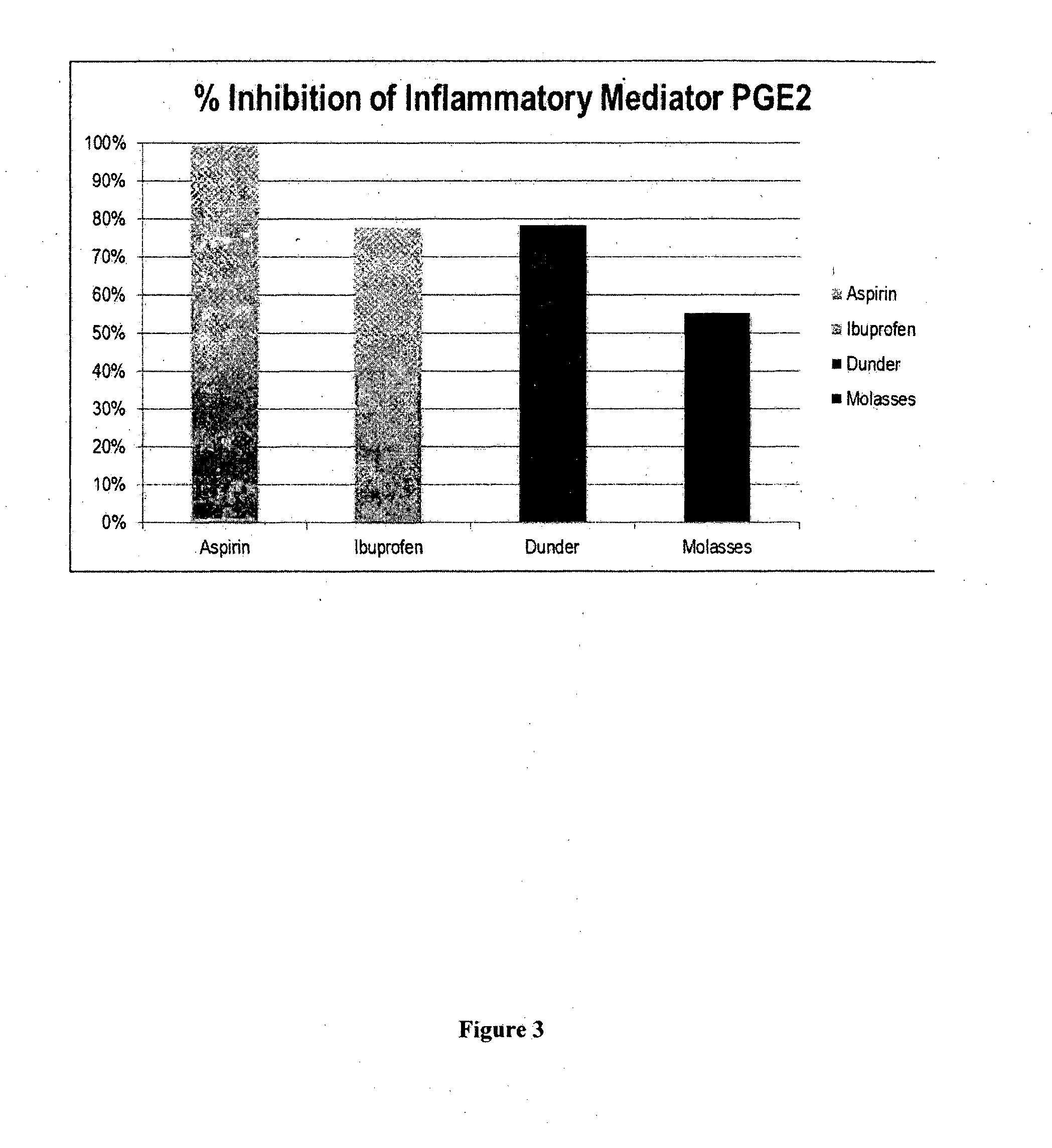

Extraction Method

InactiveUS20150201660A1Affecting palatabilityAffecting colourBiocideAntipyreticDiseaseDietary supplement

The present invention relates to a process for producing an extract derived from sugar cane, the process comprising: i) mixing a sugar cane derived product with ethanol to produce an extraction mixture comprising at least about 50% v / v ethanol; ii) allowing a precipitate to form in the extraction mixture; iii) removing the precipitate from the extraction mixture to obtain a supernatant; and iv) removing ethanol from the supernatant to produce the extract derived from sugar cane. The present invention further relates to extracts produced according to the process of the invention. The invention also relates to the use of such extracts in a method of lowering the available calorific value of a food or beverage, in treating or preventing disease, and as a nutritional supplement, dietary supplement, sports nutrition product, food coating or pharmaceutical product.

Owner:THE PROD MAKERS (AUSTRALIA) PTY LTD

Protein-containing food product and coating for a food product and method of making same

InactiveUS20100034940A1Thin coatingHigh in proteinConfectionerySweetmeatsNutritive valuesAdditive ingredient

A method for forming a complex of a protein-containing material and a lipid-based material comprises the steps of admixing said protein-containing material into said lipid material, applying heat and a shear force to said admixture to form an emulsion of protein material in said lipid material, and cooling said admixture to form a lipid-protein complex. Optionally, a liquid grinding step also may be used. The complex comprises at least about 10-50 net weight % protein, preferably no more than about 1% of an emulsifier, and an amount of a lipid-containing material sufficient to form an emulsion with the protein containing material. It is believed that higher proportions of protein could be obtained in the emulsion with high capacity pumps and shear apparatus. The complex can be used as a coating composition for a food product, or as an ingredient in a coating composition for a food product, or as an ingredient in a food article. When used as or in a coating for a snack food item such as a protein-containing energy bar, the coating can add to the nutritive value of the bar, and maintain the moisture content of the bar.

Owner:BUNGE OILS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com