Food coating prepared from raw milk as well as preparation method and application of food coating

A raw milk and coating technology, which is applied in the field of food coating and its preparation, can solve problems such as high cost, unfavorable daily consumption, and numerous raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

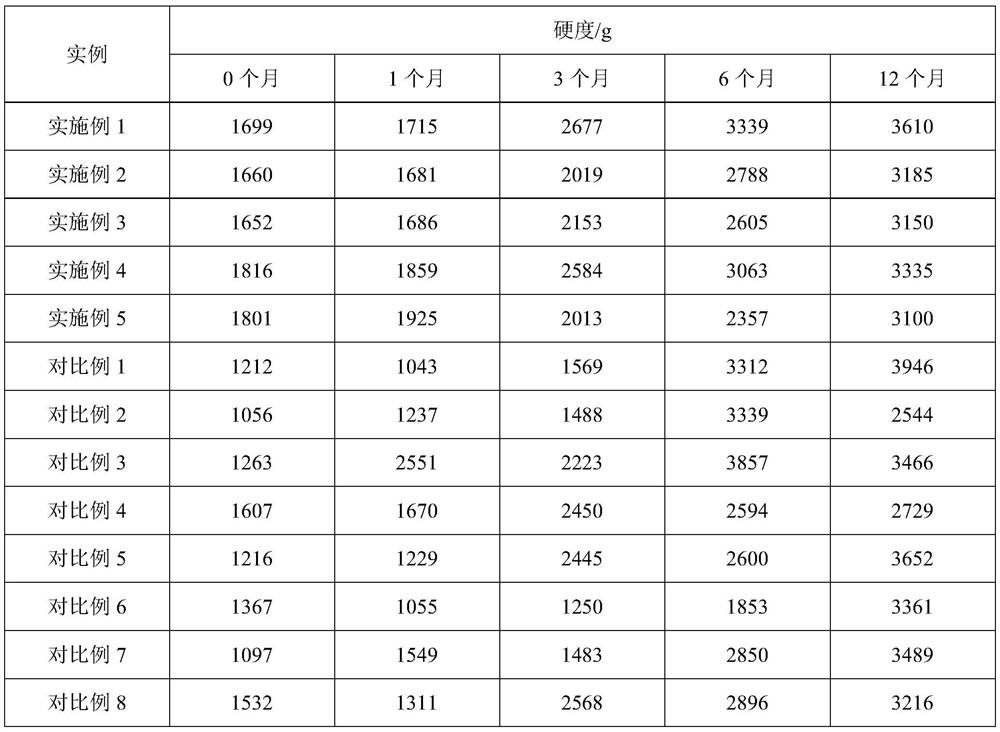

Examples

Embodiment 1

[0074] A food coating, in parts by weight, comprising the following components:

[0075] 13 parts of whole milk powder, 4 parts of polydextrose, 4 parts of carrageenan, 4 parts of xanthan gum, 1.7 parts of sodium carboxymethyl cellulose, 0.15 parts of food flavor (strawberry powder flavor, the same below), 0.2 parts of phospholipid, vegetable oil 8 parts, 1 part of anhydrous cream, 18 parts of raw milk, 3 parts of maltitol, 1 part of isomaltooligosaccharide.

[0076] The preparation method of described food coating, comprises the following steps:

[0077] (1) Take whole milk powder, polydextrose, carrageenan, xanthan gum, sodium carboxymethylcellulose, food flavor, and mix at 24°C to obtain a mixture 1;

[0078] (2) Take phospholipids, vegetable oil, and anhydrous butter, heat them at 50°C and mix them to obtain the mixed material 2;

[0079] (3) Take raw milk, maltitol, and isomaltooligosaccharide, and mix at room temperature to obtain a mixture 3;

[0080] (4) Take the mi...

Embodiment 2

[0093] A food coating, in parts by weight, comprising the following components:

[0094] 4 parts of whole milk powder, 2 parts of polydextrose, 1 part of carrageenan, 1.6 parts of xanthan gum, 0.2 parts of sodium carboxymethylcellulose, 0.3 parts of food flavor, 0.2 parts of phospholipids, 14 parts of vegetable oil, 1.8 parts of anhydrous cream , 25 parts of raw milk, 5 parts of maltitol, 1 part of isomaltooligosaccharide.

[0095] The preparation method of described food coating, comprises the following steps:

[0096] (1) Take whole milk powder, polydextrose, carrageenan, xanthan gum, sodium carboxymethylcellulose, food flavor, and mix at 20°C to obtain a mixture 1;

[0097] (2) Take phospholipids, vegetable oil, and anhydrous butter, heat them at 30°C and mix them to obtain the mixed material 2;

[0098] (3) Take raw milk, maltitol, and isomaltooligosaccharide, and mix at room temperature to obtain a mixture 3;

[0099] (4) Take the mixed material 3 and heat it to 70°C u...

Embodiment 3

[0111] A food coating, in parts by weight, comprising the following components:

[0112] 12 parts of whole milk powder, 4 parts of polydextrose, 4.5 parts of carrageenan, 1 part of xanthan gum, 0.25 parts of sodium carboxymethylcellulose, 0.02 parts of food flavor, 0.1 part of phospholipid, 6 parts of vegetable oil, 1 part of anhydrous butter , 30 parts of raw milk, 4 parts of maltitol, 2 parts of isomaltooligosaccharide.

[0113] The preparation method of described food coating, comprises the following steps:

[0114] (1) Take whole milk powder, polydextrose, carrageenan, xanthan gum, sodium carboxymethyl cellulose, food flavor, and mix at 30°C to obtain a mixture 1;

[0115] (2) Take phospholipids, vegetable oil, and anhydrous butter, heat them at 70°C and mix them to obtain the mixed material 2;

[0116] (3) Take raw milk, maltitol, and isomaltooligosaccharide, and mix at room temperature to obtain a mixture 3;

[0117] (4) Take the mixed material 3 and heat it to 100°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com