Modified wheat flour for fried food coating

A technology for fried food and wheat flour, applied in the direction of food science, etc., can solve the problems of difficult wheat flour, laborious batter liquid, lowering the temperature of the batter, etc., and achieve the effects of good dispersibility, excellent operability and crisp taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6 and comparative example 1

[0053] Thin powder (gelatinization start temperature 80.7°C, RVA peak viscosity 4400mPa·s) as raw material wheat flour is filled into a heat-resistant sachet in the form of a flat sheet with a thickness of about 5mm, and sealed after degassing. The sachets were put into a water bath at 100°C to heat-treat the thin powder. In this heat treatment, the time of various heat treatments was changed, and each modified wheat flour of Examples 1-6 and Comparative Example 1 was manufactured. The average particle diameter of the modified wheat flour of Examples 1-6 and Comparative Example 1 was all in the range of 46-77 micrometers.

[0054] 〔Test example〕

[0055] Ten panelists were asked to use the modified wheat flour of each Example and Comparative Example to prepare a batter liquid, and evaluated the operability at the time of preparation using the following evaluation criteria. The batter liquid was prepared by adding 1.5 parts by mass of baking powder and 170 parts by mass of wa...

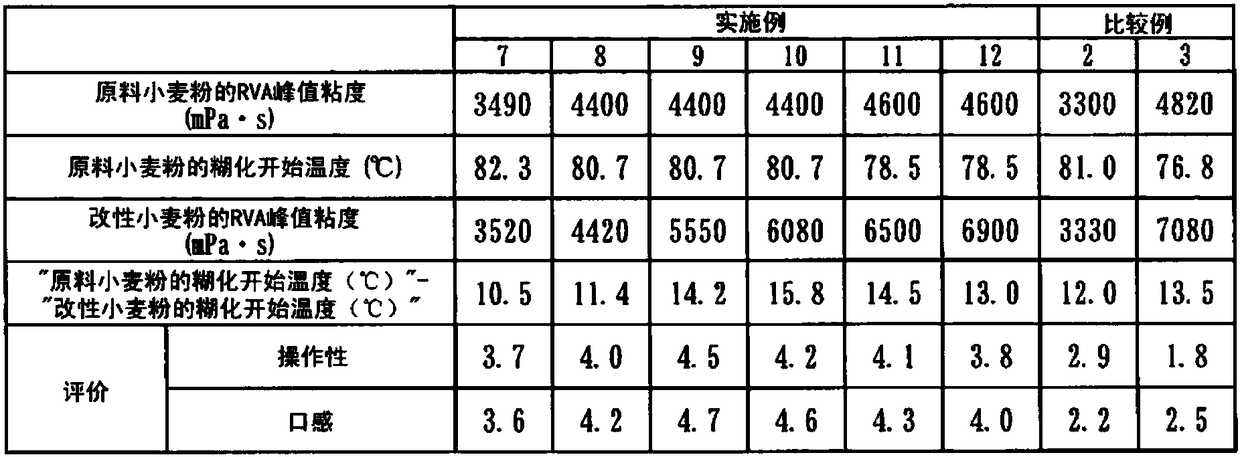

Embodiment 7~12 and comparative example 2~3

[0073] Modified wheat flours of Examples 7 to 12 and Comparative Examples 2 to 3 were produced in the same manner as in Examples 1 to 6 and Comparative Example 1, except that various raw material wheat flours having different RVA peak viscosities and gelatinization start temperatures were used. . The average particle diameter of each modified wheat flour of Examples 7-12 and Comparative Examples 2-3 was in the range of 42-79 micrometers. Each modified wheat flour was evaluated according to the above-mentioned test examples. The results are shown in Table 2 below.

[0074] Table 2

[0075]

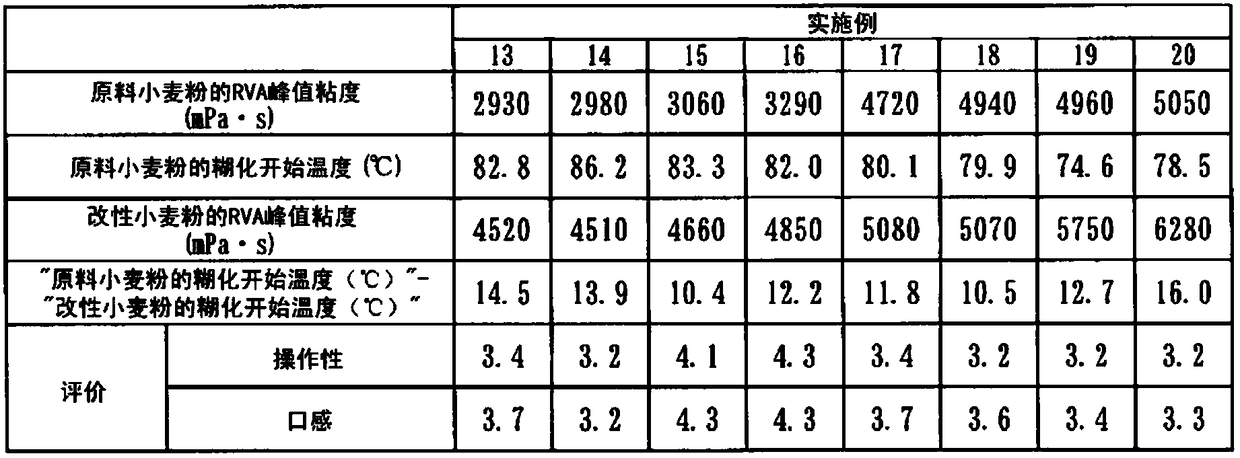

Embodiment 13~20

[0077] Each modified wheat flour of Examples 13-20 was produced similarly to Examples 1-6 and Comparative Examples 1-2 except having used various raw material wheat flours which differed in RVA peak viscosity and gelatinization start temperature. The average particle diameter of each modified wheat flour of Examples 13-20 was in the range of 40-88 micrometers. Each modified wheat flour was evaluated according to the above-mentioned test examples. The results are shown in Table 3 below.

[0078] table 3

[0079]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com