Special decorative powder coating for glass wine bottle and ceramic vessel and application

A technology for ceramic containers and powder coatings, applied in the field of coatings, can solve the problems of difficult to achieve electrostatic spraying, and no patent publications have been found, and achieve the effects of improving anti-pollution problems, excellent scratch resistance, excellent rigidity and heat and humidity resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

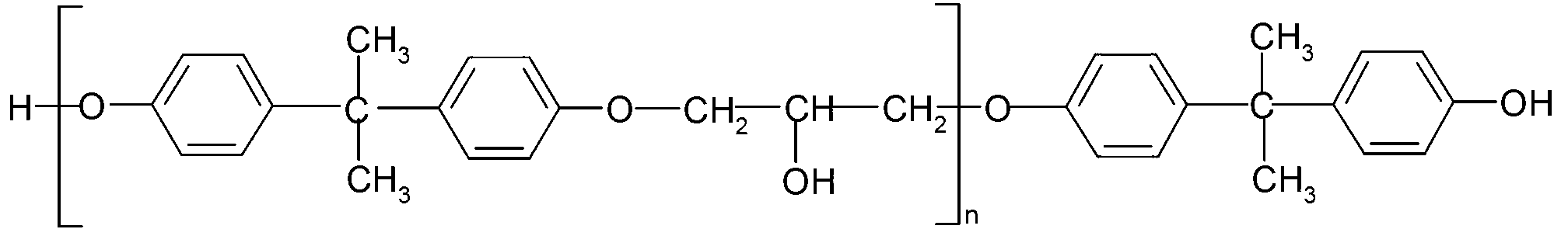

Image

Examples

Embodiment 1

[0031] A special decorative powder coating for glass wine bottles and ceramic containers, the raw material components and parts by weight are respectively:

[0032]

[0033] The steps of the preparation method of above-mentioned special decorative powder coating are as follows:

[0034] The above materials are added to the high-speed mixer according to the weight part, and then added to the extruder after dry mixing, and the conventional melting, mixing, cooling, and tableting are carried out at the extrusion temperature of 80~90°C, and then passed through the pulverizer Crushing, grading, sieving, and packaging, it becomes the finished powder coating.

[0035] The above curing agent can use pharmaceutical grade imidazoline, phenolic curing agent (V-209) (white crystal appearance, softening point of 85~95, content %≥99.5)), such as 2-methylimidazole, bisphenol A as terminal The base V-209 novolac resin is used to make the coating cure quickly at low temperature and have he...

Embodiment 2

[0038] A special decorative powder coating for glass wine bottles and ceramic containers, the raw material components and parts by weight are respectively:

[0039]

[0040] The steps of the preparation method of the above-mentioned special decorative powder coating are the same as in Example 1.

Embodiment 3

[0042] A special decorative powder coating for glass wine bottles and ceramic containers, the raw material components and parts by weight are respectively:

[0043]

[0044]

[0045] The steps of the preparation method of the above-mentioned special decorative powder coating are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com