Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Disodium pyrophosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Disodium pyrophosphate or sodium acid pyrophosphate (SAPP) is an inorganic compound consisting of sodium cations and pyrophosphate anion. It is a white, water-soluble solid that serves as a buffering and chelating agent, with many applications in the food industry. When crystallised from water, it forms a hexahydrate, but it dehydrates above room temperature. Pyrophosphate is a polyvalent anion with a high affinity for polyvalent cations, e.g. Ca²⁺.

Hydrogen Peroxide Toothpaste With Improved Stability

InactiveUS20130108559A1Improve stabilityCosmetic preparationsToilet preparationsPhosphatePhosphoric acid

Aqueous oral care compositions containing hydrogen peroxide and having improved stability, such compositions containing at least 35%, by weight of the composition, of water and further including a peroxide compatible abrasive such as fused silica, calcium pyrophosphate and / or dicalcium phosphate, a gel network, and a protection system containing sodium acid pyrophosphate, disodium phosphate, and / or phosphoric acid.

Owner:THE PROCTER & GAMBLE COMPANY

Garbage incineration fly ash treatment chelating agent

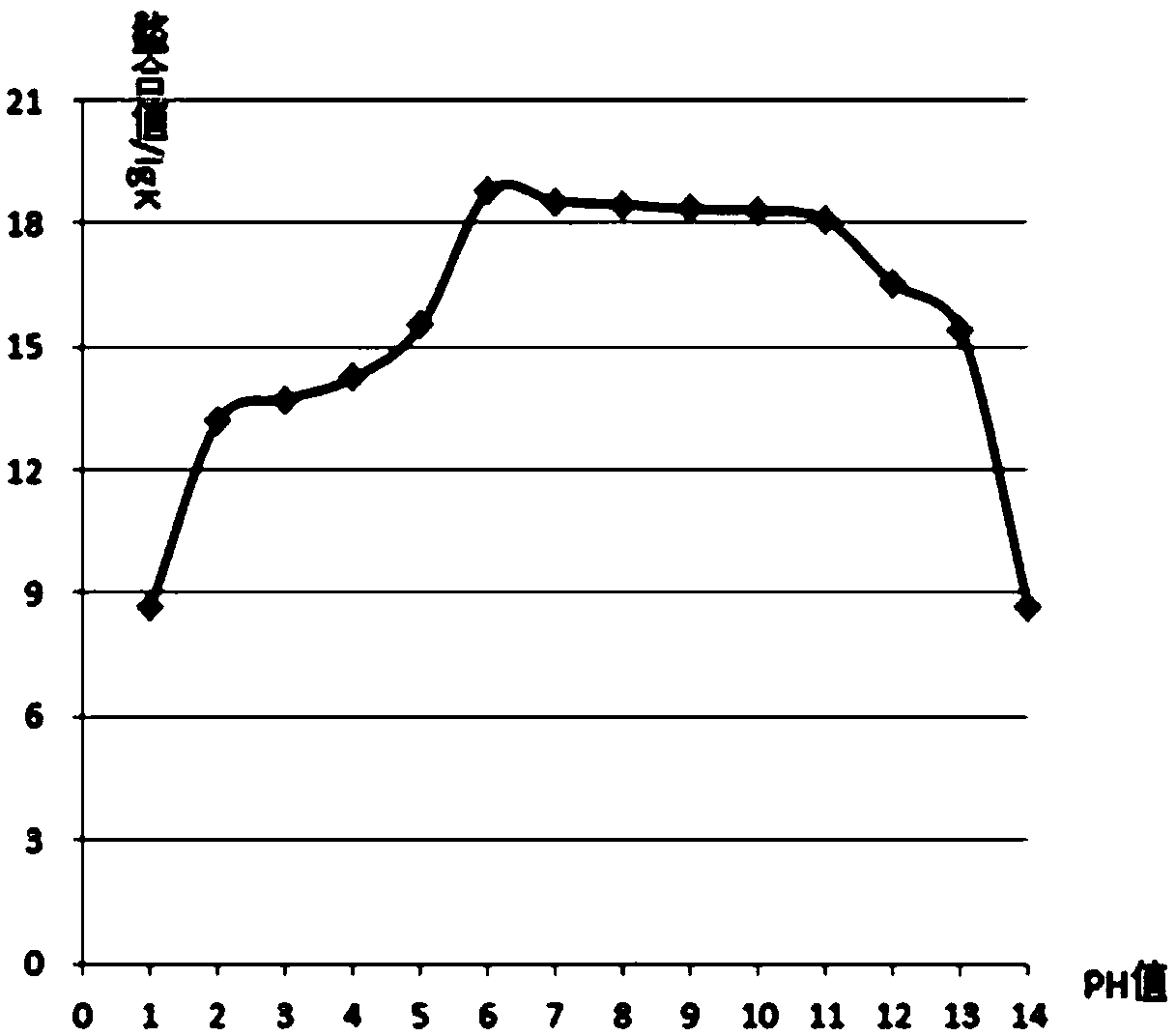

The invention discloses a composite chelating agent for treating garbage incineration fly ash, and cured products reach the related landfill standard. The composite chelating agent comprises followingcomponents including, by weight, 50-60 parts of dimethyl carbamodithioic acid, 30-40 parts of the aminodithioformic acid and dithiocarbamate mixture and 20-30 parts of composite phosphate. Aminodithioformic acid and dithiocarbamate are generated through polyolefin polyamine and CS2 under the alkali condition, wherein the polyolefin polyamine comprises ethidene diamine and diethylenetriamine. Thecomposite phosphate is the combination of any two of sodium tripolyphosphate, sodium hexametaphosphate, sodium pyrophosphate, trisodium phosphate, disodium hydrogen phosphate, sodium dihydrogen phosphate, sodium acid pyrophosphate and disodium dihydrogen pyrophosphate. During usage, the chelating agent is mixed with a component formed through curing, fly ash and water with any proportion, and thecured component is portland cement. The composite chelating agent can adapt to wide temperature and PH value usage ranges and is slightly influenced by the heavy metal ion concentration and other complex compounds.

Owner:江苏乐尔环境科技股份有限公司

Method of preparing a baked or fried product from leavened dough

The present invention relates to a method of preparing a baked or fined product from leavened dough, comprising the successive steps of: a. forming a dough by combining flour, water, a slow reacting leavening system consisting of a leavening acid and a leavening base and optionally one or more other bakery ingredients, said slow reacting leavening system containing (a) a slow reacting leavening acid selected from the group consisting of sodium acid pyrophosphate, calcium acid pyrophosphate, aluminium phosphate, sodium aluminium phosphate, glucono-o-lactone, encapsulated leavening acids and combinations thereof, and / or (b) an encapsulated leavening base; b. shaping the dough; c. proofing the dough at a temperature in the range of 5-45 DEG C for at least 40 minutes to obtain a proofed dough with a specific volume of at least 1.4 ml / g; and d. baking or frying the proofed dough; wherein prior to baking of frying the proofed dough is stored under ambient conditions for more than 1 hour. The present method yields a dough with characteristics that are very similar to yeast leavened dough, but that will not collapse even when stored under ambient conditions for several hours.

Owner:CSM NEDERLAND

Modified disodium pyrophosphate

Delayed reaction modified disodium dihydrogen diphosphate (SAPP), the preparation thereof and the use thereof as a leavening acid for the production of baked goods. The process for the preparation of the modified disodium dihydrogen diphosphate (SAPP), includes adding an aqueous solution containing at least one of sodium hydroxide and sodium carbonate to an aqueous phosphoric acid solution containing at least one compound of magnesium, calcium, potassium, aluminium the total amount of magnesium plus calcium plus potassium plus aluminium being at least 300 ppm, to obtain an aqueous solution product and dewatering the aqueous solution product at a temperature in the range of from 190 to 250° C. to obtain a modified disodium dihydrogen diphosphate product having an orthophosphate content, measured as P2O5, of <5.0 wt. %.

Owner:CHEM FAB BUDENHEIM AG

Flat bread dough composition and method for making flat breads

InactiveUS20120263854A1Dough composition to relaxDough treatmentPre-baking dough treatmentSodium aluminum phosphateSodium phosphates

The present invention relates to a flat bread dough composition, comprising: A) flour; B) shortening; C) water; and D) a leavening system having a leavening base and a leavening acid having a combination selected from the group consisting of a) sodium aluminum phosphate and dicalcium phosphate dihydrate; b) sodium aluminum phosphate and sodium acid pyrophosphate; c) sodium acid pyrophosphate and dicalcium phosphate dihydrate; d) sodium acid pyrophosphate, monocalcium phosphate, and calcium acid pyrophosphate; e) dicalcium phosphate dehydrate, monocalcium phosphate, and calcium acid pyrophosphate; f) sodium aluminum phosphate, sodium acid pyrophosphate, and dicalcium phosphate dihydrate; g) sodium aluminum sulfate and dicalcium phosphate dihydrate; and h) sodium aluminum sulfate and sodium acid pyrophosphate, the sodium acid pyrophosphate exhibiting an evolved percentage of carbon dioxide of about 30 or less at room temperature prior to baking, and the slower reacting of the leavening acids in the combination being at least 10 wt % of the total weight of the acid combination.

Owner:INNOPHOS INC

Process for preparing alpha-acetyl-gamma-butyrolactone for co-production of various phosphates

InactiveCN102617520ARealize joint productionSimple conditionsOrganic chemistryPhosphorus compoundsEcological environmentFiltration

The invention provides a process for preparing alpha-acetyl-gamma-butyrolactone for co-production of various phosphates. The process is applicable to producing the alpha-acetyl-gamma-butyrolactone through acylation and phosphoric acid neutralization of gamma-butyrolactone and acetyl reagents serving as raw materials under the catalytic action of metallic sodium, and effective separation of an organic phase and an aqueous phase is achieved through controlling the concentration of phosphoric acid and the system temperature during oil-water separation. The organic phase is rectified to obtain alpha-acetyl-gamma-butyrolactone; and sodium dihydrogen phosphate dihydrate, sodium hexametaphosphate, sodium trimetaphosphate, sodium acid pyrophosphate, sodium dihydrogen phosphate dodecahydrate, trisodium phosphate dodecahydrate, sodium tripolyphosphate and sodium pyrophosphate are obtained through steps such as pH adjustment, concentration, decompressional filtration and the like of the aqueous phase. The process produces both main products and byproducts, achieves co-production of various products by one process, energy conservation, emission reduction and ecological environment protection, and is safe in operation, simple in process, easy to industrialize and low in cost.

Owner:SHANXI UNIV +1

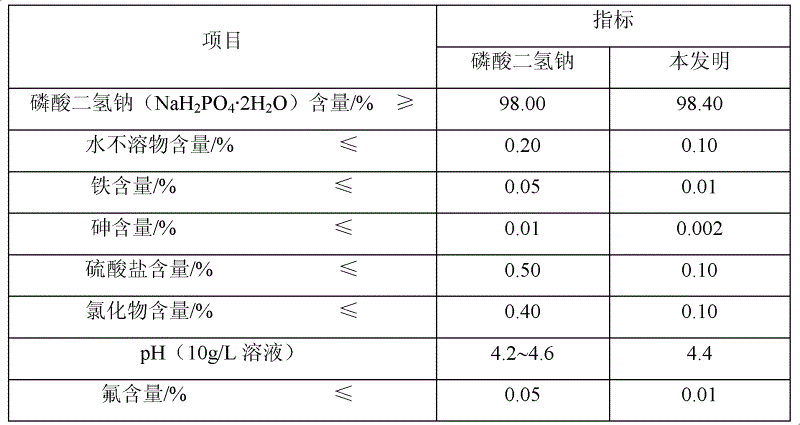

Production method of disodium dihydrogen pyrophosphate with high raising rate

InactiveCN103145111ALittle changeImprove stabilityPhosphorus compoundsPhosphoric acidPotassium hydroxide

The invention relates to a production method of disodium dihydrogen pyrophosphate and particularly relates to a production method of disodium dihydrogen pyrophosphate with a high raising rate. The production method comprises the following steps: performing a neutralization reaction on phosphoric acid and sodium hydroxide, adding potassium hydroxide at the neutralization stage, fine tuning the pH of the neutralization solution through the phosphoric acid or sodium hydroxide, controlling the ratio, and then, conducting spray drying on the neutralization solution to obtain sodium dihydrogen phosphate granules, conveying the sodium dihydrogen phosphate granules into a drum polymerization furnace to be polymerized, and cooling the product to obtain the disodium dihydrogen pyrophosphate with a high raising rate. The raising rate ROR of the disodium dihydrogen pyrophosphate produced by the method provided by the invention is 36-42, the disodium dihydrogen pyrophosphate is used as an acid salt ingredient in a composite raising agent, the ROR change within the quality guarantee period is small, and the stability is good.

Owner:XUZHOU COLLEGE OF INDAL TECH

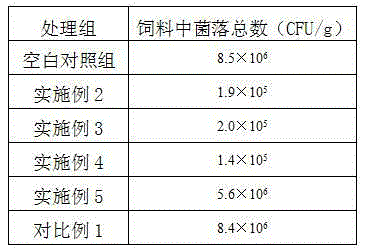

Method of extracting polysaccharides and flavonoids from mulberry leaves and application of polysaccharides and flavonoids to feed

InactiveCN104664152ARetain physiological activityRetain pharmacological activityAnimal feeding stuffFiberBeta-Carotene

The invention discloses a method for simultaneously extracting polysaccharides and flavonoids from mulberry leaves. According to the method, little equipment is adopted, the reaction condition is gentle, the cost is low, the production is safe and reliable, the product purity is high, the yield is high, and the physiological and the pharmacological activity of the polysaccharides and the flavonoids from the mulberry leaves can be kept relatively well, so that the application value is relatively great,. The polysaccharides, the flavonoids, sorbitol, beta-carotene, disodium pyrophosphate and the like extracted from the mulberry leaves are combined as feed additives, so that the diameters of pork muscle fibers are reduced, the density of muscle fibers is increased, and pork is relatively tender. The inhibition effect on mildew in the feed is strong, the feed mildew condition can be reduced, and the nutrient substances in the feed are protected from being damaged.

Owner:伏国旺

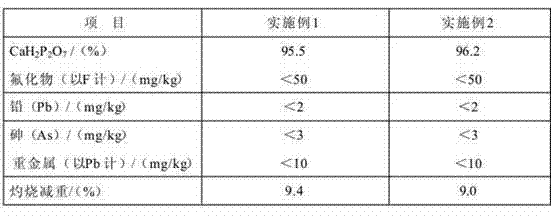

Production method of acid calcium pyrophosphate for food leavening agent

InactiveCN103030127ASolve the problem of "excessive sodium"Play a special effect of calcium supplementationDough treatmentPhosphorus compoundsPhosphoric acidPyrophosphate

The invention discloses a production method of acid calcium pyrophosphate for food leavening agent. The production method comprises the following steps: carrying out neutralization by taking phosphoric acid and lime milk, or phosphoric acid and limestone as raw materials so as to obtain a monocalcium phosphate solution; drying the monocalcium phosphate solution by a spray drying tower and polymerizing by a polymerization furnace so as to form the acid calcium pyrophosphate which is used as a food leavening agent. With the production method of the acid calcium pyrophosphate for the food leavening agent, the problem of excessive sodium in the application process of the acid calcium pyrophosphate is solved, and the acid calcium pyrophosphate has a special effect of calcium supplement, so that the acid calcium pyrophosphate can replace the acid sodium pyrophosphate in the baking field. The production technology provided by the invention is strong in operability, the technological process is very convenient for industrialization, and the produced products are high in purity.

Owner:HUBEI XINGFA CHEM GRP CO LTD

Environmental-friendly tea planting compound fertilizer and preparing process thereof

InactiveCN106242672AStrong specificityStrong targetingBio-organic fraction processingAlkali orthophosphate fertiliserSodium BentoniteBuxus

The invention discloses an environmental-friendly tea planting compound fertilizer. The environmental-friendly tea planting compound fertilizer is prepared from urea, kaolin, bentonite, humic acid, goose excrement, pig manure, sheep manure, cow dung, quail excrement, chicken manure, dipotassium phosphate, sodium acid pyrophosphate, sodium acid pyrophosphate, sodium dihydrogen phosphate, calcium nitrate, disodium hydrogen phosphate, bdellovibrio powder, bacteriophage powder, agritol powder, candida powder, cotton straw powder, rice straw powder, rhodococcus powder, buxus megistophylla wood flour, larix gmelini wood flour, plant activating enzyme and microelements. The prepared compound fertilizer contains N, P, K and other major element nutrients and further contains a certain proportion of microelements, the tea fertilizer requirement law and the current tea forest soil nutrient situation are combined, and the formula has high specificity. The environmental-friendly tea planting compound fertilizer is higher in pertinency for the tea production process and is more comprehensive, balanced and reasonable in nutrition, and the actual application effect is better.

Owner:潜山市三新茶叶专业合作社

Preparation method of borate-type brake fluid

The invention relates to a preparation method of a borate-type brake fluid, belonging to the technical field of automobile brake fluids. The method comprises the following steps: carrying out esterification and amide reaction on 1,2-propanediol and thionyl chloride in a flaxseed oil environment, and carrying out ring opening and other reactions on the reaction product, dimethylamine and pyrazole under the action of sodium hydride to form ketoximes, thereby increasing amino and hydroxy groups; combining the ketoximes with platinum ions in a platinum nitrate solution in an alkaline environment to form steric hindrance groups of platinum coordination compounds; in the process of preparing borate from propanol, epoxypropane and boric acid, combining the steric hindrance groups of platinum coordination compounds with borate by using sodium acid pyrophosphate as a chelator to increase the steric hindrance of borate, thereby resisting the attack of water molecules and enhancing the water resistance; and mixing with a diluter triethylene glycol methyl ether and other aids, thereby obtaining the borate-type brake fluid. The preparation method solves the problems of high hydrolysis tendency and poor water resistance in the traditional borate-type brake fluid.

Owner:唐林元

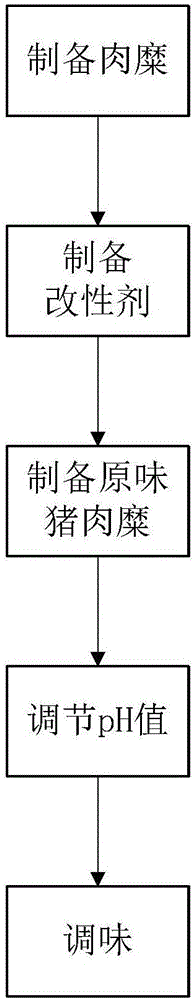

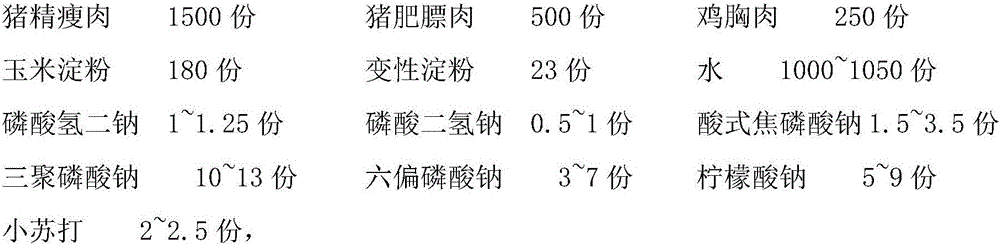

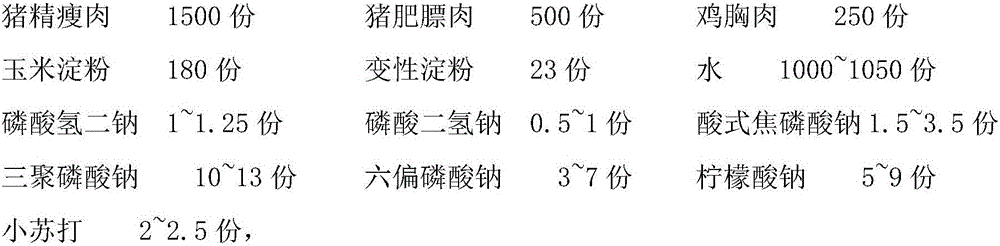

Minced pork and preparation method thereof

ActiveCN106490504ALower acquisition costsSimple preparation processFood scienceMinced chickenPyrophosphate

The invention discloses minced pork and a preparation method thereof. The minced chicken is used for replacing the minced fish so that the minced pork is ropy, mellow, chewiness, good in water retention effect, low in cost, simple in preparation process, good in forming effect, and excellent in taste. The preparation method comprises the following steps: (1) preparing minced meat; (2) preparing modifying agent: adding corn starch, modification starch, disodium hydrogen phosphate, sodium dihydrogen phosphate, sodium acid pyrophosphate, sodium tripolyphosphate, sodium hexametaphosphate and sodium citrate in prescription proportion in the water in prescription proportion, uniformly stirring to obtain the modifying agent; (3) uniformly mixing the modifying gent obtained in the step (2) with the minced chicken breast, minced lean pork and minced fat pork obtained in the step (1) in order to obtain the original minced pork; (4) regulating pH value; and (5) seasoning.

Owner:WUHAN FIRST BUSINESS SCHOOL

Wear-resistant material for mobile phone screen and preparation method of wear-resistant material

The invention discloses a wear-resistant material for a mobile phone screen and preparation method of the wear-resistant material. The material comprises the following raw materials in parts by weight: 50-60 parts of silicon dioxide, 10-20 parts of calcium oxide, 20-30 parts of aluminum oxide, 10-20 parts of potassium oxide, 15-20 parts of antimony oxide, 20-40 parts of sodium acid pyrophosphate, 30-60 parts of sodium dihydrogen phosphate, 20-60 parts of disodium hydrogen phosphate, 24-30 parts of sodium metaphosphate, 30-50 parts of sodium phosphate and 20-60 parts of tartaric acid. The preparation method comprises the following steps: uniformly mixing components, heating at 300-400 DEG.C for 1-2 hours, performing tablet stretching by using a tabletting machine to obtain the mobile phone screen material with a diameter of 0.004-0.01mm. The mobile phone screen material prepared by the invention is good in wear-resistance.

Owner:深圳市华尔基电子科技有限公司

Ceramic green body reinforcing agent for improving mobility of slurry

The invention belongs to the technical field of a ceramic green body, in particular to a ceramic green body reinforcing agent for improving the mobility of slurry. The ceramic green body reinforcing agent is prepared from the following raw materials: polyethylene glycol-polycaprolactone, sodium acid pyrophosphate, onion essential oil, inorganic binder, a regulating agent and water. Compared with the prior art, the ceramic green body reinforcing agent has the advantages that by virtue of reasonable proportioning and processing, the mobility of the slurry can be improved, and the combination performance of the powder can be improved; and by adding the regulating agent, the drying speed and sintering speed of the green body in a kiln can be improved, and the production time can be shortened;the onion essential oil facilitates the cross-linking of the reinforcing agent and the particles of the green body to form a three-dimensional cross-linking network structure with a stable structure,so that the green body strength of the green body is improved; the cooperation of the sodium acid pyrophosphate and the regulating agent can prevent the viscosity from being greatly increased, the dispersity of the green body can be ensured, and the defects of the green body such as cracks and damageable corners can be avoided; and meanwhile, the close combination of a glaze layer and the green body can be facilitated, and the durability can be improved.

Owner:界首市东城群海彩陶工作室

Sodium-modified illite-montmorillonite mixed-layer clay

InactiveCN103979560APromotes natural weatheringImprove the disintegration effectAluminium silicatesCelluloseCation-exchange capacity

The invention discloses a sodium-modified illite-montmorillonite mixed-layer clay. The technical scheme is as follows: the sodium-modified illite-montmorillonite mixed-layer clay is composed of illite-montmorillonite mixed-layer clay, magnesia, sodium carbonate, instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium acid pyrophosphate. The sodium-modified illite-montmorillonite mixed-layer clay materials are input into a mill and milled, and the milled powder illite-montmorillonite mixed-layer clay is the sodium-modified illite-montmorillonite mixed-layer clay. The sodium modification can enhance the water absorptivity, colloid index, expansion coefficient, colloid viscosity, cation exchange capacity, and dispersivity and suspension percentage in an aqueous medium of the illite-montmorillonite mixed-layer clay. The sodium-modified illite-montmorillonite mixed-layer clay has the characteristics of favorable thixotropy, favorable lubricating property, favorable heat stability, higher plasticity and higher binding property. The sodium-modified illite-montmorillonite mixed-layer clay is suitable for papermaking, cosmetics, plastics, rubber, paints, ceramics, textiles, cable insulation materials and firefighting materials.

Owner:广西上思县富石矿业有限公司

Salt composition

InactiveUS20130216667A1Improved property with respect to taste and functionalityReduced proportion of sodiumFood shapingFood preparationCalcium bicarbonateGlucono delta-lactone

Salt substitute, in particular granular, crystalline or pulverulent and preferably for use as garnish salt or salt substitute, which contains30 to 90 wt % sodium chloride or a mixture of sodium chloride and potassium chloride in a weight ratio of 1:2 to 2:1,10 to 70 wt % of a combination of at least one carbon dioxide carrier and at least one acid carrier andoptionally up to 20 wt % of further additives,wherein the carbon dioxide carrier is selected from sodium carbonate, sodium hydrogen carbonate, potassium carbonate (potash), potassium hydrogen carbonate, magnesium carbonate, magnesium hydrogen carbonate, calcium carbonate, calcium hydrogen carbonate, aluminium carbonate, aluminium hydrogen carbonate, ammonium carbonate, ammonium hydrogen carbonate, ammonium carbamate, hartshorn salt and mixtures of the above andthe at least one acid carrier is selected from sodium acid pyrophosphate (SAPP), monocalcium phosphate monohydrate (MCPM), anhydrous monocalcium phosphate (AMCP), all further hyd rates of monocalcium phosphate, d icalcium p hosphate dihydrate (DCPD), all further hydrates of dicalcium phosphate, sodium aluminium sulphate (SAS), sodium aluminium phosphate (SALP), calcium magnesium aluminium phosphate, calcium polyphosphate, calcium pyrophosphate, magnesium polyphosphate, magnesium pyrophosphate, calcium hydrogen phosphate, citric acid, fumaric acid, aspartic acid, tartaric acid, cream of tartar (potassium hydrogen tartrate), glucono-delta-lactone (GDL), sodium hydrogen citrate, lactic acid and mixtures of the above.

Owner:CHEM FAB BUDENHEIM AG

Glass containing copper oxide and preparation method of glass

InactiveCN103880284AIncrease glass-forming propertiesAdded second order nonlinear index of refractionGlass shaping apparatusDipotassium hydrogen phosphateSodium phosphates

The invention discloses glass containing copper oxide and a preparation method of the glass. The glass consists of the following raw materials in parts by weight: 10-20 parts of silicon dioxide, 10-30 parts of calcium oxide, 20-30 parts of potassium oxide, 40-50 parts of copper oxide, 50-60 parts of silver chloride, 60-65 parts of sodium phosphate, 35-38 parts of sodium pyrophosphate, 40-80 parts of sodium hypophosphite, 20-60 parts of sodium tripolyphosphate, 30-80 parts of dipotassium hydrogen phosphate, 40-60 parts of sodium acid pyrophosphate and 20-50 parts of titanium dioxide. The preparation method comprises the steps of uniformly mixing various raw materials and melting the raw materials; stirring until the raw materials are completely melted, decreasing temperature to 500-600 DEG C and taking out the glass liquid, and casting on a mold; annealing, keeping for 1-2 hours at 170-230 DEG C, decreasing temperature to 100-110 DEG C at 2-5 DEG C / hour, and naturally cooling. According to the glass disclosed by the invention, chemical stability of the glass is enhanced.

Owner:深圳市粤盾科技特种玻璃有限公司

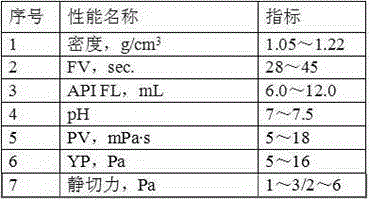

Environmental friendly drill of acid sodium pyrophosphate and preparing method thereof

InactiveCN106350037AImprove liquidityLarge solid phase capacityDrilling compositionEnvironmental resistanceAdhesive

The invention provides an environmental friendly drill of acid sodium pyrophosphate, composed of the following raw materials, by weight: 2-5% of sodium pyrophosphate, 0.2-1.5% of adhesive, 0.5-2.0% of filtrate reducer, 5-15% of weighting agent and water. The environmental friendly drill liquid of acid sodium pyrophosphate can not only provide excellent drill wall stabilizing ability, but also provide efficient sand-carrying capacity, and conforms to requirements for environmental protection, meets demands for upper drill section on Ecuador TARAPOA block, and gains good economic benefit and social benefit.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

Sodium modified chlorite

The invention discloses sodium modified chlorite, and the key points of the technical scheme are that: sodium modified chlorite ingredients comprise chlorite, magnesium oxide, sodium carbonate, instant sodium silicate, polyvinyl alcohol, hydroxypropyl methyl cellulose and sodium acid pyrophosphate. A production method of the sodium modified chlorite is as follows: sodium modified chlorite ingredients are transported into a mill for powder milling, and the milled powder is the sodium modified chlorite. By first sodium modification and then ingredient compounding, chemical reaction of the sodium carbonate and the instant sodium silicate, the polyvinyl alcohol and the hydroxypropyl methyl cellulose can be avoided. According to the needs of product quality, the sodium acid pyrophosphate is used for adjusting the PH of the sodium modified chlorite. The sodium modified chlorite has the characteristics of good adsorption, suspension property, thixotropy, lubricity and thermal stability and high plasticity, and is applicable to the production of filler, sorbents, suspending agents and lubricants for asphalt felts, paper making, pesticides and fire control products.

Owner:浙江创魏新材股份有限公司

Sodiumized green smectite clay

InactiveCN104016365BPromotes natural weatheringImprove the disintegration effectAluminium silicatesCation-exchange capacityPolyvinyl alcohol

The invention discloses a sodium-treated green smectite clay. The main point of the technical scheme is that the sodium-treated green smectite clay is composed of green stilt clay, magnesium oxide, sodium carbonate, instant sodium silicate, polyethylene Alcohol, hydroxypropyl methylcellulose and sodium acid pyrophosphate; the sodiumized green smear clay ingredients are input into the mill for grinding, and the powder after grinding is sodium green stilt clay . According to the needs of product quality, sodium acid pyrophosphate is used to adjust the pH value of the green smear clay after sodiumization. The sodium smear clay can improve the water absorption rate, colloid price, expansion multiple, colloid Viscosity, cation exchange capacity, dispersibility and suspension rate in aqueous media. Sodiumized green smectite clay has the characteristics of good thixotropy, lubricity, thermal stability, high plasticity and strong cohesiveness. Sodiumized green smear clay is suitable for the production of products in the fields of industry, agriculture, construction and fire protection.

Owner:辽宁沙海膨润土矿业有限公司

Oral care product

PendingCN113543763AReduce contentReduce accumulationCosmetic preparationsToilet preparationsO-Phosphoric AcidMouth care

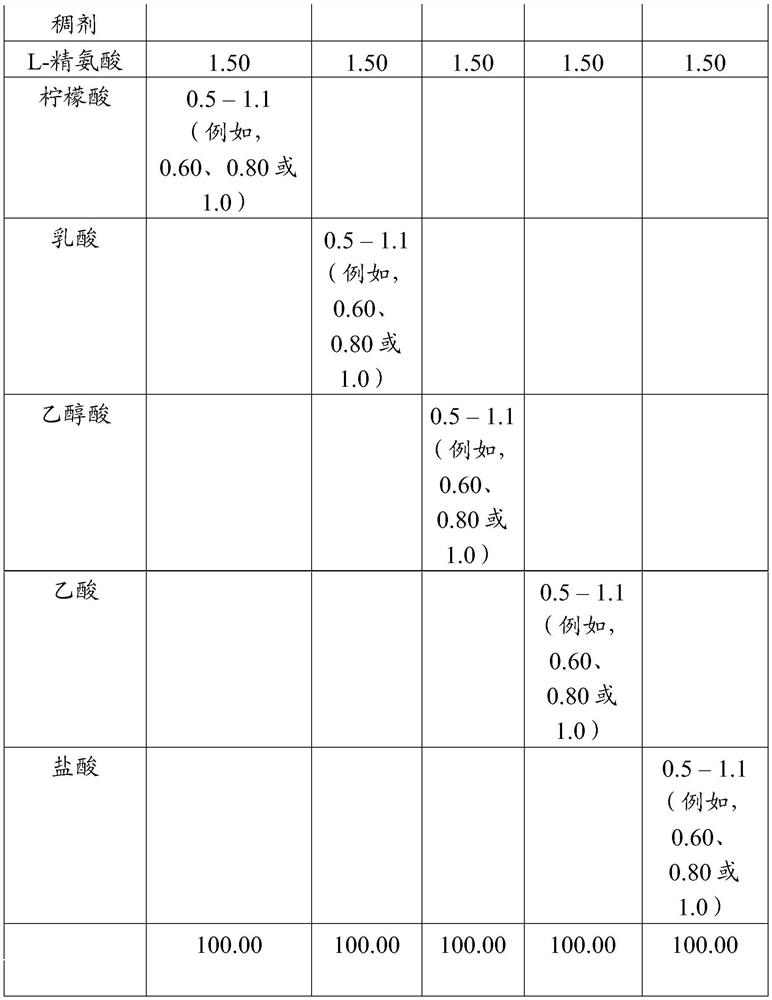

This invention relates to oral care compositions, for example comprising a salt of a basic amino acid having a pH in solution of less than 7.5, an abrasive having a pH in solution of less than 7.5, and a fluoride ion source, and an acid selected from the group consisting of: a carboxylic acid (e.g., citric acid, lactic acid, glycolic acid, acetic acid, succinic acid, or fumaric acid), and an inorganic acid, wherein the inorganic acid is not phosphoric acid or sulfuric acid (e.g., wherein the inorganic acid is hydrochloric acid or sodium acid pyrophosphate), and to methods of using and of making these compositions.

Owner:COLGATE PALMOLIVE CO

Anti-tatar oral care compositions providing crystallisation prevention

ActiveUS10080711B2Reduce and prevent formationCosmetic preparationsToilet preparationsMedicinePyrophosphoric acid

An oral composition is provided comprising at least 0.5% by weight of the composition of pyrophosphate in an orally acceptable carrier, wherein the pyrophosphate is provided by a mixture of disodium pyrophosphate and tetrasodium pyrophosphate in a ratio from disodium pyrophosphate to tetrasodium pyrophosphate in the range of from 1:0.4 to 1:1.2 and wherein the pH value of the composition is in the range of from 6.0 to 8.0. The oral composition can be used for prevention and control of tartar and / or calculus formation.

Owner:PROCTER & GAMBLE CO

Sodiumized Imonite Mixed Layer Clay

InactiveCN103979560BPromotes natural weatheringImprove the disintegration effectAluminium silicatesCation-exchange capacityPyrophosphate

The invention discloses a sodium-modified illite-montmorillonite mixed-layer clay. The technical scheme is as follows: the sodium-modified illite-montmorillonite mixed-layer clay is composed of illite-montmorillonite mixed-layer clay, magnesia, sodium carbonate, instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium acid pyrophosphate. The sodium-modified illite-montmorillonite mixed-layer clay materials are input into a mill and milled, and the milled powder illite-montmorillonite mixed-layer clay is the sodium-modified illite-montmorillonite mixed-layer clay. The sodium modification can enhance the water absorptivity, colloid index, expansion coefficient, colloid viscosity, cation exchange capacity, and dispersivity and suspension percentage in an aqueous medium of the illite-montmorillonite mixed-layer clay. The sodium-modified illite-montmorillonite mixed-layer clay has the characteristics of favorable thixotropy, favorable lubricating property, favorable heat stability, higher plasticity and higher binding property. The sodium-modified illite-montmorillonite mixed-layer clay is suitable for papermaking, cosmetics, plastics, rubber, paints, ceramics, textiles, cable insulation materials and firefighting materials.

Owner:广西上思县富石矿业有限公司

Preparation method of straw mushroom shrimp paste

InactiveCN106418293AGood colorImprove water holding capacityFood ingredientsBiotechnologyWater baths

The invention provides a preparation method of straw mushroom shrimp paste. The preparation method comprises the following steps of firstly taking straw mushrooms, thoroughly cleaning the taken straw mushrooms, airing the cleaned straw mushrooms, and crushing the aired straw mushrooms so as to obtain straw mushroom particles; then placing shrimp meat into a quality improvement agent for soaking, taking out the soaked shrimp meat, and performing mincing so as to obtain shrimp meat particles; and mixing the straw mushroom particles with the shrimp meat particles, table salt, egg white, starch and avocado oil to obtain a mixture, performing high-speed chopping to obtain paste, performing heat preservation at 35 DEG C for 20-40min, then performing heating in water bath of 90 DEG C for 15-30min, after the heating is completed, placing the heated paste into ice water for cooling, and then placing the cooled paste under the condition of 4 DEG C for 12-18h so as to obtain the straw mushroom shrimp paste, wherein the quality improvement agent is a mixed aqueous solution of sodium hexametaphosphate, trisodium phosphate, acidic sodium pyrophosphate, disodium dihydrogen pyrophosphate, sodium citrate, propylene glycol alginate and xanthan gum. The straw mushroom shrimp paste disclosed by the invention has favorable color, favorable water retention property and favorable gel intensity, the processing technology is simple, storage and transportation of products are facilitated, and the straw mushroom shrimp paste is suitable for industrialized mass production.

Owner:江苏江南生物科技有限公司

Sodiumized Illuminite Mixed Layer Clay

Owner:浙江龙鹰光电科技有限公司

Anti-tatar oral care compositions providing crystallisation prevention

ActiveUS20160120776A1Reduce and prevent formationCosmetic preparationsToilet preparationsMedicinePyrophosphoric acid

An oral composition is provided comprising at least 0.5% by weight of the composition of pyrophosphate in an orally acceptable carrier, wherein the pyrophosphate is provided by a mixture of disodium pyrophosphate and tetrasodium pyrophosphate in a ratio from disodium pyrophosphate to tetrasodium pyrophosphate in the range of from 1:0.4 to 1:1.2 and wherein the pH value of the composition is in the range of from 6.0 to 8.0. The oral composition can be used for prevention and control of tartar and / or calculus formation.

Owner:THE PROCTER & GAMBLE COMPANY

Sodium-modified illite-chlorite mixed-layer clay

The invention discloses a sodium-modified illite-chlorite mixed-layer clay. The technical scheme is as follows: the sodium-modified illite-chlorite mixed-layer clay is composed of illite-chlorite mixed-layer clay, magnesium oxide, sodium carbonate, instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium acid pyrophosphate. The sodium-modified illite-chlorite mixed-layer clay materials are milled into powder in a mill, and the powder is the sodium-modified illite-chlorite mixed-layer clay. The sodium acid pyrophosphate is adopted to regulate the pH value of the illite-chlorite mixed-layer clay according to the product quality demands. The sodium modification can enhance the water absorptivity, colloid index, expansion coefficient, colloid viscosity, cation exchange capacity, and dispersivity and suspension percentage in an aqueous medium of the illite-chlorite mixed-layer clay. The sodium-modified illite-chlorite mixed-layer clay has the characteristics of favorable thixotropy, favorable lubricating property, favorable heat stability, higher plasticity and higher binding property. The sodium-modified illite-chlorite mixed-layer clay is suitable for producing products in the fields of industry, agriculture, construction, firefighting and the like.

Owner:浙江龙鹰光电科技有限公司

Anti-tatar oral care compositions providing crystallisation prevention

ActiveUS20160120777A1Faster bitterness decreaseImprove bitternessCosmetic preparationsToilet preparationsMedicinePotassium

An oral composition is provided comprising at least 0.5% by weight of the composition of pyrophosphate in an orally acceptable carrier, wherein the pyrophosphate is provided by a mixture of disodium pyrophosphate and tetrapotassium pyrophosphate in a ratio from disodium pyrophosphate to tetrapotassium pyrophosphate in the range of from 1:0.4 to 1:1.2 and wherein the pH value of the composition is in the range of from 6.0 to 8.0. The oral composition can be used for prevention and control of tartar and / or calculus formation.

Owner:THE PROCTER & GAMBLE COMPANY

Production method of disodium dihydrogen pyrophosphate with high gas generation rate

InactiveCN103145111BLittle changeImprove stabilityPhosphorus compoundsPhosphoric acidPotassium hydroxide

The invention relates to a method for producing disodium dihydrogen pyrophosphate, in particular to a method for producing disodium dihydrogen pyrophosphate with high gas evolution rate. Phosphoric acid and sodium hydroxide are neutralized, and potassium hydroxide is added in the neutralization stage, the pH of the neutralization solution is fine-tuned with phosphoric acid or sodium hydroxide, and the specific gravity is controlled, and then the neutralization solution is spray-dried to obtain dihydrogen phosphate after drying. The sodium powder particles are sent to a barrel polymerization furnace for polymerization, and cooled to obtain disodium dihydrogen pyrophosphate with a high gas evolution rate. The disodium dihydrogen pyrophosphate produced by this method has a gas rate ROR of 36-42. As the acid salt component in the composite leavening agent, the ROR changes little during the shelf life and has good stability.

Owner:XUZHOU COLLEGE OF INDAL TECH

Special tea leaf organic composite fertilizer and preparation method thereof

InactiveCN107721653APromote absorptionImprove qualityBio-organic fraction processingAnimal corpse fertilisersBacillus thuringiensisMononucleosis

The invention discloses a special tea leaf organic composite fertilizer and a preparation method thereof. The special tea leaf organic composite fertilizer comprises the following components in partsby weight: bean dregs, bone meal, humic acid, potassium chloride, powder of nitrogen-fixing bacteria, microorganism strains, urea, bdellovibrio powder, cotton straw powder, dipotassium phosphate, sodium acid pyrophosphate, monocalcium phosphate, plant activating enzymes, bacillus thuringiensis powder, rhodococcus powder, mononucleosis powder, biogas residues, a conditioner, phosphorus bacterium powder, potassium bacterium powder, powdered rock phosphate, tapes japonica shell powder, veronica linariifolia straw powder, clam shell powder, cedarwood bits, oriental arborvitae bits and actinomycetes powder. The preparation method comprises the following steps: preparing a mixture A and a mixture B, and mixing the mixtures, thereby obtaining the fertilizer. Macroelements and microelements are reasonably proportioned, absorption of tea leaves is facilitated, the quality of tea leaves can be improved through the purely natural green fertilizer, resources can be effectively utilized, and the environment is protected.

Owner:广西梧州金广丰生物肥料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com