Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Critical test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

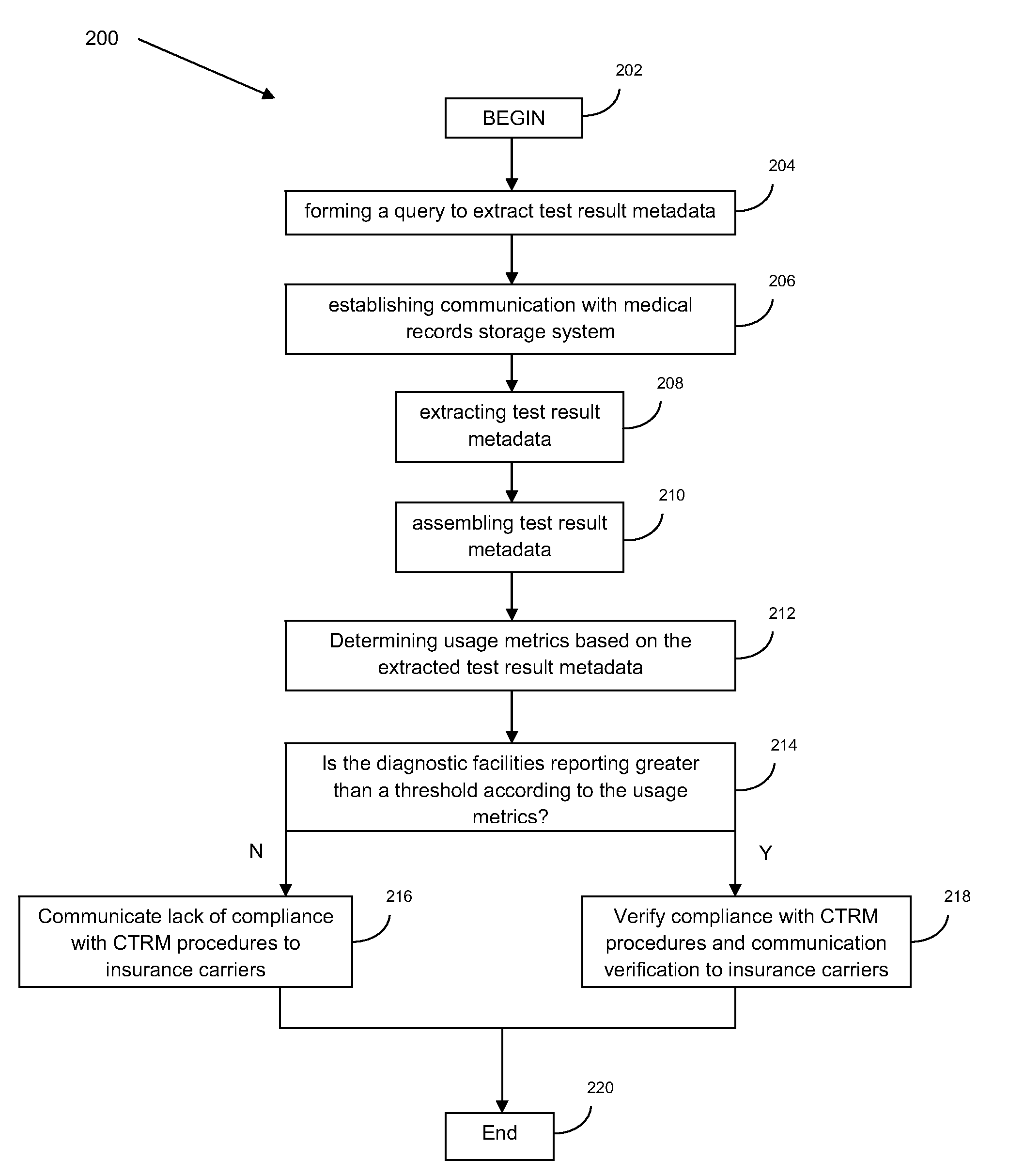

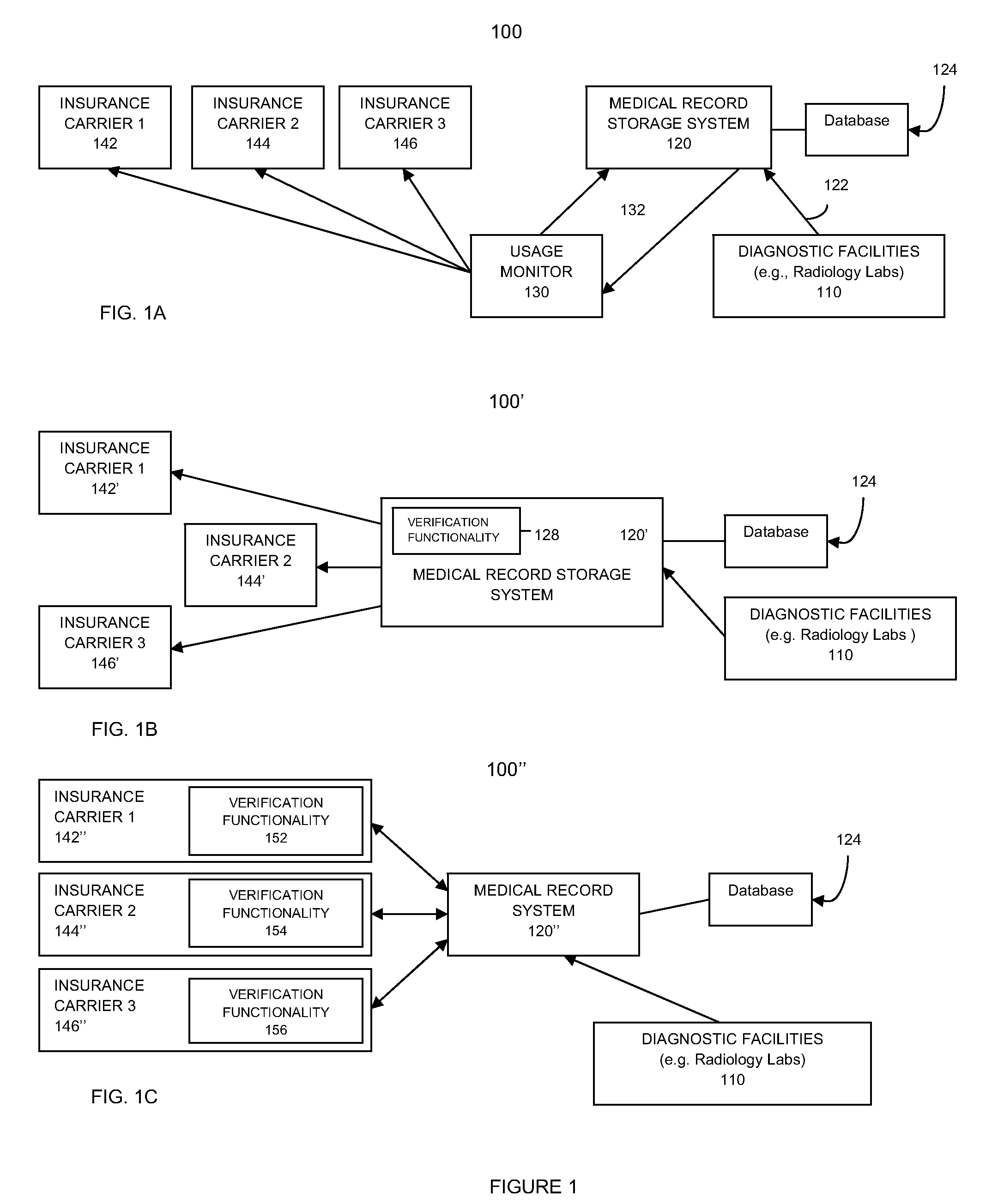

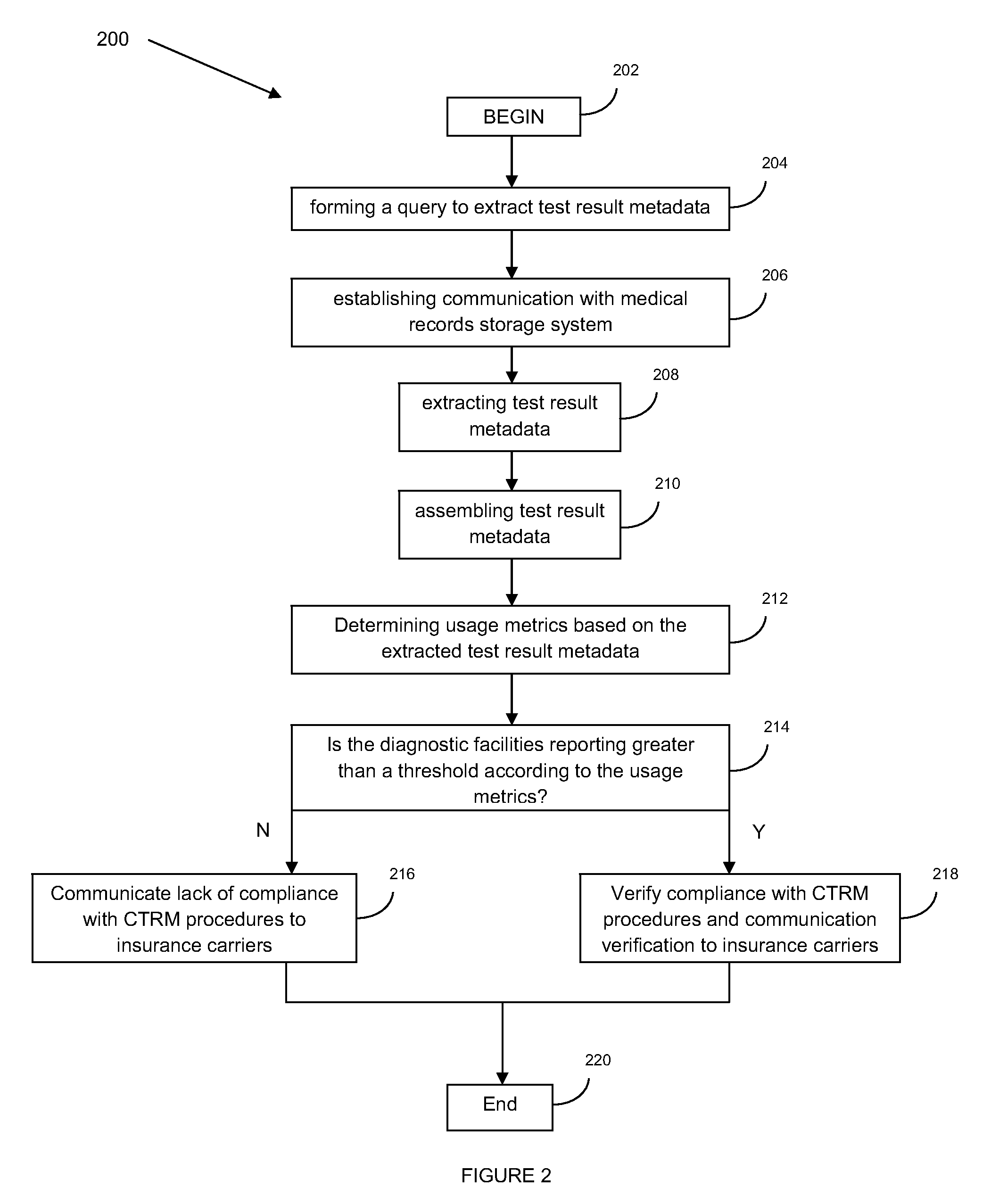

Verification monitor for critical test result delivery systems

PendingUS20100088232A1Reduce riskQuick analysisFinanceLocal control/monitoringComputer hardwareDiagnostic test

A system and method for verification monitoring of a critical test result management (CTRM) system is provided. In one embodiment, the method includes receiving test result metadata pertaining to test result messages provided to a CTRM system by a diagnostic test facility, verifying compliance of the diagnostic test facility with prescribed usage of the CTRM system using the test result metadata, and sending a message to an interested party regarding whether or not compliance of the diagnostic test facility has been verified.

Owner:BAKER SCOTT HLDG

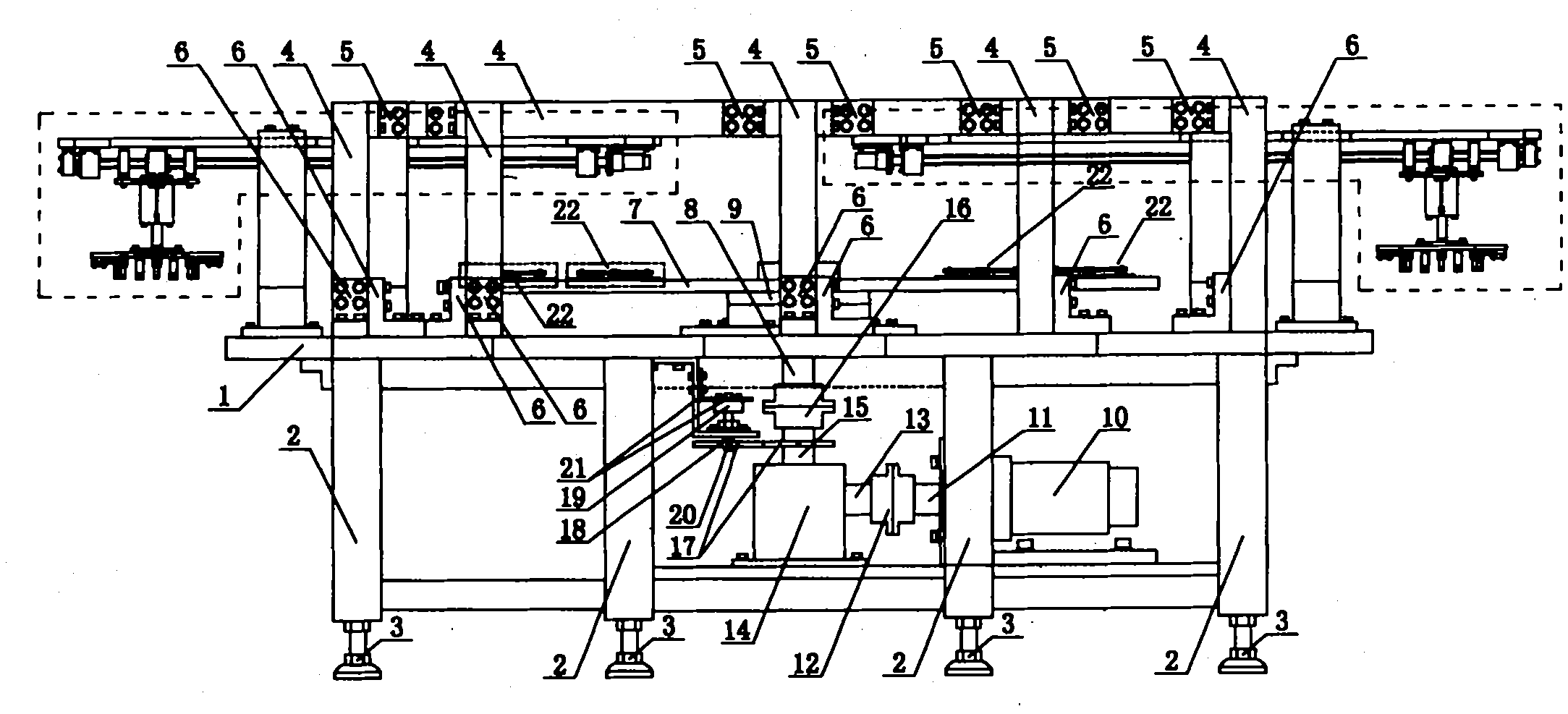

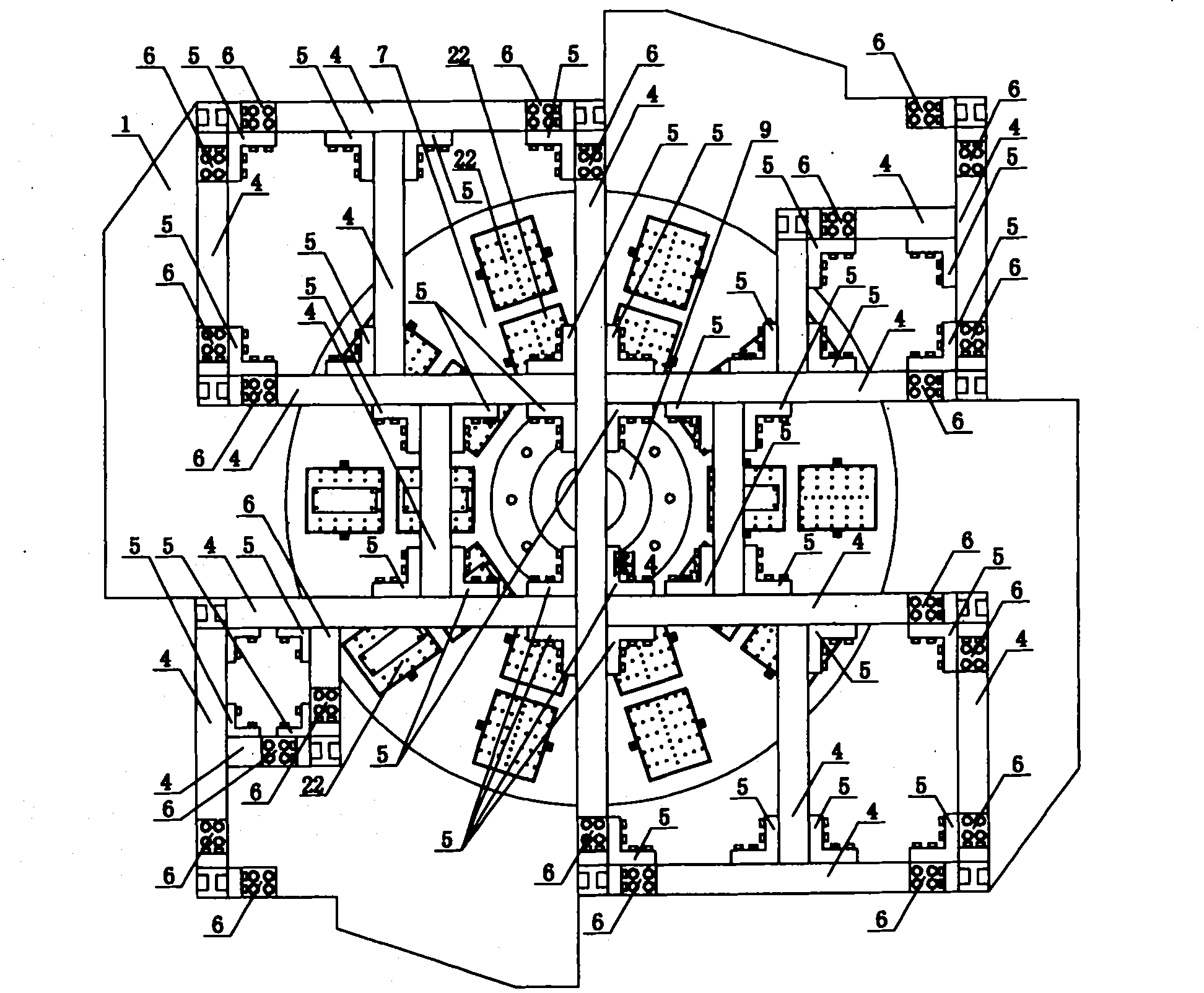

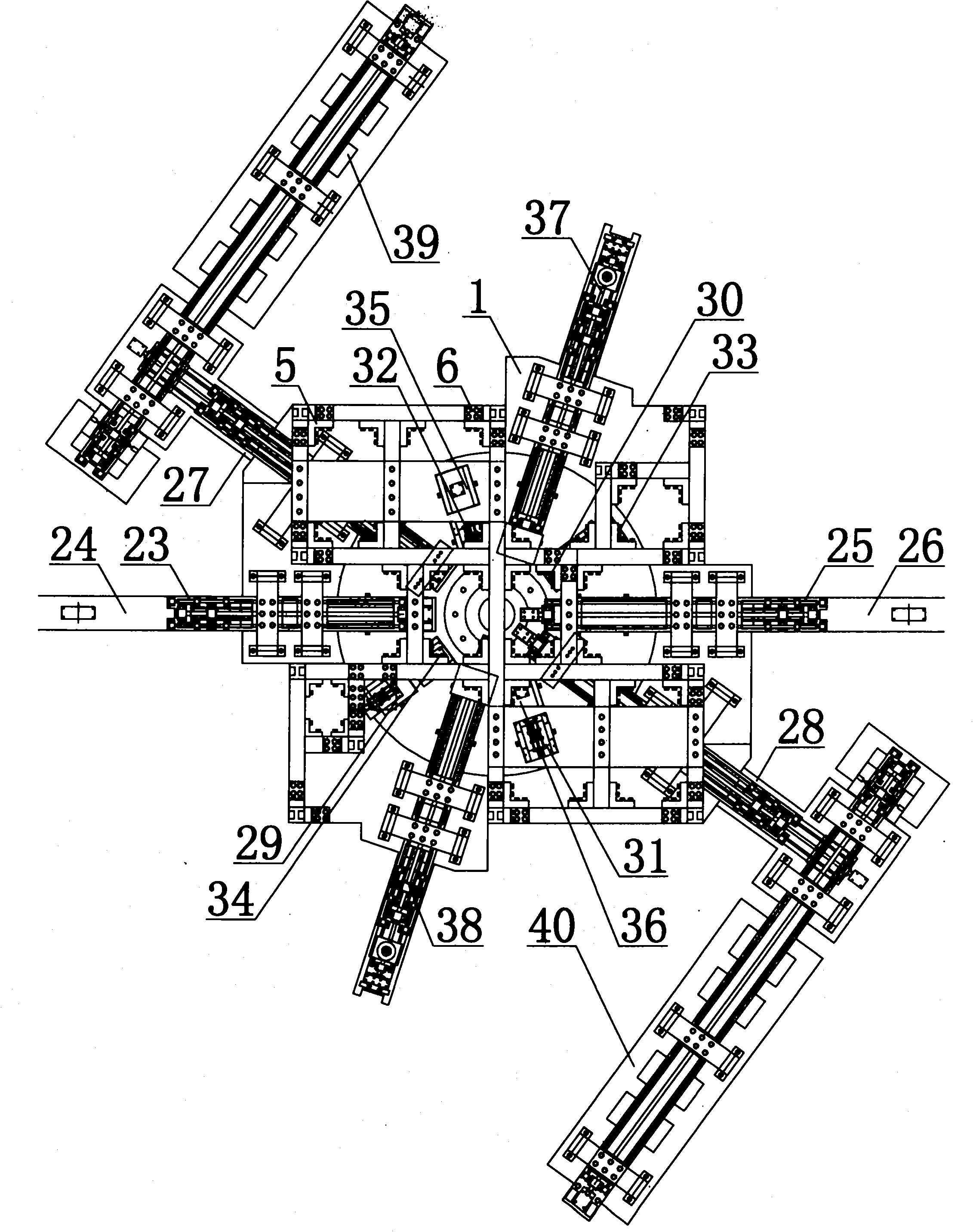

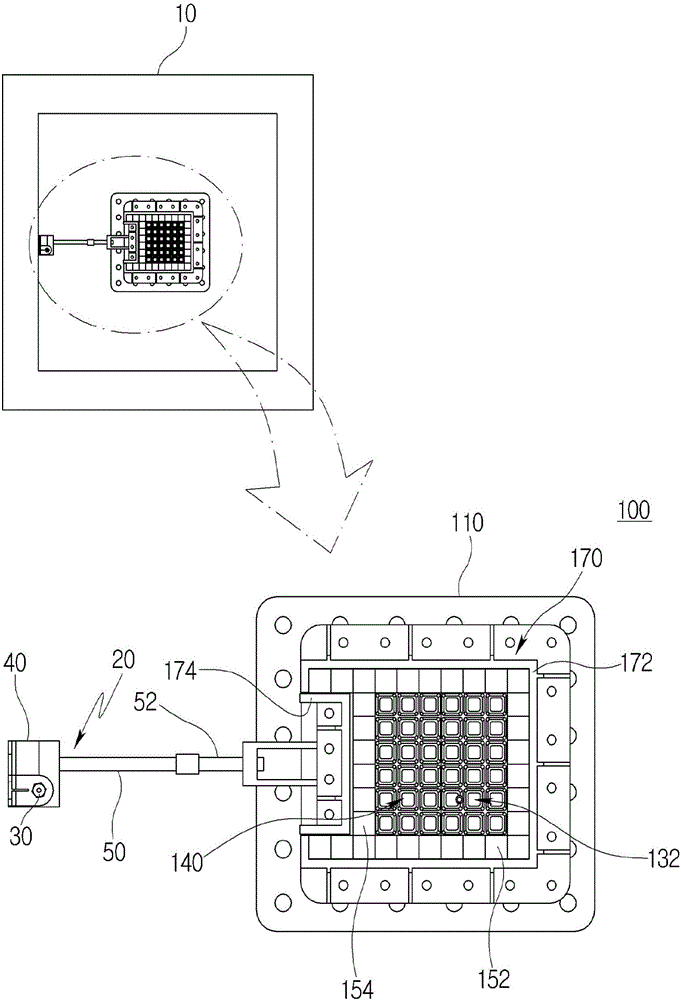

Test bed for testing comprehensive performance of LED modules

InactiveCN101995326ASolve the problem of difficult quality controlWith intelligent operation functionSpectrum investigationCurrent/voltage measurementQuality controlLead measurement

The invention discloses a test bed for testing comprehensive performance of LED modules in the technical field of LED measurement. A double-station mode is provided with two sets of independent automatic loading and unloading machines, a PCB (printed circuit board) detector, an LED module electrical parameter detector, an LED module light intensity detector, an LED module spectrum parameter and chromaticity detector, an LED module defect repairer and a qualified product and unqualified product sorter; and the LED modules of two different specifications can be tested at the same time. Multi-variety online quick test and sorting can be efficiently matched by adopting a rotary sorting mode, combining a computer and a motion control card and controlling independent operation of each tester. The test bed can be adaptive to performance test of the LED modules of multiple specifications, is simple and convenient to operate, has high automation degree, can effectively and comprehensively reflect the comprehensive performance indexes of the tested LED modules, and has actual significance for improving quality control of the LED modules and research on industrialized key test technology of the LED module industry.

Owner:上海诚测电子科技发展有限公司

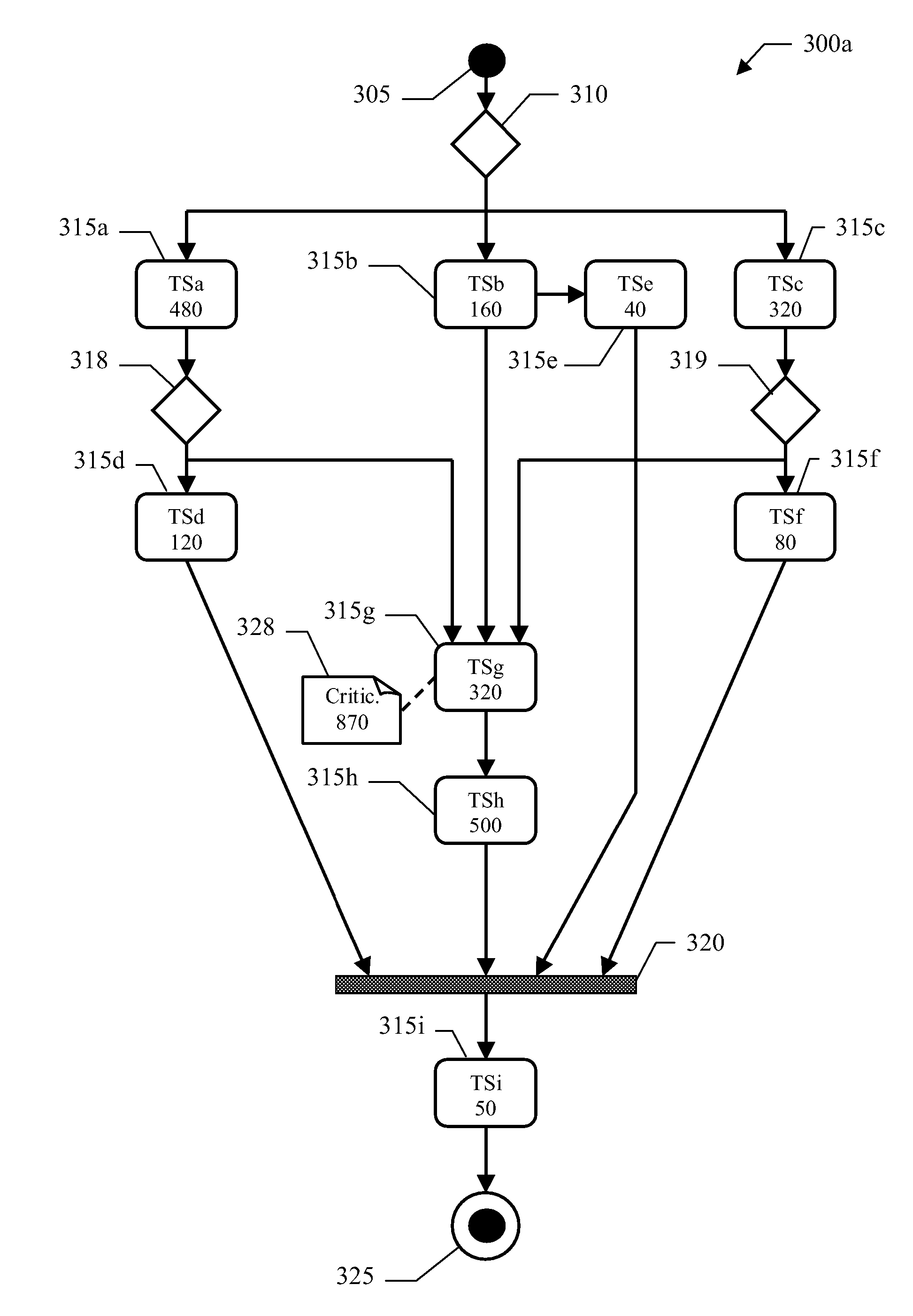

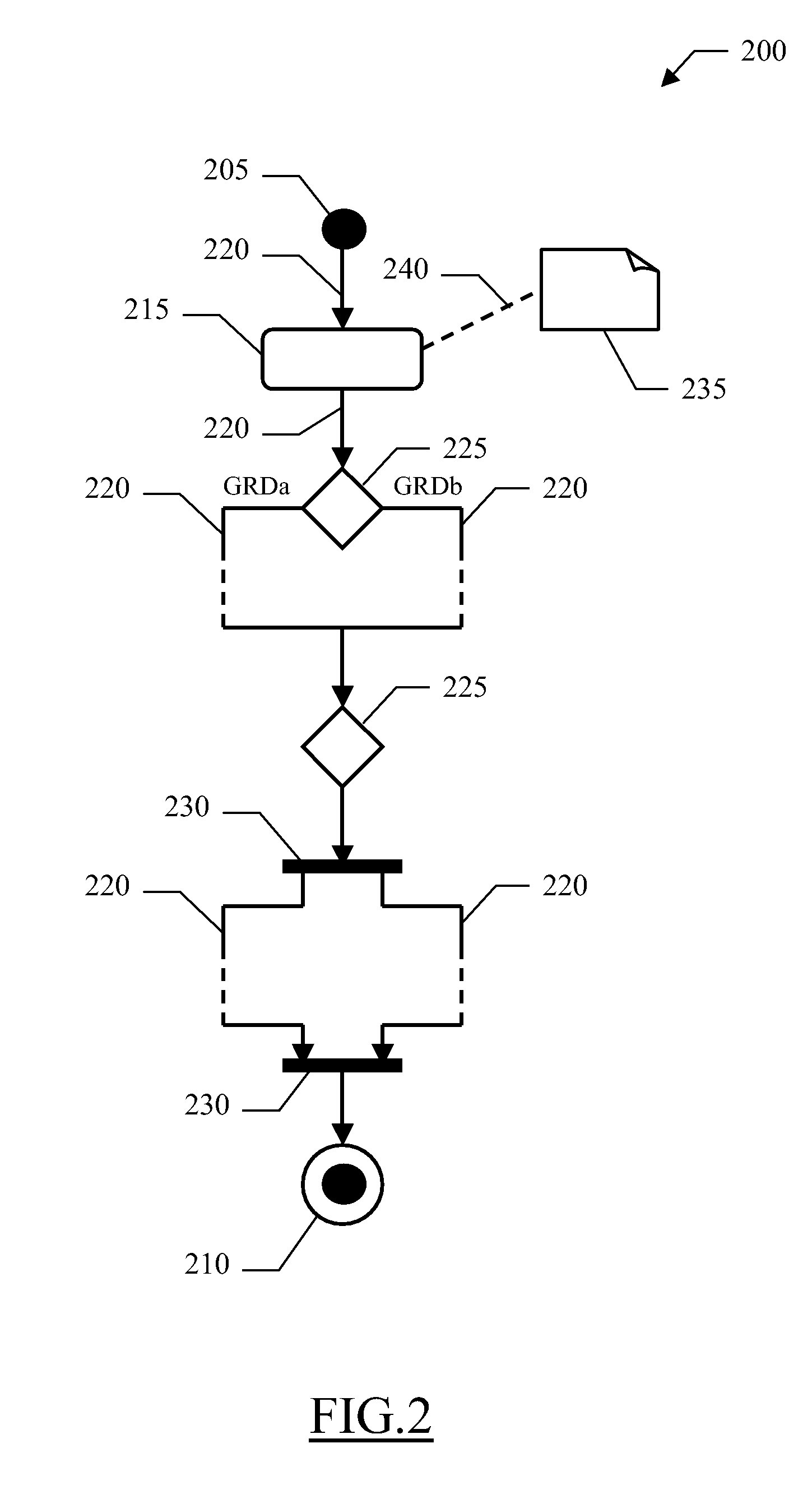

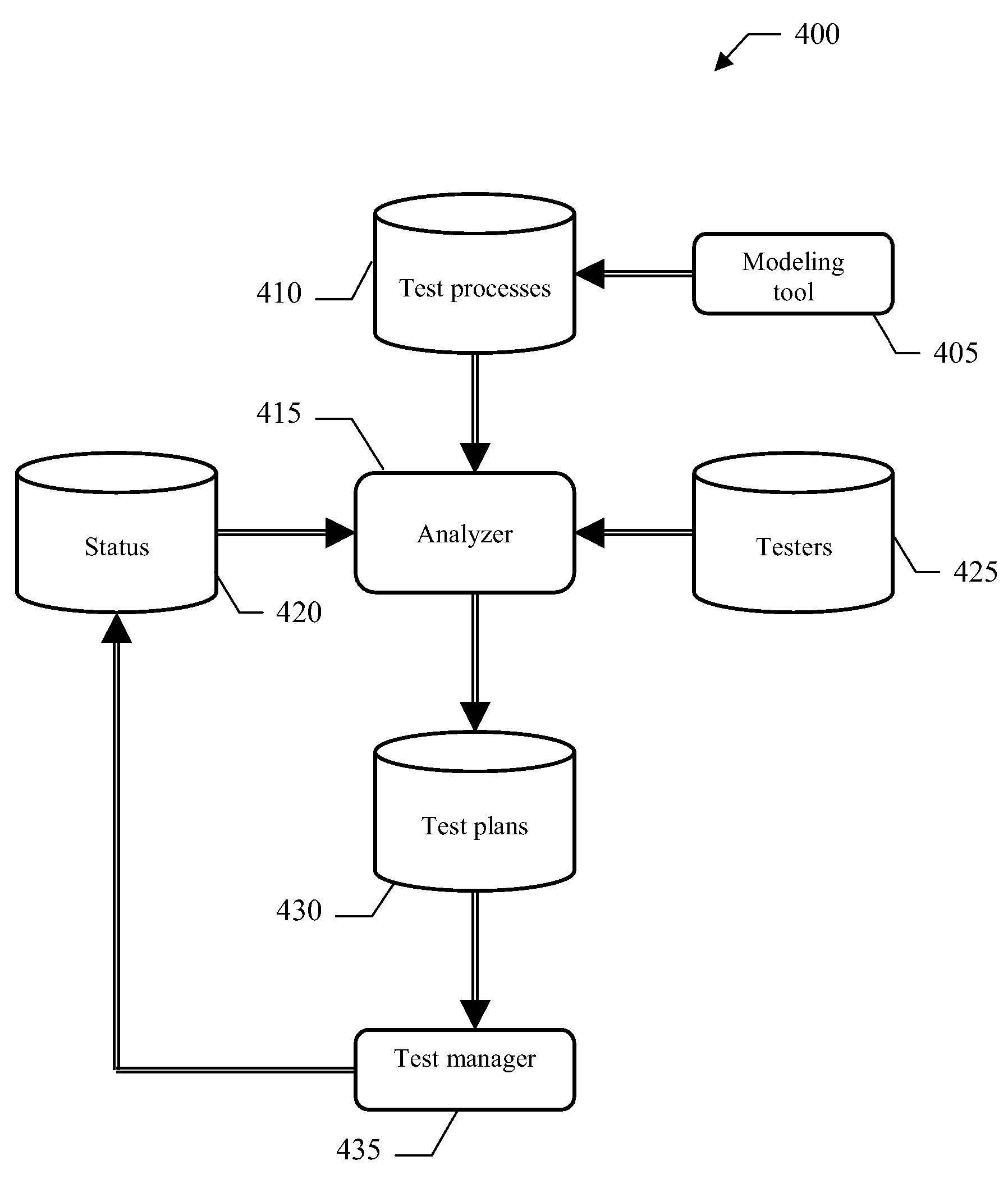

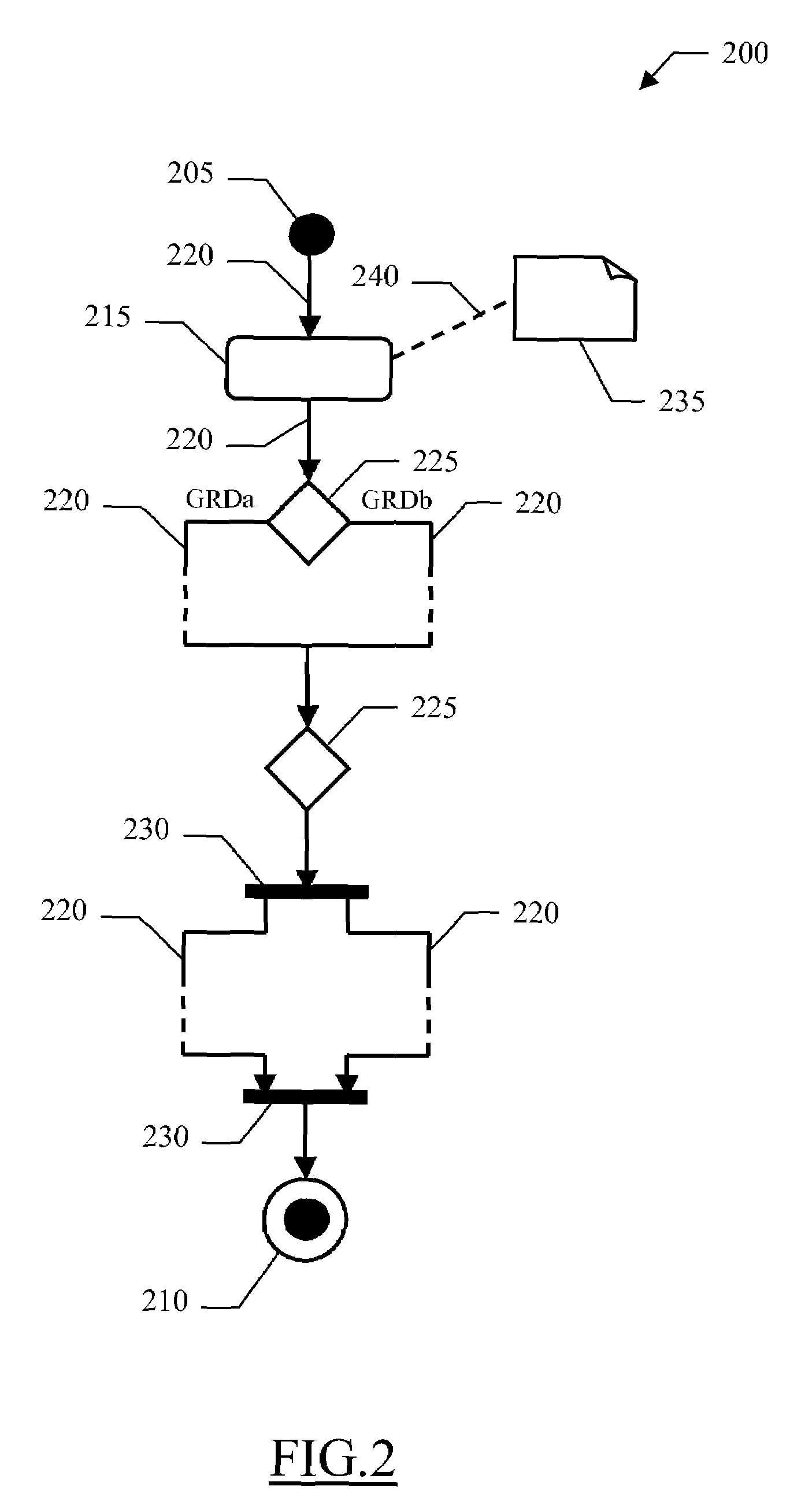

Method, system and computer program for managing test processes based on customized UML diagrams

InactiveUS20070094542A1Minimize cost functionEasy to manageError detection/correctionSoftware simulation/interpretation/emulationSuccessful completionActivity diagram

A method for facilitating the management of a test process is proposed. For this purpose, the different test scenarios included in the process and their execution dependencies are represented by means of a customized UML activity diagram (300a). An execution weight is also associated with each test scenario (for example, defined by the man-hours required for its execution). In this way, it is possible to identify critical test scenarios (315g), which may impair the execution of the whole test process when they fail (because many other test scenarios depend on their successful completion). The order of execution of the test scenarios is then arranged into a test plan, so as to minimize the time required to reach the critical test scenarios. Preferably, the same process is repeated whenever any runtime condition changes (such when a test scenario fails).

Owner:IBM CORP

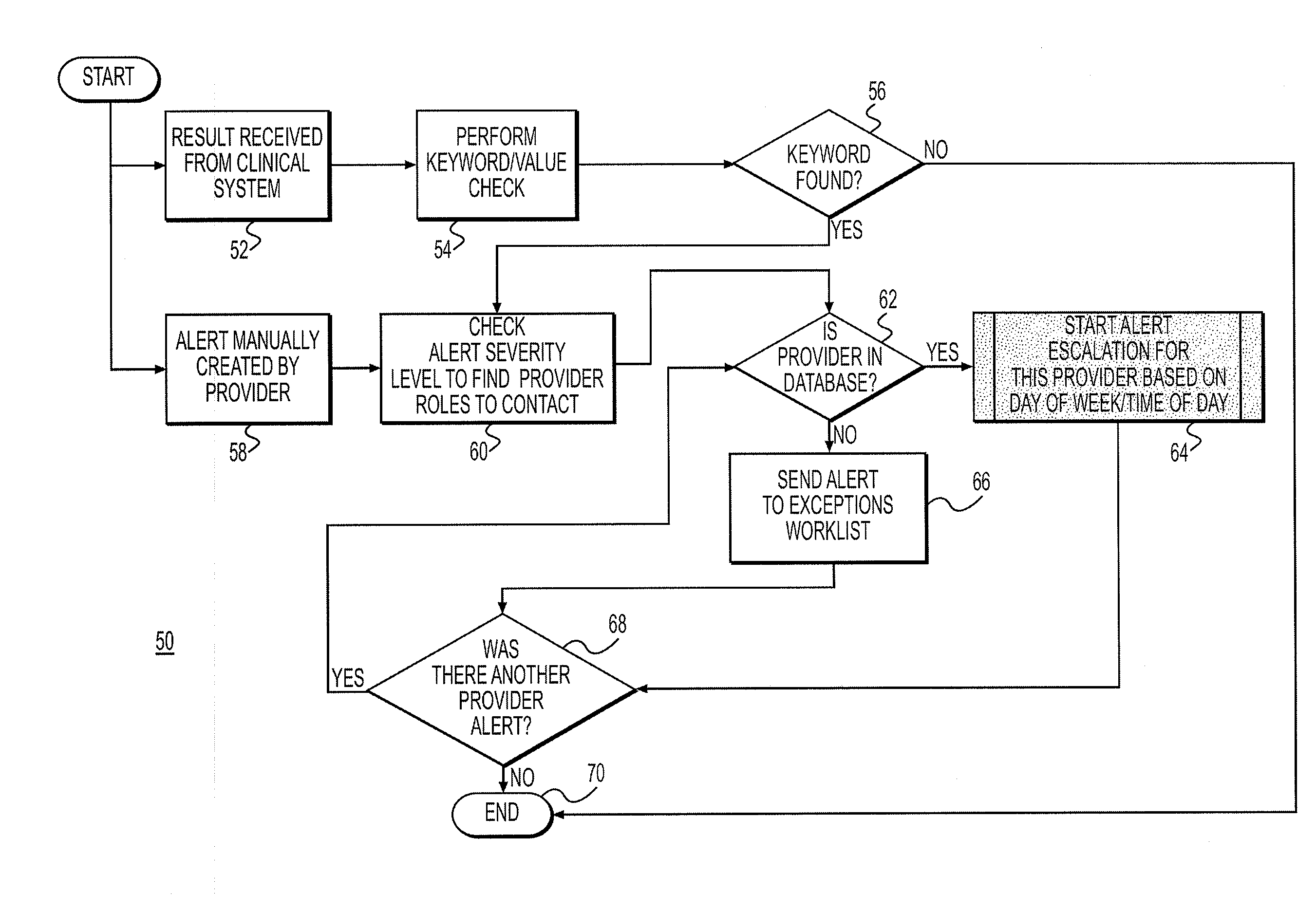

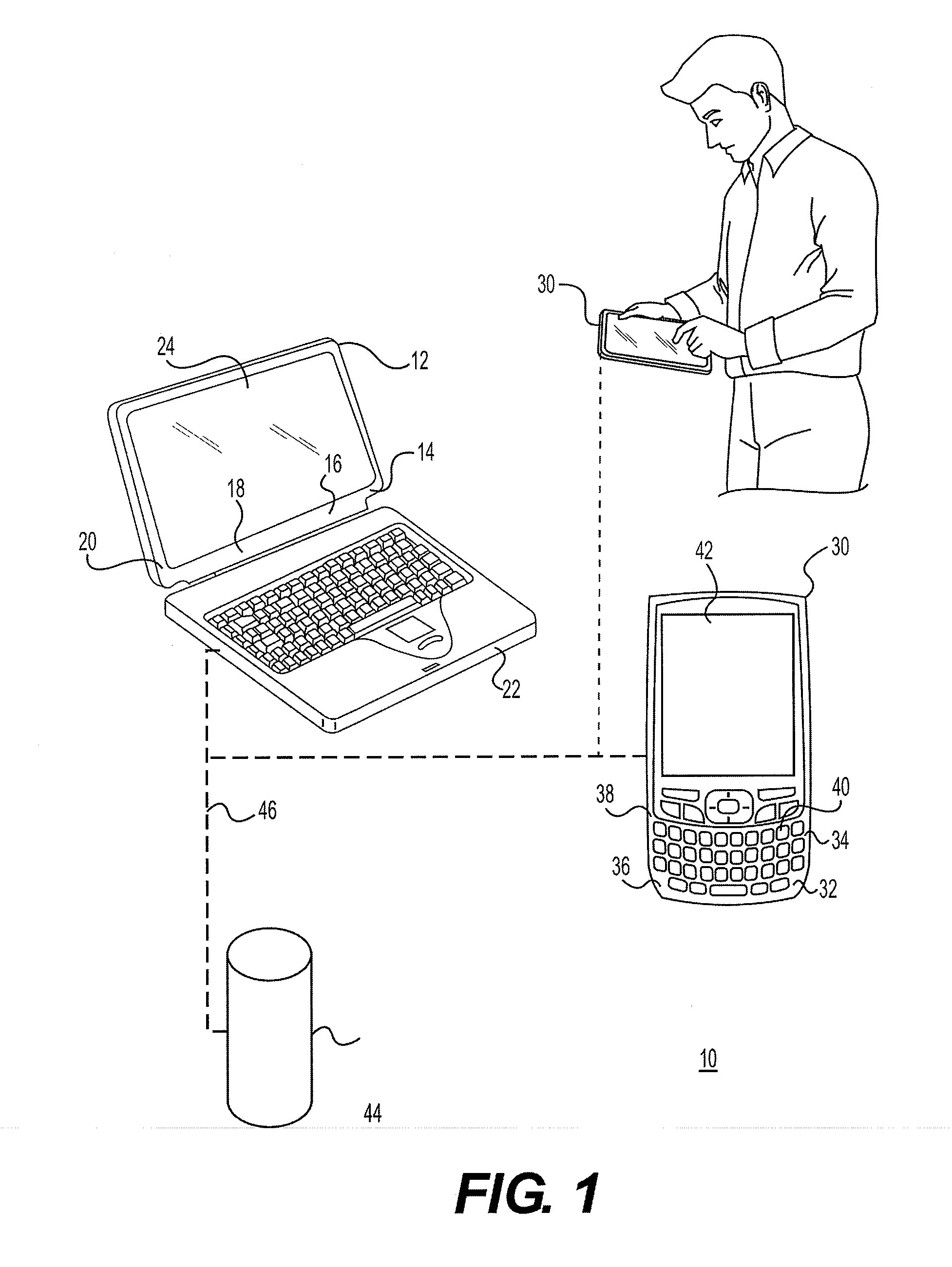

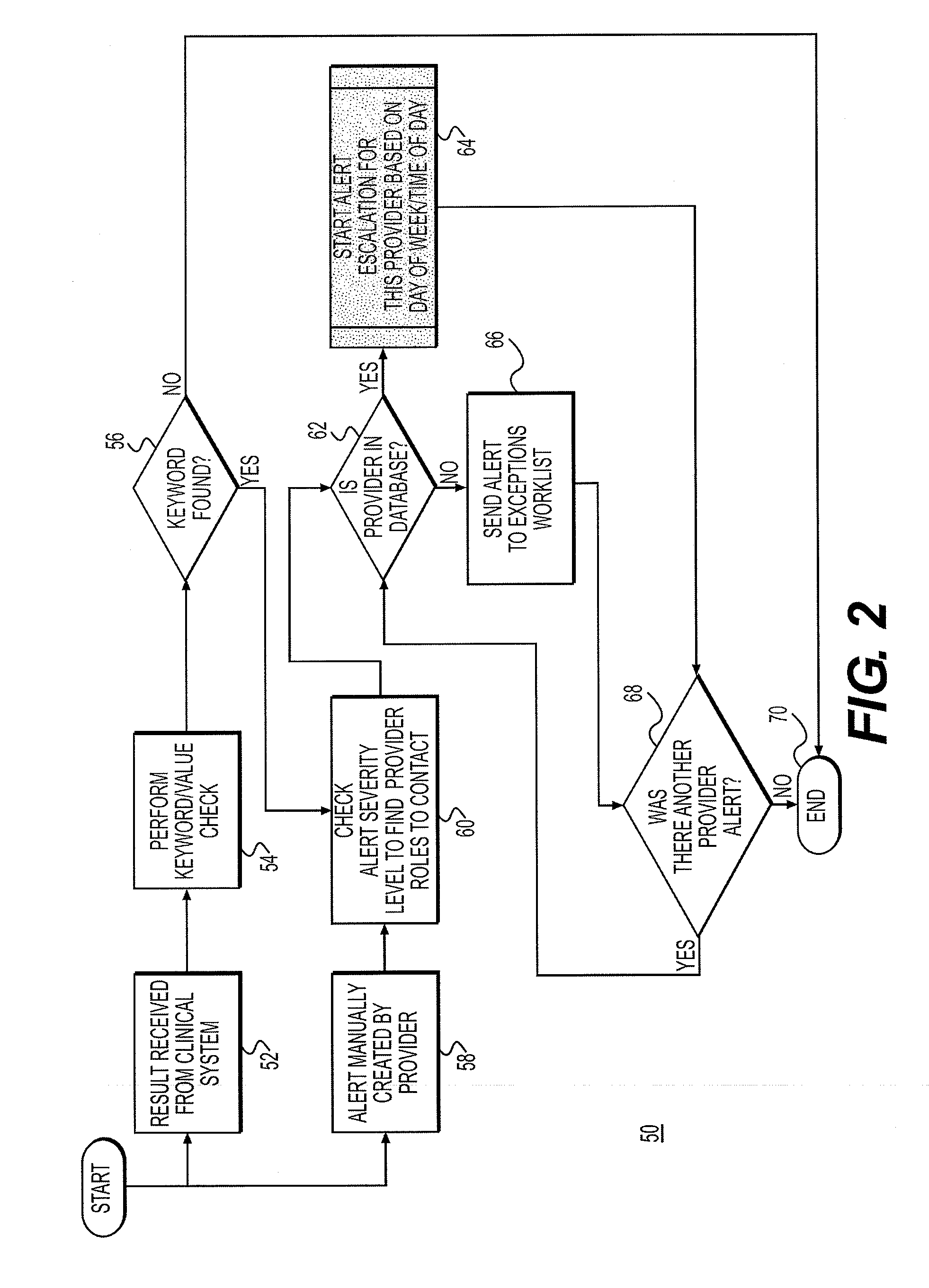

Critical test result management system and method

A critical test results management system and method for capturing test data from a test results providing program and delivering messages to interested recipients. The system and method generating alerts, escalating the alerts to message receiving devices, and tracking the status of the alerts. The recipient of an alert can access the system to obtain the contents of the alert, acknowledge receipt of the alert, and record notes related to the alert. The invention tracks when alerts were sent and if they have been acknowledged. If the alerts are not acknowledge prior expiration of a predetermined time period, further alerts are escalated to the recipient, to different receiving devices, or to different recipients.

Owner:BIDDULPH KRENTAR BRIAN

Method, system and computer program for managing test processes based on customized UML diagrams

InactiveUS7581138B2Minimize cost functionEasy to manageError detection/correctionSoftware simulation/interpretation/emulationSuccessful completionMan-hour

A method for facilitating the management of a test process is proposed. For this purpose, the different test scenarios included in the process and their execution dependencies are represented by means of a customized UML activity diagram (300a). An execution weight is also associated with each test scenario (for example, defined by the man-hours required for its execution). In this way, it is possible to identify critical test scenarios (315g), which may impair the execution of the whole test process when they fail (because many other test scenarios depend on their successful completion). The order of execution of the test scenarios is then arranged into a test plan, so as to minimize the time required to reach the critical test scenarios. Preferably, the same process is repeated whenever any runtime condition changes (such when a test scenario fails).

Owner:INT BUSINESS MASCH CORP

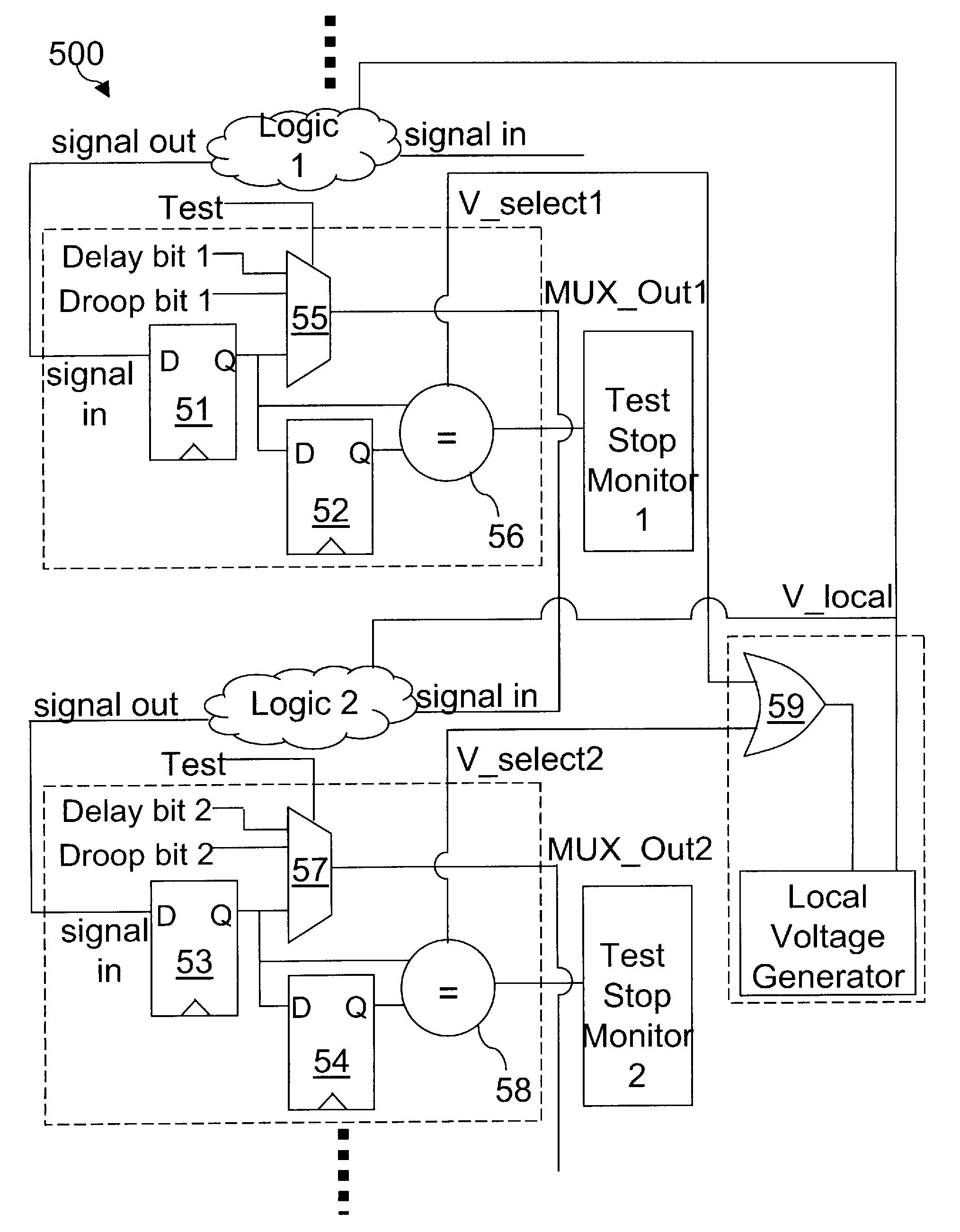

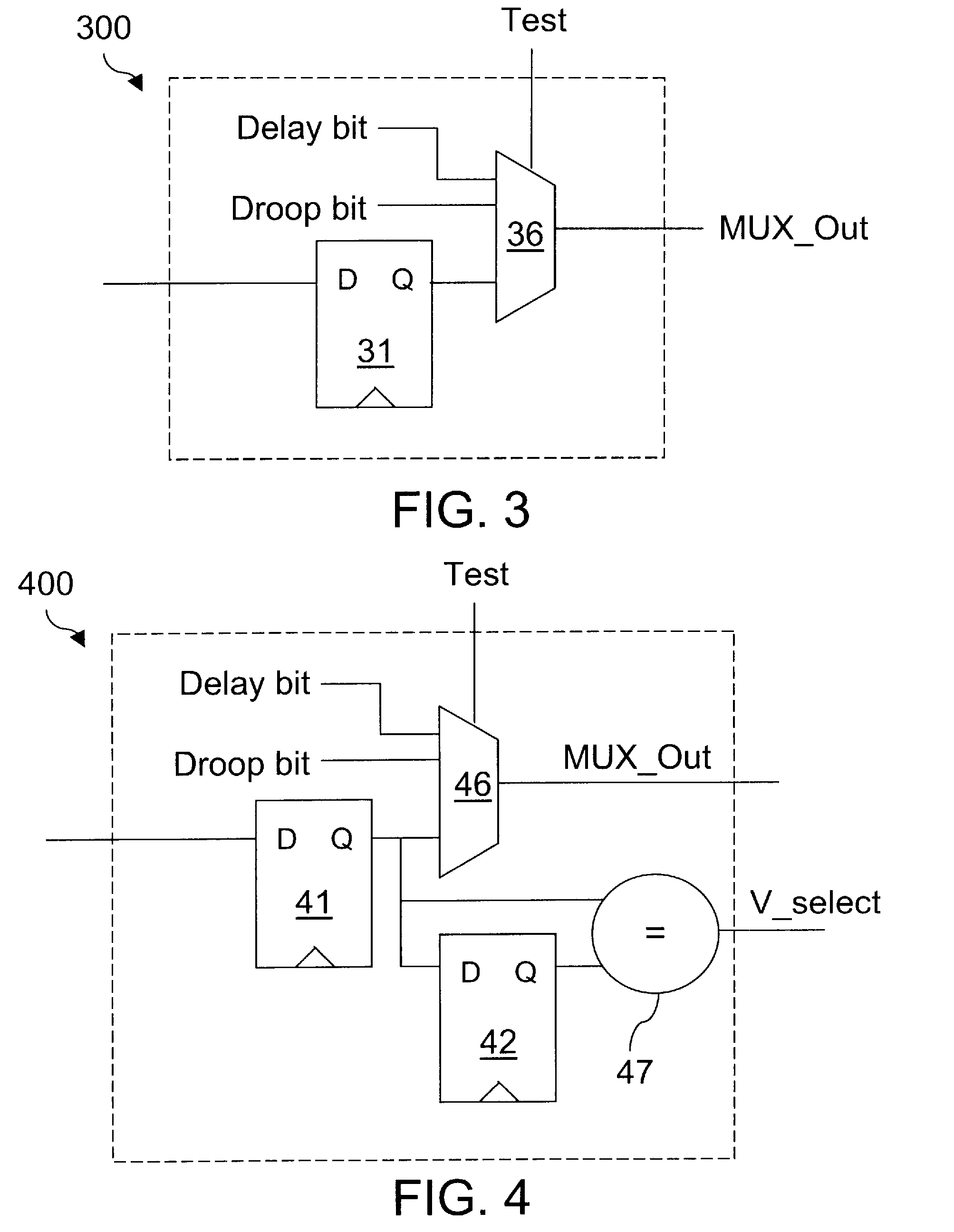

Optimal local supply voltage determination circuit

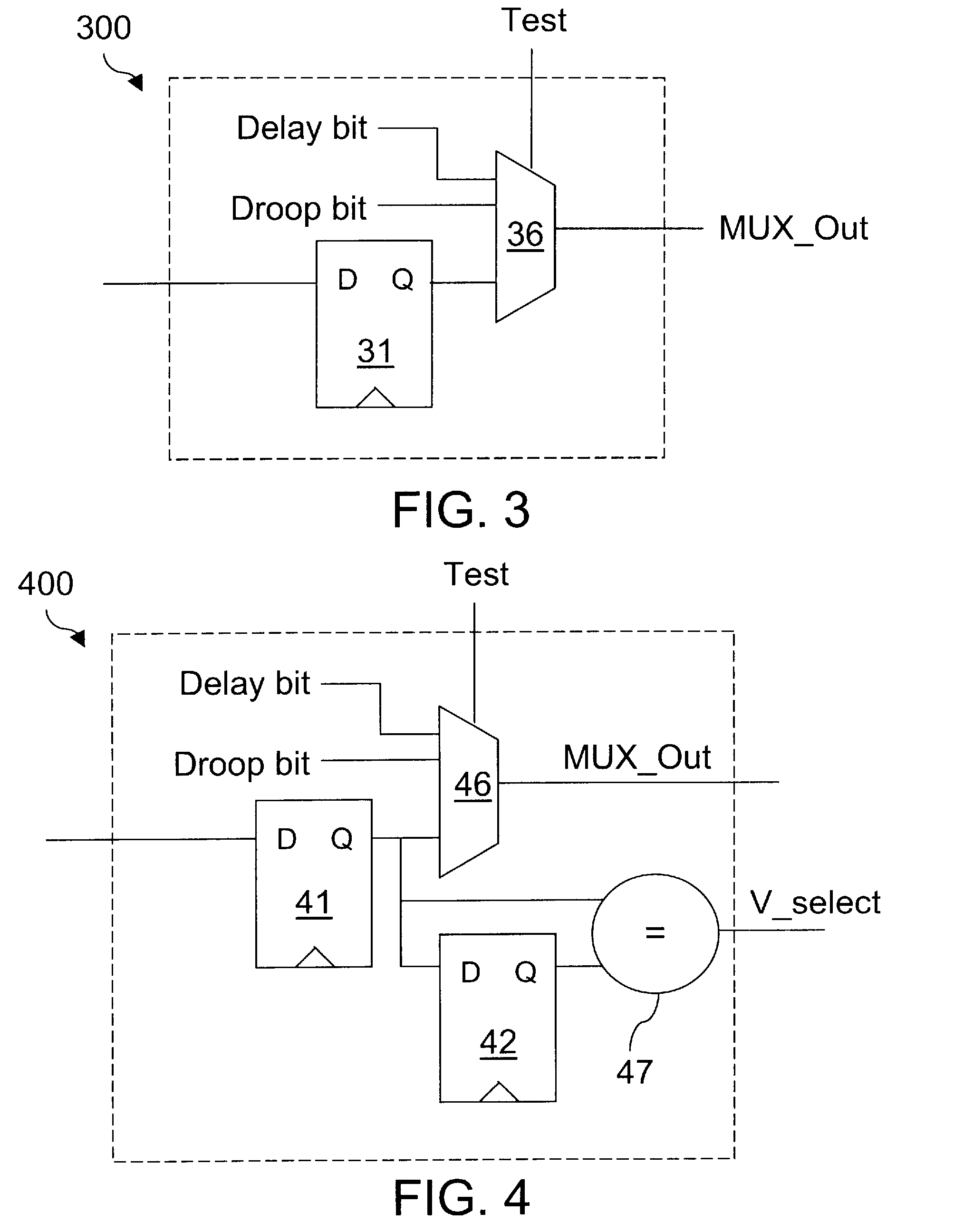

InactiveUS7898285B2Logic circuit coupling/interface arrangementsElectric variable regulationProcessor registerCritical test

A test circuit that compares test results between two tests with different local supply voltages is provided. The output of each stage of the logic circuits is stored in a first register of each test circuit. Each test is performed with a critical test vector and a local supply voltage that decreases from test to test. The outputs of successive tests are compared in each test circuit. The tests are performed iteratively with successive reduction in the value of the local supply voltage until at least one stage of the logic circuits produces non-matching results between the first and second register. The voltage immediately before producing such non-matching results is the minimum operational voltage for the local voltage island.

Owner:INT BUSINESS MASCH CORP

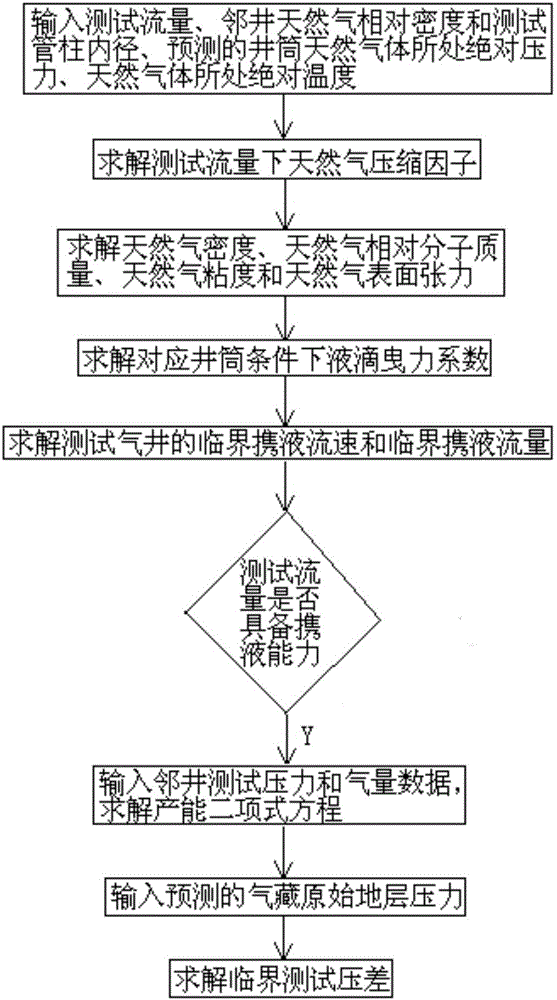

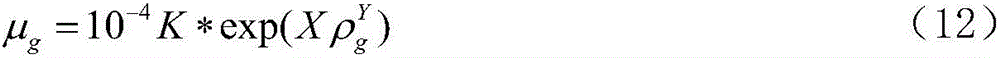

Critical liquid carrying condition optimization method in deep water gas well testing

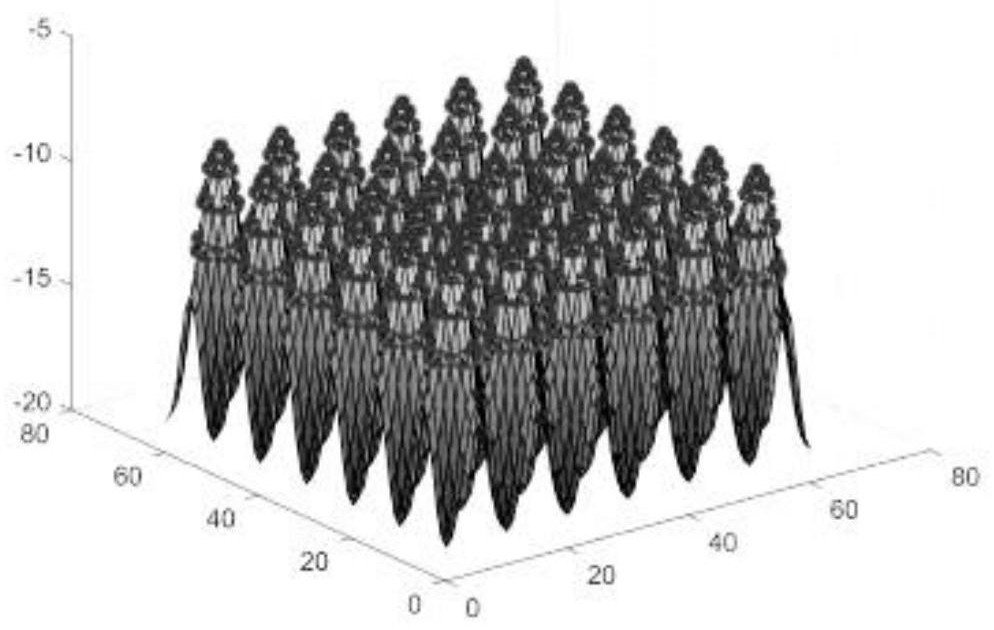

ActiveCN106600442AMeet test design requirementsImprove accuracyData processing applicationsSurface stressTest flow

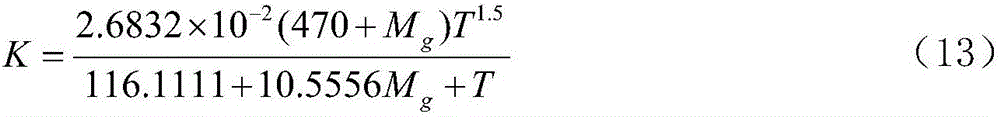

The present invention relates to a critical liquid carrying condition optimization method in deep water gas well testing. The method is characterized by comprising a first step of determining a test flow of a wellbore, calculating a natural gas compression factor of each point in the wellbore according to a natural gas relative density of an adjacent well and internal diameter data of a test pipe, a predicted absolute pressure of wellbore natural gas, and an absolute temperature of the natural gas, next, calculating natural gas density, natural gas relative molecular mass, natural gas viscosity and natural gas surface stress of a corresponding point in the wellbore according to the acquired natural gas compression factor of each point in the wellbore, and determining a drag force for carrying the drop to be out of the well of each point in the wellbore by using the acquired natural gas viscosity; a second step of calculating a critical liquid carrying flow rate and a critical liquid carrying flow in deep water gas well testing; and a third step of calculating a bottom flow pressure corresponding to the critical liquid carrying flow in deep water gas well testing according to test pressure and gas quantity data of the adjacent well, and calculating a critical test pressure difference required in deep water gas well testing by using the bottom flow pressure.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Fast bit-error-rate (BER) test

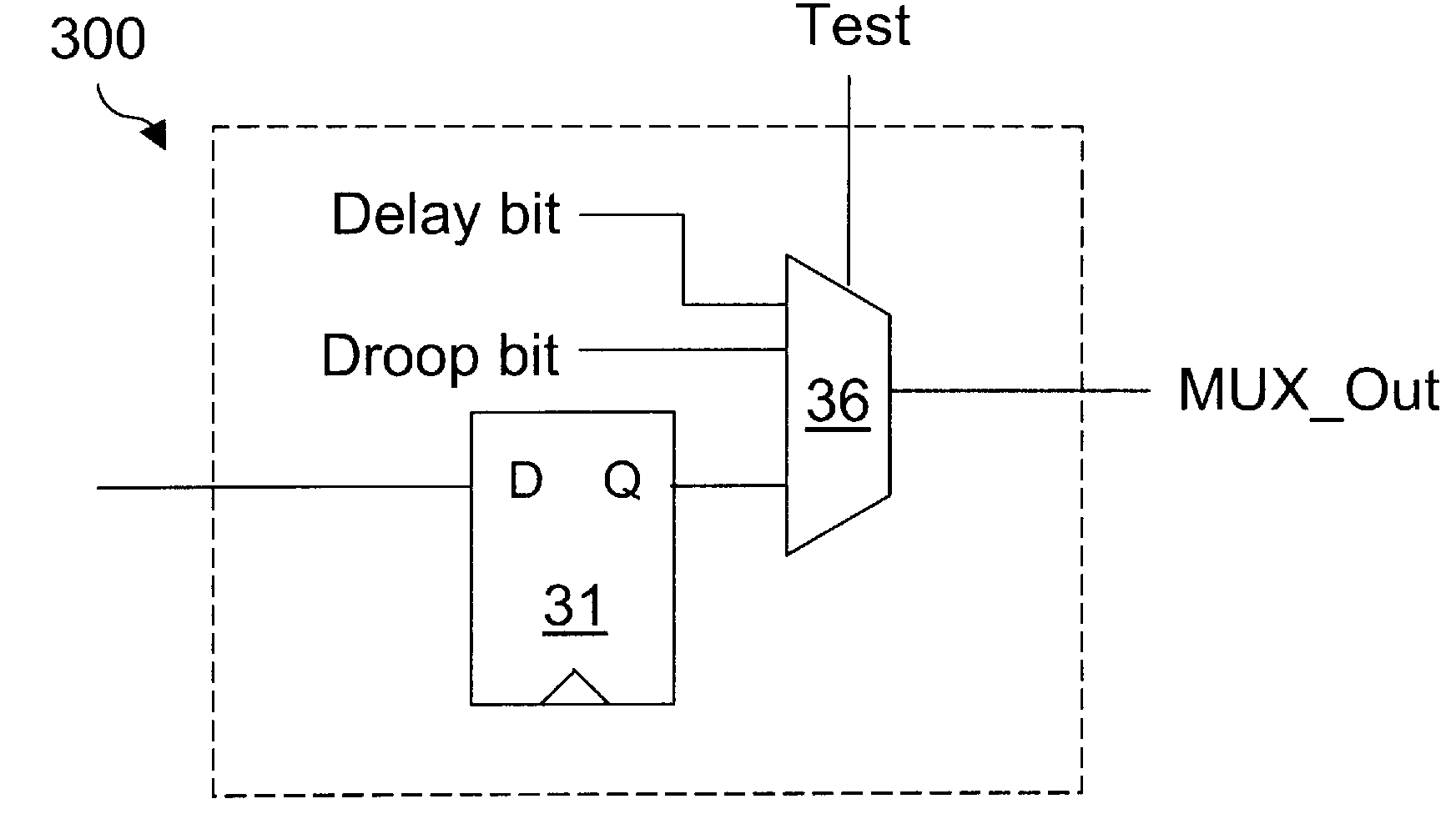

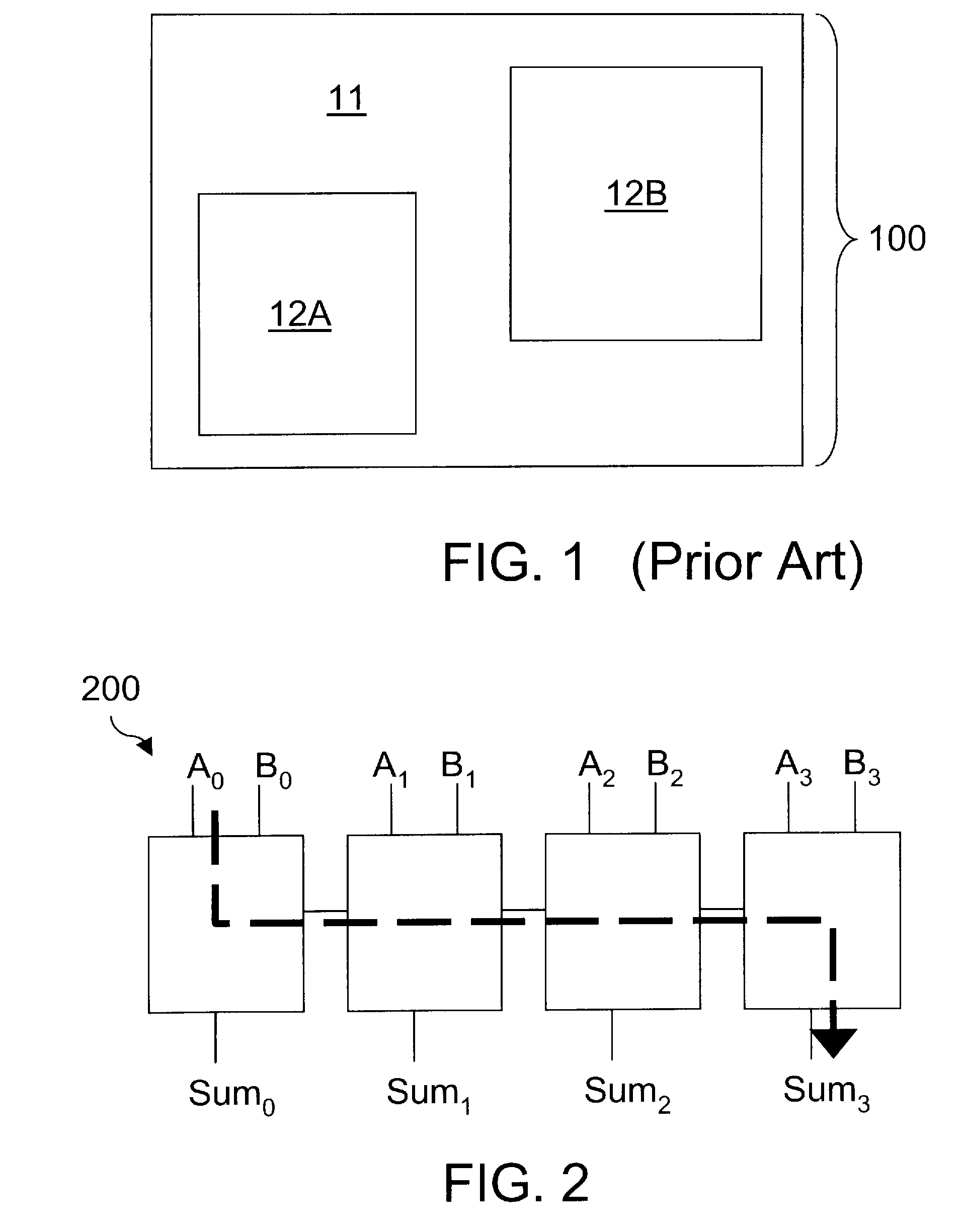

ActiveUS7079612B2Variable delayEasy to migrateDigital circuit testingCorrect operation testingEngineeringCritical test

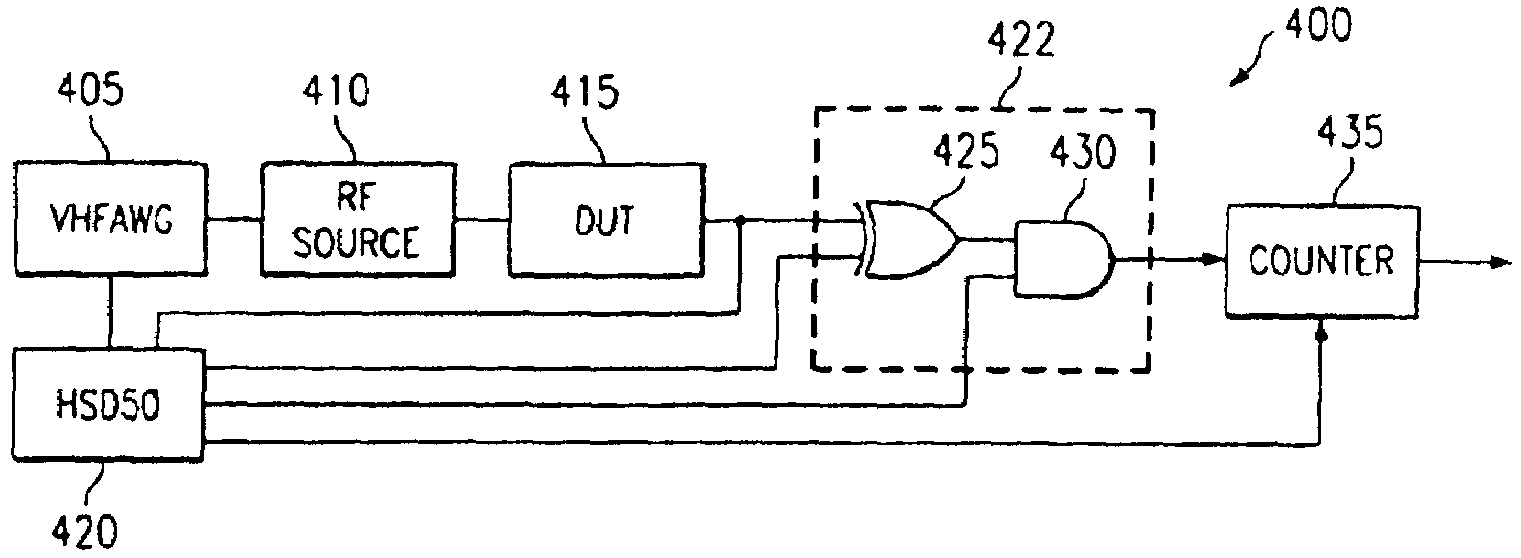

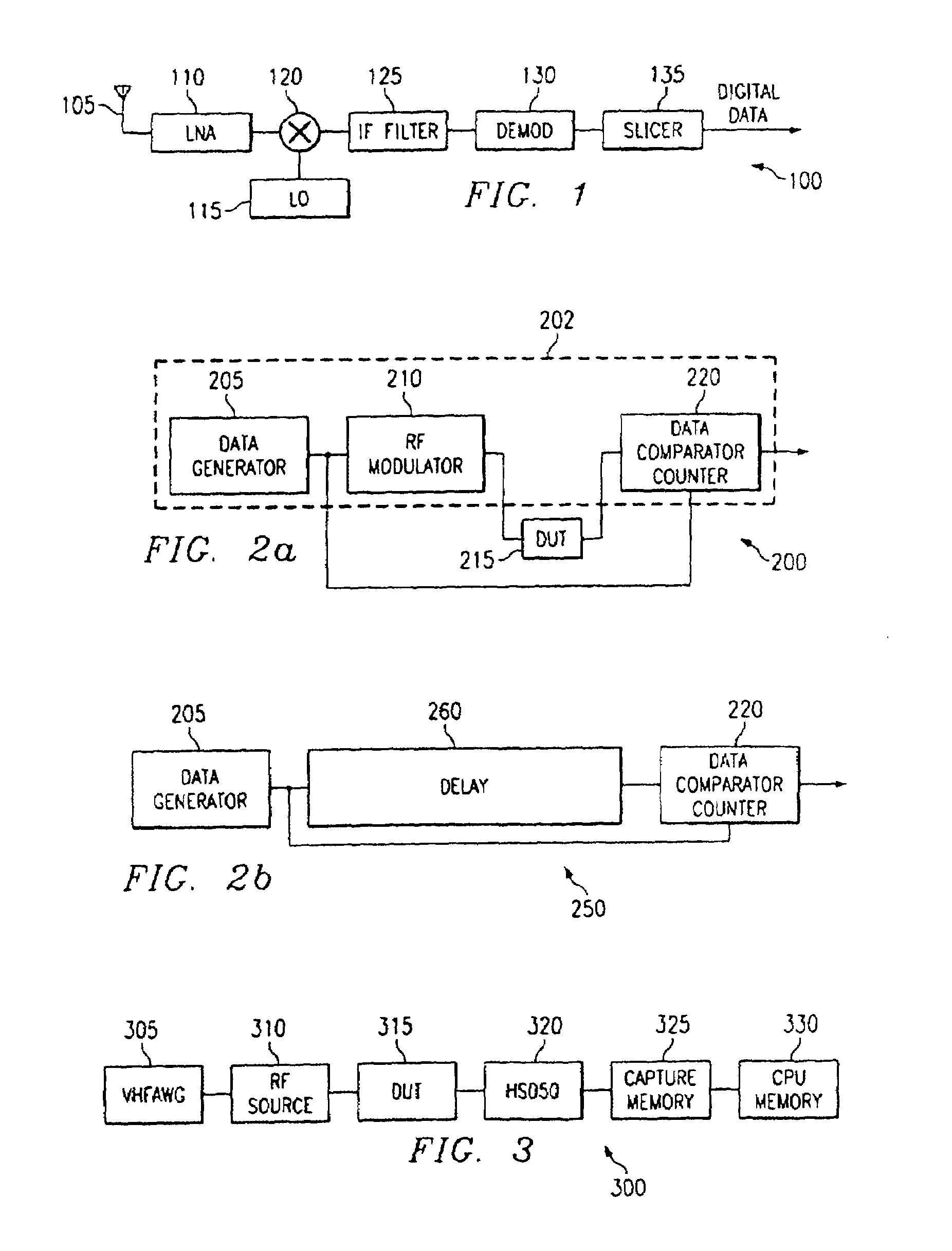

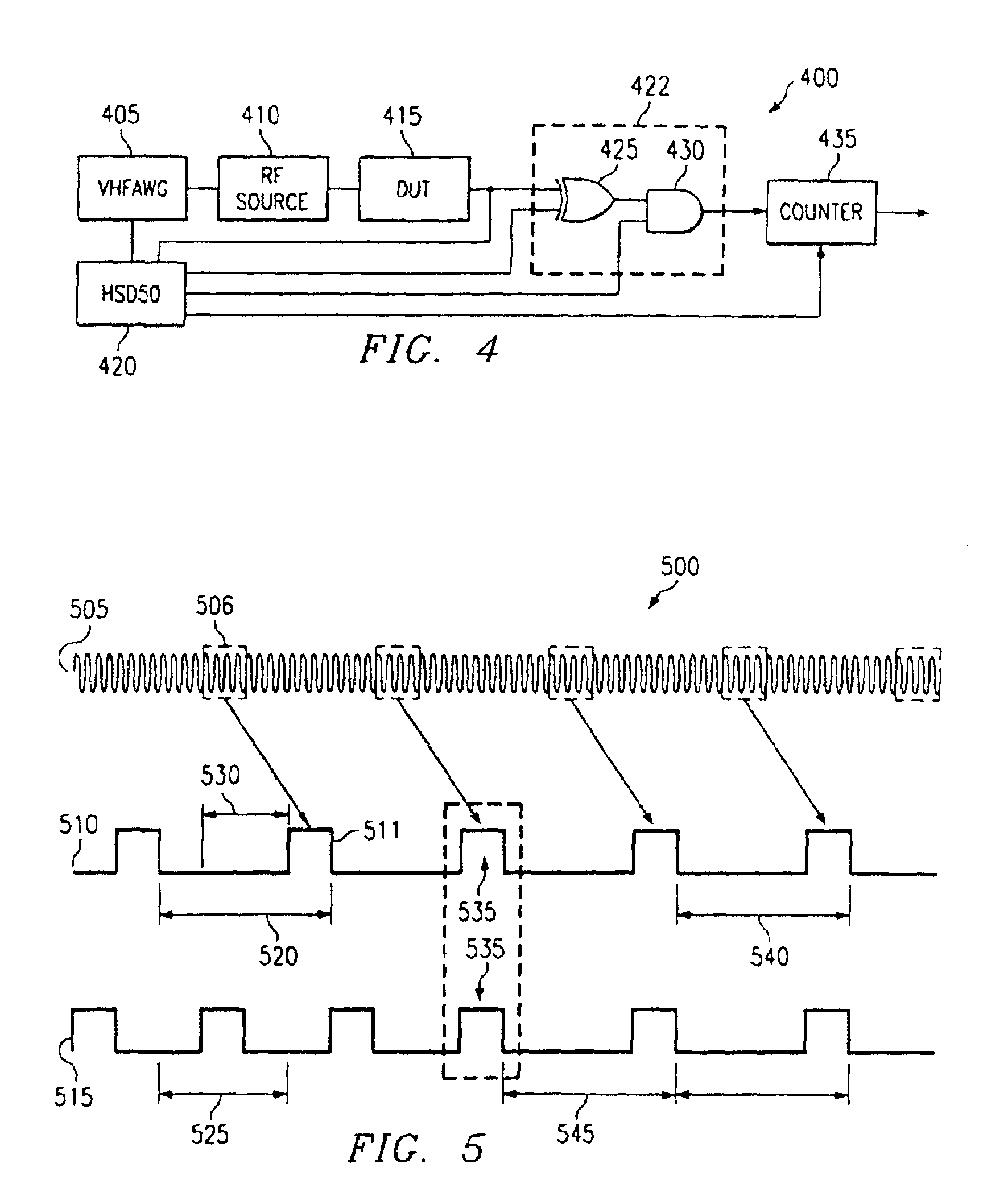

A bit-error-rate (BER) test is a crucial test for wireless devices to pass, since a device with a high BER does not perform at its best. BER tests are both costly and difficult to perform due to a delay incurred by the device under test (DUT) 215 and the testing hardware that is variable in nature. Because the delay is variable, a hardware BER test that can compensate for the delay is difficult to build and a software BER test that can easily compensate for the delay is very slow. The present invention provides a method and apparatus that can compensate for the variable delay. By doing so, a hardware BER test, which is considerably faster than a software BER test, is easily implemented.

Owner:TEXAS INSTR INC

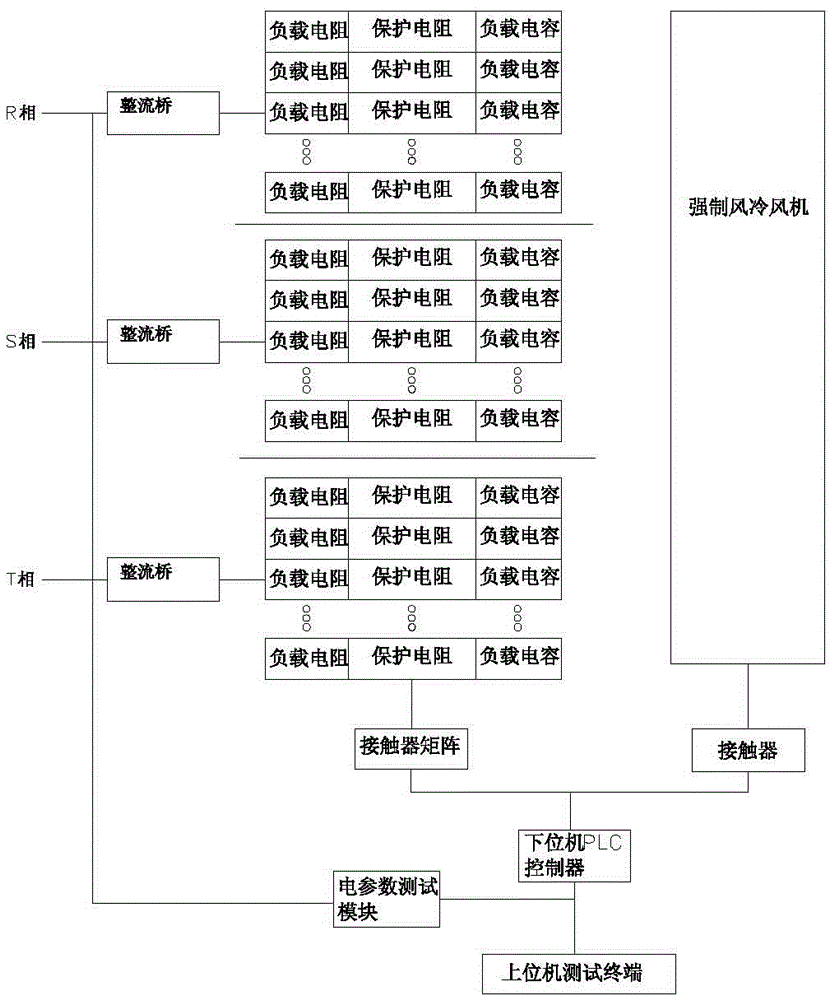

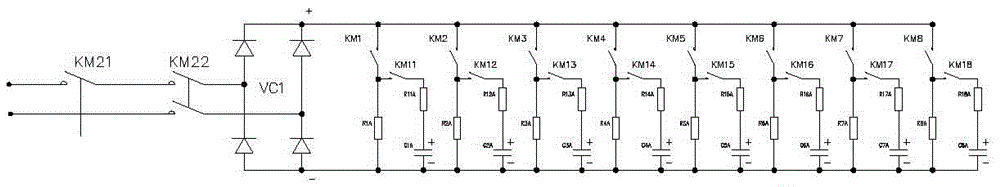

Special test load box for UPSs (uninterruptable power supplies)

The invention relates to the technical field of load test, in particular to a special test load box for UPSs (uninterruptable power supplies). The special test load box comprises three bridge rectifiers connected with R, S and T phases of a three-phase power supply respectively, wherein each bridge rectifier is connected with a power load part; each power load part comprises a resistive load part and a capacitive load part and is connected with lower computer PLC (programmable logic controller) through a contactor matrix, and the lower computer PLC is connected with a forced air cooling fan through a contactor. The special test load box for the UPSs further comprises an electrical parameter test module which is connected with the R, S and T phases of the three-phase power supply, and the electrical parameter test module and the lower computer PLC are connected with an upper computer test terminal through an RS485 communication interface. The special test load box can provide test for three UPSs independently simultaneously and can also provide test for three-phase UPSs, and provides a critical test link for ex-factory inspection.

Owner:HUNAN FUDE ELECTRICAL +1

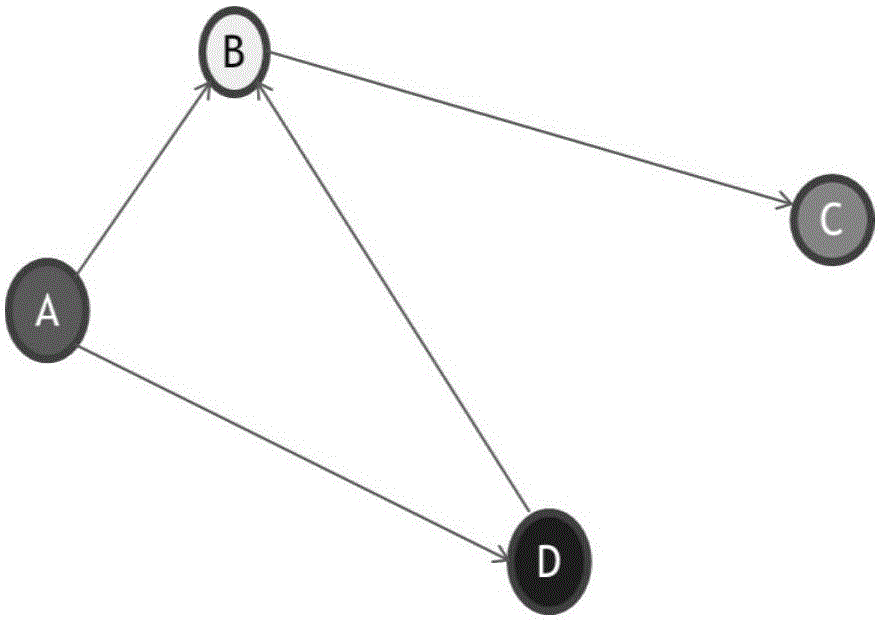

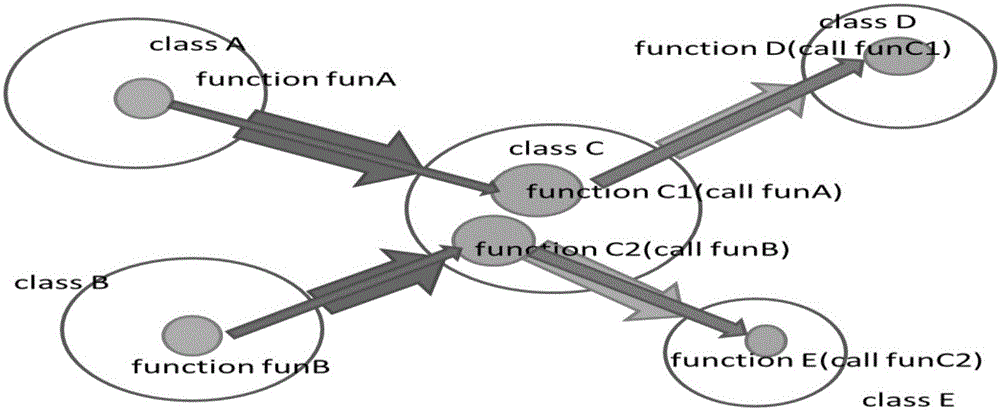

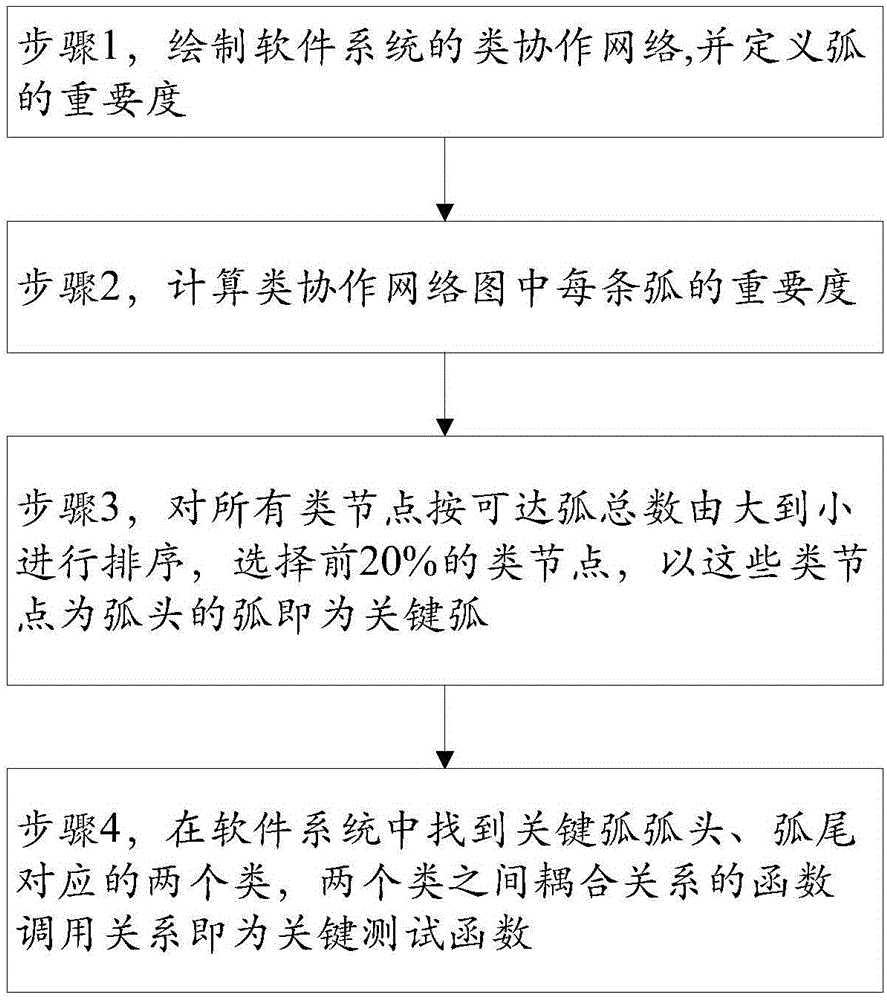

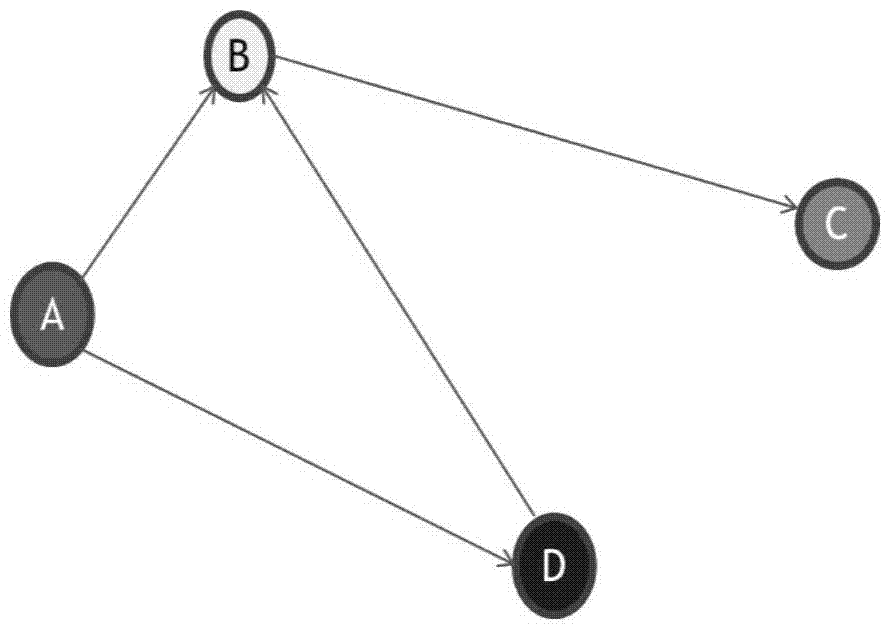

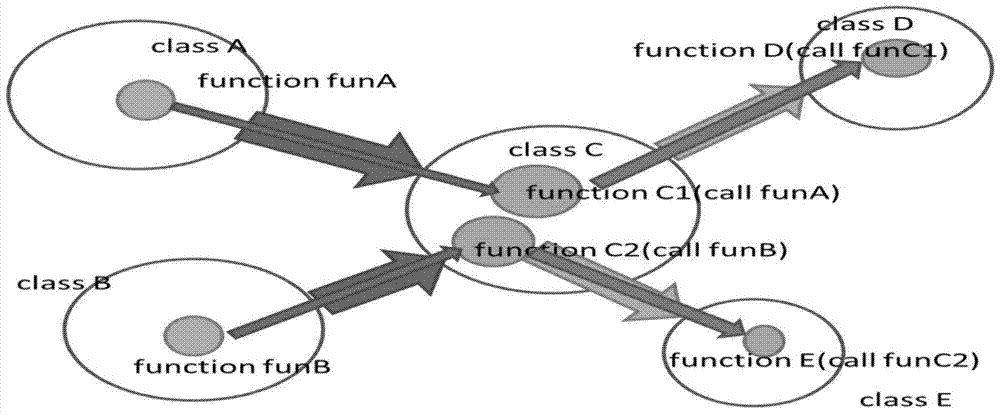

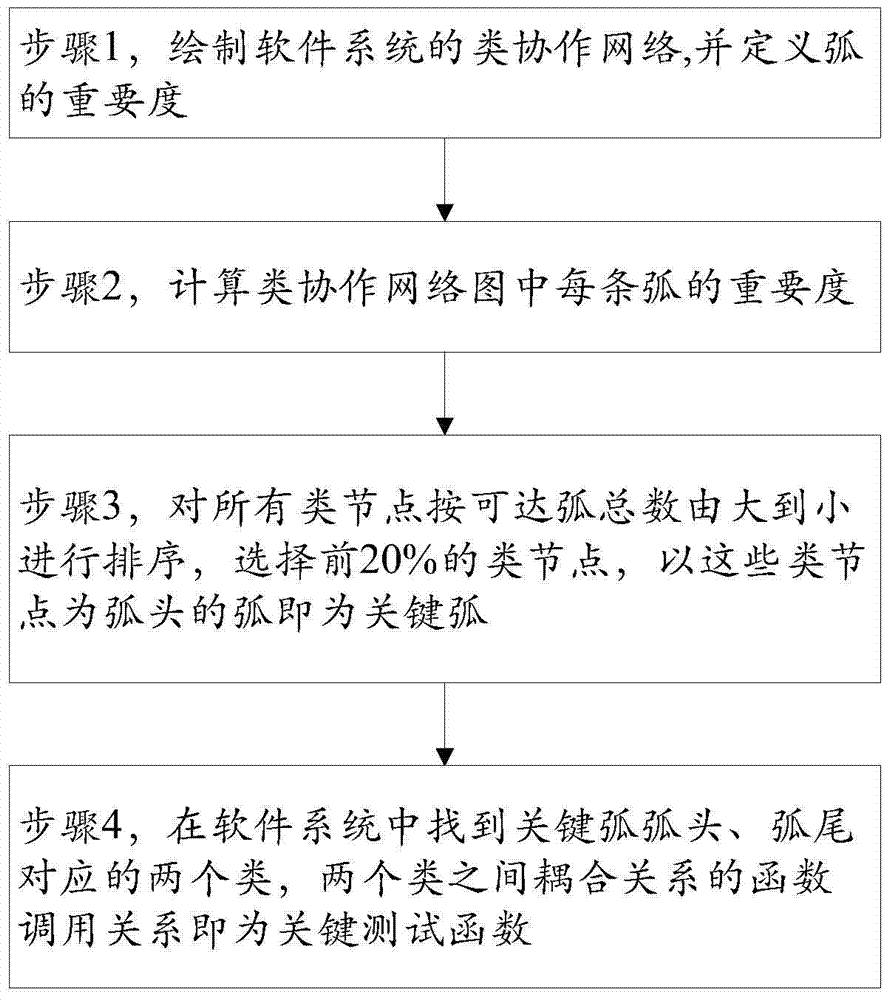

Method for discovering key test function of large object-oriented software system

ActiveCN105022689ANo increase in computational complexityQuick discoverySoftware testing/debuggingComputation complexityCoupling

The present invention discloses a method for discovering a key test function of a large object-oriented software system. By using the method, the key test function of the large object-oriented software system can be rapidly and reasonably discovered with relatively high accuracy. The method comprises: firstly, taking a class as a node and a function call between classes as an arc for drawing a class collaborative network diagram, and defining the importance degree of one arc as the quantity of arcs that are taken as initial arcs and can be traversed; then calculating the importance degree of each arc in the class collaborative network diagram, wherein the arc that takes a class node with a larger total amount of reachable arcs as an arc head is a key arc; and finally, positioning arc head and arc tail information of the key arc to two corresponding classes in the software system, wherein a function call relationship that forms a coupling relationship between the two classes is the key test function. The method overcomes two defects in an existing method, and the computing complexity is not increased along with the increase of the complexity of the software system, so that the key test function of the software system can be rapidly and effectively discovered.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

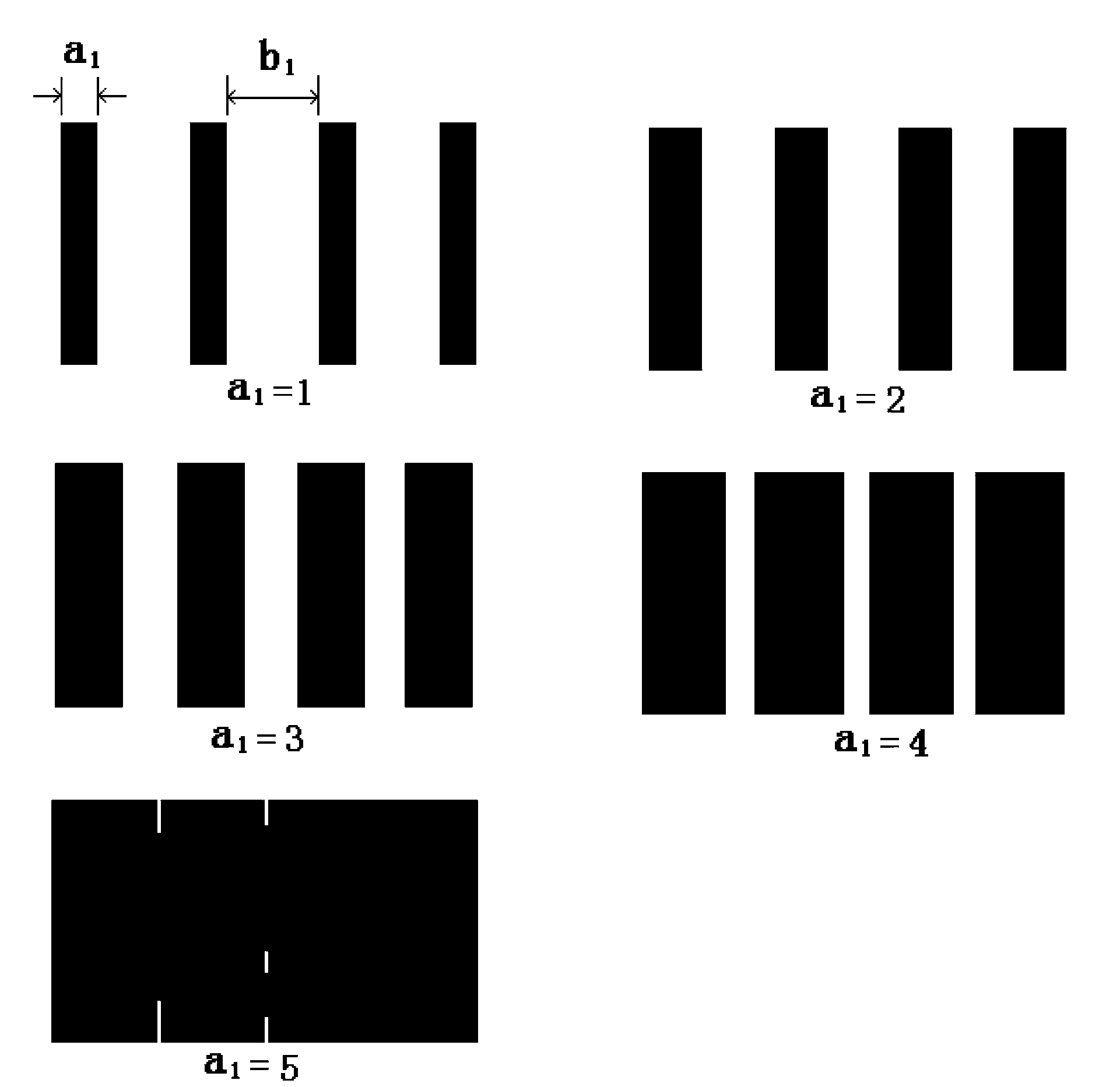

Method and system for determining one-dimensional barcode bar width compensation amount, and barcode printing method

InactiveCN103386830AReduce consumptionQuality improvementDuplicating/marking methodsTypewritersBarcodeComputer science

The invention provides a method and a system for determining one-dimensional barcode bar width compensation amount, and a barcode printing method. The invention belongs to the technical field of one-dimensional barcode. With the method and the system, a problem of excessive width during current one-dimensional barcode printing, or misidentification of the barcode, can be solved. The method for determining the one-dimensional barcode bar width compensation amount comprises the steps that: a module width and the width of a k-fold module width bar are determined; a test target of the k-fold module width bar is printed; through determining whether adjacent bars in the test target contact, a critical test target of the k-fold module width bar is found; and barcode bar width compensation amount is obtained according to the bar width of the critical test target. The one-dimensional barcode printing method provided by the invention comprises a step for determining the one-dimensional barcode bar width compensation amount with the method, and a step for printing according to the barcode bar width compensation amount. The system used for determining the one-dimensional barcode bar width compensation amount comprises a functional unit corresponding to the method. The method and the system provided by the invention can be used for printing 128-bit barcode and the like.

Owner:NEW FOUNDER HLDG DEV LLC +1

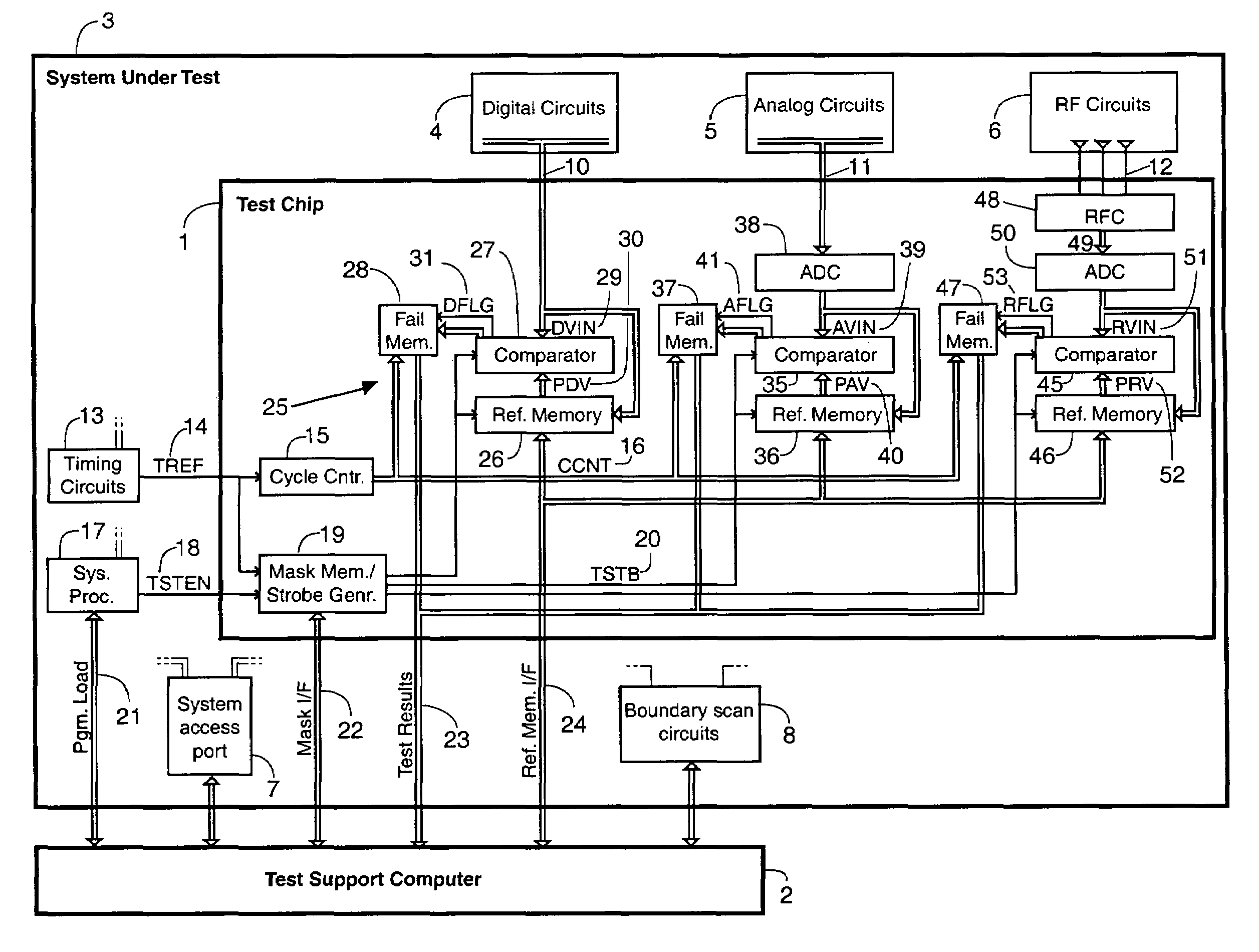

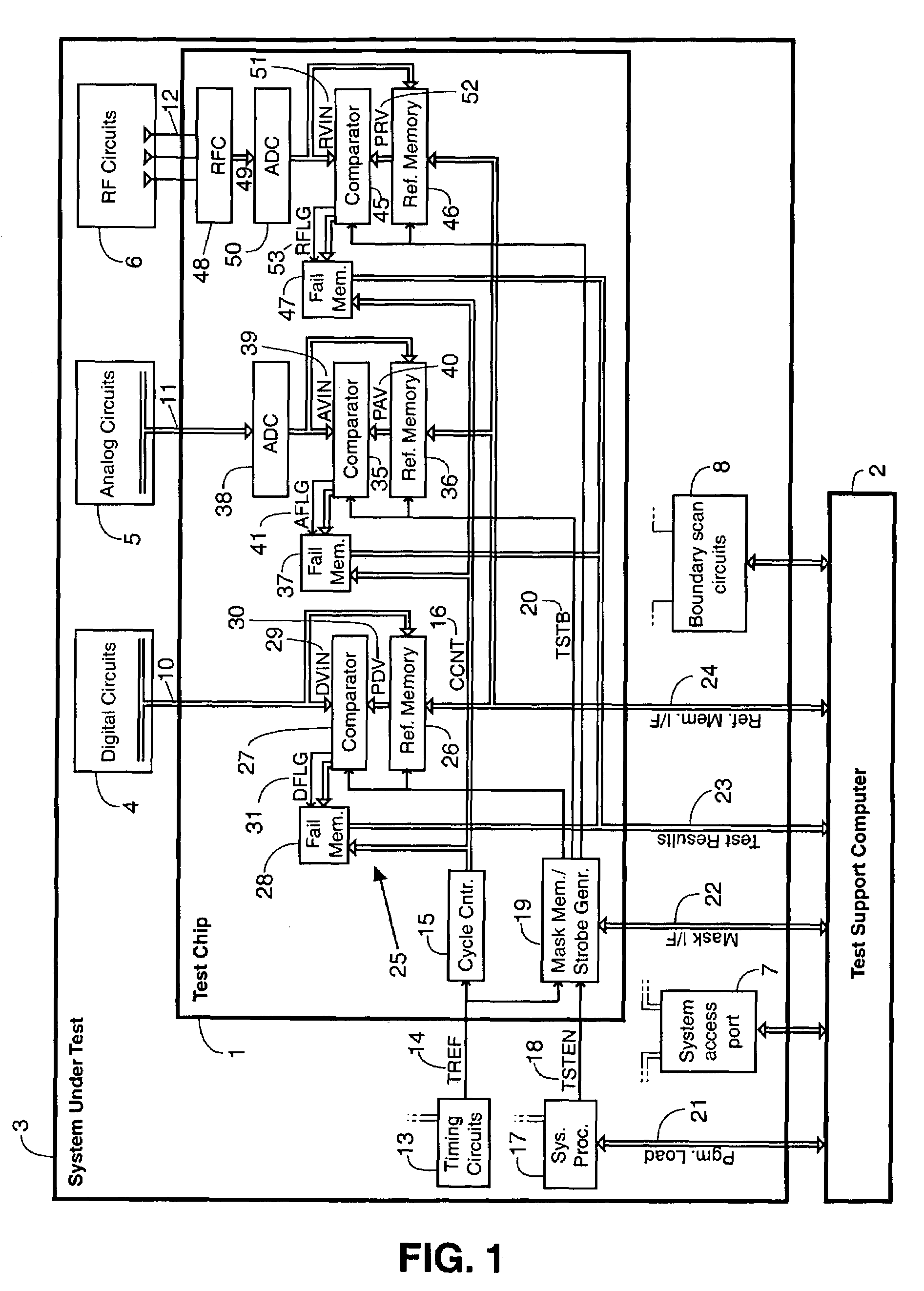

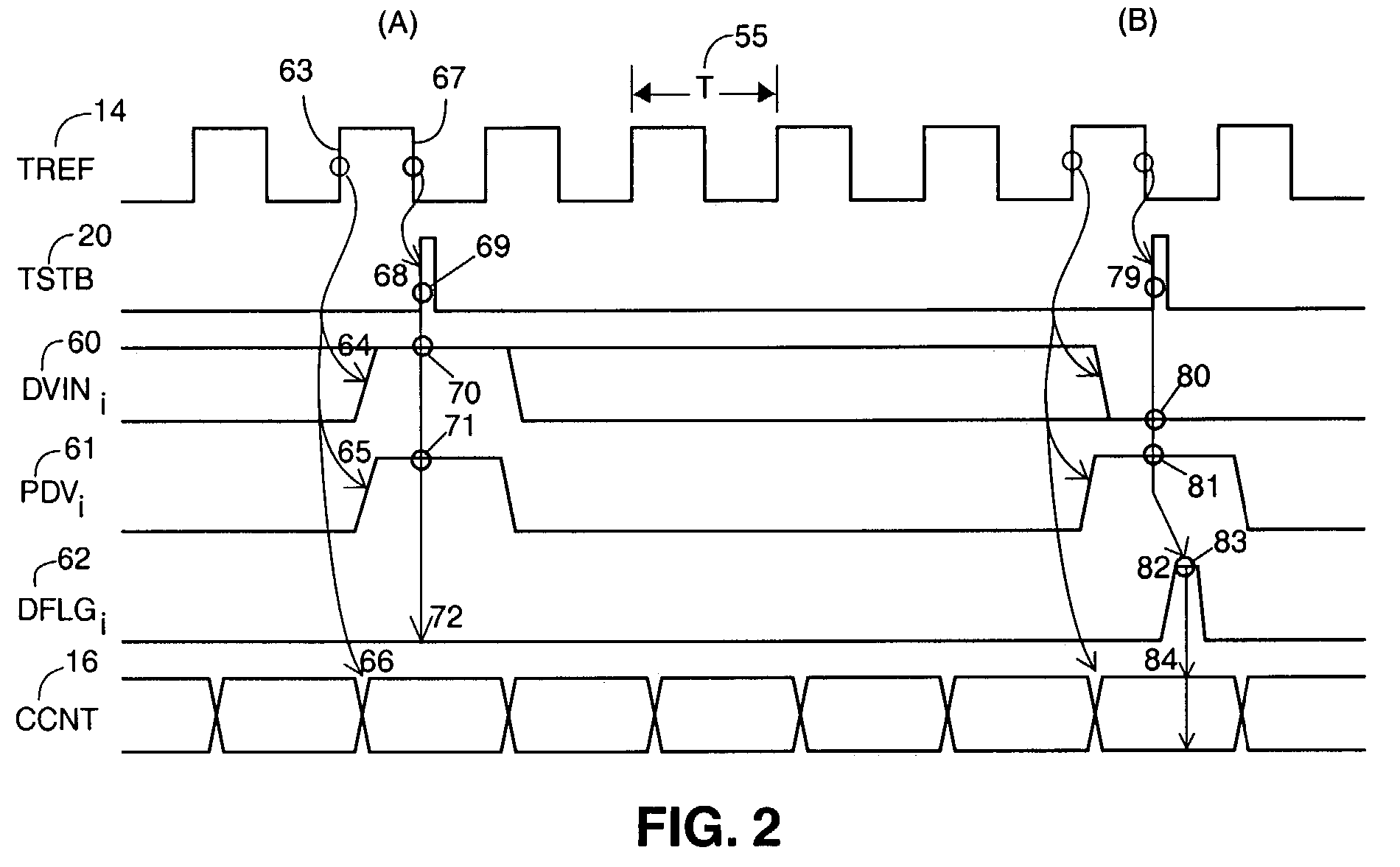

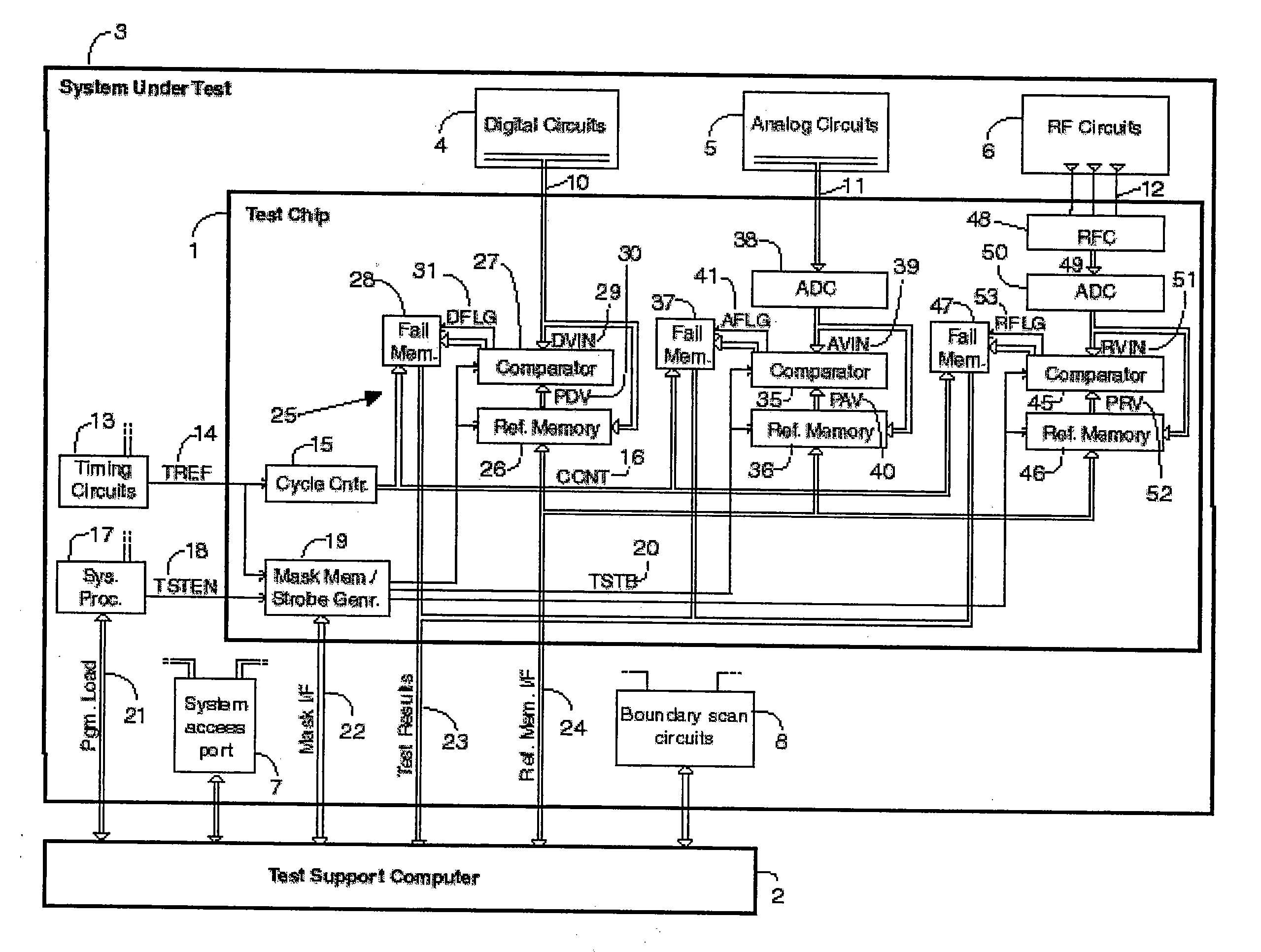

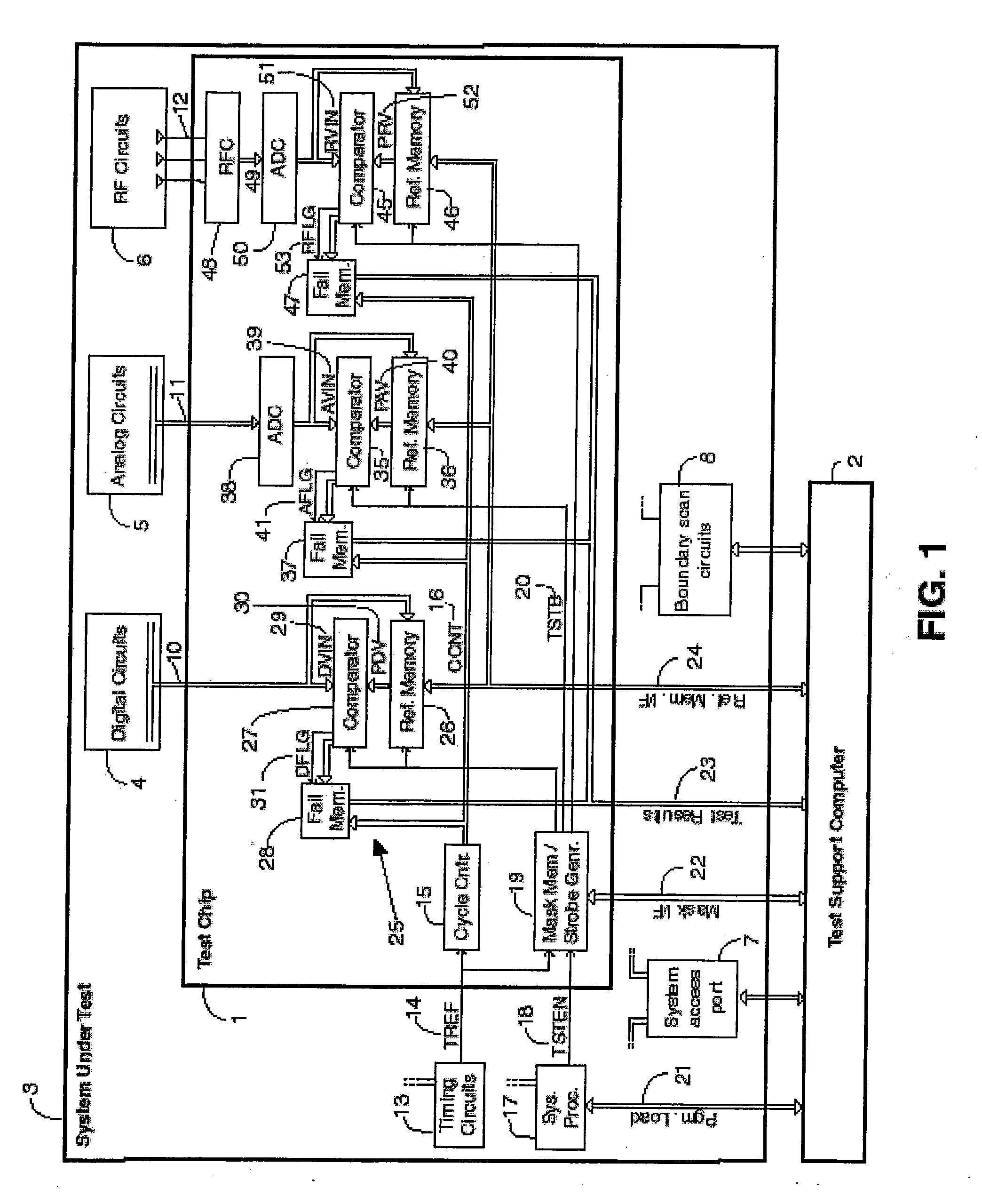

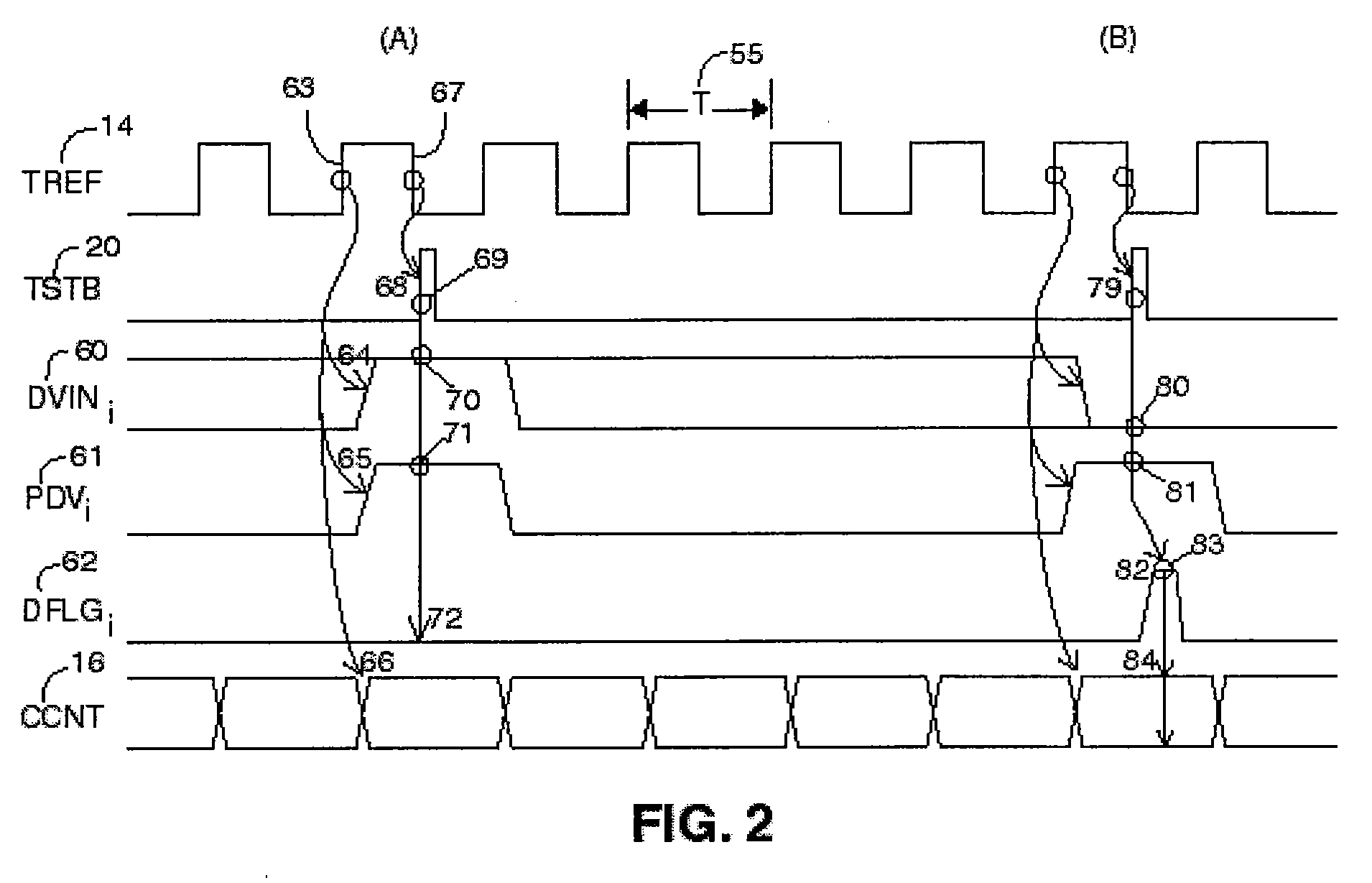

Apparatus and method for testing electronic systems

InactiveUS7505862B2Reduce the amount of memoryRedundant and unnecessary test cycleDigital circuit testingStructural/machines measurementSystem under testEngineering

The technology and economics of system testing have evolved to the point where a radical change in methodology is needed for effective functional testing of systems at clock rates of 1 GHz and higher. Rather than providing a test fixture to interface between the system under test and an external tester, it is preferable to provide critical testing functions within each electronic system in the form of one or more special-purpose test chips. An architecture is proposed that supports full-speed testing with improved noise margins, and also efficient methods for learning correct system behavior and generating the test vectors. The test program is preferably written using the same programming language as used for the system application.

Owner:SALMON TECH

Apparatus and method for testing electronic systems

InactiveUS20090192753A1Reduce the amount of memoryRedundant and unnecessary test cycleDigital circuit testingResistance/reactance/impedenceSystem under testEngineering

Owner:SALMON PETER C

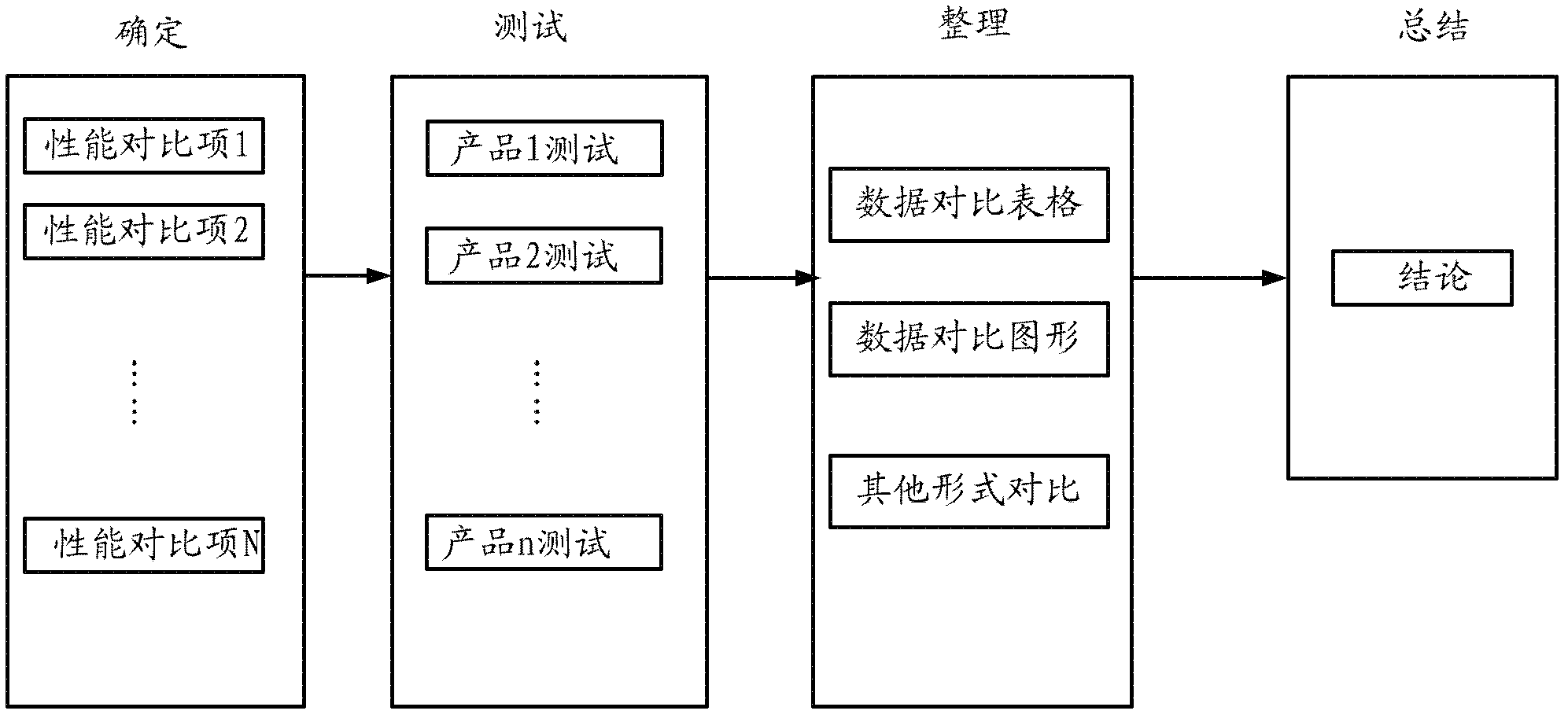

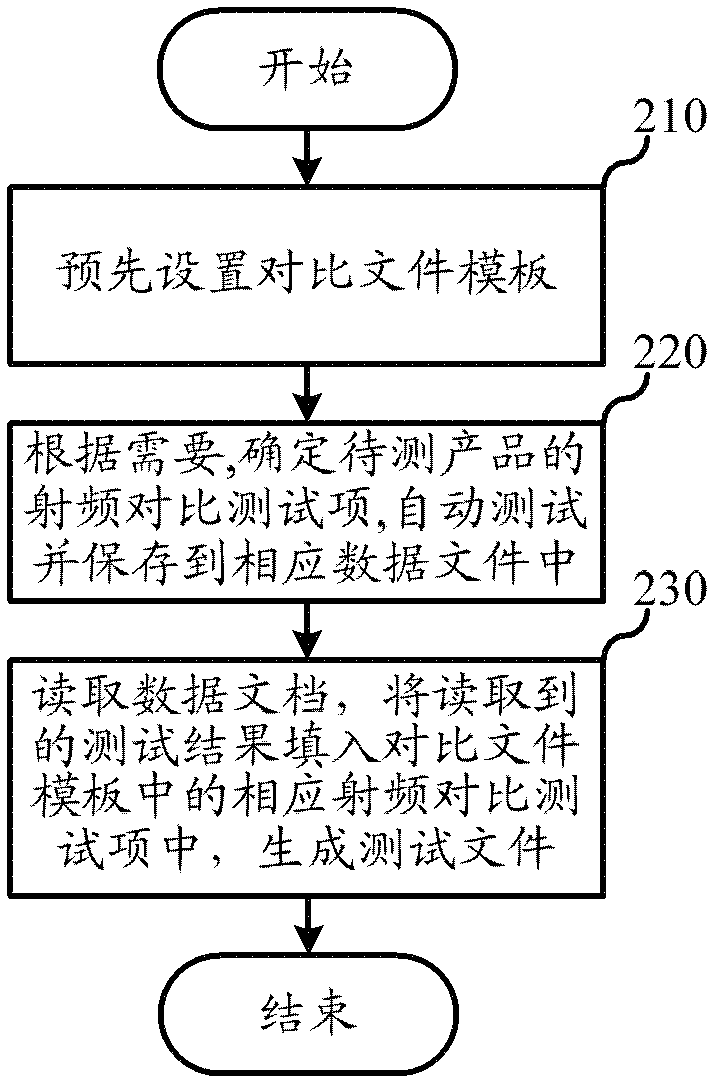

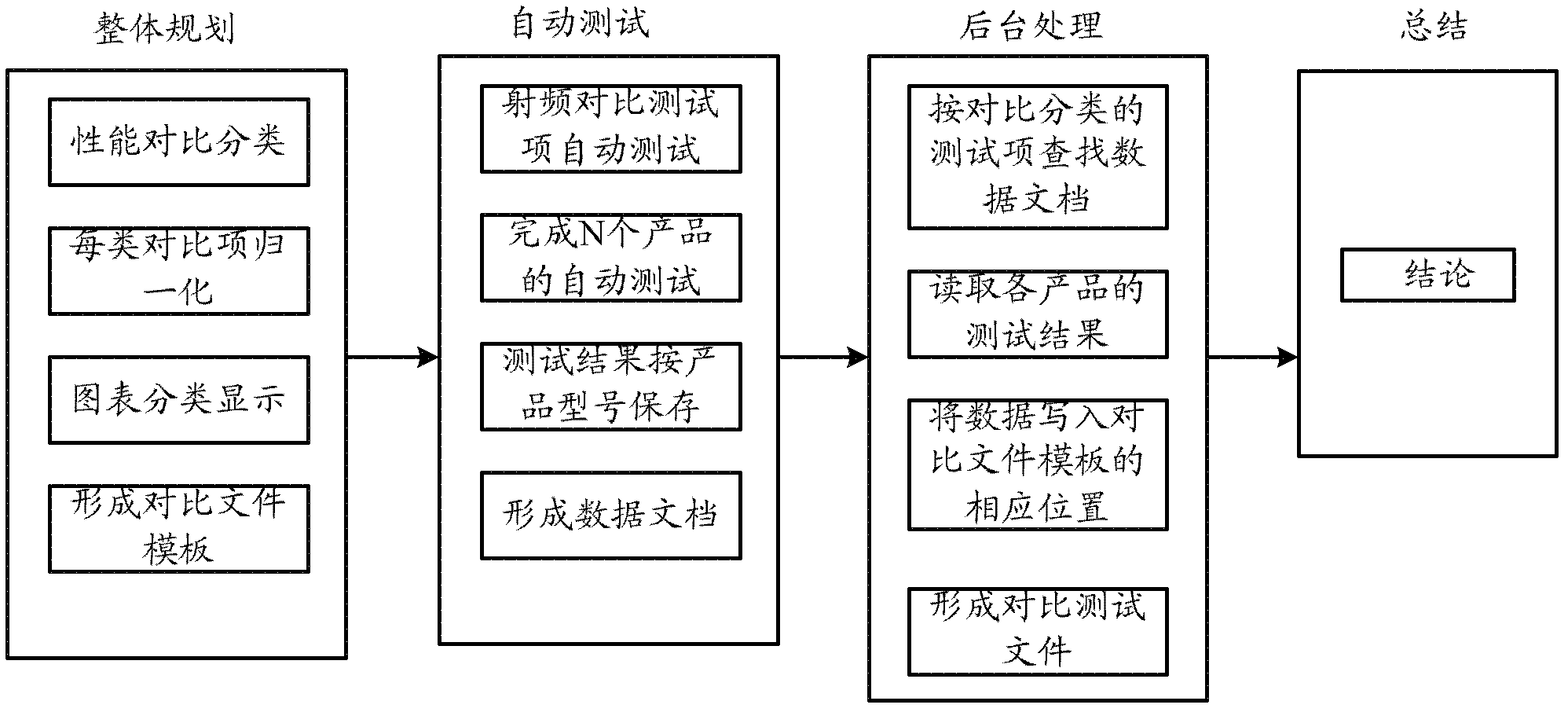

Automatic test method and device for radio-frequency performance comparison

ActiveCN102882611AEnsure consistencyImprove readabilityTransmitters monitoringReceivers monitoringTest efficiencyAutomatic test equipment

The invention relates to the communication field, and discloses an automatic test method and device for radio-frequency performance comparison. According to the invention, the method comprises the following steps of: presetting a complete comparison file template, determining comparison test items of a product according to the comparison requirement, carrying out the critical test of each comparison test item automatically, and storing the test results in the data file. A background data processing software automatically inputs the comparison data result to the comparison file template, and creates a comparison test file for the testing personnel to get the comparison conclusion. The test efficiency of the radio-frequency performance comparison and the data processing efficiency are improved, the artificial complexity is reduced, and the effect of rapid comparison is achieved.

Owner:JLQ TECH CO LTD

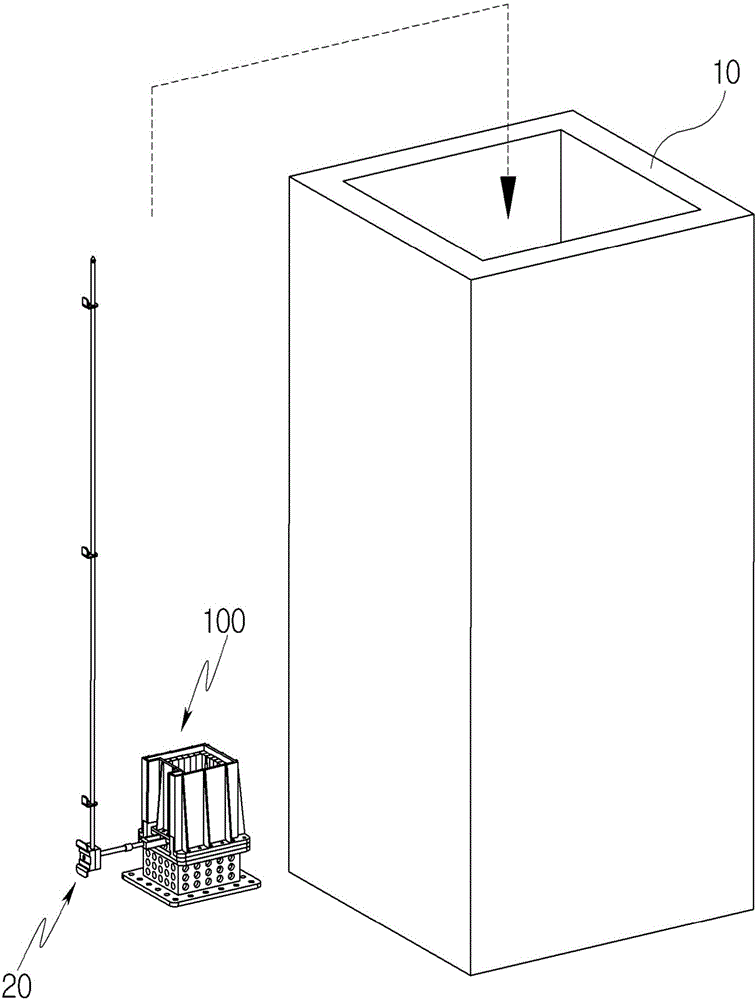

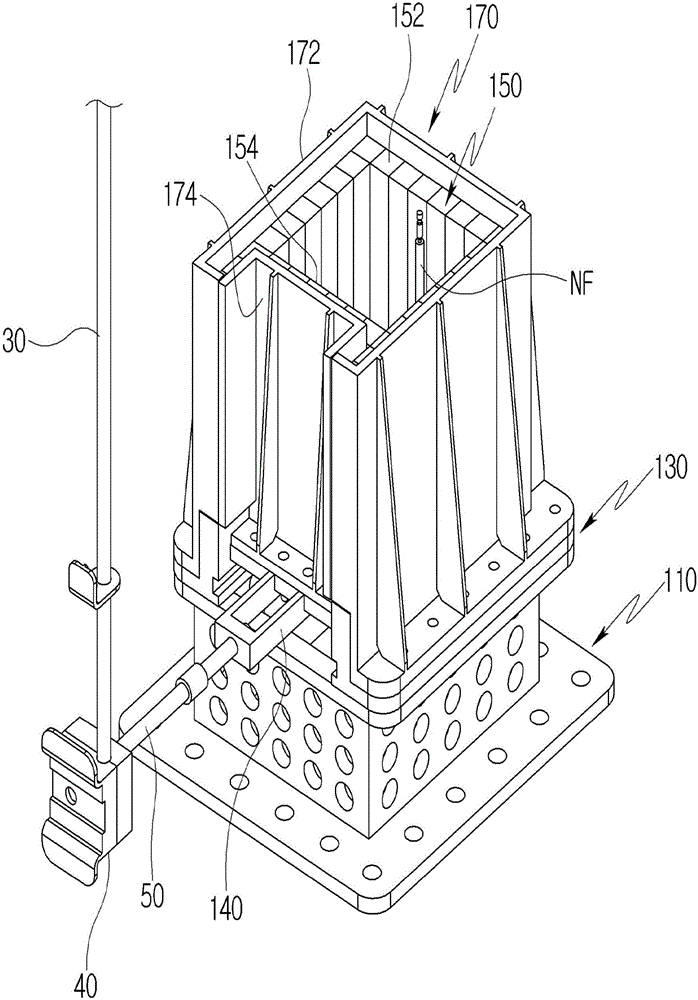

Hybrid nuclear reactor with separable core

InactiveCN106531228ASecuring Space for Critical ExperimentsReduced number of unit gridsNuclear energy generationFuel element assembliesNuclear reactorOperation mode

The present invention provides a core separation type hybrid reactor capable of realizing the same output operation as a conventional reactor with a single reactor or as a critical facility. When used as a critical facility, a grid of the reactor constituent material is loaded in a space for a portion of the separation core that is laterally moved to form a critical test space therebetween, thereby performing a grid characteristic experiment. The reactor includes a core separation type mixed reactor 100 provided inside the concrete water tank 10, and a mode switching driving section 20 for adjusting the operation mode of the hybrid reactor 100, and the core separation type mixed reactor 100, comprising: a lattice structure 130 of a separate structure disposed on a bottom surface portion of the concrete water tank 10; a reflector structure 150 of a separate type structure disposed at an edge portion of the grid structure 130; and a type partition wall structure 170 in which the reflector structure 150 is surrounded by an upper portion of the grid structure 130.

Owner:KOREA ATOMIC ENERGY RES INST

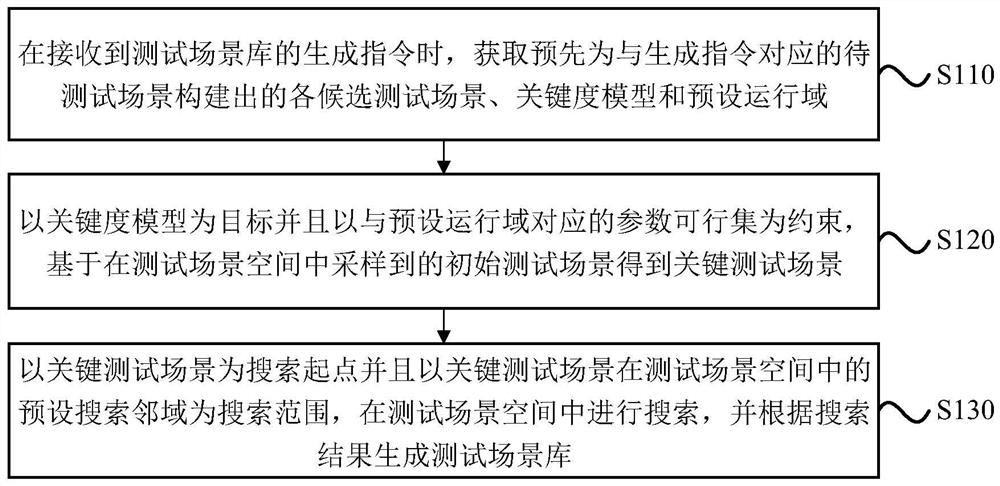

Test scene library generation method and device, equipment and storage medium

PendingCN113849400AGenerate efficientlyGuaranteed accuracySoftware testing/debuggingSimulationTest scene

The embodiment of the invention discloses a test scene library generation method and device, equipment and a storage medium. The method comprises the steps: when a generation instruction of a test scene library is received, obtaining candidate test scenes, a criticality model and a preset operation domain which are constructed for a to-be-tested scene corresponding to the generation instruction in advance; taking the criticality model as a target and taking a parameter feasible set corresponding to a preset operation domain as a constraint, and obtaining a key test scene based on an initial test scene obtained by sampling in a test scene space, wherein the test scene space comprising the candidate test scenes; and searching in the test scene space by taking the key test scene as a search starting point and taking a preset search neighborhood of the key test scene in the test scene space as a search range, and generating a test scene library according to a search result. According to the technical scheme provided by the embodiment of the invention, the test scene library with relatively high accuracy can be efficiently generated.

Owner:JINGDONG KUNPENG (JIANGSU) TECH CO LTD

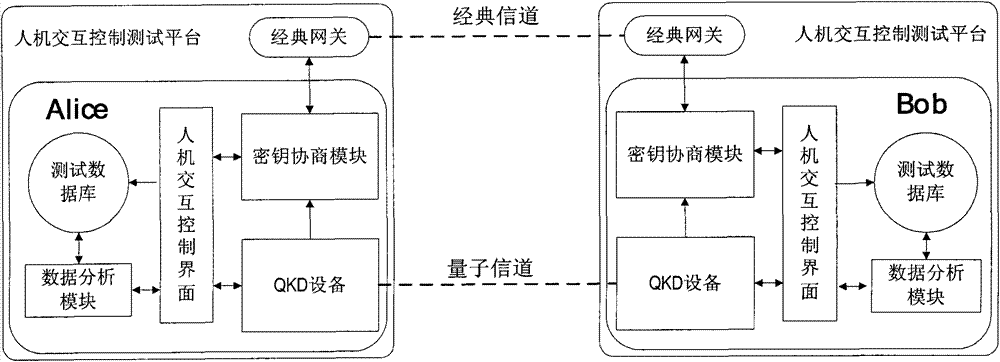

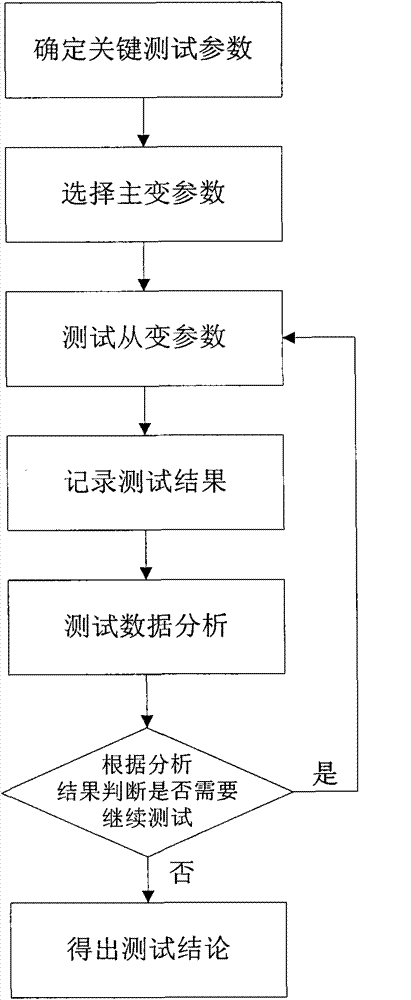

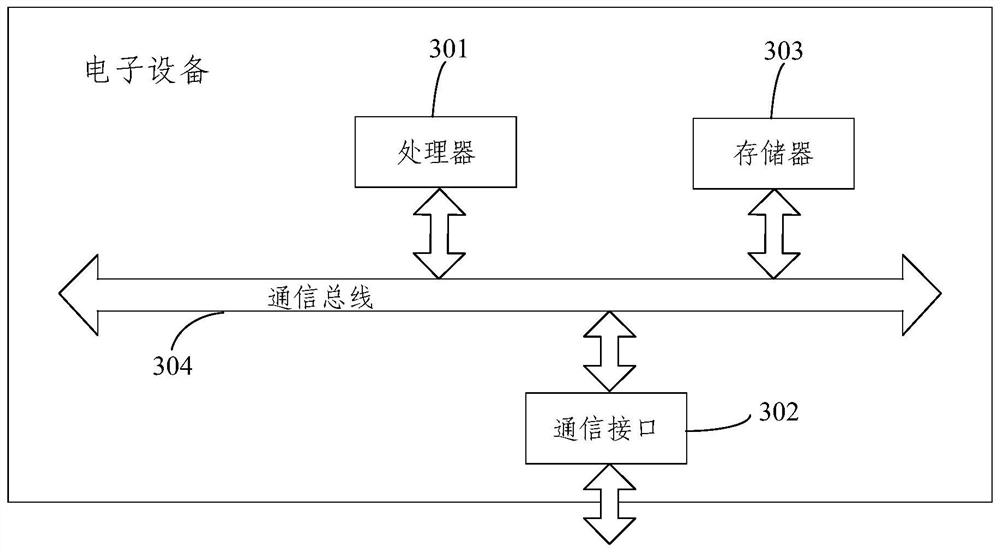

Method for testing key devices in quantum key distribution system

ActiveCN104516816AReduce complexityEliminate blindnessKey distribution for secure communicationSoftware testing/debuggingTest efficiencyComputer hardware

The invention belongs to the quantum secret communication technical field and provides a method for testing key devices in a quantum key distribution system. The method comprises the following steps of step 1, determining the key devices in the quantum key distribution system which needs to be tested and key test parameters of every key device; step 2, selecting main change parameters of the key test parameters and enabling other parameters to serve as from change parameters; step 3, setting a value of every main change parameter through a man-machine control interface and testing the from change parameters; step 4, writing test data into a database; step 5, performing analysis on the test data in the database and display an analysis result; step 6, judging the analysis result and returning to the step 3 to continue to test if necessary; step 7, performing statistical analysis on the test data in the database and obtaining a test conclusion. According to the method for testing the key devices in the quantum key distribution system, the key test parameters are controlled based on the result of the analysis on the test data and accordingly the blindness in a test is eliminated to a certain extent, the test efficiency is improved, and the test cost is reduced.

Owner:QUANTUMCTEK

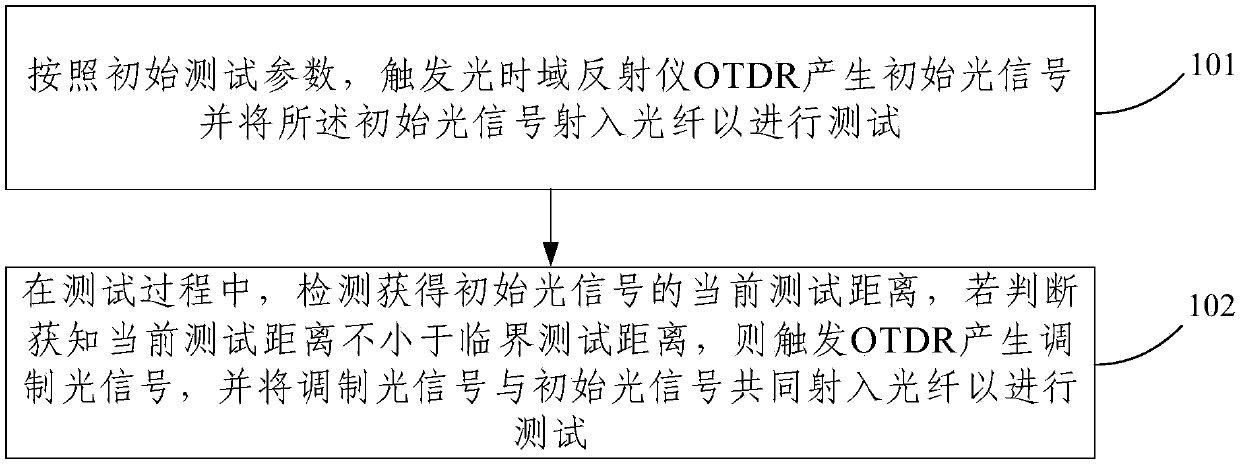

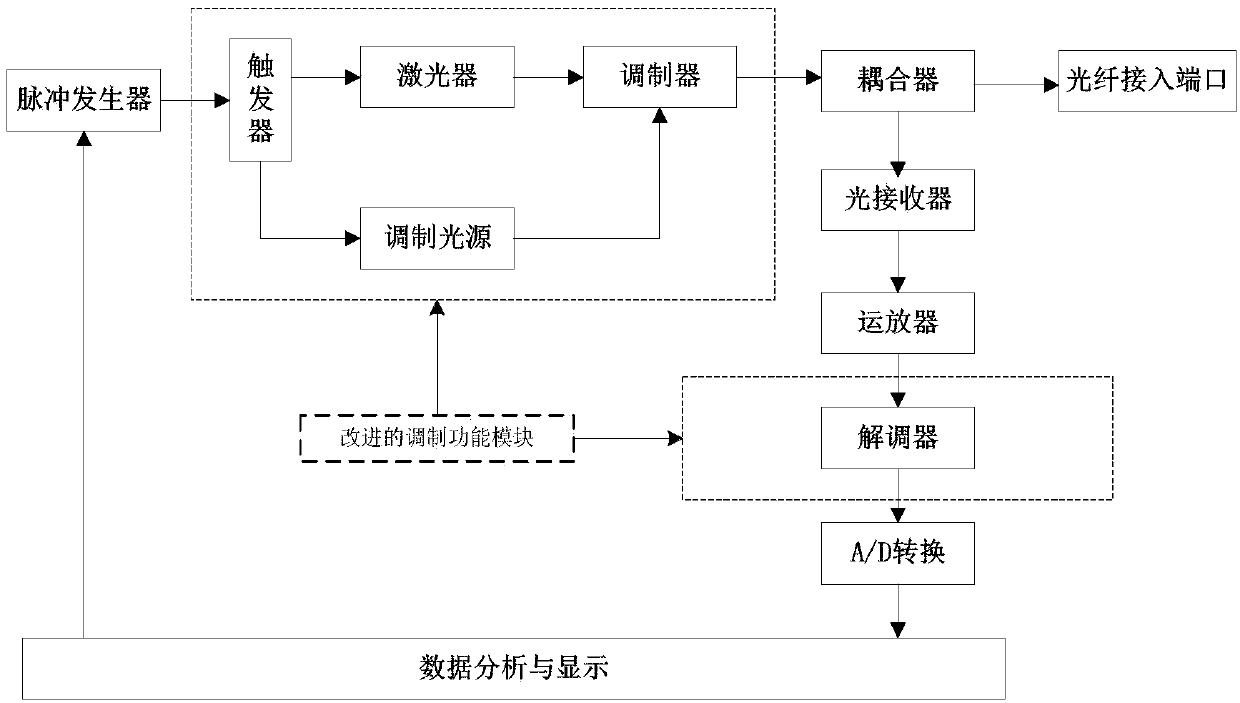

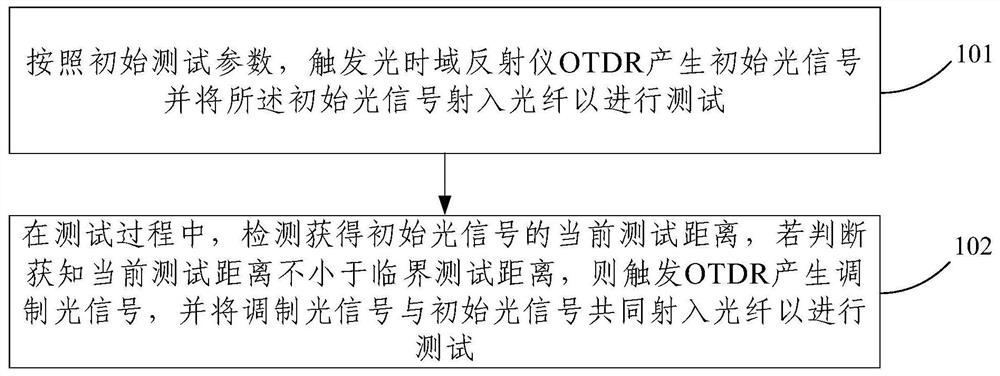

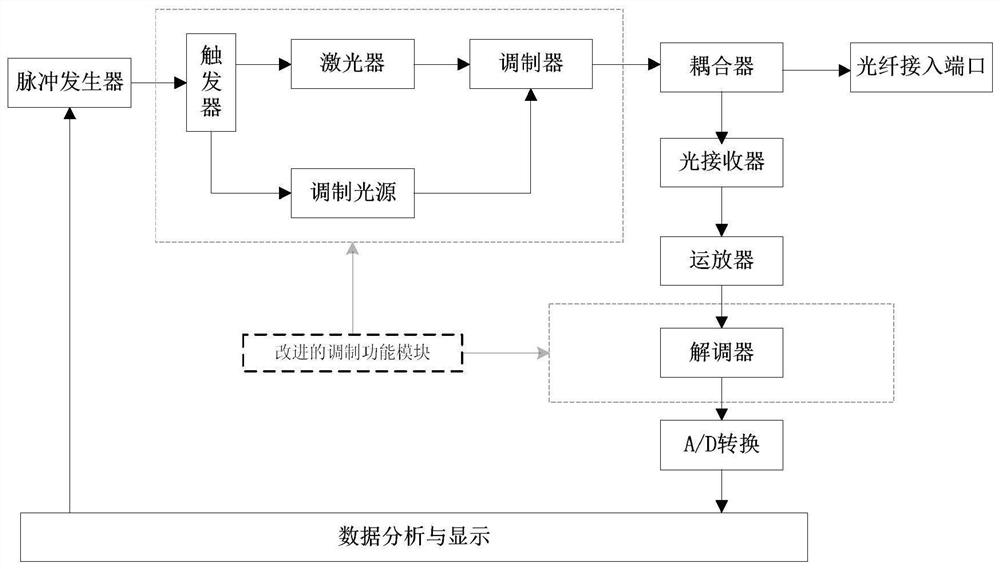

Optical time domain reflectometer test method and optical time domain reflectometer

ActiveCN111162834ALarge measuring rangeIncrease optical powerElectromagnetic transmissionTime-domain reflectometerTime domain

The embodiment of the invention provides an optical time domain reflectometer test method and an optical time domain reflectometer. The method comprises the steps of triggering an optical time domainreflectometer OTDR to generate an initial optical signal according to an initial test parameter, and enabling the initial optical signal to be transmitted into an optical fiber for testing; obtainingthe current test distance of the initial optical signal through detection in the testing process, if it is judged that the current test distance is not less than a critical test distance, triggering the OTDR to generate a modulated optical signal, and jointly emitting the modulated optical signal and the initial optical signal into the optical fiber for testing. According to the embodiment of theinvention, the optical power of the test input end is improved by triggering the OTDR to generate the modulated optical signal when the current test distance is not less than the critical test distance, so that the measurement range of the OTDR can be expanded, and the problems that the measurement range of the OTDR is fixed and the measurement track is submerged by noise are solved.

Owner:CHINA MOBILE GRP HENAN CO LTD

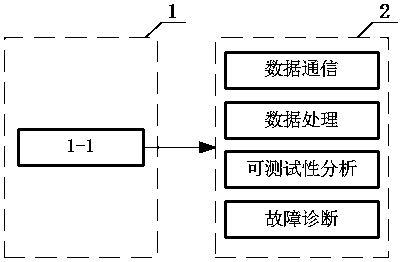

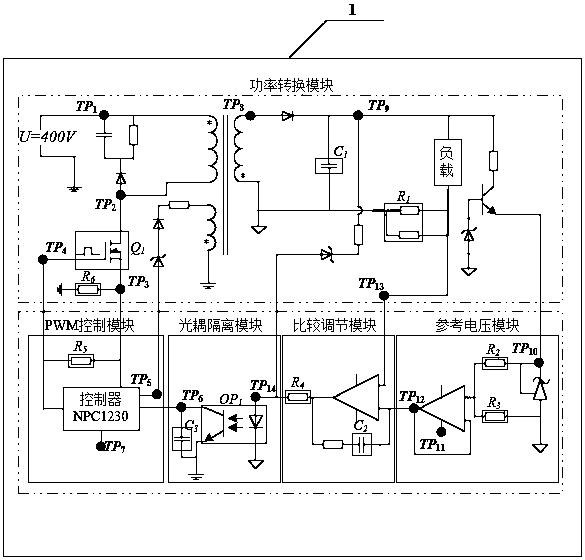

Fyback power supply with testability analysis and fault diagnosis functions and test method thereof

InactiveCN108375742AMonitor voltage signal changesHigh transplantabilityPower supply testingTestability analysisEngineering

The invention discloses a flyback power supply with the testability analysis and fault diagnosis functions and a test method thereof. The flyback power supply is composed of a flyback power supply module and an upper computer system. A plurality of key testing nodes are arranged in the flyback power supply module; and the upper computer system is connected with the flyback power supply module. According to the invention, on the basis of not changing the original topology of the flyback power supply, the power supply is divided into a plurality of modules based on functions and key testing nodes of all modules are taken and are led out; and the upper computer is used for real-time monitoring, extracting a fault feature parameter, and constructing a fault-testing correlation matrix, so thatthe testability analysis of the flyback power supply as well as the fault diagnosis of the flyback power supply is realized. The flyback power supply having high portability is suitable for state monitoring and testability analysis of most of switch power supplies and is capable of providing a platform for state monitoring and testability analysis of other power supplies.

Owner:HARBIN INST OF TECH

Chemical process for passivation of primary loop system during pre-critical test of nuclear power plant

InactiveCN110306177AReduced dose rateLong-term stable and reliable operationMetallic material coating processesDose rateNuclear power

The invention relates to a chemical process for passivation of a primary loop system during a pre-critical test of a nuclear power plant. The chemical process comprises the following steps that duringthe pre-critical test performed after initial loading of nuclear fuel in a core of a nuclear reactor, Zn2+ is added to a coolant so that the Zn2+ contacts the metal surface in the primary loop systemduring the pre-critical test to form an initial zinc-containing oxide film. According to the chemical process, the zinc is added to the coolant during the pre-critical test of a new nuclear power unit, so that the zinc contacts with the metal surface in the primary loop system during the pre-critical test, and the initial zinc-containing oxide film is formed on the metal surface; the reliabilityof the passive film is improved through implementation of zinc-injecting passivation of the new nuclear power unit, good protection is provided for a primary loop metal component during the running life time of nuclear power, long-term stable and reliable operation of the nuclear power unit is ensured, the total amount of corrosion products which can deposit on the fuel and become activated duringnormal power operation is also significantly reduced, and accordingly the fuel performance is improved and the plant dose rate is reduced as much as possible.

Owner:中广核工程有限公司 +2

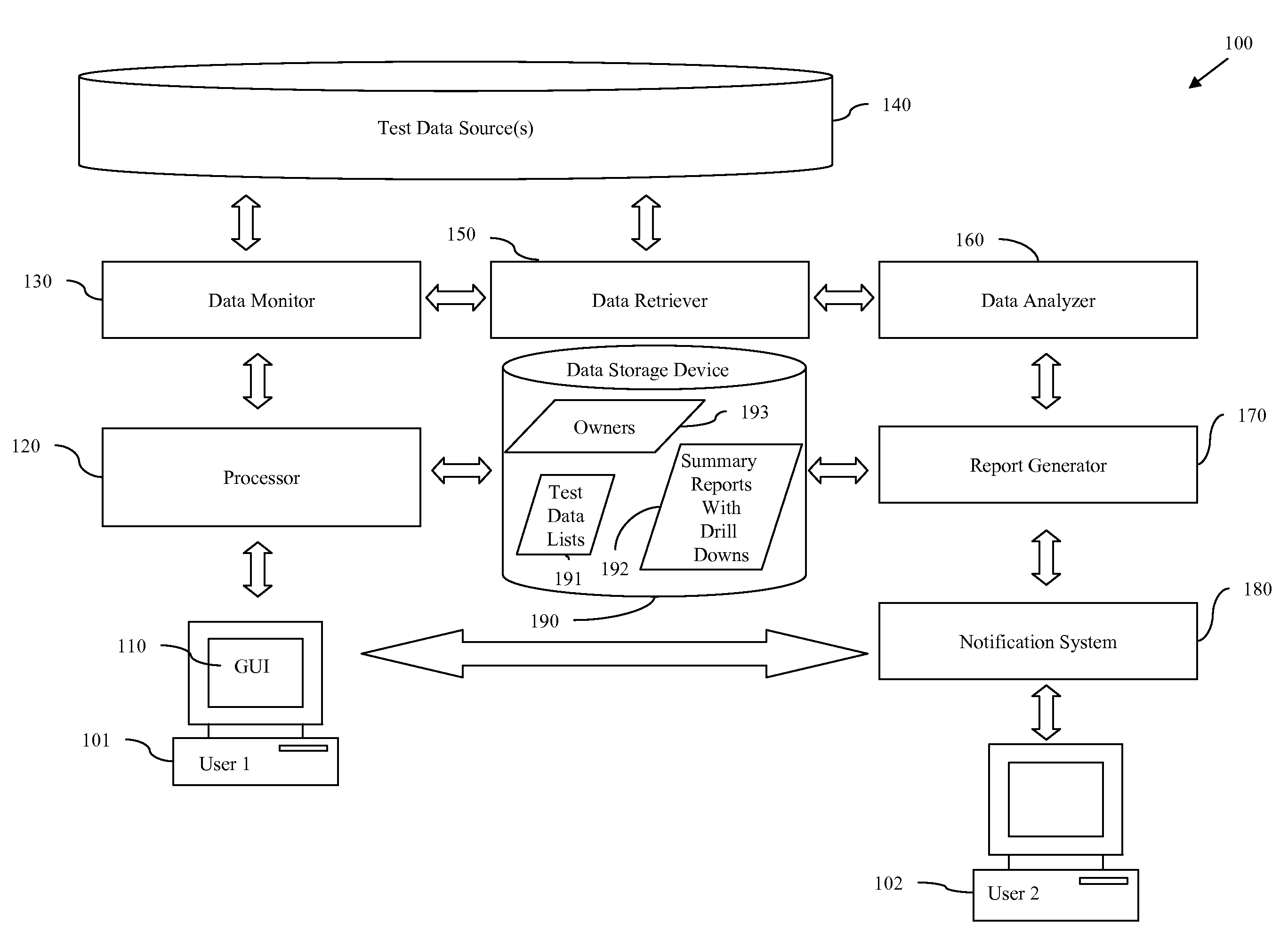

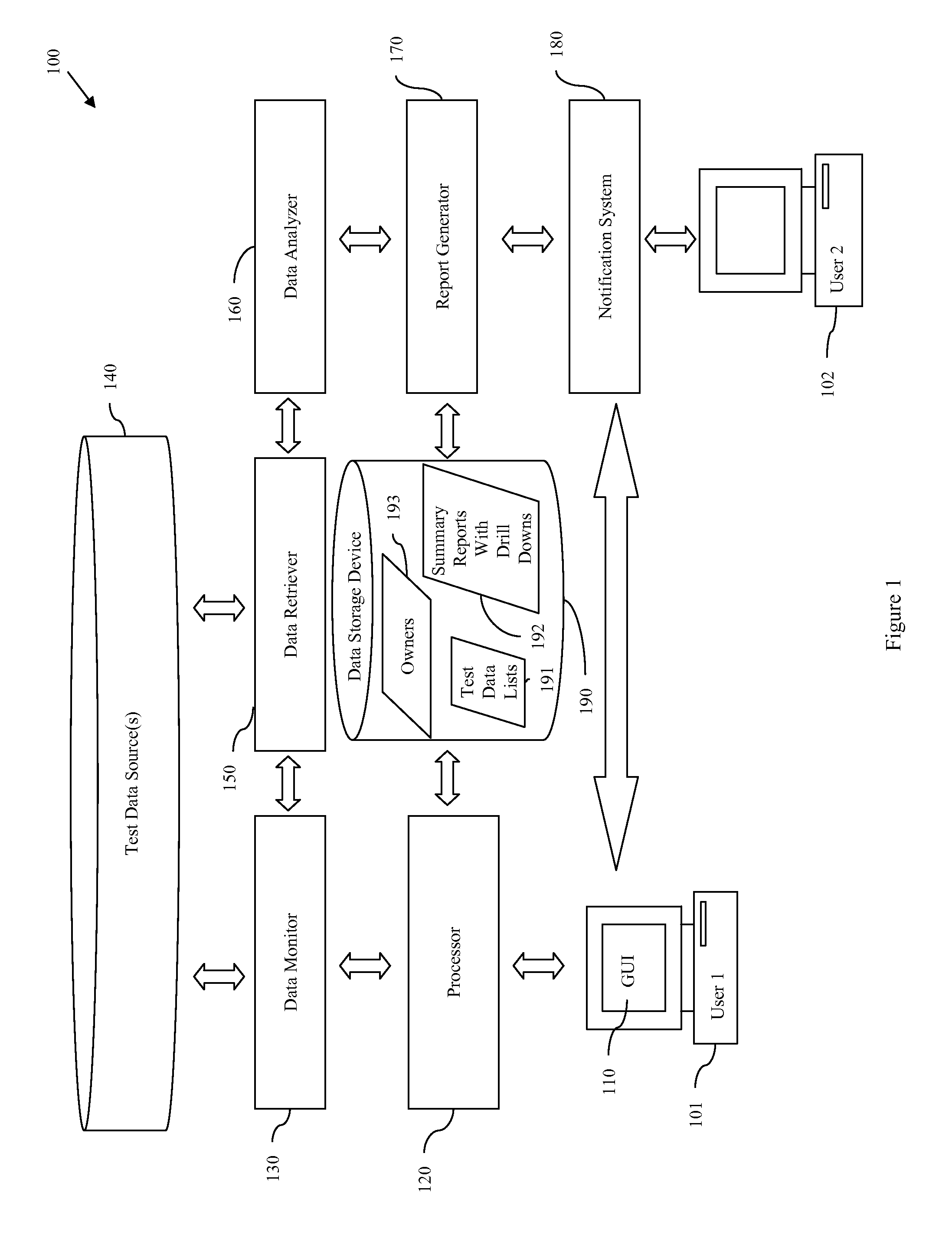

Automated yield split lot (EWR) and process change notification (PCN) analysis system

InactiveUS20090125829A1Delayed yield learningReduce manufacturing productivityProgramme controlSemiconductor/solid-state device testing/measurementProcess moduleData analysis system

Disclosed are an automated data analysis system and method. They system provides a standardized data analysis request form that allows a user to select an experiment (e.g., a wafer-level based yield split lot (EWR) analysis, a lot-level based process change notification (PCN) analysis, and lot-level based tool / mask qualification analysis) and a data analysis for a specific process module of interest. For each specific data analysis request, the system identifies critical test parameters, which are grouped depending on in-line test levels and photolithography levels. The system links the analysis request to test data sources and automatically monitors the test data sources, searching for the critical test parameters. When the critical test parameters become available, the system automatically performs the requested analysis, generates a report of the analysis and publishes the report with optional drill downs to more detailed results. The system further provides automatic e-mail notification of the published report.

Owner:IBM CORP

Optical time domain reflectometer test method and optical time domain reflectometer

ActiveCN111162834BLarge measuring rangeIncrease optical powerElectromagnetic transmissionTime-domain reflectometerTime domain

An embodiment of the present invention provides an optical time domain reflectometer test method and an optical time domain reflectometer. The method includes: triggering an optical time domain reflectometer OTDR to generate an initial optical signal according to initial test parameters, and injecting the initial optical signal into an optical fiber During the test, the current test distance obtained by detecting the initial optical signal is detected, and if it is judged that the current test distance is not less than the critical test distance, the OTDR is triggered to generate a modulated optical signal, and the modulated optical signal and the initial optical signal are emitted together. into the fiber for testing. The embodiments of the present invention increase the optical power of the test input end by triggering the OTDR to generate a modulated optical signal when the current test distance is not less than the critical test distance, so the measurement range of the OTDR can be expanded, thereby solving the problem of the fixed measurement range of the OTDR and the noise of the measurement track flooding problem.

Owner:CHINA MOBILE GRP HENAN CO LTD

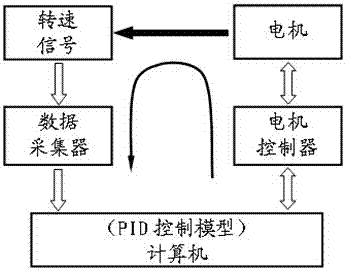

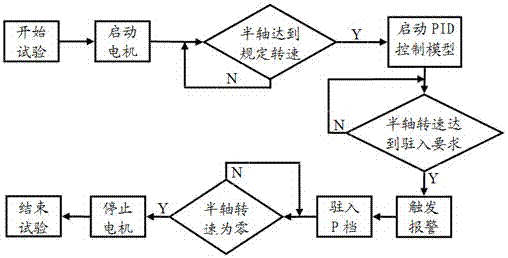

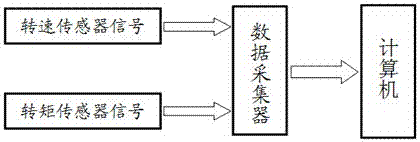

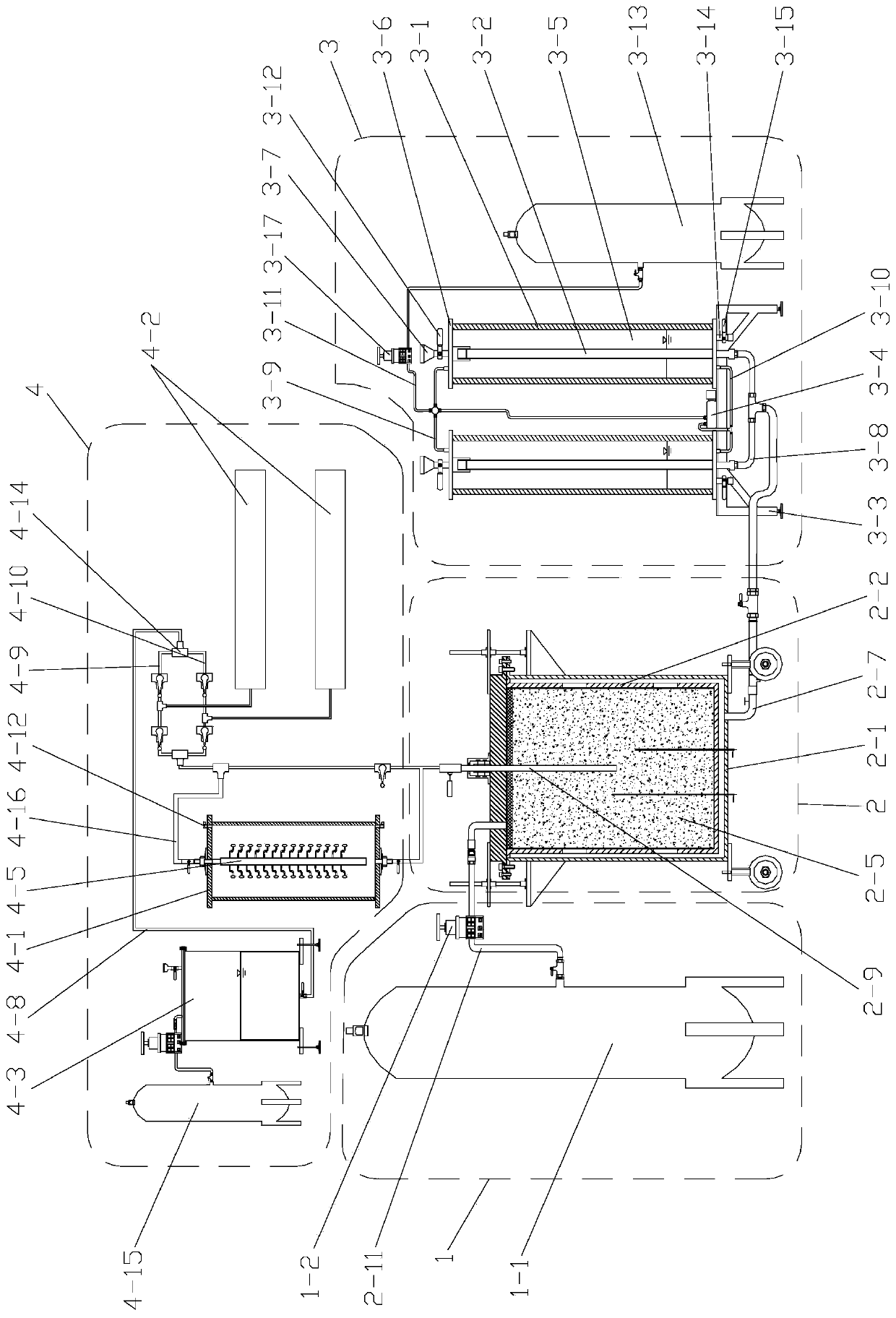

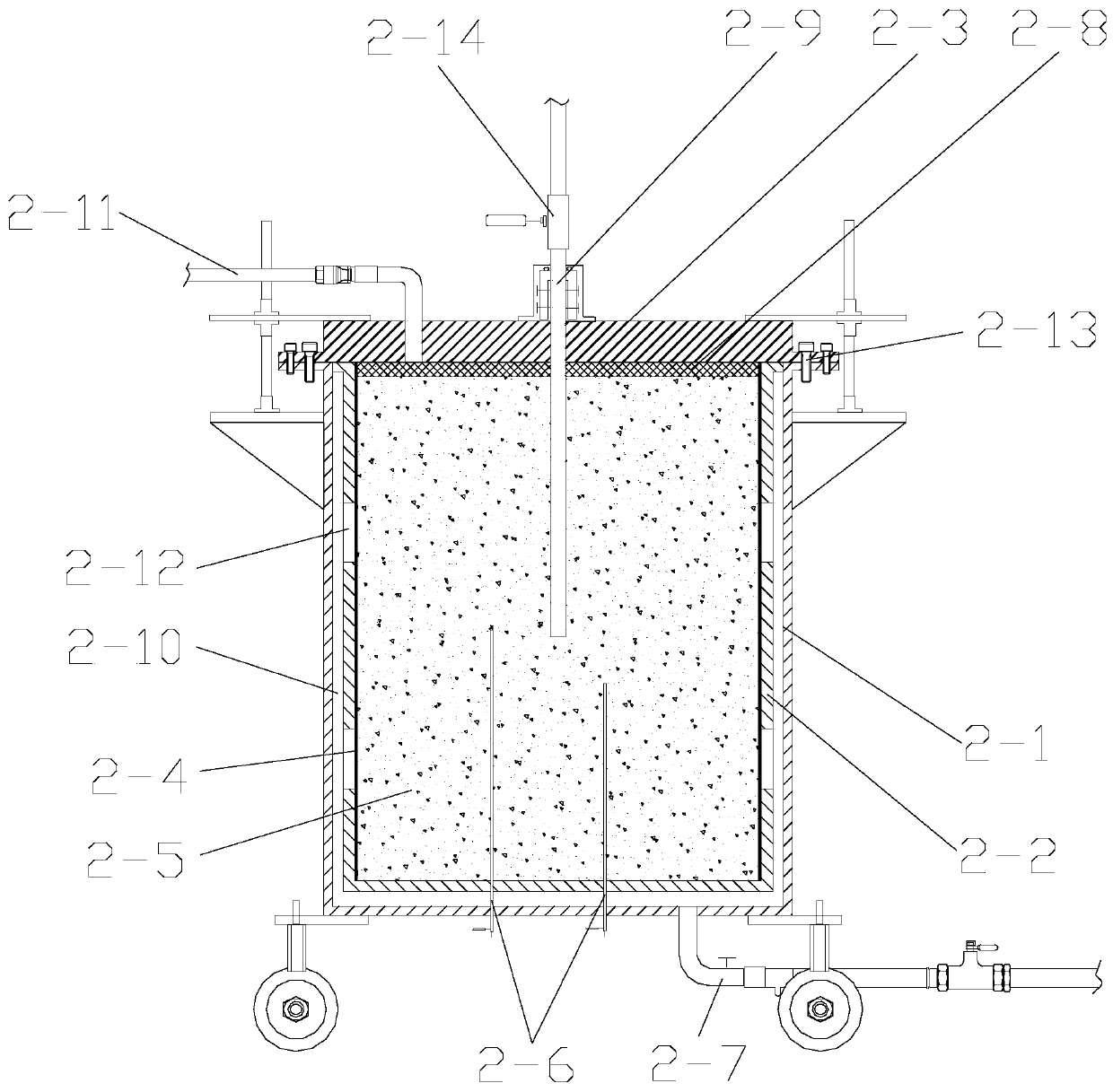

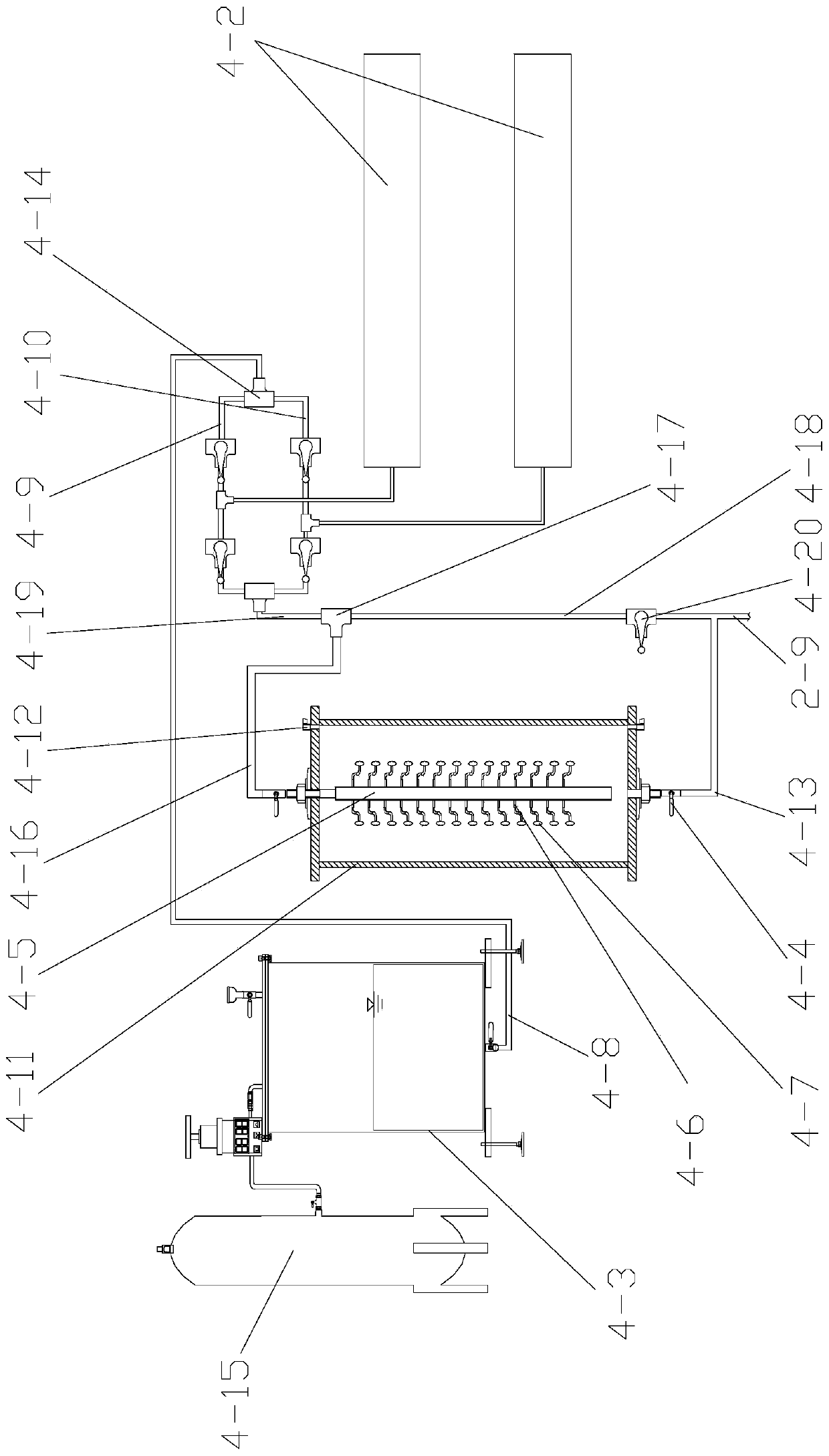

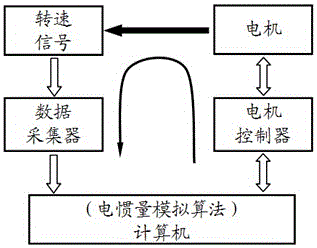

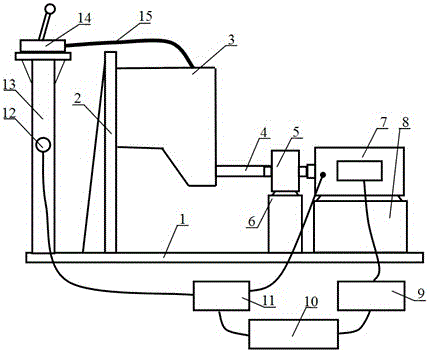

Test and measurement method for the critical parking speed of automatic transmission in P-block parking

InactiveCN104713726BEasy to implementReliable measurementMachine gearing/transmission testingData acquisitionDrive motor

The invention discloses a test method for measuring the parking critical parking speed of automatic transmission P gear. Collector; 2) Adjust the inertia of the flywheel disc of the inertia flywheel box; 3) Install the shifter and the shift cable to the test measurement device; 4) The computer controls the drive motor according to the test requirements; The torque data is saved, processed and displayed by the computer in real time; 5) The half-shaft speed at the last moment when the half-shaft speed suddenly changes to zero is obtained through computer analysis, and the half-shaft speed is converted into the corresponding vehicle speed, which is the automatic transmission P gear Parking critical parking speed. The invention can accurately measure the critical parking speed of the P-gear under the simulated automatic transmission vehicle test condition, thereby providing strong support for the test of the P-speed of the automatic transmission.

Owner:CHONGQING UNIV OF TECH +1

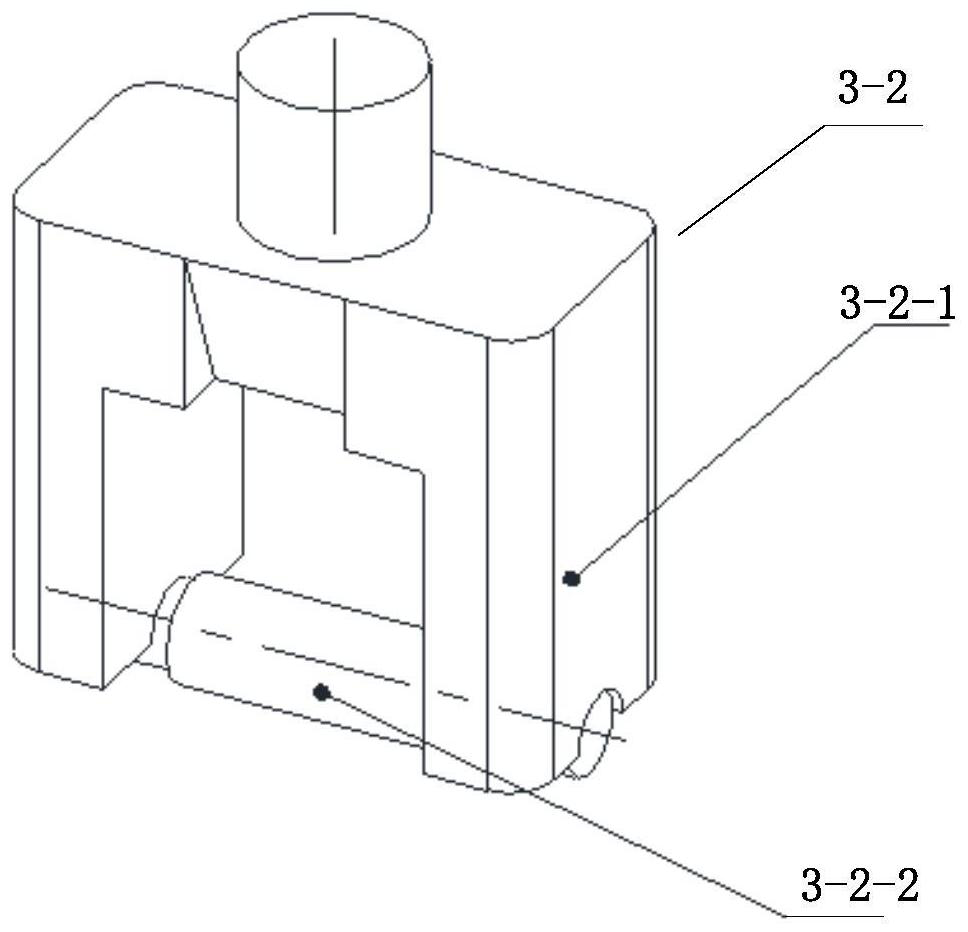

A critical test simulation equipment for penetration splitting grouting

ActiveCN108717039BAvoid Split Grouting SituationsShorten the timePermeability/surface area analysisSoil sciencePipe

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A Method for Discovering Key Test Functions of Large Object-Oriented Software Systems

ActiveCN105022689BNo increase in computational complexityQuick discoverySoftware testing/debuggingNODALComputation complexity

The invention discloses a method for discovering key test functions of a large-scale object-oriented software system. The invention can quickly and reasonably discover key test functions of large-scale object-oriented software systems with high accuracy. The present invention first draws the class collaboration network diagram of the software with classes as nodes and function calls between classes as arcs, and defines the importance of an arc as the number of arcs that can be traversed starting with the arc; then calculates The importance of each arc in the class collaboration network diagram, the arc whose arc head is the class node with the largest total number of reachable arcs is the key arc; finally, the arc head and arc tail information of the key arc are located in the software system For the corresponding two classes, the function call relationship that constitutes the coupling relationship between the two classes is the key test function. The invention overcomes two defects in the existing method, and the calculation complexity does not increase with the complexity of the software system, and can quickly and effectively find the key test function of the software system.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

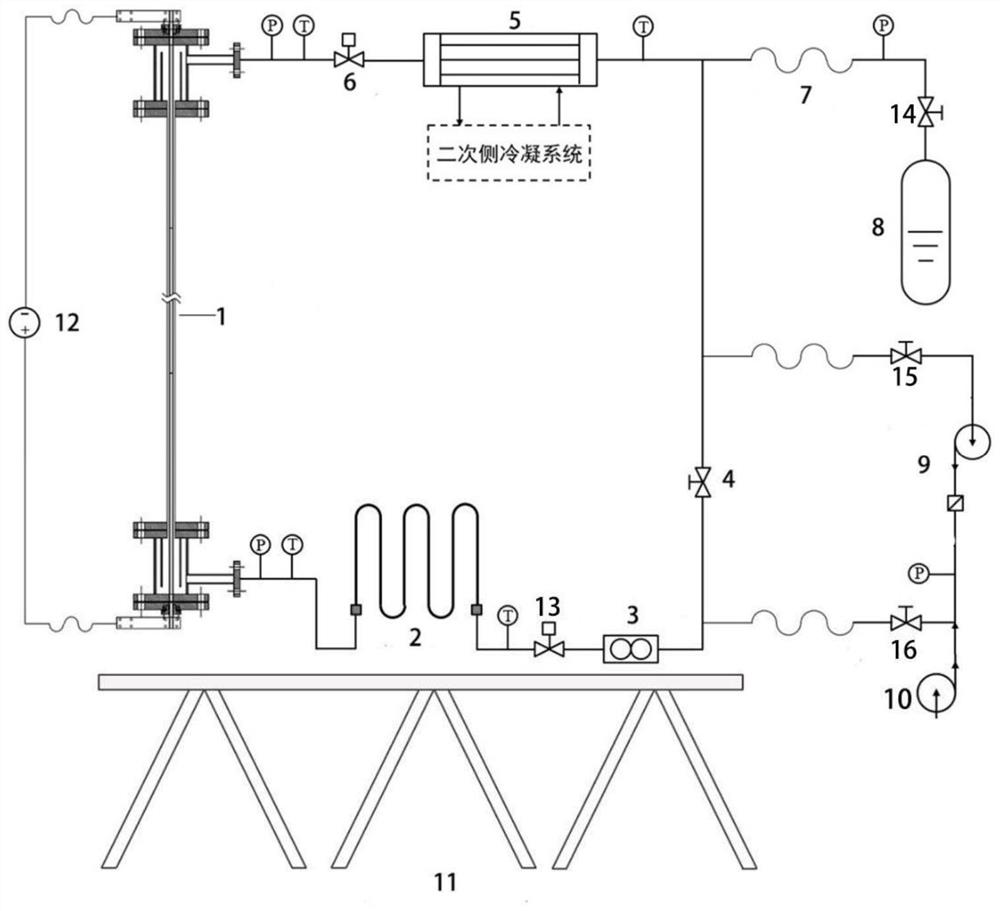

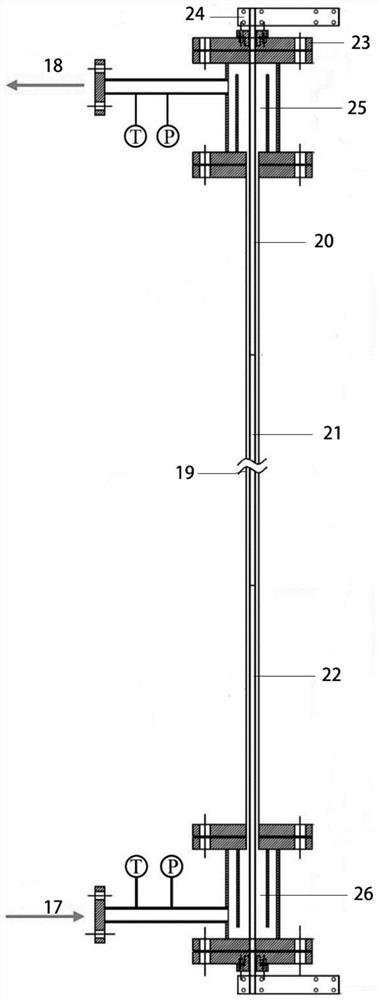

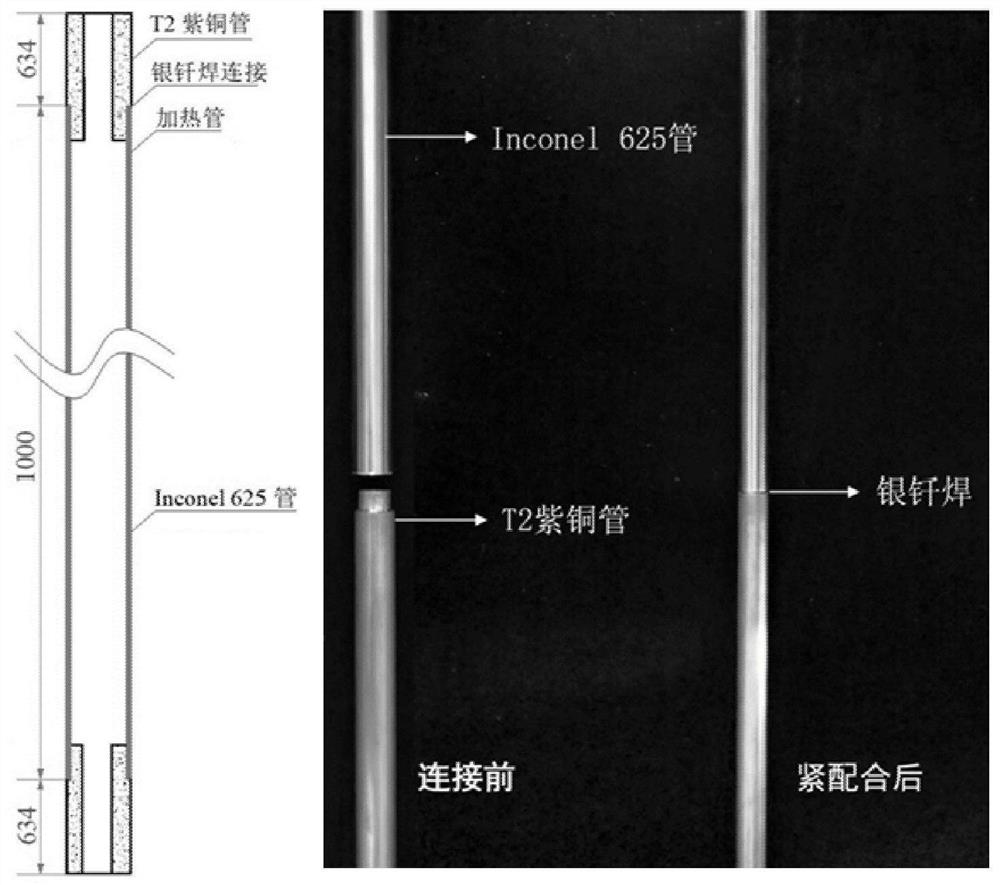

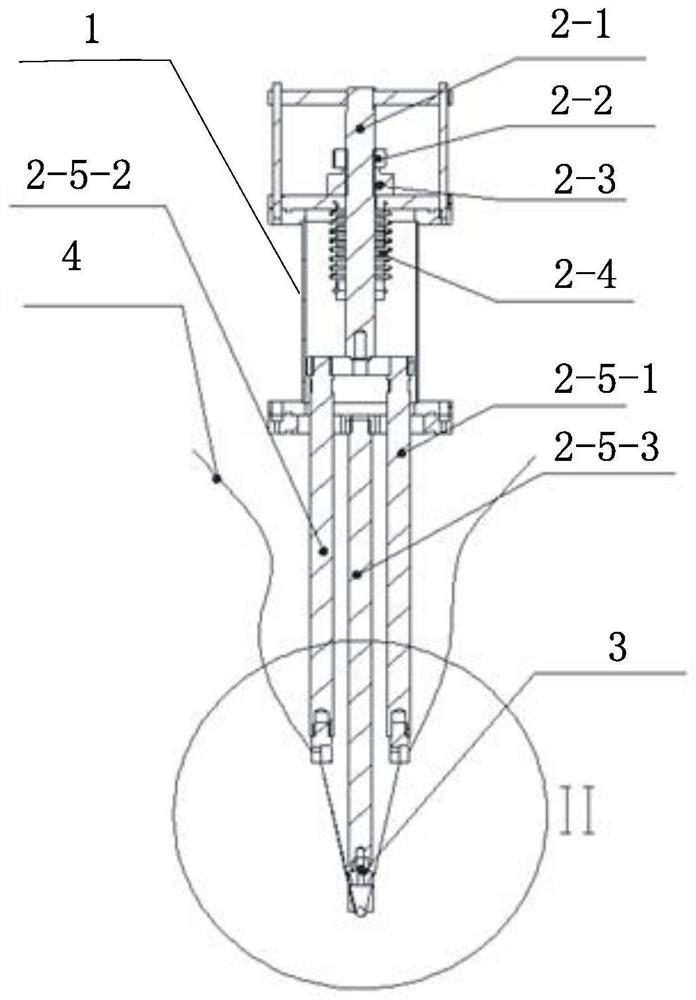

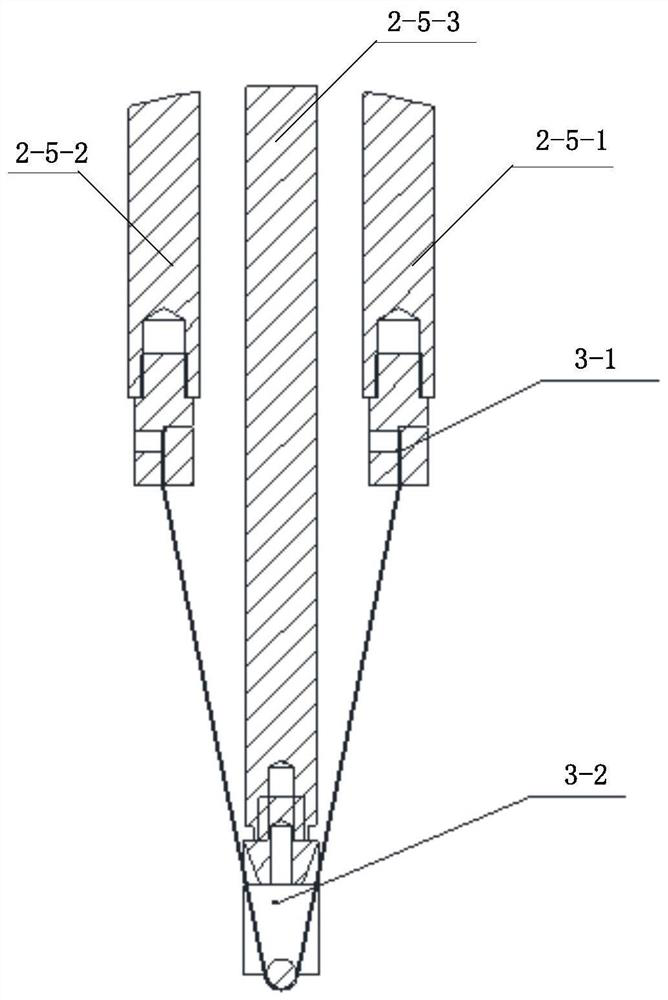

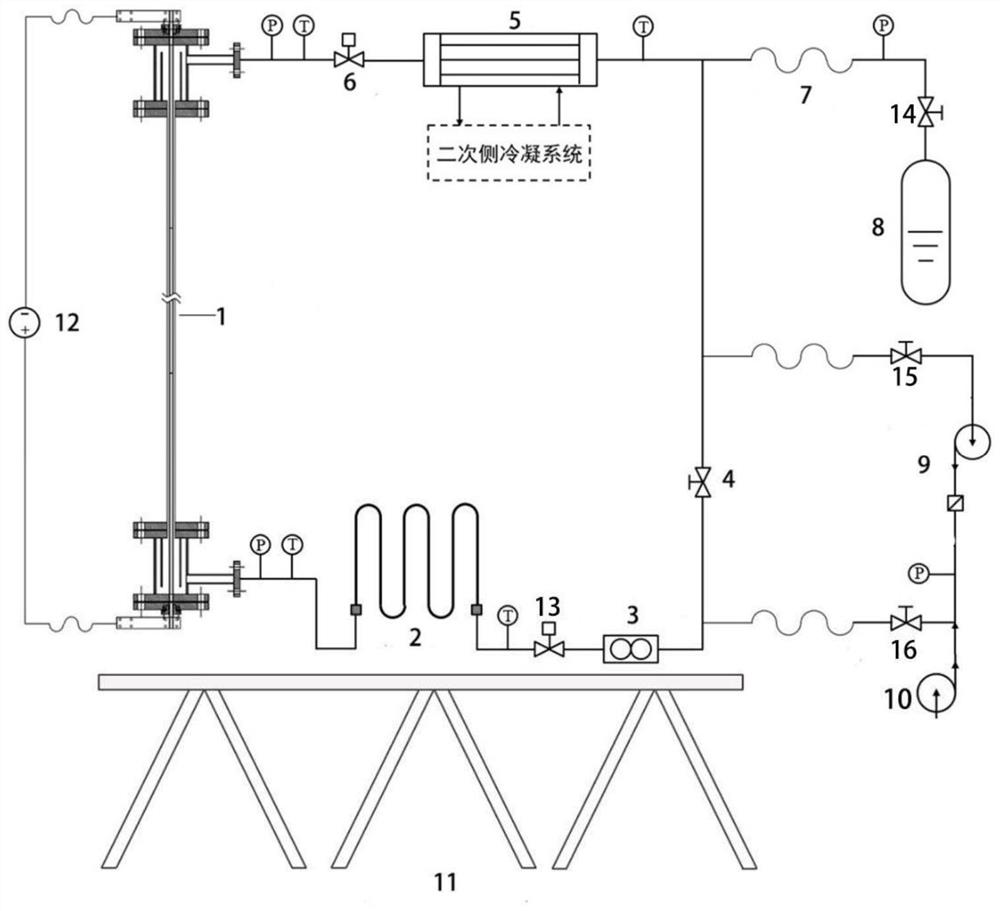

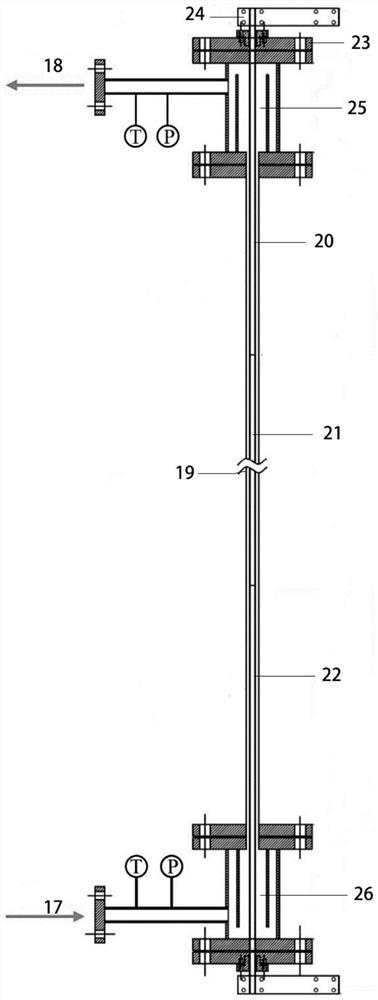

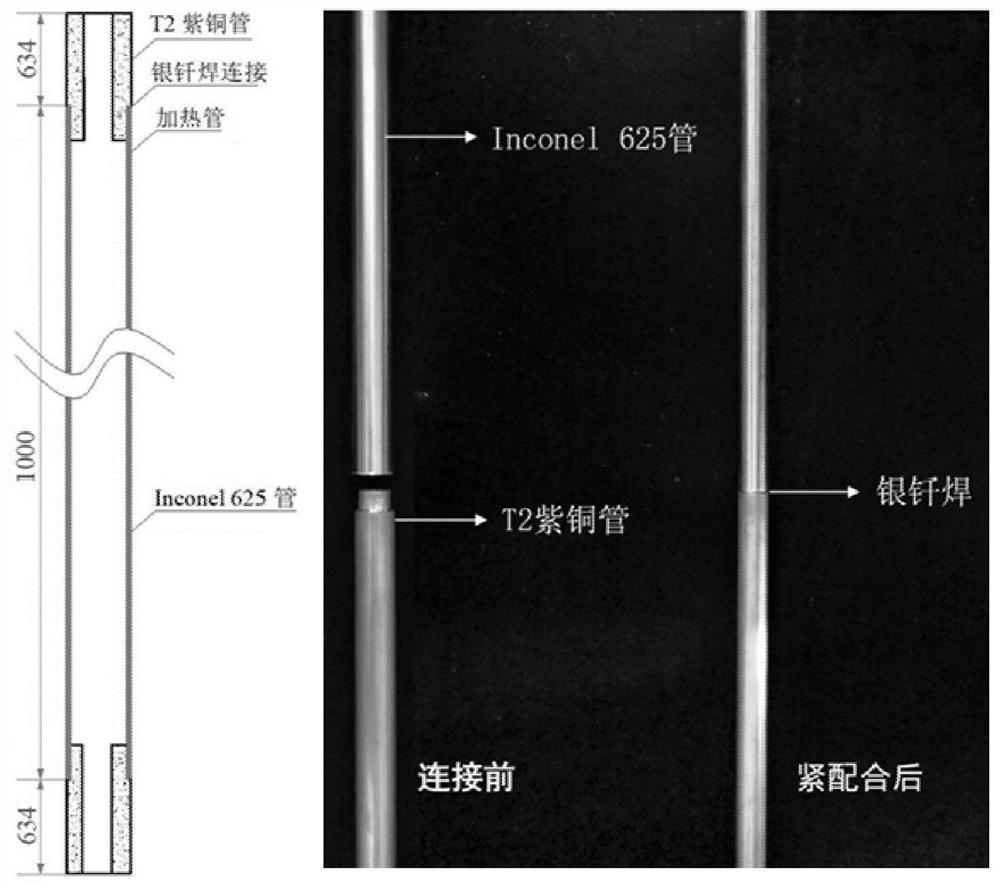

Nuclear reactor single rod boiling critical test device and method under six-degree-of-freedom motion condition

ActiveCN114121319ASolve the problem of excessive resistanceNo leaksNuclear energy generationNuclear monitoringNuclear reactorHeat flow

The invention discloses a nuclear reactor single rod boiling critical test device and method under the condition of six-degree-of-freedom motion, the test device can carry out closed forced circulation and natural circulation flow heat exchange tests, and the test device comprises a shield pump, a voltage stabilizer, an orifice plate flowmeter, a preheating section, a test section, a heat exchanger, a metal hose, a make-up pump and the like. A test section adopts an electric heating mode, and a main loop is integrally placed on a two-ton six-degree-of-freedom motion platform, so that related research on the influence of ocean conditions on critical heat flux density can be completed. Deionized water is selected as a flowing working medium, enters the horizontal snakelike preheating section from a voltage stabilizer and a shield pump (natural circulation does not pass through the shield pump), then enters the test section, passes through a heat exchanger and finally returns to the voltage stabilizer to form closed circulation.

Owner:XI AN JIAOTONG UNIV

Method for testing critical characteristics of superconducting tape in multiple deformation modes

PendingCN114739899AAchieve the effect of online adjustmentEliminate distracting factorsSuperconductive properties measurementsUsing mechanical meansEngineeringMechanical engineering

The invention discloses a critical characteristic test method of a superconducting tape in a multi-deformation mode. The method comprises the following steps: selecting a multi-deformation mode of a current superconducting tape to be tested; if the bending deformation mode is selected, the curvature specification is further selected, a part conforming to the current specification is fixed to the lower end of a third G10 pull rod, a whole strip with the proper length is selected to be subjected to a critical test of bending deformation, and online stress adjustment is conducted; if the stretching and twisting deformation modes are selected, the stretching and twisting angle specifications of the replaceable clamping part are selected, the replaceable clamping part conforming to the angle specifications is fixed to the lower end of a G10 pull rod III, and two strips with proper lengths are selected for a critical test of stretching and twisting deformation; according to the invention, an axisymmetric structure is arranged, the stress difference between the superconducting tape without loading current and the superconducting tape with loading current is compared and observed, and an error value caused by thermal stress disturbance is found, so that interference factors in superposed stress are eliminated, and the stress test precision is improved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Device and method for single-rod boiling criticality test of nuclear reactor under six-degree-of-freedom motion conditions

ActiveCN114121319BSolve the problem of excessive resistanceNo leaksNuclear energy generationNuclear monitoringNuclear chemistryTest rig

Owner:XI AN JIAOTONG UNIV

Optimal local supply voltage determination circuit

InactiveUS20090243648A1High power supply voltageLogic circuit coupling/interface arrangementsElectric variable regulationProcessor registerEngineering

A test circuit that compares test results between two tests with different local supply voltages is provided. The output of each stage of the logic circuits is stored in a first register of each test circuit. Each test is performed with a critical test vector and a local supply voltage that decreases from test to test. The outputs of successive tests are compared in each test circuit. The tests are performed iteratively with successive reduction in the value of the local supply voltage until at least one stage of the logic circuits produces non-matching results between the first and second register. The voltage immediately before producing such non-matching results is the minimum operational voltage for the local voltage island.

Owner:IBM CORP

Test method of vehicle automatic transmission p-gear parking critical parking speed test

InactiveCN104697790BEasy to implementReliable measurementMachine gearing/transmission testingAutomatic transmissionDrive motor

The invention discloses a test measuring method for the critical P-gear parking automobile speed of an automobile automatic gearbox. According to the method, a computer regulates the speed of a driving motor to a set rotating speed, and an electrical inertia simulation control model is started; the computer collects the rotating speed of an axle shaft of the automatic gearbox to be measured in real time and obtains the preset rotating speed value of the driving motor at the next moment through calculation, and meanwhile the computer sends the preset rotating speed value to the driving motor in real time, and sequential circulation control is performed; when the rotating speed of the axle shaft meets the requirement for P-gear parking, a tester manually operates a gear shifting device to park at the P gear, and when the computer measures that the rotating speed of the axle shaft is zero, the driving motor is controlled to stop, and one time of testing is ended. The critical P-gear parking automobile speed can be accurately measured through simulating the whole test working conditions of the automobile gearbox, and the accurate and reliable support is provided for test research performed on the critical P-gear parking automobile speed of the automobile gearbox.

Owner:CHONGQING UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com