Critical liquid carrying condition optimization method in deep water gas well testing

An optimization method and gas well technology, applied in the field of exploration and development of oil and gas fields, can solve problems such as low accuracy, small pressure range, and small design results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

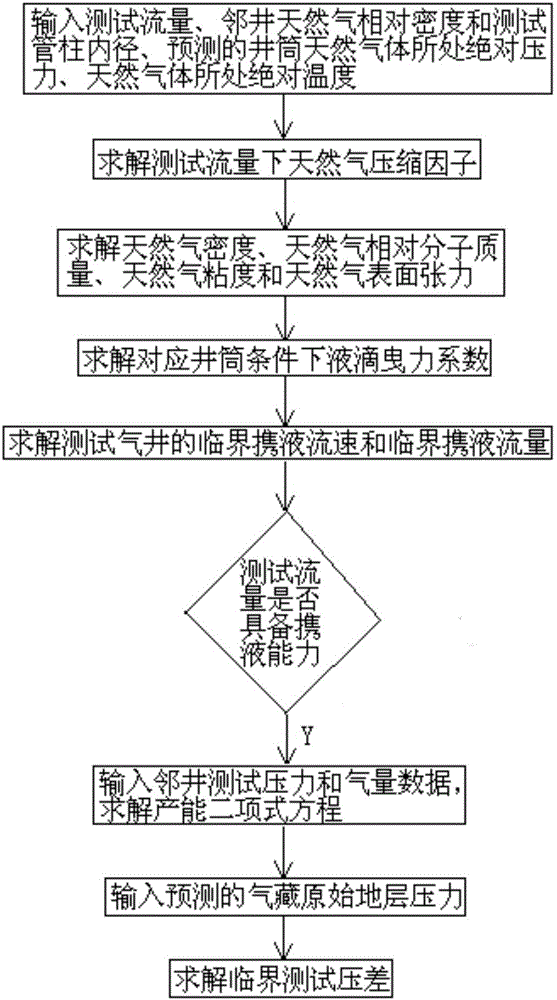

[0072] Such as figure 1 As shown, the deep-water gas well test critical liquid-carrying condition optimization method proposed by the present invention comprises the following steps:

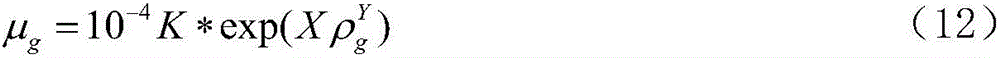

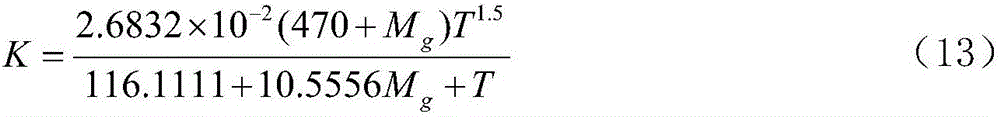

[0073] 1) Determine the test flow rate of the wellbore, and calculate the natural gas compression factor at each point in the wellbore according to the relative density of natural gas in the adjacent well and the inner diameter of the test string, as well as the predicted absolute pressure and temperature of the natural gas in the wellbore. Then calculate the natural gas density, natural gas relative molecular mass, natural gas viscosity and natural gas surface tension at the corresponding points in the wellbore according to the obtained natural gas compression factors at each point in the wellbore, and use the obtained natural gas viscosity to determine the liquid drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com