Nuclear reactor single rod boiling critical test device and method under six-degree-of-freedom motion condition

A boiling critical and test device technology, applied in nuclear reactor monitoring, reactors, nuclear engineering, etc., can solve problems such as cladding burning and radioactive material leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

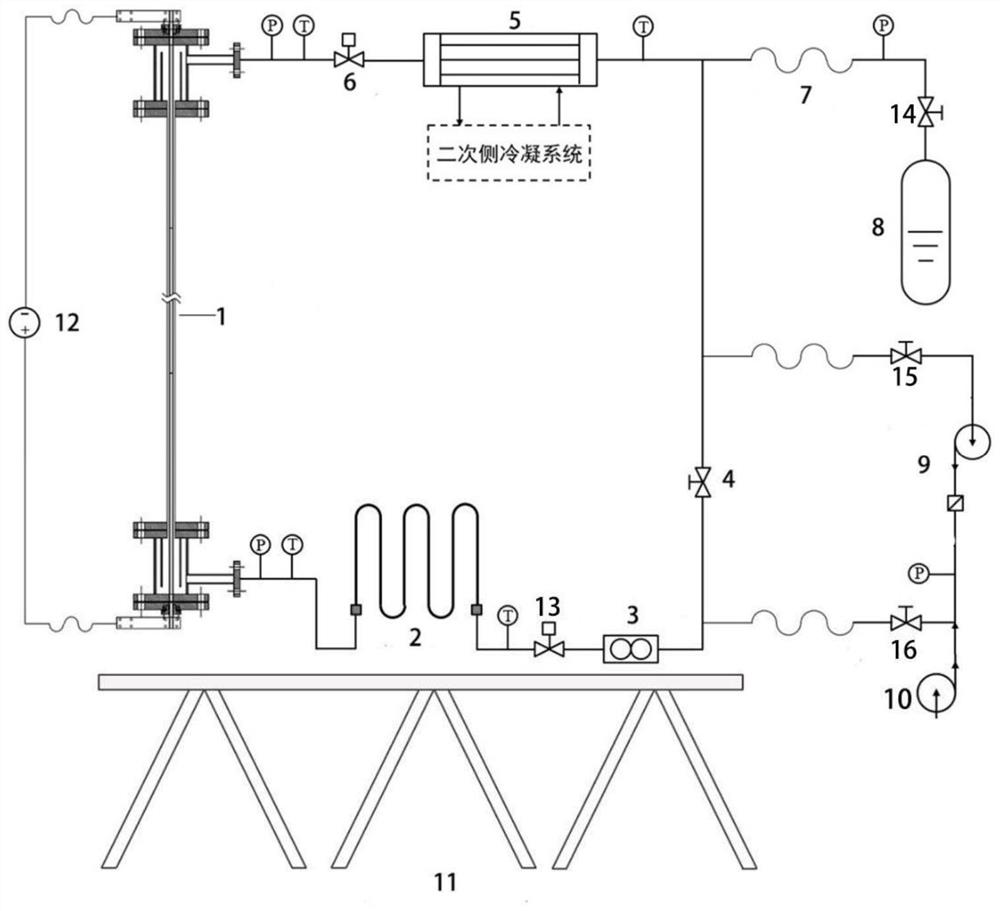

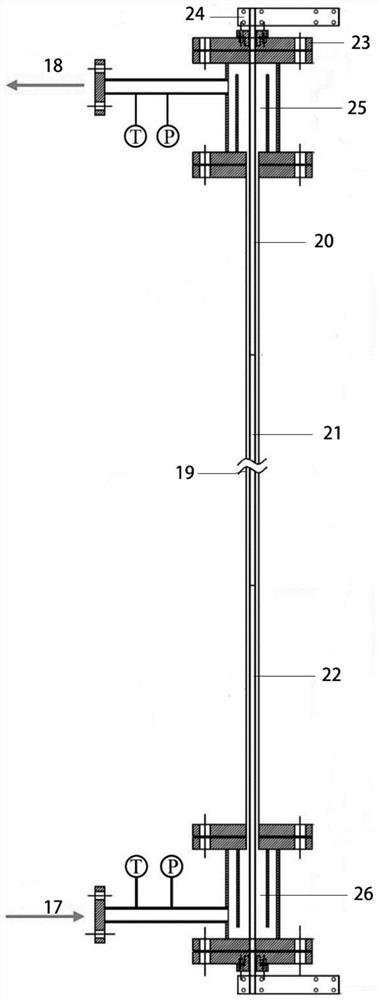

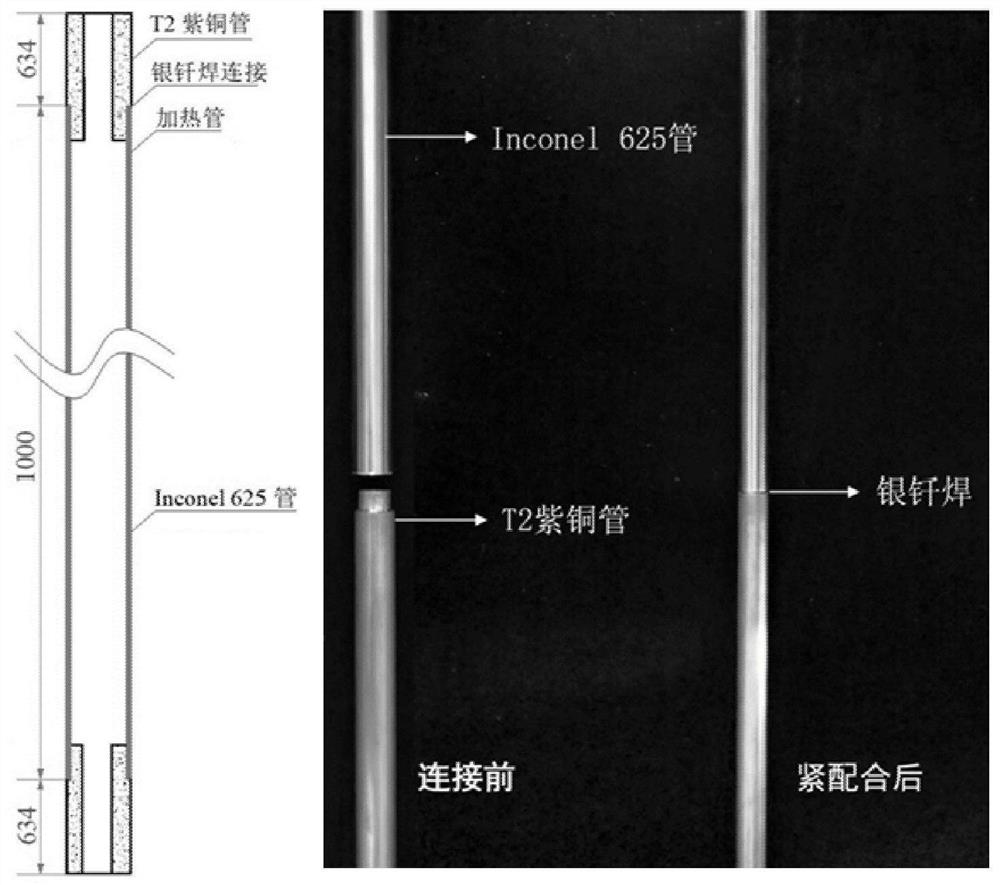

[0027] Such as figure 1 As shown, the present invention is a nuclear reactor single-rod boiling critical test device under six-degree-of-freedom motion conditions. The test device includes a single-rod test section 1, a preheating section 2, a second regulating valve 13, an orifice flowmeter 3, A test circuit composed of a stop valve 4, a heat exchanger 5 and a regulating valve 6 connected through pipelines in turn, the test circuit is placed on a two-ton six-degree-of-freedom motion platform 11, and the relevant research on the influence of ocean conditions on the critical heat flux is completed; The pipeline between the first shut-off valve 4 and the heat exchanger 5 leads to two metal hoses 7, one metal hose 7 is connected to the voltage regulator 8 through the second shut-off valve 14, and the other metal hose 7 is passed through the third The cut-off va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com