High-frequency low-loss filter, resonator and preparation method

A low-loss, filter technology, applied in the field of sensors, can solve the problems of increased electrode resistance, large insertion loss, etc., and achieve the effect of reducing electrode resistance, reducing insertion loss, and improving quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

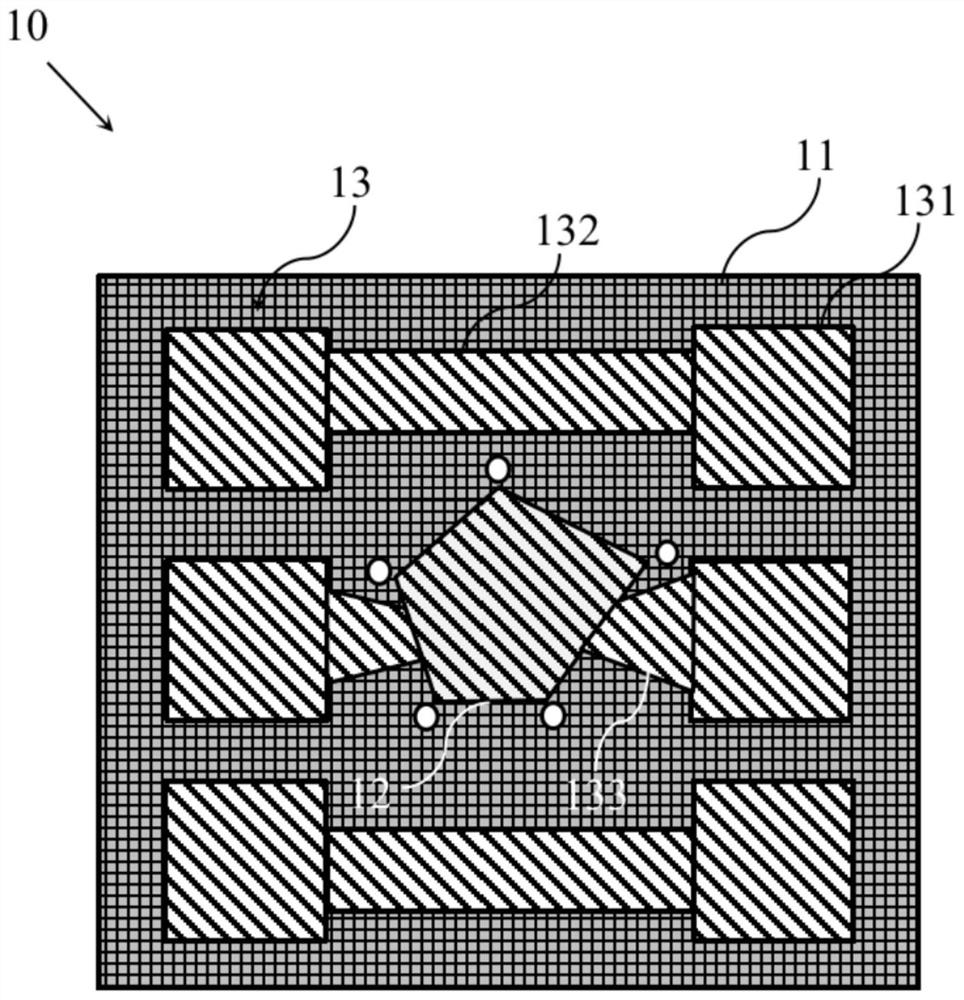

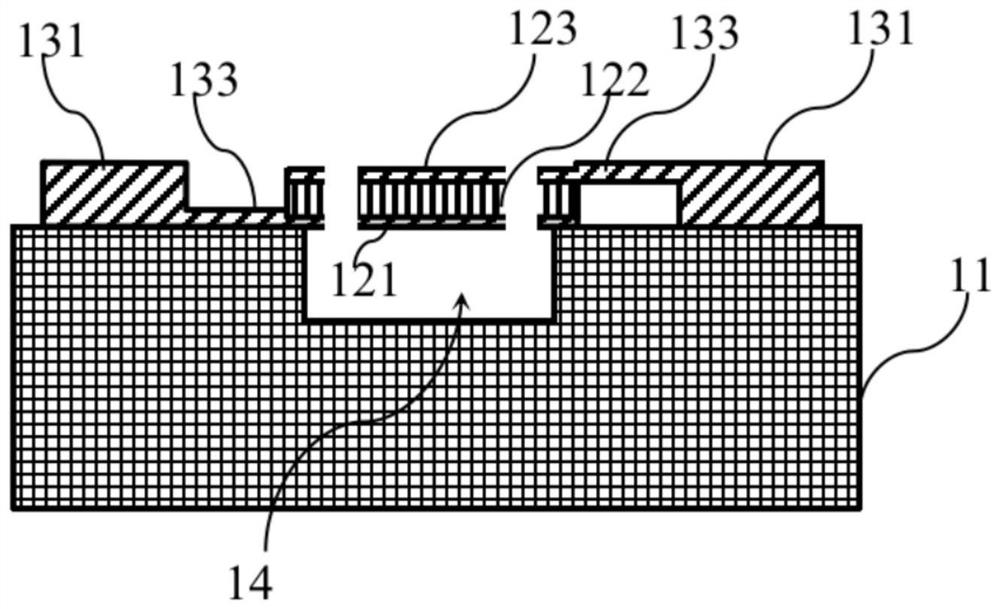

[0046] Such as figure 1 with 2 As shown, the high-frequency low loss resonator 10 provided in the present embodiment includes a substrate 11, an effective resonance portion 12, and a non-active resonance portion 13.

[0047] The middle portion of the substrate 11 has a groove upward opening.

[0048] The effective resonance portion 12 (piezoelectric oscillator stack) is formed on the main region of the substrate 11, and the effective resonance portion 12 includes a bottom electrode 121, a piezoelectric layer 122, and a top electrode 123 from the bottom to top. The groove and the effective resonance portion 12 on the substrate 11 are each form a cavity 14. The effective resonance portion 12 is uniformly provided with a release hole, which is provided for the preparation of the cavity 14. In this embodiment, the patterned effective resonance unit 12 is an irregular five-sided shape.

[0049]The non-active resonant portion 13 is formed on the substrate 11 including a six-piece electr...

Embodiment 2

[0061] Such as Figure 17 with 18 As shown, the high-frequency low loss filter 20 provided in the present embodiment includes a substrate 21, six effective resonance unit 22, and a non-active resonance portion 23.

[0062] The middle region of the substrate 21 is provided with six upward openings, respectively correspond to the six effective resonance units 22, respectively.

[0063] The six effective resonance unit 22 (piezoelectric oscillator piles) are formed on the main region of the substrate 21, and each of the effective resonance units 22 includes a bottom electrode 221, a piezoelectric layer 222, and a top electrode 223 from the bottom to top. The groove and the effective resonance portion 22 on the substrate 21 are each form a cavity 24. The effective resonance portion 22 is uniformly provided with a release hole, which is provided for the preparation of the cavity 24. In this embodiment, the patterned effective resonance unit 22 is an irregular five-sided shape.

[0064] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com