Device and method for single-rod boiling criticality test of nuclear reactor under six-degree-of-freedom motion conditions

A boiling critical and test device technology, applied in nuclear reactor monitoring, reactors, nuclear engineering, etc., can solve problems such as cladding burning and radioactive material leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

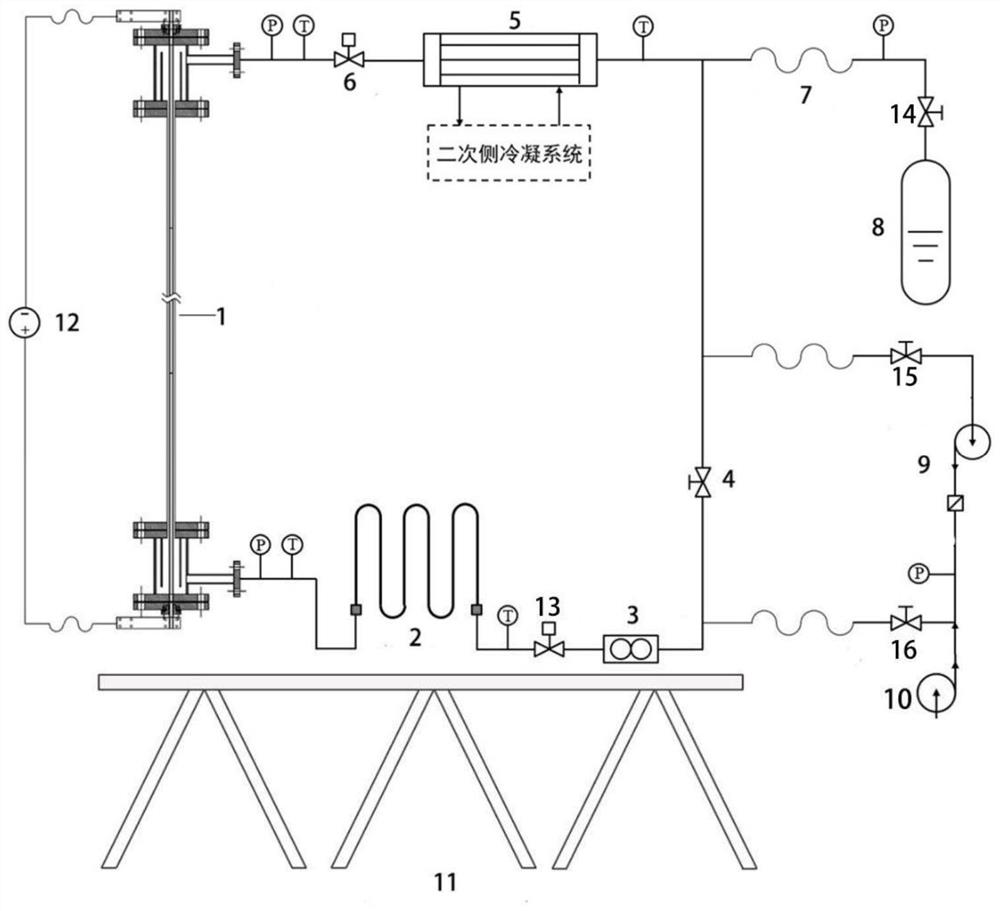

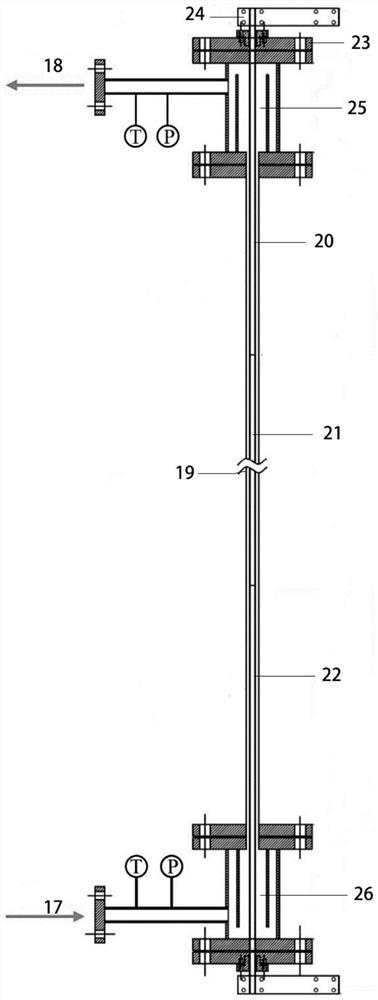

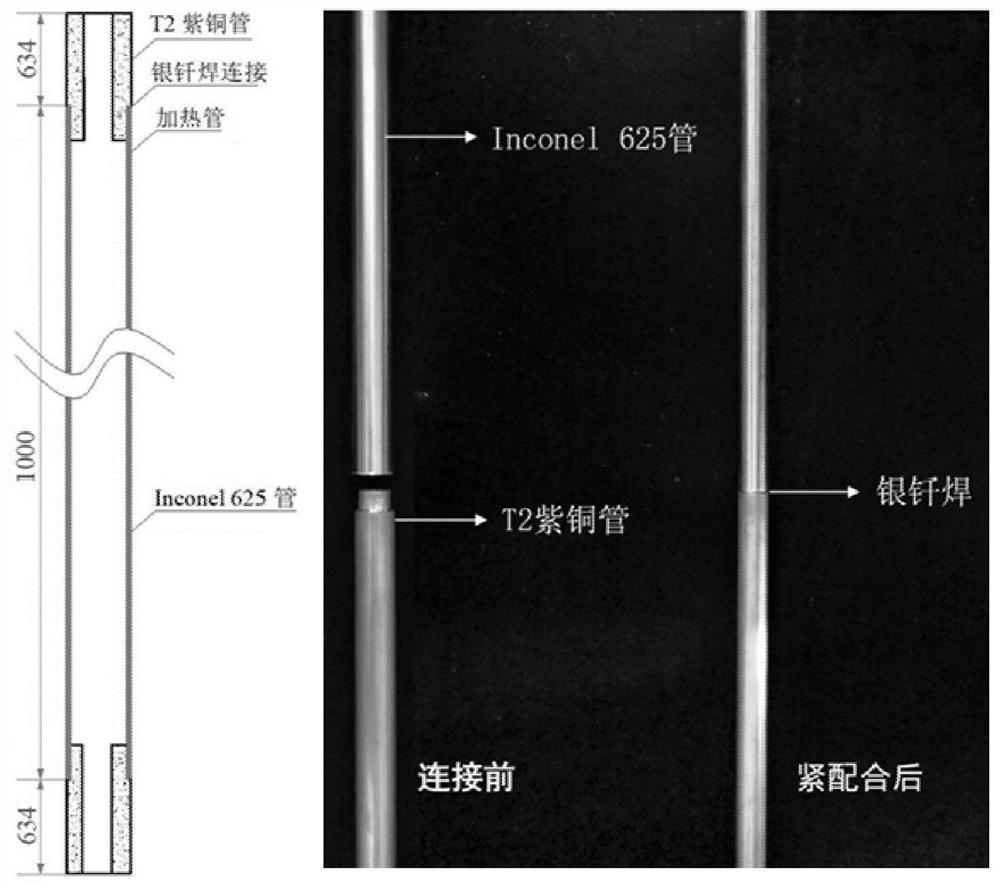

[0027] like figure 1 As shown in the figure, the present invention is a single-rod boiling critical test device for a nuclear reactor under the condition of six degrees of freedom motion. The test device includes a single-rod test section 1, a preheating section 2, a second regulating valve 13, an orifice flowmeter 3, A test loop formed by connecting the shut-off valve 4, the heat exchanger 5 and the regulating valve 6 through the pipeline in sequence, the test loop is placed on the two-ton six-degree-of-freedom motion platform 11 to complete the relevant research on the influence of ocean conditions on the critical heat flux density; The pipeline between the first stop valve 4 and the heat exchanger 5 leads out two metal hoses 7, one metal hose 7 is connected to the regulator 8 through the second stop valve 14, and the other metal hose 7 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com