Method and system for determining one-dimensional barcode bar width compensation amount, and barcode printing method

A compensation amount, dimensional barcode technology, applied in the field of one-dimensional barcodes, can solve the problems of easy to be wrongly identified, the width of one-dimensional barcodes is too large, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a method for determining the bar width compensation amount of a one-dimensional barcode, including determining the bar width compensation amount y of k times the module width bar k The steps of , where k is a positive integer, determine y k The steps include:

[0037] Determine the module width n in units of the number of printed pixels and the width kn of k times the module width bar;

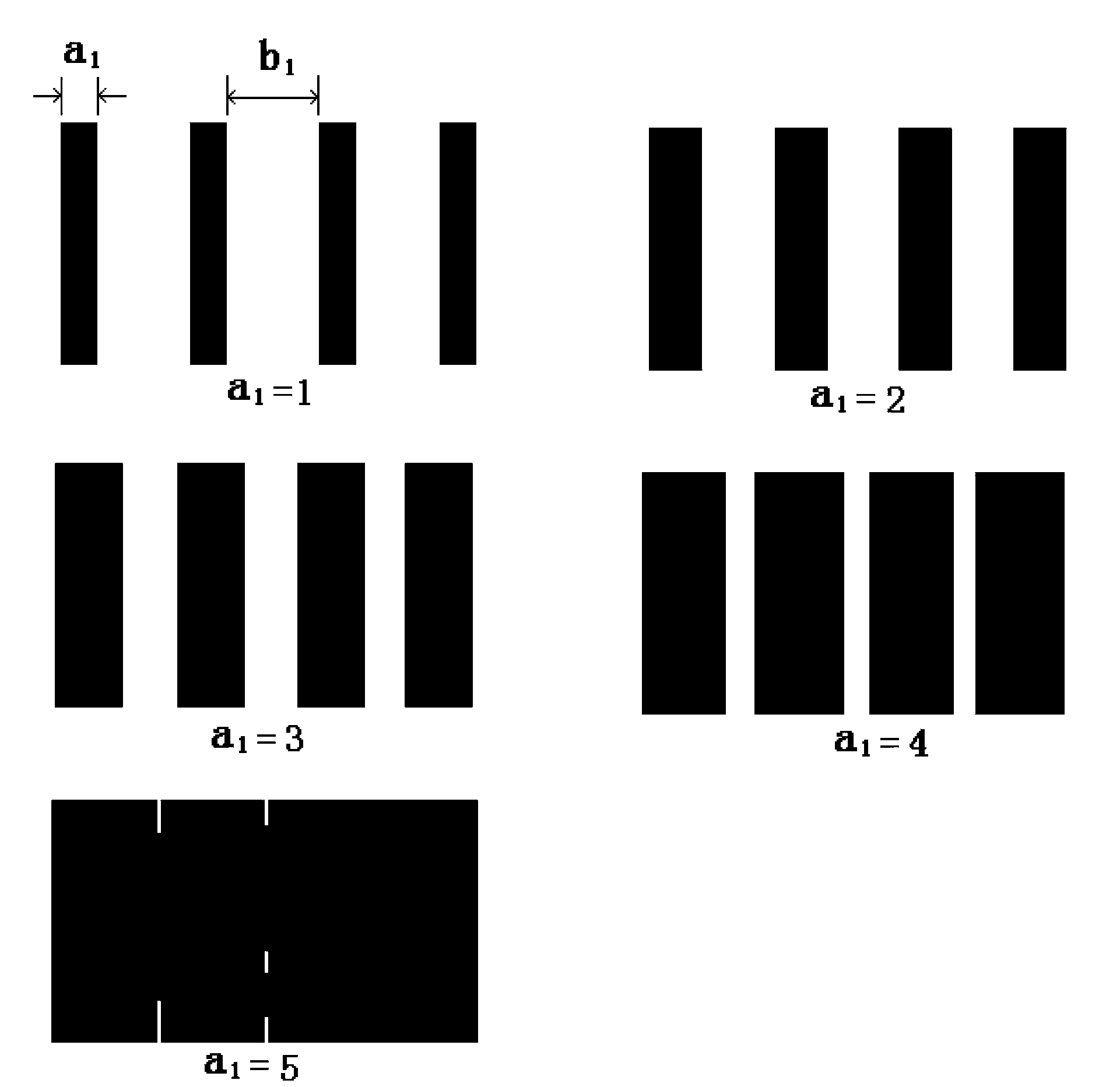

[0038] Use a printing device to print a test target with strips of k times the width of the module on the carrier, each test target includes at least two strips and a space, and the strip width a in units of the number of printed pixels k with empty width b k meet: a k k +b k =kn,a k = kn when b k =1;

[0039] By judging whether the adjacent strips in the test target are in contact, find out the critical test target of k times the module width strip, the critical test target is that the adjacent strips do not touch, and the strip width value is a k large...

Embodiment 2

[0043] This embodiment provides a method for determining the bar width compensation amount of a one-dimensional barcode, which includes determining the bar width compensation amount y of k times the module width bar k steps, k is a positive integer.

[0044] This method specifically comprises the following steps:

[0045] S01, set k=1, that is to determine the strip width compensation y of the 1 times module width strip 1 , which specifically include:

[0046] S011. Determine the module width n, and accordingly determine the width kn of the k-times module width bar, and the width of the 1-times module width bar is also n. Among them, n takes the number of printing pixels as the unit (so it is obviously a positive integer), and the printing pixel is the smallest point that the printing device can print. The module width is n, which means that the module width is equal to the connected size of n printing pixels .

[0047] Preferably, the module width n can be determined by t...

Embodiment 3

[0077] This embodiment provides a method for printing a one-dimensional barcode, which includes the following steps:

[0078] Determine the strip width compensation y of the k times module width strip by the above method k ;

[0079] Use a printing device to print a one-dimensional barcode bar on the carrier, and when it is necessary to form a bar of k times the width of the module, use the printing device to print a width of (kn-y k ) of the strip.

[0080] That is, assuming n=5, k=2, y 2 =2, then the required width of the 2 times the module width bar is 2*5=10 printing pixels, at this time, if you want to print the 2 times the module width bar, then instruct the printing device to print the width at the position of the bar: (2n -y 2 ) = (2*5-2) = 8 printing pixels of the strip, after the width of the strip is increased, that is, the width of the closest to 10 printing pixels of the strip.

[0081] Of course, for strips without corresponding strip width compensation (for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com