Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

163 results about "Center effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

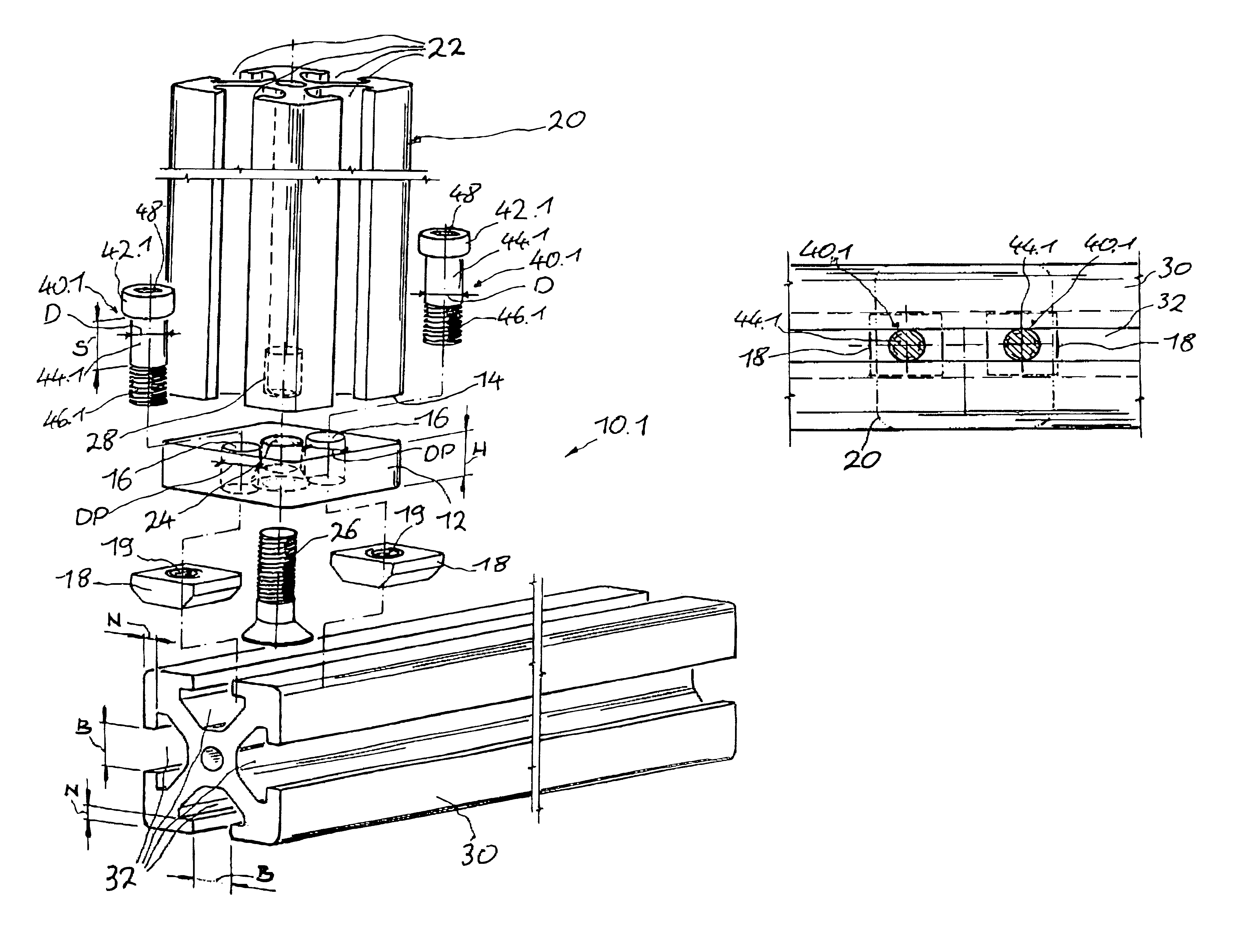

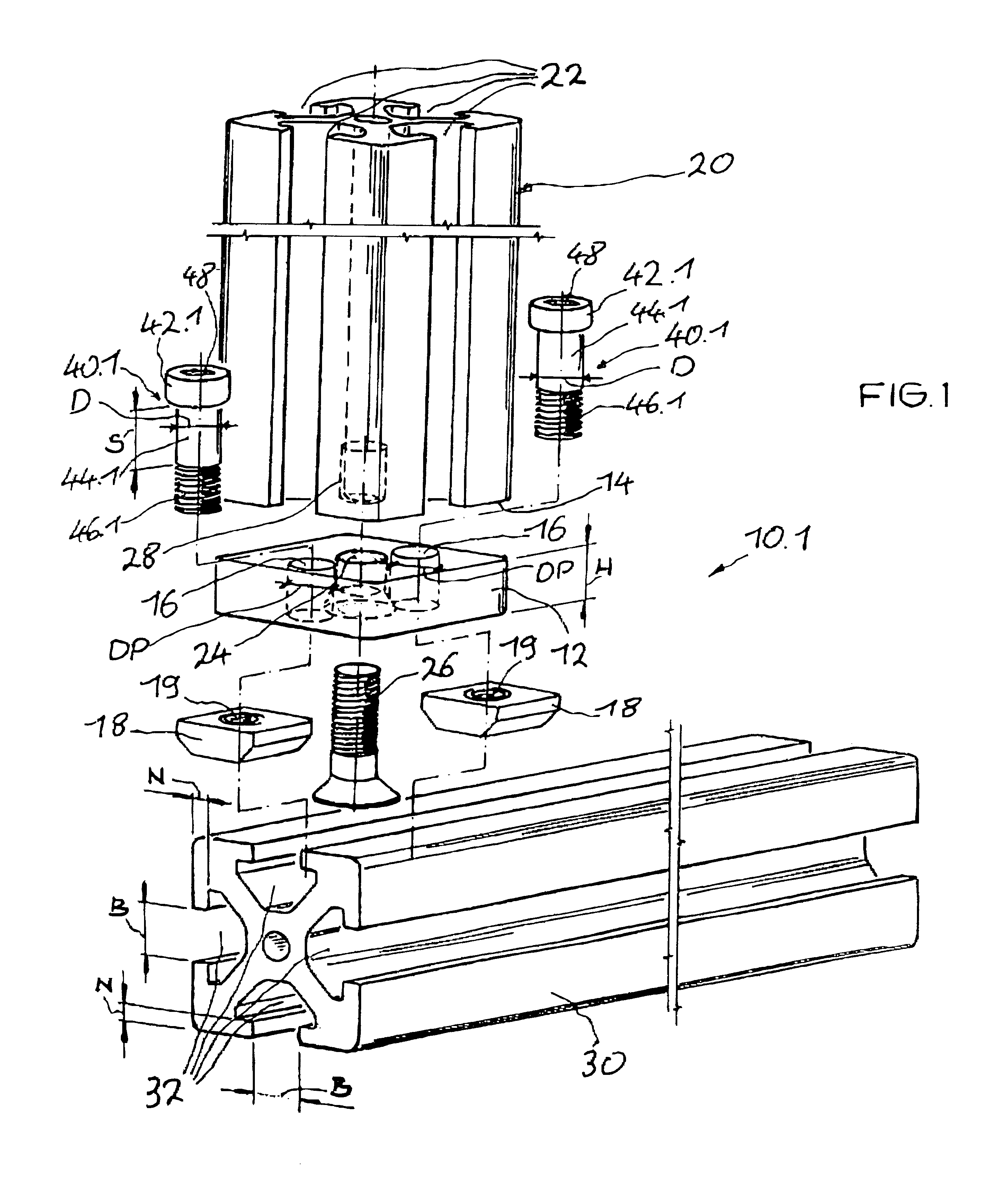

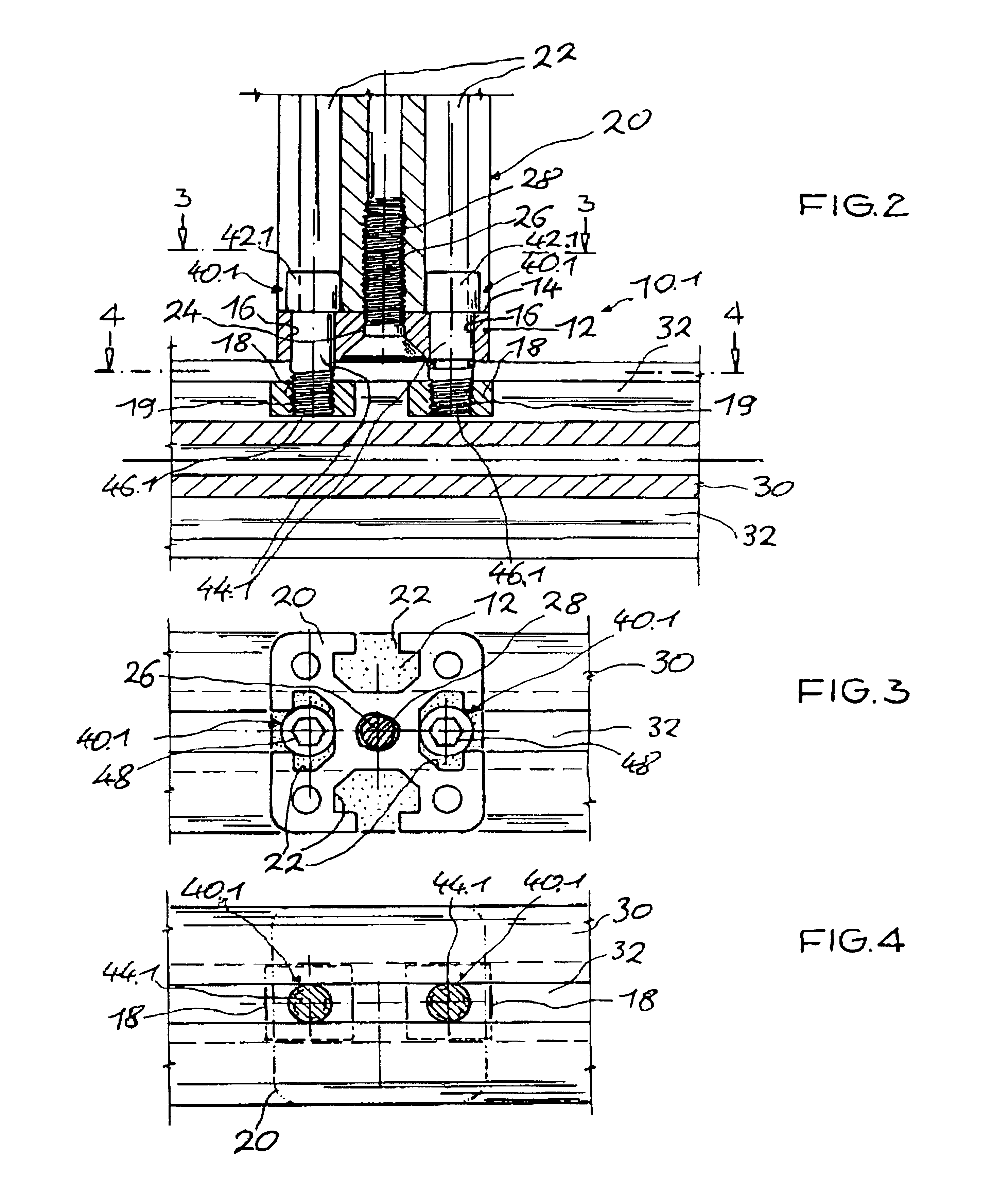

Connecting device for profiled bars with grooves

A connecting device for connecting at least two profiled bars that are essentially perpendicular to one another and have grooves, in conjunction with sliding blocks, one plate connector unit is fastened to the end of a first profiled bar and anchored in a groove in the second profiled bar by way of screw units they extend in recesses in the plate connector unit. The geometry of the screw head of the screw unit is configured such that it centers the screw unit within the groove in the first profiled bar and the engages with a centering effect in the groove in the second profiled bar.

Owner:FMS FORDER UND MONTAGE SYST SCHMALZHOFER

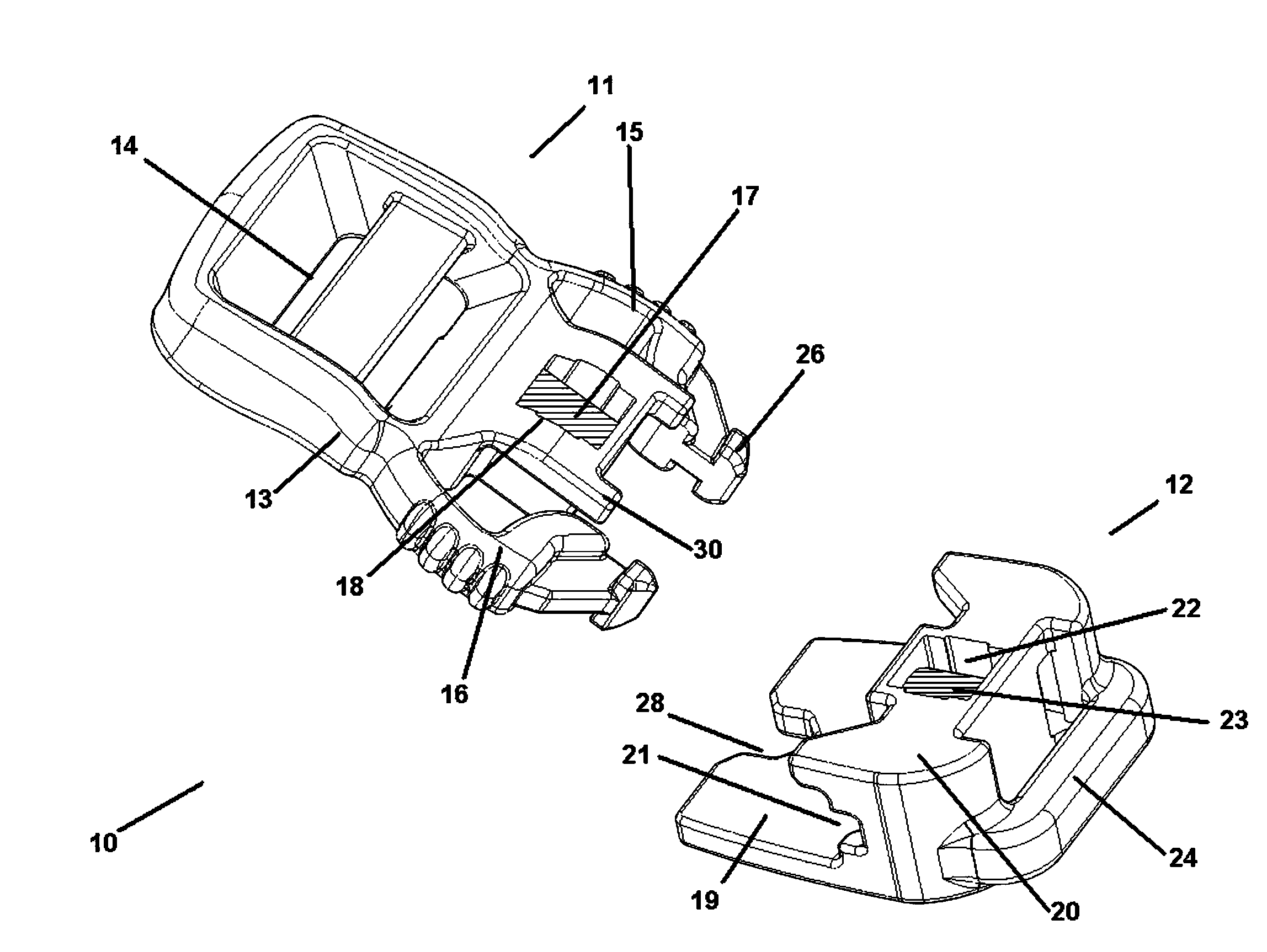

Magnetic fastening buckle provided with permanent magnets and a mechanical locking

A magnetic fastening buckle includes a first plug-in element (11) provided with a first permanent magnet (17), and a second receiving element (12) comprising a flat support plate (19) surmounted by a support cap (20) for a second permanent magnet (23). The body (13) of the first plug-in element (11) moreover comprises one pair of guiding pins (30) protruding on both sides of the first housing opening (18) of the first permanent magnet (17), both guiding pins (30) being parallel to the longitudinal axis XY of the buckle. The whole ensures a self-centering effect of the first plug-in element (11) in said longitudinal direction XY.

Owner:ZEDEL CORP

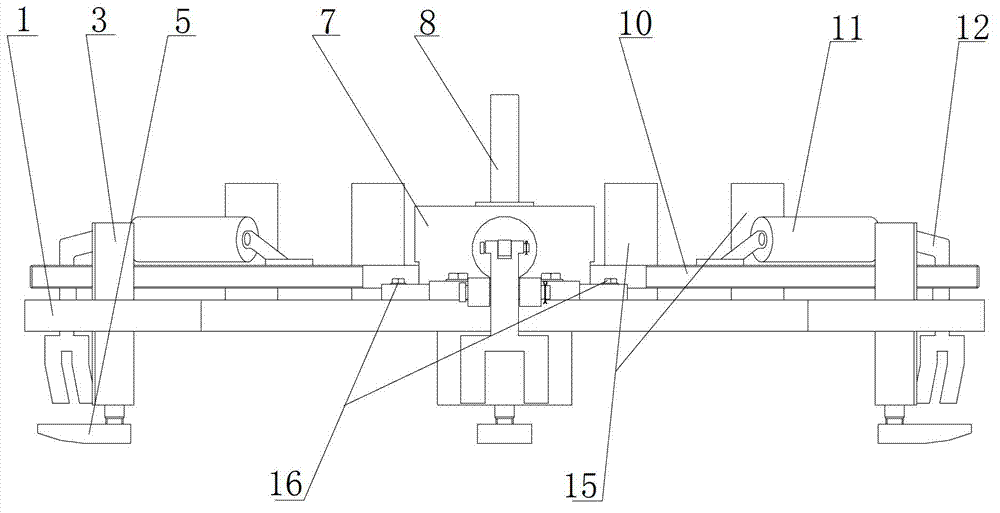

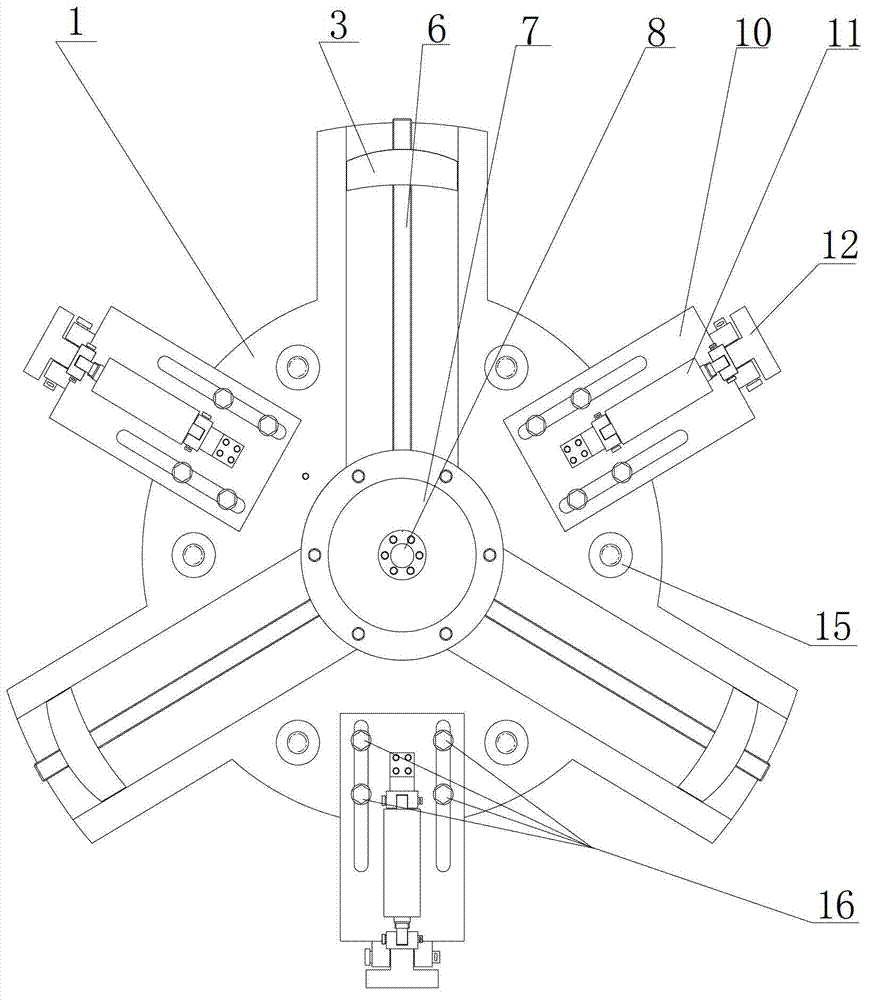

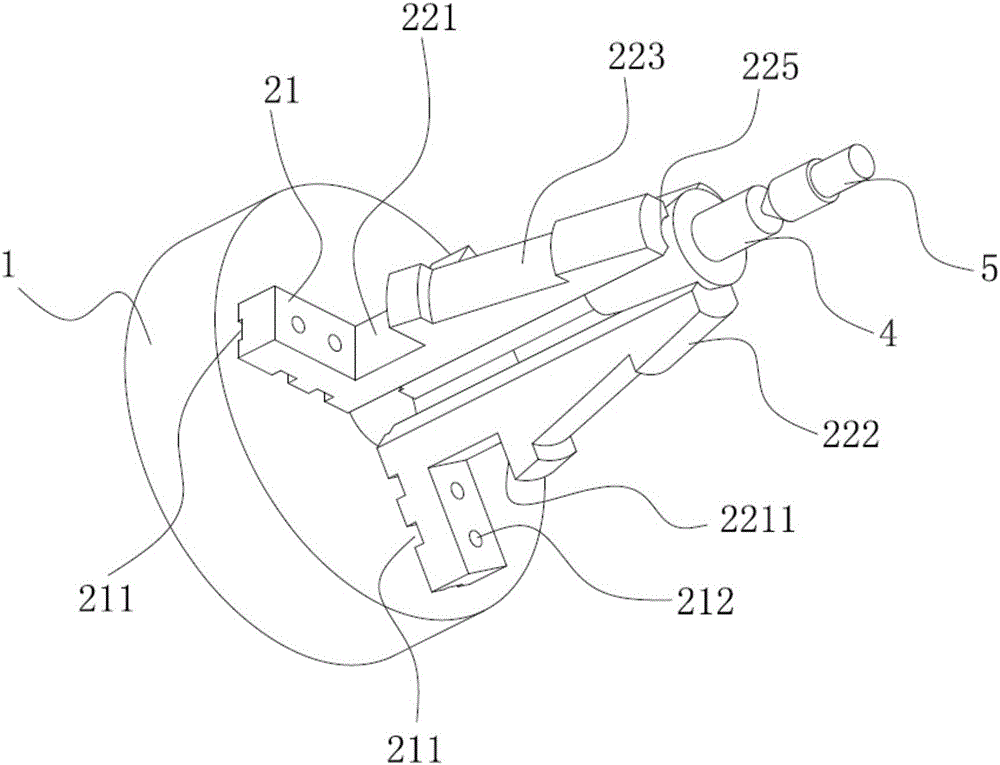

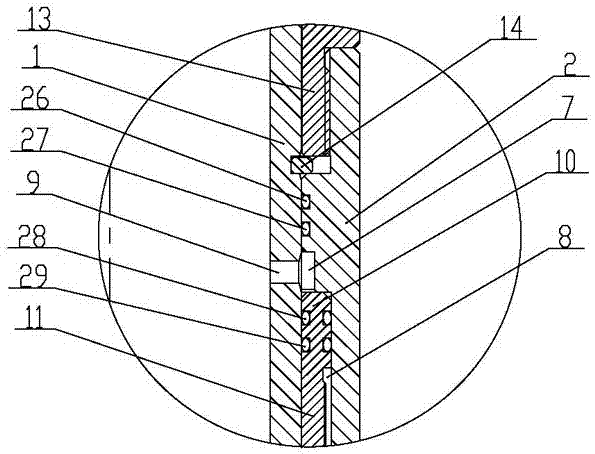

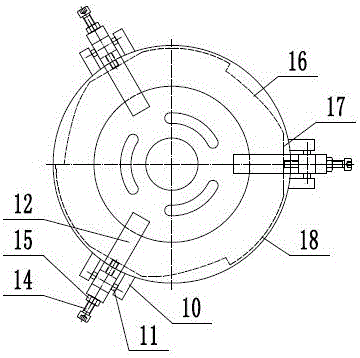

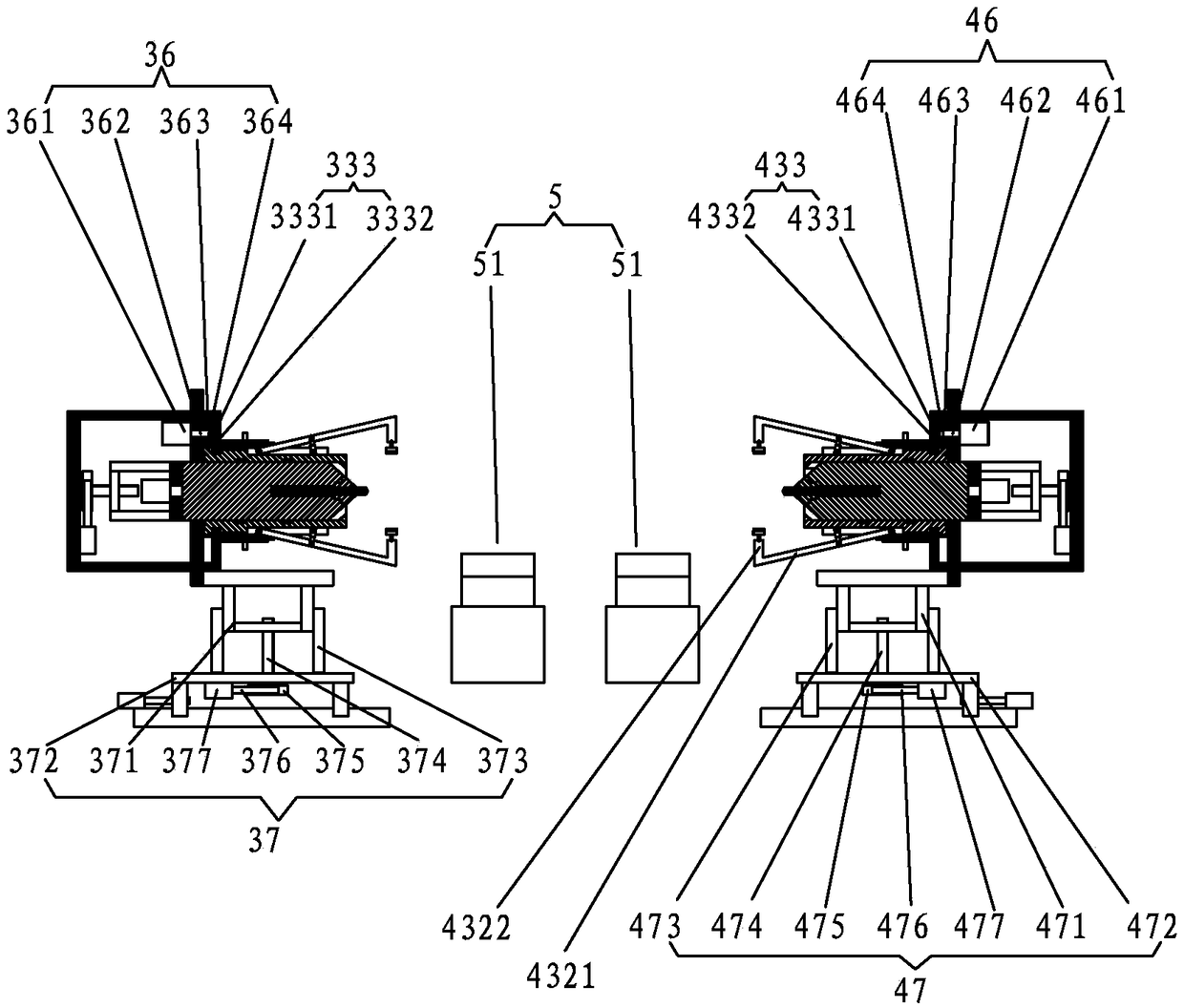

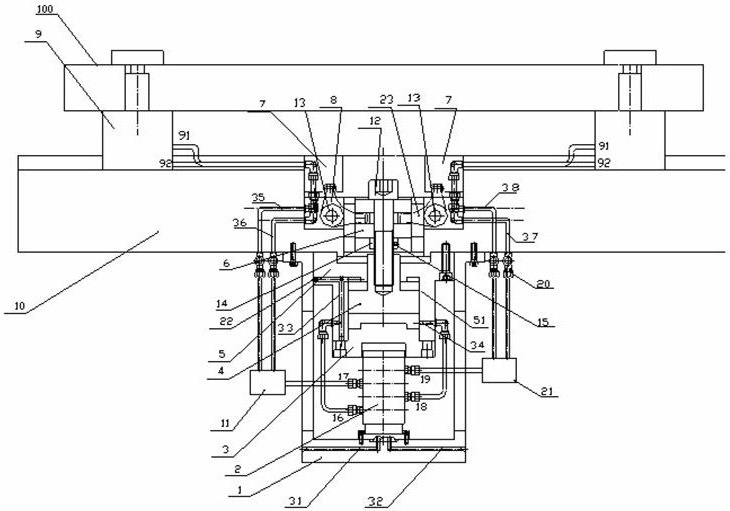

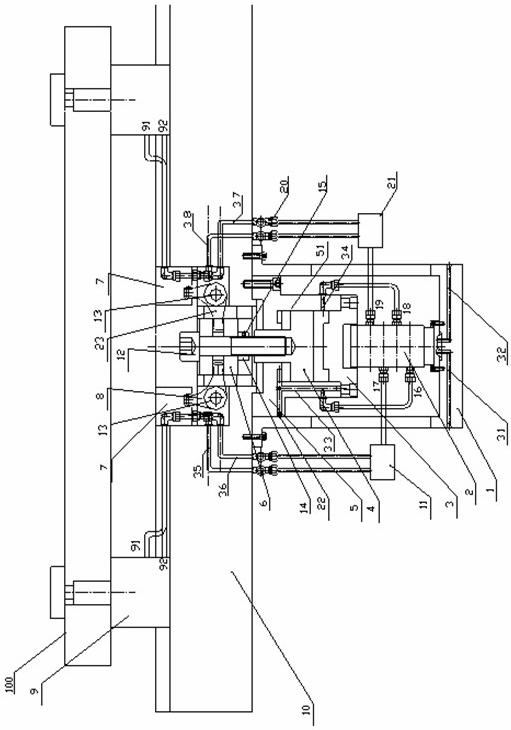

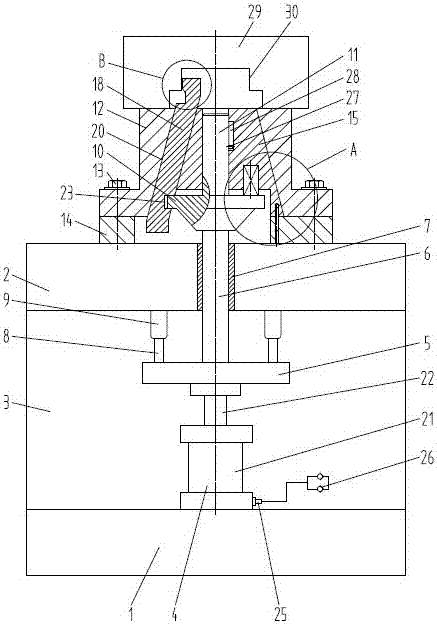

Automatic centering fixture for workpiece with revolution boss and/or hole

ActiveCN102765002AReduce workloadShorten the timePositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses an automatic centering fixture which comprises a base plate, at least one internal clamping device, at least one external clamp and a centering drive device, wherein a plurality of guide rails are radically and uniformly arranged on the base plate; an automatic centering slide block is arranged on each guide rail in a sliding manner; each internal clamping device is fixed on the corresponding automatic centering slide block so as to achieve the centering effect through tightly clamping the workpiece from an inner hole or propping against the workpiece from the outer outline of a revolution boss; the external clamps are radically mounted on the base plate so as to clamp the workpiece from the outer outline of the revolution boss; and the centering drive device is used for driving the automatic centering slide blocks to slide along the guide rails, so as to enable the internal clamping devices to be suitable for inner holes with different diameters and to achieve the clamping of the workpieces. Due to the adoption of the fixture provided by the invention, the workload and time for clamping and centering the workpiece with the revolution boss and / or the hole are greatly reduced, and the centering is accurate and the clamping is reliable.

Owner:JIANGSU GAOJING MECHANICAL & ELECTRICAL EQUIPMENT CO LTD

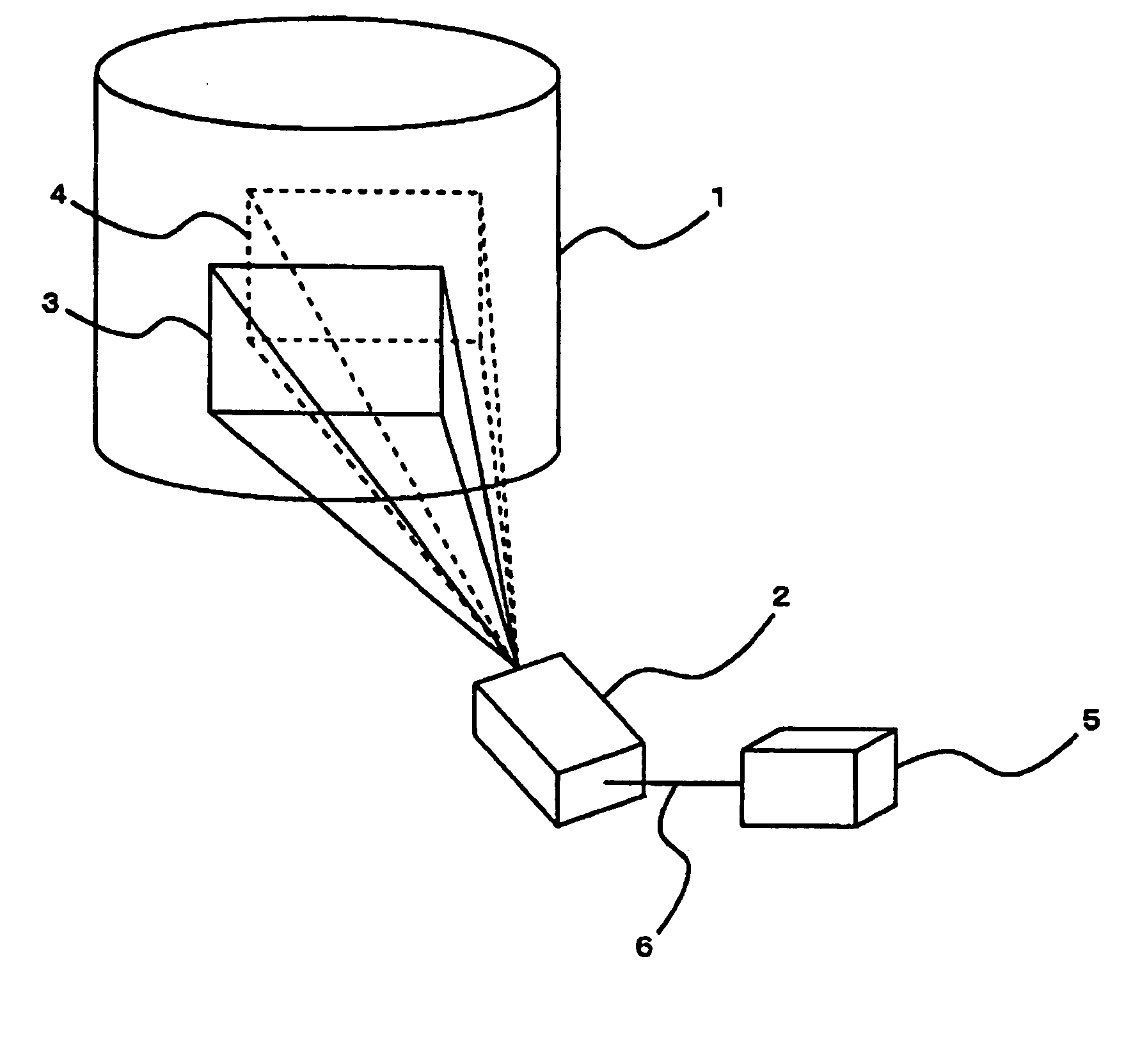

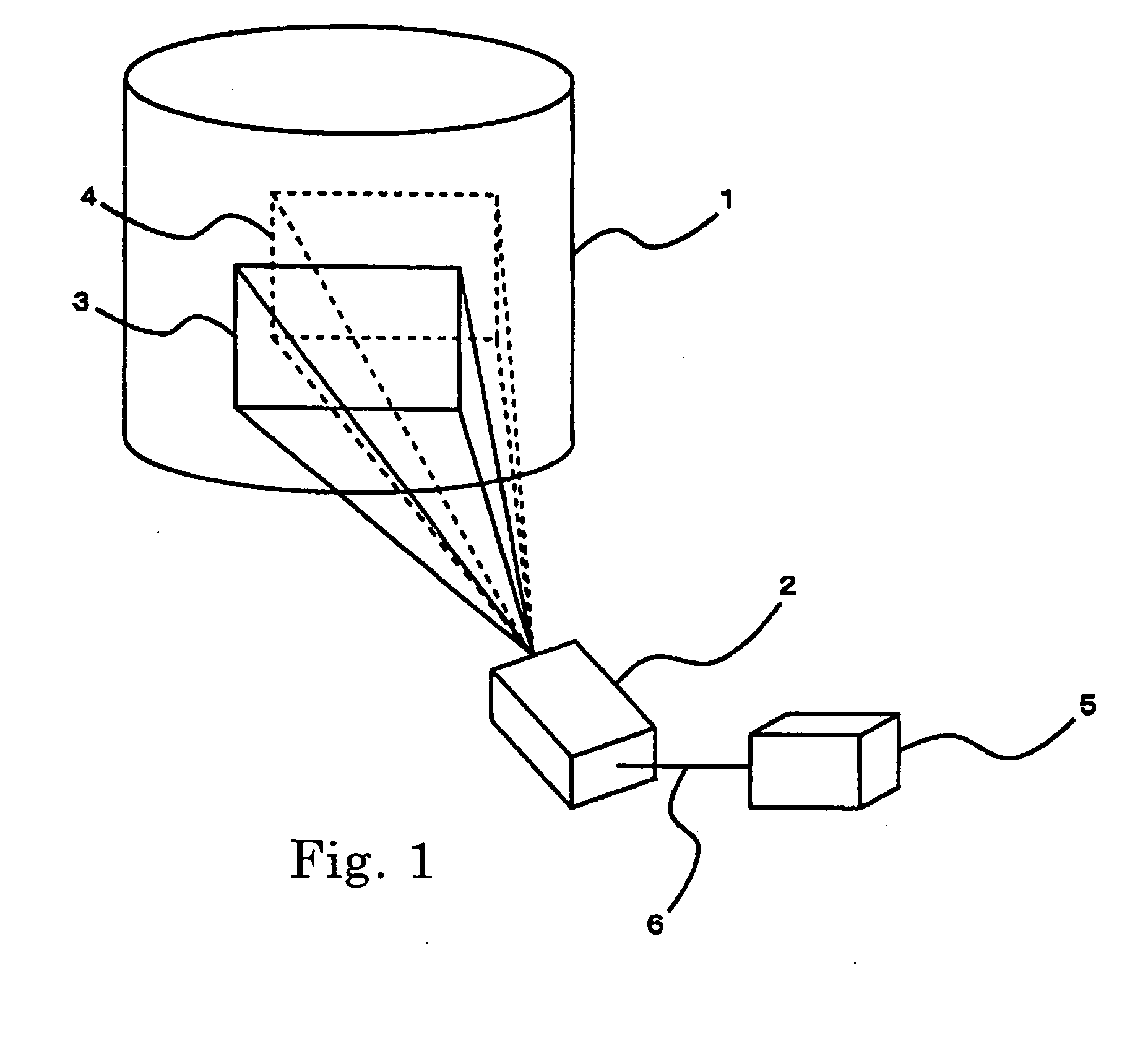

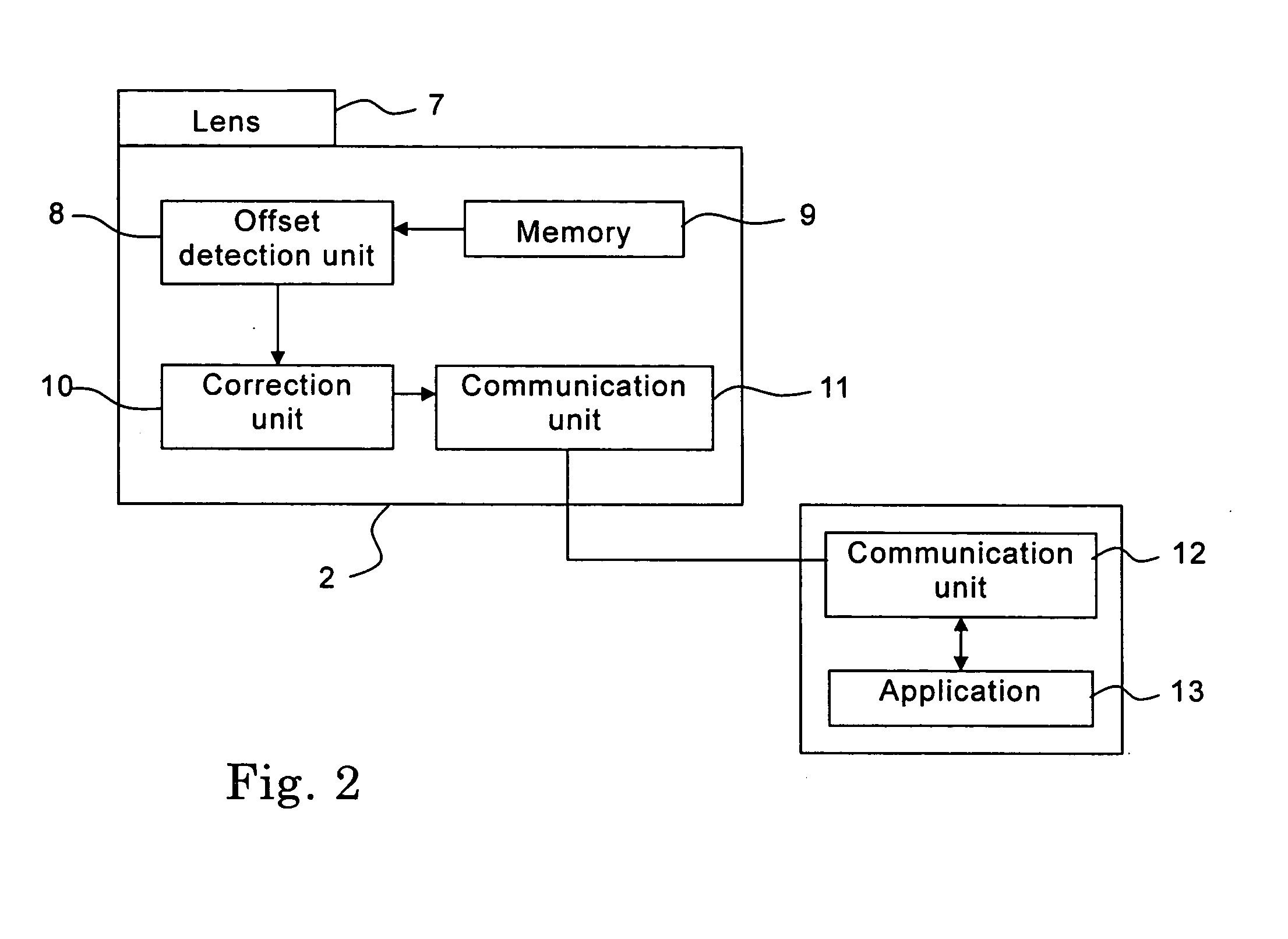

System for correcting optical center linked with lens shift

InactiveUS20050068506A1Television system detailsProjector focusing arrangementLens effectCenter effect

A system for correcting an optical center is provided with: a lens control unit for shifting a lens in vertical and horizontal directions; an offset detection unit for detecting a displacement of the optical center with respect to a screen on a basis of a magnitude of a shift of the lens effected by the lens control unit; a memory unit for storing in advance data on the centrally aligned location of the lens and also data on the positions of the optical center effected by lens shifts; and a correction unit for linking the displacement of the optical center detected by the offset detection unit with the data on the centrally aligned location of the lens and the data on the position of the optical center effected by the lens shift stored in the memory unit to correct the displacement of the optical center.

Owner:NEC VIEWTECH

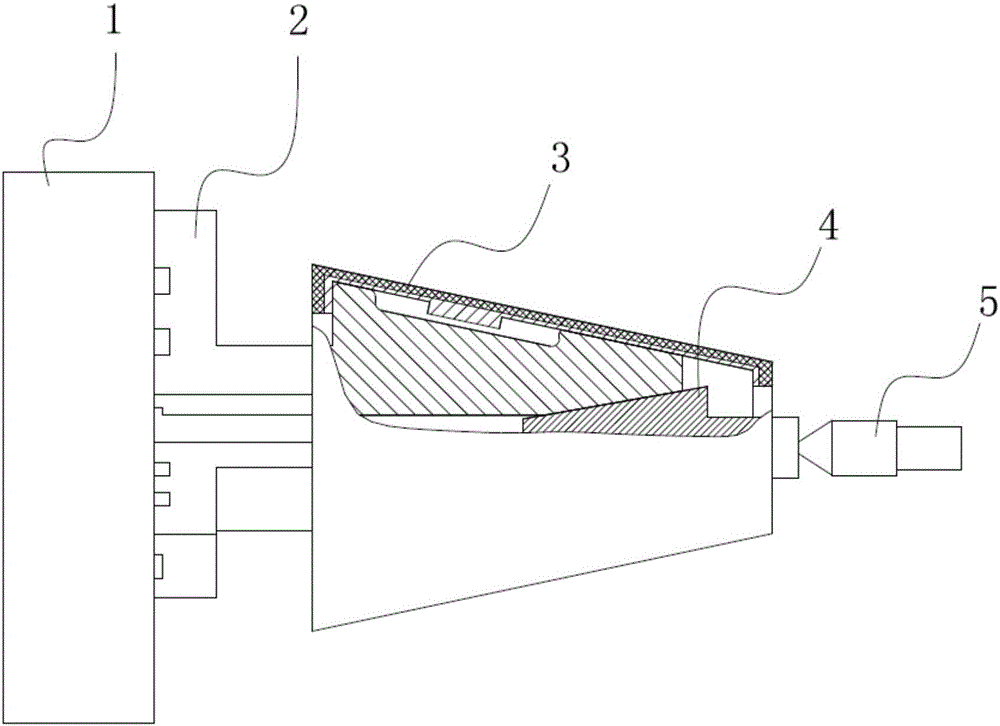

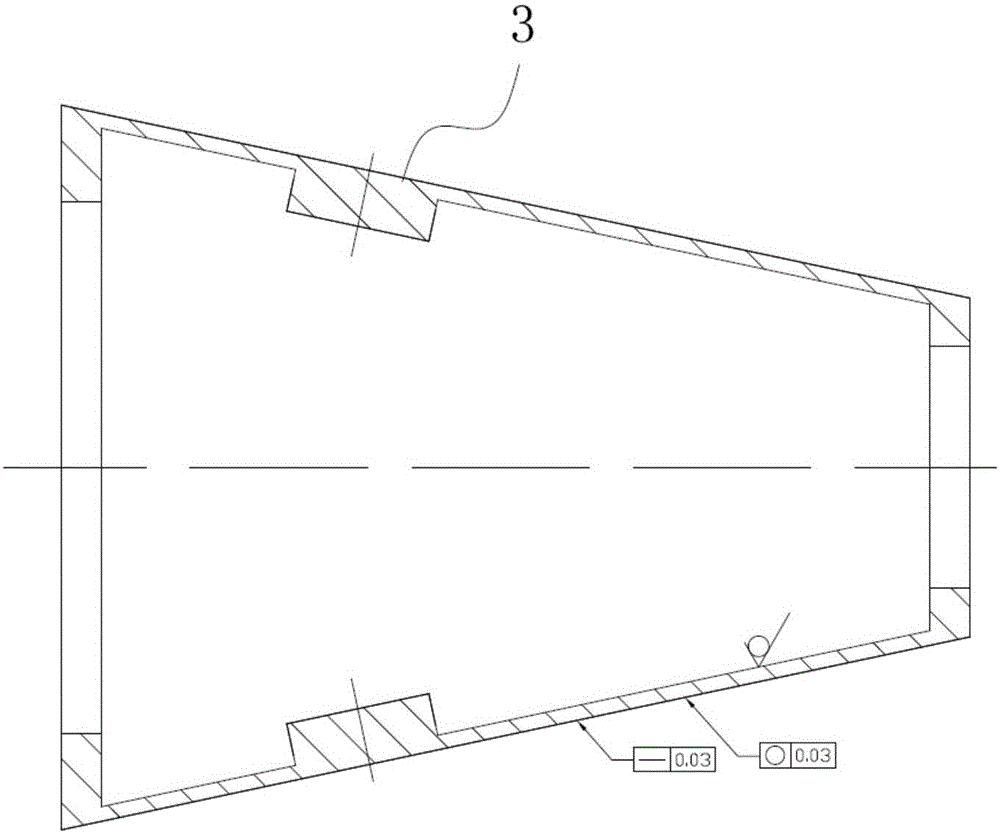

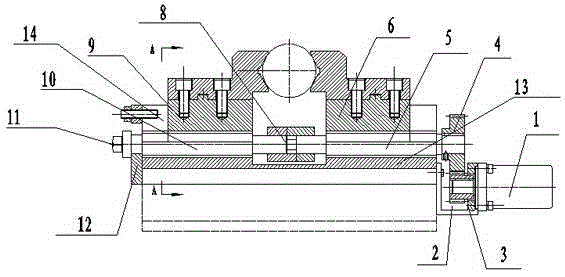

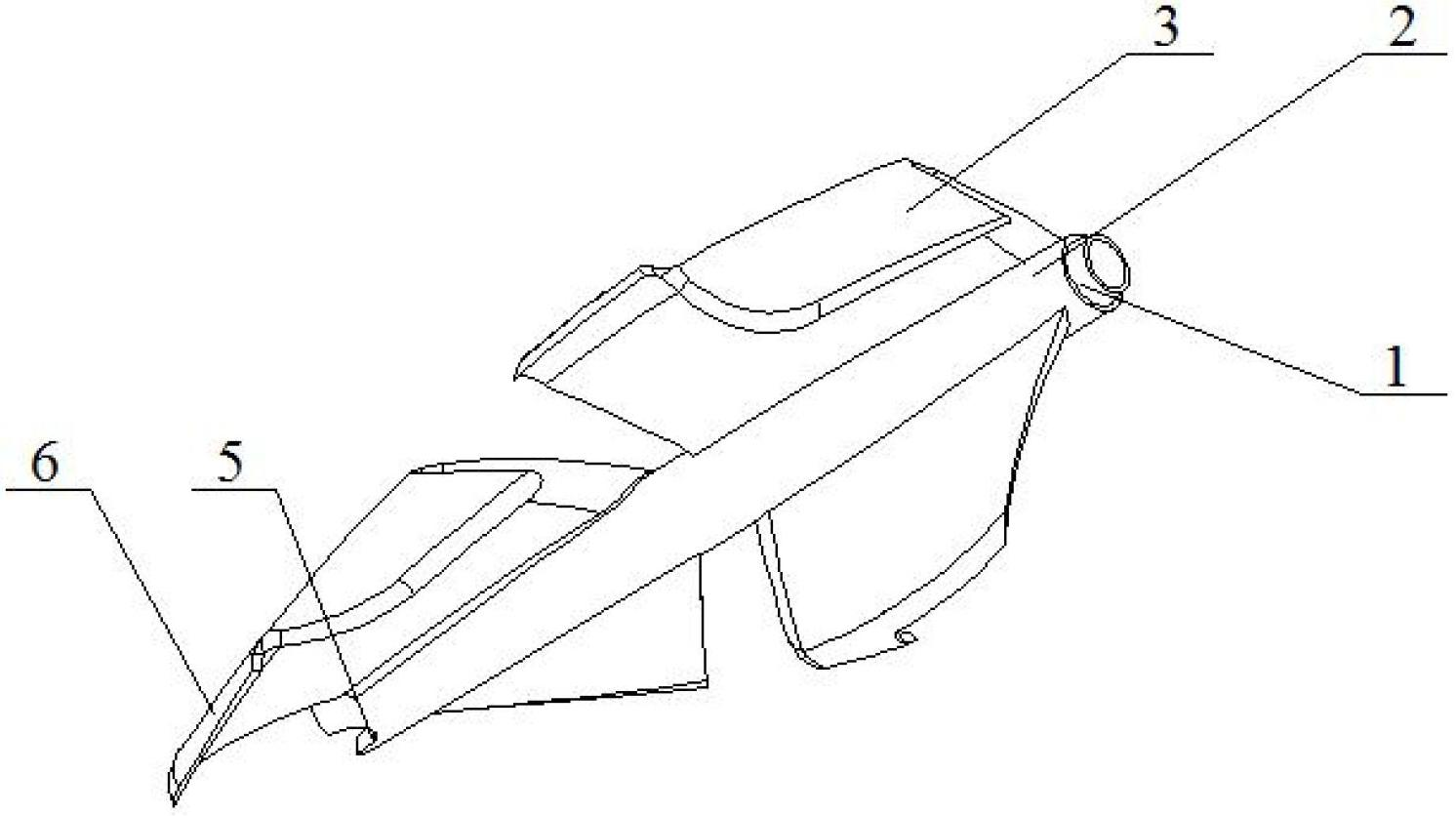

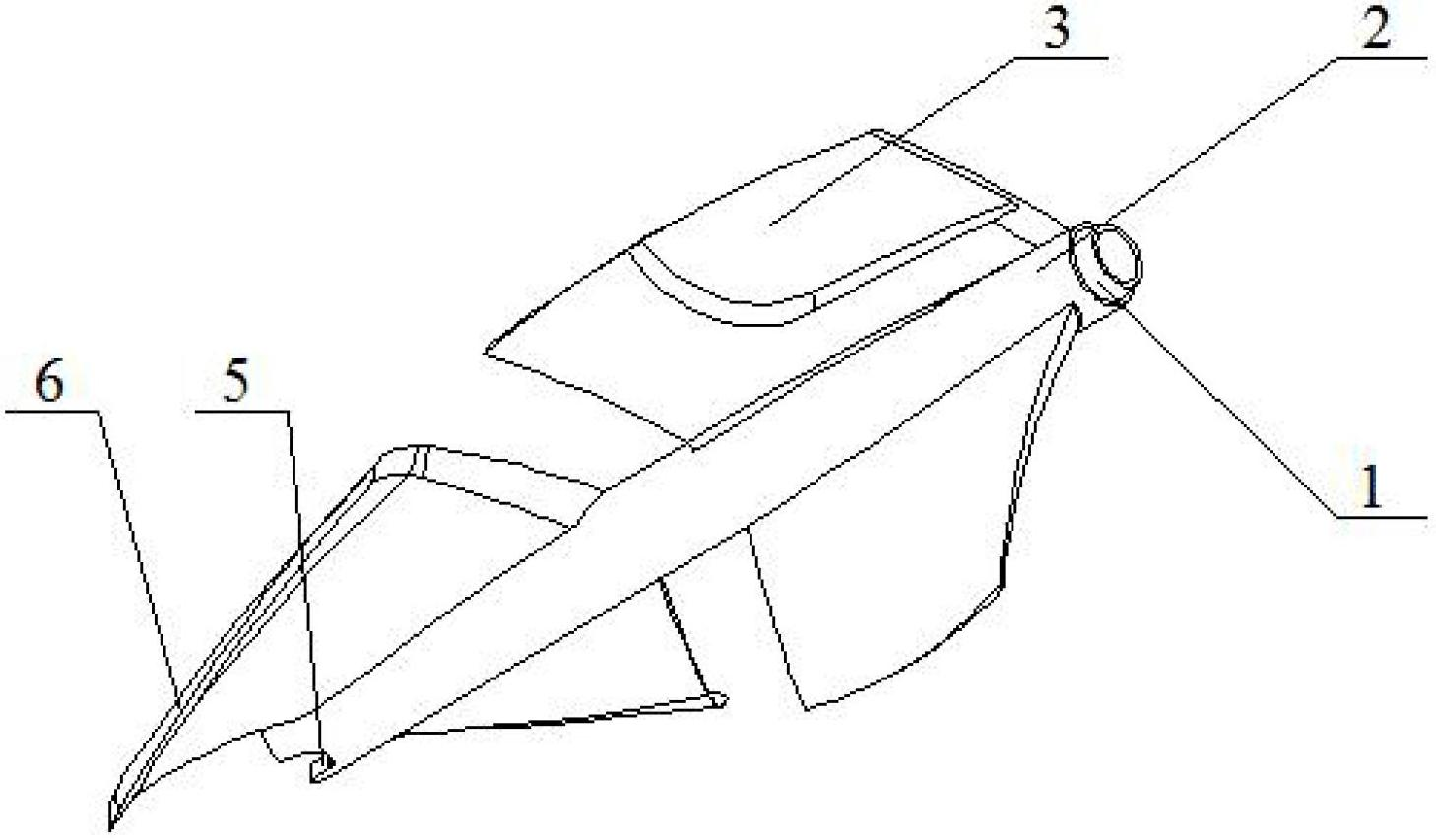

Machining device and method for conical thin wall shell body

ActiveCN106112035AHigh dimensional accuracyUniform wall thicknessExpansion mandrelsChucksIsoetes triquetraMachining process

The invention discloses a machining device and method for a conical thin wall shell body. The machining device comprises a chuck, three soft claws and a positioning tail cone, wherein the three soft claws are distributed in an equilateral triangle mode and installed on the chuck; and the front end shape of the positioning tail cone is matched with the shape of a conical groove, and the rear end of the positioning tail cone is provided with a centre hole. According to the machining device and method for the conical thin wall shell body, a clamping method that the soft claws with elastic claw parts are matched with the positioning tail cone, the positioning tail cone supports the tails of the soft claws, a center abuts against the positioning tail cone and enables the positioning tail cone to unfold the soft claws so that the soft claws can support the inner wall of a component is adopted, and the inner wall of the component and the inner side surface of the large end of the component are positioned. The soft claws support the inner wall, a lathe automatic centering effect and positioning of the positioning tail cone are combined, and the effect that the gyration center of the component and a lath spindle are concentric after clamping is ensured, so that quick clamping in the component machining process can be achieved, the gyration center of the component is automatically centered, and precise positioning is conducted; and the efficiency is high, clamping deformation is small, the machining dimensional precision of the component is high, the wall thickness is uniform, and the component dimensional precision requirements can be met more easily.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

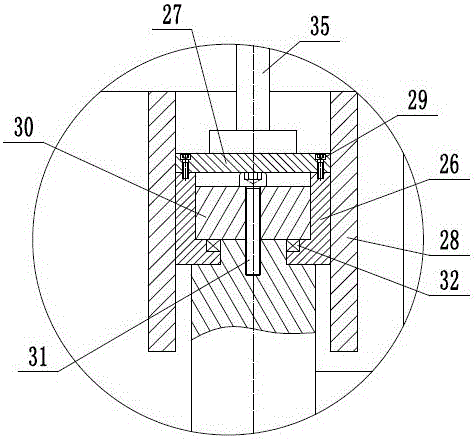

Clamping tool for cylinder-type workpiece

InactiveCN103121170ALarge clamping forceGood reassuring effectPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a clamping tool for a cylinder-type workpiece. When the clamping tool for the cylinder-type workpiece is worked, the cylinder-type workpiece is embedded in a center hole of a tensioning sleeve. When an adjustable bolt is tightened, a piston compresses liquid plastics. The expansion of the liquid plastics forces the inner hole to expand inwards so that the workpiece is clamped. The clamping tool for the cylinder-type workpiece has the advantages of being strong in clamping force and good in centering effects.

Owner:徐州市恒基伟业建材发展有限公司

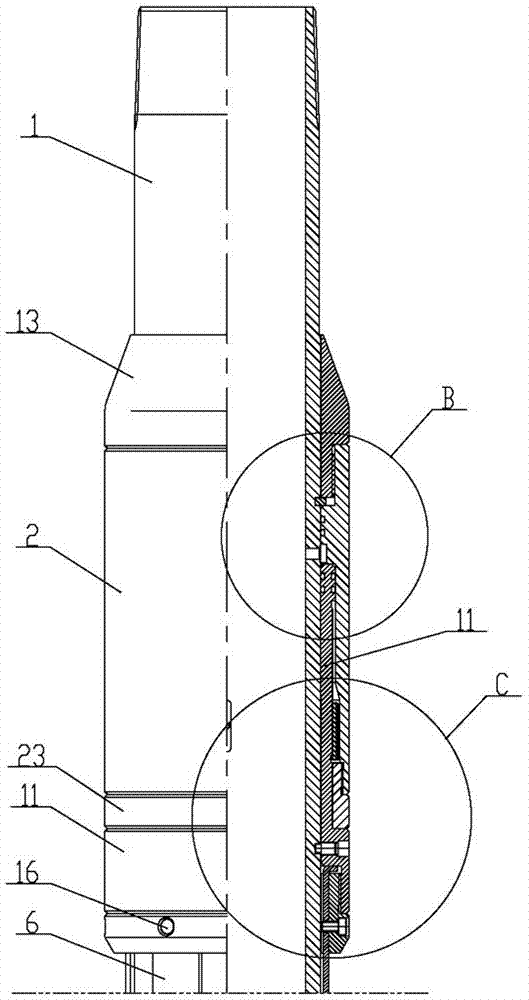

Hydraulic type sleeve pipe centralizer

InactiveCN107120073AWon't scratchStable supportDrilling rodsDrilling casingsHydraulic cylinderControl engineering

The invention relates to the technical field of oil-gas field down-hole tools and provides a hydraulic type sleeve pipe centralizer. The hydraulic type sleeve pipe centralizer comprises a core shaft, a hydraulic cylinder sleeve, a shearing dowel, an expanding assisting block and a centralizer plate spring; the upper portion of the hydraulic cylinder sleeve is mounted on the upper portion of the core shaft through a first fixing assembly, a liquid inflow hole is formed in the side wall of the core shaft, and a piston cylinder is mounted in a second annular cavity; a piston rod is mounted at the lower end of the piston cylinder; the lower end of the piston rod is mounted on the outer wall of the core shaft through the shearing dowel; the upper end of the centralizer plate spring is fixedly connected with the lower end of the piston rod through a second fixing assembly; the expanding assisting block is fixedly mounted on the outer wall of the middle of the core shaft; and the lower end of the centralizer plate spring is fixedly mounted on the outer wall of the lower portion of the core shaft through a third fixing assembly. The hydraulic type sleeve pipe centralizer is compact in structure, and stabbing and scraping over the well wall cannot be caused when the device is placed into a drill hole; hydraulic expanding seal is adopted, the outer diameter after expanding seal is large, the centering effect is better, center of a down-hole horizontal-section sleeve pipe is achieved, a cement loop is uniform, and improvement of the well cementation quality is facilitated.

Owner:CNPC XIBU DRILLING ENG

Nano-silver anionic far-infrared element fabric underwear for preventing and treating rheumatic arthritis

The invention discloses nano-silver anionic far-infrared element fabric underwear for preventing and treating rheumatic arthritis, and belongs to the technical field of the production of health element fiber fabric underwear. The content of zinc in human bones is 50 percent of the total amount of the zinc in a human body, and intractable arthritis is caused by the deficiency of zinc, selenium, strontium, calcium and the like in human bodies and the unbalance of elements in the human bodies. In the invention, anionic tourmaline nano-powder can be automatically generated by using medical stone nano-powder which is rich in trace elements; the anionic tourmaline nano-powder, selenium and germanium elements which are rare on the earth and are deficient in the human bodies and Chinese medicines are nano-crushed and then are specially treated by a high-tech process to ensure that each kind of trace element has a positive charge center effect; then the elements are refined into the manufacturing process of a fiber fabric so as to obtain a durable functional element fiber fabric; and the elements are permeated into the human bodies through skin pores and sweat pores by closely contacting the skin so as to balance the elements in the human bodies, strengthen organism immunity and improve disease resistance; therefore, the element fabric underwear for preventing and treating rheumatic arthritis fulfills the aim of better curing the disease.

Owner:成进学

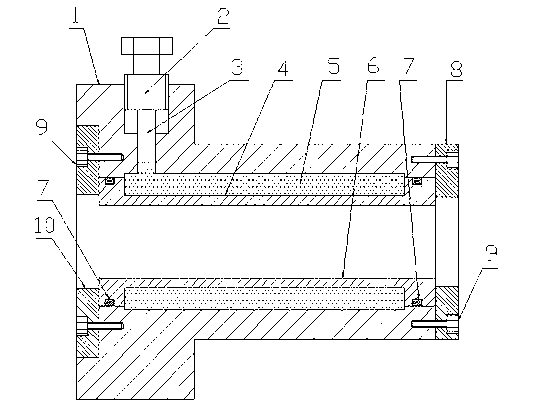

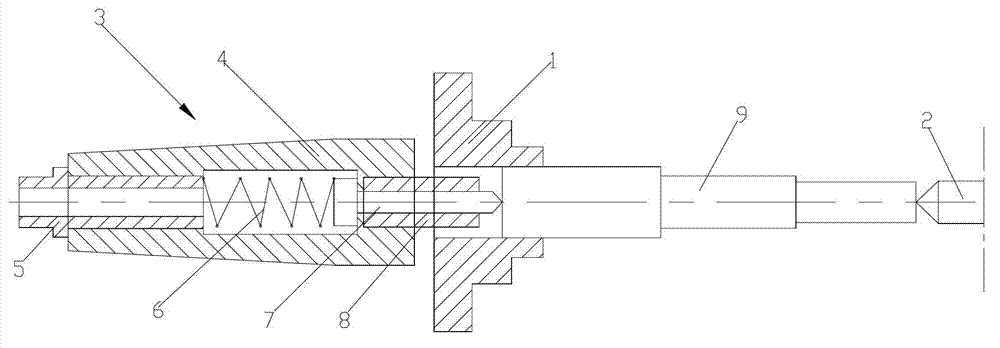

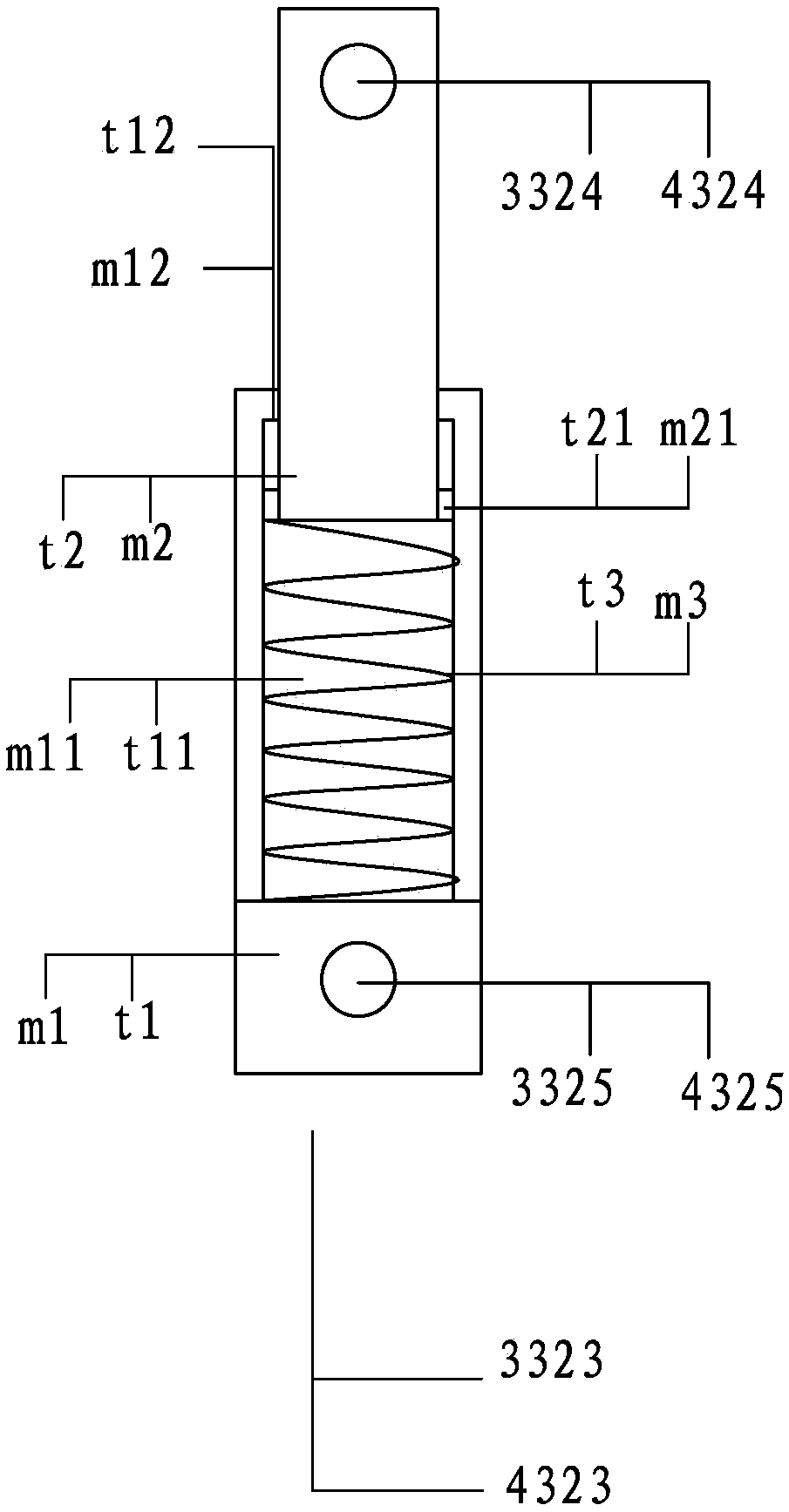

Device for clamping workpiece of machine tool

InactiveCN102806477AGuaranteed length dimensionGuaranteed machining accuracyTailstocks/centresPositioning apparatusMachine toolCenter effect

The invention discloses a device for clamping a workpiece of a machine tool. The device comprises a three-jaw chuck and a back tip, wherein an elastic movable tip is arranged behind the three-jaw chuck, and comprises a taper sleeve; a plug, a compression spring and a front tip are arranged in the taper sleeve; the compression spring is connected between the plug and the front tip; the front tip is extended towards the inside of the three-jaw chuck; a limit block which is extended towards the inside of the three-jaw chuck is sleeve on the rod part of the front tip; and the center of the front tip and the center of the back tip are positioned on the same horizontal line. Due to the adoption of the elasticity of the compression spring, the front tip can be stretched and retracted in the axial direction, is matched with a central hole at the positioning reference end of the workpiece all the time and has a centering effect, and the other end of the workpiece is pressed by the back tip, so that the front tip is compressed to the positioning reference end surface of the workpiece and then is contacted with the limit block, the three-jaw chuck is tightly locked, and the axis of the workpiece in the length direction and the center of the workpiece are positioned on the same horizontal line; and therefore, the machining accuracy of the workpiece is ensured, and the yield of a product is improved.

Owner:SUZHOU DONGLI MACHINERY

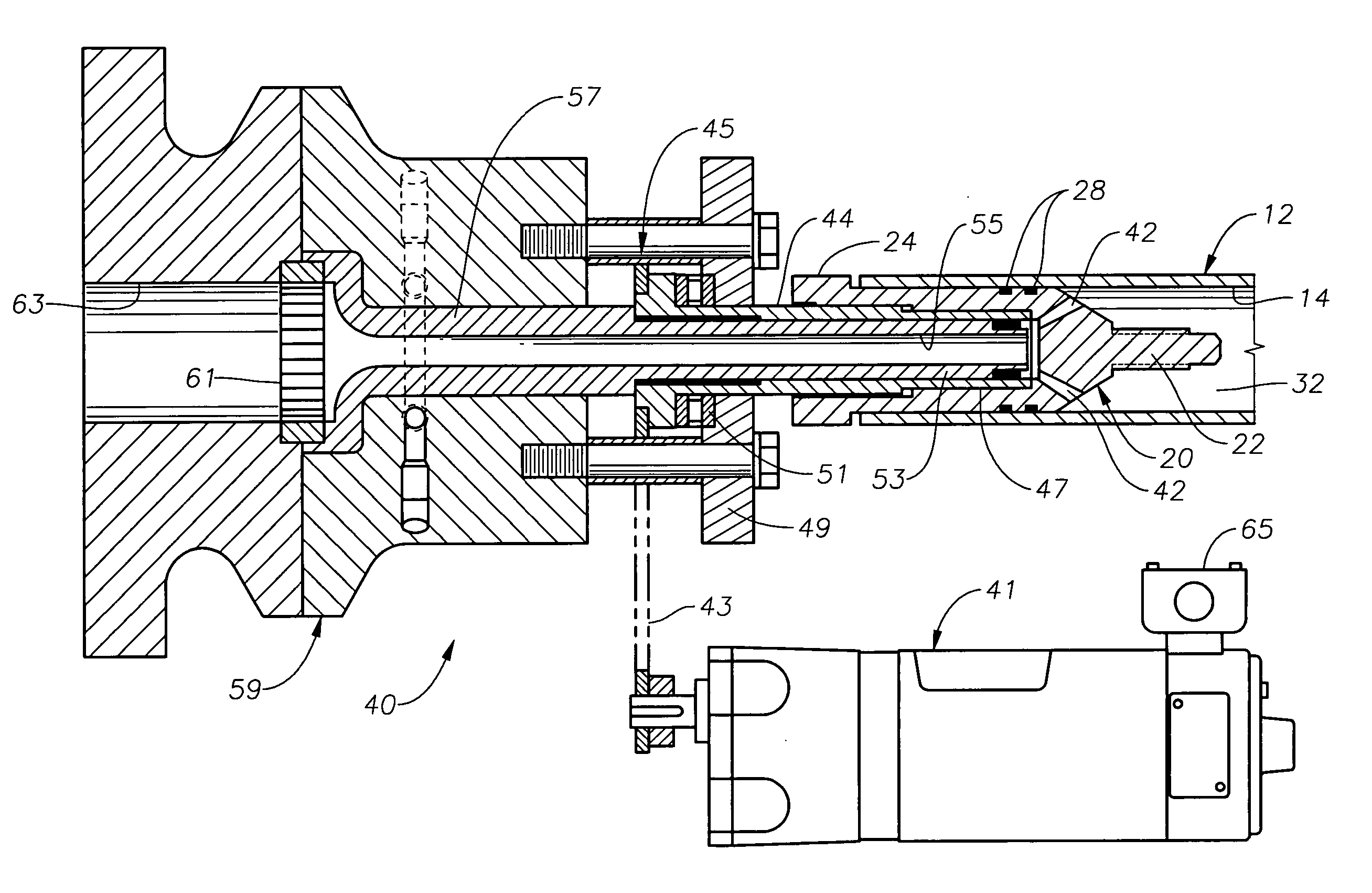

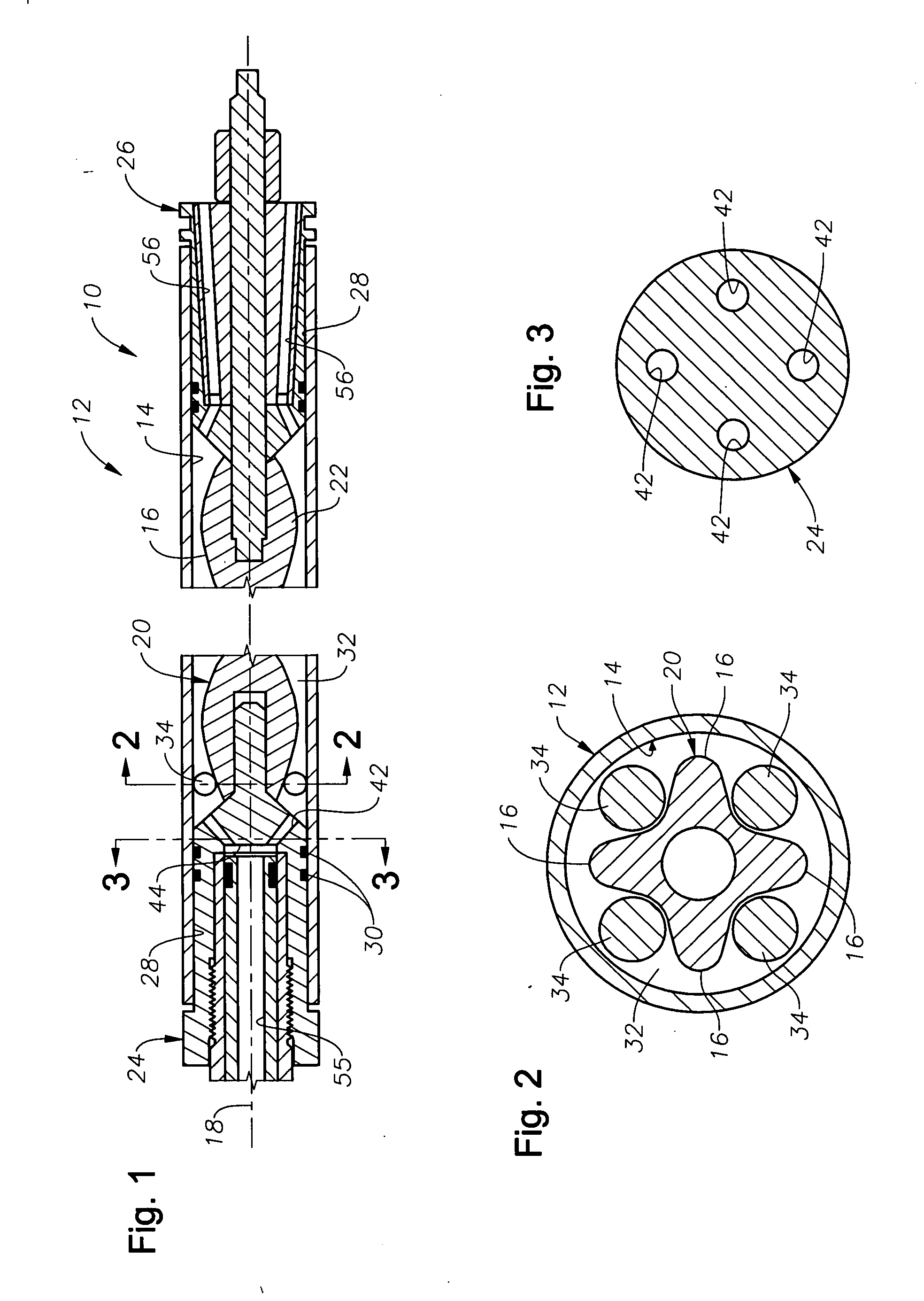

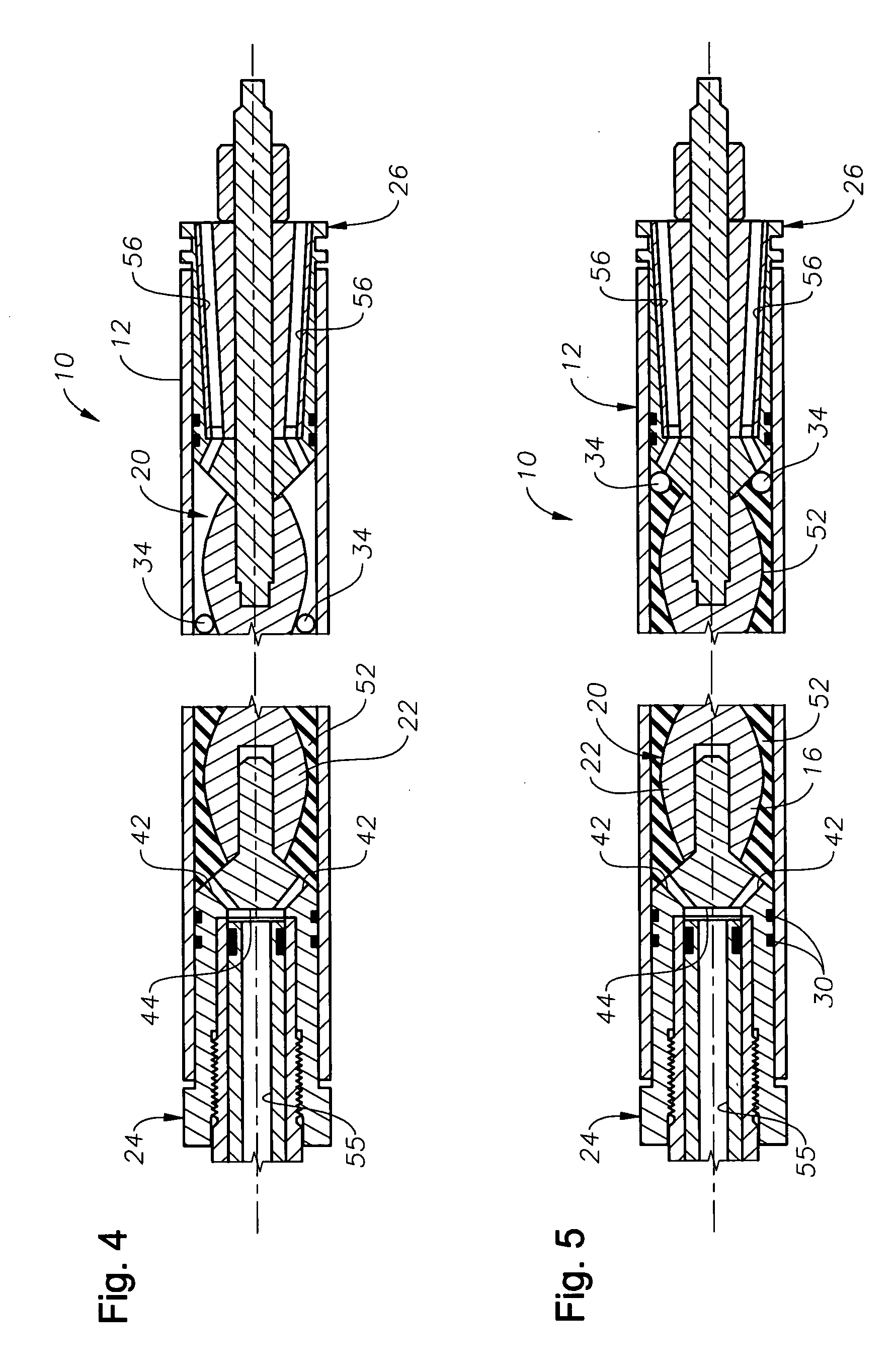

Method of molding progressive cavity pump stators

InactiveUS20050285305A1Without effectUniform shapeRotary piston pumpsCeramic shaping apparatusInterference fitEngineering

Devices and methods for construction of a stator for a progressive cavity pump without the off centering effect created by gravity. A stator mold is assembled by placing a center section, or core, inside an outer stator housing tube to form a mold assembly. The core has a narrow central portion and a cone-shaped end portion at each axial end. The end assemblies provide an interference fit within the outer housing tube and retain the narrow central portion centrally within the housing tube. A mold space, or injection space, is defined between the housing tube and the core. Traveling spacers are disposed within the mold injection space and are capable of lateral movement therewithin. During injection molding and curing, the mold assembly is oriented in a substantially horizontal position and rotated about its central longitudinal axis.

Owner:BAKER HUGHES INC

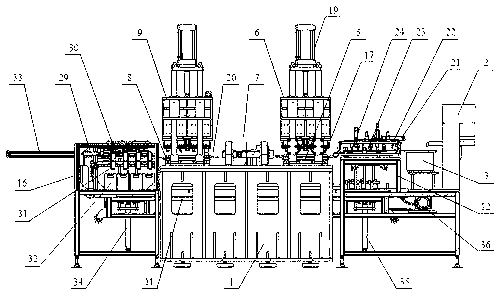

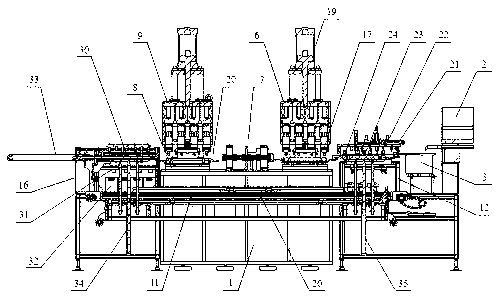

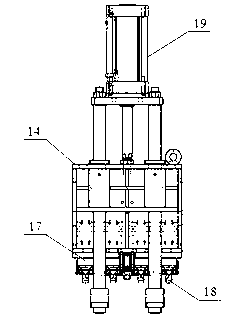

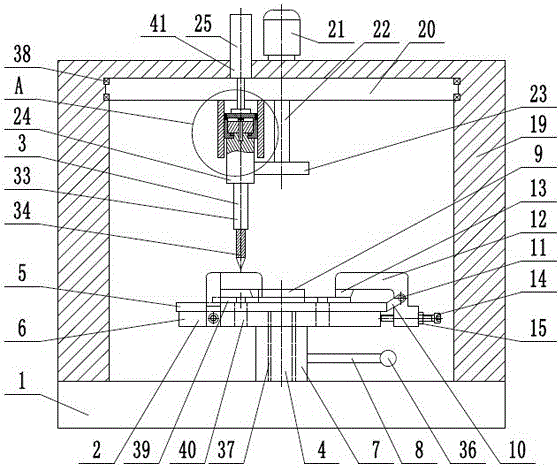

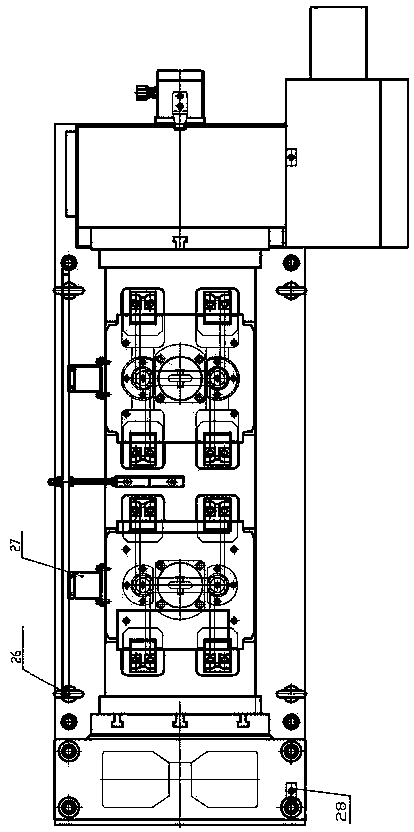

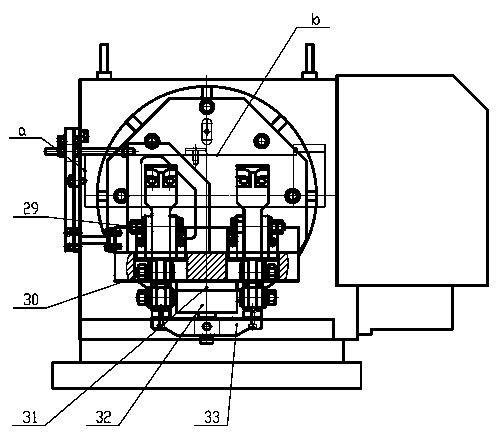

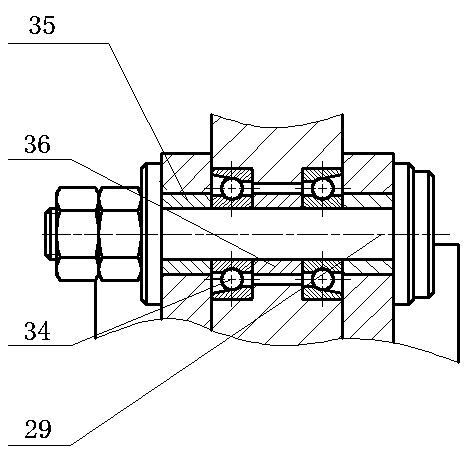

Multi-station electrolysis precise grinding automatic machine

InactiveCN103273402AReduce lossGuaranteed machining accuracyGrinding machinesGrinding work supportsElectrolysisEngineering

The invention relates to a multi-station electrolysis precise grinding automatic machine, and belongs to devices for conducting full-automatic grinding machining on the inner surface and the outer surface of a shaver net. The multi-station electrolysis precise grinding automatic machine adopts a follow clamp of a ship-plate type structure, can automatically feed and discharge materials, can conduct simultaneous operations at eight stations, uses an electrolytic action and an electric conduction grinding wheel with mechanical grinding capacity to conduct machining on the shaver net, greatly improves work efficiency, machining stability and accuracy, reduces losses of the grinding wheel and saves production cost. Machining on the front face and the back face of a machined piece can be achieved on one machine through a turnover device. Electrolytic machining is carried out on the machined piece through the electrode power supply electric conduction mode, the soft sheet connection electric conduction mode, the floating steel ring electric conduction mode and the insulation sleeve insulation electric conduction mode. Zirconia ceramics are made into a base to serve as a support due to the characteristics of insulation, abrasion resistance and high temperature resistance of the zirconia ceramics, and the centering effects of the machining position of the machined piece are achieved. An air-tight seal is adopted to prevent the situation that electrolytes spill out or atomize so as to enter a main grinding shaft box to abrade parts when the grinding wheel conducts grinding.

Owner:DALIAN JIADEHENG SCI & TECH

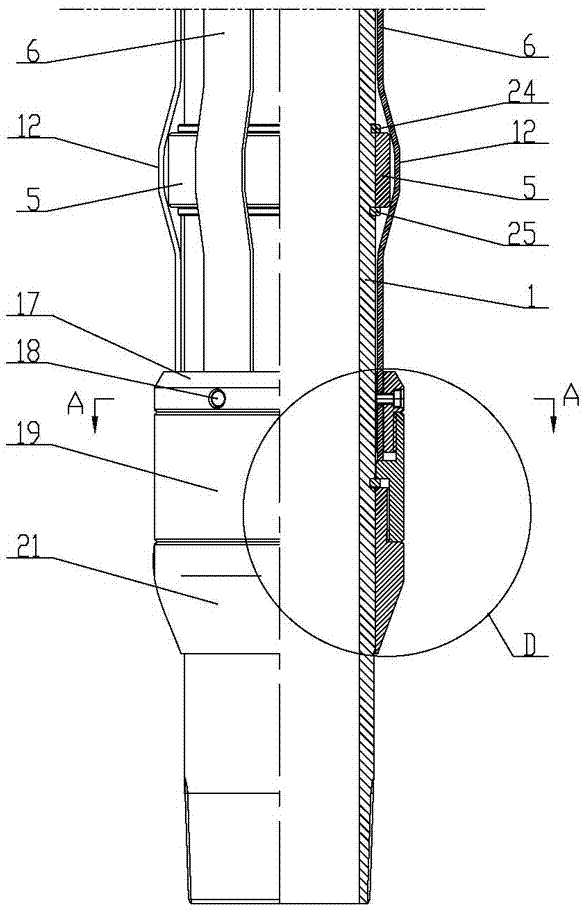

Tubular pile centering device for slant well drilling rig

InactiveCN103452505ANeutral goodEasy to handleDrilling rodsDrilling casingsHydraulic cylinderWell drilling

The invention relates to an oil-field slant well drilling rig, in particular to a tubular pile centering device for a slant well drilling rig. Two ends of a front connecting rod and a rear connecting rod of the device are connected to an auxiliary arm and a main arm through rotary shafts, a mechanical limit device is welded to the auxiliary arm, a screw seat and guide rail of a distance regulating device are connected to the main arm through bolts, a supporting rod of the distance regulating device is connected to a rear connecting rods through a pin, a hydraulic cylinder seat is welded to the main arm, and a hydraulic cylinder operated with the hydraulic cylinder seat is connected to the front connecting rods. By the aid of the tubular pile centering device, centering a tubular pile which is horizontally stored and which is moved accurately and rapidly with a wellhead drilling pile can be realized, tubular pile centering performances are fine, so that the drilling rig tubular pile processing procedure is simple, secure and reliable, automation degree of a slant well drilling rig tubular pile processing system can be increased, and the defects that an existing slant well drilling rig tubular pile processing procedure is complex, tubular pile centering effect is unexpected, operating efficiency is low, and security is poor are overcome.

Owner:CNPC BOHAI EQUIP MFG +1

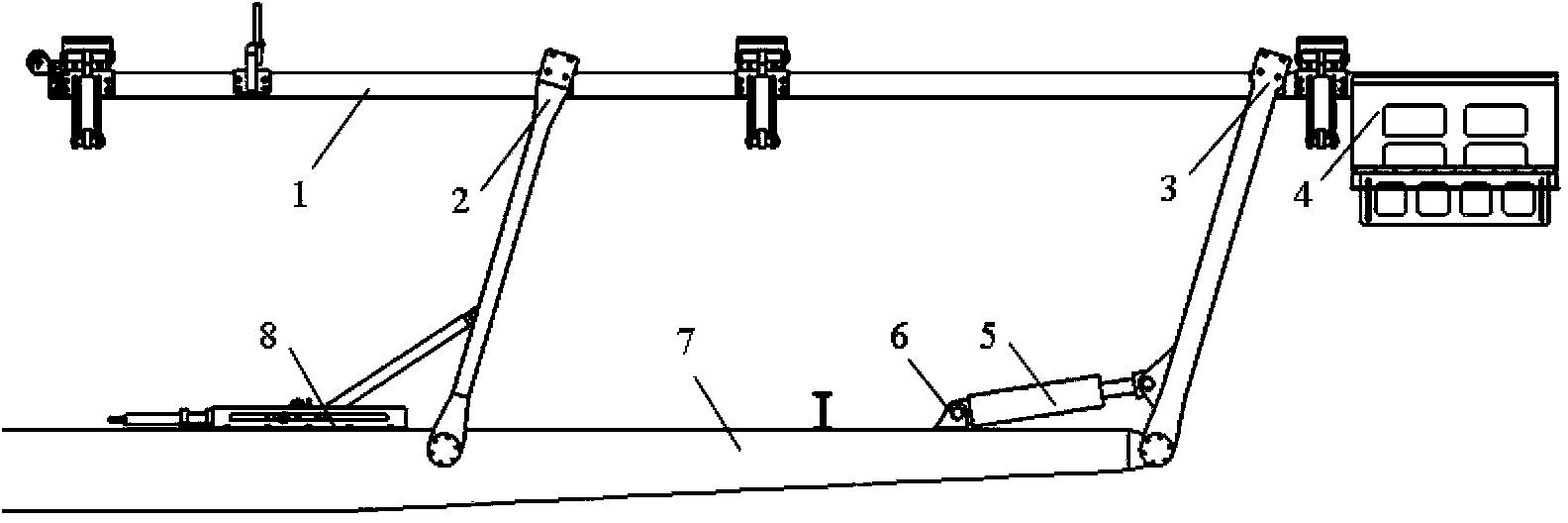

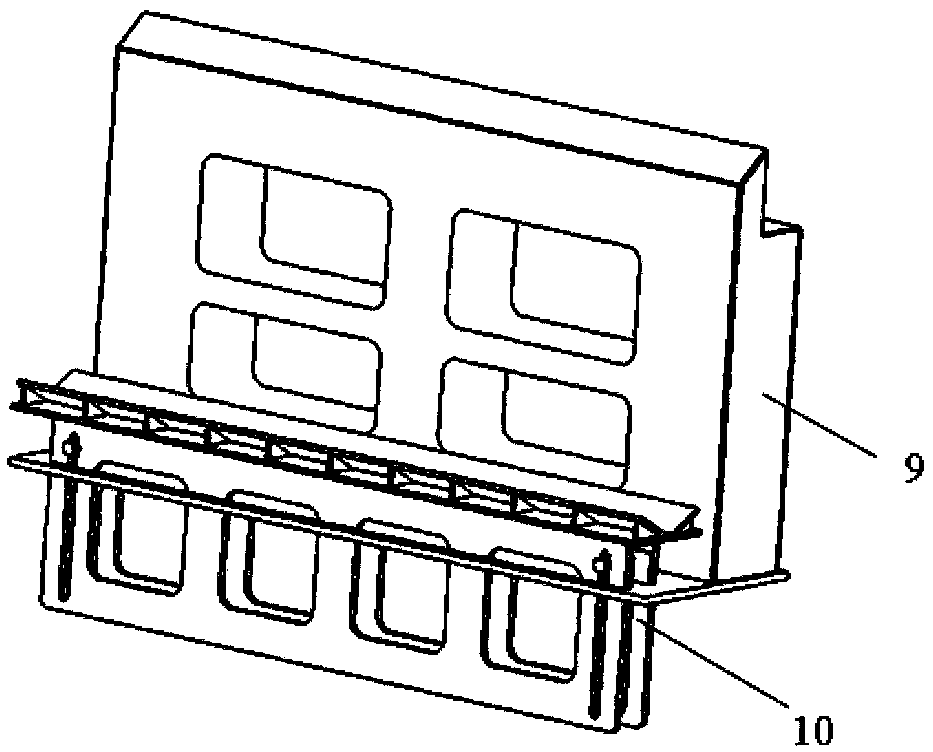

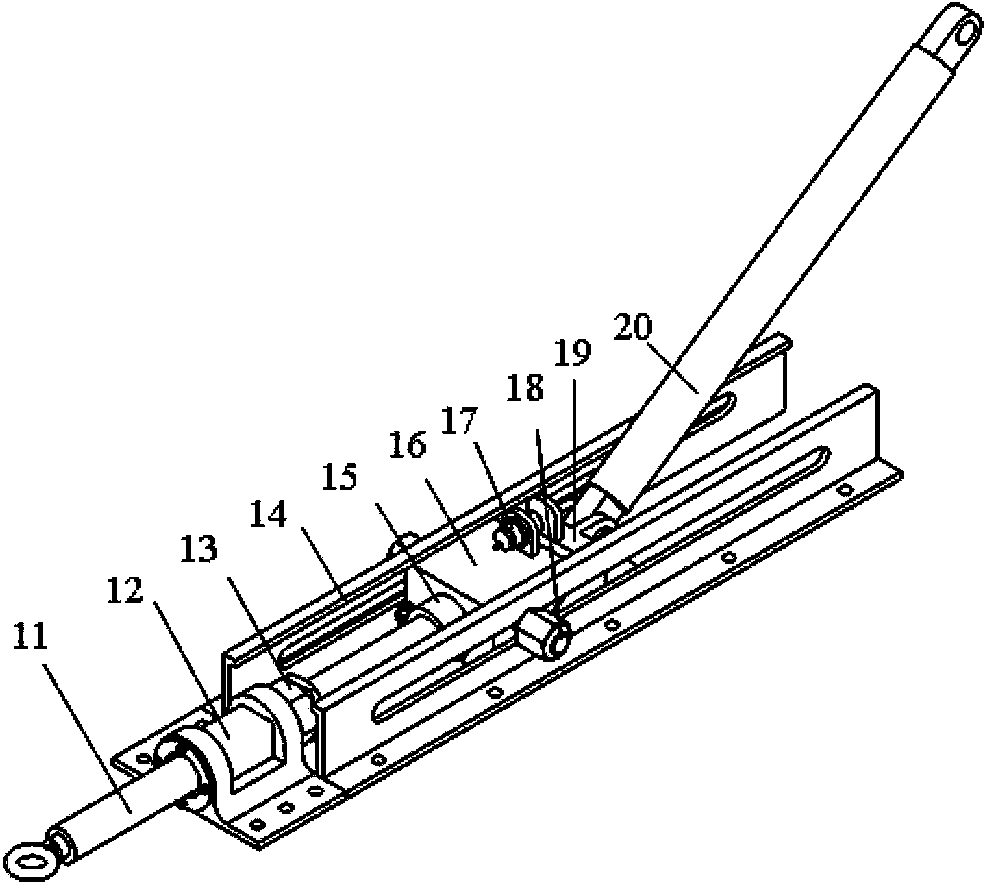

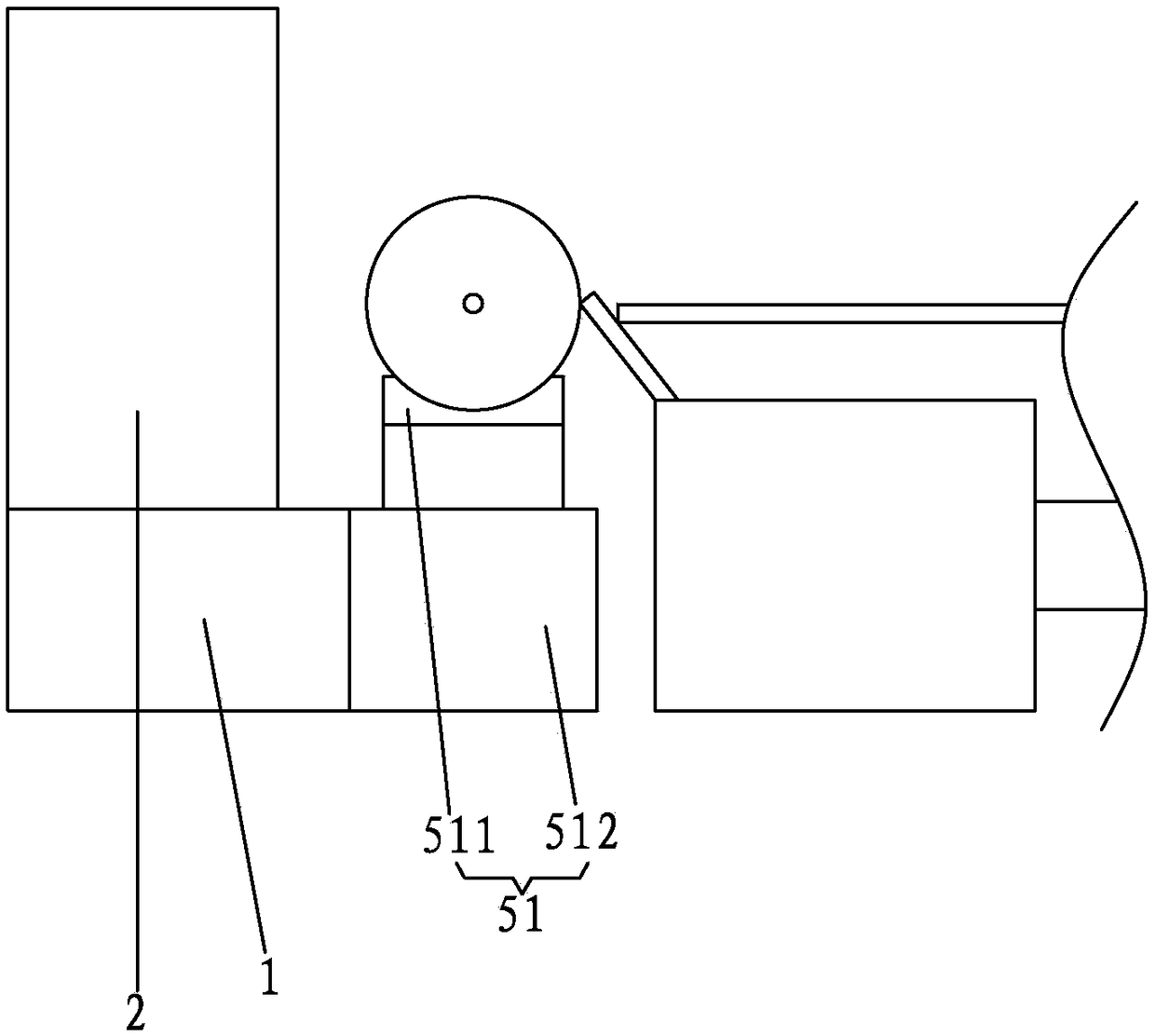

Single-rail crane for belt conveyor overhead automatic inspection system

InactiveCN104386445AImprove structural strengthCompact structureConveyorsControl devices for conveyorsAnti jammingAutomatic routing

The invention provides a single-rail crane for a belt conveyor overhead automatic inspection system. The single-rail crane mainly consists of two sliding frames and a tensioning device, wherein the two sliding frames are symmetrically arranged in an I-shaped steel guide rail groove, a centering mechanism and a rail cleaning device are symmetrically arranged on a support plate of the sliding frames, the intensity of the tensioning force of the tensioning device can be regulated through a screw bolt regulating mechanism, and the centering mechanism can ensure the centering effect through regulating the deformation quantity of the centering wheel, so that the anti-deflection performance of the single-rail crane is ensured; the rail sweeping device can realize the cleaning on sundries on the rail surface used for carrying the single-rail crane, and the anti-jamming cavity of the single-rail crane can be enhanced. The single-rail crane provided by the invention is applicable to an overhead automatic routing inspection system of coal mine transportation, and is particularly applicable to the overhead automatic routing inspection system of a belt roadway of a belt conveyor. The single-rail crane has the advantages that the structure is compact, safety and high efficiency are realized, and meanwhile, the single-rail crane has higher stability and reliability.

Owner:CHINA UNIV OF MINING & TECH +1

Slot body processing device of brake disc

InactiveCN106808001AAchieve clampingAchieve regulationFeeding apparatusMilling equipment detailsGear wheelDrive motor

The invention provides a slot body processing device of a brake disc, and belongs to the technical field of mechanical processing. The slot body processing device comprises a clamping mechanism and a slot body processing mechanism, wherein a cam and a supporting sleeve of the clamping mechanism can be rotatably arranged on a supporting shaft; a clamping jaw is hinged on a supporting lug through a pin roll; a regulating bolt is always in contact with the cam under dead weight of the clamping claw; a drive motor of the slot body processing mechanism is coaxially connected with a rotary disc through a rotary disc shaft; the drive motor is further coaxially connected with a first gear; a slide supporting base can be arranged on a guide supporting base up and down in a sliding mode; an end cover is connected with a slide supporting base through a fastening bolt; the lower end of a piston rod of a drive air cylinder is connected with the end cover; a rotary support can be rotatably arranged in the slide supporting base; a connecting bolt is connected with the rotary support and a second gear; the first gear is mutually engaged with the second gear; and a drill bit is mounted on a tool mounting base. The slot body processing device is good in clamping and centering effect on the brake disc, realizes processing of a long U-shaped slot of the brake disc, is reasonable in structure and is good in reliability.

Owner:桐乡市大周商贸有限公司

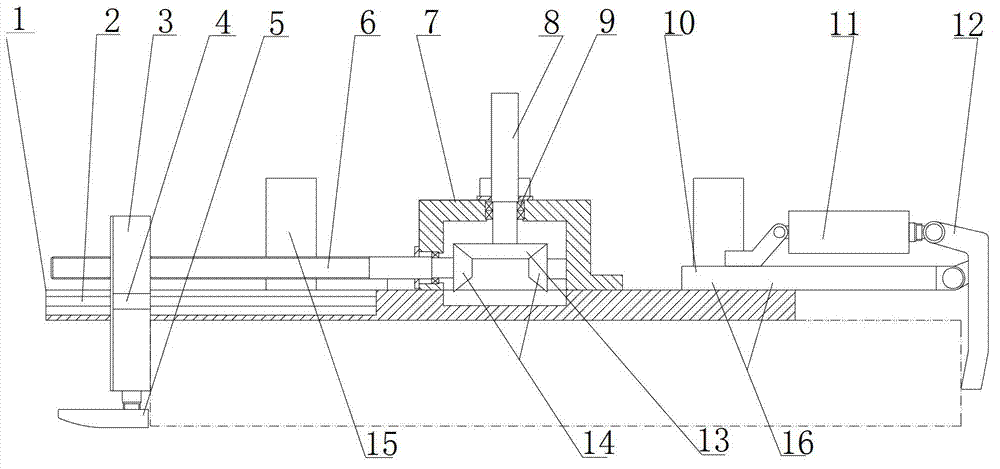

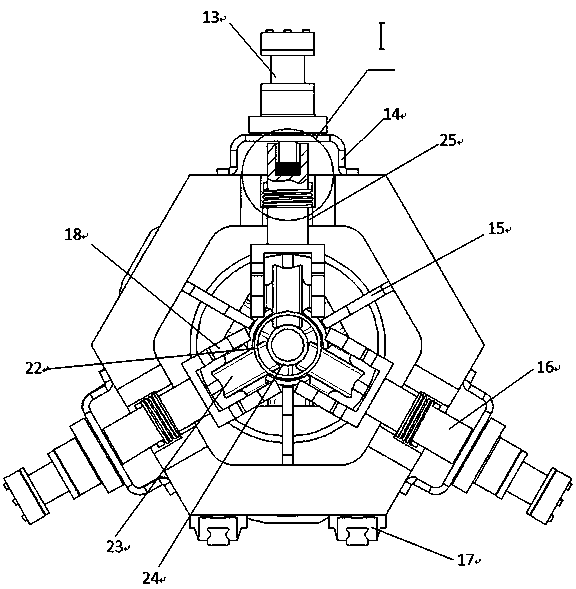

Automatic centering and clamping device for pipes

InactiveCN105619100AReliable clampingThe clamping process is automatically centered and firmWork holdersPositioning apparatusMotor driveEngineering

An automatic centering and clamping device for pipes is provided with a base 13, wherein a right screw rod 5 and a left screw rod 10 are arranged in the base 13, and a right rotation slide base 6 is arranged in a T-shaped groove, located above the right screw rod 5, of the base 13; when a hydraulic oil motor 1 works, a pinion drives a gearwheel to do rotation motion, then the left screw rod 10 and the right screw rod 5 rotate synchronously, a left rotation slide base and the right rotation slide base are driven to move inwards or outwards simultaneously, and therefore a V-shaped clamping jaw 7 automatically clamps or releases the pipes. By arranging the clamping jaw to be of the V shape, the pipes can be automatically centered in the clamped process and can be clamped more firmly. The hydraulic oil motor drives the pinion and the gearwheel to rotate for driving the screw rods to rotate, and therefore the left rotation slide base and the right rotation slide base move outwards after moving inwards simultaneously for clamping or releasing the pipes. The automatic centering and clamping device is simple in structure, good in centering effect, large in clamping force and high in clamping efficiency.

Owner:扬州市油田金达实业有限公司

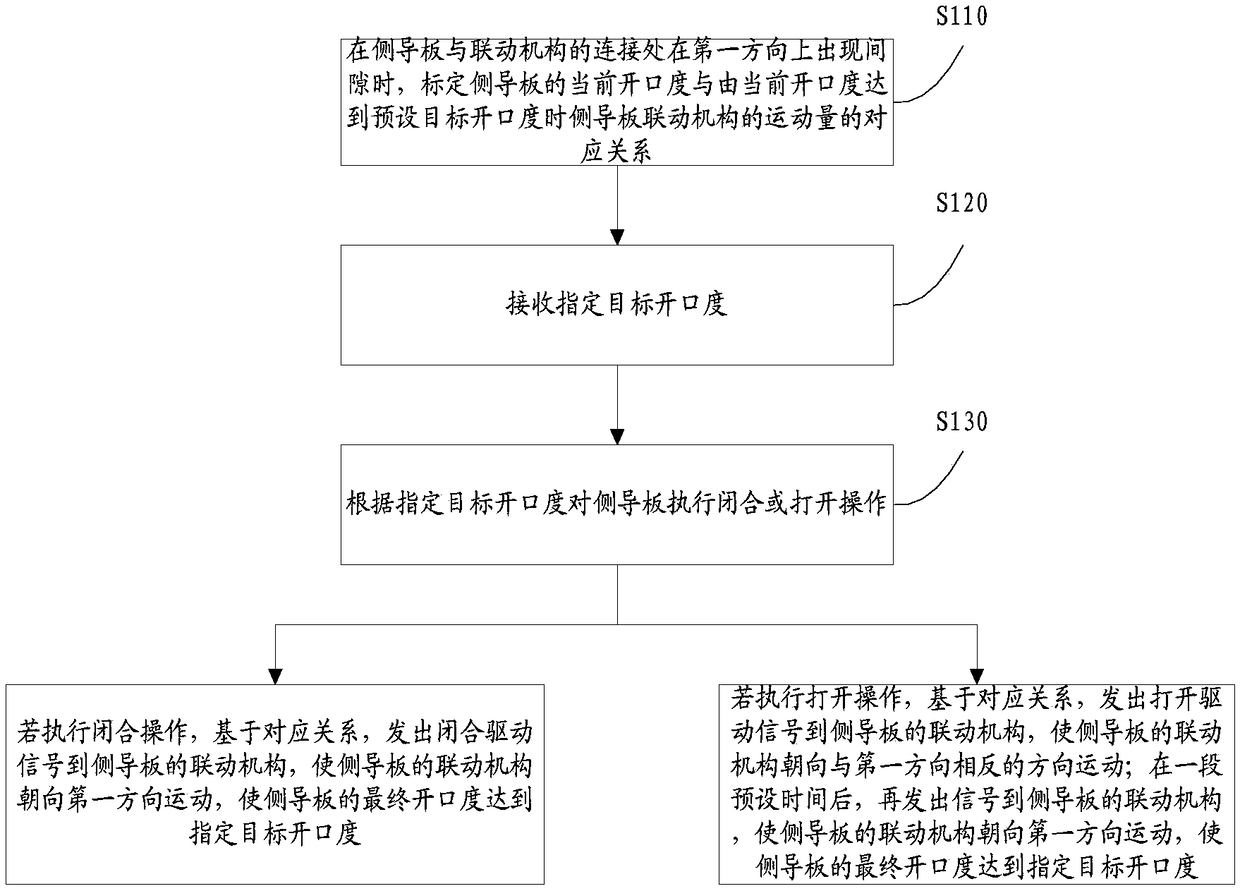

Control method and system of side guide plate

ActiveCN108655190ASolved the technical issue where the effect of the gap on the final opening of the side guides could not be eliminatedGuaranteed rolling precisionGuiding/positioning/aligning arrangementsRoll mill control devicesStrip steelCenter effect

The invention discloses a control method and a system of a side guide plate. By controlling of an action process of the side guide plate, so that the side guide plate can always move to a target opening degree in the same direction when being opened or closed, so that a mechanical gap is always concentrated on the same side, and the influence of the mechanical gap on a final opening degree of theside guide plate is eliminated; and a centering effect and threading stability of strip steel are improved, and then the rolling precision of the strip steel is guaranteed.

Owner:BEIJING SHOUGANG CO LTD

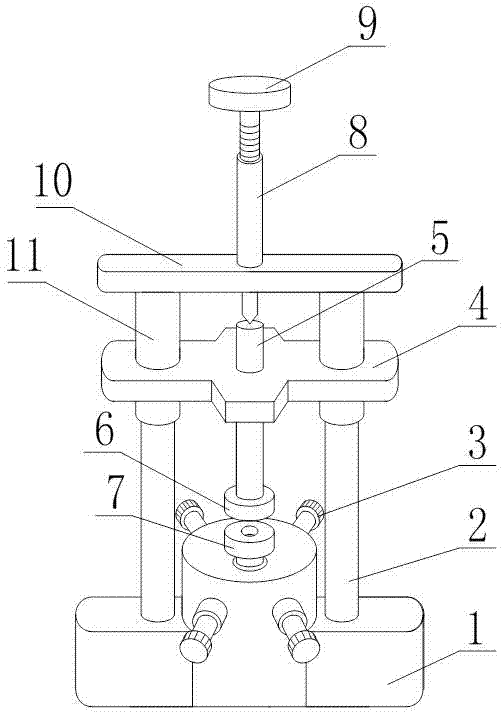

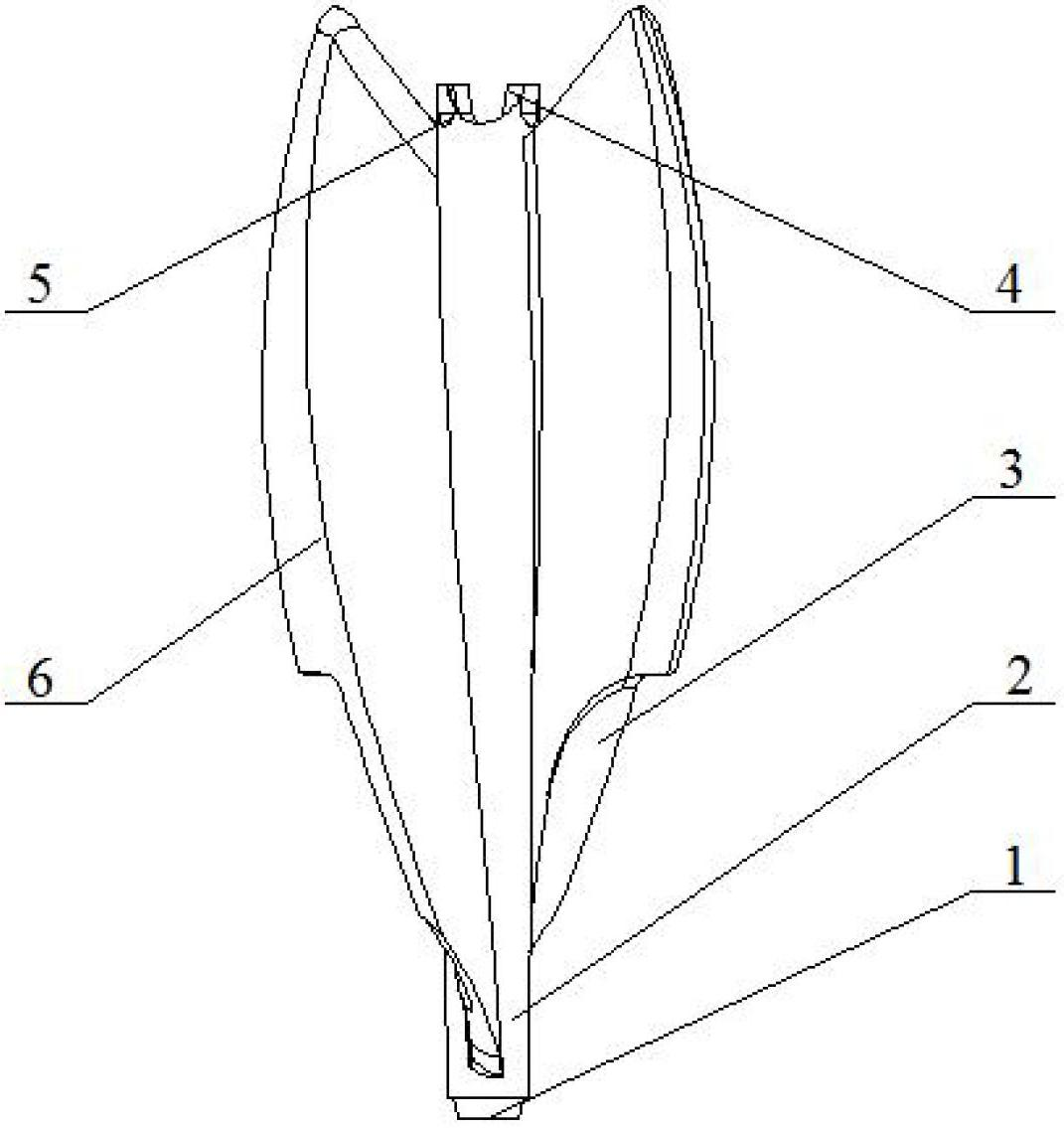

Tool used for welding optical elements

InactiveCN103286503AImprove stabilityImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesRelative displacementEngineering

The invention discloses a tool used for welding optical elements. The tool used for welding optical elements comprises a welding pedestal (1), a first vertical pillar (2), an adjustment bolt (3), a first cross beam (4), a pressing pillar (5), a discharging seat (7), a pressing bolt (9), a second cross beam (10) and a second vertical pillar (11). The tool used for welding optical elements is simple in structure, can act on optical elements to be welded through the pressing pillar or the combined action of the pressing pillar and the pressing bolt according to pressing requirements, and can effectively prevent relative displacement among the optical elements in the welding process. If the centering effect is not good after the optical elements are placed, the optical elements can be conveniently adjusted through the adjustment bolt. In addition, the optical elements are convenient to take and place, the selective pressing modes and the arranged adjustment bolt are both beneficial to the improvement of the welding efficiency.

Owner:成都网动光电子技术股份有限公司

Nanometer selenium germanium negative-ion far-infrared anti-mite electromagnetic-shielding fabric clothes for treating apoplectic hemiplegia

InactiveCN102817091APromote circulationFunction increaseAnthropod material medical ingredientsArtificial filaments from viscoseElectromagnetic shieldingFar infrared

The invention provides a nanometer selenium germanium negative-ion far-infrared anti-mite electromagnetic-shielding fabric clothes for treating apoplectic hemiplegia, which belongs to the technical field of production of functional healthy fabric clothes. Key points of a technical scheme in the invention are as follows: a mixture of selenium and germanium rich elements, traditional Chinese medicines, tourmalinite, Chinese medical stone, far-infrared electromagnetic-shielding materials, negative ion powder and an anti-mite finishing antiseptic is processed by a nanometer technology apparatus to obtain nanometer particles, a modern high-tech special treating process is utilized to enable every trace element in each particle to have a positive charge center effect, then the nanometer particles are refined and added into manufacturing of fiber spinning liquid, and finally the fabric clothes for treating apoplectic hemiplegia is manufactured; thus, adjuvant therapy for enhancing physique of patients, improving immunity of the patients, releasing trace element negative ions, promoting element balance and acid-base balance in human bodies and spurring an early recovery of apoplectic hemiplegia is realized.

Owner:成钢

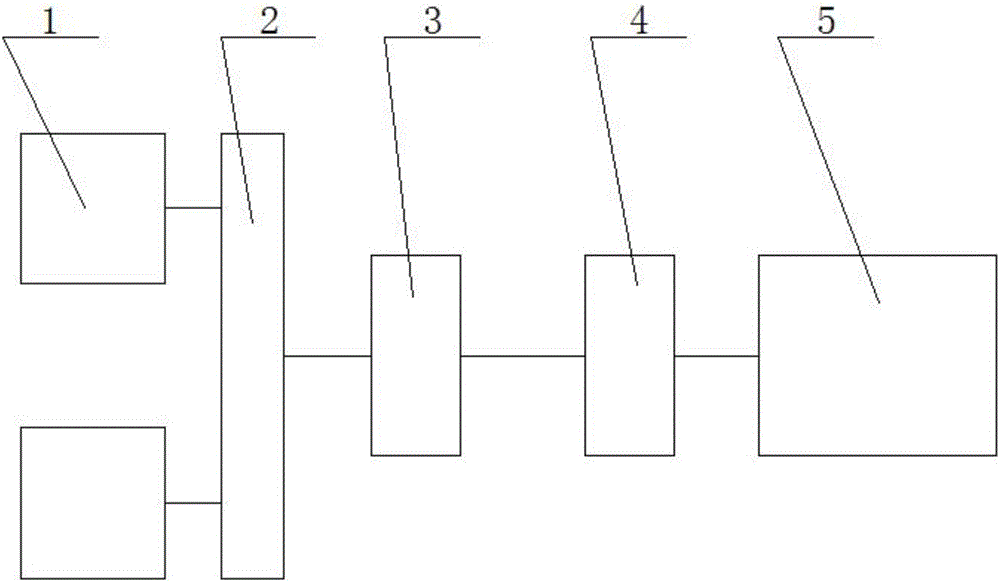

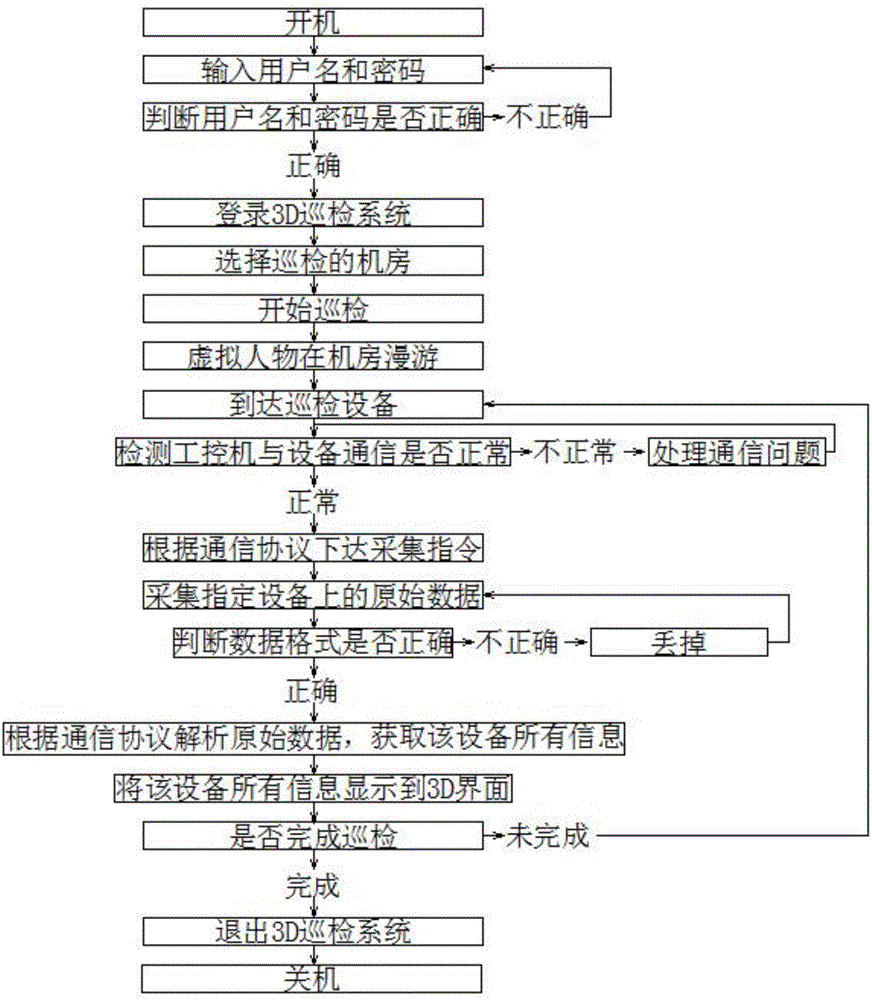

Machine room smart 3D inspection system

InactiveCN106445777AReduce casualtiesEnsure safetyHardware monitoringIntegrated monitoringFire - disasters

The invention relates to the technical field of automatic inspection and specifically relates to a machine room smart 3D inspection system. The system comprises an information collection box, a comprehensive monitoring management platform, a 3D simulation server and a display screen. The information collection box, the comprehensive monitoring management platform, the 3D simulation server and the display screen are electrically connected. According to the machine room smart 3D inspection system provided by the invention, the monitoring center effect of the system is the same to the actual effect; both building appearances and operation states of the devices are consistent; according to the products of the system, the 3D virtual reality displaying effect is finished through adoption of a 3D modeling technology and a high-efficiency displaying engine; parameters, states and alarm of various devices in a machine room are displayed centrally through 3D virtual reality products; the long-term objective evaluation can be carried out on the operation condition of the devices; the power supply security can be ensured by replacing space-time point devices appropriately; moreover, the device investment is reduced; the utilization efficiency of the devices is improved; according to the system, the device operation reliability can be improved; and the occurrence of serious accidents such as fire disasters and personnel casualties can be reduced.

Owner:GUANGZHOU HEYUN TECH DEV CO LTD

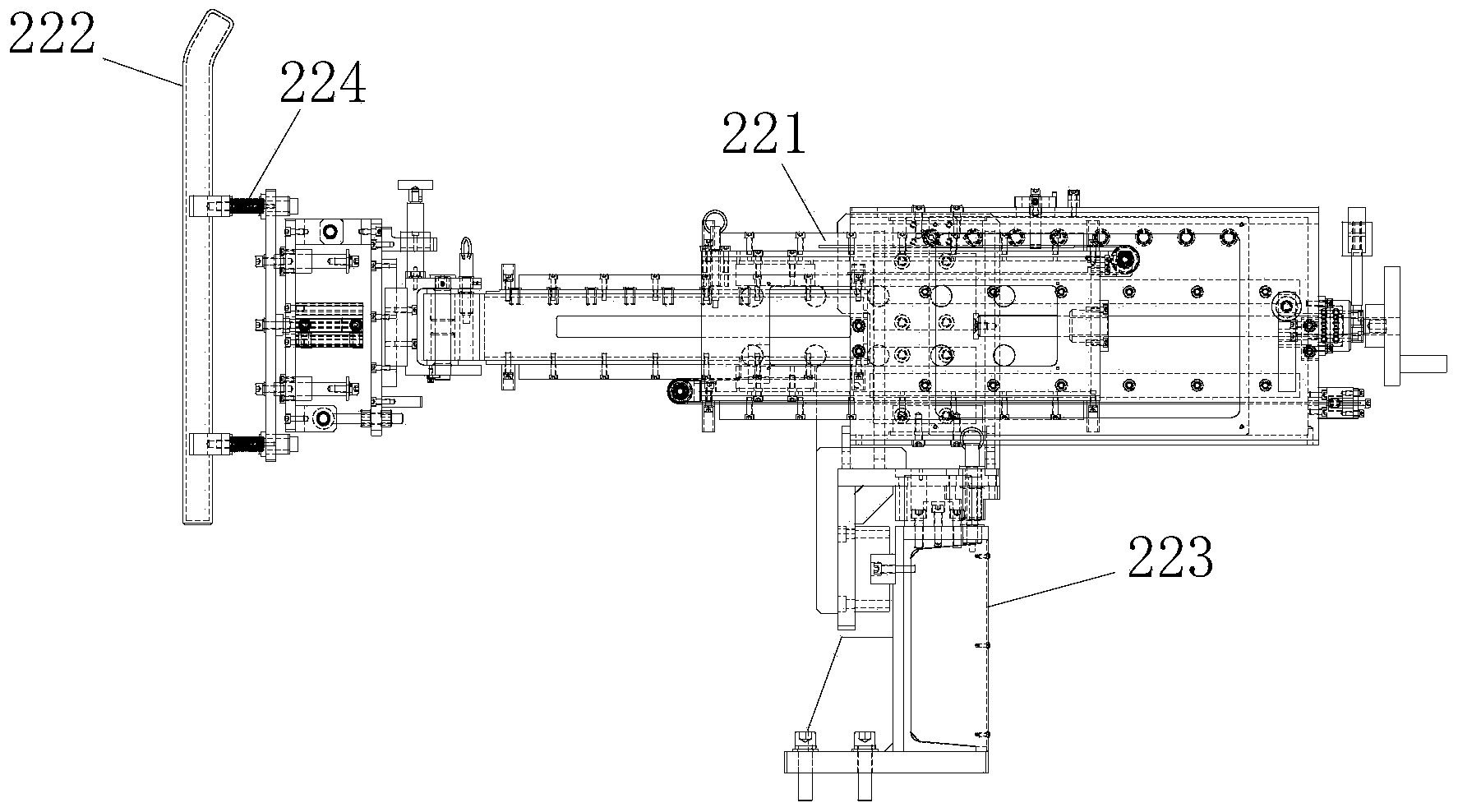

Pipe pushing rolling device for high-performance magnesium alloy seamless pipes

The invention provides a pipe pushing rolling device for high-performance magnesium alloy seamless pipes. The pipe pushing rolling device structurally comprises a floating supporting pressing roller device, a driven pressing roller set, a pushing device, an I-shaped guiding rail, a sliding key and a heating heat-insulation device. The floating supporting pressing roller device has the auxiliary supporting and centering effects; the driven pressing roller set rolls pipe blanks through pushing force on the pipe blanks; the pushing device is driven by a stepper motor, and after deceleration is conducted through a tapered tooth deceleration gear set, a gear rack transmission set drives a trolley to push the pipe blanks; the heating heat-insulation device conducts heat supplementing on the rolling process of the pipe blanks or preheating before rolling through joule heat generated by a heating coil; and the pushing device and the floating supporting pressing roller device are fixed to the I-shaped guiding rail through sliding blocks. The cracking and snapping phenomena in the rolling process of the pipe blanks can be significantly lowered, the structure performance of the rolled pipes is improved, the device is extremely larger in process flexibility, and the magnesium alloy pipes with different diameters and lengths can be rolled.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

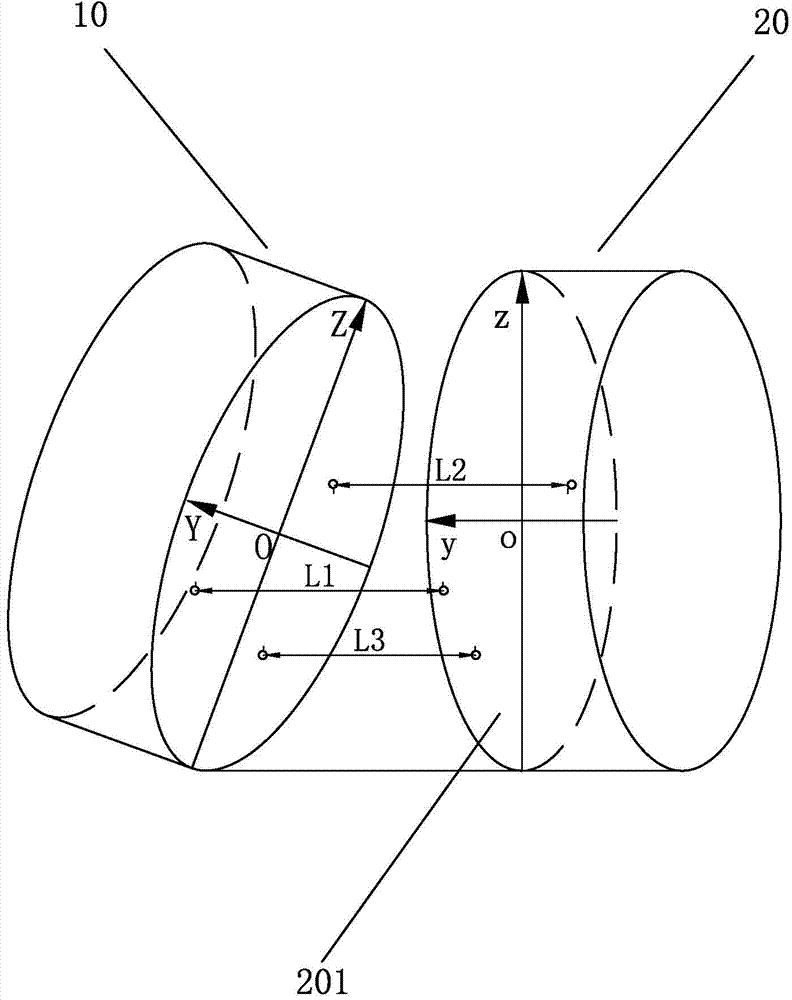

Fast centering method

ActiveCN104731015ARapid positioningLaser measurement deviation is smallNumerical controlClosed loopSupport point

The invention provides a fast centering method. The method includes the following steps that (1) benchmark conversion is conducted on the centering benchmark, and a YOZ plane is selected for a centering product, a yoz plane is selected for a target product, and the YOZ plane and the yoz plane are the same in size; (2) parallel adjusting is conducted on the YOZ plane and the yoz plane till the YOZ plane is parallel to the yoz plane; (3) projection overlapping adjusting is conducted on the YOZ plane and the yoz plane till the YOZ plane is completely overlapped with the yoz plane in projection, and centering is finished. The fast centering method is high in measuring accuracy, good in centering effect and high in operation efficiency, accurate positioning of products super-long in length and low in rigidity is achieved, and fast centering is achieved through a closed-loop measuring feedback system, large-load supporting points and a drive device.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

Grooving spiral curling rotor in heat exchange tube

InactiveCN102645122AAvoid depositionSave materialHeat transfer modificationRotary device cleaningEngineeringHeat transfer fluid

The invention relates to a grooving spiral curling rotor in a heat exchange tube. The rotor is composed of a hollow shaft and a blade, wherein the hollow shaft is of a tubular structure; the blade is located on the outer surface of the hollow shaft; the blade surface is smooth and spiral around the hollow shaft; the blade of the rotor is composed of a grooving blade and a curling blade; a water-facing surface of the grooving blade is provided with a diversion trench structure along the radial direction of the hollow shaft; the radial thickness of the grooving blade is reduced; a water-back surface is not provided with a diversion trench structure; the edge of the grooving blade in contact with the fluid first is subjected to beveling or rounding; and a curling structure is arranged at the top end of the curling blade and is in transition connection through a smooth curved surface. In the invention, when the grooving blade rotates, the heat transfer fluid generates centrifugal movement along the surface of the diversion trench and is thrown to the wall of the heat exchange tube; a curling structure is arranged at the top end of the curling blade; and the rotor can realize a good self-centering effect when rotating in the fluid according to the self-suspension mechanism of the curling blade so as to reduce the scraping effect between the top end of the blade and the inner wall of the heat exchange tube and increase the fluid turbulence degree.

Owner:BEIJING UNIV OF CHEM TECH

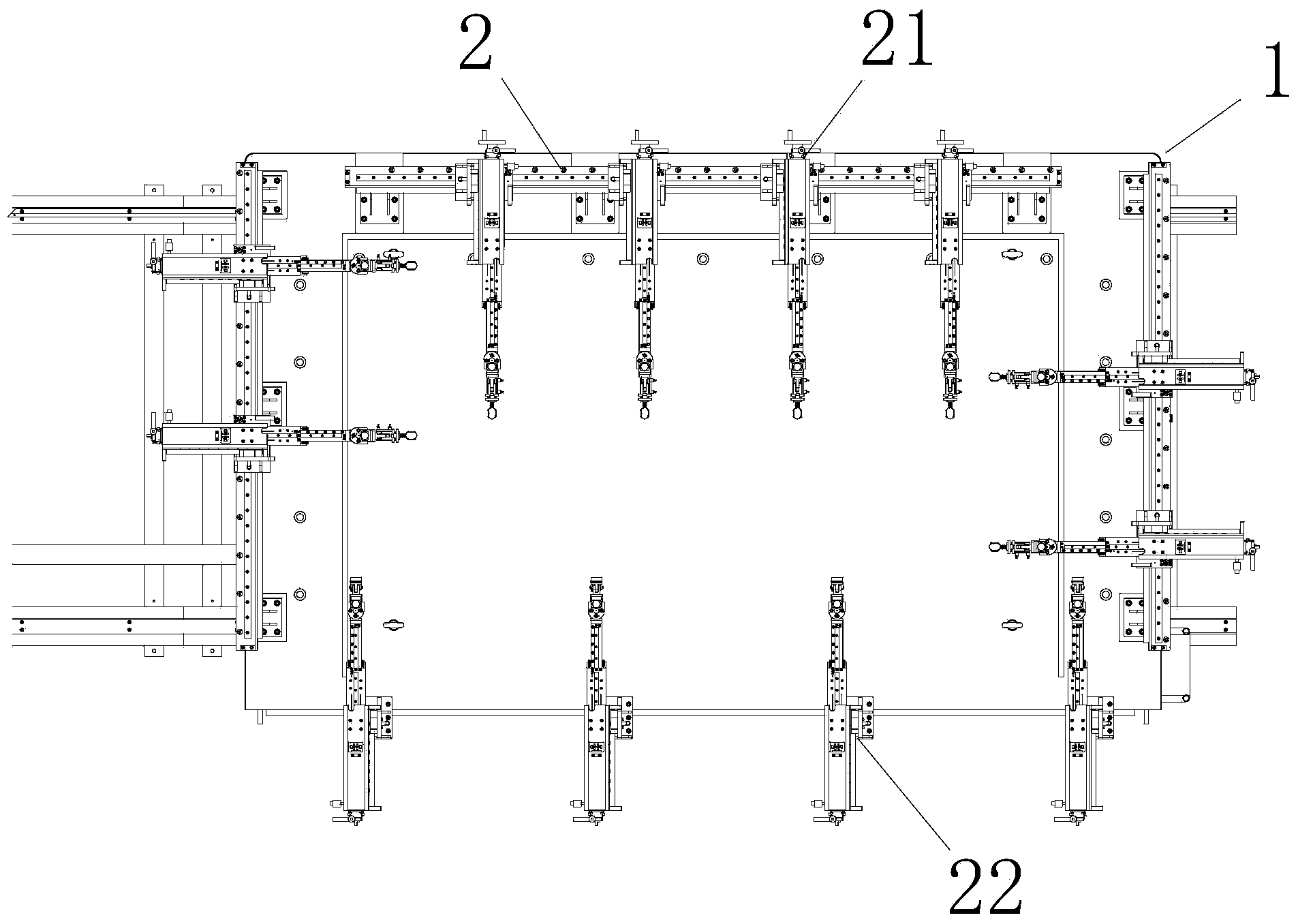

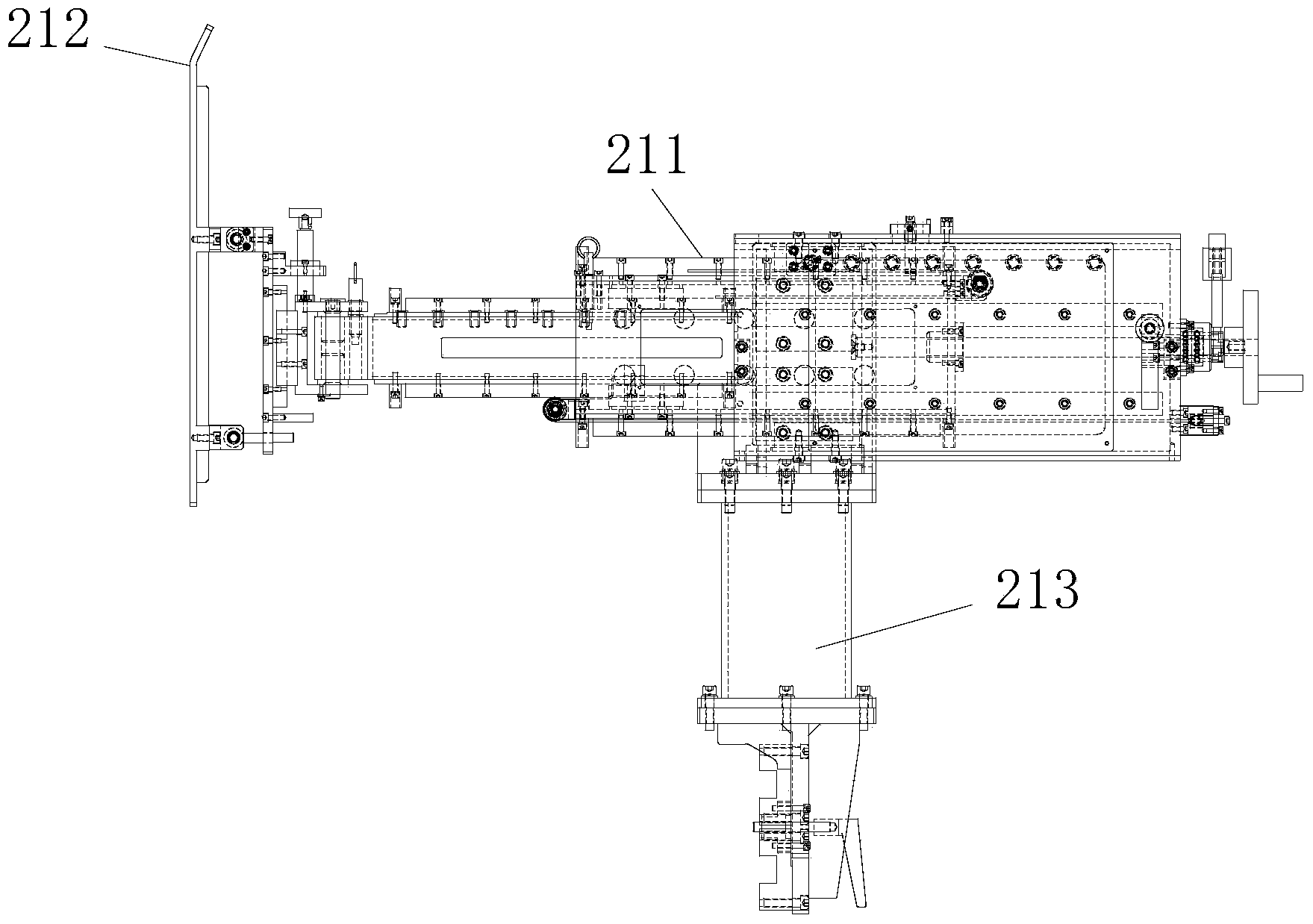

Semi-automatic plate centering stacking pallet and centering method thereof

InactiveCN103752717ARealize semi-automationReduce the risk factorMetal-working feeding devicesPositioning devicesSemi automaticEngineering

The invention discloses a semi-automatic plate centering stacking pallet and a centering method thereof. The semi-automatic plate centering stacking pallet comprises a pallet body and a centering mechanism, wherein the upper surface of the pallet body is rectangular; the centering mechanism is arranged on the upper surface of the pallet body and comprises a plurality of stopping mechanisms and a plurality of beating mechanisms; the stopping mechanisms and the beating mechanisms are extensible; each beating mechanism is provided with a buffering mechanism; the stopping mechanisms are uniformly arranged at two adjacent edges of the upper surface of the pallet body; and the beating mechanisms are uniformly arranged at the other two edges on the upper surface of the pallet body. The stopping mechanisms and the beating mechanisms are added on the basis of the prior art, plates are initially positioned by using the stopping mechanisms, and then are accurately positioned by using the beating mechanisms, so that a whole operation process is semi-automatic, and the purposes of improving the centering effect, saving labor resources and reducing danger coefficients of operators are achieved.

Owner:WECAN M&E SHANGHAI

Efficient self-centering rotary cutter

The invention discloses an efficient self-centering rotary cutter. In the rotary-cut process, a first lifting drive device drives a first lifting frame to lift and lower along a first guide frame until the center of a positioning cutting knife is roughly at the same height as the center of a log, a user operates a first operating handle to push a first sleeve body to move along a thread towards the log, the first sleeve body has inward pressure on a first positioning arm through a first top abutting sleeve, the first positioning arm performs clamping through a first top abutting gripper, and top abutting grippers of three positioning arms can perform all-dimensional clamping on the log. A first advance and retreat motor drives a first advance and retreat worm wheel to rotate through a first advance and retreat worm, the first advance and retreat worm wheel drives a first shaft body to slide towards the log through a first advance and retreat screw, a first blade is in contact with thelog in a top abutting mode and the log is rotated to cut a groove corresponding to a first conical head, a first end cover is automatically in contact with the groove formed by rotary cutting in a topabutting mode, and the self-centering effect is realized.

Owner:漳州市炯辉机械有限公司

Back elevation clamp of initial die

ActiveCN103817544AGuaranteed machining accuracySimple and fast operationLarge fixed membersPositioning apparatusTailstockCenter effect

The invention discloses a back elevation clamp of an initial die. The back elevation clamp comprises a turntable tailstock bridge plate structure, self-centering locating and clamping mechanisms and lateral locating mechanisms. A main board of the turntable tailstock bridge plate structure is provided with two sets of self-centering locating and clamping mechanisms, and the lateral locating mechanisms are arranged in front of the self-centering locating and clamping mechanisms. The back elevation clamp has the beneficial effects that one cylinder drives one mechanism, four pressing plates are controlled simultaneously, the die is compressed, and the centering effect is realized, so that the production precision is guaranteed, and the processing yield is improved; operation of processing parts is convenient, adjusting while remodeling is convenient, and the work time is saved; furthermore, the clamp is a double-station clamp, two parts can be processed at a time, processing contents on two faces can be processed at a time through the turntable tailstock bridge plate structure, the cost is reduced, and the processing efficiency is improved.

Owner:WUXI RUIZHEN PRECISION MACHINERY

Self-centering and work piece clamping device for working table and control method of self-centering and work piece clamping device

InactiveCN102554662AAchieve self-centerednessAvoid deformationAutomatic control devicesFeeding apparatusSolenoid valveCompression method

The invention discloses a self-centering and work piece clamping device for a working table and a control method of the self-centering and work piece clamping device. The device comprises hydraulic claws which are pushed by a piston to close or open. The work piece is clamped by compression method instead of clamping method in the prior art, so as to prevent deformation of thin-wall parts during the clamping process. The closed or opened state of each oil outlet is controlled by an integrated solenoid valve, so that the work piece has the self-centering effect. The invention has the advantages that the device changes the conventional manual centering and inner / outer-side clamping structure in the prior art, increases the work piece clamping efficiency, prevents deformation of the work piece during the clamping process, improves the reliability of work piece machining, and reduces the production cost.

Owner:SANY GRP

Pore throat recognition method with consideration of pore throat tail end

ActiveCN104778678AImprove centeringRelatively small errorImage analysisCharacter and pattern recognitionWavelet noiseThroat

The invention relates to a pore throat recognition method with consideration of a pore throat tail end and in particular to a method for recognizing pores and throats in microscopic visualization model oil displacement experiment images in the field of oilfield development. The method comprises the following steps: carrying out binaryzation treatment on images; carrying out length transformation on space of pores and throats; extracting a center line by using a turning point algorithm; cancelling inner paths in the pores to obtain path curves of the rest of paths; carrying out wavelet noise reduction on the path curves; finding bottleneck positions of the pores and the throats and carrying out pore throat recognition without consideration of the tail end; extracting a center line by using a combustion algorithm and finding the pore throat tail end; extracting a center line of the tail end by using the turning point algorithm by means of an endpoint of a combustion center line of the tail end; and combining the center line of the turning point algorithm and carrying out the pore throat recognition method with consideration of the pore throat tail end. With combination of the combustion algorithm and the turning point algorithm, the tail end part can be independently recognized; the extracted center line is good in centering effect; the relative errors of recognition of the pore throat length are reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

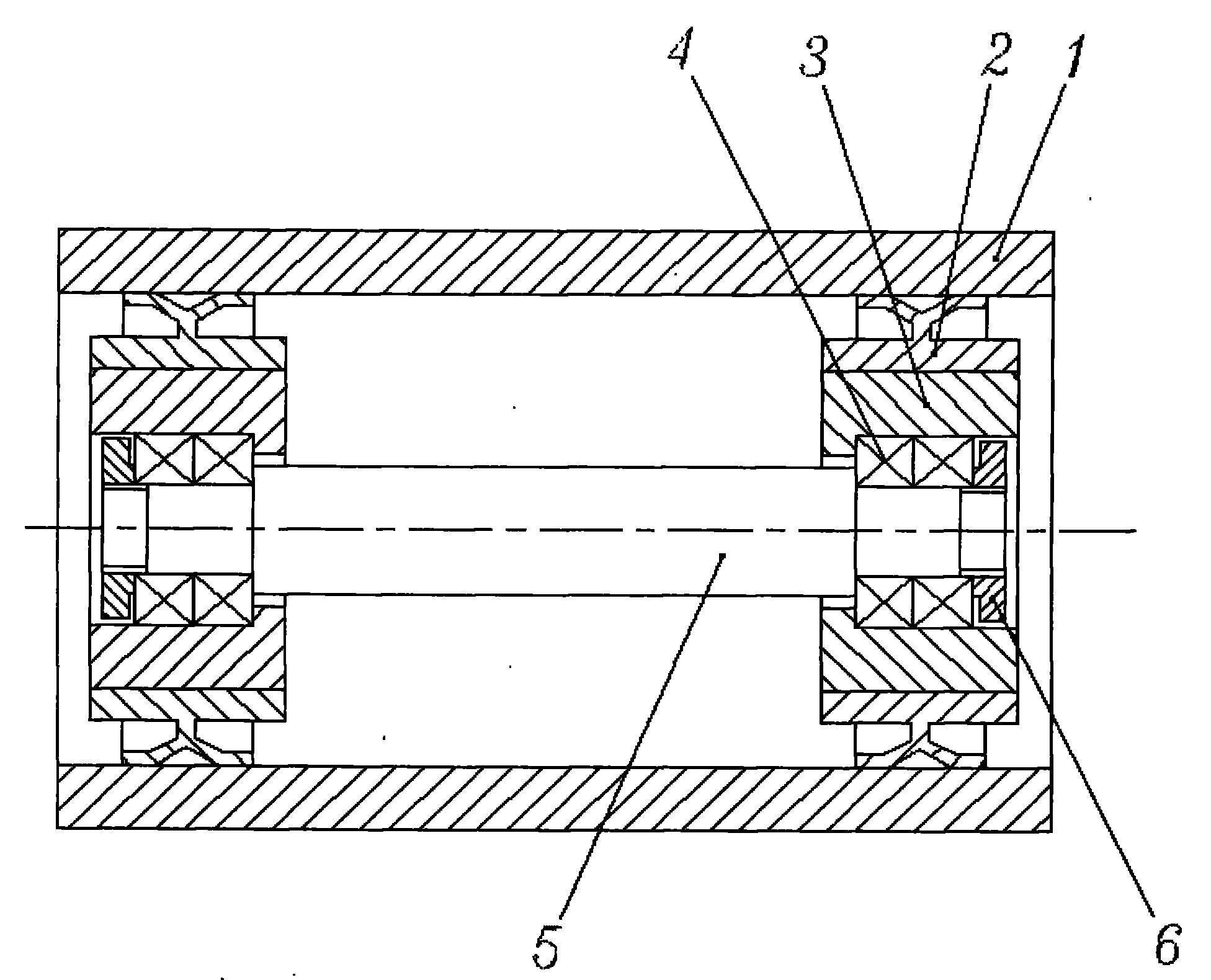

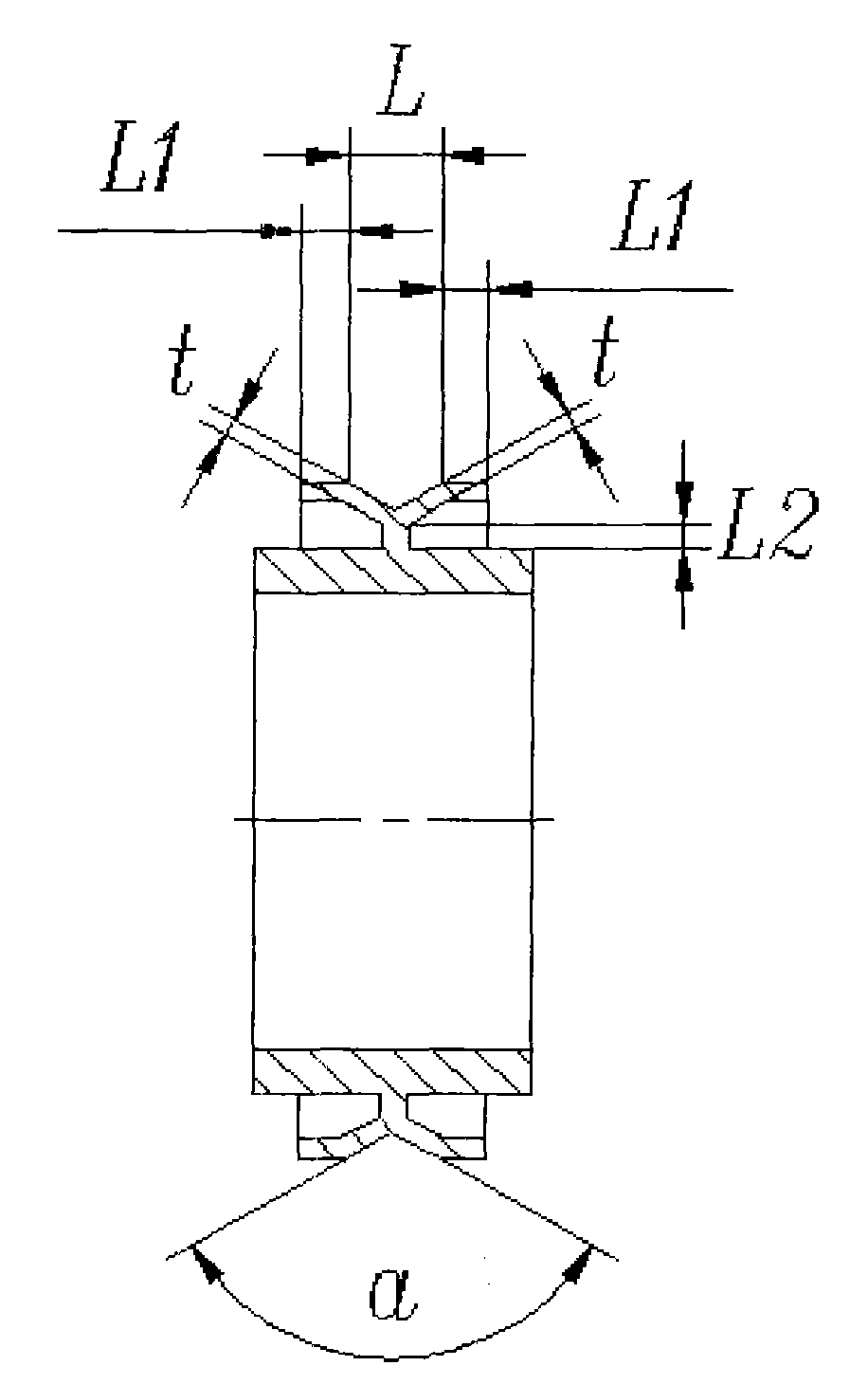

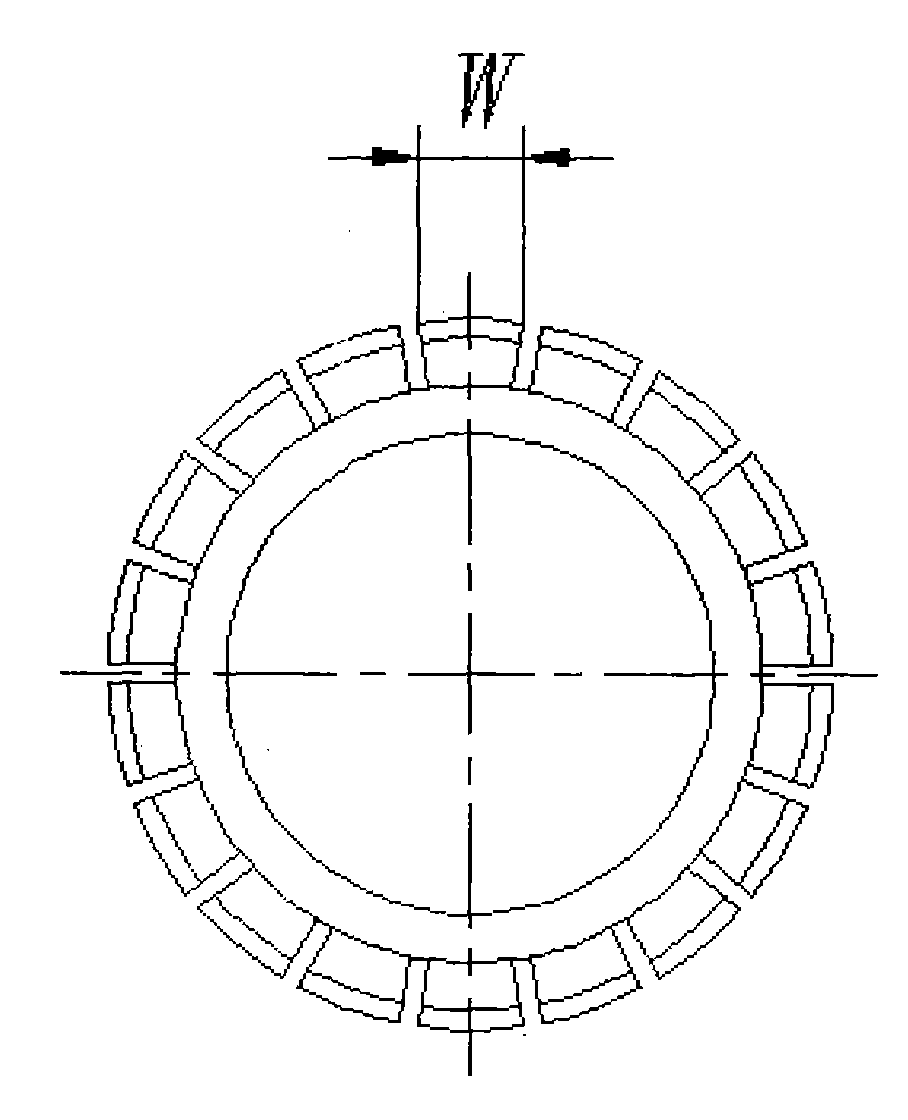

Method for reducing vibration or bending deformation of spindle rotor in high-speed electric spindle

InactiveCN101776126AWide range of elastic stiffnessExtend your lifeNon-rotating vibration suppressionEngineeringSupport point

The invention relates to a method for reducing vibration or bending deformation of a spindle rotor in a high-speed electric spindle. Supporting points at two ends of the spindle rotor (5) are respectively provided with an elastic supporting ring (2) and a bearing seat (3), which have the same structures; when impact load which is triggered by vibration generated by high-speed rotation of the spindle rotor is transmitted to the elastic supporting ring through a bearing (4) and the bearing seat, and an Y-shaped raised wing of the elastic supporting ring has elastic deformation which can absorb part of vibrating energy, so the impact load among the bearing, the bearing seat and a sleeve (1) is lightened; as the Y-shaped raised wing of the elastic supporting ring has elasticity, rigid restriction borne by the supporting points at the two ends of the spindle rotor is weakened; therefore, the vibration or the bending deformation of the spindle rotor is effectively released; the self-centering effect of high-speed rotation of the spindle rotor is enhanced; and the method effectively prevents the bending deformation of the spindle rotor, reduces the force borne by the bearing, and improves the service life of the high-speed electric spindle.

Owner:LUOYANG BEARING RES INST CO LTD

Clamping-claw-type centering clamping device

InactiveCN106975763AOvercoming elasticityAvoid pinchingExpansion mandrelsMechanical engineeringCenter effect

The invention provides a clamping-claw-type centering clamping device and belongs to the technical field of automobile parts. The clamping-claw-type centering clamping device comprises a driving disc, a cone and clamping claws; three spring supporting grooves are formed in the lower end of the cone and are distributed at equal intervals of 120 degrees; three inclined sliding grooves are formed in the cone and are distributed at equal intervals of 120 degrees; the spring supporting grooves and sliding grooves are mutually staggered by 60 degrees; a pushing rod is arranged on an upper support in a sliding up and down mode; a guide rod is arranged on the cone in a sliding up and down mode; a pushing plate is coaxially fixed to the lower end of the pushing rod; the pushing plate is connected with the upper end of a piston rod of a driving air cylinder; the upper ends of compression springs and the spring supporting grooves are attached; the lower ends of the compression springs and the upper end surface of the driving disc are attached; the clamping claws are slidably arranged on the sliding grooves of the cone; and clamping grooves at the lower ends of the clamping claws are clamped on the driving disc. Centering and clamping of a disc-shaped workpiece are achieved through the clamping claws, and the clamping claws are distributed at equal intervals of 120 degrees, so that the centering effect on the disc-shaped workpiece is good.

Owner:苏州卓尔旺精密机械有限公司

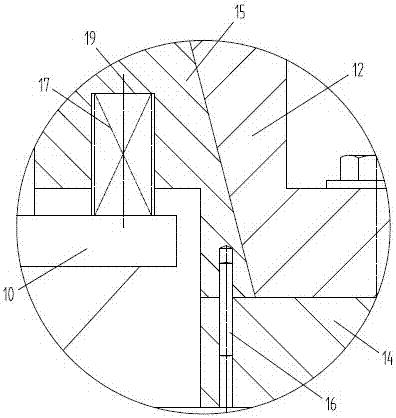

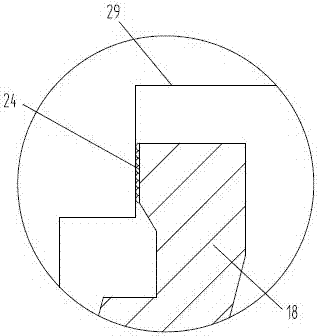

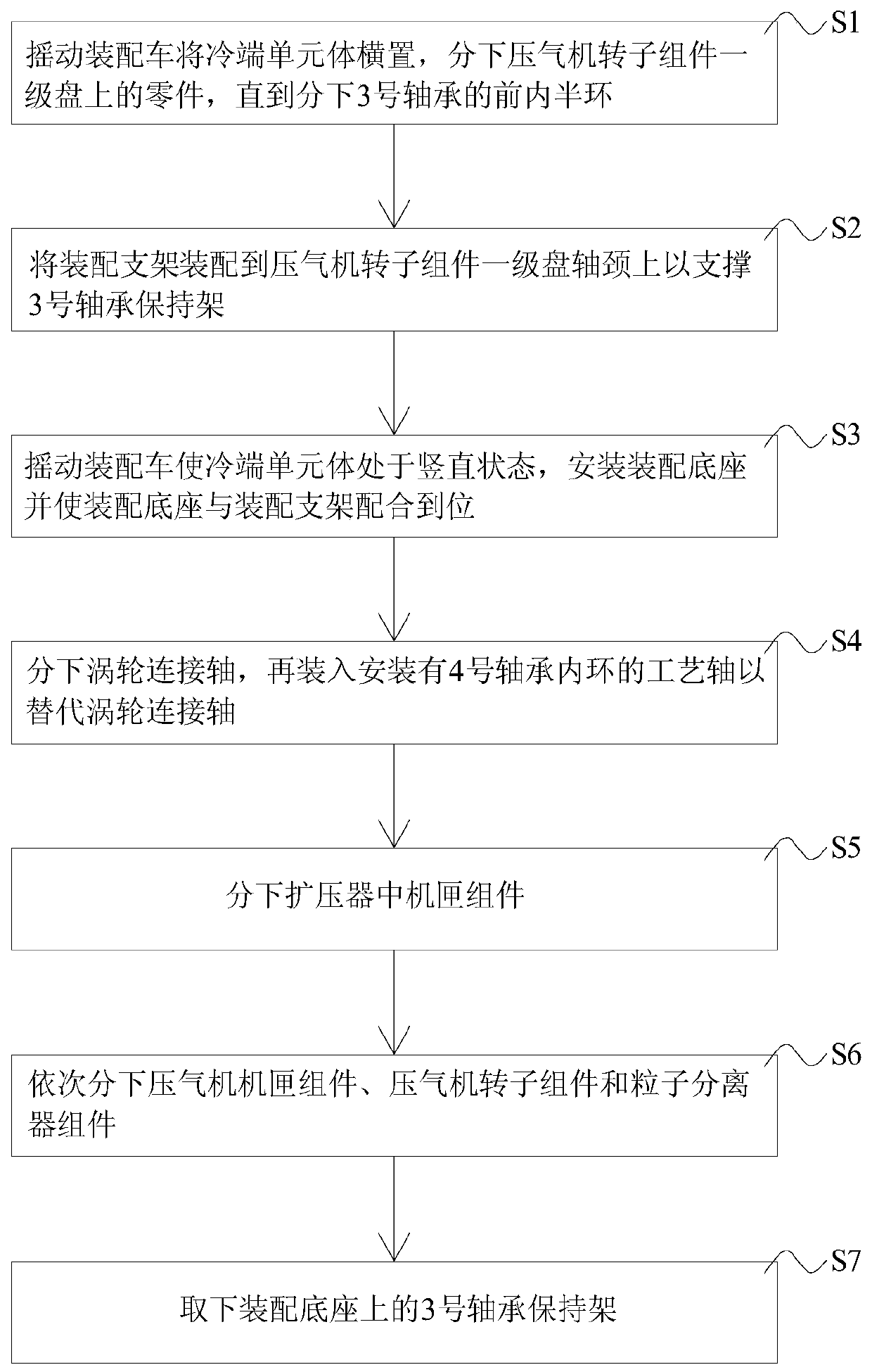

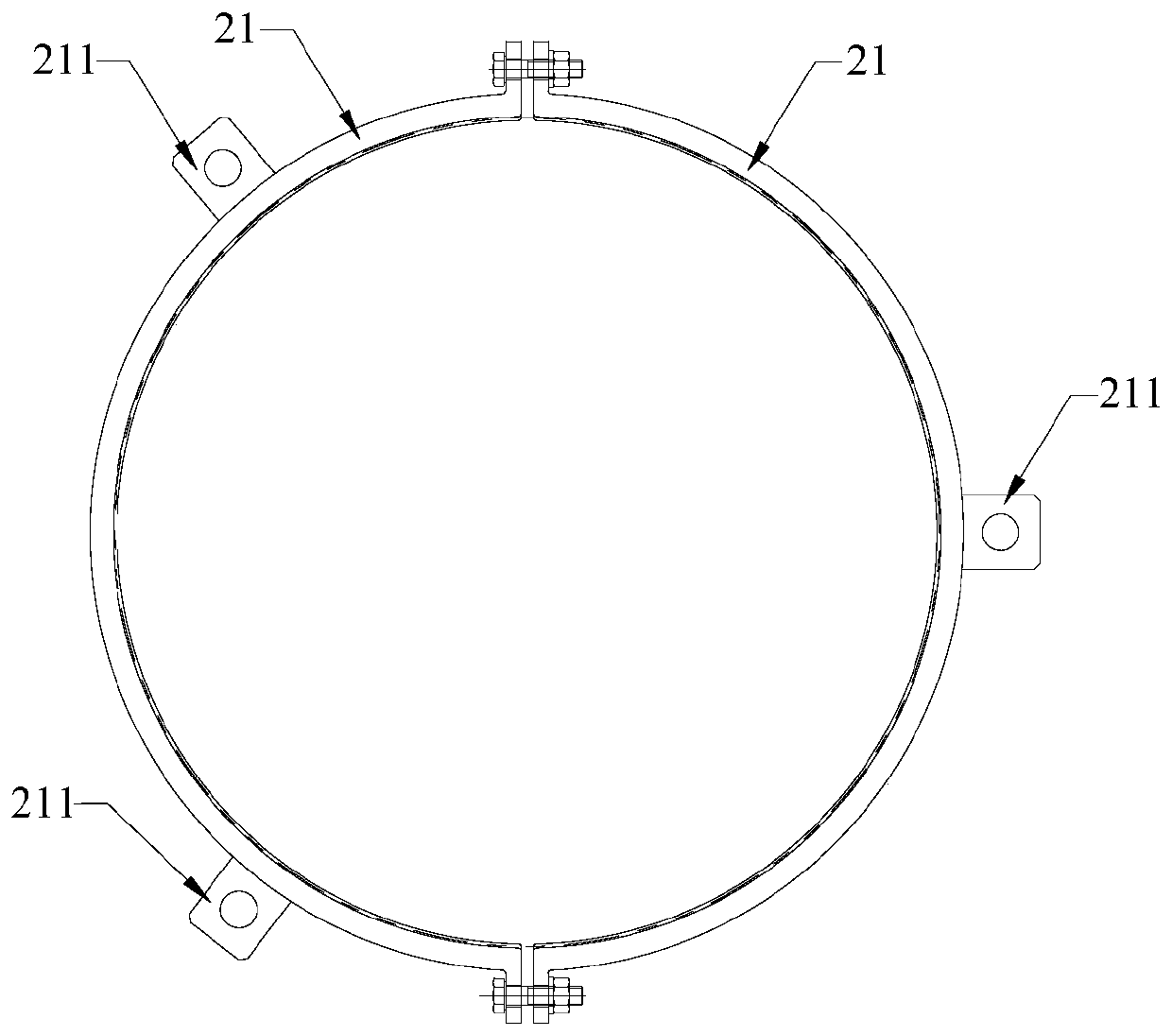

Disassembling method of cold-end unit body

ActiveCN110497169APlay a reassuring roleCentering effect maintainedMetal working apparatusTurbineCenter effect

The invention discloses a disassembling method of a cold-end unit body. According to the disassembling method of the cold-end unit body, a third bearing retainer is supported by an assembling bracketand an assembling base sequentially, thus, a third bearing can maintain the centering effect in the disassembling process, after a turbine connecting shaft is disassembled, a process shaft provided with a fourth bearing inner ring is used for replacing the turbine connecting shaft, therefore, the fourth bearing can maintain the centering effect, then a casing assembly in a diffuser, a compressor casing assembly, a compressor rotor assembly and a particle separator assembly are disassembled in sequence, and finally the third bearing retainer on the assembling base is taken down. According to the disassembling method of the cold-end unit body, the third bearing and the forth bearing maintain the centering effect in the entire disassembling process, the problems of rotor jamming, rotor and stator axial abrasion and falling-off of the third bearing retainer are avoided in the disassembling process, the reliability, stability and safety of the disassembling process are improved, and the scientific research and production progresses are ensured.

Owner:CHINA HANGFA SOUTH IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com