Device for clamping workpiece of machine tool

A workpiece clamping and machine tool technology, which is applied in positioning devices, metal processing machinery parts, clamping, etc., can solve problems that affect processing accuracy, cannot guarantee workpiece shape and position tolerance, and affect workpiece processing quality, so as to ensure processing accuracy, The effect of improving the qualified rate of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described below in conjunction with accompanying drawing.

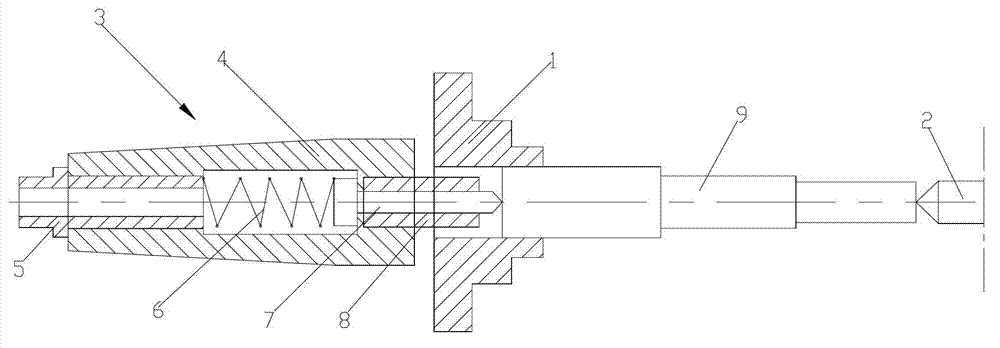

[0011] attached figure 1 It is a clamping device for a machine tool workpiece according to the present invention, which includes a three-jaw chuck 1 and a rear top 2, and an elastic movable top 3 is arranged behind the three-jaw chuck 1; the elastic movable top 3 includes a taper sleeve 4 ; The taper sleeve 4 is provided with a plug 5, a compression spring 6, and a front tip 7; the compression spring 6 is connected between the plug 5 and the front tip 7; the front tip 7 extends into the three-jaw chuck 1; The bar of the front center 7 is sleeved with a limit block 8 extending into the three-jaw chuck 1 ; the center of the front center 7 is on the same level as the center of the rear center 2 . Cooperate the center hole of the positioning reference end of the workpiece 9 with the front top 7, the front top 7 plays a centering role, and the other end of the workpiece 9 is supported by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com