Machine room smart 3D inspection system

An inspection system and 3D technology, applied in error detection/correction, instruments, electrical and digital data processing, etc., can solve problems that are unfamiliar to operation and maintenance personnel, unable to realize real-world simulation exercises for operation and maintenance personnel, and unable to improve the response of operation and maintenance personnel speed and other issues to achieve the effect of reducing fire, ensuring safety and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

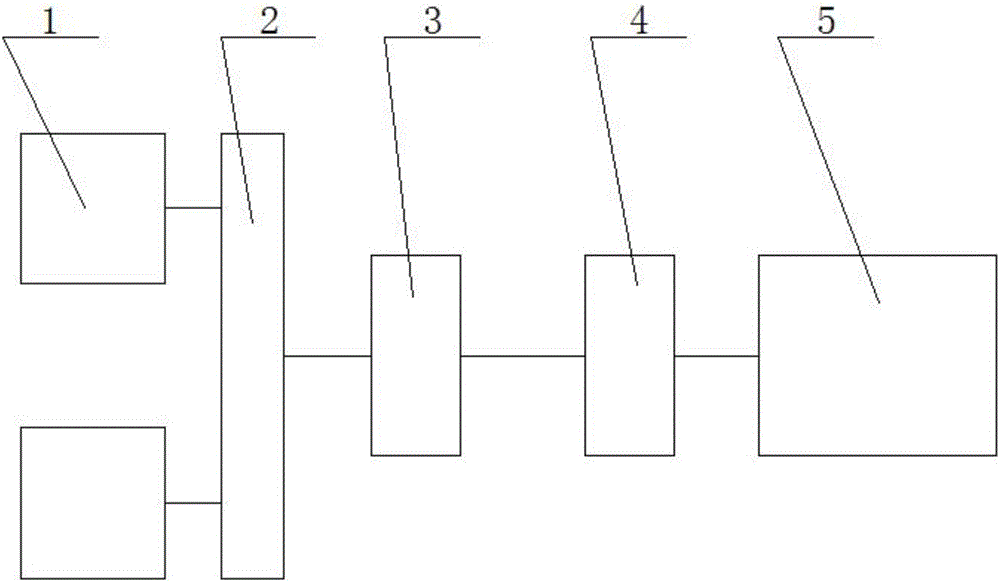

[0013] Such as figure 1 As shown, the computer room intelligent 3D inspection system described in this specific embodiment includes an information collection box 2, an integrated monitoring and management platform 3, a 3D simulation server 4, a display screen 5; an information collection box 2, an integrated monitoring and management platform 3, The 3D simulation server 4 is electrically connected to the display screen 5; the information collection box 2 is connected to the equipment 1 that needs to be inspected.

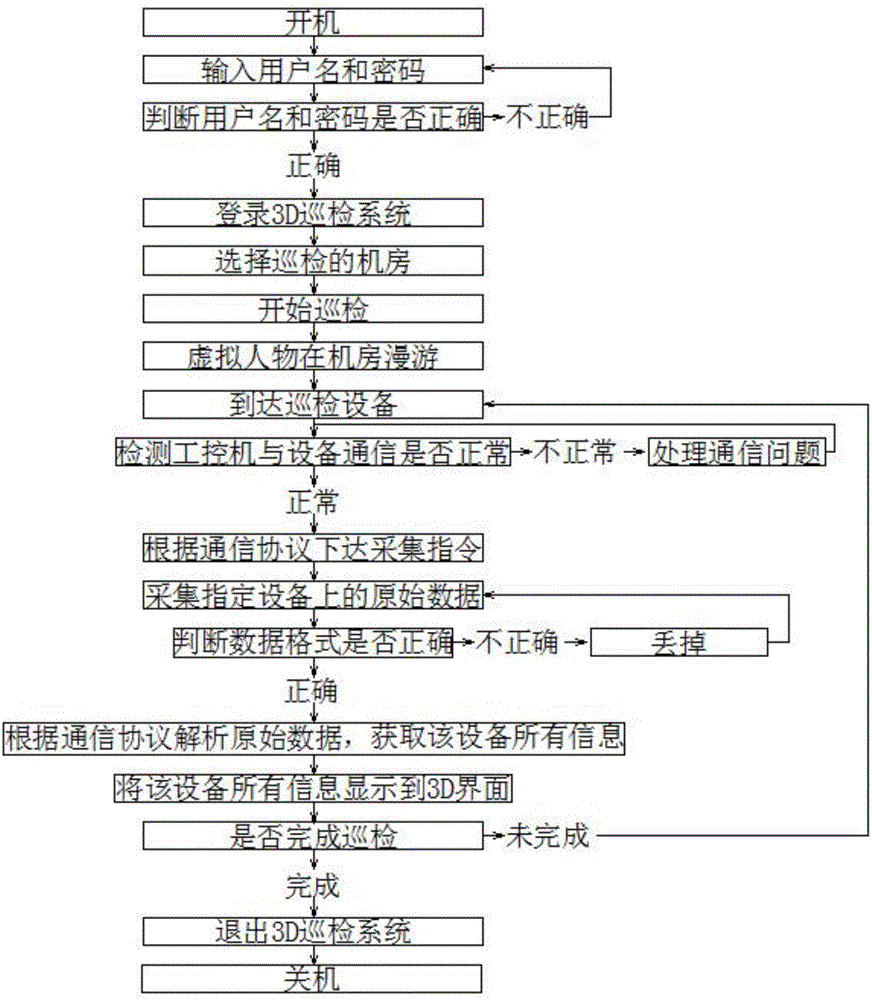

[0014] The computer room intelligent 3D inspection system of the present invention, its specific operation process is: 1, start up; 2, input user name and password; 3, judge whether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com