Tool used for welding optical elements

An optical device and tooling technology, applied in the field of fixed tooling for welding, can solve the problems of low production efficiency, poor alignment accuracy, troublesome clamping process, etc., and achieve the effect of good stability and improved welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

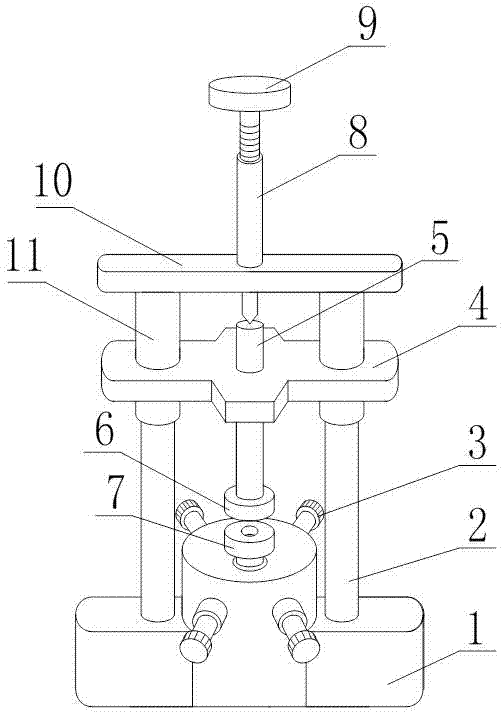

[0023] like figure 1 Shown: the tooling used for optical device welding of the present invention comprises a cylindrical lower object seat 7, a welding pedestal 1, and the middle part of the welding pedestal 1 is a hollow cylindrical structure, and the lower object seat 7 is placed in the hollow structure , also includes a plurality of adjusting bolts 3, the plurality of adjusting bolts 3 are evenly distributed on the same circumference of the hollow barrel structure, and are threadedly connected with the welding pedestal 1, the threaded end faces of the plurality of adjusting bolts 3 are connected to the lower The side of the object seat 7 is in contact, and the welding platform 1 is also provided with lugs symmetrical to the center line of the welding platform 1, and also includes two first vertical columns 2, a first beam 4, a pressure column 5, and a second vertical column 11 , the second beam 10 and the compression bolt 9, the first vertical column 2 is located in the ver...

Embodiment 2

[0026] This embodiment makes the following further limitations on the basis of embodiment 1: as figure 1 : the frock for optical device welding of the present invention includes welding pedestal 1, first vertical column 2, lower object seat 7, first beam 4, pressure column 5, second beam 10 and second vertical column 11, It also includes an upper object seat 6 and an inner wire sleeve 8. The welding platform 1, the first vertical column 2, the second vertical column 11, the lower object seat 7 and the upper object seat 6 are all made of cast iron that is not easy to rust and has low cost. The pressure column 5 and the first crossbeam 4 are made of stainless steel so as not to aggravate the wear of the mating surface of the pressure column 5 and the first beam 4 due to rust spots. Simultaneously, a section of the pressure column 5 close to the side of the upper end is also provided with concavo-convex patterns. The operator can conveniently hold the pressure column 5, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com